Best 3d printer for abs and nylon

7 Best 3D Printers for ABS, ASA & Nylon Filament – 3D Printerly

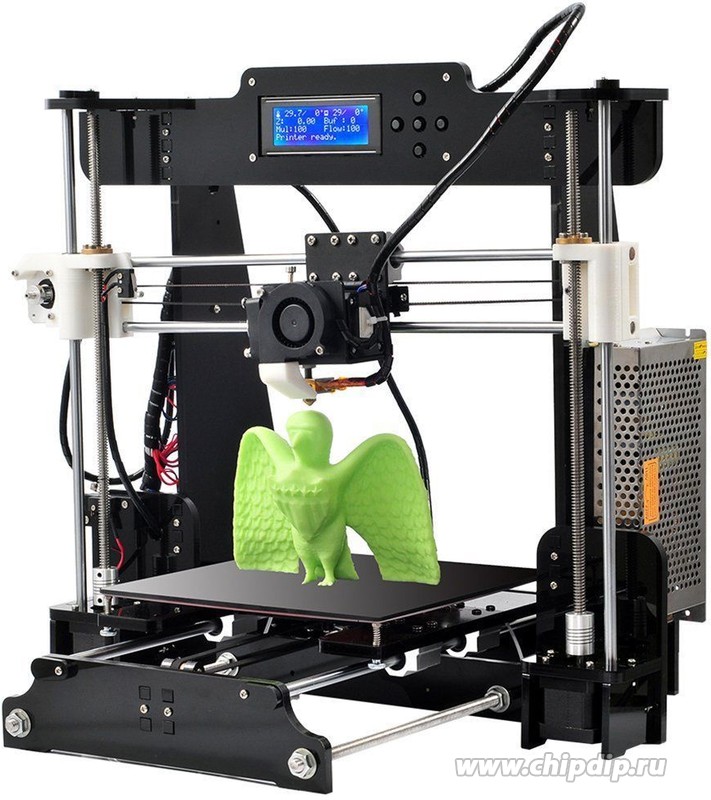

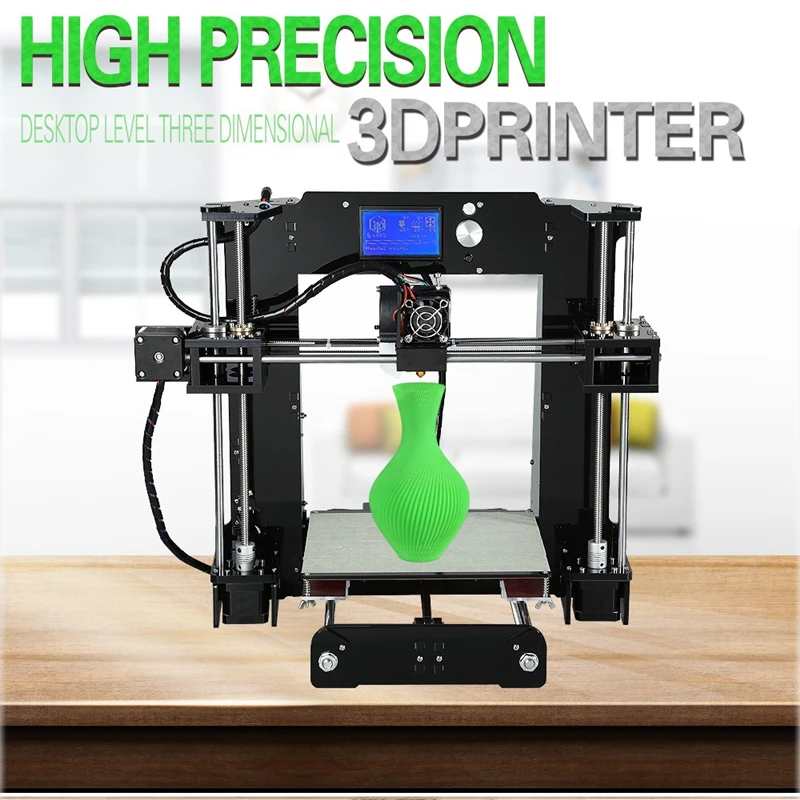

3D printing has plenty of materials that you can choose from to create your 3D models, but some 3D printers are better than others to get the job done.

For materials like ABS, ASA, Nylon and other filament, it requires a certain level of 3D printer, as well as an environment to get it perfect.

Noticing this, I decided to put together a solid list of 7 great 3D printers for 3D printing these advanced level filaments, so have a good read and pick your desired 3D printer out of this list for a great printing experience for your filament.

You can really create some amazing models with these machines. There are different price ranges and levels of features that these provide.

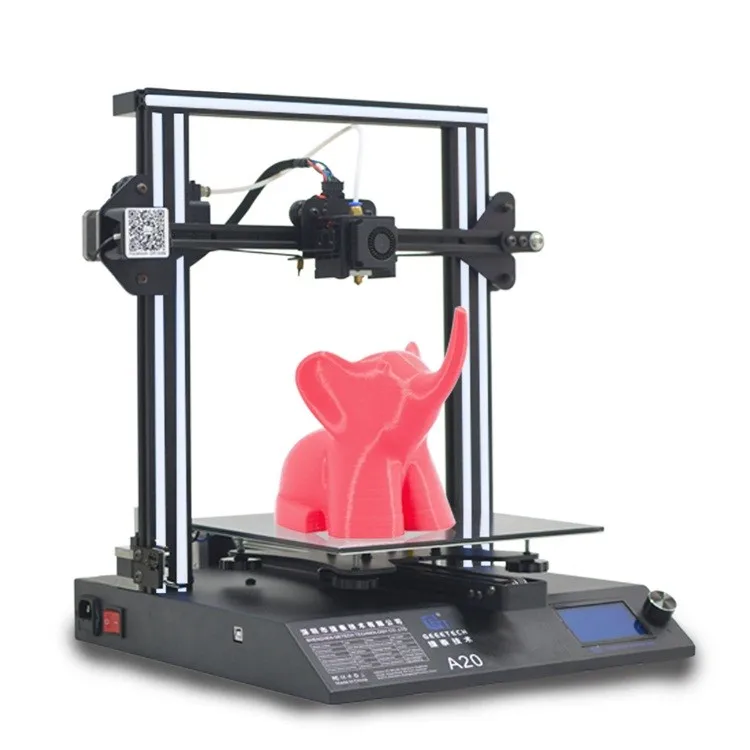

The Flashforge Adventurer 3 is a fully enclosed desktop 3D printer that offers easy and affordable 3D printing.

Most features seem to be based on ease of use and functionality such as removable print bed, built-in HD camera for monitoring, filament detection, and automatic feeding system.

With its reasonable price, it is a full package of 3D printing for beginners and even experienced users.

Its ease of usage makes it a good choice for printing ABS, ASA & Nylon especially if you are trying to know 3D printing.

Features of the Flashforge Adventurer 3

- Compact and Stylish Design

- Upgraded Nozzle for Stable Filament Loading

- TurboFan and Air Guide

- Easy Nozzle Replacement

- Fast Heating

- No Leveling Mechanism

- Removable Heated Bed

- Integrated Wi-Fi Connection

- 2 MB HD Camera

- 45 Decibels, Quite Operating

- Filament Detection

- Auto Filament Feeding

- Work with 3D Cloud

Specifications of the Flashforge Adventurer 3

- Technology: FFF/FDM

- Brand/Manufacturer: Flash Forge

- Body Frame Dimensions: 480 x 420 x 510mm

- Operating Systems: Windows XP/Vista/7/8/10, Mac OS X, Linux

- Display: 2.8 Inch LCD Color Touch Screen

- Mechanical Arrangements: Cartesian

- Extruder Type: Single

- Filament Diameter: 1.

75mm

75mm - Nozzle Size: 0.4mm

- Layer Resolution: 0.1-0.4mm

- Build Volume: 150 x 150 x 150mm

- Print Bed: Heated

- Maximum Build Plate Temperature: 100°C Degrees Celsius

- Maximum Printing Speed: 100mm/s

- Bed Leveling: Manual

- Connectivity: USB, Wi-Fi, Ethernet Cable, Cloud Printing

- Supported File Type: STL, OBJ

- Best Suitable Slicers: Flash Print

- Compatible Printing Material: PLA, ABS

- Third-Party Filament Support: Yes

- Weight: 9 KG (19.84 Pounds)

User Experience of the Flashforge Adventurer 3

Printing with the Flashforge Adventurer 3 printer is very simple to do and has been recommended for beginners and even children, so you know operation is easy. This doesn’t mean it sacrifices in quality though!

The simplicity of its design and operations is a key feature, but it should not be surprising that there are some limitations for professional or experienced 3D printer users because they need a high level of features and improvements.

The model of a 3D Benchy using PLA was printed at 210°C extruder temperature and 50°C bed temperature on Adventure 3, the results were pretty impressive.

There were no signs of stringing and layer visibility was there but far less than many other 3D printed models.

Due to its extreme shrinkage rate, printing ABS could be difficult. A test model was printed with ABS and print came out perfectly without any delamination or warping issues. You may face some adhesion problems while printing with ABS.

Pros of the Flashforge Adventurer 3

- Easy to use

- Supports third party filaments

- Great sensor features for better safety and operation

- Multiple connectivity options available

- 3D prints are easy to remove with the flexible and removable build plate.

- Flexible and removable build plate

- Quiet printing

- High resolution and precision

Cons of the Flashforge Adventurer 3

- Large filament rolls may not fit in a filament holder

- Sometimes emits a knocking sound while printing third party filaments

- The instruction manual is a bit messy and difficult to understand

- Wi-Fi connectivity may cause issues in terms of updating software

Final Thoughts

If you are a beginner and want to have an introduction to 3D printing, this simple, easy to use and friendly machine is your go-to option.

Get the fully enclosed Flashforge Adventurer 3 3D printer on Amazon today.

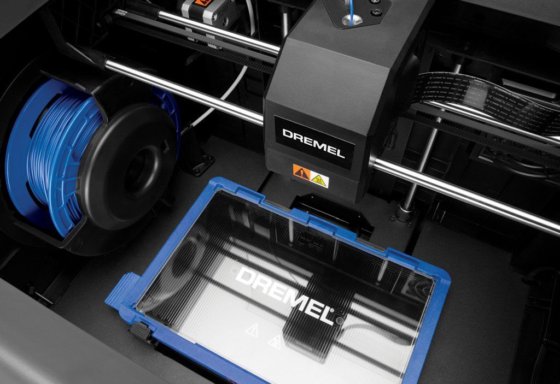

Features of the Dremel Digilab 3D45

- Automated 9-Point Levelling System

- Includes Heated Print Bed

- Built-In HD 720p Camera

- Cloud-Based Slicer

- Connectivity Through USB and Wi-Fi Remotely

- Fully Enclosed With Plastic Door

- 4.5″ Full Color Touch Screen

- Award Winning 3D Printer

- World-Class Lifetime Dremel Customer Support

- Heated Build Plate

- Direct Drive All-Metal Extruder

- Filament Run-Out Detection

Specifications of the Dremel Digilab 3D45

- Print Technology: FDM

- Extruder Type: Single

- Build Volume: 255 x 155 x 170mm

- Layer Resolution: 0.05 – 0.3mm

- Compatible Materials: PLA, Nylon, ABS, TPU

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Bed Levelling: Semi-Automatic

- Max. Extruder Temperature: 280°C

- Max.

Print Bed Temperature: 100°C

Print Bed Temperature: 100°C - Connectivity: USB, Ethernet, Wi-Fi

- Weight: 21.5 kg (47.5 lbs)

- Internal Storage: 8GB

User Experience of the Dremel Digilab 3D45

The Digilab 3D45 has mixed reviews from its users, most of which are positive. It looks like in the early days, Dremel had some quality control issues and saw failures in some machines which got dealt with by customer service.

Since that time, it looks like they have drastically improved their quality control issues and corrected problems that customers had, leading to a very positive experience for users who are interested in getting the 3D45 for themselves.

The best part about this 3D printer is just how easy it is to use, even being simple to operate for children and beginners. When it comes to your ABS, ASA & Nylon printing needs, this enclosed and high quality machine can provide wonderful models.

Many users talk about just how you can get started 3D printing in just a few simple steps, especially within 20-30 minutes. If you already understand the printing process and know what you are doing, you can get started even quicker.

If you already understand the printing process and know what you are doing, you can get started even quicker.

When you get this 3D printer, you can expect outstanding quality prints, a smooth printing experience, and even cool time-lapse videos with the featured in-built camera.

Dremel’s technical support is just one phone cal away, and they provide remarkable customer service, with an actual person.

Whether this is your first 3D printer, or one to add to your collection, it’s a choice you’ll grow to love. It comes fully assembled which makes it safer than other printers, as well as a perfect solution for printing filament like Nylon and ABS.

It’s also pretty quiet when running and has auto-leveling for easier operation.

Pros of the Dremel Digilab 3D45

- Reliable and high print quality

- Easy to operate, even for beginners and kids

- Comes with great software and support

- Has multiple connectivity options so you can choose what’s best for you

- Sturdy and secure design and frame

- Relatively quiet printing experience

- Setting up is simple and fast as it is fully-assembled

- Great for educational or professional purpose

- Prints are easy to remove with the removable glass build plate

Cons of the Dremel Digilab 3D45

- They advertise a limited filament range, mainly being PLA, ECO-ABS, Nylon & PETG

- The webcam isn’t the best quality, but still relatively good

- Some people reported the drive motor not extruding at times, but these errors seem to have been fixed

- Dremel don’t recommend third party filament, but it can still be used

- The nozzle is sold with the heating block, which can be quite pricey together ($50-$60)

- The printer itself is pricey compared to other machines

Final Thoughts

The Dremel Digilab 3D45 is a 3D printer that you can believe in, so I would recommend it if you have the budget and long-term goals for your 3D printing journey. It’s jam-packed full of features and has amazing reliability and customer service.

It’s jam-packed full of features and has amazing reliability and customer service.

Get yourself the Dremel Digilab 3D45 from Amazon today.

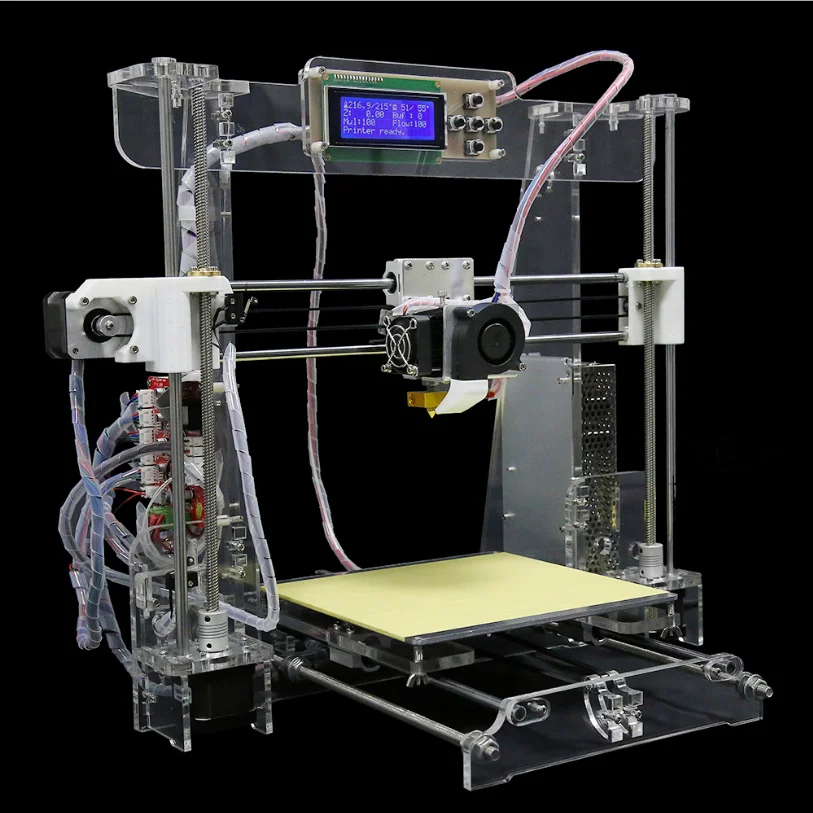

The Ender 3 V2 includes much-improved hardware including a 32-bit mainboard, a smoother stepper motor, a cleaner look with silky design, and many other minor touches. It is almost the same as its previous versions but with some upgrades and improvements.

Some work has been done to reduce major issues that were present in previous models such as difficulties in opening the filament feeding part.

You also get the integrated toolbox, compact design with the power supply underneath, and a friendly user interface.

The Ender 3 V2 is a great machine to work with PLA, ABS, ASA, Nylon, PETG, and even TPU as well. No doubt, you’d want to include an enclosure to print with some of the filaments because they print better under hotter ambient temperatures (ABS, ASA, Nylon).

A great enclosure for the Ender 3 V2 is the Creality Fireproof & Dustproof Enclosure from Amazon.

Features of the Ender 3 V2

- Tempered Glass Print Bed

- Quiet Printing

- Large Size Color LCD Touch Screen

- XY-Axis Tensioners

- Mean Well Power Supply

- Integrated Toolbox

- Resume after Power Outage

- User-Friendly New Style User Interface

- Effortless Filament Feeding

- Integrated Structure Design

- Big Size Bed Balancing Nuts

Specifications of the Ender 3 V2

- Technology: FDM

- Brand/Manufacturer: Creality

- Maximum Build Volume: 220 x 220 x 250mm

- Body Frame Dimensions: 475 x 470 x 620mm

- Display: LCD Color Touch Screen

- Extruder Type: Single

- Filament Diameter: 1.75mm

- Nozzle Size: 0.4mm

- Layer Resolution: 0.1mm

- Maximum Extruder Temperature: 255°C

- Print Bed: Heated

- Maximum Heated Bed Temperature: 100°C

- Maximum Printing Speed: 180mm/s

- Layer height: 0.1mm

- Feeder Mechanism: Bowden

- Bed Leveling: Manual

- Connectivity: USB, MicroSD Card

- Supported File Type: STL, OBJ

- Compatible Printing Material: PLA, ABS, PETG, TPU, Nylon

- Third-Party Filament Support: Yes

- Resume Printing: Yes

- Assembly: Semi Assembled

- Weight: 7.

8 KG (17.19 Pounds)

8 KG (17.19 Pounds)

User Experience of the Ender 3 V2

Assembly is fairly simple because many of the parts have been pre-assembled for you, but you do have to connect a few pieces together. I’d recommend following a step-by-step YouTube video guide, so you know exactly how to put it together.

Bed leveling is manual and is made easier with the large rotary leveling knobs. Operation of the Ender 3 V2 is praised by its thousands of users, especially with the addition of the newer user interface.

Compared to the Ender 3’s user interface, the V2 has a much smoother and modern experience, allowing for an easier printing process.

Getting the right adhesion could be difficult sometimes, but as long as you level your bed well, use a good bed temperature, and have an adhesive, you can 3D print ABS, ASA & Nylon very well.

Plenty of people are producing amazing quality 3D prints on this machine, and I’m sure you can follow suit when you get yourself the Ender 3 V2.

Once you get to know this 3D printer, it offers you print of high quality with the option to efficiently print a wide range of printing filaments such PLA, ABS, Nylon, etc.

Pros of the Ender 3 V2

- Easy to use

- Provides good quality prints right out of the box

- Effortless filament feeding

- A self-developed silent motherboard offers quiet operating

- UL certified means well power supply

- Carborundum glass platform

Cons of the Ender 3 V2

- Pointlessly detachable display

- Could be costly as compared to other 3D printers with these features.

- Require a separate enclosure as it comes without one.

Final Thoughts

The Ender 3 series, which includes the Ender 3 V2 are probably some of the most popular 3D printers of all time. You can definitely create some amazing 3D prints at a really competitive price, being under $300.

If you are looking for a great 3D printer to build up some ABS, ASA & Nylon 3D prints, you can count on this machine to get the job done.

Get your Ender 3 V2 3D printer on Amazon today.

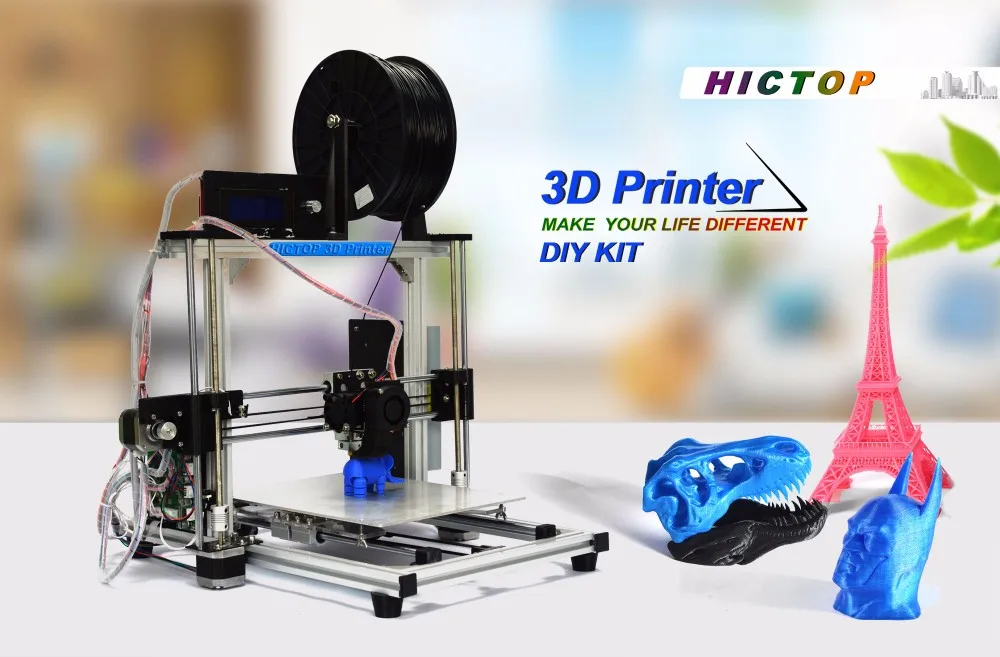

This china-based manufacturer has gained plenty popularity in the 3D printers’ market. Qidi Tech aims to offer 3D printers at an affordable price while including many premium features.

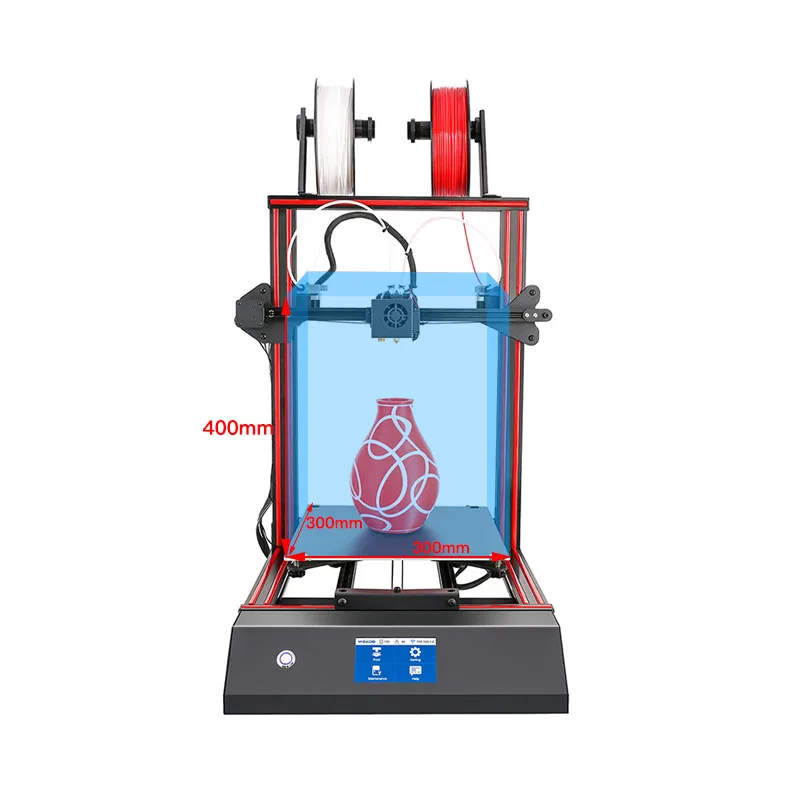

Qidi Tech X-Max offers a large build area to print extra-sized models. This 3D printer has the ability to efficiently print with advanced filaments such as Nylon, Carbon Fiber, ABS, ASA, and TPU.

This printer should be considered by small businesses, professionals, and experienced hobbyists, though beginners can definitely jump onboard.

Features of the Qidi Tech X-Max

- Supports Plenty of Filament Material

- Decent and Reasonable Build Volume

- Closed Print Chamber

- Color Touch Screen with Great UI

- Magnetic Removable Build Platform

- Air Filter

- Dual Z-Axis

- Swappable Extruders

- One Button, Fats Bed Leveling

- Versatile Connectivity from SD Card to USB and Wi-Fi

Specifications of the Qidi Tech X-Max

- Technology: FDM

- Brand/Manufacturer: Qidi Technology

- Frame Material: Aluminum

- Maximum Build Volume: 300 x 250 x 300mm

- Body Frame Dimensions: 600 x 550 x 600mm

- Operating Systems: Windows XP/7/8/10, Mac

- Display: LCD Color Touch Screen

- Mechanical Arrangements: Cartesian

- Extruder Type: Single

- Filament Diameter: 1.

75mm

75mm - Nozzle Size: 0.4mm

- Accuracy: 0.1mm

- Maximum Extruder Temperature: 300°C

- Maximum Heated Bed Temperature: 100°C

- Print Bed: Magnetic Removable Plate

- Feeder Mechanism: Direct Drive

- Bed Leveling: Manual

- Connectivity: Wi-Fi, USB, Ethernet Cable

- Suitable Slicers: Cura-Based Qidi Print

- Compatible printing Material: PLA, ABS, Nylon, ASA, TPU, Carbon Fiber, PC

- Assembly: Fully Assembled

- Weight: 27.9 KG (61.50 Pounds)

User Experience of the Qidi Tech X-Max

The Qidi X-Max is one of the highest rated 3D printers on Amazon, and for good reason. Based on user experiences, you can expect amazing print quality, easy operation, and great customer support.

One user has used their 3D printer regularly for 20+ hours a day for over a month, and it keeps on going strong.

The packaging for the X-Max is done very well with plenty of protective closed-cell foam, so your printer arrives in one order. It is fully enclosed and comes with all the tools you need to print some great models.

It is fully enclosed and comes with all the tools you need to print some great models.

You also get to make use of the Wi-Fi function and their Qidi Print Slicer Software to create your files to transfer into the printer.

While printing hard-to-handle materials such as ABS, ASA & Nylon, you may need to apply some bed adhesives to mitigate adhesion problems.

ABS, ASA & Nylon usually come out with great print quality, but models printed with Nylon X could be improved.

With Nylon X, sometimes it comes up with the effects of delamination or layer separation at the bottom or middle of the print.

One of the best things about this 3D printer is its amazing customer service.

You may find other printers at a low price, but it can be difficult to find a 3D printer that has such a large build area and temperature capacity of up to 300°C.

These factors allow you to print large-size models with ABS and Nylon without little hassle.

Pros of the Qidi Tech X-Max

- Smart design

- Large build area

- Versatile in terms of different printing materials

- Pre-assembled

- Excellent user interface

- Easy to set up

- Includes a pause and resume function for additional ease of printing.

- Fully enclosed illuminated chamber

- Low level of noise

- Experienced and helpful customer support service

Cons of the Qidi Tech X-Max

- No dual extrusion

- A heavyweight machine as compared to other 3D printers

- There is no filament run-out sensor

- No remote control and monitoring system

Final Thoughts

With its 300°C max. nozzle temperature and fully enclosed design, it is a great choice for people who want to print with a wide range of materials including PLA, ABS, Nylon, ASA, and many more at a high quality.

Get yourself the Qidi Tech X-Max on Amazon right now.

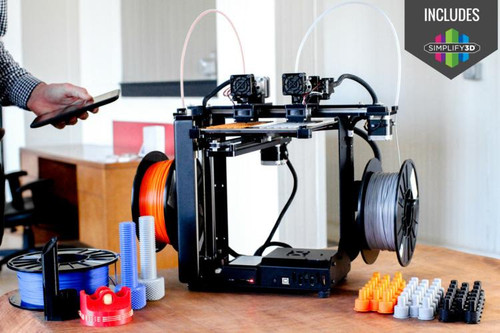

This is quite a unique 3D printer in a good way, mainly down to just how many features and abilities this thing has in store. Although it’s not as popular as 3D printers like the Creality Ender 3, this can definitely out-perform some of the best machines out there.

I’d definitely look into checking out this 3D printer as a potential choice for your ABS, ASA and Nylon printing desires.

Features of the BIBO 2 Touch

- Full-Color Touch Display

- Wi-Fi Control

- Removable Heated Bed

- Copy Printing

- Two-Color Printing

- Sturdy Frame

- Removable Enclosed Cover

- Filament Detection

- Power Resume Function

- Double Extruder

- Bibo 2 Touch Laser

- Removable Glass

- Enclosed Print Chamber

- Laser Engraving System

- Powerful Cooling Fans

- Power Detection

Specifications of the BIBO 2 Touch

- Technology: Fused Deposition Modeling (FDM)

- Assembly: Partially Assembled

- Mechanical Arrangement: Cartesian XY head

- Build Volume: 214 x 186 x 160 mm

- Layer Resolution: 0.05 – 0.3mm

- Fuel System: Direct Drive

- No. of Extruders: 2 (Dual Extruder)

- Nozzle Size: 0.4 mm

- Max. Hot End Temperature: 270°C

- Maximum Temperature of Heated Bed: 100°C

- Material Print Bed: Glass

- Frame: Aluminum

- Bed Leveling: Manual

- Connectivity: Wi-Fi, USB

- Filament Sensor: Yes

- Filament Materials: Consumables (PLA, ABS, PETG, flexible)

- Recommended Slicer: Cura, Simplify3D, Repetier-Host

- Operating system: Windows, Mac OSX, Linux

- File Types: STL, OBJ, AMF

User Experience of the BIBO 2 Touch

BIBO definitely had some issues at first with their 3D printer, showing from some of the negative views in the early days, but they got their act back together and delivered 3D printers which hold up well and print even better.

Users who were looking for a machine that was enclosed, had a reliable heated bed, as well as a dual extruder found exactly that with this 3D printer. Many reviewers on YouTube, on Amazon, and elsewhere swear by the BIBO 2 Touch.

The 3D printer is very well-made, and they even have videos on the SD card which help you set the printer up, and the instructions are actually good, unlike many 3D printer manufacturers out there.

Once put together, people admired the quality that they could produce, especially once they tried out the dual extrusion feature. Another lovely feature that people love is the laser engraver, as you can imagine you can do some great things with it.

Many FDM 3D printers max out at a layer resolution of 100 microns, but this machine can go right down to a layer height of 50 microns or 0.05mm.

On top of that great quality, the control and operation is really easy, as well as being able to easily print ABS, ASA, Nylon and many other high level materials since it can reach temperatures of 270°C

One user mentioned how easy setup was, saying that the hardest part was simply unboxing the machine! When you follow the instructions, you can get up and running really quickly.

Their customer support is another huge bonus. Some people reported that they welcome you with a nice email before receiving the printer, and quickly address any queries and issues you may have.

Pros of the BIBO 2 Touch

- Gives you the ability to print with two colors, even having a mirror function for faster printing

- 3D prints are easier to remove with the removable glass bed

- Very stable and durable 3D printer

- Easy operation with the full-color touchscreen

- Great customer support

- Safe and secure packaging for a reliable delivery

- You can make use of the Wi-Fi controls to help operate the 3D printer

- Allows you to engrave objects with the laser engraver

Cons of the BIBO 2 Touch

- Build space is not very large

- Some people have experienced under extrusion due to the extruder, but this may have been a quality control issue

- Previously experienced quality control issues, though recent reviews show these have been solved

- Troubleshooting can be challenging with dual extruder 3D printers

Final Thoughts

The BIBO 2 Touch is a special kind of 3D printer which has so many features and abilities, you can trust it to expand your creative horizons. When it comes to 3D printing materials like ABS, ASA, Nylon and plenty more, this 3D printer can definitely get the job done.

When it comes to 3D printing materials like ABS, ASA, Nylon and plenty more, this 3D printer can definitely get the job done.

Get yourself the BIBO 2 Touch from Amazon today.

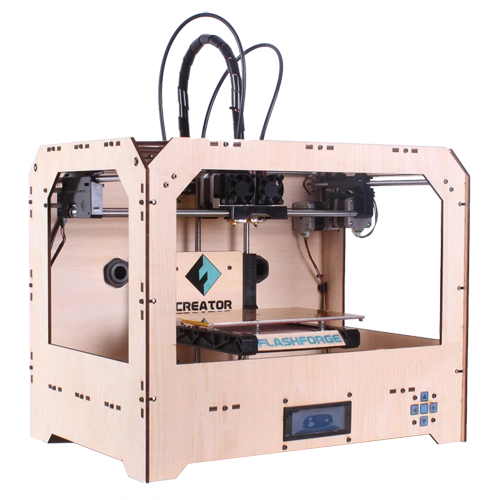

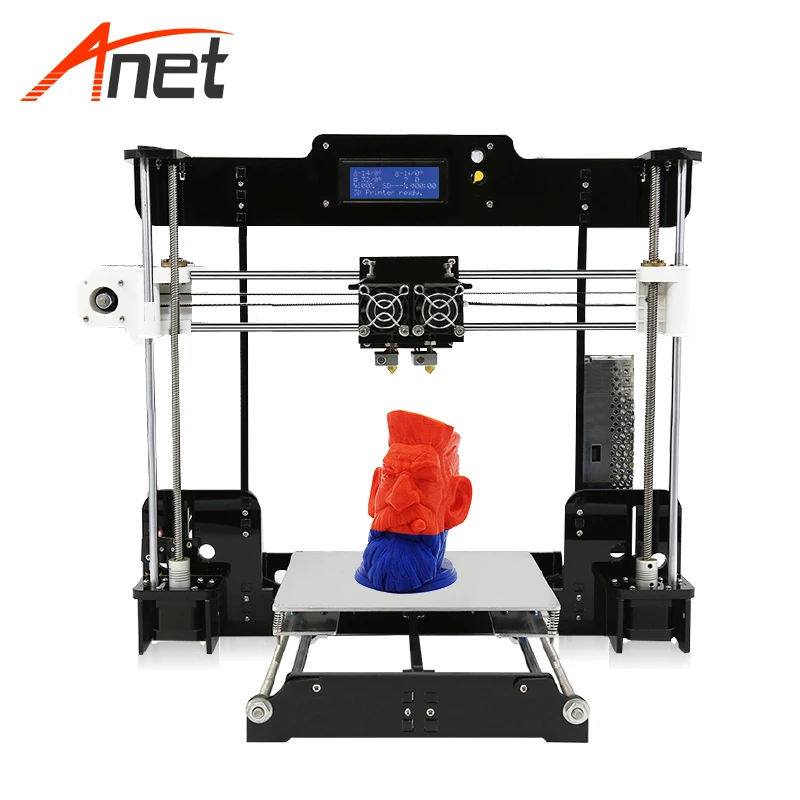

The Flashforge Creator Pro 3D printer is one of the most affordable and cable 3D printers in the market that offers dual extrusion.

Its heated build plate, sturdy construction, and fully enclosed chamber allow 3D printer users to print models with different printing materials.

It can print effectively with temperature-sensitive filaments while protecting them from warping or stringing. This 3D printer has a protective and helpful user base and is available at a relatively low price.

Features of the Flashforge Creator Pro

- Dual Extruders

- Advanced Mechanical Structure

- Enclosed Printing Chamber

- Heated Print Bed

- Installation Free Top Lid

- Open-Source Technology

- 45° Degrees Viewing, LCD Screen Control Panel

- 180° Front Door Opening

- Side Handle

- Ready to Print Just Out of the Box

Specifications of the Flashforge Creator Pro

- Technology: FFF

- Brand/Manufacturer: Flashforge

- Maximum Build Volume: 227 x 148 x 150mm

- Body Frame Dimensions: 480 x 338 x 385mm

- Extruder Type: Dual

- Filament Diameter: 1.

75mm

75mm - Nozzle Size: 0.4mm

- XY-Axis Positioning Accuracy: 11 microns

- Z-Axis Positioning Accuracy: 2.5 microns

- Maximum Extruder Temperature: 260°C

- Maximum Heated Bed Temperature: 120°C

- Maximum Printing Speed: 100mm/s

- Layer Height: 0.1mm

- Bed Leveling: Manual

- Connectivity: USB, MicroSD Card

- Supported File Type: STL, OBJ

- Suitable Slicers: Replicator G, FlashPrint

- Compatible Printing Material: PLA, ABS, PETG, PVA, Nylon, ASA

- Third-Party Filament Support: Yes

- Assembly: Semi Assembled

- Weight: 19 KG (41.88 Pounds)

User Experience of the Flashforge Creator Pro

When you receive your Flashforge Creator Pro, you’ll be beside a professional looking 3D printer that is of high quality. It’s a dual extruder machine that is respected in the 3D printing community.

It’s full of high quality parts, an optimized build platform, and an acrylic cover that allows you to see through the enclosure at your 3D prints.

Setup is straightforward, so you can get things worked pretty quickly out of the box. You can 3D print all sorts of filaments like PLA. ABS, PETG, TPU, Polypropylene, Nylon, ASA and plenty more.

One person who previously had the Dremel 3D20 for many years got himself the Flashforge Creator Pro, and never looked back.

Right out of the box he got amazing 3D prints without needing to do any special adjustments or upgrades.

Even with no experience, many users found this 3D printer to be a great one to use. It has some serious accuracy and precision with its models.

This 3D printer is great for people who want to learn in a rapid manner and don’t want to go through too many steps for the setup and printing process.

Pros of the Flashforge Creator Pro

- Reasonably high-quality prints

- Include dual extrusion capabilities

- Operates quietly

- Affordable price with some advanced features

- Durable and strong metal frame

Cons of the Flashforge Creator Pro

- Recommend slicer software for this 3D printer is not so good

- Requires initial assembly which could be annoying, but still quicker compared to other 3D printers

- Insufficient instructions for the setup process

- Has been known to jam in some cases when using the dual extrusion, but can be improved with the right software

- The spool holder may not fit some brands of filament, but you can print another compatible spool holder.

Final Thoughts

The Flashforge Creator Pro 3D printer is highly recommended for enthusiasts, hobbyists, casual users, small businesses and offices.

It’s great for people who are looking for a 3D printer that can work efficiently with different types of filaments ranging from simple PLA to hard materials such as ABS, ASA, Nylon, PETG and more.

If you are one of such users, check out Flashforge Creator Pro at Amazon today.

Qidi Tech has strived to balance affordability and advanced features on a single line. Well, they have got a lot of success with the Qidi Tech X-Plus 3D printer.

This 3D printer includes some features that not many other 3D printer in this price range includes. It’s price is higher than those budget 3D printers, but its capabilities and reliability is up there with the best.

Features of the Qidi Tech X-Plus

- Dual Extruder System

- Two Build Plates

- Two Filament Holders

- Fully Enclosed 3D Printer Chamber

- Color LCD Display Screen with Intuitive UI

- Dual Z-Axis Structure

- Enhanced Cooling System

- One Button Quick Bed Leveling

- Updated and Improved Cura-Based Slicing Software

Specifications of the Qidi Tech X-Plus

- Technology: FDM (Fused Deposition Modeling)

- Brand/Manufacturer: Qidi Tech

- Body Frame: Aluminum

- Body Frame Dimensions: 710 x 540 x 520mm

- Operating Systems: Windows, Mac OX

- Display: LCD Color Touch Screen

- Mechanical Arrangements: Cartesian XY-Head

- Extruder Type: Single

- Filament Diameter: 1.

75mm

75mm - Nozzle Size: 0.4mm

- Maximum Build Volume: 270 x 200 x 200mm

- Maximum Extruder Temperature: 260°C

- Maximum Heated Bed Temperature: 100°C

- Layer Height: 0.1mm

- Feeder Mechanism: Direct Drive

- Bed Leveling: Assisted Manual

- Print Bed Material: PEI

- Connectivity: Wi-Fi, USB, LAN

- Supported File Type: STL, AMF, OBJ

- Suitable Slicers: Simplify3D, Cura

- Compatible printing Material: PLA, ABS, PETG, Flexibles

- Third-Party Filament Support: Yes

- Print Recovery: Yes

- Filament Sensor: Yes

- Assembly: Fully Assembled

- Weight: 23 KG (50.70 Pounds)

User Experience of the Qidi Tech X-Plus

One of the most common things that users talk about with Qidi is their customer service, which is second to none. That alone is worth plenty, but let’s talk about the 3D printer itself.

One user who saw videos of the X-Plus in operation as well as the positive comments about it decided to get one for themselves. They noticed just how solidly build and heavy duty the machine was, which is usually a good sign.

They noticed just how solidly build and heavy duty the machine was, which is usually a good sign.

In terms of the print quality, this was at a very high standard and what’s even better is how the build plate is removable and reversible.

One side is meant for standard filaments like PLA, ABS, TPU & PETG, while the other side is for the advanced materials like Nylon, Polycarbonate & Carbon Fiber.

Adhesion on the build plate is top quality, as well as having a flexible build plate which can be used to remove prints easily.

Unfortunately, there isn’t a filament sensor which isn’t ideal, especially for a machine that has a large build volume. You can try to estimate how much filament you have left by eye, but this can take some time to get a good gauge.

It isn’t a dual extruder 3D printer like the BIBO 2 Touch or the Qidi Tech X-Max, but it still holds up as a great 3D printer.

You can place filament either inside the printer or on the outside, which is great for those filaments that print better within an enclosed build space.

You also have two newly developed extruders which has one specially for general materials, and a second extruder for those advanced materials.

It’s a perfect 3D printer to create models with materials like ABS, ASA, Nylon, Polycarbonate and much more.

Pros of the Qidi Tech X-Plus

- Removable build plate makes removing 3D prints easier

- Large and responsive touchscreen for easy operation

- Offers a relatively large print area

- Provides excellent precision and accuracy

- Includes a heated print bed

- Assisted bed leveling makes the leveling process easy

- Supports several types of 3D printing filaments

- Sturdy body frame

Cons of the Qidi Tech X-Plus

- Large base area or footprint

- Filament is known to drag when printing larger models, so you should install a longer PTFE tube

- No dual extruder included

- The printing speed is quite limited, with users mentioning it could just about hold 50mm/s

- Lacks auto-bed leveling

Final Thoughts

If you want a 3D printer that includes a full package of amazing feats at an affordable price while providing you with efficient print quality, Qidi Tech X-Plus could be a go-to option.

If you want to take a look at the Qidi Tech X-Plus 3D printer, you can check it out on Amazon for a competitive price.

Hopefully, this article has assisted you on choosing a great 3D printer for your chosen material, and I’m sure you’ll have a positive journey with any of the 3D printers above!

The 8 Best Nylon 3D Printers for Easy Nylon Printing (2022) – Clever Creations

Nylon filament is one of the most versatile 3D printing materials that you can print on a desktop 3D printer. It has excellent tensile strength, is flexible, and has a high melting point, making it ideal for functional prototypes and interlocking prints that undergo high wear and tear.

Despite these benefits, 3D printing Nylon filament has its own set of challenges, and not all 3D printers are equipped or designed to print with Nylon. For someone looking for printing with Nylon, this might become a challenge and confuse them further as to what printer will deliver the best results with Nylon.

To help make it easier for you and to make you aware of your choices in the market, we’ve curated a list of some of the best Nylon 3D printers that you can buy right now. We have also included the things you should look for when getting a Nylon printer.

Read on to learn how to choose the best Nylon 3D printer for you!

| Best Nylon 3D Printer | Summary | Build Volume | Price (~) | Best Offer |

|---|---|---|---|---|

| Matterhackers Pulse XE | Best overall | 250 x 220 x 215 mm | $899 | MatterHackers |

| Ultimaker S5 | Best high-end | 330 x 240 x 300 mm | $6355 | MatterHackers |

| Flashforge Adventurer 3 | Best on a budget | 150 x 150 x 150 mm | $369 | Flashforge |

| Creality Ender 3 S1 | Most silent | 220 x 220 x 270 mm | $429 | Creality |

| QIDI Tech X-Plus | Highest print temperature | 270 x 200 x 200 mm | $699 | Geekbuying |

| FlashForge Adventurer 4 | Best air filtration | 220 x 200 x 250 mm | $799 | Flashforge |

| Dremel DigiLab 3D45 | Most user-friendly | 254 x 152 x 170 mm | $1880 | MatterHackers |

| Raise3D Pro 2 | Largest Nylon 3D Printer | 305 x 305 x 300 mm | $3999 | MatterHackers |

The Best Nylon 3D Printers in 2022

Matterhackers Pulse XE

Best overall

Check Price

MatterHackers

The Matterhackers Pulse XE is a 3D printer specifically designed to print with NylonX material. It comes with a hardened steel nozzle, a specially engineered bed surface, and a maximum extruder temperature of 300 °C, letting you print Nylon filament with ease.

It comes with a hardened steel nozzle, a specially engineered bed surface, and a maximum extruder temperature of 300 °C, letting you print Nylon filament with ease.

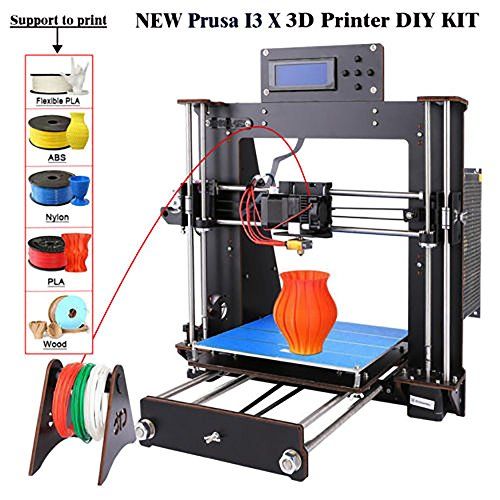

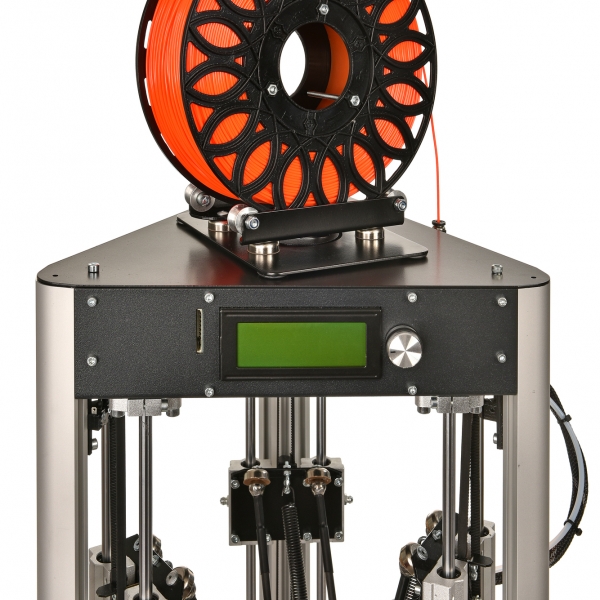

You get a Prusa i3 style open-frame design, and a BLTouch leveling sensor for ease of use. The print surface is textured with Garolite, which guarantees better print adhesion with Nylon and is durable enough to last for many print cycles. The Pulse XE uses the best components currently available right now, such as a Bondtech extruder and a E3D V6 hot end, to deliver high-quality 3D prints.

For under $1000, the Pulse XE is a feature-packed printer, which serves excellent value to the end-user, making it the best overall Nylon 3D printer on the list. It will print anything you throw at it with ease, and if you’re in the market for a professional-grade Nylon 3D printer, the Pulse XE is the best choice for you.

Standout Features

- BLTouch leveling probe

- Garolite print surface

- Robust i3 design

Technical Details | |

|---|---|

| Build Volume | 250 x 220 x 215 mm |

| Materials | PLA, ABS, PETG, Nylon, Carbon Fiber, PC |

| Bed leveling | Automatic |

| Max hot end temperature | 295°C |

| Max bed temperature | 100°C |

| Connectivity | SD card, USB |

| Supported slicers | Mattercontrol |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to upgrade

- Hardened steel nozzle

- Easy to use interface

Could Be Better

- Lacks enclosure

- Outdated LCD

Find Matterhackers Pulse XE at

MatterHackers

Ultimaker S5

Best high-end

Check Price

AmazonMatterHackers

Ultimaker 3D printers are known for their premium build quality and excellent print results. The Ultimaker S5 is the flagship 3D printer in the Ultimaker printer lineup and comes with the best features that make it great for printing industrial prototypes and end-use components.

The Ultimaker S5 is a dual extruder 3D printer with a large print volume of 330 x 240 x 300 mm that lets you fully take advantage of its dual print heads. It offers convenient swappable print cores and a removable glass bed to print with advanced materials such as NylonX, Polycarbonate, and Polypropylene.

The airflow manager add-on maintains a stable printing temperature, which is useful when printing with Nylon. And with the material station, you can easily store Nylon filament without having to resort to a filament dry box.

And with the material station, you can easily store Nylon filament without having to resort to a filament dry box.

Given its features and the high-end components, printing with Nylon should be as easy as printing with PETG or PLA filament on the Ultimaker S5. Overall, it’s an excellent 3D printer that will deliver consistent printing results and cover nearly all FDM 3D printing needs.

Standout Features

- Dual extrusion

- Swappable print cores

- Large build volume

Technical Details | |

|---|---|

| Build Volume | 330 x 240 x 300 mm |

| Materials | PLA, ABS, PETG and CPE, ASA, Nylon, NylonX and NylonG, PV, Polycarbonate, Polypropylene |

| Bed leveling | Automatic |

| Max hot end temperature | 280°C |

| Max bed temperature | 140°C |

| Connectivity | Wi-Fi, Ethernet, USB |

| Supported slicers | Ultimaker Cura |

| Filament diameter | 2. 85 mm 85 mm |

What We Like

- Multi-material printing

- Premium components

- Remote monitoring

Could Be Better

- Serious investment

- Separate enclosure kit

Find Ultimaker S5 at

AmazonMatterHackers

Flashforge Adventurer 3

Best on a budget

Check Price

AmazonFlashforgeBanggood

The Flashforge Adventurer 3 is a fully-enclosed 3D printer designed to be easy to use and beginner-friendly. With its intuitive interface and an excellent feature set, it gives you excellent value for your money.

The Adventurer 3 comes with an interchangeable nozzle design that lets you upgrade the default nozzle set up to a high-temperature nozzle that goes up to 265 °C, letting you print with ABS, PETG, PC, and Nylon. Its heated print bed and the enclosure help maintain a passively heated, stable printing temperature, further improving print quality.

Its automatic filament loading, inbuilt camera, and remote monitoring greatly benefit the user experience and are nice features for beginners to use the 3D printer efficiently and safely.

Overall, the Flashforge Adventurer 3 is a great package that comes at an affordable price of under $400. It is excellent for beginners and hobbyists that need a reliable 3D printer that can print with Nylon filament on a budget.

Standout Features

- Detachable nozzle design

- Automatic filament loading

- Wireless 3D printing

Technical Details | |

|---|---|

| Build Volume | 150 x 150 x 150 mm |

| Materials | PLA, ABS, PETG, Nylon |

| Bed leveling | Automatic |

| Max hot end temperature | 240°C / 265°C |

| Max bed temperature | 100°C |

| Connectivity | USB stick, Wi-Fi, Ethernet FlashCloud, PolarCloud |

| Supported slicers | Flashprint |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Beginner-friendly

- Fully enclosed

- Removable print bed

Could Be Better

- Small build area

- Only compatible with FlashPrint

Find Flashforge Adventurer 3 at

AmazonFlashforgeBanggood

Creality Ender 3 S1

Most silent

Check Price

AmazonCrealityCreality3DOfficialMatterHackers

The Creality Ender 3 S1 is the latest printer from Creality and comes with all the best features you would expect from a desktop 3D printer in 2022. The PC-coated flexible spring steel bed is a new inclusion in the Creality lineup and is perfect for adhesion with printing materials such as Nylon.

It also offers a newly designed “sprite” extruder that weighs less than traditional direct drive setups and is excellent for printing flexible filaments like TPU. It comes with a 32-bit motherboard with silent stepper motors, letting it print at < 50 dBs. This makes it one of the quietest 3D printers available right now, especially when coupled with its official enclosure.

This makes it one of the quietest 3D printers available right now, especially when coupled with its official enclosure.

The hot end is designed to reach up to 260 °C, letting you print Nylon filament with ease. However, the aforementioned enclosure is something you will need as well if your goal is to 3D print Nylon filament. It helps prevent the warping of your Nylon prints, significantly increasing your success rate with this tricky filament.

The Creality Ender 3 S1 is a superb hobbyist-level printer resulting from years of community feedback. Its silent stepper drivers make it an ideal 3D printer for a home or an office setup. It is a great fit if you want a Nylon 3D printer with all essential features, that is easy to set up and delivers excellent print quality.

Recommended:

Creality Ender 3 S1 Review: A New Standard

Standout Features

- Improved "sprite" extruder

- Dual Z-axis design

- PC spring steel print bed

Technical Details | |

|---|---|

| Build Volume | 220 x 220 x 270 mm |

| Materials | PLA, TPU, PETG, ABS, Nylon |

| Bed leveling | Automatic |

| Max hot end temperature | 260°C |

| Max bed temperature | 100°C |

| Connectivity | Type-C USB, SD Card |

| Supported slicers | Ultimaker Cura |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to assemble

- Automatic bed leveling

- Direct extrusion for TPU, TPE

Could Be Better

- Open-frame design

- Enclosure comes separately

Find Creality Ender 3 S1 at

AmazonCrealityCreality3DOfficialMatterHackers

QIDI Tech X-Plus

Highest print temperature

Check Price

AmazonGeekbuyingAliExpressBanggood

The QIDI Tech X-Plus 3D printer is one of the rare 2-in-1 3D printers that is fine-tuned for printing with basic and advanced materials alike. It has two separate direct-drive extruders and bed surfaces, each configured for different printing materials.

You get one extruder that reaches up to 250 °C, combined with a textured print surface meant for printing with PLA, ABS, and PETG. The second hotend-extruder set up can go as high as 300 °C and can be combined with the smooth bed surface on the opposite side of the printing bed. This second setup enables you to 3D print with Nylon, PC, and Carbon Fiber.

This second setup enables you to 3D print with Nylon, PC, and Carbon Fiber.

The dual Z-axis setup delivers stable and precise printing and the enclosed spool holder design, too, is beneficial when printing with Nylon filament.

One of its biggest shortcomings, however, is its relatively small build height (200mm) given the machine’s price. If your needs include printing tall Nylon 3D prints, the Tech X-Plus is not the best option.

Considering the features and ease of switching hot ends when printing with different materials, the QIDI Tech X-Plus offers a great printing experience. It is a great choice for hobbyists and even professionals who need a versatile 3D printer that is well-built and delivers reliable results.

Standout Features

- Two different extruder setups

- Dual print surface

- Double Z-axis

Technical Details | |

|---|---|

| Build Volume | 270 x 200 x 200 mm |

| Materials | PLA, ABS, PETG, Flexibles, Nylon, PC |

| Bed leveling | Automatic |

| Max hot end temperature | 260°C / 300°C |

| Max bed temperature | 100°C |

| Connectivity | USB, WiFi, LAN |

| Supported slicers | QIDIPrint, Cura, Simplify3D |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to set up and configure

- Stores filament inside

- Wi-Fi connectivity

Could Be Better

- Easy to damage print surface

- No filament guiding system

Find QIDI Tech X-Plus at

AmazonGeekbuyingAliExpressBanggood

FlashForge Adventurer 4

Best air filtration

Check Price

AmazonFlashforgeGeekbuyingAliExpress

The Flashforge Adventurer 4 is the next iteration of the Adventurer 3 / 3 Pro 3D printers and keeps many of the existing features while improving in areas related to the design and user experience of the printer.

It offers a fully-enclosed print chamber to maintain a stable printing environment and a HEPA 13 air filtration system to keep away any harmful 3D printer fumes. This is something that is of use when working with Nylon filament.

Additionally, the Adventurer 4 offers an interchangeable nozzle design to let you quickly swap between high-temperature nozzles and a flexible metal printing plate that facilitates easy print removal.

The Adventurer 4 is designed for beginners, hobbyists, prosumers, and educational use. The air filtration system is excellent for using the printer indoors and near kids or pets. With this Nylon 3D printer, you get a machine that is full of features and that is safe to use.

Standout Features

- HEPA 13 air filtration

- Quick release nozzle

- Built-in spool holder

Technical Details | |

|---|---|

| Build Volume | 220 x 200 x 250 mm |

| Materials | ABS/PLA/PC/PETG/PLA-CF/PETG-CF/Nylon |

| Bed leveling | Automatic |

| Max hot end temperature | 265°C/240°C |

| Max bed temperature | 110°C |

| Connectivity | USB. Wi-Fi, Ethernet, Cloud |

| Supported slicers | FlashPrint |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Easy to use

- Remote monitoring

- Fully enclosed design

Could Be Better

- Small build volume

- Assisted bed leveling

Find FlashForge Adventurer 4 at

AmazonFlashforgeGeekbuyingAliExpress

Dremel DigiLab 3D45

Most user-friendly

Check Price

AmazonMatterHackers

Coming from a renowned tool manufacturer, the Dremel DigiLab 3D45 is easy and intuitive to use, even when 3D printing with advanced materials such as Nylon, PC, and Carbon Fiber.

The DigiLab 3D45 comes with 9-point automatic bed leveling, removing the need for manual leveling and improving first-layer adhesion. You get a hot end capable of reaching up to 280°C and a maximum print bed temperature of 110°C for easy and high-quality prints with high-temperature filaments such as ABS and Nylon.

It also includes 30 lesson plans, which is a valuable addition to a 3D printer designed to improve the educational experience in classrooms. The 3D45 is just that, with an intuitive user-friendly touchscreen that makes it easy for students to access all of the printer’s features, and a design that is focused on safety.

The 3D45 is just that, with an intuitive user-friendly touchscreen that makes it easy for students to access all of the printer’s features, and a design that is focused on safety.

While the Dremel DigiLab 3D45 is specifically designed for use in classrooms, based on its features and capabilities to print with advanced materials, you can equally use it for your hobby and prosumer prototyping needs. Do keep in mind that it comes at a significant 3D printer cost. As far as Nylon 3D printers are concerned, it is one of the most expensive.

Standout Features

- RFID Filament recognition

- Remote 3D print monitoring

- Industrial design

Technical Details | |

|---|---|

| Build Volume | 254 x 152 x 170 mm |

| Materials | PLA, Eco-ABS, Nylon, PETG |

| Bed leveling | Manual |

| Max hot end temperature | 280°C |

| Max bed temperature | 110°C |

| Connectivity | Wifi, USB, Ethernet |

| Supported slicers | Dremel DigiLab 3D Slicer (Cura), Dremel Print Cloud (3DPrinterOS) |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Plug-n-play design

- Over 30 lesson plans

- Intuitive touchscreen

Could Be Better

- Manual bed leveling

- Small build volume

Find Dremel DigiLab 3D45 at

AmazonMatterHackers

Raise3D Pro 2

Largest Nylon 3D Printer

Check Price

AmazonMatterHackers

The Raise3D Pro 2 is a large-sized, fully enclosed dual extruder 3D printer built for professionals. It includes a 305 x 305 x 300 mm large print volume that offers enough space for larger Nylon 3D prints.

In terms of features, it has a hot end capable of going up to 300 °C and a heated bed that reaches up to 110 °C, letting you print with Nylon, Metal PLA, Carbon Fiber, and PC. The dual extruders allow you to do multi-material printing, for example, letting you print with soluble supports.

The addition of a large 7-inch touchscreen, a HEPA filtration system, a filament sensor, and a 32-bit mainboard are all designed to enhance the user experience. However, with a price tag of $3999, the Raise3D Pro 2 is aimed squarely at professional users.

However, with a price tag of $3999, the Raise3D Pro 2 is aimed squarely at professional users.

It is one of the best Nylon 3D printers on the list and combines the best of all the others mentioned. The Raise3D Pro 2 is an ideal fit for your professional 3D printing workflow or use in print farms and industries.

Standout Features

- Dual extrusion

- Large build volume

- High-temp hot end

Technical Details | |

|---|---|

| Build Volume | 305 x 305 x 300 mm |

| Materials | PLA, ABS, HIPS, TPU, PC, NYLON, TPE, FLEX, PETG, Metallic PLA, Wood PLA, Carbon Fiber Reinforced Materials |

| Bed leveling | Automatic |

| Max hot end temperature | 300°C |

| Max bed temperature | 110°C |

| Connectivity | WiFi, LAN, USB Port |

| Supported slicers | Ideamaker |

| Filament diameter | 1. 75 mm 75 mm |

What We Like

- Multi-material printing

- Large touchscreen

- Inbuilt spool holders

Could Be Better

- Reliability issues

Find Raise3D Pro 2 at

AmazonMatterHackers

What to look for in a Nylon 3D printer

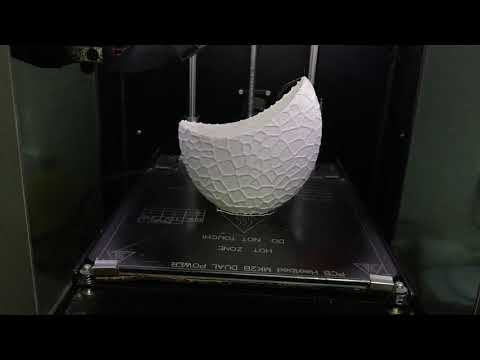

Enclosure

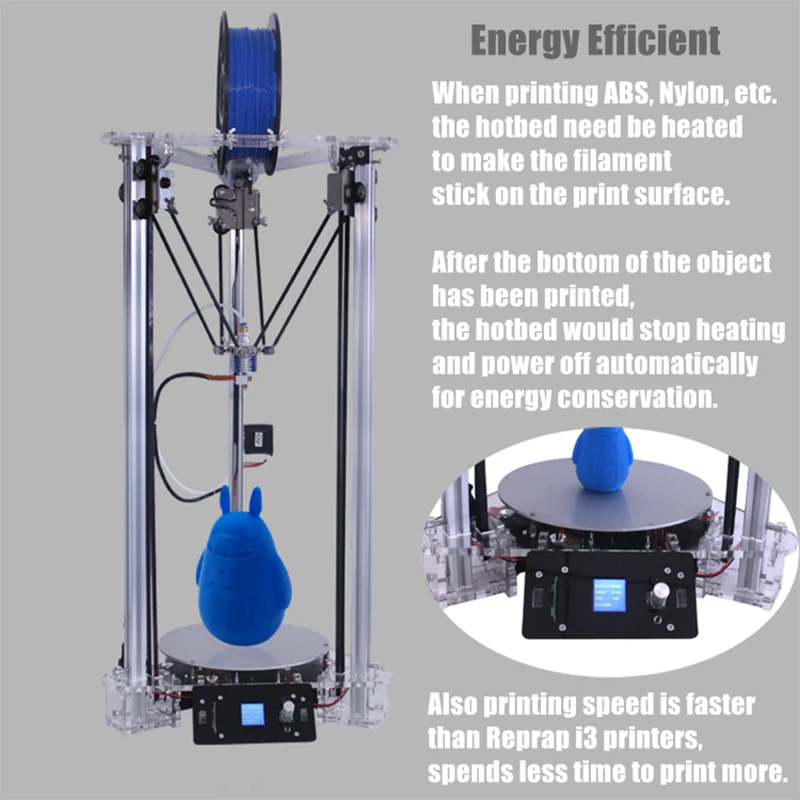

Nylon is a high-temperature material, meaning it extrudes at high temperatures beyond 230 °C. This makes it prone to warping quickly with even the slightest temperature differences in the print chamber. Enclosed 3D printers help to dial down these issues.

With an enclosure, you get a stable printing temperature, and the heat emitted from the bed stays contained in the print chamber, keeping an evenly heated area near the print. Moreover, a fully enclosed 3D printer that offers internal spool storage is able to keep Nylon filaments from absorbing any external moisture.

If the Nylon 3D printer you have an eye on is not enclosed, you can always opt for a DIY 3D printer enclosure or an aftermarket one.

Maximum nozzle temperature

As mentioned earlier, Nylon filament has a high melting temperature. Its typical extrusion temperature lies somewhere between 230°C – 270°C depending on the filament brand. When getting a 3D printer to print Nylon, you need to ensure that it has an all-metal hot end capable of reaching and sustaining these temperatures.

All of the 3D printers mentioned in this list are capable of printing at such high temperatures, with the maximum nozzle temperature of some printers going as high as 300°C. It gives a bit of freeway to print Nylon at higher temps and better quality. Higher nozzle temperatures let you set a faster printing speed, too, as they can melt and push Nylon filaments at a high rate.

Heated bed

The high-temperature hot end and a heated bed go hand in hand while printing with Nylon filament. A heated bed helps with better print surface adhesion of Nylon, while also passively heating the print area. It leads to relatively stable printing temperatures, thus reducing warping with Nylon prints.

For printing with Nylon filament, you need bed temperatures between 70°C – 90°C. The exact temperature varies from brand to brand, which you will need to figure out with a bit of experimentation or by reading the recommended temperatures in the documentation.

In addition to the heated bed, you need to look at the print surfaces too. A Garolite print surface and a glass bed with a PVA glue stick result in the best bed adhesion and can easily sustain the heating temperatures of 70 °C and beyond that is required to print with Nylon filament.

Build volume

The build volume of a 3D printer is one of its defining characteristics, and it becomes an important criterion to consider when deciding to get a printer to print with Nylon filaments.

Nylon filament has excellent mechanical properties with high resistance to abrasion and a low coefficient of friction.

Having a large print volume for such applications will give you more freedom to print bigger models in a single piece. It will lead to better uniformity throughout the print, resulting in excellent mechanical properties. Similarly, you can print larger-sized display pieces in a single part, thus saving you post-processing times and giving you a seamless model.

It will lead to better uniformity throughout the print, resulting in excellent mechanical properties. Similarly, you can print larger-sized display pieces in a single part, thus saving you post-processing times and giving you a seamless model.

Remote monitoring

Nylon as a filament is expensive compared to other materials like the PLA, ABS, and PETG. It is difficult to 3D print too, and there are chances of print failures due to poor bed adhesion or something else going wrong during the printing process. It leads to material losses, wasted filament, and an overall loss in productivity.

With a remote monitoring setup, you get a camera and Wi-Fi connectivity to view the current printing progress remotely. If something were to go wrong, you can immediately stop the print and remedy any issue. Asides from this, you get the flexibility to be away from the 3D printer and continue with any other work without worrying about the print’s status.

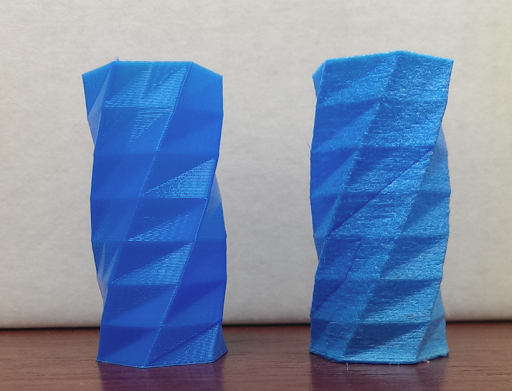

Common problems with 3D printing nylon

Moisture Absorption

Nylon is a hygroscopic material, which means that it readily absorbs moisture from its surroundings. It will cause under-extrusion issues, air bubbles, or blobs on the print’s surface, eventually leading to print failures.

It will cause under-extrusion issues, air bubbles, or blobs on the print’s surface, eventually leading to print failures.

It is recommended to store Nylon in airtight containers with desiccants that absorb any moisture. Before printing, drying it in an oven or a filament dryer will help remove any residual moisture from the material. And an enclosure that will isolate the material from the external environment will help keep the filament dry during the printing process.

Warping

We’ve established that Nylon is a high-temperature material that melts between 230°C – 270°C. If we cannot control this cooling rate once Nylon is extruded out of the nozzle and let its temperature come down drastically, it will contract rapidly and result in warping and layer separation issues.

To counter this, you need a heated bed to maintain a heat zone near the print’s surface and an enclosure to prevent any sudden air drafts and keep the hot air inside the print chamber. A printing surface with Garolite or PVA glue stick also helps with better bed adhesion and reduces any warping of Nylon.

Advantages of Nylon filament

High impact strength

Nylon has the highest impact strength than PLA, ABS, and PETG. It makes it highly durable and perfect for applications where parts are constantly subject to impact loads such as hammering, banging, or crashing with each other.

Low coefficient of friction

Nylon has a low coefficient of friction, meaning it can easily slide on other parts without substantial damage to the surface. It is beneficial for applications such as interlocking gears and constant motion mechanisms.

Flexibility

Nylon’s flexibility can be varied by varying its thickness. If you have thinner models or print thin walls, you can create a very flexible part that flexes without breaking apart.

Post-processing

Nylon’s hygroscopic nature makes it easier for you to use fabric paints or dyes with it as the print will quickly absorb the color leading to quick and easy post-processing.

Disadvantages of Nylon filament

Absorbs moisture

Nylon filament will readily absorb the moisture from the air, even during the printing process, and it results in poor print quality and might even cause print failures.

Warping

Nylon has a high melting point. If it is allowed to cool down gradually or the print area is not at a stable temperature, the Nylon print will warp, resulting in a deformed part.

Prior drying

Even if you’ve stored Nylon in an airtight container, there are chances of still some moisture being present in the filament. It would be best to dry Nylon before printing to remove any leftover moisture. This can be a cumbersome process and adds to the overall time spent on 3D printing Nylon.

Frequently Asked Questions

Can 3D printers print Nylon?

Yes, 3D printers can print Nylon. However, the printer needs to be calibrated properly to ensure proper printing quality. In addition, you also need to take into account the high printing temperature and warping issues that come with using Nylon filament.

What is a good brand of Nylon filament?

There are many brands of Nylon filament available in the market. Some of the more popular brands include OVERTURE, Taulman3D, and Polymaker. Either of these brands likely has the right Nylon filaments to cover your needs.

Either of these brands likely has the right Nylon filaments to cover your needs.

Polymaker Nylon Filament 1.75 Black, Easy to Print Nylon Filament...

180 Reviews

Check PriceWhat are some applications where Nylon filament can be used?

Nylon filament can be used in a variety of applications including industrial parts, mechanical parts, and consumer products. It has high impact strength and low friction making it ideal for use in wearable products, automotive parts, and other moving parts.

What type of Nylon is used for 3D printing?

There are two types of Nylon that are used for 3D printing: Nylon 6 and Nylon 12. Nylon 6 is the most popular type as it has a low melting point and is easier to print with. Nylon 12 has a higher melting point and is less brittle, but it is more difficult to print with.

Is Nylon stronger than PLA?

Nylon is stronger than PLA filament, but it also has a higher printing temperature. It is more flexible than PLA and can withstand more impact loads. However, it is also more prone to warping. Both are likely to absorb moisture from the air and need proper filament storage.

However, it is also more prone to warping. Both are likely to absorb moisture from the air and need proper filament storage.

What 3D printer will print in Nylon?

Not all 3D printers can print in Nylon. The printer needs to be able to handle temperatures up to 260 degrees Celsius in order to print with Nylon filament. In addition, the printer also needs to be calibrated properly to ensure good printing quality. An enclosure is beneficial as well.

Is Nylon hard to 3D print?

Nylon is not hard to 3D print. However, the high printing temperature and tendency to warp can cause some issues if the printer is not calibrated properly. It is important to make sure that the area where the print is taking place is at a stable temperature.

Can Nylon be used without a heated bed?

Nylon can be used without a heated bed, but it is not recommended. The print will likely not stick to the bed and the quality of the print may be affected. A heated bed helps to keep the Nylon filament at a stable temperature, which reduces warping and helps get high-quality prints.

Conclusion

Nylon is an excellent 3D printing material with outstanding mechanical strength and practical applications. You can use Nylon in functional components, interlocking gears, constant motion mechanisms, and even display models owing to its various properties.

In our comparison, the Matterhackers Pulse XE stands out as the best Nylon 3D printer that covers all of your Nylon printing needs. Since it is designed to print with Nylon material, it has all the features you need to achieve excellent print results. You get a high-temperature hot end, a heated bed with Garolite, and a decent print volume, all at a relatively budget price.

The only thing the Pulse XE lacks is an enclosure. And this is where the QIDI Tech X-Plus and the Flashforge Adventurer 4 have the edge. These 3D printers come with a fully-enclosed design, are easy to use, can print at high temps with ease, and have loads of other valuable features to make the Nylon 3D printing experience a little easier.

Let us know your thoughts on the list, and if you have anything else to add, feel free to comment below.

Overview of high-temperature FDM plastics for industrial 3D printing / Sudo Null IT News materials in stock. To understand what materials are needed to obtain a strong and lightweight part, we are moving from personal printing to industrial printing. PLA, ABS, SBS are consumables that are familiar to all printers. PETG, nylon, polycarbonate - rather exotic. But these are far from the most serious materials.

Where are superplastics needed?

Plastics with outstanding properties are very useful in space. No, it’s not yet possible to print a rocket engine out of plastic, the heat resistance is not even close to the same, but it is ideal for various parts around. An example is Stratasys and the "climate control" of Atlas V rockets. 16 printed parts instead of 140 metal parts - faster, lighter, cheaper. And this is not a theoretical project, it has already flown into space.

Another example is aviation. The flight altitude is lower, but the application is more massive. Here, too, there is a reason to reduce the mass of parts, switch to plastic where possible. It is used in the aircraft industry and direct metal printing, when it comes to engine components or fuselage frame parts, but less loaded structural elements, such as cabin ventilation and interior elements, are best made from plastic. This direction is being developed, for example, by Airbus.

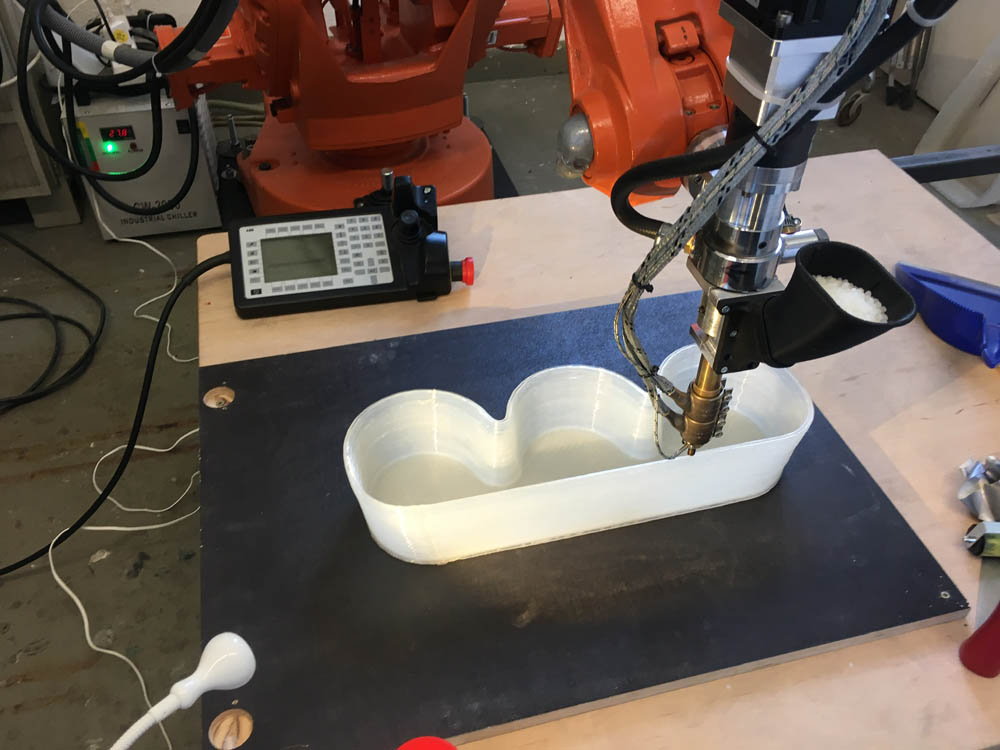

We descend from heaven to earth: here the mass is no longer so critical, other properties of engineering plastics are of interest. Resistance to aggressive chemicals and elevated temperatures, the ability to create structures inaccessible to classical methods. At the same time - a lower price, in comparison with metal printing. Printed products are used in medicine, oil and gas industry, chemical industry. As an example, a mixing block with a complex channel structure, made for illustration in a section.

Difference from conventional plastics

Why not launch PLA into space and make air vent grilles from ABS? A number of requirements are applied to engineering plastics related to resistance to high and low temperatures, fire resistance, mechanical strength. Usually all at once. So, it is undesirable to launch PLA “floating” when interacting with the environment or perfectly burning ABS into the sky.

Now - to what, in fact, plastics are used in industrial printing using FDM / FFF technology.

Polycarbonate filaments

Polycarbonate is a common industrial plastic with high impact resistance and transparency, also produced for the needs of FDM printing. The material holds temperature better than ABS, is resistant to acids, but is sensitive to UV radiation and is destroyed by oil products.

Clear polycarbonate, PC

The maximum operating temperature for polycarbonate products is 130 °C. Polycarbonate is biologically inert, products made from it can withstand sterilization, which makes it possible to print packaging and auxiliary equipment for medicine.

Polycarbonate is biologically inert, products made from it can withstand sterilization, which makes it possible to print packaging and auxiliary equipment for medicine.

- Stratasys PC, PC-ISO for Fortus printers. The first is general purpose, the second is certified for biocompatibility, for medical use.

- Intamsys PC;

- Esun ePC;

- SEM PC;

- PrintProduct PC;

ABS/PC

Polycarbonate/ABS alloy combines the sanding and painting capabilities of ABS with higher impact resistance and operating temperature. Retains strength at low temperatures down to -50 °C. Unlike pure PC, it is better applicable in cases where it is necessary to eliminate the layered structure of the part by grinding or sandblasting. Application: production of housings and elements of controls for piece and small-scale production, replacement of mass-produced plastic parts in equipment, parts for which have ceased to be produced.

- Stratasys PC/ABS;

- Roboze PC-ABS;

- SEM ABS/PC;

- BestFilament ABS/PC.

Polyamide based filaments

Polyamides are used in the production of synthetic fibers, a popular material for printing by selective laser sintering (SLS). For printing using FDM / FFF technology, polyamide-6 (kapron), polyamide-66 (nylon) and polyamide-12 are mainly used. Common features of polyamide-based filaments include chemical inertness and anti-friction properties. Polyamide-12 is more flexible and resilient than PA6 and PA66. Operating temperature approx. 100 °C, some modifications up to 120.

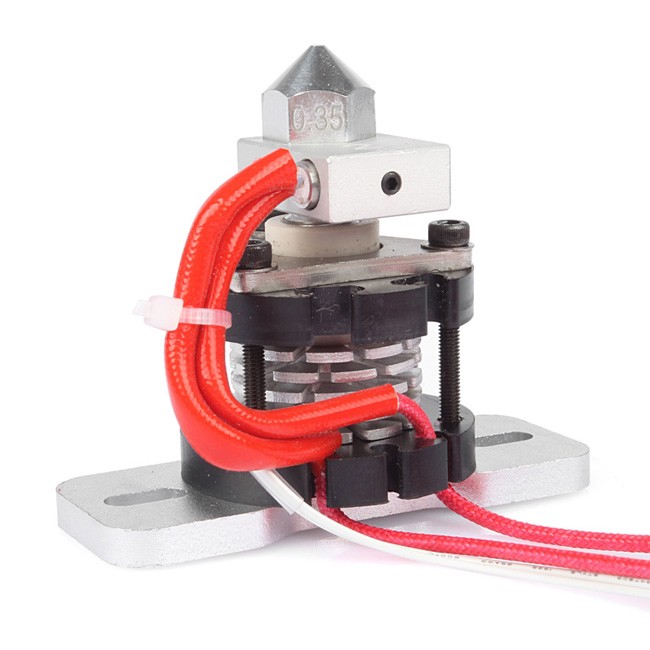

First of all, gears are printed from polyamide. The best material for this purpose, which can be worked with on a regular 3D printer with a closed chamber. Abrasion resistance allows you to make rods, cams, sliding bushings. In the line of many manufacturers there are composite filaments based on polyamide, with even greater mechanical strength.

- Stratasys Nylon 6, Nylon 12, Nylon 12CF. The latter is filled with carbon fiber.

- Intamsys Nylon, PA6.

- Taulman Nylon 618, Nylon 645 based on PA66 and PA6 respectively. Nylon 680 is approved for use in the food industry. Alloy 910 is a low shrinkage polyamide alloy.

- PrintProduct Nylon, Nylon Mod, Nylon Strong;

- REC Friction;

- BestFilament BFNylon.

Moving on to the fun part

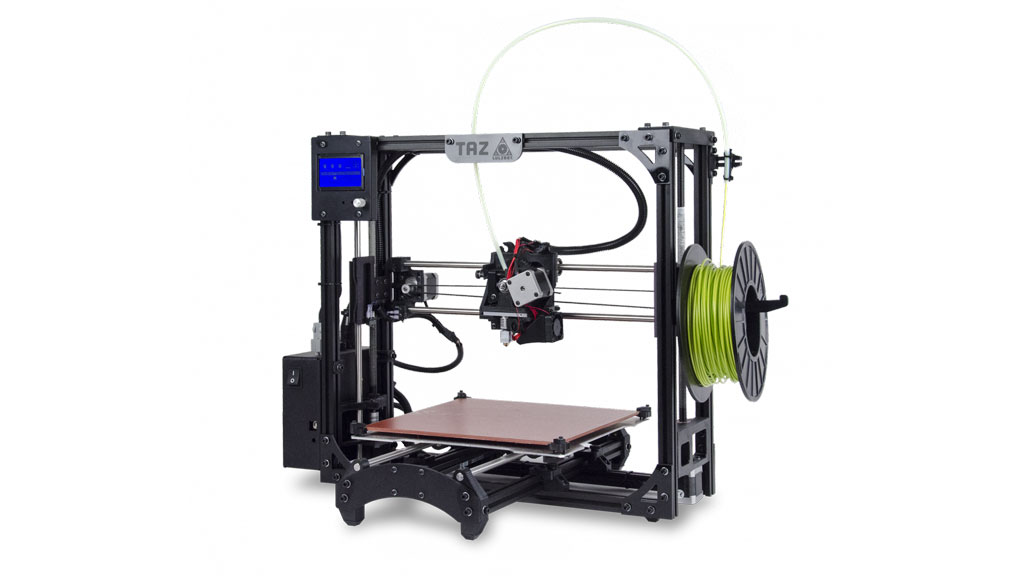

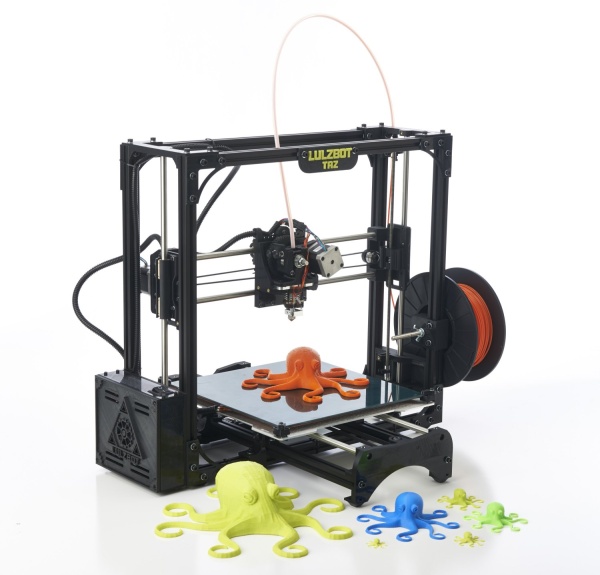

You can work with polycarbonate or polyamide on a regular 3D printer. With the filaments described below, it is more difficult, they require other extruders and maintaining the temperature in the working chamber, that is, you need special equipment for printing with high-temperature plastics. There are exceptions - for example, NASA, for the sake of experiment, upgraded the Lulzbot TAZ popular in the USA to work with high-temperature filaments.

Polyetheretherketone, PEEK

The operating temperature of PEEK products reaches 250 ° C, short-term heating up to 300 is possible - indicators for reinforced filaments. PEEK has two disadvantages: high price and moderate impact resistance. The rest is pluses. The plastic is self-extinguishing, heat-resistant, chemically inert. Medical equipment and implants are produced from PEEK, abrasion resistance makes it possible to print parts of mechanisms from it.

PEEK has two disadvantages: high price and moderate impact resistance. The rest is pluses. The plastic is self-extinguishing, heat-resistant, chemically inert. Medical equipment and implants are produced from PEEK, abrasion resistance makes it possible to print parts of mechanisms from it.

- Intamsys PEEK;

- Apium PEEK;

- Roboze PEEK, Carbon PEEK. The second is reinforced with carbon fiber.

Polyetherimide, PEI

He is Ultem. A family of plastics developed by SABIC. The characteristics of PEI are more modest than those of PEEK, but the cost is noticeably lower. Ultem 1010 and 9085 are Stratasys' primary materials for printing functional parts. PEI is in demand in the aerospace industry - the mass is much less compared to aluminum alloys. Operating temperatures of products, depending on the modification of the material, reach 217 ° C according to the manufacturer and 213 - according to the results of tests by Stratasys.

The advantages of PEI are the same as those of PEEK - chemical and temperature resistance, mechanical strength. It is this material that Stratasys is promoting as a partial replacement for metal in the aerospace industry, for drones, the manufacture of tooling for molding, the rapid printing of functional parts in pilot production.

Atlas V rocket cooling system components and Airbus plastic parts shown as an example at the beginning of the review are made of Ultem 9085.

- Stratasys Ultem 1010 and 9085, for Fortus 450mc and 900mc printers.

- Intamsys Ultem 1010 and 9085;

- Roboze Ultem AM9085F;

- Apium PEI 9085.

Polyphenylsulfone, PPSF/PPSU

Another material that combines in its properties temperature resistance, mechanical strength and resistance to chemical attack. Stratasys PPSF is certified for aerospace and medical applications. Positioned as a raw material for the production of auxiliary medical devices, it can be sterilized in steam autoclaves. It is used in the production of parts for laboratory installations in the chemical industry.

Positioned as a raw material for the production of auxiliary medical devices, it can be sterilized in steam autoclaves. It is used in the production of parts for laboratory installations in the chemical industry.

- Stratasys PPSF;

- 3DXTech Firewire PPSU.

Polysulfone, PSU

Less common than PPSU, similar physical characteristics, chemically inert, self-extinguishing. 175°C operating temperature, up to 33% cheaper than PPSU.

- 3DXTech Firewire PSU

Comparison of filament characteristics

* calcination for 2 hours at 140 °C.

** Apium PEEK 450 natural, impact test results not available with similar methods. Temperature resistance is specified for unfilled PEEK.

Data shown for Stratasys filaments, excluding PEEK. If a range of values is indicated, then the tests were carried out along and across the layers of the part.

About composite filaments

Most FDM printing materials have composite versions. If we talk about PLA, then metal or wood powders are added to it to change the aesthetic properties. Engineering filaments are reinforced with carbon fiber to increase the rigidity of the part. The influence of such additives on the properties of plastic depends not only on their quantity, but also on the size of the fibers. If a fine powder can be considered a decorative additive, then the fibers already significantly change the characteristics of the plastic. By itself, the word Carbon in the name of the material does not yet mean outstanding properties, you need to look at the test results. For example: Stratasys Nylon12CF has almost twice the tensile strength, when tested along the layers, than Nylon12.

Exotic variant - implementation of continuous reinforcement from Markforged. The company offers a reinforcing filament for co-FDM printing with other plastics.

Other specific properties

Engineering plastics are not only resistance to high temperatures and mechanical strength. For housings or boxes for storing electronic devices, and in environments where flammable volatile liquids are used, materials with antistatic properties are required. In the Stratasys line, this is, for example, ABS-ESD7.

- Stratasys ABS-ESD7;

- Roboze ABS-ESD

Conventional ABS does not have UV resistance, which limits its outdoor use without a protective coating. As an alternative, ASA is offered, which has characteristics similar to ABS, except for the UV resistance.

- REC Eternal;

- SEM ASA;

- BestFilament A.S.A.

Original alternative

Plastic can replace metal in many areas, as it is superior in lightness, thermal and electrical insulation, resistance to reagents. But printouts from the best FDM filaments do not reach the physical indicators of metal products.

But printouts from the best FDM filaments do not reach the physical indicators of metal products.

Chemical giant BASF offers the Ultrafuse 316LX FDM filament, with a stainless steel content of 80%. The part is printed on an FDM printer and then placed in an oven where the binder plastic is burned off and the metal is sintered. The part obtained in this way is much cheaper than the one made by direct metal printing. With an FDM printer and a suitable oven, no new equipment is needed at all.

Note that a similar solution is offered by the Virtual Foundry company - its Filamet, with bronze or copper powder, is baked in a similar way. The choice of metal hints at decorative rather than engineering applications.

AIM3D has its own implementation of this principle - the ExAM 255 printer does not work with filament, but with granules. This allows the use of raw materials for FDM printing, which are usually used in MIM installations, Metal Injection Molding. For sintering the part, the company offers an ExSO 9 furnace0. It is also possible to print with plastic granules, which is usually cheaper than using traditional filament.

For sintering the part, the company offers an ExSO 9 furnace0. It is also possible to print with plastic granules, which is usually cheaper than using traditional filament.

Special machinery for engineering plastics

To recap. In a nutshell: the considered consumables differ from the usual materials in high printing temperature, which requires the use of special equipment, and serious heat resistance and mechanical strength of the manufactured parts. To work with such filaments, 3D printers with an extruder operating temperature of 350 °C and a heat-stabilized working chamber are required. Top 3D Shop specialists will help you with the selection of an industrial 3D printer and plastics for solving the most interesting tasks.

Want more exciting news from the world of 3D technology?

Follow us on social. networks:

Choosing a liquid photopolymer for a 3D printer. Classification of materials for SLA/DLP 3D printing.

Contents:

- Introduction

- SLA Overview

- SLA Standard Resins

- Standard photopolymer resin - Standard

- Clear Photopolymer Resin - Clear

- Engineering photopolymer resins

- Rigid photopolymer resin - Tough (like ABS)

- Durable photopolymer resin - Durable (PP-like)

- Heat resistant photopolymer resin - Heat resistant

- Rubber-like photopolymer resin - Rubber-like (Elastic)

- Ceramic photopolymer resin - Ceramic filled (Hard)

- How to choose the right resin for your application

- Dental and medical SLA resins

- Medical Device Photopolymer Resin - Custom Medical Appliances (Class I Biocompatibility)

- Dental Long Term Biocompatible Resin (Class IIa Biocompatible)

- Class I biocompatibility vs Class IIa biocompatibility

- Castable SLA resins

- Cast resin for jewelry making ) , rubber -like ( flexible ) , Dental ( Dental ) .

The information from the article will help you choose a photopolymer resin for your needs.

The information from the article will help you choose a photopolymer resin for your needs. Catalog of photopolymer 3D printers

Photopolymers from FormLabs

Detailed review of the Formlabs Form 3 3D printer

Introduction

The stereolithography prints plastic parts with high resolution, good fine detail, and a smooth surface. Due to the variety of photopolymer resins available for SLA, this technology is used in many different industries:

-

"Standard" photopolymers are used for prototyping

-

Engineering photopolymers have certain mechanical and thermal properties

-

Dental and medical photopolymers have biocompatibility certificates.

-

Cast photopolymers have a zero ash content after burning.

SLA 3D Printing Resin Overview

SLA uses a laser to cure a liquid photopolymer resin. This process is called photopolymerization. Various combinations of polymers and other additives that are part of the resin allow you to get different material properties.

The main advantages and limitations that are common to all resins in SLA 3D printing are:

Benefits:

Weaknesses:

Base photopolymers for SLA

Post-Processing SLA/DLP 3D Printing Article

Standard photopolymer resin - StandardStandard resins produce parts with high stiffness, detail and a smooth surface. The low cost of resins, from $250 per liter, makes them ideal for prototypes.

The color of the resin also affects its properties. For example, in FormLabs products, gray resin is suitable for models with fine details, and white resin for parts that require the smoothest possible surface.

Benefits of using Standard grade resins:

Cons Standard:

Also included in the class of "Standard" photopolymer resins from FormLabs is the Color KIT - a set of special dyes and "Color Base" photopolymer resin for mixing and obtaining a variety of color solutions. This eliminates the need for painting parts after 3D printing.

FormLabs Engineering Photopolymer Resins

Engineering resins have a range of properties for injection molded plastics.

All engineering resins require additional UV curing, such as using the Form Cure, to achieve their maximum properties.

Tough photopolymer resin - Tough (ABS equivalent)Tough resin was developed for models that need to withstand high loads and be durable.

This material produces strong, shatter-resistant parts and functional prototypes such as snap-on housings.

Pros:

Cons:

Ideal for: functional prototypes, mechanical parts

Durable photopolymer resin - Durable

Durable resin is a wear-resistant and flexible material with mechanical properties similar to polypropylene.

Durable photopolymer produces models with a smooth glossy surface and high resistance to deformation.

Durable Resin is ideal for:

- Bushings and bearings;

- Various functional compounds

Pros:

Cons:

-

Not suitable for thin wall parts (recommended minimum wall thickness 1mm)

-

Low heat distortion temperature

-

Low flexural strength (lower than hard resin)

Ideal for: functional prototypes.

Refractory Photopolymer Resin - Formlabs High Temp ResinThe heat resistant resin is ideal for parts that require high temperature resistance and operate at high temperatures.

Formlabs High Temp Resin provides the highest melting point (HDT): 238°C at 0.45 MPa.

The resin should be used to print detailed, accurate prototypes with high heat resistance.

Pros:

Cons:

Flexible ResinRubber-like resin allows flexible parts to be made. This material has a low tensile strength and high elongation at break and is well suited for parts that will be bent or compressed.

It can also be used to add ergonomic features to multi-material assemblies such as: dies, wearable prototypes, handles, pads and grips.

Pros:

-

High flexibility (high elongation at break)

-

Low hardness (simulates 80A durometer rubber)

-

High impact resistance

Cons: