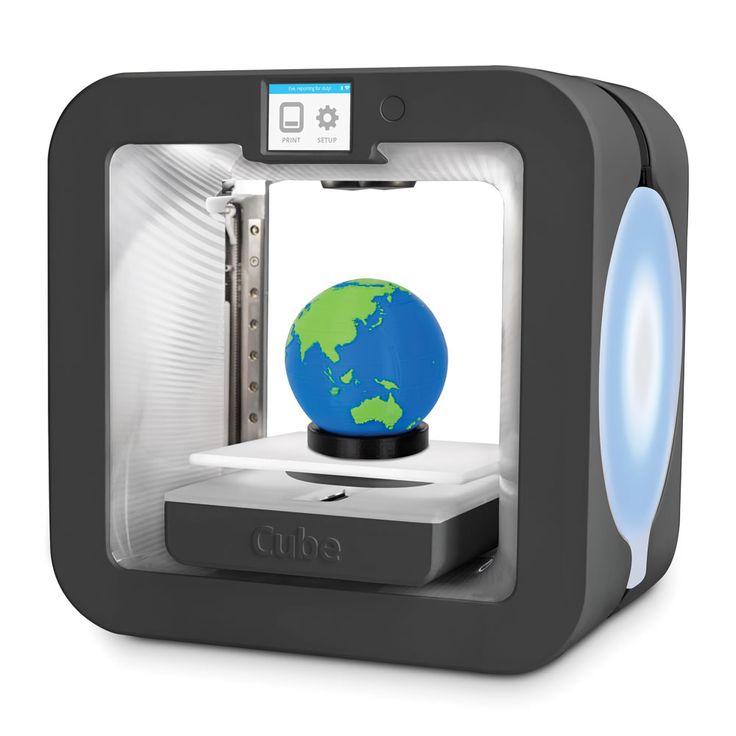

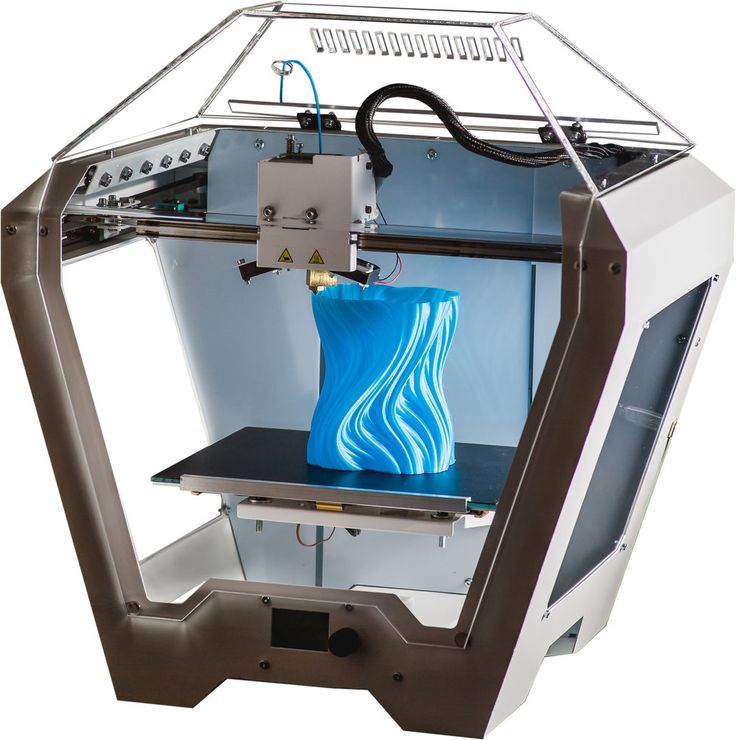

Axiom 3d printer

Airwolf 3D AXIOM DUAL EXTRUDER 3D Printer

Properties

| Build Volume | 317 x 200 x 230 mm (12.5 x 8 x 9.5 in.) |

| Layer Resolution Low | 350 micron (0.013 in.) |

| Layer Resolution High | 100 micron (0.004 in.) |

| Nozzle Diameter | 0.5 mm |

| Filament Diameter | 3 mm |

| Print Speed Max. | 150 mm/s |

Documents

- usermanual_axm960_E.

pdf

| Brand | Airwolf 3D |

| Machine type | 3D Printer |

| Technology | FDM (Fused Deposition Modeling) |

| Materials | PLA, ABS, Nylon, FLEX (Elastic TPE) |

| Website | http://airwolf3d.com/shop/dual-extruder-3d-printer |

| Average Price | $4,995.00 |

- Independently Controlled Hotends are capable of printing in 2 colors, or creating parts which require soluble support material

- The new AXIOM Dual Extruder 3D printer features a fully enclosed print chamber providing a thermally stable environment which minimizes the incidence of warpage while sustaining optimal print quality, especially when applied to very large 3D prints.

- The AXIOM Dual Extruder 3D printer automatically calibrates its print bed ensuring optimal bed leveling and head spacing before beginning every print.

- The AXIOM Dual Extruder 3D printer End-User Replacement Cassette enables users to rapidly replace components or to install device upgrades which minimizes downtime and extends the AXIOM_x0083_??s service life. Previous single extruder AXIOM owners can easily upgrade their machines to an AXIOM Dual Extruder 3d Printer utilizing this revolutionary system.

- AXIOM draws new filament into its print head automatically.

- The silky smooth CoreXY motion control system used in the AXIOM provides unparalleled speed (250mm/s print, 400mm/s traverse), precision, and print quality.

- The AXIOM Dual Extruder 3D Printer’s improved Dual JrX Hotend reaches independently controlled temperatures of 315?øC (599?øF) and is designed to resist troublesome clogs.

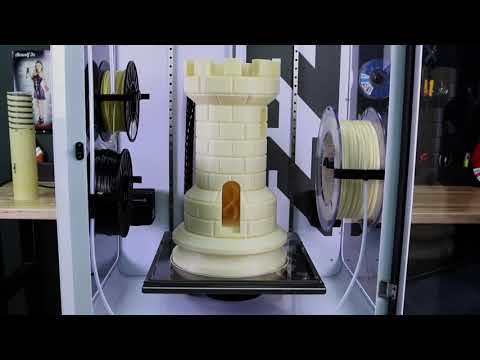

- The AXIOM Dual Extruder 3D Printer’s build volume allows for very large 3D prints making it the ideal desktop solution for rapid prototyping and manufacturing functional products.

- The AXIOM Dual Extruder 3D printer is capable of printing in most thermoplastic materials including high-temperature polycarbonate and nylon filaments.

Airwolf 3D Printers | GoMeasure3D

New Standard in Desktop 3D Printers

Airwolf AXIOM

Customers using Airwolf’s 3D Printing Technology:

Speed Meets Precision

With unparalleled speed, resolution, ease of use, and durability in one sleek package, Airwolf3D (AW3D) printers set a new standard in desktop printing. The AXIOM model of 3D printers offer performance and features that simply beat other 3D printers 3x the price. It produces larger, cleaner, and more detailed models than other competing models.

New

The toughest, tallest, and most precise 3D printer in its class, the AXIOM 20 has 3x the build volume and 4x the build speed of the original AXIOM 3D printer.

Features

-

High Speed For Faster Print Times

Operates at printing speeds of up to 250 mm per second, and travel speeds as high as 400 mm per second.

-

High Accuracy 3D Printer

With a 40 micron minimum layer height, and an X, Y resolution of 20 microns, the printer is extremely accurate.

-

Quality Construction

Rugged built construction with high strength extruded aluminum and injection molded polycarbonate enclosure.

-

Easy Feed Filament System

AXIOM 3D printer draws new filament into its print head automatically.

-

Jam Prevention

3D printer’s hotend reaches high temperatures designed to resist clogs.

-

Made In USA

Manufactured in USA with one year parts and labor warranty.

Select a Model

AXIOM 3D printers provide a wide selection of materials to print, from tough and rigid to soft and flexible.

All models now come with the Direct Drive extruder.

Extruder System Prints Difficult Materials

Learn MoreWhy Choose AXIOM 3D Printers?

Prevents Warpage

AXIOM’s fully enclosed print chamber provides womb-like protection in a thermally stable environment. A heated environment prevents warping and cracking while providing optimal print quality. This is highly critical when printing very large 3D prints.

View Bed Adhesives

Bigger Prints

Compared to other 3D printers out on the market, Axiom has the best build-to-size ratio in the world of enclosed printers. With a build volume ranging from 912 in³ (AXIOM Dual), 1000 in³ (AXIOMe/AXIOM), to 3000 in³(AXIOM 20), it is ideal for making large 3D prints for rapid prototyping and manufacturing functional products.

Build to Size Ratio

No Need for Calibration

No more headaches to calibration issues by eliminating calibration altogether. The Auto Leveling system minimizes setup time. Simply start a print and AXIOM will handle the rest. The 3D printer automatically calibrates its print bed ensuring optimal bed leveling and head spacing before beginning every print.

Precision at High Speed

The revolutionary Core-XY motion control provides excellent print resolution at amazing speed commonly found in high-end manufacturing equipment such as CNC machines. The system provides equal push-pull torque on both sides of the print head, eliminating nasty backlash commonly found in other 3D printers.

Long Term Investment

End-User Replacement Cassette (ERC) enables users to easily replace components or to install device upgrades with minimal downtime and extends AXIOM’s service life. With rapid advances in 3D printing technology, ERC protects user investment by ensuring that the latest advances can be incorporated into the machine quickly, easily, and inexpensively.

Applications

Commercial Applications

AXIOM 3D printers print in a wide range of materials from rubber-based TPE and TPU to strong, hard materials like polycarbonate and polypropylene. They are a great investment for companies looking to create functional prototypes at an affordable price. How will Airwolf 3D printers transform the way you design your products?

Learn More

3D Printing in the Classroom

AXIOM 3D printers have the durability, ease-of-use, and safety features that make them ideal for teaching STEM. They provide students in universities, colleges, and technical institutions relevant skill sets to improve their chances at employment. What are the benefits of implementing Airwolf 3D printers into your school?

Learn More

Video Demonstration

Request a Quote

how a bioprinter can save a life / Sudo Null IT News

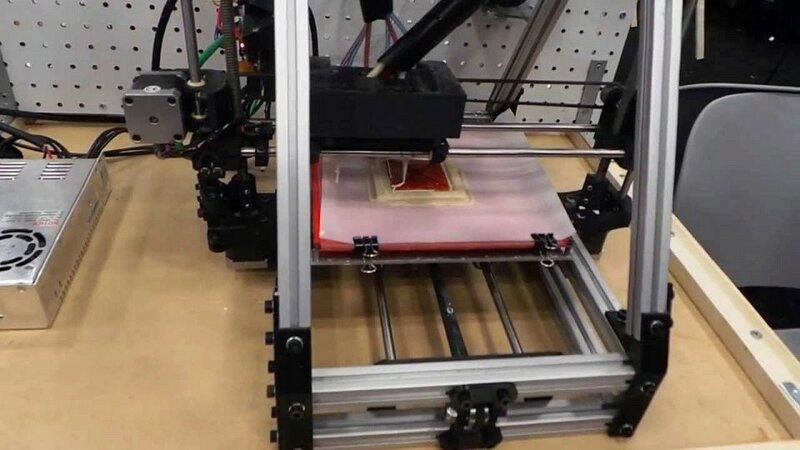

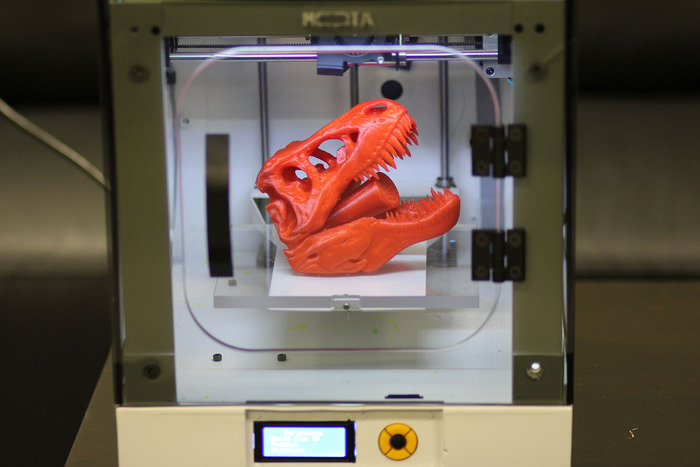

An ordinary printer functions in two-dimensional space, transferring an image to some material. The 3D printer improves this technology in many ways, since the X, Y and Z axes are available to it. Three-dimensional printing is reduced to the layer-by-layer construction of an object specified by the operator using a computer. Already now we are able to make car parts, toys and sculptures. However, a 3D printer can not only facilitate production processes, but also save people's lives.

The 3D printer improves this technology in many ways, since the X, Y and Z axes are available to it. Three-dimensional printing is reduced to the layer-by-layer construction of an object specified by the operator using a computer. Already now we are able to make car parts, toys and sculptures. However, a 3D printer can not only facilitate production processes, but also save people's lives.

The fact is that a living organism is essentially a biomachine. Its success directly depends on how coordinated and high-quality the organs-details will work.

Our bodies have come a long way before becoming what they are today. Each of them has its own structure, anatomical features, and also occupies a certain place in the cascade of physiological reactions.

The human body has evolved with a brutal reserve of strength. We are capable of living in traumatic conditions for a very long time. Contaminated air. Wrong nutrition. Toxins in food. All this slowly but surely upsets our vital activity. What to do when an organ fails? At the beginning of the 20th century, science approached the milestone at which the emergence of transplantology became possible. It would seem that everything is simple: remove the donor organ, implant it in the patient and enjoy the success. What to do when an organ fails? At the beginning of the 20th century, science approached the milestone at which the emergence of transplantology became possible. It would seem that everything is simple: remove the donor organ, implant it in the patient and enjoy the success. |

Only now our cells expose original antigen flags on the surface of membranes. If the immune system sees something not under its "banner", it instantly triggers an inflammatory response. T-killers produce antibody drones that swim towards foreign cells. They begin to perforate cell membranes, killing tissue.

In the case of the bone marrow, aggression is known not from the body towards the organ, but from the graft towards the recipient. A weakened organism is not able to withstand the conflict between its parts. This leads to the most terrible consequences up to the death of a person.

The technical execution of the operation depends on the skill and experience of the surgeon. The problem of organ engraftment is a long-standing scourge of transplantology. Modern technologies, developed in close cooperation with IT, offer a dizzying prospect of solving this difficulty - and saving thousands of lives. The fact is that it is not necessary to look for an organ that is suitable for the antigenic composition of the patient. An organ can be created artificially. This is where bioprinters and 3D printing technology come into play.

The problem of organ engraftment is a long-standing scourge of transplantology. Modern technologies, developed in close cooperation with IT, offer a dizzying prospect of solving this difficulty - and saving thousands of lives. The fact is that it is not necessary to look for an organ that is suitable for the antigenic composition of the patient. An organ can be created artificially. This is where bioprinters and 3D printing technology come into play.

How a 3D printer works

The bioprinter does not differ from its industrial counterpart, except for the fact that it prints with living cells on a collagen matrix. Collagen is a filamentous protein that acts as a scaffold for specialized cells. Doctors take the patient's cells and place them in an incubator where conditions are created for their reproduction. Having accumulated enough material, the operators will be ready for the actual printing.

This process is relevant for simple fabrics like leather. Some cells, for example, blood bodies or cardiomyocytes, are at the final stages of their evolution. Propagating them in a cup is a thankless job. Such intractable comrades are much easier to make from stem cells.

Some cells, for example, blood bodies or cardiomyocytes, are at the final stages of their evolution. Propagating them in a cup is a thankless job. Such intractable comrades are much easier to make from stem cells.

| On the fingers, a cell can be compared to a biological plant that produces certain substances. All cells have the same genes. The nucleus plays the role of a computer, and the DNA chains act as a hard disk on which the program is written. In molecular biology there is a dogma "gene-protein-trait". These same genes can be turned on or off, causing the cell to work in completely different ways. |

Stem cells can be considered progenitor cells from which anything grows. They can be pushed onto the road of specialization, forcing them to become the right fabric. It is she who will be the structural unit of the body.

Soft

Creation of a three-dimensional structure begins with a computer model.

Speaking about the creation of organs, one should mention computer and magnetic resonance imaging. These diagnostic methods create two-dimensional sections of the anatomical structure. The model built on the basis of slices will be the reference for 3D printing.

Speaking about the creation of organs, one should mention computer and magnetic resonance imaging. These diagnostic methods create two-dimensional sections of the anatomical structure. The model built on the basis of slices will be the reference for 3D printing.

| Allevi is a major player in the bioprinting market. In September 2015, the Allevi Bioprint PRO program became available to specialists. Cloud software is available from any computer and has built-in model generation technology with integrated slicing. This allows specialists to focus on biomedical production, rather than time-consuming printer setup. |

At the same time, a new product from Cellink made a major claim to be the most flexible and advanced bioprinting software. The BIO X6 printer, which has no analogues in the world, realizes the possibility of combining a colossal array of materials, cells and other tools for the artificial creation of organs.

What can be created with a bioprinter

The human body is a complex structure that combines a huge array of living tissues. coordinate their work. Satisfy needs. Explain to each body what is required of it. All this imposes a colossal responsibility on the specialist, but saving the patient and ensuring a high quality of life is worth all the hard work.

The organs are permeated with a dense network of capillaries. Each blood vessel functions as a freeway that carries blood, oxygen, nutrients, and nerve cells. Nerve wires distribute commands from the nuclei of the brain. Many cells sort of “know” which direction they should grow, but even so, they will need a scaffold of biological fibers.

Years pass from the moment of discovery of some physiological process to understanding how to influence it. Years of clinical research, collection of statistics and processing of received information. But you still need to find out how safe the invented method of treatment is and what its long-term consequences will be. It also takes time and effort to develop specialized software. High-tech medicine is developing in close integration of mathematics, biology, cell culture and information technology. It also takes time and effort to develop specialized software. High-tech medicine is developing in close integration of mathematics, biology, cell culture and information technology. |

Programmers, doctors, engineers and biologists work day and night to ensure that people who need help can get it. Now the technology of three-dimensional printing is far from perfect, but the success is already impressive. So what can be printed on a 3D printer? Let's start from simple to complex.

Artificial leather

The skin acts as the first barrier that separates the internal environment of the body from the world. The skin can regenerate. It readily responds to stimulation of growth in the laboratory, and its structural elements tolerate the lack of oxygen well.

Skin grafting is of great importance for combustiology, the branch of medicine that deals with the treatment of burns. A burn is not just pain.

A research team at Wake Forest School of Medicine has tested a bioprinter capable of printing skin directly onto a burn. The scanner examines the surface and depth of the wound. The printhead applies the cell culture. To effectively heal a wound, covering one tenth of the area of the defect is enough. Once on the body, skin cells begin to increase in number and heal the wound.

Cartilage

The cartilage is denser than the skin, but calmly tolerates the bioprinting procedure. The ears and eyes form the aesthetic contour of the face. Patients who have survived traffic accidents or other injuries become clients of plastic surgeons. Now there is a wide choice of silicone prostheses, outwardly barely distinguishable from the native nose. The trouble is that the body perceives silicone as a stranger.

In 2015, researchers in Zurich found a way to print a real nose in just 20 minutes. Here's what Matti Kesti has to say about it:

| “The cells of the victim are taken from the knee, broken nose or ear. We make them breed in the lab. After they are mixed with a biopolymer. From this suspension, the bioprinter makes a model of the cartilage of the nose. The surgeon implants it during the operation. Subsequently, the polymer matrix degrades, leaving only native cartilage. An additional advantage is that the implant grows with the patient, which is especially important for children.” |

Blood vessels

Blood flows through the vessel, as if through a pipe. The trophism of organs directly depends on how healthy this vessel is. Vascular accidents claim thousands of lives. The first of them is associated with atherosclerosis, when a fatty plaque clings to the vessel wall.

Of course, atherosclerotic plaques can be removed by vascular surgery. But why not grow a healthy vessel? Monica Moya from the Livermon National Laboratory coped with this task. Vessels made using its technology are able to independently grow into the underlying tissues. Combining the Moya technique with classical bioprinting, it is possible to create much more complex organs than skin or cartilage.

Monica Moya at work.

Bones

Fractures are managed by traumatology. The bone skeleton forms a framework on which other tissues are held. Bone articulations are different, but in the context of bioprinting, injuries of the spine and joints are of particular importance. Despite their hardness, the bones are alive, and therefore tend to become inflamed and die.

Adding fuel to the fire is the need for compliance between cartilage and bone. Without it, the work of the joint will be impossible. A team from Swansea University has developed a technique for manufacturing bioprostheses.

A small bone is printed within 2 hours. So, it can be done in the operating room. The points where the implant will adhere to human tissues are covered with its own stem cells. The cell culture is supported on a gel-like alginate matrix. After implantation, recovery processes are launched in the body, the result of which will be a full-fledged bone.

Bladder

Wake Forest University in the US has made impressive strides in bladder replacements. However, the creation of American scientists is more than a bioprosthesis. This is a complete organ that is fully grown in an incubator. After implantation into the patient's body, the dissolution of the biopolymer begins, and in the end only living tissue remains.

Kidneys

Diseases of the excretory system claim many lives every year. The kidneys continuously filter the blood, clearing it of toxins. If this process is disturbed, the body literally suffocates in its own poisons. Hemodialysis and plasmapheresis technologies partially solve this problem, but the patient remains face to face with the need to regularly visit the dialysis center.

The kidney has a complex internal structure of coils and loops. It would seem that such a thing is impossible to create. Scientists from the Institute of Regenerative Medicine strongly disagree with this.

Anthony Atala, professor of urology, demonstrated a complete kidney from a bioprinter that uses an inkjet printing method. The patient's cells were placed on a matrix. The matrix is created on the basis of two-dimensional sections obtained by magnetic resonance imaging.

Heart

In the cohort of vital organs, the heart stands out especially.

| It is possible to live for some time with failed kidneys. But rhythm and conduction disturbances are fatal, not to mention all kinds of heart attacks. The heart regenerates badly. If some part of it had time to die, this fact is no longer corrected. |

An additional problem is the difficulty in heart transplantation. It is not enough to get a living organ from the body of an already dead donor: it still needs to be preserved before the operation. A heart transplant is also not easy. To do this, it is necessary to maintain the circulation of the patient in the absence of a main pump.

Bioprinting does not solve all problems, but in the future it may solve some of them.

And again, the Wake Forest Institute of Regenerative Medicine was noted here. In 2015, viable cardiomyocytes were obtained there, which fought well in unison. Israel spoke next. In 2019, they managed to produce a fully functional heart there.

The breakthrough is that Israeli scientists have created the world's first working heart, not just a part of it. The bottom line is that the heart is the same muscle, and for work it requires a continuous blood supply. Under natural conditions, this is done by the coronary vessels.

| In the words of Professor Tal Dvir: “this is the first time that someone, somewhere, has designed, designed and printed a whole heart with all the ventricles, chambers and blood vessels.” |

Of course, scientists have dealt with this issue before. Prior to Tal Dvir's breakthrough, the technology to build an aortic valve already existed, but a part of the heart is no match for the complexity of a whole organ.

At the moment, the artificial heart is the size of a large cherry and is more of a technology demonstration. Nevertheless, the achievements of the Tel Aviv team give hope to many patients in cardiac clinics.

Conclusion

Much has been said about the advantages of bioprinting. It may seem that in the 21st century medicine has come close to creating a panacea for all diseases. Of course, this is not true. Bioprinting puts forward huge demands on the engineering and technological part. It can be provided only in countries with a powerful industrial complex. Information technology is developing every hour, and the help of specialists in this industry is needed by doctors more than ever.

In addition, bioprinting has faced legal and ethical issues. The axiom is that any promising technology will be expensive and costly not only in terms of money, but also in terms of the necessary materials.

The good news is that artificial organs are rarely tested on animals. But what about patients who received printed grafts? The effects of treatment show themselves over a long period of time. The pitfalls of the methodology can only be identified through randomized and mass clinical trials. But behind every statistic is someone's life.

| Of course, these issues will be resolved along the way. Medicine is on the threshold of a new era, and in 20, 50 or 100 years it will be very different. Progress cannot be stopped. Soon our lives will be different. Longer, healthier and more productive. It remains only to pay tribute to the people who work for the benefit of humanity and those who need help most urgently. |

Author: Nikita Ignatenko

A UFO flew in and left here a promotional code for our blog readers:

— 15% for all VDS tariffs (except for the Warming up tariff) — HABRFIRSTVDS

Materials:

1. All images are taken from open sources and belong to their authors.

2. Ken Doyle. Bioprinting: From Patches to Parts // Genetic Engineering & Biotechnology News. — 2014-05-14. - T. 34, no. 10. - S. 1, 34-35. — ISSN 1935-472X. - doi:10.1089/gen.34.10.02.

3. Dan Thomas. Engineering Ourselves - The Future Potential Power of 3D-Bioprinting. engineering.com

4. https://ethz.ch/en/news-and-events/eth-news/news/2015/03/nose-made-by-bioprinters.html

5. https://str.llnl.gov/march-2016/moya

6. https://iview.abc.net.au/show/catalyst

7. https://school.wakehealth.edu/research/institutes-and-centers/wake-forest-institute-for-regenerative-medicine

8. https://www.allevi3d.com/

9.

3D printing: more promising than ever - Blog

Back to the list of posts

If a few years ago 3D printing did not disappear from the headlines, now it is discussed less frequently. Does this mean that she did not justify the hopes placed on her? There is an opposite opinion: its time is only coming.

A couple of years ago, it might have seemed that a 3D printer was about to come to every home, and this did not happen - however, Wired notes that 3D printing is now making huge strides, just in areas less visible to the average consumer.

In medicine, the ability to print tissue opens up new horizons for regenerative problems. With this technology, researchers are even trying to catalyze the body's natural regenerative processes. With a high probability, this will lead to a revolution in the market for custom organs, now suffering from long waiting lists.

One of the pioneers of 3D printing, the aerospace industry uses 3D printing to produce individual parts, saving time, materials and costs. It also has an industry-critical benefit: weight reduction. And at the same time, it allows you to drastically shorten the supply chain, easily creating simple parts as needed.