Anycubic 3d printer mega zero v2

Anycubic Mega Zero 2.0 3D Printer In-Depth Review

ADVERTISEMENT

8.7Expert Score

Anycubic Mega Zero 2.0

Anycubic Mega Zero 2 has a simple design, is highly functional, available at a low cost, and yet has an amazing set of features.

Affordability

10

Quality

7

Speed

9

Capability

8

Practicality

8

User Expectations

10

PROS

- Fast heating bed speeds up the entire printing process.

- Large leveling knobs for a better user experience.

- Large build volume.

- Metal frame for stability.

- Resume from the power outage.

- Double Gear Extrusion.

- Quick Assembly.

- Magnetic printing bed.

CONS

- Open body meaning temperature maintenance would be a problem.

- Safety issues while printing from home.

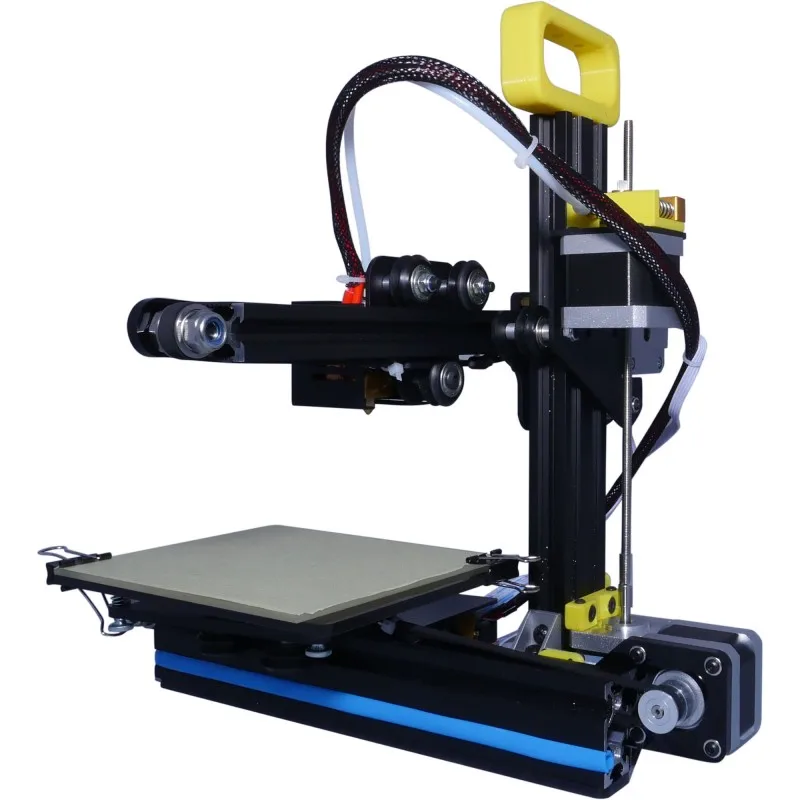

Extending a large build volume of 220 mm * 220 mm * 250 mm, Anycubic mega zero 2.0 is a budget-friendly FDM 3D printer for hobbyists. Its double gear ...

Add to wishlistAdded to wishlistRemoved from wishlist 1

Add to compare

|

Table of Contents

Updated versions of former 3D printers usually have one major benefit i. e. the limitations of their former versions are upgraded! That’s the same with Mega Zero 2.0.

e. the limitations of their former versions are upgraded! That’s the same with Mega Zero 2.0.

Anycubic has ensured all your feedbacks regarding Mega Zero is worked upon to create a new improved more efficient 3D printer in approximately the same price range. So, let’s dive into various aspects of version 2.0.

ADVERTISEMENT

Features

Mega Zero 2.0 is way different than Mega Zero. How do we claim that? By comparing their features.

Double Gear Extrusion and Single Y-axis rail

A Bondtech-like dual-gear extruder which was also a part of the initial kit for the first Mega Zero is also the part of Mega Zero 2.0.

Additionally, this one is a little more muscular, powerful, and consistent one. It lessens the likelihood and slippage and should prove reliable overtime dealing with various nozzles.

Potentially, the extruder is also a little better at feeding the more challenging filaments which have more chances of failure if not taken proper care of.

Overall, the result of using this double gear extrusion is a high-quality print result and smoother extruding.

More compatibility with flexible filaments, a stronger torque, a feeding optimization, and printing even with TPU filament!

Because having a single Y-axis rail in the printer’s construction, it’ll make it a bit easier to get to the knobs that control the height of the bed.

Essentially this will help in bed leveling which is responsible for getting a perfect first layer printed and hence increasing the overall quality of the print.

This enables you to make bed adjustments without squishing your hand into smaller spaces, which means lesser efforts for you and yet the same results in prints.

ADVERTISEMENT

Heated Print bed and commendable build volume

Unlike former 3D printers by the same manufacturer, the print bed in this is heated. It can withstand temperatures up to 110 degrees Celsius. Meaning that you do not have to worry about prints not sticking well enough to your bed anymore.

Additionally, it also means that you can print with more than one type of filament than you were able to print with on the original Mega Zero, and this is pure bliss if whether you are a learner, an intermediate, or a professional in the field of 3D printing.

It’s worth noting how the temperature that the nozzle can be heated up to has not changed at all, and the maximum temperature it can resist is 255 degrees Celsius. This will help you get some ABS, PETG, and Wood prints out with amazing quality.

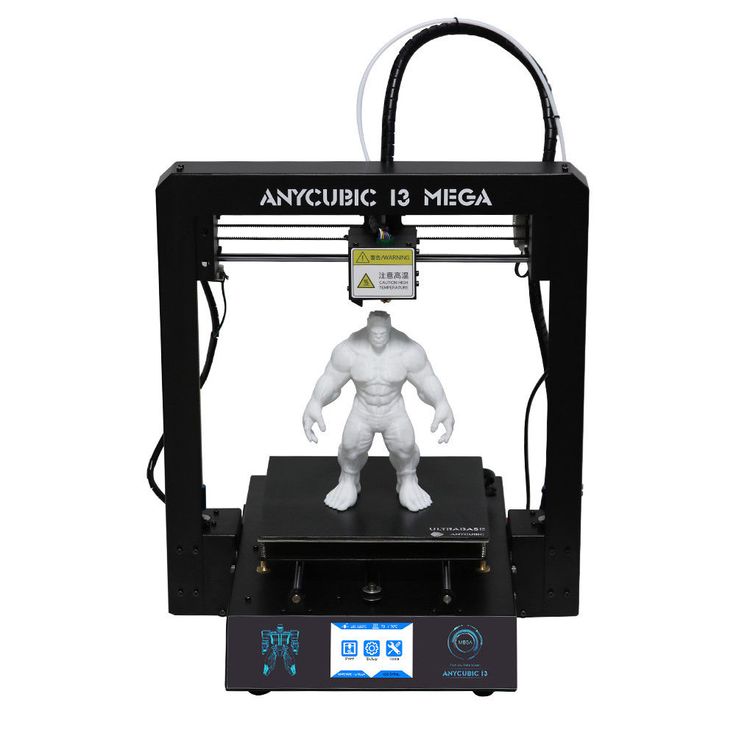

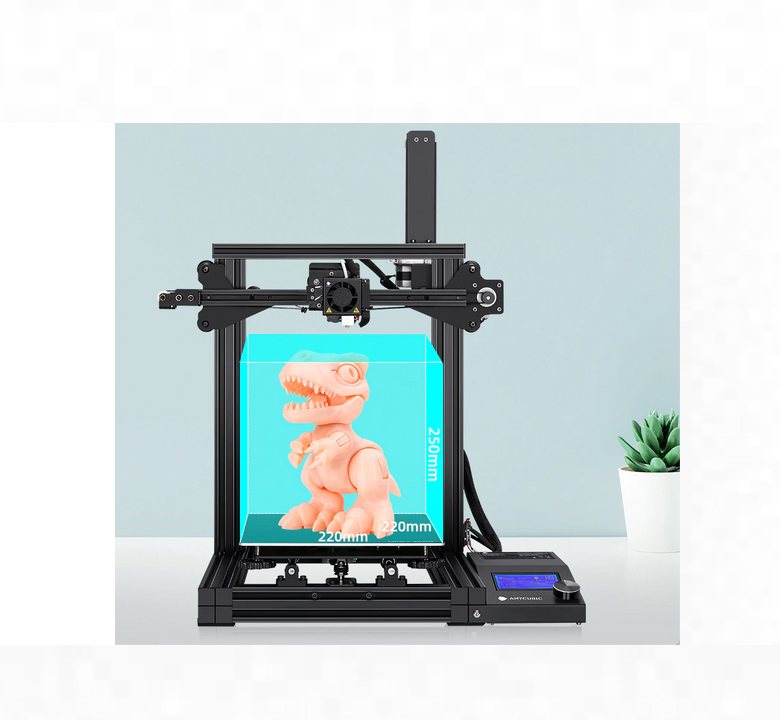

Stating about quality, the printer retains the same build volume as its forerunner at 220 mm * 220 mm * 250 mm.

Not only the build volume has remained unchanged, but also the layer resolution and positioning accuracy remain the same i.e. as found in the original Mega Zero.

Removable Magnetic print bed

The print bed which was non-magnetic is now magnetic. Meaning that you can peel it off, flex it and get your prints to snap off.

It’ll make you get your prints off the production area and into your life or the place where it’s meant for application just a little bit easier.

Because of the magnetic print bed, it is possible to expedite the time that goes into post-processing.

Not always these types of beds can be a bit annoying, but that is not the case with this one. Also, the print bed provides excellent bed adhesion with various types of filaments.

The magnetic build plate can be reused. It allows you to remove the prints even without using any kind of tape or glue.

When the printed parts are cooled down to an extent, you can easily bend the plate and snap off the print with ease.

ADVERTISEMENT

Quick assembly and easy leveling

Mega Zero 2 has a modular design that allows you to have a simple assembly. This saves your time in setting up the printer to get it started quickly.

Unlike other printers in the same price range, the setup of Mega Zero 2 does not take much time; it is almost like any other plug-and-play printer.

Large leveling knobs are added by the printer manufacturer for a better user experience. It helps you quickly locate the corners of the print platform during leveling.

It helps you quickly locate the corners of the print platform during leveling.

So even though the leveling of the printer is meant to be done manually, it does not take much time. Also, it enables you to do accurate leveling which is the most essential part of the 3D printing process.

If you haven’t done your leveling correctly, you are not going to get good quality printed parts or functional prototypes. So, in a way you are quality assured with Mega Zero 2’s bed leveling.

Specifications

Offering a build volume of 220 mm * 220 mm * 250 mm, Mega Zero 2 allows you to print parts with big volumes in one go.

The printer is based on FDM i.e. Fused Deposition Modeling 3D printing technology and when it arrives at your place, it is already semi-assembled.

The mechanical arrangement of the printer is Cartesian XZ-based. The feeder system used for extruding filaments of various types in the printer is Bowden style.

Mega Zero 2 features a nozzle of a diameter of 0. 4 mm. It has a hot end temperature that can withstand a maximum temperature of 255 degrees Celsius, whereas the heated bed temperature of 110 degrees Celsius.

4 mm. It has a hot end temperature that can withstand a maximum temperature of 255 degrees Celsius, whereas the heated bed temperature of 110 degrees Celsius.

As mentioned in the features section, the print bed of Anycubic Mega Zero 2 is a removable magnetic type. The frame of the printer is made up of sheet metal.

For bed leveling you would not have to press a button to make it happen, instead, you would have to use your hands to rotate the screws present on the body of the machine.

You can connect with Mega Zero 2 using two options i.e. USB and TF card. For printing various parts and functional prototypes on the printer you need to use a filament of diameter 1.75 mm.

Yes! You are allowed to print with third-party filaments. The materials with which you are 3D print on the printer are PLA, ABS, PETG, TPU, and Wood.

The printer weighs 7 kilograms and its frame dimensions are 505 mm * 431 mm * 607 mm.

Every part printed from the printer has a layer height around 0. 1 mm and it can be printed with a print speed ranging anywhere between 20 to 100 millimeters per second.

1 mm and it can be printed with a print speed ranging anywhere between 20 to 100 millimeters per second.

The ambient operating temperature condition for the printer ranges between 8 to 40 degrees Celsius.

ADVERTISEMENT

Price

At the time of writing the article, the price of Anycubic Mega Zero 2 as mentioned on its website is $199.

First Impressions

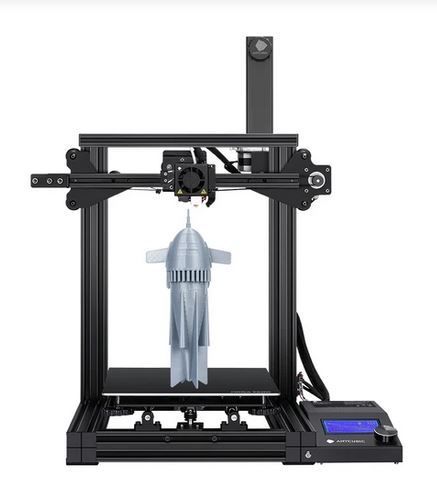

For those who have seen any Cartesian type 3D printer, you’d be able to relate to Mega Zero 2 instantly. It has the typical open body, filament spool holder over the top of the print head of the printer.

A touch screen user interface at the right end of the front face, with a circular button, allows you to control various functions on the printer.

Typical gantry supporting the print bed of the machine, two support pillars connecting which the print head of Mega Zero 2 holds a nozzle system.

The pillars have good quality rails on them allowing for the movement of the print head for letting the nozzle come at a good distance with the print bed to lay the liquid filament over the print bed according to the geometry of the part that’s to be 3D printed.

There is a lot of wiring on the back of the 3D printer connecting the filament spool holder with the extruder and the nozzle system, etc.

Setup

As mentioned in the specification section, Anycubic Mega Zero 2 comes semi-assembled. Meaning that it’s not exactly a plug-and-play type 3D printer. You will have to spend some time adjusting the bed leveling of the printer.

And that you need to do manually by adjusting knobs and not by pressing a single button or automatically!

The printer comes with:

- Plier

- Six M5 screws

- Scraper

- Tool Set

- Card Reader

- Filament

- SD Card

- User manual

- Power Adapter

- Power Cord

- USB Cable and

- Service Card

Also, you are recommended to go through the user manual that comes with Mega Zero 2. Doing so would make you familiar with different parts of the printer, which will be very helpful if this is your first time interacting with a 3D printer.

Doing so would make you familiar with different parts of the printer, which will be very helpful if this is your first time interacting with a 3D printer.

After doing that you can attach a TF card or USB cord to transfer your sliced file to the printer to start printing.

ADVERTISEMENT

Printing Type/Cost

In Fused Deposition Modeling 3D printers, a solid filament of various materials is used to print parts and functional prototypes that can be used in various applications.

The solid filament is melted in an extruder where its temperature is brought to the level of its glass transition temperature. The arrangement is connected with a nozzle, which starts flowing as soon as it is melted.

Till then the print head which was at a specific distance has come down, near the print bed and according to the geometry of the part that’s to be printed, the first layer is laid down.

After this, the print head moves one layer height above and prints the second layer and there onwards the complete part.

This is exactly how parts are printed on Mega Zero 2. The cost of printing per part depends on many factors, but one can easily claim that printing a part on this printer is cheaper than other printers that depend on SLA, SLS, or other 3D printing technologies.

Print Quality

Credit: top3dshopThe test prints on Anycubic Mega Zero 2 runs pretty smoothly. You get good quality parts with a nice surface finish using the printer. Parts possess a layer height around 0.1 mm which is standard for all FDM 3D printers in the same range.

ADVERTISEMENT

Software

Anycubic recommends Cura for slicing files on the printer. It is a very user-friendly software that is not much technical at the same time highly functional for making various settings necessary for your print.

Customer Support

Anycubic offers world-class support with its technical team that can be reached out in various ways. Apart from that, there is also a separate tab on the printer manufacturer’s website which you can go through to download information related to your printer and also watch videos.

Parameters Influencing Buying Decision

Having stated different aspects about the printer in an elaborative fashion, below mentioned are the key criteria on which you can judge whether or not to buy the printer in brief.

3D Printer Cost: Affordable even for beginners in the field of 3D printing.

3D Printer Quality: Although not as good as high-end FDM 3D printers or even low-end SLA 3D printers, it’s manageable seeing the price at which the printer is available.

3D Print Speed: Speed is something where the printer steals the show. There’d hardly be 3D printers in the same price range offering print speed range as much as the printer does.

3D Printer Capability: Being a printer that costs under $200, Mega Zero 2 offers you 3D printing with almost all the popular 3D printing filaments.

3D Printer User Expectations: You can expect decent quality prints at a very affordable cost with amazing features such as a removable print bed, huge build volume, amazing print speed, and a lot with the machine.

The Verdict

Anycubic Mega Zero 2 has a simple design, is highly functional, available at a low cost, and yet has an amazing set of features. Agreed that the print quality is a little bit of a concern, but that’s not the only thing that is to be looked upon as a 3D printer, yeah?

Do you want to buy an FDM 3D printer?

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

Creality Ender 5 Pro- High stability and precision

- Removable platform

- Large construction area

-

FlashForge Creator Pro 2- Independent dual extruder

- Enclosed build space

- Solid metal frame

-

Artillery Sidewinder X2- Very large installation space

- Automatic bed levelling

- Titan extruder

-

Creality CR-6 SE- Intelligent auto-levelling

- Modular hotend

- Reliable extruder

-

Artillery Genius Pro- 220 x 220 x 250 mm build space

- Titan extruder & modular nozzle set

- 32-bit motherboard upgrade

-

Creality Sermoon V1 Pro- "Sprite" Direct Dual Gear Extruder

- 175 x 175 x 165 mm build volume

- HD camera for print monitoring

-

Creality Ender 3 Neo- Automatic print bed levelling over 16 points

- Extremely quiet operation

- Full metal Bowden extruder

-

FlashForge Adventurer 4- Flexible printing platform

- Quick-remove nozzle

- Integrated HD camera

-

MINGDA Magician Max- 320 x 320 x 400 mm build volume (L x W x H)

- Direct drive extruder with dual gear drive

- Dual Z-axis with a toothed belt

-

MINGDA Magician Pro- 400 x 400 x 400 mm build volume (L x W x H)

- Direct drive extruder with dual gear drive

- Dual Z-axis with a toothed belt

-

Zortrax M200 Plus- Wi-Fi Module

- Filament Sensor

- Improved Cooling System

-

Anycubic Kobra Plus- Large build volume (LxWxH: 300 x 300 x 350 mm)

- LeviQ bed levelling

- Bowden dual gear extruder

-

FlashForge Creator 3 Pro- Dual extruder

- Large build space

- Optimised extruder structure

-

FlashForge Creator 3 V2- Independent twin extruder setup

- Flexible building board

- Wireless connection

-

Creality Ender 3 V2- New screen

- Resume function

- Quiet TMC2208 driver

-

Anycubic Kobra- LeviQ - Automatic Print Bed Leveling

- Direct Drive Extruder

- Modular design

-

FlashForge Adventurer 3- Enclosed installation space

- Easy handling

- Compact design

-

Zortrax M300 Dual- Large build space

- Touchscreen

- Blackout System

-

Zortrax M300 Plus- Large build space

- Filament sensor

- Wi-Fi connection

-

Creality Ender 3 S1- Direct dual gear extruder

- CR-Touch Automatic bed levelling

- 32-bit silent mainboard

-

CraftBot Flow- Large printing area

- Reinforced steel frame

- Metal hotend

-

Anycubic Vyper- Cortex-M3 CPU

- Automatic levelling

- Magnetic PEI platform

-

Elegoo Neptune 3- Automatic print bed levelling

- Flexible PEI spring steel

- Modular construction

-

Creality Ender 3- Large space

- Heated print bed

- Easy construction

All prices incl. VAT.

VAT.

Anycubic Mega Zero 2.0 Review: Features and Specifications

Anycubic Mega Zero 2.0 is out. Come on!? Already? Let's see what kind of animal it is.

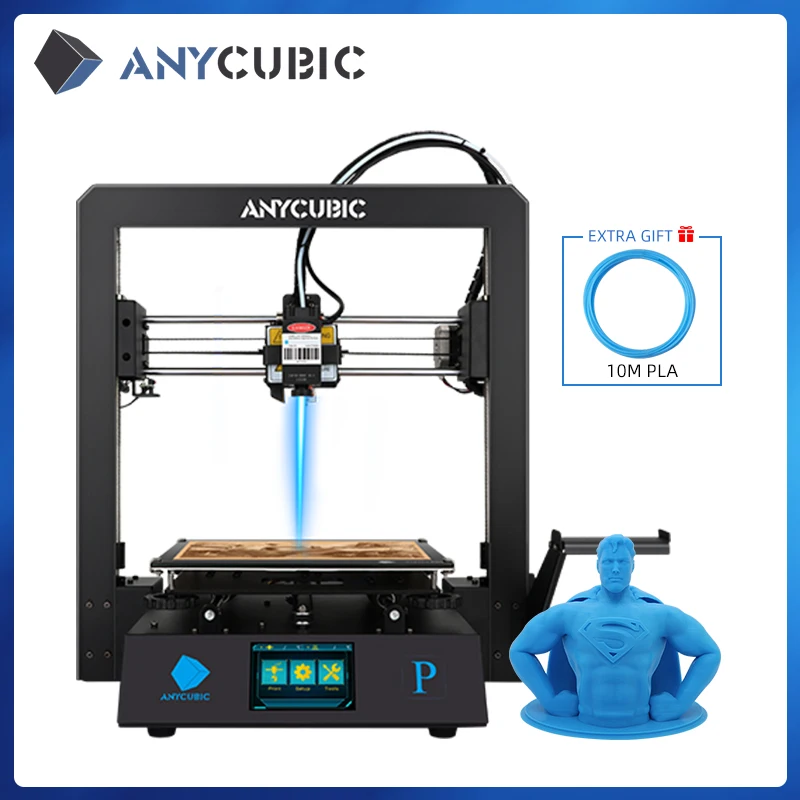

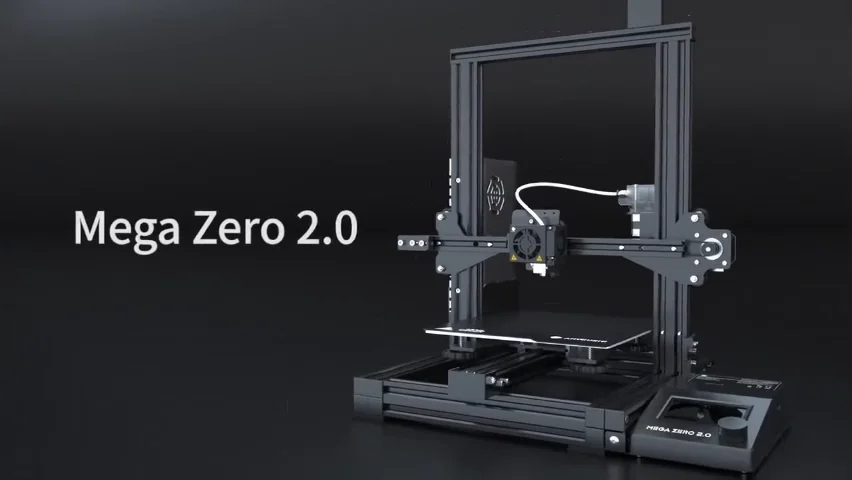

It doesn't seem like it's been that long since Anycubic released the first Mega Zero, but it "seems" because something is wrong here. Deliberately spartan, very affordable and simplistic, the FDM printer tried to give users everything they could ever need and absolutely nothing (Zero) that they don't. It was back in the spring of this year. Autumn has just ended, and Anycubic came out with Anycubic Mega Zero 2.0. Miracles. Where to buy

If the first Mega Zero was really "zero" in its philosophy, then why do we have a second zero now - and in just a few months? Anycubic has now decided that a Mega Zero is possible with a heated, magnetic and detachable print bed, something that was not originally possible.

The same is pretty much true of other changes besides the single Y-rail. So, is Mega Zero following the same path as studio apartments, coffee shops or Volkswagens, forgetting the original simplicity that meant affordability? Maybe now it's just a way to make money? Or is this how they now expand the choice and upgrade options for customers?

Features

REMOVABLE MAGNETIC PRINT PLATFORM

The print bed is now magnetic, which means you can peel it off and bend it to separate it. This should make it a little easier to move objects from the workspace into real life, saving you some nerves - or something like that.

This should make it a little easier to move objects from the workspace into real life, saving you some nerves - or something like that.

Sometimes such platforms piss me off, but we'll see. Otherwise, with the printing platform, for example with its dimensions, nothing has changed compared to the original Mega Zero.

VOLUME

The Mega Zero 2.0 retains the same displacement as its predecessor, 220 x 220 x 250 mm. Without changes. Other non-changes include layer resolution and positioning accuracy, which remain the same as the original Mega Zero.

HEATED PLATFORM

Yep, you guessed it, the print bed is now heated. The temperature can be raised up to 110°C, which means you no longer have to worry about insufficient adhesion. It also means that you can now use more material types than in the original Mega Zero - if that's what you want.

It is worth noting that the temperature to which the nozzle can be heated has not changed and remains at 255 °C. But here's the consolation platform that opens the door to some ABS, PETG, and wood filament options.

But here's the consolation platform that opens the door to some ABS, PETG, and wood filament options.

SINGLE Y GUIDE

To be honest, we're not entirely sure this change is in Mega Zero's favor. Perhaps this makes it a little easier to access the platform adjustment knobs, and now you don’t have to excel in playing with your fingers in a microscopic space.

DUAL EXTRUDING

Extruder changed

The Bondtech type twin extruder was part of the original set of the first Mega Zero. The story continues. This beefier, stronger, tighter extruder reduces slippage, should last a long time, and should be somewhat better at handling difficult filaments.

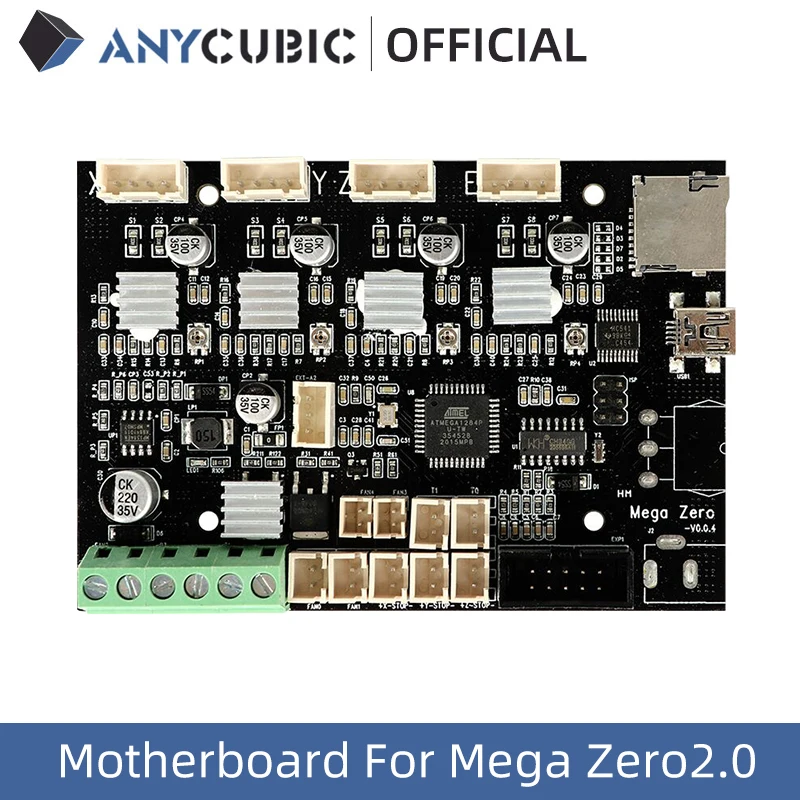

Specifications

| Technology | FDM |

| Year of manufacture | 2020 |

| Assembly | semi-assembled |

| Mechanical | Cartesian to XZ |

| Manufacturer | Anycubic |

| Displacement | 220 x 220 x 250 mm |

| Delivery system | Bowden |

| Nozzle diameter | 0. 4 mm 4 mm |

| Max. hot end temperature | 255°C |

| Max. heated platform temperature | 110°C |

| Print Platform | removable, magnetic |

| Frame | sheet metal |

| Print platform alignment | manual |

| Interfaces | USB, TF |

| Resume printing | no |

| Camera | missing |

| Filament cross section | 1.75 mm |

| Third party filaments | supported |

| Filament materials | PLA, ABS, PETG, TPU, wood |

| Recommended Slicer | Cura |

| Operating systems | Windows, macOS |

| File formats | STL, OBJ, AMF |

| Frame dimensions | 505 × 431 × 607 mm |

| Weight | ok. 7 kg 7 kg |

Anycubic MEGA ZERO 3D Printer Review / Sudo Null IT News

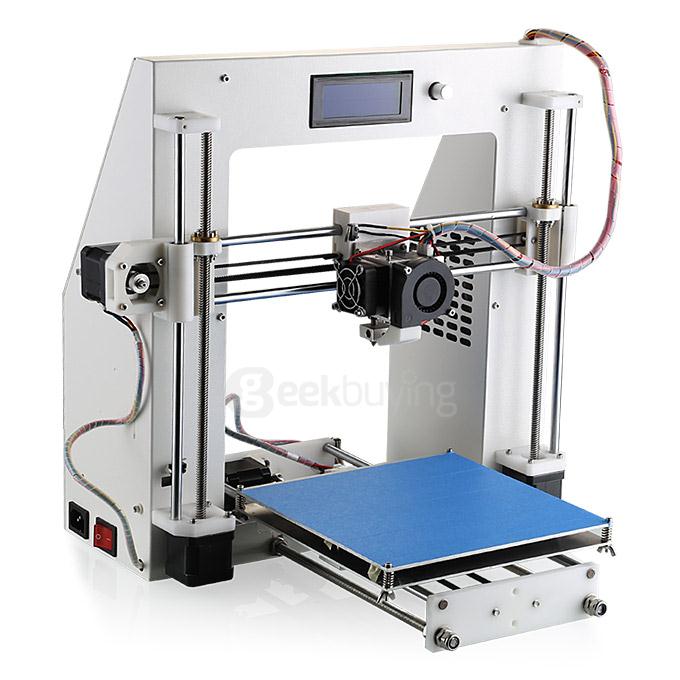

The Chinese company Anycubic is well known in the world of 3D printing, especially for its flagship models such as the i3 Mega FDM 3D printer or the Photon resin printer.

Relatively recently, Anycubic has launched the MEGA Zero, a new entry-level 3D printer. The 3D printer market still has a small selection of printers at such an affordable price. Let's see how good he is.

General specifications

Source: top3dshop.ru

No assembly problems

The Anycubic Mega Zero 3D is a pre-assembled 3D printer that saves on shipping costs. Well-protected parts are laid in a cardboard box in two layers. Everything you need is included. Among other things, Anycubic provides a cutter, a spatula, as well as several meters of filament.

The printed manual is very clear, with step by step assembly breakdowns and drawings. The most complex knots have already been assembled.

The most complex knots have already been assembled.

The supplied 8 GB memory card contains an even more detailed manual in digital format. Anycubic also posted a very detailed MegaZero assembly video on his Youtube channel.

Everything is clearly marked, so it's hard to connect anything wrong. Power cables are insulated, belts are well tensioned.

The control box is located on the right side. There is a small monochrome display and a rotary knob. The unit contains the motherboard, but no power supply. Electricity comes from an external power supply.

On the right side of the control box is a microSD card reader and a USB-A port for direct control (not recommended).

Simple but good design

Anycubic has accumulated experience in producing reliable 3D printers at a low cost. The frame of MEGA ZERO is completely made of aluminum, with a large margin of stability.

The MEGA ZERO 3D printer measures 504 mm × 396 mm × 607 mm and weighs 6. 4 kg. Due to the control unit moved to the side, the width has increased.

4 kg. Due to the control unit moved to the side, the width has increased.

General design - portal type. The print head moves along the X axis, which in turn moves up and down along the Z axis. Finally, the platform moves along the Y axis. The dual drive system increases the traction force applied to the plastic thread. The extruder holds the filament well even if you are using a soft material like TPU.

Print head - traditional design, with ventilation.

The manufacturer has added two guides to the design of the carriage, which makes the desktop more stable, printing is of high quality, and the result is stable.

User interface

3D printers that have been released recently are increasingly offering a color touch screen. The Anycubic Mega Zero has a simple blue screen with white font and a push-and-turn selector system.

Minimal information is displayed on the main screen. It shows the current and target nozzle temperature, printing progress as a progress bar, elapsed time, the name of the file being printed, and XYZ coordinates.

Pressing the button displays a menu in English, with tree-like navigation logic.

The photo below shows various screen states.

The logic is a bit confusing. For example, to level the platen, you must first select HOME and then HOME ALL to change the position of the printhead before moving on to selecting LevelCorners. At your choice, the printhead moves to each of the four corners of the platform so you can adjust the height. The adjustment wheels under the platform are large so they are easy to turn.

To load or unload filament, the extruder must be preheated with the Preheat PLA command and then moved to Move Axis/Extrude to allow the filament to move forward or backward. You can also pull the filament by hand.

Once printing has started, you can also adjust the print speed, fan speed, or nozzle temperature.

Print preparation and printing

Once the 3D printer is assembled and the filament is loaded, it's time to print something.

There are two small but not very interesting examples on the included 8 GB MicroSD card. Stefan also recommends downloading files from free 3D modeling sites such as Thingiverse, CULTS 3D, and My Mini Factory.

The software that Anycubic provides for the Mega Zero is the classic Ultimaker CURA slicer, version 4.4.

The user manual on the memory card explains how to set up CURA. Customization is done by manual data entry or using the included profile files, one for PLA and one for TPU printing.

The author of the article recommends leveling the platen twice for perfect results.

It should be noted that Anycubic MEGA ZERO does not have a heated platen. The manufacturer had to make such a compromise in order to reduce the price. This is not critical as filaments such as PLA, TPU, HIPS, PETG or Wood do not necessarily require table heating, although it does reduce the risk of peeling.

3D models printed on Mego Zero in different types of plastic.

75 mm 0.07 in

75 mm 0.07 in