Largest consumer 3d printer

The Best Large 3D Printers in November 2022 (Every Price)

Some may be content printing within the confines of their small, desktop FDM 3D printer — but for big home projects, or large prototyping, size matters. For these bigger jobs, you’ll need a large 3D printer capable of printing the Goliath structures they need for their commercial business or hobbyist project.

So, whether you want to print large-scale figures, model cars or cosplay helmets as home projects, or large commercial prototypes, we’ve split this article into two sections covering both:

- The best under $1,000 (the largest 3D printers for home use)

- The best large-scale 3D printers for commercial use

Here are our top picks overall:

BUDGET PICK

Ender 5 Plus

Lowest cost reliable large 3D printer

Very versatile and upgradeable

Excellent 350x350x400mm build volume

Available at creality here Amazon here

MID-RANGE PICK

Anycubic Kobra Max

Even larger 450 x 400 x 400 mm print area

Upgraded accuracy and print speed

The largest 3D printer under $1000

Available At anycubic here Amazon here

PREMIUM PICK

Ultimaker S5

Fantastic 20-micron precision

Optional Pro Bundle adds on filament holder and air filter

Excellent for large part prototyping

Available at Dynamism here matterhackers here

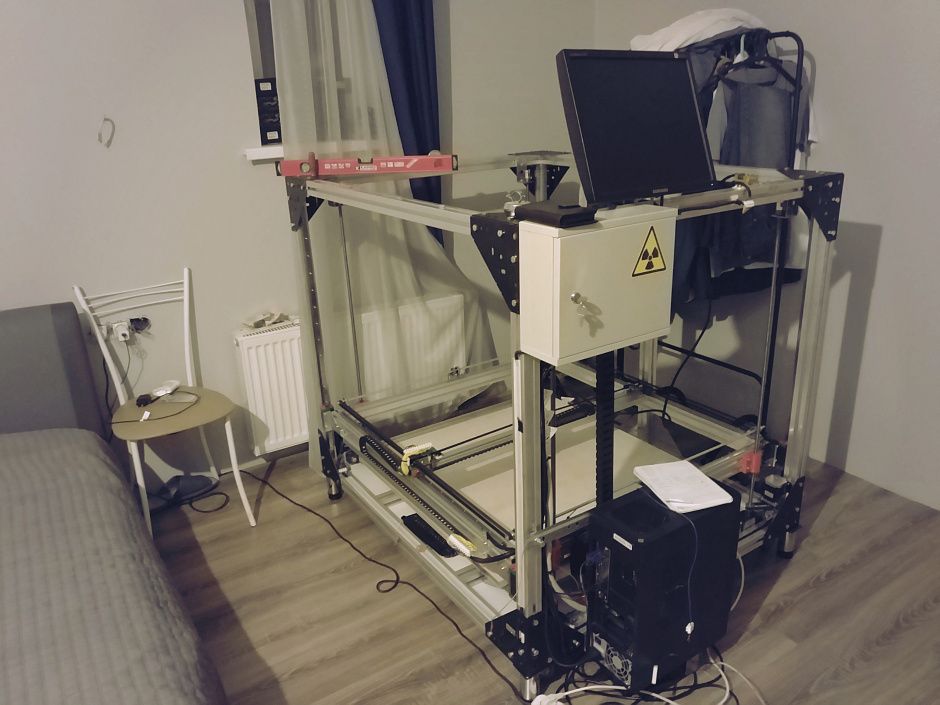

Some inspired makers have even built enormous 850mm tall printers at home as DIY projects.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

This article includes the best large bed 3D printers, as well as buying guide with what factors to consider when buying a larger printer, tips and tricks for printing based on the elements that change as you scale up print bed size, and some FAQs on large-scale printing.

| Brand and Name | Max Print Size (mm) | Price | Where To Buy for Best Price? | Alternative Purchase Option |

|---|---|---|---|---|

| FLSUN QQ-S PRO | 255 x 255 x 360 | $369 | Amazon here | |

| Qidi Tech X-Plus | 270 x 200 x 200 | $699 | Amazon here | |

| Tronxy X5SA PRO | 330 x 330 x 400 | $399 | Amazon here | |

| Creality CR-10 MAX | 450 x 450 x 470 | $1,099 | Amazon here | 3DJake UK & Europe |

| Peopoly Phenom | 276 x 155 x 400 | $1,999 | Matterhackers here | |

| Raise3D Pro2 / Pro2 Plus | 305 x 305 x 300 (605) | $3,999 / $5,999 | Pro2 on Amazon here | Dynamism Store here |

| BCN3D Sigma D25 | 420 x 300 x 200 | $3,995 | Dynamism Store here | Matterhackers here |

| Modix Big-60 V3 Kit | 600 x 600 x 660 | $4,700 | Matterhackers here | Dynamism Store here |

| Ultimaker S5 | 330 x 240 x 300 | $5,995 | Dynamism Store here | |

| BigRep Studio G2 | 1000 x 500 x 500 | Quote | BigRep |

Large 3D Printer Reviews: The Criteria

In assessing which of the following huge 3D printers deserved to be on our ranking, we used the following criteria:

- Size relative to price: a large print volume on a low-cost printer is relatively more impressive.

- Quality of print: it’s irrelevant if you can print larger objects if they come out looking terrible. Only high-quality XXL 3D printers made the cut.

- Enclosed or open build chamber: a large print area is more impressive on an enclosed 3D printer.

- Reliability, versatility and ease of use: what materials does it support, how simple is the printer’s interface to navigate, and how prone is the printer to errors.

Best Large 3D Printer – 2022 Reviews

Ender 5 Plus – the best budget large 3D printer

- Price: Check latest price at Creality here / Amazon here

- Build Volume: 350 x 350 x 400 mm

- Minimum Layer Height: 100 Microns

- Max Nozzle Temperature: 260°C

- Filament Compatibility: PLA, ABS, TPU, PETG

Pros

Lowest cost reliable large 3D printer

Very versatile and upgradable

Excellent 350x350x400mm build volume

Cons

Open air printer requires an enclosure for ABS to prevent warping in a more stable printing environment

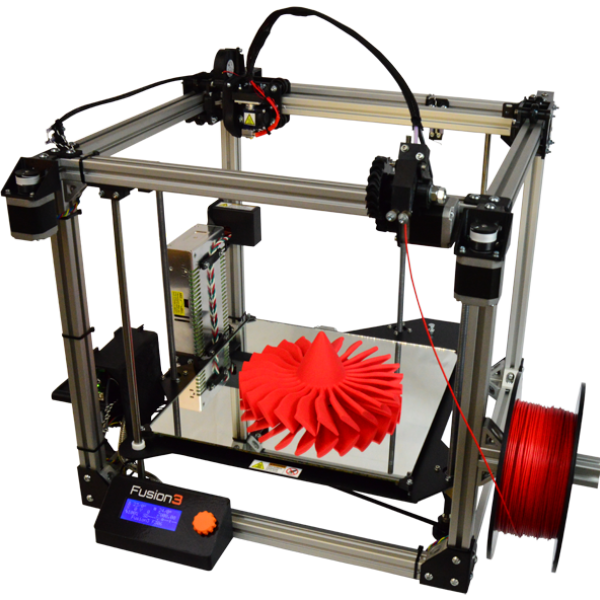

A perennial favorite among makers that balances great value and large print capacity, the Ender 5 Plus delivers on its large-format promise with a roomy 350 x 350 x 400 mm build volume.

The capacity offered by the Ender 5 Plus opens the door to projects that simply aren’t on the cards with most standard-size printers: helmets, masks, cosplay props and accessories, tall vases, tabletop gaming terrain, and so on.

Size aside, the Ender 5 comes with other notable features. A pre-installed BLTouch automatic bed leveling probe makes easy work of calibrating the bed, while dual z-axis rods ensure smooth lead screw movement even when using the entire print bed for a huge print.

Speaking of axes, the Ender 5 uses a rather novel system whereby the Z-axis is responsible for lowering the bed. It’s bolstered by a beefy stepper motor that moves both belts on the Y-axis in unison for clean, precise movements that help reduce layer shifting.

Ender 5 Plus printing a mech. Source: TwitterExtras like print resume, a filament run-out sensor, and a removable tempered glass build platform, which delivers solid first-layer adhesion and ensures prints snap off cleanly with little effort, score points for ease of use.

If you’re partial to improving your printers through upgrades and modifications, the Ender 5 mimics its Ender 3 sibling with a wide array of upgrades available.

From 3D printed mods like cable strain relief brackets to extruder knobs all the way to purchased upgrades like an all-metal extruder, quiet mainboard, and why not a pivot to a direct drive system, there’s no shortage of ways to make the Ender 5 even better.

Anycubic Kobra Max – largest 3D printer under $1000

- Price: Check latest price at Anycubic here / Amazon here

- Build Volume: 450 x 400 x 400 mm

- Minimum Layer Height: 50 microns

- Max Nozzle Temperature: 260°C

- Filament Compatibility: PLA, ABS, PETG, TPU

Pros

Even larger 450x400x400mm area

Upgraded accuracy and print speed

Best large 3D printer under $1000

Cons

Open air printer requires an enclosure for ABS to prevent warping

The largest of Anycubic’s most recent batch of affordable large FDM printers, the Anycubic Kobra Max gives you a massive 450 x 400 x 400 mm – the largest build volume 3D printer under $600. That ultra-large build volume alone justifies a slot on our list, but there’s plenty more to like about the Kobra Max.

That ultra-large build volume alone justifies a slot on our list, but there’s plenty more to like about the Kobra Max.

Despite the large capacity, the Kobra Max is made stable by the dual z-axis threaded lead screws, each with a dedicated stepper motor and two support rods to reduce wobble and keep things running smoothly.

With a 50-micron minimum layer height, the Kobra Max delivers solid precision and can theoretically crank sprint speeds up to a dizzying 180 mm/s.

It also has a tempered carborundum glass print bed, coated with Anycubic’s proprietary Ultrabase microporous coating.Kobra Max printing models: a skeleton (Source: Reddit) and a 280% scale sluggo (Source: Reddit).

Elsewhere, Anycubic has bundled in its in-house-developed LeviQ fully automatic bed leveling. We tested it ourselves on the Kobra and continue to be impressed with the accuracy and hands-off, set-and-forget ease of use it delivers. Anycubic is on to something special here, and it’s a delight to see LeviQ ported over the larger Kobra Max.

Other notable features include filament runout detection, the same responsive 4.3″ touchscreen display found on the smaller Kobra, adjustable belt tensioners, an E3D Volcano-inspired hot end, and reasonably quiet operational noise levels at 58 dB.

Overall, it’s definitely the largest 3D printer for home use, and a reliable FDM pick.

Peopoly Phenom — Large Resin 3D printer

- Price: $1,999 — Available on Matterhackers here

- Maximum build volume: 276 x 155 x 400 mm

Pros

Largest set of resin 3D printers for the price

Super fast bulk printing due to resin printers curing entire layers at once

Cons

XY resolution falls slightly if you purchase a larger Phenom model

The Peopoly Phenom is the only resin 3D printer that features on our ranking. Resin printers are not known for having large print areas, making the Peopoly Phenom’s large size all the more impressive.

Peopoly first made a name for themselves following their successful Kickstarter campaign to bring the Peopoly Moai to market. Now they have the Phenom range, using MSLA technology (combining LCD screens with LED lights) to build parts.Phenom on a 49-hour print job (Source: Reddit) and a sample print (Source: Reddit).

Now they have the Phenom range, using MSLA technology (combining LCD screens with LED lights) to build parts.Phenom on a 49-hour print job (Source: Reddit) and a sample print (Source: Reddit).

The idea for an LCD 3D printer with a huge build area is a very good one. LCD 3D printing involves solidifying a whole layer of resin at once, unlike FDM where the 3D printer’s extruder needs to trace each layer. Combining this ability to print multiple objects simultaneously with a large format 3D printing area opens up possibilities for truly scalable 3D printing. It’s very exciting.

The printer itself is very impressive. 72-um accuracy is precise and will offer better surface finishes than almost all FDM 3D printers. Peopoly recommends you use their Deft resin, but this large 3D printer kit is compatible with those made by other manufacturers.

If you already own a smaller, low-cost resin printer like an Elegoo Mars or AnyCubic Photon, upgrading to the Phenom is easy as it also runs on the CHITUBOX.

Read more: the best large build volume resin 3D printers

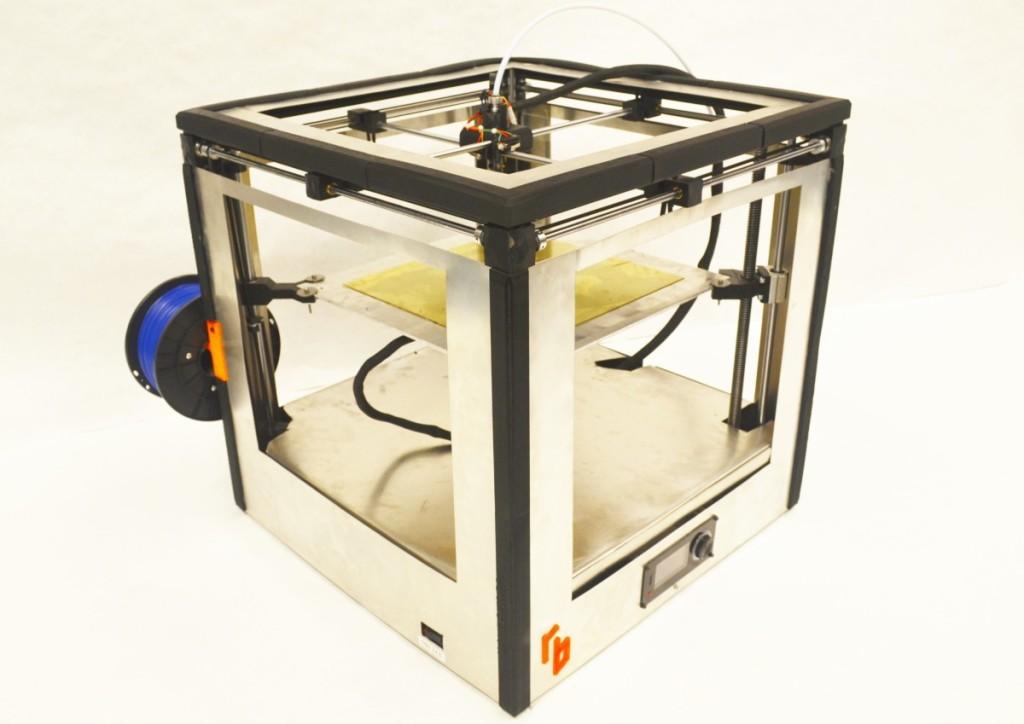

Modix Big-60 V3 Kit — huge 3D printer for heavy-duty use

- Price: $4,700 — Available at Matterhackers here / Available at Dynamism here

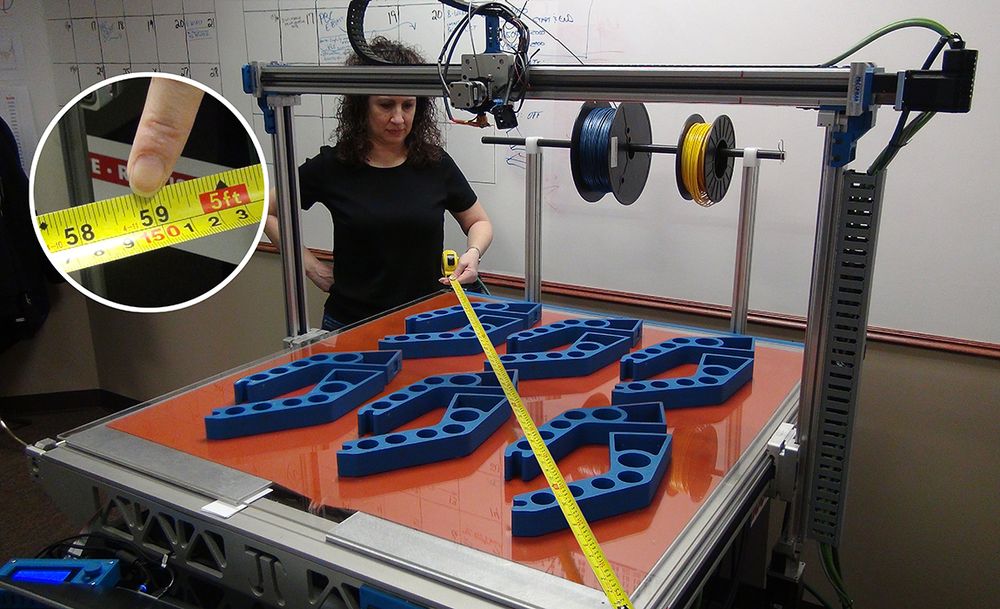

- Build volume: 600 x 600 x 660 mm

Pros

Excellent for large part prototyping

Premium parts – E3D hot ends and Duet3D controllers

Cons

Kit so needs to be assembled — rather than being plug’n’play

The Big-60 makes the previously mentioned printers look tiny, with its enormous 600 x 600 x 660 mm build volume able to print even the largest prototypes and parts in one large part.

This is a huge advantage as you can print these large models without having to assemble them together – so surface finish isn’t affected by post-processing.

It’s a large 3D printer kit, but experienced operators or 3D printing makers will have no trouble assembling the Model Big-60 V3, especially as it comes with such detailed instructions that take you through every step of the assembly process. Big-60 V3 printing a model. Source: Modix3D

Big-60 V3 printing a model. Source: Modix3D

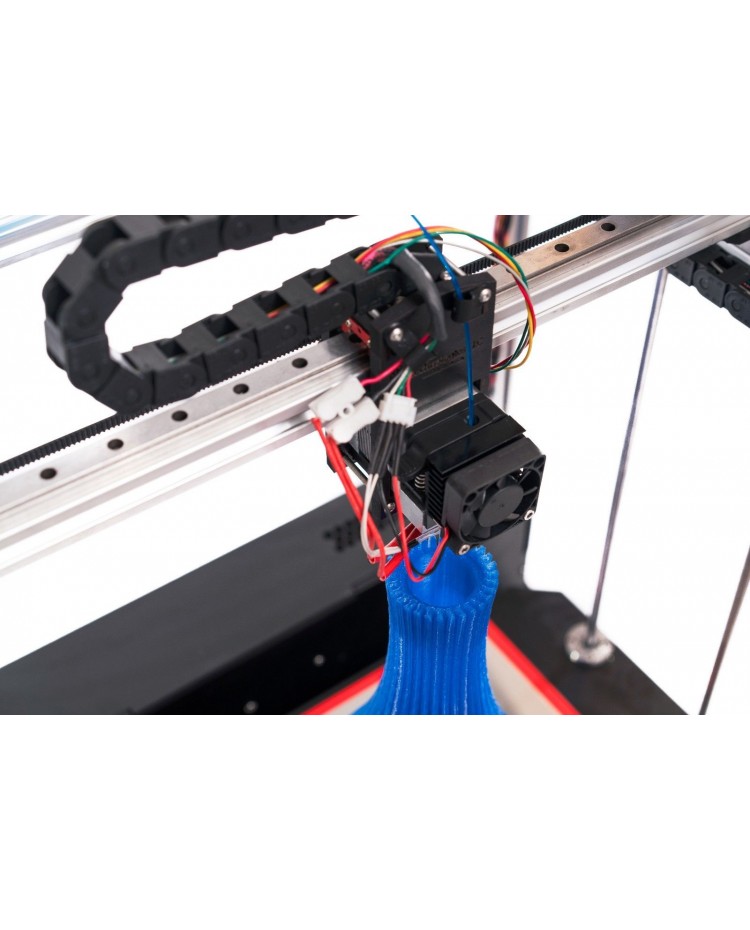

The Big-60 V3 kit features premium parts all around, for example, a high-quality E3D hot end, and Duet3D controllers as standard. Despite being designed for industrial, heavy-duty use, the Big-60 is designed also to be modular enough that you can easily install any upgrades tailored to your 3D printing needs.

These could be custom, third-party upgrades, or any one of a number of available upgrades you can buy with the printer, such as the enclosure kit, a super high-temperature nozzle for industrial material printing like PEEK or ULTEM, or a secondary print head.

Overall, it’s a large area 3D printer but at a much lower medium-range price, and it’s certainly a large 3D printer for big 3D printer projects.

Modix Big 40 – Best 400mm 3D Printer

- Price: $5,250 — Available at Matterhackers here / Dynamism here

- Build Volume: 400 x 400 x 800 mm

- Minimum Layer Height: 40 microns

- Max Nozzle Temperature: 340°C

- Filament Compatibility: PLA, ABS, Carbon Fiber, Wood, Copper, Brass, Magnetic, PHA, PVA, HIPS, Nylon, TPE, TPU, PETG

Pros

Ideal for tall part production with 800mm z-axis height

Seamless workshop/small business workflow: 7” ergonomic touchscreen, accessible WiFi, 100-point auto-levelling system for fast calibration

Cons

Kit so needs to be assembled — rather than being plug’n’play

While the Modix Big 60 V3 pitches towards a large uniform build volume on all axes, the Modix Big 40 is all about giving makers and businesses extra height to produce tall parts and models.

To achieve this, it offers a 400 x 400 x 800 mm build volume. Even a 3D printer with 400 x 400 x 400 mm is considered large, but the Modix Big 40 doubles that again with higher z-axis.

The advantage is clear, with the Modix 40, you can print large pieces, such as leg prosthetics and towering prototypes, in a single print, removing the need to print in parts and assemble them post-print.

Turning to the Modix Big 60’s other specifications, it ships with Wi-Fi connectivity, 100-point mesh automatic bed leveling, a premium powder-coated laser cut chassis, and a 7′ inch touch screen.Printing with PVA. Source: Modix3D

Elsewhere it has a precise 40-micron minimum layer height, milled cast aluminum print bed, PEI print surface, and a proprietary Griffin print head consisting of a custom-made Bondtech extruder and an in-house developed hot end reaching up to 340°C with a heated bed to handle carbon fiber and other tough filaments.

Much like the Big 60 V3, the Modix Big 40 is all about options and additional upgrades, available when you order the printer. This suits small businesses with different needs and requirements, with upgrades including:

This suits small businesses with different needs and requirements, with upgrades including:

- An enclosure

- Second print head

- High-temperature nozzles

- An E3D Aero or E3D Volcano hot end

- Magnetic beds, casters, air filters, and more

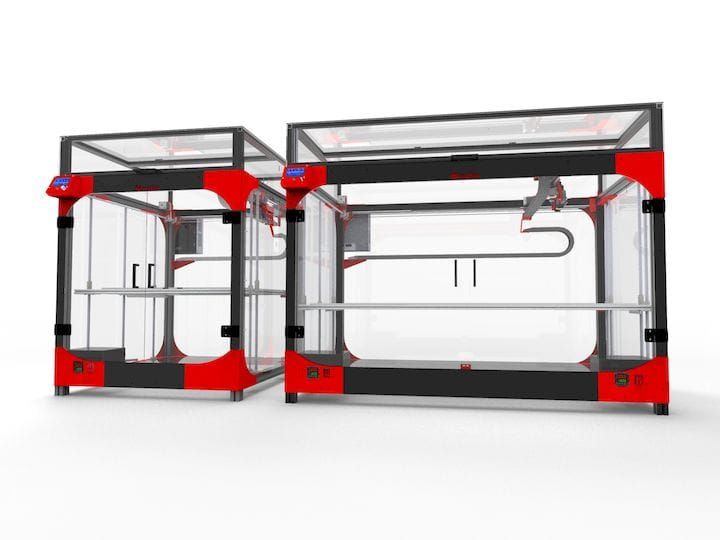

Raise3D Pro2 & Pro2 Plus — Large Build Area 3D Printer for Small Businesses

- Pro2 Price: Check price on Amazon here / Dynamism Store here

- Pro2 Plus Price: Check price on Amazon here / Dynamism Store here

- Maximum build volume: 305 x 305 x 300 / 605 mm (300 mm for Pro2, 605 mm for Pro2 Plus)

Pros

Choice of standard or extra-large Pro2 Plus version

Excellent built-in analytics for in-depth real-time print analytics

Ideal prototyping 3D printer for industry

Cons

Newer versions are now available (but are more expensive)

Raise3D printers feature in our best 3D printer ranking as well as our best dual extruder 3D printer ranking — and for good reason.

It’s ideal for multi-material printing (for example, ABS with dissolvable HIPS supports) as well as standard large format printing — and we recommend it for any small business looking to print large prints and prototypes in-house.

Raise3D are a highly reputed 3D printing company whose printers are used by 3D printing services and small businesses as these large 3D printers can create big parts on demand. Expanded to a 605mm max part height, you should have no problems printing large structures with the Pro2 Plus.A Pro2 printing in vase mode (Source: Youtube) and a Pro2 Plus getting tuned up (Source: Reddit)

For a closed build chamber (with better temperature control), even the Pro2’s build volume is huge. But the Pro2 Plus expands it further, doubling the maximum height you can print up to a whopping 605 mm.

Not only is this colossal 3D printer large, but both the Pro2 and Pro2 have strong reputations for being reliable workhorses. And even if you do have a problem, Raise3D has a California-based support team to help solve your problems.

Raise3D cleverly appeals to the customer segments in between consumers and professional printers, offering industrial-grade quality on their large-format 3D printers but at lower than industrial prices. The 7-inch touchscreen and features offered make it feel like a factory-grade machine, when in fact even the Pro2 Plus costs the same as the Ultimaker S5.

BCN3D Sigma D25 — Large Workhorse 3D Printer

- Price: $3,995 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 420 x 300 x 200 mm

Pros

IDEX dual extruder for multi-material, multi-color, or duplicate print options

Very reliable and well-known workhorse

Cons

Not as large as some other options on this list

Another very effective fused deposition modeling printer, Spanish industrial 3D printer manufacturer BCN3D have outdone themselves with their latest iteration of the Sigma range, the Sigma D25.

Featuring a dual extruder and immense print volume at 420 x 300 x 200 mm, the Sigma D25 still stands out for reasons other than just being a 3D printer with a large print bed. It’s extraordinarily versatile, happily printing with 3D printer filaments ranging from ABS and PLA to HIPS, ASA, and more.

However, this is no standard dual extruder — instead, BCN3D’s IDEX (independent dual extruder) system allows each of the extruders to move independently, vastly speeding up part production for similar parts, as well as allowing for multi-material printing and soluble filament printing, such as PVA.

Newly set up Sigma D25. Credit: Al DeanPerhaps most impressively, the Sigma’s duplication and mirror modes capitalize on its dual extruder to enhance the scalability of part production. Duplication mode prints identical models simultaneously, while mirror mode prints mirror designs to speed up part production.

The D25 has also been upgraded with a stainless steel frame to anchor down the X and Y axes and improve print quality and features E3D hotends and Bondtech extruders for extremely reliable and high-quality printing. It’s a large enclosed 3D printer- ideal for printing ABS and other high-temp filaments with a stable thermal environment.

It’s a large enclosed 3D printer- ideal for printing ABS and other high-temp filaments with a stable thermal environment.

The 5-inch touchscreen makes the Sigma D25 a very simple-to-use large-format 3D printer, with fantastic 50-micron minimum layer heights and very precise XY and Z resolutions for intricate part printing.

- For more information on resolutions, we have a guide to resolutions in 3D printing.

Moreover, Sigma D25 is a BCN3D printer that now has WiFi printing capabilities as well as USB and SD card printing, and even updates itself automatically with the latest firmware for the latest developments.

Ultimaker S5 — Extremely precise large format 3D printer

- Price: $5,995 — Available on Dynamism Store here / Available on Matterhackers here

- Maximum build volume: 330 x 240 x 300 mm

Pros

The gold standard in high-quality desktop FDM 3D printing

Excellent, best-in-class precision and accuracy

Fits well into an existing workflow: Ultimaker offer software products for industrial needs and 3D printer factories

Cons

Not as large as some cheaper alternatives

The follow-up to the acclaimed Ultimaker 3, the Ultimaker S5 is the Dutch company’s launch into a higher price range, more industrial printer.

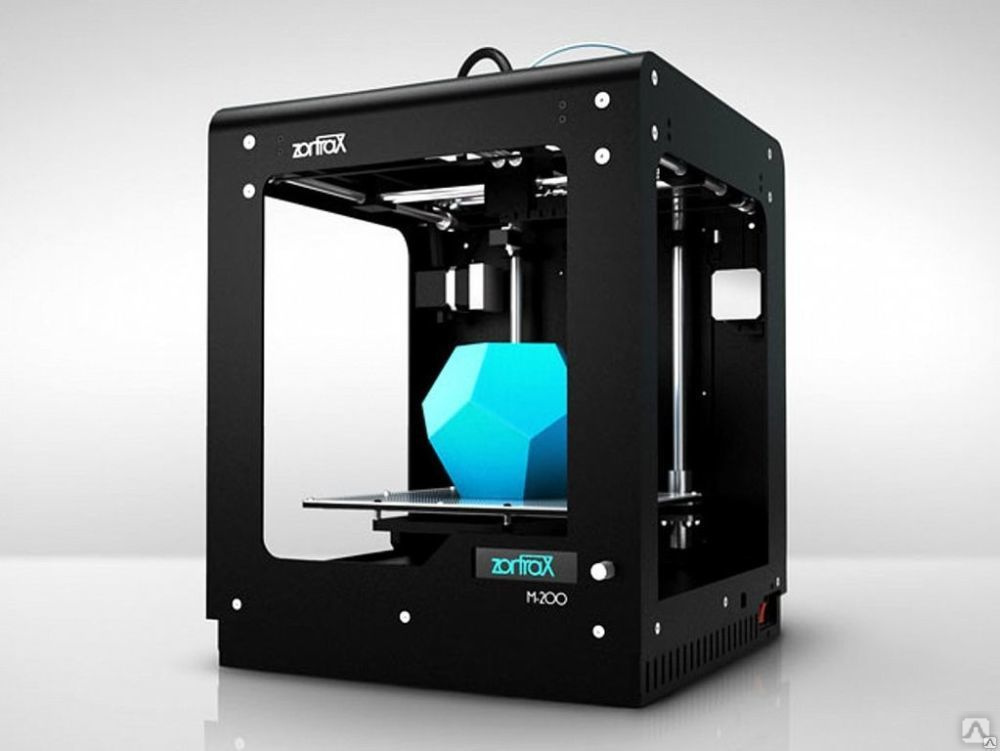

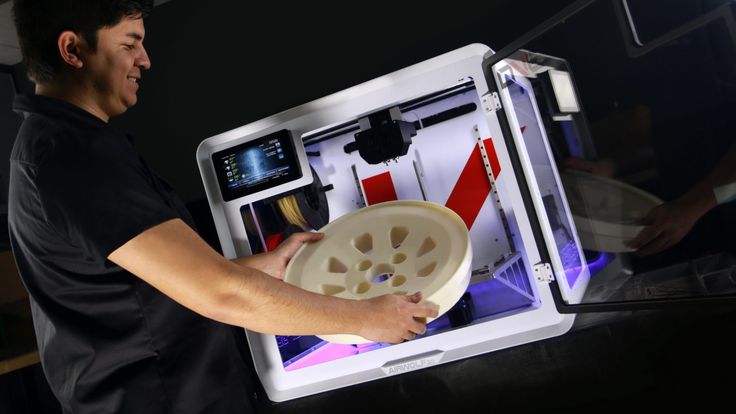

A large build volume 3D printer, the S5 is geared towards a more professional and industrial clientele, expanding the build volume and focusing on the scalability of rapid prototyping.

S5 and some test prints. Source: TwitterThough more expensive than its predecessor, clocking in at just under $6K, Ultimaker are not struggling for clients. The printer is said to be used by Volkswagen, showing just how highly rated Ultimaker’s printers are. It’s the best 300mm 3D printer around – though you may require larger build volumes than 330 x 240 x 300 mm offers.

While not enormous, the sheer precision, quality and reliability still earn it a place as one of the best large 3D printer ranges for professional prints. Its broad material compatibility is a plus (Ultimaker sell their own brand of high-temperature materials) for printing large objects in PP, CPE, Nylon, PC, and more.

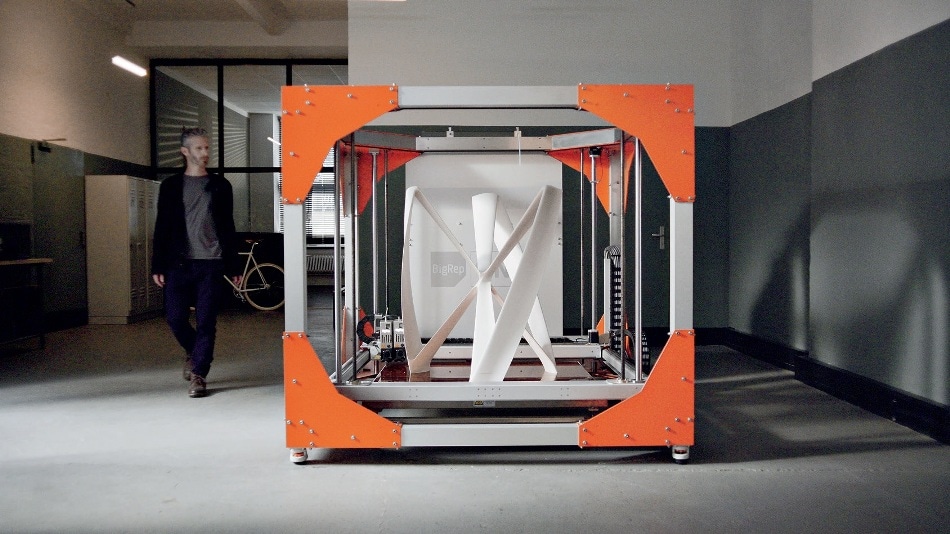

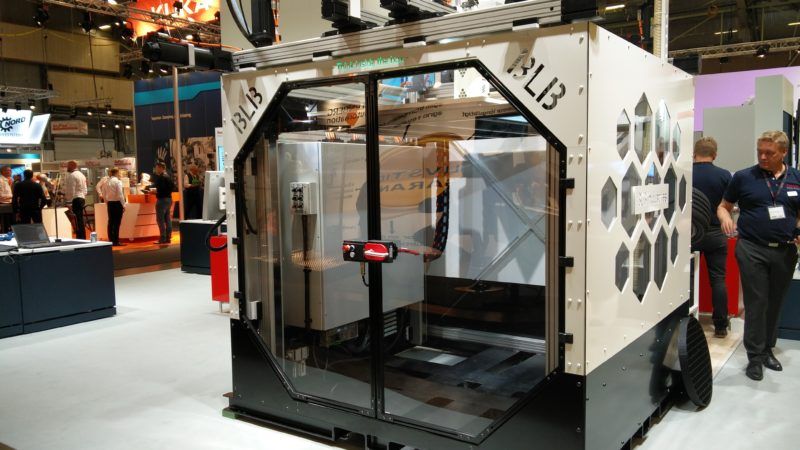

BigRep Studio G2 — Gigantic 3D Printer!

- Price: requires a quote

- Build volume: 1000 x 500 x 500 mm

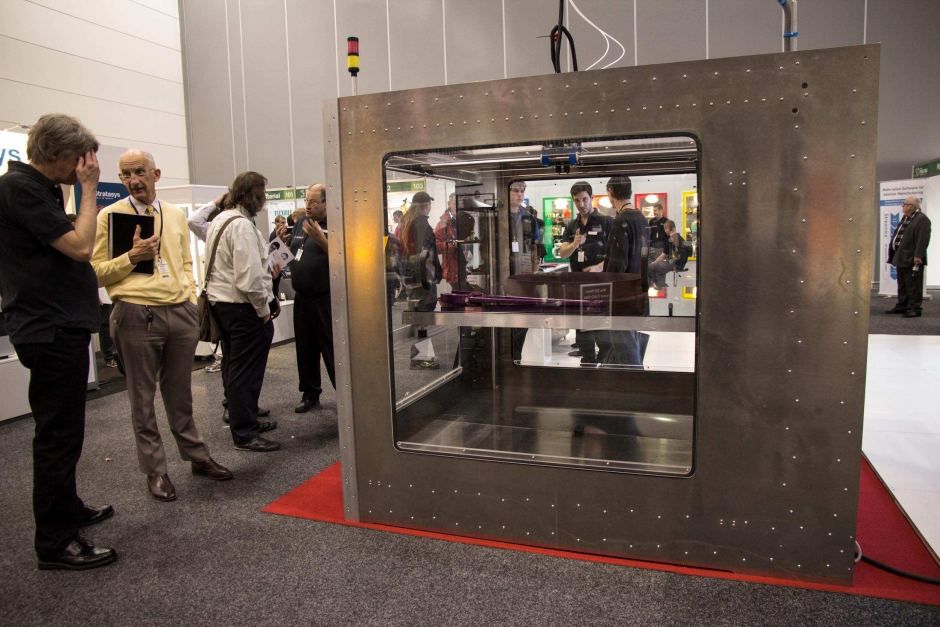

This behemoth is a huge 3D printer, one of the many immense beasts that German manufacturer BigRep sells to their industrial clientele. It’s quite possibly the largest FDM printer you’ll come across.

It’s quite possibly the largest FDM printer you’ll come across.

Used for prototyping and in the medical, automotive, and aerospace sectors, the BigRep Studio weighs in at over a quarter of a ton owing to its massive build volume.Studio G2 and some test prints: Source: Reddit

BigRep sells a number of custom materials for use in their large 3D printers, including commonly used printer filaments like PLA and PETG, as well as more niche materials such as flexible filaments, HT, and HS. The advanced air filtration system, completely enclosed build area, and tool steel nozzle makes it perfect for 3D printing carbon fiber filaments, ASA, and Polyamides like Nylon.

The Studio G2 works seamlessly with BigRep’s Blade 3D printer software, prints up to 100mm/s, and can print with up to 0.1mm minimum layer heights.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

Concept Laser X Line 2000R — Largest 3D printer in the world

- Price: request a quote

- Build volume: 800 x 400 x 500 mm

One of the world’s largest 3D printers and also one of the world’s most expensive, the Concept Laser X Line 2000R uses Direct Metal Laser Sintering to print strong and accurate metal parts, and costs millions. However, this machine is such an engineering feat that we felt compelled to include it, with large print volumes exponentially harder to achieve with metal 3D printing technologies.

However, this machine is such an engineering feat that we felt compelled to include it, with large print volumes exponentially harder to achieve with metal 3D printing technologies.

Undoubtedly a leader in its sector — and you can also check out our metal 3D printer ranking — the ability to create metal parts up to 800 x 400 x 500 mm in size is an invaluable asset. If you’re not a billion-dollar company then you’re unlikely to buy one, but this machine is a lock-in for our large 3D printer list, able to print metal structures at sizes never achieved prior.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

Tips for Large-Format 3D Printing

Keep time in mind

It’s important to remember how long it takes to print these enormous parts. In rapid prototyping, it’s common to leave your printer running overnight and come back to it the next day, but if you’re printing a 50 x 50 cm prototype with a 0.4mm nozzle and small-ish layer heights, it could take several days to print.

A natural solution is to replace the standard 0.4mm nozzle that comes on most large-scale 3D printers with a larger (0.8-1.2mm) nozzle. Then, if printing larger layer heights (200 – 400 microns) you massively increase print speed.

However, this opens another can of worms. Less powerful hotends can struggle to melt such a large amount of filament quick enough to extrude in time, so you may want to upgrade your hotend to print without issue. We have a guide to some great hotends here.

Is it worth buying a large 3D printer, or using a 3D printing service instead?

This is another question you should ask yourself. If you’re only planning on printing a few prototypes for the year, you might find it advantageous to instead outsource your printing needs to an external service.

It’ll be more expensive than if you were to just pay for the materials to print yourself, but if you don’t have much use for the large-scale 3D printer, it’ll sit there collecting dust in your workshop for the rest of the year.

This is a simple value judgment — do you think you’ll use it enough?

The answer could even be to keep/buy a standard smaller 3D printer, use that for day-to-day prototyping, and if you have an enormous printer project, outsource those. We have a ranking of some of the best 3D printing services.

1 big 3D printer, or multiple smaller printers for many small parts

A common line of thought is that buying one large 3D printer gives you the capacity to print many smaller parts simultaneously.

This is true, but not necessarily efficient. Yes, you can print 10-20 small pieces at the same time on a large 3D printer, but it’ll take 20 times as long as you could have printed these parts on 20 desktop 3D printers. So, if you’re planning on printing many small parts, consider instead going with a 3D printer farm.

That said, the best 3D printer for large objects is certainly one with a big print volume – it’s a hassle gluing multiple parts together, and affects the final part’s strength.

Large 3D Printer Applications

- Large, single-part prototypes — for parts where surface finish is important, and where assembling multiple parts post-print would make this difficult. Also when time is not an issue it’s less hassle to just print one large part over time.

- TV and movie props, and cosplays — Redditors have shown extensions they’ve made to their enormous 3D printers to print large cosplay parts, and the TV & film industry have begun using 3D printing for props and other appliances for sets.

- Furniture — increasingly, large volume 3D printers are being used in similar ways to 4×8 CNC routers to create furniture like chairs, stools, and tables. We cover a variety of ways to do this in our feature story on 3D printed furniture.

Large 3D Printer FAQs

What’s the Biggest 3D Printer You Can Buy?

The largest 3D printer you can currently buy is the Massivit 10000. It offers a massive 1420 x 1110 x 1500 mm build volume and is roughly the size of a small room.

What 3D Printer Has the Biggest Bed Size?

The Massivit 10000 has a 1420 x 1110 x 1500 mm build volume, followed closely by the Industry Magnum, which has a 1500 x 1200 x 1200 mm build volume. Other notable mentions include the CreatBot F1000 with a 1000 x 1000 x 1000 mm build volume, and the BigRep Pro, which has a 1000 x 1000 x 1000 build volume.

How Much Does a Huge 3D Printer Cost?

A consumer-grade 3D printer with an ultra large-format build volume can cost as low as $600, such as the Anycubic Kobra Max and Ender 5 Plus. For an industrial-grade printer, prices sort well into the thousands of dollars, with some, such as the Industry Magnum, costing well above $100,000.

What Is the Biggest 3D Printer Out There and What Does It Print?

The biggest 3D printer out there is the Massivit 10000. It can print custom molds, tools, mandrels, jigs, fixtures, and plugs for the marine, rail, automotive, construction, sporting, and aerospace industries.

If you enjoyed this ranking, you may also be interested in:

- Our ranking of the best small 3D printers

- The best dual extruder 3D printers

- The best 3D pens

- How much does a 3D printer cost to buy and maintain?

- The best commercial 3D printers

- The best 3D printers for small businesses

- Best 3D printers for $5000

- 500x500x500mm 3D printers

- Nylon 3D printer buyer’s guide

Shop the Best Large Format 3D Printers in 2022 (Including Best Large 500mm 3D Printer)

Welcome to the Thomas guide to the best large format 3D printer 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

Printing larger items with most at-home or small-scale 3D printers is possible but consists of separately printing different parts of the project and then connecting them all together afterward to make the much larger finished product. In this way, many 3D printing enthusiasts, such as cosplayers, for instance, are able to get past the 3D printing size limitations and use their machines for much larger products than the print bed will allow.

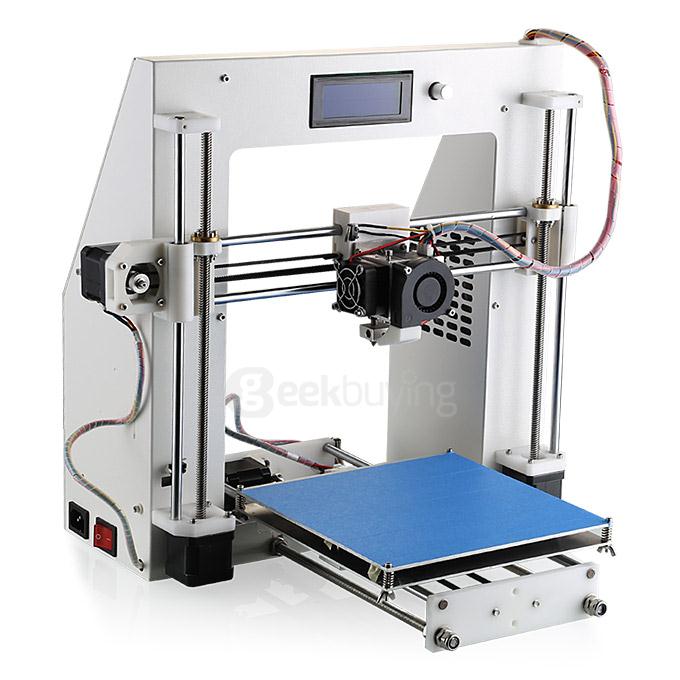

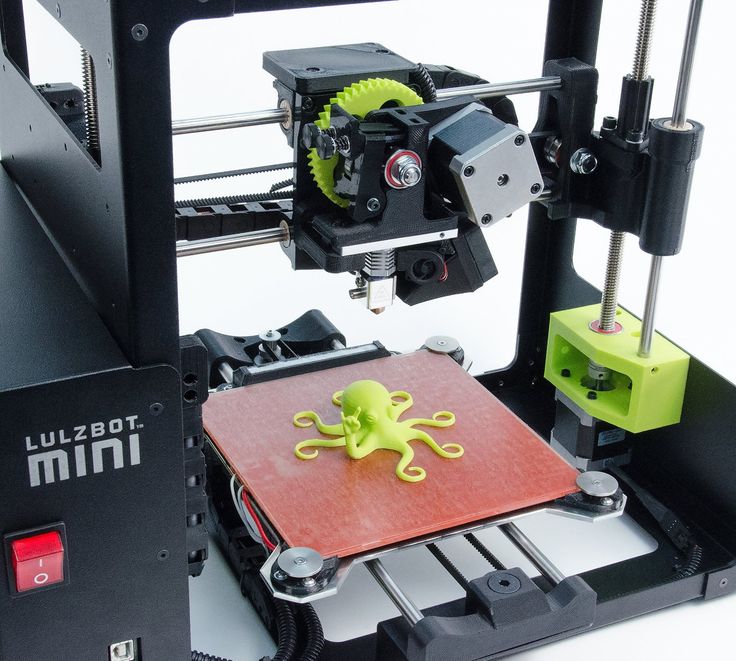

A large-format 3D printer in actionImage credit: Shutterstock/asharkyu

However, purchasing a large-format 3D printer can provide an increase in opportunities for creativity and a decrease in the amount of "putting together" necessary for those larger projects.

Large-Format 3D Printer—Buying Guide

With the average printing bed size of a 3D printer intended for general use being around 150–300mm, if you wanted to scale up the size of your 3D creations, a printer of 350mm–500mm would be ideal, and luckily, there are a few worthy large-scale models available on the market for you to choose from.

Benefits of a Large 3D Printer

Development in 3D printing technology means that we've recently been presented with 3D printed houses, cars, bikes, camper vans, life-size statues, and even sofas and other pieces of furniture.

Obviously, the "large format" we're referring to in this article is less about making grand-scale structures, and more about moving on from miniatures, ornaments, and other small objects or parts that an ordinary, non-industrial-sized 3D printer can produce.

Since you'll have a little more print bed area to play with, with a large-format 3D printer you can create detailed products that don't require a magnifying glass to really appreciate and also larger parts that would otherwise need to be printed in separate sections.

Thomas’ Top Picks for the Best Large Format 3D Printer 2022

If you're ready to step up your 3D printing game, and have a blast doing it, here are some of the best large format 3D printers currently available to buy now.

Scroll down to see more on our top picks for the best large format 3D printer, according to many happy buyers.

*Prices listed in this article were as shown in US$ on Amazon.com (USA) and other online retailers as of February 2022

1. Best Large 500mm 3D Printer—Crealty Large 3D Printer 500x500x500mm

As one of the 3D printers with the largest printing beds currently available, the Creality CR-10 S5 3D printer has 500x500x500mm of printing space meaning you can really let your imagination run wild.

Installation is super quick and easy as the machine comes in three pre-assembled parts with clearly labeled wires and instructions. Other features include a resume-printing function in the event of loss of power, and you also get a one-year warranty from the manufacturer.

One buyer who gave this machine five stars helpfully mentioned that you need to have plenty of room to accommodate this huge printer, writing, "The main thing to consider is its sheer size. It requires over a yard, possibly a full meter of depth to move the build plate."

BUY NOW: US$719, Creality 3D2. Best Large 400mm 3D Printer—ANYCUBIC 3D Printer 400x400x450mm

A large-format 3D printer from a trusted brand, the ANYCUBIC Chiron is for anyone who doesn't mind spending some extra time and effort on leveling the bed or working out the settings.

Users have reported this as being rather tricky, but the trade-off is a great 400mm 3D printer with impressive capabilities, plus, a superb customer service department that helped with any and all issues pertaining to the printer, from setup to product completion. One fan wrote, "It took me a long time to dial in my settings and get high-quality prints but I was able to get the printer working and printing decent quality the same day I put it together."

One fan wrote, "It took me a long time to dial in my settings and get high-quality prints but I was able to get the printer working and printing decent quality the same day I put it together."

Another happy user who has "completed more than 4,000 hours of printing" and "used many hundreds of rolls of filament," described, "The results I am getting are amazing even with some prints taking over 300 hours to complete. In fact, I have just started a seven-part 700-hour print which is going very well."

BUY NOW: US$623.75, Amazon3. Best Large 3D Printer Under $1000—Creality Ender 5 Plus 3D Printer 350x350x400mm

With pretty much the same capabilities as its equally highly-rated sister model, the Creality Ender 5 Pro, including an automatic bed leveling sensor, bed stabilizer, color touch screen, and easy assembly, the Ender 5 Plus has one major difference; its huge size which accommodates its large build plate.

This sturdy thing works straight out of the box, and in addition to great customer support, there is also a massive Creality community to quickly get any answers and assistance you may require.

"I have printed several large helmets with great results," one happy purchaser wrote, and another added, "I love having the bigger print bed for very big projects. There is some fine-tuning you will have to do but after that, you are ready to rock and roll."

BUY NOW: US$599 (Was US$649), Amazon4. Best Industrial Large 3D Printer—Snapmaker 3-in-1 3D Printer 320x350x330mm

For advanced hobbyists or pros who want to up their 3D printing game, the Snapmaker 2.0 will make a proud addition to your workspace and open up a world of 3D opportunity and creativity. In addition to its large printing capacity, it is fast, powerful, and also allows you to do much more than 3D printing, like engraving, cutting, and CNC carving.

At this price, it's a unit for those who are pretty serious about 3D printing, but for small businesses that rely on the craft, it will end up paying for itself in no time. One reviewer who bought this to enhance their graphic design business, wrote, "It's been a valuable asset so far. We are making our own business cards on metal which is super unique and our customers love the added services we can now offer."

Another happy buyer who raved about its versatility and build quality, added, "I have been making non-stop with this machine... [It] allows for the imagination to go absolutely wild with ideas!"

BUY NOW: US$1,799, Amazon5. Best Large 3D Printer under $500—SUNLU S8 3D Printer 310x310x400mm Upgraded

Another good printer with a large print bed, and a tiny price to boot, the upgraded SUNLO S8 only weighs around 26 pounds so is not as much of a task to move as some of the other large 3D printers.

At under US$300, you get many features like high stability, accurate printing, filament runout detection, a Z-axis dual linear rail, and simple assembly. There's also a resume printing function for power failures.

"This printer provides great value for the cost," one buyer explained. "Not only is the print size large enough to do just about anything you can think of, but at 310x310x400 it is the largest in its price class." Another happy customer wrote, "Awesome printer for the price. Can't beat it. It's open-source so it's super easy to add upgrades if you want. Huge build size."

BUY NOW: US$279.99, Amazon6. Best Cheap Large 3D Printer—LONGER LK1 3D Printer 300x300x400mm

With an even smaller price tag, the Longer LK1 3D printer is another option for those wanting to dabble in 3D printing but unsure whether to fork out the big bucks just yet.

It provides plenty of features to learn the art, and the customer service is helpful with any questions you may have. The leveling is not the best, but it is easy to assemble and users have been satisfied with the print quality.

The leveling is not the best, but it is easy to assemble and users have been satisfied with the print quality.

"This is an awesome entry-level printer," one satisfied shopper explained. "I was pleasantly surprised, how easy it was to set up... If you're looking for bang for your buck and [to] familiarize yourself with 3D printing, then don't go wasting money on expensive printers; this one works great."

BUY NOW: US$270.39, WalmartThe Best Large Format 3D Printer—Summary

With one of the largest printing beds currently available for a non-industrial 3D printer, the Creality CR-10 S5 3D printer (US$719, Creality 3D) provides an impressive 500x500x500mm of printing space. The Anycubic Chiron (US$623.75, Amazon) is another large-format printer with impressive capabilities and has a superb customer service department too.

We hope our review of the best large format 3D printer has been helpful. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

The most expensive 3D printers in the world

- home

- News AT

- World

- The most expensive 3D printers in the world

Various technologies do not stand still, they are constantly evolving. This article proposes to consider the evolution of industrial 3D printers today, which are the most expensive in the world and why.

This article proposes to consider the evolution of industrial 3D printers today, which are the most expensive in the world and why.

3D printers are unique in terms of the variety of different 3D printing methods, materials used and their applications. You can spend as little as $100 to get a reliable 3D printer to make a huge variety of parts from affordable plastic material. On the other hand, you can spend over a million dollars to buy a 3D printer to 3D print parts with large and complex construction geometries. They can be used in the aerospace industry, the production of space satellites or miniature biocompatible devices for medical purposes. The most expensive 3D printers on the market today use 1 to 12 powerful lasers to fuse metal powder, sinter polymer materials, or polymerize resin, and 3D printing from a given 3D model occurs by applying the powder layer by layer, which is a process additive manufacturing.

It can be noted that the size of the 3D printer does not determine how expensive the 3D printer will be. Today, the price often depends on advanced patented technologies and features that allow a 3D printer to produce fast and high-quality 3D-printed parts without requiring special technical knowledge from the operator.

Today, the price often depends on advanced patented technologies and features that allow a 3D printer to produce fast and high-quality 3D-printed parts without requiring special technical knowledge from the operator.

Some of the most expensive printers are not even for sale. Carbon 3D's 3D printers are available for rent only, which allows them to be used by many users. Others use their 3D printers on a project-by-project basis, such as the Vulcan construction printer from homebuilder Icon 3.

Stargate, the world's largest metal 3D printer built by Relativity Space to 3D print rockets, it's not for sale, but if it was, it would definitely be on our list. Many of the most exciting technologies in 3D printing can only be used for custom 3D printing, not for purchase. (Source: Relativity Space)

Let's look at the criteria that affect the cost of a modern industrial 3D printer.

Features 3 D -printers affecting their price:

- The uniqueness of technology when creating

- How automated the processes in 3D printer

- The size of the working chamber

- Functions allowing quality control

- Self -software software

- Numerous controls and adjustments

- Controlled environment inside the working chamber (use of inert gas, possibility of heating/cooling the working platform)

Let's break down these features:

Features that drive up the price of 3D printers include printer technology-specific software, real-time 3D printing control systems, and anything that automates processes that sometimes are performed manually in cheaper systems (layer leveling, subsequent post-processing or powder sieving) or processes that require knowledge of metallurgy or polymers.

Production technology that requires a vacuum chamber in a 3D printer, filling the working chamber with an inert gas, or printers that are certified for use in clean rooms and have these characteristics are significantly reflected in the final price of this equipment.

The materials used in the 3D printing process also have a significant impact on the final cost of a 3D printer. Many 3D printers only work with proprietary materials that have been developed by the manufacturer for that 3D printer. They can be metal powder, special resins filled with carbon fiber particles, and unique polymer powders. At this point in time, it is possible to 3D print anything from pure gold to advanced engineering plastics on 3D printers, even in the harsh environment of space.

There are 3D printers that can 3D print multiple materials in one job, and there are multicolor 3D printers that are also in the higher price segment.

THE MOST EXPENSIVE 3 D -PRINTERS

The 3D printer manufacturers discussed below are reluctant to publish exact prices for their products. This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

This is due not only to competition, but also to the fact that 3D printers have a basic package, as well as a package with additional options according to customer requirements. That said, with that in mind, below is a look at some of the most expensive 3D printers available today - all costing over half a million US dollars - and what they provide.

E-Plus3D EP-M450H

3D printer EP-M450H LPBF (Source: E-Plus 3D)

E-PLUS3D produces industrial metal 3D printers with a large camer of the building for additive manufacturing for various industries in the country. These 3D printers are used in the aerospace, automotive, electronics, and engineering industries to produce not only large-sized parts such as heavy-duty molds, but also mass-produced parts.

The EP-M450H Metal 3D Printer is the company's largest 3D printer with a build chamber of 456 x 456 x 1080 mm, producing 99.9% density metal parts from a wide range of materials at a speed of 55 cm³ per hour.

XJet Carmel 1400C

Israeli company XJet has developed a unique ceramic 3D printing technology. NanoParticle Jetting (NPJ) technology allows the production of metal and ceramic parts with a high level of detail, smooth surface roughness and geometric accuracy. The high cost of this 3D printer is not only due to the technology itself, patented materials that make this printer a serious investment, but also to the advanced automation of the 3D printer itself, which makes it easy to use.

Carmel 1400C, equipped with one of the largest 1400 cm² work platform in the industry, which allows you to simultaneously produce several ceramic parts.

SLM Solutions NXG Xll 600

Large Metal 3D Printer NXG XII 600 (Source: SLM Solutions) range of printers, but its NXG Xll 600 is what the company says is a revolution in industrial additive manufacturing. The NXG XII 600 was designed for high-volume additive manufacturing and features the industry's first 12 1,000W lasers with a 600x600x600 build chamber. Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

Lasers provide high build speed up to 1000 cm 3 /h and capacity not available for other machines.

In addition to lasers, the NXG Xll 600 has all the benefits that SLM Solutions customers have been asking for over the years, including automatic start-up, laser focusing, closed powder feed and material screening, and other latest developments.

UpNano NanoOne Bio

The Austrian company UpNano has developed a two-photon 3D printer using hydrogel-based bio-ink, which allows direct printing of 3D structures containing living cells, both at the meso- and microscale. The NanoOne Bio printer is based on the NanoOne line of laser printers capable of creating structures of 12 orders. The new hydrogel is the only commercially available resin that allows live cells to be embedded directly from culture plates into 3D printed structures for biological applications.

UpNano claims that the combination of X Hydrobio INX U200 and NanoOne Bio opens up new possibilities in biomedical research and development, both in industry and academia, allowing pharmaceutical companies and research institutes to create cell models that mimic natural growth conditions in the body person.

Black Buffalo 3D

Black Buffalo's new 1G construction printer (Source: Black Buffalo)

Black Buffalo 3D, an American company based in South Korea, officially unveiled its Nexcon 1G earlier this year, which is a 3D printer for building houses and other large concrete objects. The printer can create a 92.9 square meter structure in less than 20 hours. It uses Black Buffalo's patented cementitious material, the company calls it ink, that can be dyed to a chosen color and is also customizable to 3D print locally according to the temperature, humidity and altitude conditions of the area.

The Nexcon 1G is a modular 3D construction printer that can be extended along the X, Y and Z axes to scale up (or down) a project up to three stories high. The 1G printer is unique in that users can reposition the base rails and move the printer to a new printable area without having to remove the X or Z axis.

Optomec LENS 860

Energy Deposition (DED), which allows the recovery of large titanium components, such as those used in aircraft engines. Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

Optomec offers several models of 3D printers that have large build chambers like 860x600x610 and laser power of 3 kW.

The LENS 860 machining systems are ideal for the fabrication, repair or coating of medium to large metal parts.

ExOne S-Max Pro

While many ExOne printers (now owned by Desktop Metal), they are still very affordable given that high volume 3D printers can cost quite a few zeros.

3D printers are used to 3D print complex and detailed sand molds and cores for foundries producing large metal parts for industrial use. The S-Max Pro features a 1,260 liter build chamber for fast 3D printing of sand molds and cores. A new automated print head enables fast 3D printing, while improved sand compaction ensures the density and strength of complex sand mold designs. As the most advanced system in the ExOne family of sand 3D printers, the S-Max Pro is focused on continuous 24/7 production and offers Industry 4.0 integration with cloud connectivity and real-time machine monitoring.

In conclusion, I would like to know the opinion of Russian industrialists and users of industrial 3D printers: Is it possible to integrate these 3D printers into the Russian industry? Do Russian developers of this equipment need to produce the same expensive 3D printers in Russia?

Share article:

The largest metal 3D printer is built in the USA

News

Subscribe to the author

Subscribe

Don't want

2

Ingersoll, MELD Manufacturing and Siemens will build the world's largest metal 3D printer. The system will rely on adapted friction welding technology and will be able to grow parts up to ten meters long.

The work is carried out in the interests of the US military: such 3D printers are planned to be used primarily in the production of mine protection for army vehicles. During the Vietnam War, 73 percent of equipment losses were due to explosions on anti-personnel and anti-tank mines. Modern armored vehicles and armored personnel carriers are designed with enhanced protection, and an important role is played by thick, armored bottoms, often V-shaped and with a minimum of welds.

Modern armored vehicles and armored personnel carriers are designed with enhanced protection, and an important role is played by thick, armored bottoms, often V-shaped and with a minimum of welds.

An American Cougar armored vehicle that hit a mine in Iraq in 2006 and drove another three kilometers to the safe zone. The personnel escaped with minor injuries. Photo: Marine Sergeant Christopher Clare

Previous work on the Jointless Hull project of the Army ManTech research program has looked at forging, forming and welding at high current density to reduce weld porosity. The results were rated as satisfactory in terms of strength, but at the same time, there was a lack of geometric freedom and manufacturing flexibility.

As a result, it was decided to abandon forging, forming and welding in favor of another technology - production by the method of additive friction deposition with mixing (Additive Friction Stir Deposition, AFSD), that is, Friction Stir Welding, adapted for 3D printing, FSW).

Development work consists of two stages. Not the first one is planned to assemble a demonstrator with a construction area measuring 1x1x1 meter to test the technology and software. The design must then be scaled up to a working volume of 10x6.5x4 meters - the largest among "metal" 3D printers. Length is a conditional characteristic, since the portal structure will move along the rails. Siemens is responsible for the control systems and software.

The large-format version is already being assembled by Ingersoll, which has considerable experience in working on large additive systems. In 2019, this venture helped the University of Maine set three Guinness records at once: to make the largest 3D printed boat (seven meters in length), aka the largest one-piece 3D printed object, on the largest 3D printer for working with polymers and polymer composites. The same system is used in the production of large molding tooling, for example for the manufacture of helicopter blades.

The new 3D printer, as already mentioned, will deposit metals using friction stir deposition. This technology is being developed by MELD Manufacturing using the Edison Welding Institute (EWI). The build-up is carried out by plastic deformation at temperatures below the melting threshold, thereby achieving high isotropy and density without shrinkage and the risk of hot cracks, without the need for a vacuum chamber or protective gas environment. The technology also allows you to create gradient structures from different metals or alloys. Consumables are usually rounded bars with the possibility of using powders of different fractions and even metal shavings.

MELD Manufacturing already offers several models of additive systems. The latest commercial offer is the L3 3D printer released in 2020 with a working area of 1143x584x584 mm, although the K2 system with a useful volume of 2100x1100x1000 mm is the leader in terms of dimensions. The equipment allows you to work with various steel grades, as well as aluminum, copper, titanium, magnesium and nickel alloys. As a rule, such 3D printers stack layers about one millimeter thick and 38 mm wide, keeping the temperature of the material at 60-90% of melting point. Since the resolution of 3D printing is low, the resulting blanks require intensive machining, but with much less labor and waste than milling from blanks, and with high scalability, which is planned to be demonstrated in practice by the joint efforts of Ingersoll, MELD Manufacturing and Siemens. The commissioning of the large-format system is scheduled for the fourth quarter of this year.

As a rule, such 3D printers stack layers about one millimeter thick and 38 mm wide, keeping the temperature of the material at 60-90% of melting point. Since the resolution of 3D printing is low, the resulting blanks require intensive machining, but with much less labor and waste than milling from blanks, and with high scalability, which is planned to be demonstrated in practice by the joint efforts of Ingersoll, MELD Manufacturing and Siemens. The commissioning of the large-format system is scheduled for the fourth quarter of this year.

Siemens MELD Ingersoll rotary welding

Follow the author

Follow

Don't want

2

More interesting articles

fourteen

Subscribe to the author

Subscribe

Don't want to

It used to be that in cases of revocation of airworthiness certificates for storks and poor harvest of cabbage, children came .