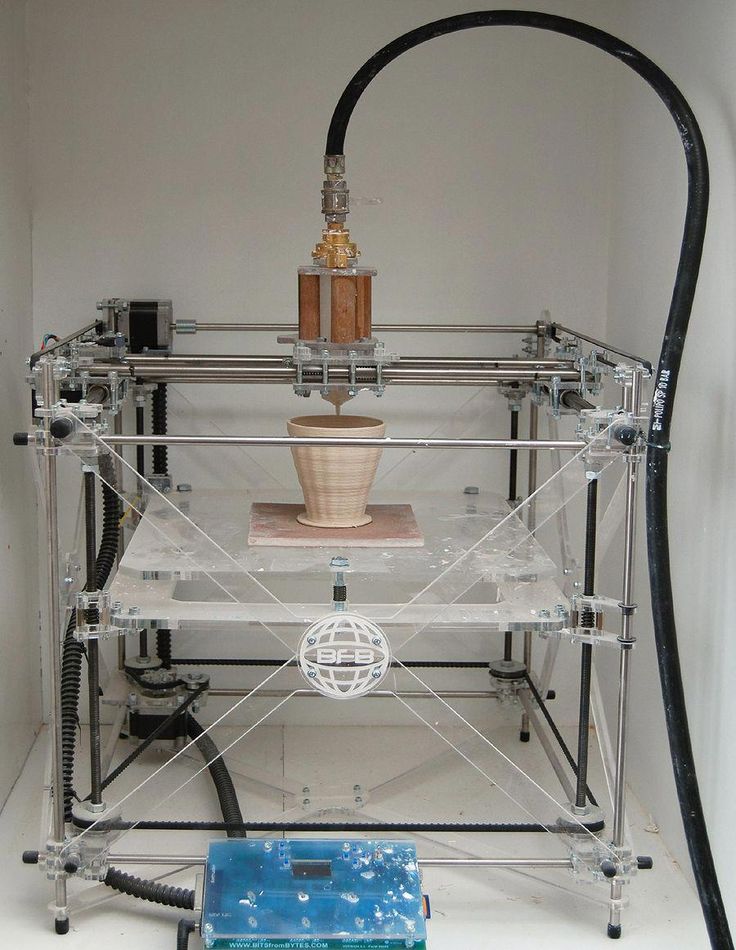

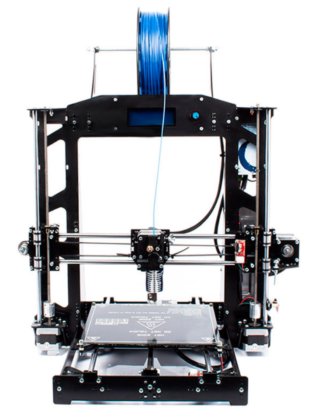

Beast 3d printer

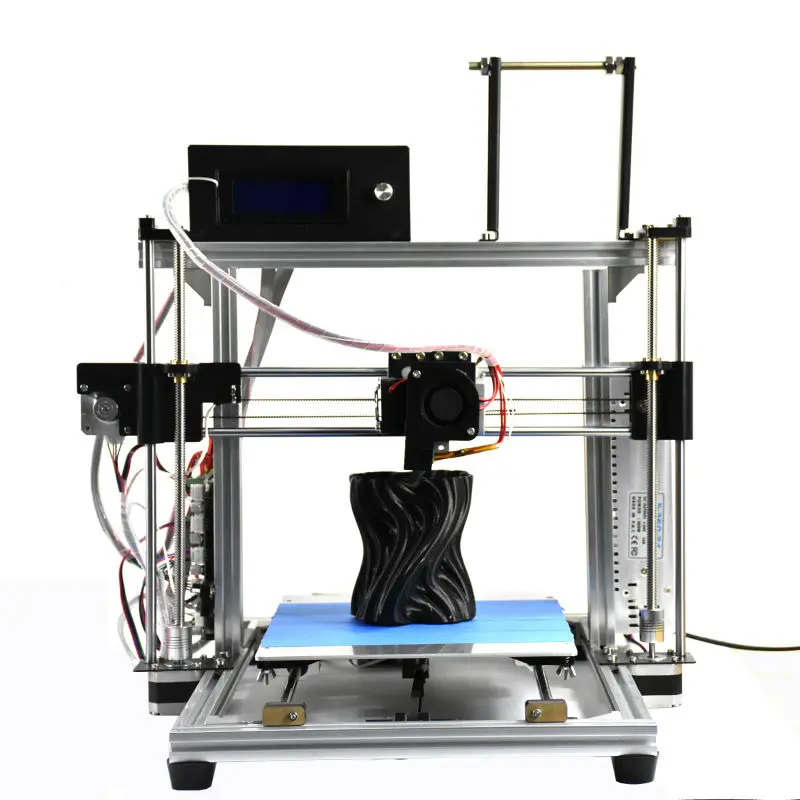

Cultivate3D Official – Elevator Multi Material 3D Printer

-

Cultivate 3D Elevator

No Lead Screws, Efficient Multi Material. Lightning Fast Tool Change -

Elevator Naked

Light Weight, Extensible. -

Design Files now Available

See our documentation : docs.cultivate3d.com

Features

Features

Elevator isn't "just" another big 3D printer. Each Elevator and Elevator Naked features the following :

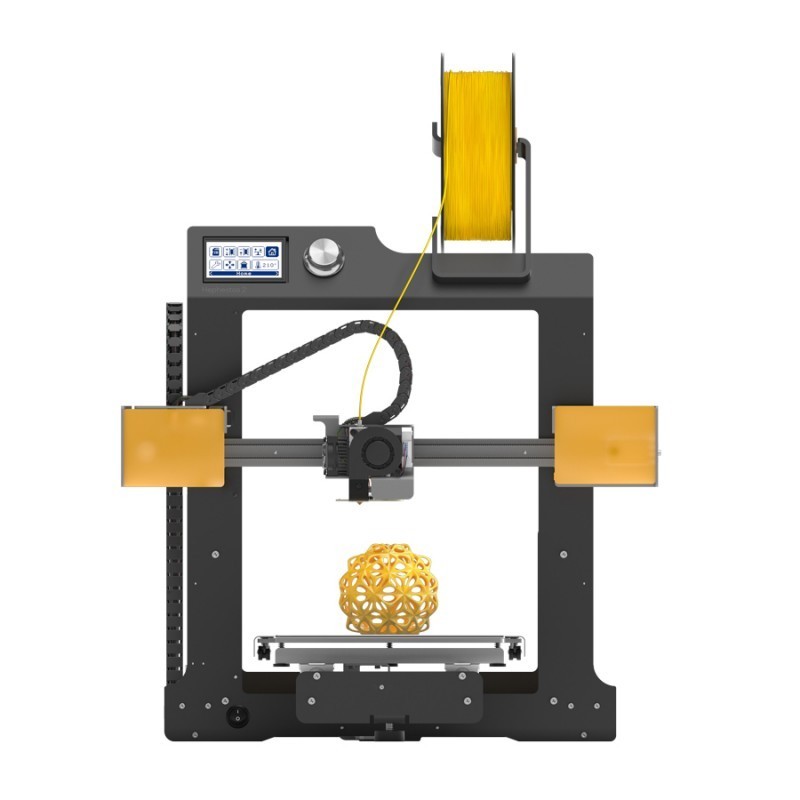

Specifications.

Elevator Fully Enclosed. Kit Build and Fully Assembled

Elevator Naked. Kit Build and Fully Assembled

| Standard Build Volume | 1000w x 660d x 500h (mm) |

| Extruders | 2x Bondtech BMG |

| Hotends | 2x Slice Mosquito Magnum |

| Multi Material System | Medusa |

| Motherboard | Bigtreetech GTR 32 Bit |

| Positional Accuracy X Y | 6 Micrometer (160 Steps per mm) |

| Positional Accuracy Z | 4 Micrometer (240 Steps per mm) |

| Firmware | Marlin 2. |

| Controller | Touch Screen and native Marlin |

| Connectivity | SD Card, USB, Wifi (optional) |

| Resume on Power Out | Yes – UPS required to park printer |

| Filament runout sensors | Yes |

| Automatic Bed Mapping | Yes, Unified Bed Leveling |

| Heated Bed | Yes, Supplied (SSR Software Controlled) |

| Build Platform | No – Not supplied |

| Stepper Motors X | 1x Nema 17 |

| Stepper Motors Y | 2x Nema 17 |

| Stepper Motors Z | 1x Nema 23 |

| Power | 110/240v 250w |

| Power Heated Bed | 110/240v 3500w *Duty cycle reduced to 1500w |

| Assembly required | Yes. Full assembly and wiring Full assembly and wiring |

| Support | Yes. Unlimited free support |

Medusa in Detail

Why is it important?

Blog Posts

Medusa Multi Material Printing

Medusa is our solution to many of the problems encountered with existing Multi Material FDM Printers. With traditional 2/2 (2 input 2 Read more

BYO Build Platform.

While we DO supply a silicone heated bed with each order, to reduce unnecessary shipping weight and volume, we have decided not Read more

Filament Choice

Medusa, having 2 distinct Heater-blocks gives you ultimate flexibility of material choice. As Medusa is essentially a 2/2 system, unlike Read more

Documentation

Designed with user assembly in mind, our 4th 3D Printer kit; many of the design decisions with The Elevator are Read more

Easily customisable

With a 32Bit Bigtreetech GTR mainboard, dual function touch screen LCD , Bondtech BMG extruders and Slice Mosquito Magnum hotends, we can’t imagine Read more

F. A.Q

A.Q

Q: Why does your Kit build 3D Printer cost so much!A: Because it's big and has some really expensive parts Read more

Image Gallery

The Beast V2 - Second Generation Large Format 3D Printer by cultivate3d — Kickstarter

The Beast V2 by Cultivate3D

We're really excited about this 3D printer, our second product, The Beast V2 is the culmination of 3 years R&D since the release of our V1 unit. We've listened to our users feedback and implemented countless design changes to make what we believe is the best value large format 3D Printer available anywhere.

Our V1 unit can be found in Design Labs, Universities, Hospitals and Backyards world wide. Our V2 unit is a massive improvement on the last model and costs the same. We want The Beast V2 to invigorate the imagination of designers who think big, without costing big $$.

See the full story about Dr Ezekiel Tan, Surgeon from the Gold Coast University Hospital who used The Beast V1 here

Rather than tack on some new additions to our old design, we’ve taken the feedback and experience accumulated over the past 2 years and completely redesigned our large scale 3D printer from the ground up with much improved accuracy, reliability and ease of use.

Having produced thousands of the V1 model, we gained priceless experience from our customers as to where our design could be improved. Now with the benefit of this experience, “The Beast V2” is the culmination of non stop re-design, re-evaluation and 1000’s of hours of testing since the successful funding of our first model over 2 years ago.

- Comparatively Inexpensive.

- Huge Print Volume : 490x500x670mm.

- Heated Bed Standard.

- Layer Resolution 100 - 800 Microns.

- Dual Material Printing Option.

- 4x Synchronous Printing Option.

- Fully enclosed print area, if printing with volatile filament, fumes can be ported outside.

- SD Card and Computer Tethered Printing.

- Build time approximately 40% of original V1 unit. (Varies depending on experience - as little as 1 day or less).

- Filament Out Detection.

- Auto Leveling Sensor.

Boasting a truly massive build volume of 490x500x670, we’ve added nearly 20% volume to our build envelope over the previous V1 unit.

This means you could for example, print a whole chair in one piece, duplicate a small child, print massive sculptures or perhaps an entire Cuirass (chest armour) in once piece for your next cosplay event.

Many 3D printers use proprietary components which limit the print quality to that of the supplied hotend.

The Beast V2 is supplied with industry leading E3D Hotends, as well compatible with nearly every other hotend on the market. In the unlikely event you don’t like the Hotends we supply? Feel free to source and use your own. Chances are it’s compatible.

As well as the full range of E3D nozzles, our printer can support E3D’s new .15mm nozzles and a layer height of just .01mm for an industry leading level of detail. This is also made possible through the use of E3D Titan geared extruders (included), available in either direct drive or bowden extrusion configurations.

The method of changing hotends or hotend configurations has been refined and simplified so that it can now be done in a matter of minutes.

Levelling the print bed of any 3D printer is absolutely crucial to print success, as well as finicky and frustrating, this is amplified greatly when you are using a print bed that is 535mm2.

Thankfully, as part of one of our most significant improvements in the V2 system, we have implemented a completely new, 2 part system that involves an auto levelling sensor and an easy to adjust mechanical system that permanently links all Z axis' together. This make initial levelling as easy as possible and more importantly, it helps to ensure the bed stays level.

Wide Range Of Materials

Nearly all FDM 3D printer filaments on the market are supported!

Having a heated bed and enclosed build area means a much wider array of materials can be used with the V2 printer.

ABS, PLA, Nylon, PET, PETG, Ryno, Carbon Fibre Filled, CopperFill, Ninjaflex, NylonX, ASA, PP, TPE, PCTPE, TPU, Soft PLA, Laybrick, Woodfill, Conductive, CeramicFill, Proto Pasta Stainless and Steelfill, Magentic Iron PLA, Polycarbonate, Bendlay, Moldlay, Continuous Fibre, PVA, HIPS, LayaPVA and more. .

.

This list is not exhaustive, new materials are continually being release, most are made with E3D hotends and nozzles in mind (supplied as standard with the Beast V2).

The Beast v2 features dual-extrusion technology, capable of MULTI-COLOUR or MULTI-MATERIAL printing.

Applications include:

Dual colour printing - Demonstrative and aesthetically pleasing product models, it is possible even to use transparent and opaque materials on the same object

Multi Material - Uniquely functional objects through the use of dissimilar materials e.g. rigid and flexible materials combined to create flexible joints

Support Material - Print previously impossible designs with the use of WATER SOLUBLE support materials.

The Beast v2 also has the ability to use 4 hotends and extruders to replicate 4 of the same print jobs (one object or a whole set of objects) at the same time, effectively reducing print and production time by 300%. It is also possible to use different colours and materials on each of the extruders in this configuration.

It is also possible to use different colours and materials on each of the extruders in this configuration.

Newly implemented radial fans and custom ducts ensures better cooling, high quality bridges, sharp edges and improved surface finish.

Effective cooling is also extremely beneficial when increasing print speeds and flow rates.

We now officially support Simplify3D. We have optimized profiles for a variety of configurations and application, with detailed information on customisation.

Simplify3D offers a superior build quality to many of the open source slicers available. Simplify3D is also the only slicer we've tested to work well with very large nozzle sizes such as those used with the E3D Volcano.

The Beast v2 is also still compatible with all the open source slicers, Slic3r, Cura etc. Along with alternative paid options.

The Beast v2 a full enclosure with port for standard 100mm (4 inch) ducting.

Enclosing the build area results in a much more stable temperature through the duration of long prints and helps to improve print quality and eliminate artifacts caused by temperature variation and unwanted airflow. The ducting option is perfect for use in situations where the printer is installed in an office or any indoor environment where the molten plastic fumes need to be removed.

The V2 unit has been designed with ease of build high on the list of priorities.

At around 50% of the original V1 build time, you can be up and printing with the V2 in as little as one day.

Prioritizing simplicity with much fewer components and joints, has the added advantage of creating a structure which is more solid and accurate, requiring less maintenance, increased reliably and reduced down time. We have also simplified the wiring to an enormous degree, with custom cables and looms, all components now simply plug into one and other or use a screw terminal.

At .05mm layer height, you cant see layers with the naked eye. Surfaces are smooth to touch and slightly matt in appearance.

Surfaces are smooth to touch and slightly matt in appearance.

Our printer can print solid objects right down to .01mm. Just how fine (or coarse) you set the layer height is entirely up to you.

Because our printer utilises 3rd party, non proprietary slicing software such as Simplify3D and Slic3r, layer heights are infinitely adjustable to suit your needs.

We haven't yet finished writing the build manual for the V2 unit, but we can say the new manual will be detailed and full of clear pictures. The Beast V2 is much easier to assemble with much fewer parts so we expect the new manual won't have as many pages as the previous If you'd like to see what our previous manual looked like, you can download it here : The Beast V1.2 Build Manual

A page from The Beast V1.2 Build ManualThe Beast V2 Comes with absolutely everything required to build a fully functional single hotend printer. Additional hotends will be required in order to take advantage of Synchronous printing or Multi-material Printing. Build time varies depending on your level of experience with Kits and 3D Printers. As little as 12hrs can be required to start printing. More for those who have little 3D Printing experience.

Build time varies depending on your level of experience with Kits and 3D Printers. As little as 12hrs can be required to start printing. More for those who have little 3D Printing experience.

- Hex Screw Driver Set (to suit m3 and m5 socket screws)

- Long Nose Pliers Small Spanner/Wrench Set to Suit M5 Bolts

- Motor Grease / Lubricant

- Small Spirit Level

- Small L-Square

- IEC 13 Cable to Suit your Country's power outlet type

- IEC 19 Cable to Suit your Country's power outlet type

- 1x The Beast V2 Kit

- 1x E3D V6 Hotend

- 1x Heated Bed with Borosilicate Glass Bed

- 1x 110v/240v Switchable Power Supply

As easy as we try to make it, building a 3D Printer sometimes isn't easy, especially if you're not familiar with the process. We encourage our customers to call us on the phone or skype if they have problems during the build. We're happy to answer questions via email, however experience tells us our customers get much more out of a one on one chat via skype than can be achieved via countless emails. Our Skype and Phone line will be available 9am-5pm AEST.

Our Skype and Phone line will be available 9am-5pm AEST.

Industrial engineers and programmers Josh and Dan met in 2015 and quickly became friends due to their common, but individual projects, each to make a large 3D Printer.

Dans direction was to make a 2m tall Delta Printer, Josh's a cartesian printer which would later become known as "The Beast". This union eventually became known as Cultivate3D.

Dan's background is in IT. Josh's background is in Mechanical Engineering.

"We've put our heart and soul into this printer. The Beast V2 is the culmination of countless ideas, arguments and solutions based on our experience with the previous model. This printer is our passion, it's everything we've been thinking about for the past 3 years. We hope this printer provides as much opportunity to evolve your ideas as it has ours and look forward to seeing pictures of all the crazy contraptions our clients come up with".

What kind of beast is a food 3D printer?

3D printing technology is really impressive. The amazing food 3D printers, which seemed impossible yesterday, have become a reality today, and it is quite possible that they will turn out to be something quite ordinary in the near future.

The amazing food 3D printers, which seemed impossible yesterday, have become a reality today, and it is quite possible that they will turn out to be something quite ordinary in the near future.

The operation of a 3D food printer is very similar to that of a conventional inkjet printer. Only instead of cartridges with liquid dyes, the food printer uses cartridges with food ingredients. There are many recipes stored in the printer's memory. To print a dish, you must select one of the recipes and press the button. After that, the printer, in accordance with the algorithm embedded in it, will begin to lay out the ingredients in layers on the work surface or on a plate. The product thus obtained is cooled or baked.

MIT scientists have developed the Digital Chocolatier, a 3D printer that prints treats from chocolate, fruits and nuts. The printer consists of a carousel with ingredients, a temperature-controlled mold and a user interface.

Digital Chocolatier 3D Printer

As the ingredients are fed into the heat-controlled mold, it cools quickly, fixing the shape of the chocolate and preventing it from spreading over the surface. All recipes can be stored in the 3D printer's memory and used again and again if necessary.

Another 3D printer developed by the Massachusetts Institute of Technology is called the Virtuoso Mixer.

Virtuoso Mixer 3D Food Printer

This 3D printer is also carousel mounted. In the upper tier of the Virtuoso Mixer, we see 8 cartridges with scales and temperature sensors to control the amount and properties of the food that is stored in them. Such cartridges are refilled with ready-made food components. In the middle tier there are 8 cartridges with built-in miniature crushers and mixers for mixing ingredients. Finally, the last, lower tier functions as an extrusion tray on which food is prepared and stored. This tier is equipped with powerful thermoelectric heating and cooling devices, as well as an insulating glass lid for quick baking of ready mixes.

This tier is equipped with powerful thermoelectric heating and cooling devices, as well as an insulating glass lid for quick baking of ready mixes.

How to make a Chocolate Hazelnut Dessert with Virtuoso Mixer 3D Printer

The Virtuoso Mixer interface is designed to allow users to quickly and easily experiment with different combinations of ingredients. The final recipe can eventually be saved for later use.

Various desserts that can be made with the Virtuoso Mixer

The same MIT laboratory created a prototype food 3D printer for printing multi-component dishes. The installation was named Cornucopia, which translates into Russian as "Cornucopia". The role of cartridges here is performed by tubes with food components, which should be stored in the refrigerator.

Digital Fabricator 3D Food Printer

According to the cooking recipe, nutrients are squeezed into the extruder head of the food printer. The mixer, combined with an extruder, forms the mixtures of proteins, fats, carbohydrates and flavors specified in the recipe. From the resulting mass, the finished dish is printed layer by layer with an accuracy of 0.5 millimeters. The printhead of the printer has two additional tubes designed to heat and cool the product using a laser.

The mixer, combined with an extruder, forms the mixtures of proteins, fats, carbohydrates and flavors specified in the recipe. From the resulting mass, the finished dish is printed layer by layer with an accuracy of 0.5 millimeters. The printhead of the printer has two additional tubes designed to heat and cool the product using a laser.

Digital Fabricator 3D Food Printer

As conceived by the developers, the Digital Fabricator 3D food printer allows you to control the taste, aroma and nutritional value of future dishes to the smallest detail. An interesting feature of a 3D printer is the ability to receive orders over the Internet. Just imagine: it is enough for you to choose the desired dish from your workplace, and when you return home, the ordered crispy chicken cutlets, fragrant donuts and airy strawberry soufflé will already be ready.

Digital Fabricator 3D Print Head

Food 3D printer cartridges are filled with a wide variety of food components that can be ordered based on your own preferences. If there is not enough content in the cartridges to print the ordered dish, then the printer offers the user another recipe with similar ingredients.

If there is not enough content in the cartridges to print the ordered dish, then the printer offers the user another recipe with similar ingredients.

Not far behind the scientists of the Massachusetts Institute of Technology and Philips researchers, who invented a model of a 3D food printer capable of printing dishes with molecular accuracy.

Philips 3D Food Printer Prototype

Philips 3D Food Printer Prototype

This model is especially appealing to parents who need to feed their baby healthy but unattractive food. Using the printer, you can print carrot spaghetti, potato candy, Brussels sprout ice cream, broccoli foam.

Philips 9 food 3D printed dish0016

dish printed by the PHILIPS

PHILIPS PHILIPS

PHILIPS 3D printer. When designing their device, the laboratory specialists collaborated with experts from the French Culinary Institute. The 3D food printer developed by the laboratory specialists was named Cornell. Using a printing device, you can print a dish of any conceivable and unthinkable design with any ingredients, taste and nutritional value. The Cornell printer is designed for restaurant chefs and homemakers who can now print exciting new dishes with healthy ingredients. Unlike 3D printers, which have remained a concept, Cornell is a device that is almost ready to use.

When designing their device, the laboratory specialists collaborated with experts from the French Culinary Institute. The 3D food printer developed by the laboratory specialists was named Cornell. Using a printing device, you can print a dish of any conceivable and unthinkable design with any ingredients, taste and nutritional value. The Cornell printer is designed for restaurant chefs and homemakers who can now print exciting new dishes with healthy ingredients. Unlike 3D printers, which have remained a concept, Cornell is a device that is almost ready to use.

Cornell

3D food printer The developers suggest using everything that can be squeezed out through a cooking syringe as food colors: soft cheese, melted chocolate, shortbread dough, ice cream, etc. Food coloring can also be made from solid foods that are crushed and mixed with water, milk, or other edible liquids.

The Cornell Food Printer is capable of creating highly intricate edible designs. Laboratory workers tried to combine cornmeal with water and print a "curly" cake. This flatbread, with its light-weight flower-shaped structure, proved to be even easier to fry than the traditional Indian flatbread.

Laboratory workers tried to combine cornmeal with water and print a "curly" cake. This flatbread, with its light-weight flower-shaped structure, proved to be even easier to fry than the traditional Indian flatbread.

3D Printed Curly Flatbread

3D food printers open up a whole new horizon of possibilities for cooking unusual dishes. How do you like a spaceship printed with green peas or carrots?

A spaceship printed from carrots

It is likely that in some 5-10 years in every house next to a microwave oven and an electric kettle there will be a wonderful modern 3D printer that will print any food that only its owner can imagine.

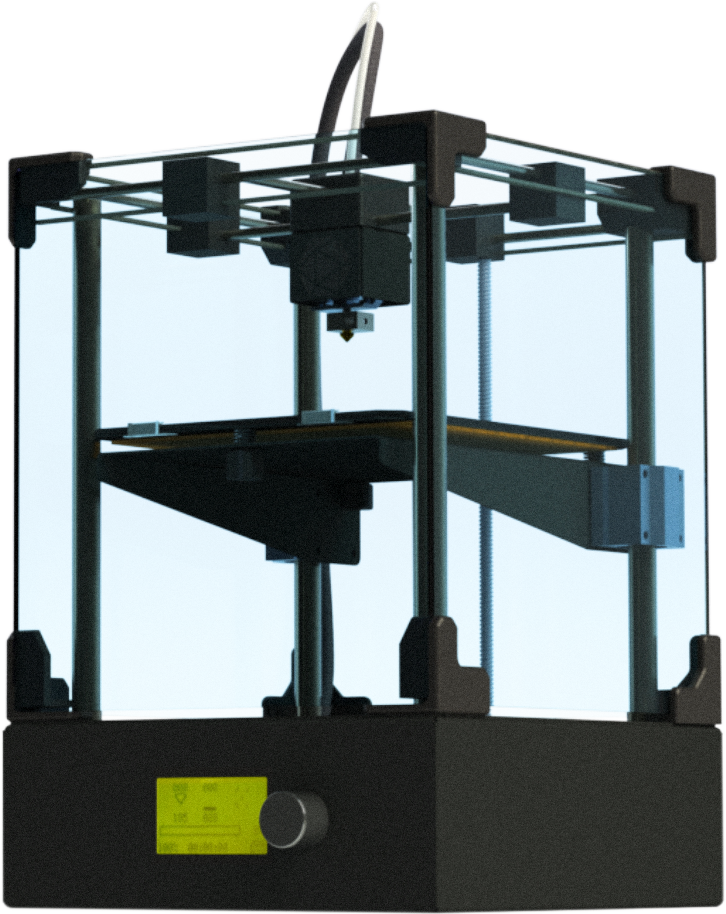

3D printer Beast 2.0

- LCD screen 7inch 1920*1200

- Wi-fi 802.11 b/g/n

- micro sd slot

- Bluetooth 4.0

- WEB camera

- Processor 2.16 GHz

- Windows 8

- Usb connector -4 pcs

- Audio output, RJ45

- HDMI output

- Remote control

| Manufacturer: | The beast |

| Bluetooth: | There is |

| Camera: | There is |

| Print material: | ABS, hips, PLA, PVA |

| Number of heads: | 2 |

| Country of origin: | Russia |

| Printing area: | 53 x 45 x 70 cm |

| Thread thickness: | 1. 75 mm 75 mm |

| Connection: | USB, Card Reader |

| 3D printing technology: | FDM (fused deposition modeling) |

| Print speed: | up to 150 mm/s |

| Layer thickness: | 0.05 mm |

| Dimensions: | 730 x 730 x 1300 mm |

| Body material: | closed case |

| Nozzle diameter: | 0. |