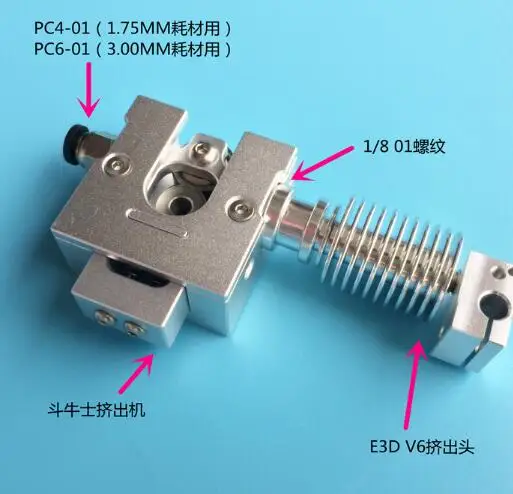

All metal 3d printer extruder

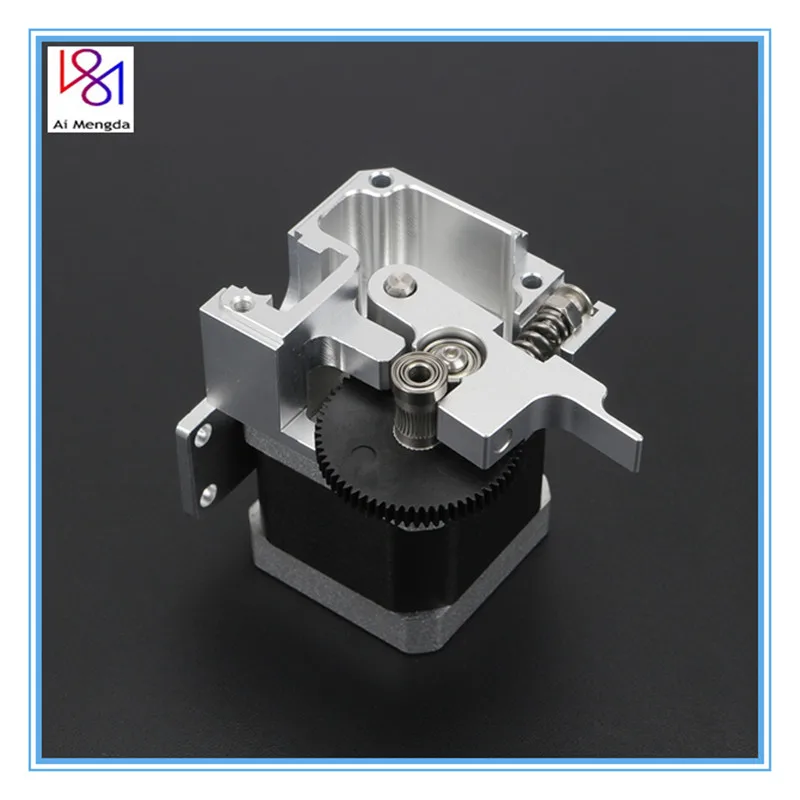

DyzeXtruder Pro - All-Metal Professional Extruder

- Overview

- Tech Specs

- Buy

Extrusion better than ever

DyzeXtruder Pro is a very lightweight all-metal extruder and also one of the smallest on the market. It is not larger than the NEMA 17 it uses, making it very space efficient on a multiple extruder configurations. Besides, the extruder is stronger than ever. With the improved teeth and new bearings types, the DyzeXtruder Pro is able to push as much as 10 kg (22 pounds) of force. This is more than necessary for all 3D printing applications. Finally, the new backblock has cooling fins for increased heat spreading in room environments.

BUY NOW

Only CA$275

Designed for professional printing

Stronger

With the improved teeth and new bearings types, the DyzeXtruder Pro is able to push as much as 10 kg (22 pounds) of force. This is more than necessary for all 3D printing applications.

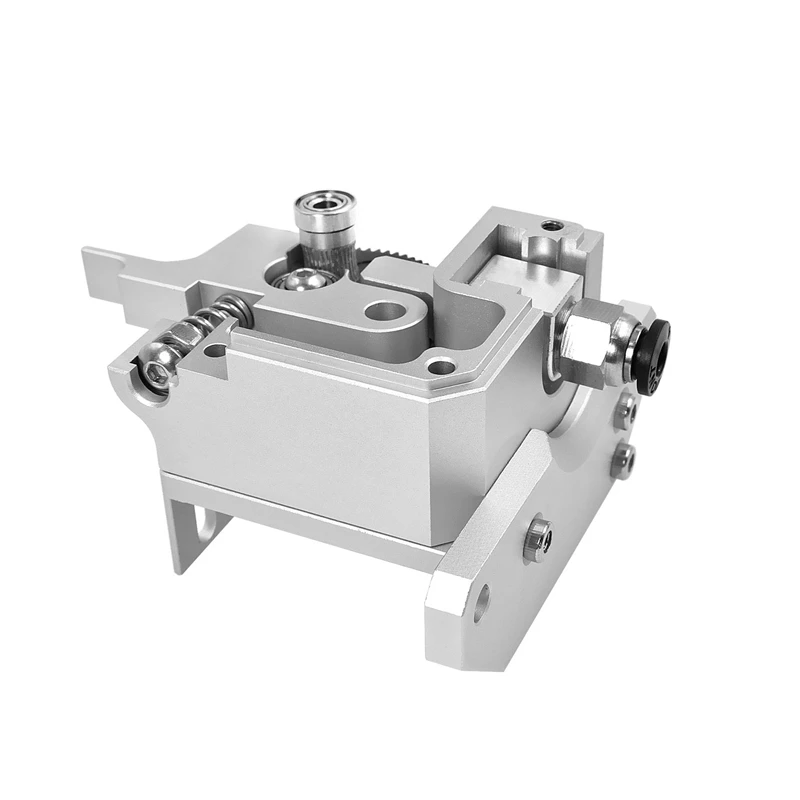

Toolless HotEnd Removal

Take your hotend off your extruder in just a few seconds with the thumb screw. This will loosen the groove mount and free your hotend.

Multiple Mounting Possibilities

The side mounting threads make it very easy to assemble; two M3 screws are included to fit the DyzeXtruder Pro on a printer, bracketless. You can also mount the extruder on a panel.

Cooling Fins

The new backblock has cooling fins for increased heat spreading in room environment. The fins are thick enough to offer the same thermal conductivity performance as the GT block in watercooled environment.

Guided Filament

The guides conduct the filament out of the extruder. They follow the teeth shape, allowing no other exits for the filament. The whole part has a low friction coating, increasing the pushing efficiency.

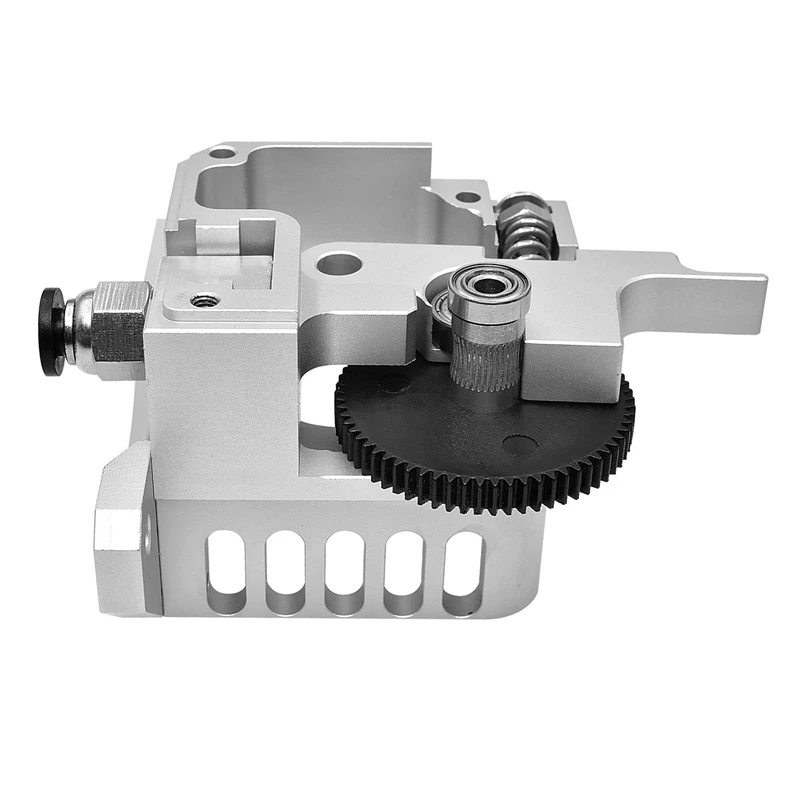

Completely Redesigned Teeth

35% more pushing force with rigid filaments

25% more pushing for with flexible filaments

Keep the filament round, even after 100+ passages

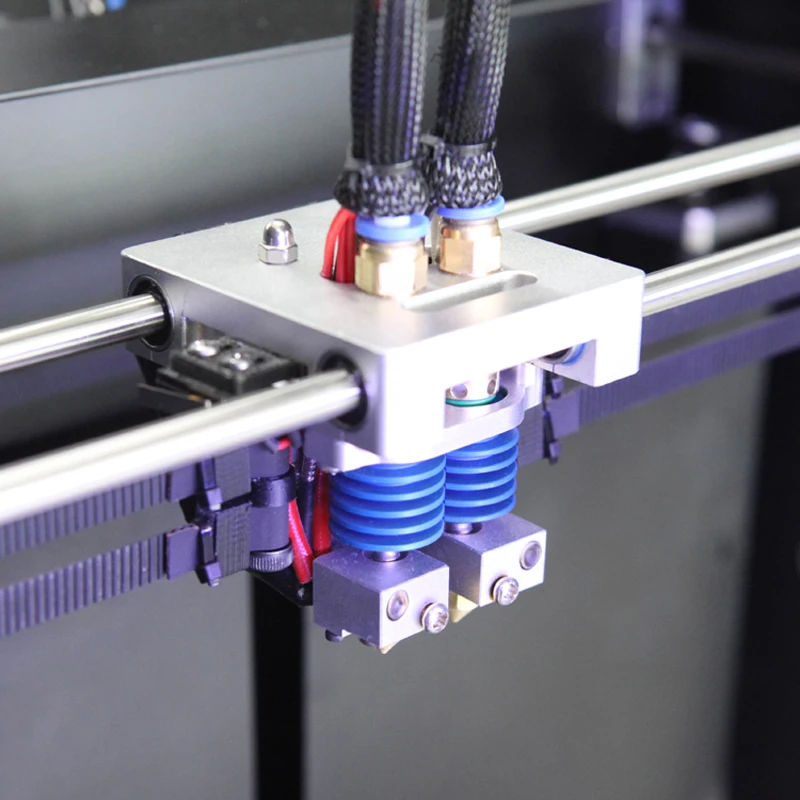

Dual pinch drive system

The dual-pinch system allows a higher pushing force with a lower filament pressure. It reduces the risk of flattening the filament when highly detailed prints require a lot of retractions.

It reduces the risk of flattening the filament when highly detailed prints require a lot of retractions.

All metal

The aluminum housing is designed to offer a reliable operation, even in a high temperature environment when combined with a liquid cooling system.

Lightweight

The gear ratio was chosen to get the best of a very small motor.The DyzeXtruder Pro is a lot lighter than a traditional extruder with a planetary gearbox, allowing for faster printer accelerations.

Small form factor

The DyzeXtruder Pro is not larger than the NEMA 17 it uses, making it very space efficient on a multiple extruders configuration and one of the smallest on the market. Saving space on a carriage can allow you to print larger parts on a single printer.

Connectors

The DyzeXtruder Pro comes with a connector and a cable for its motor so you can easily maintain it.

Metal Reduction Gears

The DyzeXtruder Pro has a 5.65 : 1 gear ratio. This ratio has been chosen to use the full potential of a very small motor while, enabling very high pushing forces. The gears are custom made from high strength hardened steel. This combination allows low friction operations and a longer life. The gears and bearings are designed to last for hundreds of kilograms in extreme conditions.

The gears are custom made from high strength hardened steel. This combination allows low friction operations and a longer life. The gears and bearings are designed to last for hundreds of kilograms in extreme conditions.

Constant pressure

The custom spring has been redesigned to provide the optimal pressure at the filament with the new teeth. You’ll always get the same output flow, reducing the variations involved in changing filaments.

Matched included motor

The included motor is chosen to match the maximum torque tolerated by filaments. The motor won’t grind your filament and will prevent any damage inside the extruder.

Bowden Ready

The DyzeXtruder Pro always comes with a special push to connect fitting. A PTFE tube can be inserted through the connector to guide the filament as far as possible inside the mechanism. A single modification in the firmware can easily transform a direct drive setup into a bowden.

Hotend Positioning

A small pocket under the extruder makes it even easier to locate the hotend.

Print any plastics

The DyzeXtruder Pro is able to print every single type of plastic filaments currently sold on the market

- Standard

- Flexible

- Support

- Advanced

- Engineering

- Other

Standard

- PLA

- ABS

Flexible

- TPE

- TPU

Support

- PVA

- HIPS

Advanced

- PC

- PET

- PETG

- NYLON

Engineering

- PEEK

- PEI

Other

- Metal Powder Filled

- Wood Filled

- Carbon Fiber Filled

Technical Information

| Parameter | Value |

| Weight | 300g |

| Filament diameter | 1.75mm |

| Operating current | 0. 9A 9A |

| Operating temperature | Up to 30°C |

| Operating temperature (liquid cooled) | Up to 120°C |

| Top fitting tube OD | 4.00mm |

| Gear ratio | 5.65 : 1 |

| Groove mount head thickness | 2 – 5mm |

| Mounting screw thread | M3 |

| Mounting screw min thread depth | 5mm |

DyzeXtruder Pro Support

The 7 Best 3D Printer Hot Ends (All-Metal!) – Clever Creations

When it comes to 3D printing, the hot end is one of the most important components. It’s responsible for melting and extruding the filament, so it’s crucial that you have a good one.

In this article, we’ll discuss some of the best 3D printer hot ends on the market. We’ll also give you a few tips on how to choose the right one for your needs. So, without further ado, let’s get started!

| 3D Printer Hot End | Max. Temp Temp | Filament Dia. | Voltage(s) | Price (~) | Best Offer |

|---|---|---|---|---|---|

| E3D V6 | 300 °C | 1.75 mm, 2.85 mm | 12V, 24V | $59 and up | Amazon |

| Micro Swiss All Metal Hotend Kit | 300 °C | 1.75 mm | 24V | $63 | MatterHackers |

| E3D RapidChange Revo | 300 °C | 1.75 mm | 12V, 24V | $88 and up | E3D |

| Slice Engineering Mosquito | 500 °C | 1.75 mm | 12V, 24V | $145 | MatterHackers |

| E3D Supervolcano Upgrade Kit | 300 °C | 1.75 mm, 2.85 mm | 12V, 24V | $96 and up | E3D |

| DyzEnd PRO | 500 °C | 1.75 mm | 12V, 24V | $130 | MatterHackers |

| Phaetus Dragonfly Hot End | 500 °C | 1. 75 mm 75 mm | 12V, 24V | $69 | BIQU |

What is the hot end in a 3D printer?

A hot end is the heating element in a 3D printer. It comprises several parts, including the heating element, nozzle, heat sink, and heat break.

The heating element is responsible for heating the filament to its melting point. The nozzle is a small hole through which the molten filament is extruded. And finally, the heat break limits the amount of heat that transfers to the heat sink.

These elements work together to provide an even flow of melted material and give you a smooth 3D printing experience.

What makes a good hot end?

The best 3D printer hot ends have good heat management, durability, material compatibility, and material flow rate. They minimize heat creep and maintain a stable printing temperature during extended 3D printing times. A stable hot end temperature reduces the chances of the hot end clogging up and prevents print failures.

A hot end with a high flow rate lets you print at faster print speeds and larger layer heights. This reduces print times and creates a strong 3D printed part.

Another aspect you need to consider is the material composition of the hot end. 3D printer hot ends with brass nozzles are not the best for printing with abrasive materials. Instead, you should look for hot ends with stainless steel or hard-coated nozzles. These nozzles are more wear-resistant and can handle abrasive materials better.

Similarly, if you want a hot end for 3D printing high temperature (>300°C) filaments, you are best off with a hot end with a copper-plated heater block, a high-powered heater cartridge, and a thermocouple. These hot ends can handle the higher temperatures required for printing with polycarbonate, PEEK, and other engineering-grade filaments.

The Best All-Metal 3D Printer Hot Ends in 2022

E3D V6

Best overall

Check Price

AmazonE3DMatterHackers

E3D manufactures some of the highest quality hot ends and the E3D V6 is one such example of that. It is simple yet effective and delivers excellent printing performance. It is suitable for both direct and Bowden drive extruders, and you can further customize it for your 3D printer directly through E3D’s website.

It is simple yet effective and delivers excellent printing performance. It is suitable for both direct and Bowden drive extruders, and you can further customize it for your 3D printer directly through E3D’s website.

The E3D V6 is an all-metal hot end capable of reaching temperatures of up to 300 °C in the standard configuration. The cartridge-style heating block facilitates the easy removal of heater cartridges and thermistors for easy installation and maintenance. Its heatbreak is designed to maintain consistent and accurate temperature in longer prints.

As with all E3D products, the V6 has excellent community support, ensuring that you can quickly resolve any issues. Overall, it is a superb hot end that will take care of most of your printing needs and is suitable for hobbyists and professionals alike.

Standout Features

- All-metal heatbreak

- Cartridge style heating block

- Simple design

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1. 75 mm, 2.85 mm 75 mm, 2.85 mm |

| Available voltages | 12V, 24V |

What We Like

- Excellent printing performance

- Available in several configurations

- Excellent community support

Could Be Better

- Big form factor

Find E3D V6 at

AmazonE3DMatterHackers

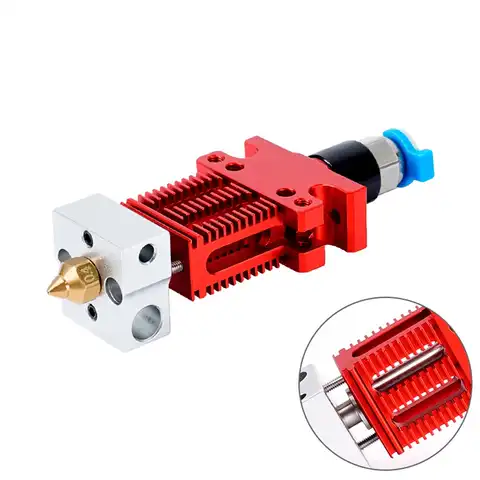

Micro Swiss All Metal Hotend Kit

Best hot end for Ender 3

Check Price

AmazonMatterHackers

The Micro Swiss hot end is an upgraded version of the stock hot end for Creality 3D printers. You can install it directly on the default setup of CR-10 and Ender 3 series 3D printers without any extra mounting systems and brackets.

The Micro Swiss comes with a similar appearance to the stock Ender setup, albeit delivering improved performance. You get a titanium heat break that does an excellent job in thermally separating the hot and cold regions of the hot end resulting in a more defined melt zone.

You will need to recalibrate your retraction settings and ensure proper assembly of this hot end, however. Set it up correctly, and the Micro-swiss hot end is an excellent upgrade for anyone who wants to print high-temperature materials on a budget.

Standout Features

- Aluminum heater block

- Titanium heat break

- Brass plated MK8 nozzle

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1.75 mm |

| Available voltages | 24V |

What We Like

- Easy to use with Creality printers

- Good build quality

- Good customer support

Could Be Better

- Requires tweaking

- Potential retraction and leakage issues

Find Micro Swiss All Metal Hotend Kit at

AmazonMatterHackers

E3D RapidChange Revo

Best high-end

Check Price

E3DMatterHackers

Swapping out a 3D printer nozzle can be a labor-intensive process and result in significant downtimes in your 3D printing process. To speed this process up, the E3D Rapid Change Revo comes with a unique design that lets you quickly change your nozzles without any tools.

To speed this process up, the E3D Rapid Change Revo comes with a unique design that lets you quickly change your nozzles without any tools.

It features a design similar to the E3D V6 hot end but in a more compact and lightweight form factor. The hot end comes with a redesigned heating block that is engineered for safety and maximum heating performance. The Revo is compatible with most high-temperature materials and delivers superb print quality out of the box.

You can get the hot end in three configurations – Revo Micro, Revo Six, and the Revo Hemera. Each version is developed for different use cases. Together, the Revo Rapid change system covers a wide range of 3D printing applications.

A RapidChange Revo hot end is well-suited for professional users who are looking for the best hot ends with easy maintenance.

Standout Features

- Quick-swappable nozzles

- Lightweight design

- Fast heating times

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1. 75 mm 75 mm |

| Available voltages | 12V, 24V |

What We Like

- Compact form factor

- Faster print speeds

- Easy maintenance

Could Be Better

- Limited nozzle options

- Pricy nozzles

- Not compatible with 2.85 mm filament

Find E3D RapidChange Revo at

E3DMatterHackers

Slice Engineering Mosquito

Best for high-temperature filaments

Check Price

AmazonMatterHackers

The Slice Mosquito hot end comes with a unique design that separates it from other hot ends. The heater block is entirely separated from the frame of the hot end with the help of four support rods. It helps to eliminate heat creep and improves thermal performance.

This design allows the hot end to be highly compact and lightweight, resulting in extra vertical height and faster print speeds. Its rigid construction allows for one-handed nozzle changes making maintenance an easy task.

In contrast to the previously mentioned hot ends, the Slice Mosquito is rated to print at high temperatures of up to 500 °C, covering filaments such as PEEK, ULTEM, and PPSU.

At a starting price point of $144.99, it is certainly not for budget 3D printer users. However, the Slice Engineering Mosquito hot end is ideal for professionals who need a high-performance hot end that delivers excellent print quality and broad material compatibility.

Standout Features

- Unique design

- High printing temperatures

- High structural rigidity

Technical Details | |

|---|---|

| Maximum temperature | 500 °C |

| Filament diameter | 1.75 mm |

| Available voltages | 12V, 24V |

What We Like

- Lightweight and compact design

- No heat creep

- Compatible with majority of FDM 3D printers

Could Be Better

- No liquid cooling option

Find Slice Engineering Mosquito at

AmazonMatterHackers

E3D Supervolcano Upgrade Kit

Best for large 3D printers

Check Price

AmazonE3DMatterHackers

The E3D Supervolcano upgrade kit is specifically designed for fast printing of large objects. It delivers up to 11x more volumetric flow rate than regular E3D V6 hot ends. This lets you 3D print at higher speeds with large layer heights and widths.

It delivers up to 11x more volumetric flow rate than regular E3D V6 hot ends. This lets you 3D print at higher speeds with large layer heights and widths.

Wider layers allow for better interlayer adhesion resulting in a stronger 3D printed part. While 3D print strength is something you can also increase by choosing the strongest infill pattern and strongest filament, printing wider layers gives you another option to do so.

The Supervolcano can reach a maximum print temperature of 300 °C, letting you print with materials like PLA, ABS, PETG, and TPU. It is fully compatible with various other E3D hot ends and extruders, so you can easily upgrade your default setup to a Supervolcano.

This is the best 3D printer hot end for a large format 3D printer to carry out high-volume printing. If your printing workflow consists of large-scale and high-volume 3D printed parts, the Supervolcano kit is crucial in reducing your 3D printing times.

Standout Features

- 11x volumetric flow rate (compared to V6)

- Copper plated heat break

- Readily compatible with E3D hot ends

Technical Details | |

|---|---|

| Maximum temperature | 300 °C |

| Filament diameter | 1. 75 mm, 2.85 mm 75 mm, 2.85 mm |

| Available voltages | 12V, 24V |

What We Like

- High filament melting rate

- Suitable for large objects

- Option for second thermistor

Could Be Better

- Reduces print height

- Increased chances of thermal runaway and safety issues

Find E3D Supervolcano Upgrade Kit at

AmazonE3DMatterHackers

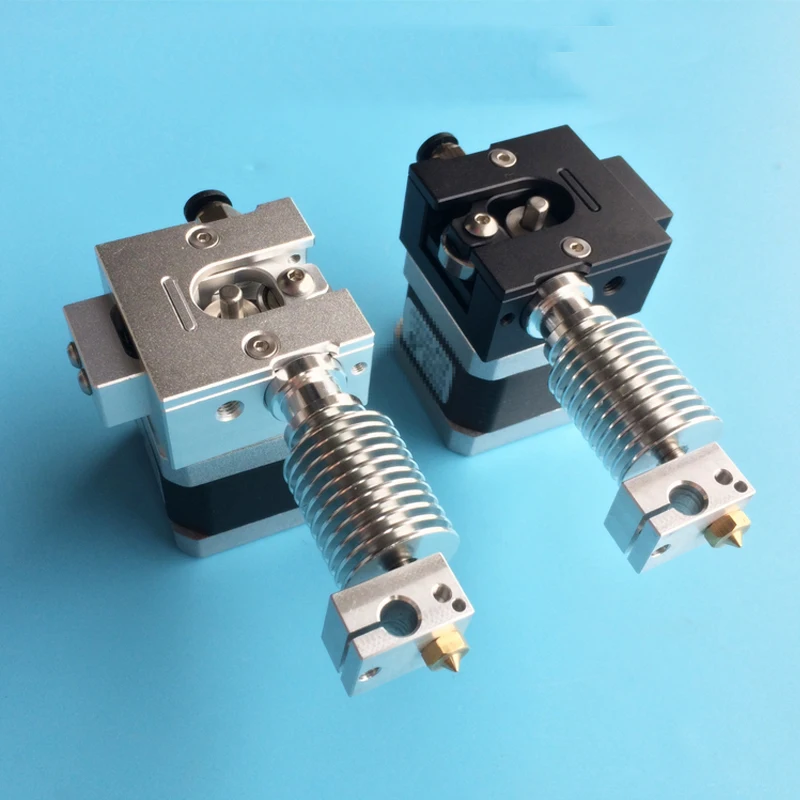

DyzEnd PRO

Most durable nozzle

Check Price

MatterHackers

The DyzEnd Pro hot end is a high-performance hot end developed for a professional workflow. It comes in a lightweight and compact design that takes up less space.

This hot end comes with a tungsten carbide nozzle with excellent wear resistance. This means you can use the DyzEnd PRO for 3D printing abrasive materials, like carbon fiber or glow-in-the-dark filament, without fear of it wearing out.

Its all-metal heat zone and steel heater block ensure that you can print materials up to 500°C with ease. You can also quickly cold swap the nozzle on the DyzEnd Pro for less downtime and easy repairability.

You can also quickly cold swap the nozzle on the DyzEnd Pro for less downtime and easy repairability.

It is a superb hot end meant for serious professionals who regularly print with high-temperature materials. If you’re looking for a lightweight, robust and good quality hot end for your 3D printing workflow, the DyzEnd Pro is one of the best hot ends available.

Standout Features

- Cold swappable nozzle design

- High maximum temperature

- Liquid cooling ready

Technical Details | |

|---|---|

| Maximum temperature | 500 °C |

| Filament diameter | 1.75 mm |

| Available voltages | 12V, 24V |

What We Like

- Fast printing speeds

- Increased durability with abrasive filaments

- Compatible with different temperature sensors

Could Be Better

- Limited nozzle sizes

- Requires considerable fine-tuning

Find DyzEnd PRO at

MatterHackers

Phaetus Dragonfly Hot End

Check Price

AmazonBIQU

The Phaetus Dragonfly hot end is an all-metal hot end designed for hobbyists and professionals. It uses copper alloy material for its heat sink for better heat dissipation. The Dragonfly also lets you print at up to 500 °C, making it one of the cheaper 3D printer hotends that can reach these high temperatures.

It uses copper alloy material for its heat sink for better heat dissipation. The Dragonfly also lets you print at up to 500 °C, making it one of the cheaper 3D printer hotends that can reach these high temperatures.

This hotend has a smooth inner surface that aids in getting an uninterrupted filament flow. Its conical heat break designs allow fast heat dissipation, maintaining good thermal separation and a stable melt zone.

Compared to the other hot ends that can reach 500 °C on this list, the Dragonfly is reported to come with more quality control issues. This is something that can be expected given its low price but it is still something we think you should be aware of.

The Dragonfly Hot end comes in two variations suitable for Creality and Prusa 3D printers. It is ideal for individuals who need a high-temperature hot end that’s easy to use and comes at a budget price.

Standout Features

- All-metal design

- Conical heat break

- Copper alloy construction

Technical Details | |

|---|---|

| Maximum temperature | 500 °C |

| Filament diameter | 1. 75 mm 75 mm |

| Available voltages | 12V, 24V |

What We Like

- Excellent heat dissipation

- High printing temperature

- Relatively low price

Could Be Better

- Quality control issues

- Inconsistent printing performance

Find Phaetus Dragonfly Hot End at

AmazonBIQU

Buyer’s Guide – How to Choose a 3D Printer Hot End

3D Printer CompatibilityHot ends are not a generic component and are often designed for a specific set of 3D printers. Checking the hot end’s compatibility with your 3D printer is essential for getting the best results. It will ensure that you get the right hot end that supports your 3D printer’s hardware and electronics.

One of the things to look for is the heater cartridge voltage on the hot end. It has to match the printer’s voltage to ensure proper heating of the hot end.

You also need a mounting system for the hotend. Any additional mounting plates and hardware will translate to an increase in the cost, even though you can 3D print these yourself sometimes.

Any additional mounting plates and hardware will translate to an increase in the cost, even though you can 3D print these yourself sometimes.

Material Compatibility

A hot end with wide material compatibility is always a good thing to have. This allows you to experiment with different materials and find the ones that work best for your needs.

The most important thing to look for is the maximum temperature that the hot end can reach. This number will give you a good idea of the range of materials that the hot end can work with.

Typical all-metal hot ends can reach up to 300 °C and can easily print most thermoplastics. This range covers PLA, ABS, PETG, Nylon, and flexible filaments like TPU and TPE.

If you need to print high-performance plastics such as PEEK, ULTEM, Polycarbonate, and PEI, you will need a hot end that has a maximum printing temperature of 500 °C.

High-performance hot ends will be more expensive than the basic ones and might not yield good results when printing at lower temperatures. If you primarily print with materials that melt below the 300 °C points, basic all-metal hot ends like the E3D V6 and the Microswiss should be enough for you.

If you primarily print with materials that melt below the 300 °C points, basic all-metal hot ends like the E3D V6 and the Microswiss should be enough for you.

Nozzle Compatibility

A nozzle is an important component of the hot end assembly. Nozzles are designed with their hot end’s specifications in mind. The nozzle you use defines the printing capability and material compatibility of your hot end.

A larger nozzle size will let you print fast and with large layers, while a fine nozzle is suitable for printing detailed parts. Both can be properties to look for when looking to make money with your 3D printer.

Similarly, a nozzle’s material will also affect the print quality. Nozzles made from stainless steel can handle higher temperatures and are more wear-resistant. As a result, they can last longer, but they might not be the best choice for printing with PLA.

On the other hand, brass nozzles are a good all-around choice and can be used with most materials. If you are unsure about the material of the nozzle, always check with the hot end’s manufacturer.

If you are unsure about the material of the nozzle, always check with the hot end’s manufacturer.

Due to the hot end’s design, nozzles aren’t interchangeable between 3D printer hot ends from different brands. For example, the DyzEnd nozzle is specific to the DyzEnd Pro hot end. Similarly, the E3D Supervolcano exclusively supports E3D nozzles of sizes 0.6 mm – 1.2 mm.

If you 3D print with parts of varying layer heights and with different materials, you need to ensure that you get a hot end that’s compatible with various nozzle sizes and materials.

Build Quality

A hot end is the critical component of the 3D printer and is responsible for extruding the filament smoothly. A poorly manufactured hot end will lead to many issues down the line.

Nozzle clogs, hot end jamming, filament leakage, and improper filament flow all indicate poor hot end build quality. These issues can be frustrating and time-consuming to deal with. Checking the user reviews before you purchase the hot end will give you a better idea about its build quality.

Cheaper hot ends tend to have poor overall quality and while they might work well in the beginning, they can experience many issues after prolonged use.On the other hand, a well-manufactured hot end will have a high upfront cost and give you consistent printing performance and a high-quality experience.

Should You Buy an All-Metal Hotend or Not?

All-metal hot ends are helpful for printing materials like ABS, PETG, and Nylon. Where PTFE-lined hotends are only suitable for printing up to around 250°C, an all-metal hot end typically reaches temperatures of either 300°C or 500°C

These temperatures are more than enough for printing a wider variety of materials. The all-metal design also eliminates the need to replace the PTFE liner in the hotend over time, as the PTFE tube is no longer exposed to extreme temperatures.

However, the all-metal design can create more filament jamming issues when not configured correctly. A shorter retraction distance helps to minimize stringing and consequently prevent filament jams, however.

If you plan on printing with a lot of different materials or if you want to experiment with higher temperatures, an all-metal hot end is a good investment. Otherwise, a PTFE-lined hot end will suffice for most applications.

That said, you can’t ever go wrong with an all-metal hotend upgrade. If you simply want the best 3D printer hot end for your machine, all-metal is the way to go.

FAQ

When should I replace my 3D printer hot end?

There’s no need to replace your 3D printer hot end unless you’re looking for an upgrade to get better performance. You might have to periodically replace certain components, like the nozzle, when they wear out, however.

If you are experiencing issues with your prints, then it may be time to check your hot end for any damage or debris that may be causing problems.

Is an all-metal hot end good for PLA?

Yes. While all-metal hotends are ideal for higher-temperature filaments, they can also be used with lower-temperature filaments like PLA. Some users find that they get better results using an all-metal hotend with PLA than they do with a standard hotend with PTFE lining.

Some users find that they get better results using an all-metal hotend with PLA than they do with a standard hotend with PTFE lining.

What type of hotend does the Ender 3 use?

The Ender 3 uses a PTFE-lined hot end, which allows for smoother filament flow and reduced clogging. PTFE is a low-friction material that is resistant to wear and tear, making it an ideal choice for a hot end.

If you want to upgrade your Ender 3 hot end, the Microswiss is one of the best hot ends to swap the stock one out with.

Which hot end is best?

In our opinion, the E3D V6 hotend is currently the overall best hot end on the market. It is made of high-quality materials and has a modular design that makes it easy to assemble and maintain. It also has a wide range of compatibility with different types of printers, making it a popular choice for both beginners and experienced users.

Conclusion

Choosing the right hot end for your 3D printer will extend your printing potential. The best 3D printer hot end minimizes heat creep while maintaining a stable printing temperature. However, you need to check that the hot end you select fits your 3D printing needs and is compatible with your 3D printer.

The best 3D printer hot end minimizes heat creep while maintaining a stable printing temperature. However, you need to check that the hot end you select fits your 3D printing needs and is compatible with your 3D printer.

The E3D V6 hot end ranks on the top as the best 3D printer hot end. It is one of the most reliable hotends that has been well-tested over the years and is suitable with a good of materials. It has an all-metal design, broad 3D printer compatibility, and excellent build quality at a reasonable price.

Its only drawback is its limited range of printing materials. With a maximum temperature of 300°C, it won’t handle true engineering materials like PEEK.

This is where the Slice Engineering Mosquito and the DyzEnd Pro hot end step in. These are rated to print up to 500 °C and come with unique designs with elegant features.

So, what is the best 3D printer hot end for you? It depends on your specific needs. Consider the type of materials you want to print with, your budget, and your 3D printer compatibility when making your decision.

Let us know your experience if you’ve used any of these hot ends. We’d love to hear if you have anything else to add in the comments below.

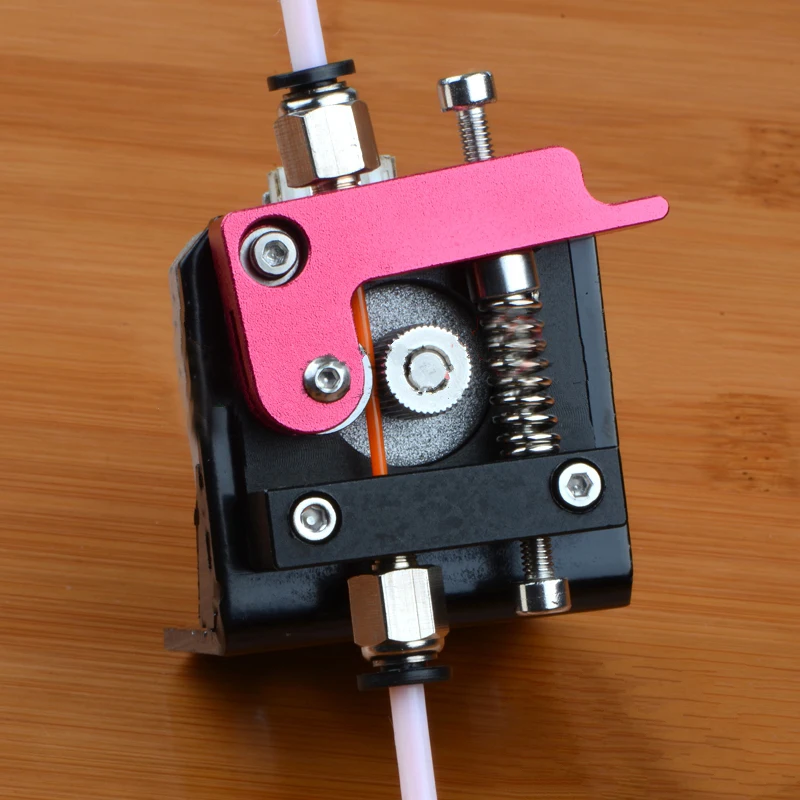

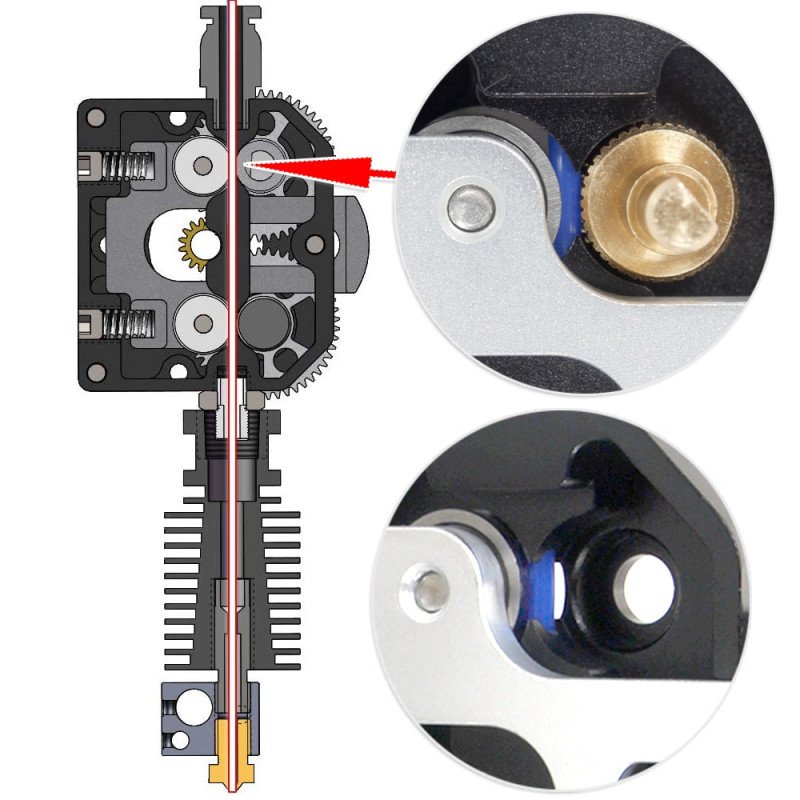

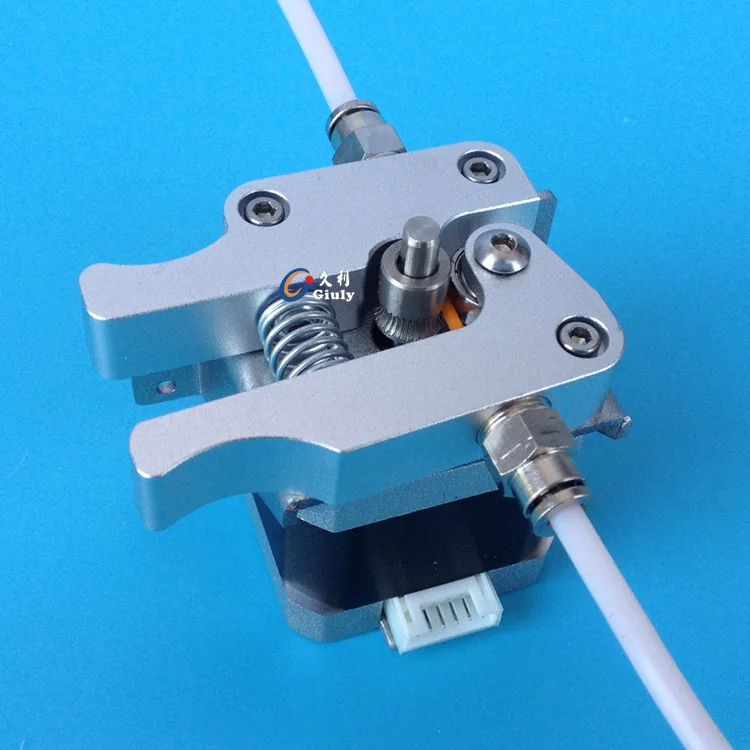

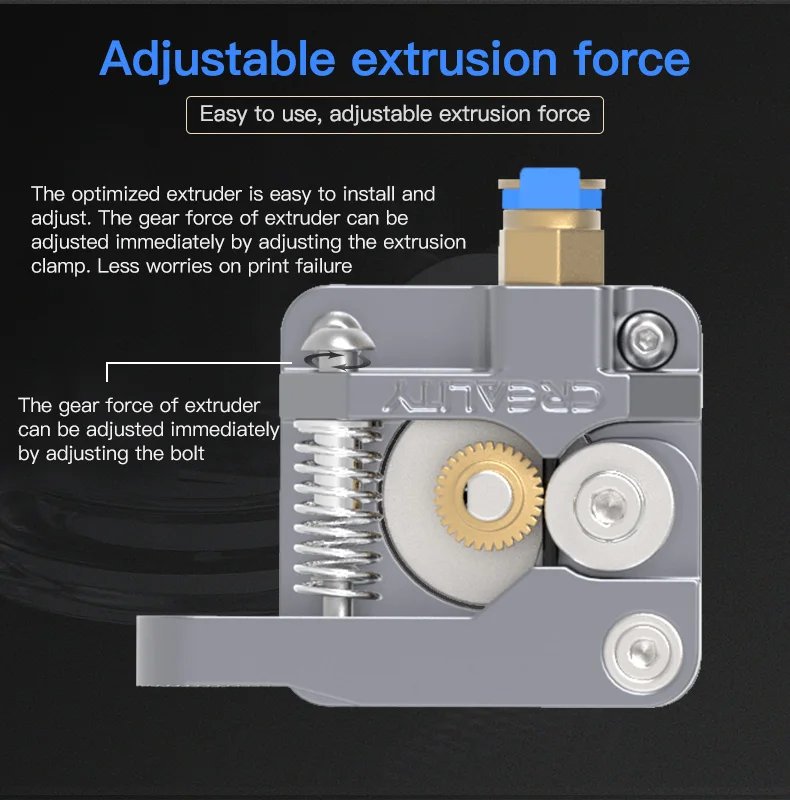

I bought myself an all-metal extruder

Personal diaries

One quiet spring evening, when the green amphibian built into me by my parents fell asleep, and I still didn’t sleep, having seized the moment, I ordered an extruder for myself. E3D titanium was in direct, but I wanted aero. Aero already bought but the radiator did not fit and the toad was indignant zhudko. In short, I ordered an all-aluminum extruder. Whatever one may say, cooling at the same time and the motor will not hurt either, the heat transfer of the screws, although not very large, is there. nine0003

So it arrived, quite quickly (11 days free shipping) packed in a plastic box. Collected.

The motor was left from another extruder, as well as a silicone cover for the stove, so I ordered it without the motor that I had, but with a 24 volt heater and a temperature sensor.

The Chinese boasted strongly about the nozzle in the description, like it is correct and everything is so even and it is clearly done according to the drawing, ok I think, we will check. The packaging of the nozzle when I saw it inspired some optimism

I think I’ll take a look under strong magnification, and suddenly, as usual, a square triangular oval with notches

but no, the nozzle turned out to be at the level, I didn’t take a photo from the reverse side, it’s difficult, but everything turned out to be good there too

The extruder itself at first glance, it caused some concerns, the fact is that the filament drive axle is mounted only on one side, and not, as usual, on two bearings at the beginning and end of the axis.

Mounting design, in principle, is not the worst, 2 bearings, a partition between them, while it works well. Although the console, but the bearings work as thrust in different directions, there is YET no backlash. I will look further, but with proper lubrication and without fanaticism, I should walk with a clamp. nine0003

Although the console, but the bearings work as thrust in different directions, there is YET no backlash. I will look further, but with proper lubrication and without fanaticism, I should walk with a clamp. nine0003

Motor gear metal, smooth.

Fastening on the carriage, here was the first ambush, I did not find anything ready. The first idea was a steel L-shaped plate, so my MK8 was attached. Half a day of picking and I realized that it was nonsense. In the end, common sense won over laziness and I sat down to draw. Modeling skills are initial, at that time I didn’t chalk the full concept, and therefore I went by trial and error. There were two printers, one worked - I printed at the pace of a waltz, I measured it, redid it and printed it again. A few bad decisions and, in principle, I did what I wanted, I already printed from abs and firmly and not from kopets, as I did intermediate empty ones inside. I put plastic on it - a probe, it was enough and left. nine0003

I miscalculated by 1 mm with the fastening of the blatch, for a start I solved the issue with gaskets. Then I reprinted.

Then I reprinted.

airflow, initially the idea was to make a circular airflow, with an additional mount on the extruder foot, and therefore it was composite for ease of modeling, then after trying how it works with it left it straight, simplifying it to the maximum

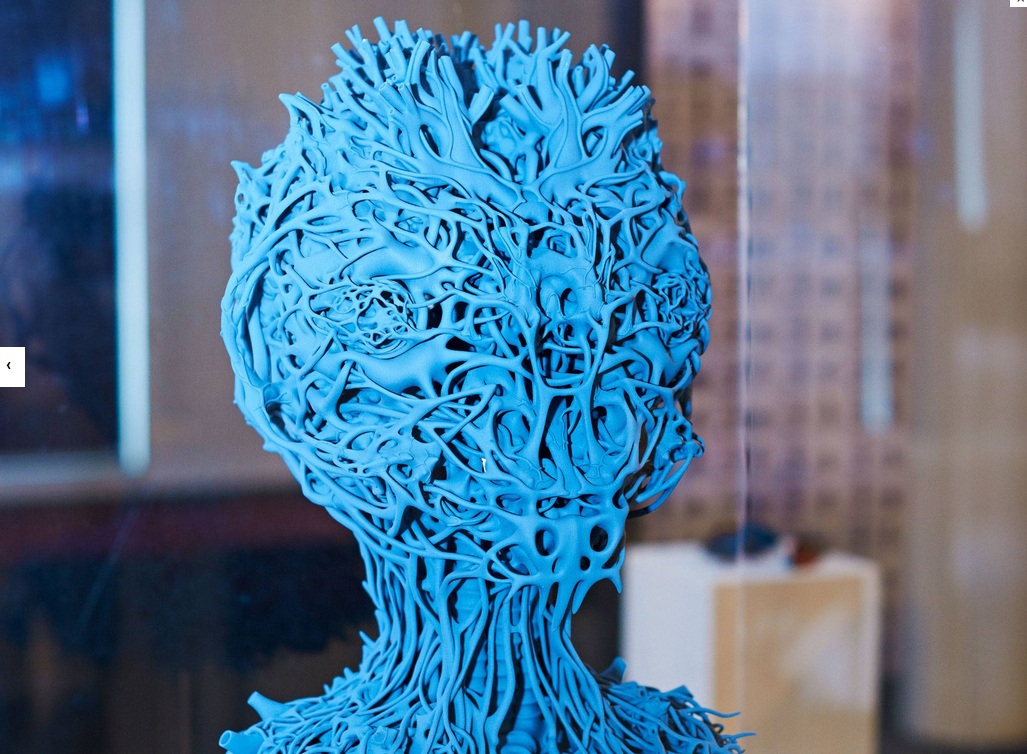

The overall impressions of the work are extremely positive. There are no words for the nozzle, if the nozzle is overheated, it flows smoothly and does not twist the spiral, as on most nozzles, the print quality has also increased significantly. nine0003

Weight, 390 grams assembled, not much different from a fully assembled titanium with a conventional heatsink. The filament drive is composite as elsewhere, there is a small ellipse, within 1-2 dozen, that is, it is not critical at all, the move is smooth without jamming.

Included is a temperature sensor, oddly accurate, and not a glass capsule, but a steel capsule, the clamping screw is very pleasant. The stove is 24 volts, it goes 240 degrees for everything while the bltouch passes through 9 points of the table . ..

..

I printed flex abs and digs with plastics, all without problems. If anyone needs it, then I can lay out the mounts for the extruder and blatch + airflow. Although the design is simple and it is not difficult to repeat from the picture. In addition, on some carriages, I think there will be enough regular paws. nine0003

Subscribe to the author

Subscribe

Don't want

2

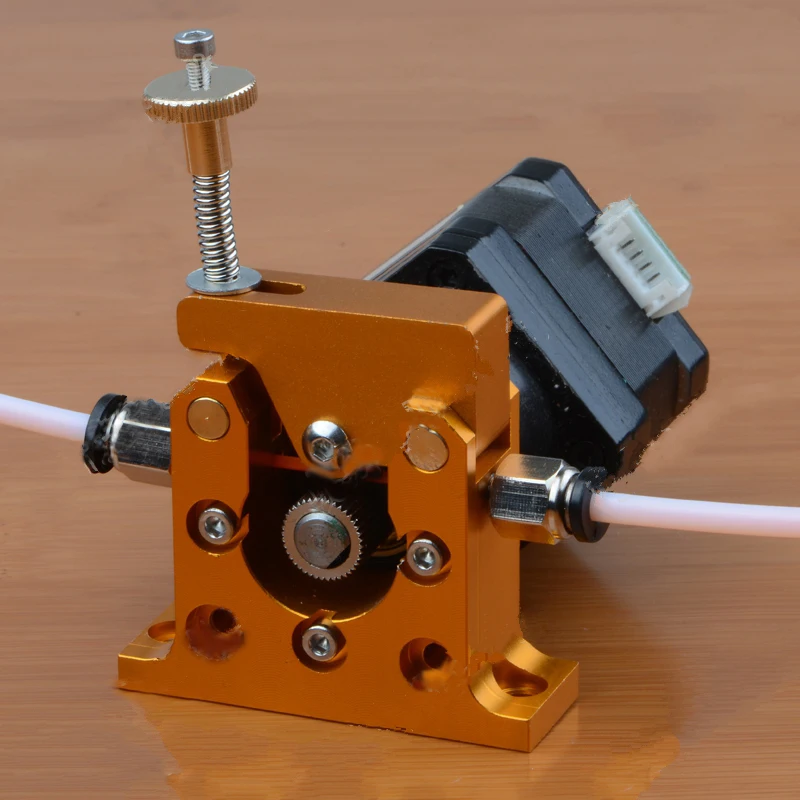

Direct extruder for 3d printer: an overview of the best types and types, which one is better to choose

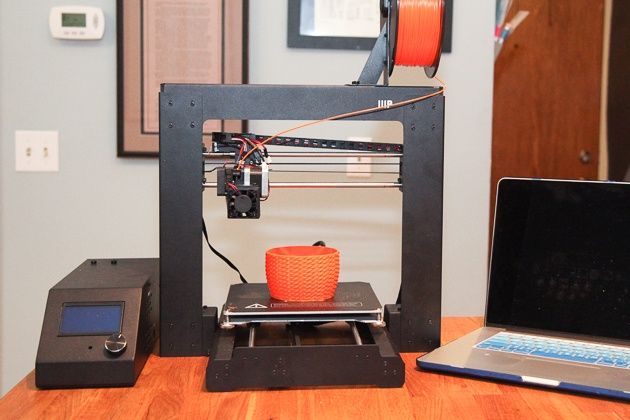

The extruder is called the working head of a 3D printer. The plastic thread passes through it, melts and is squeezed out through the nozzle onto the work table. This is how objects are built layer by layer.

Types of extruders for 3D printer

There are two types of extruders: direct and bowden. They are slightly different in design and have their pros and cons. nine0003

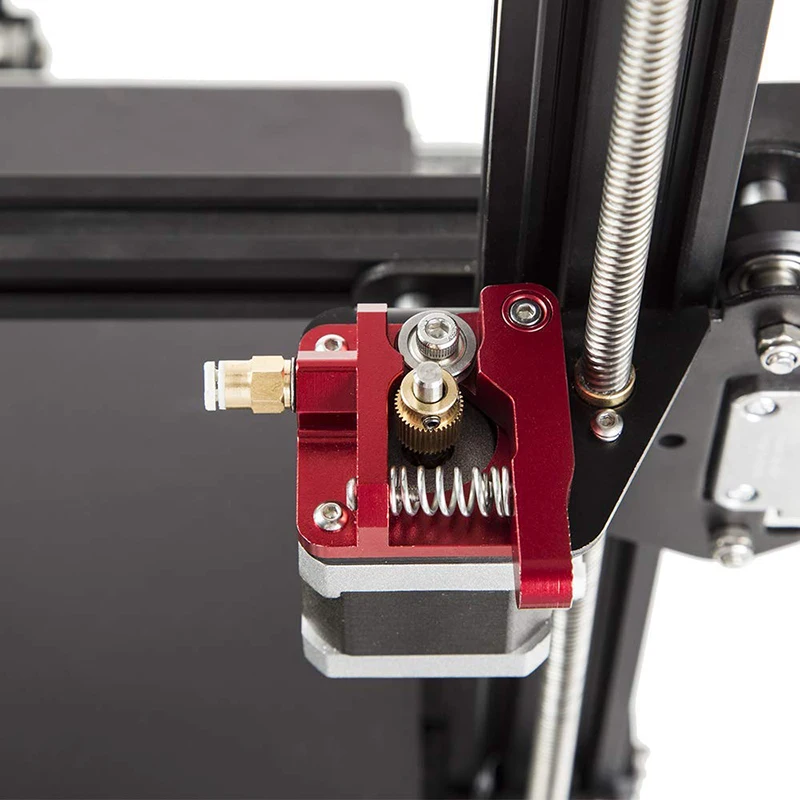

Direct extruder

Direct extruders are located directly above the hot end. Due to this, the distance from the gear train is minimal, which ensures more reliable work with flexible threads.

Due to this, the distance from the gear train is minimal, which ensures more reliable work with flexible threads.

If a direct head is installed on the printer, this does not mean that it will print well with flexible filaments. In order for the print to be of high quality, it is necessary to monitor the position of the clamp, as well as pay attention to the gear device. nine0003

Direct extruders have more precise retraction control compared to Bowden. Positioning above the hot end significantly reduces the distance between the thread and the clip. Therefore, the thread has less room for bending.

The direct printhead is bulkier. Because of this, inertia increases. Good print quality requires a solid rail design. Also, large head sizes affect print speed.

Main advantages of direct extruders:

- Media can be replaced quickly and easily;

- minimum feed distance reduces error;

- flexible plastics can be used at relatively high speeds.

Disadvantages:

- increased weight compared to bowden;

- head design is more complex.

Bowden Extruder

When using a Bowden Extruder, the gear train and the motor are assembled on the machine frame. The weight of such a print head is less than with a direct extruder. nine0003

The main disadvantage of bowden is that during the movement of the thread through the Teflon tube that connects the hot end and the feed mechanism, it can deviate. The amount of deflection depends on the length of the tube. This disadvantage is especially pronounced during the use of flexible plastics. The print settings and the amount of retraction must be selected empirically.

The problem of friction must also be solved. The thread must be pushed through the tube. It is important that the torque is sufficient to carry out this process. nine0003

REFERENCE. Most home delta 3D printers come with bowden extruders.

Advantages:

- reduced weight of the carriage due to the fact that the engine is located on the frame;

- The print head is small.

Disadvantages:

- Printing with flexible plastic is difficult;

- needs a powerful motor to feed material;

- Printer error increases in proportion to tube length. nine0080

What is the best filament extruder to buy?

Now the cost of 1 kg of the cheapest thread is about $20. And the price of plastic from trusted manufacturers can reach up to 50% per 1 kg. Therefore, the issue of self-manufacturing of the filament is very relevant.

Filament extruders:

- Lyman extruder. This device was invented by Hugh Liman. It can make filament with a diameter of 1.75 and 3 mm with an error of 0.01 mm and saves about 80% on the purchase of filament. nine0080

- Fischer extruder or STRUdittle.

This is a compact device that allows you to make thread from ABS plastic. The speed of work is 30-60 cm per minute. The error does not exceed 0.05 mm if the filament is freely output. If you use a spool that automatically winds the thread, then the error is reduced to 0.03 mm.

This is a compact device that allows you to make thread from ABS plastic. The speed of work is 30-60 cm per minute. The error does not exceed 0.05 mm if the filament is freely output. If you use a spool that automatically winds the thread, then the error is reduced to 0.03 mm. - Filabot Original. The most famous development, which has good performance. Can work with ABS, HIPS and PLA. The starting material can be granulated plastic or plastic waste. If waste is used, the particle size should not exceed 5 mm. nine0080

- FilaMaker. The device combines the functions of a crusher and an extruder. It has a neat design, high functionality and good performance. Can produce up to 1 m of filament per minute with an accuracy of 0.05 mm. The only drawback is the high price - $1200.

- Filastruder. Relatively cheap extruder, with which you can get 1 kg of thread in 12 hours. The speed of work is from 15 to 60 cm per minute. Speed depends on operating temperature, nozzle diameter and material used.

The device is designed for ABS, but it can also be used for PLA, HIPS and nylon. nine0080

The device is designed for ABS, but it can also be used for PLA, HIPS and nylon. nine0080

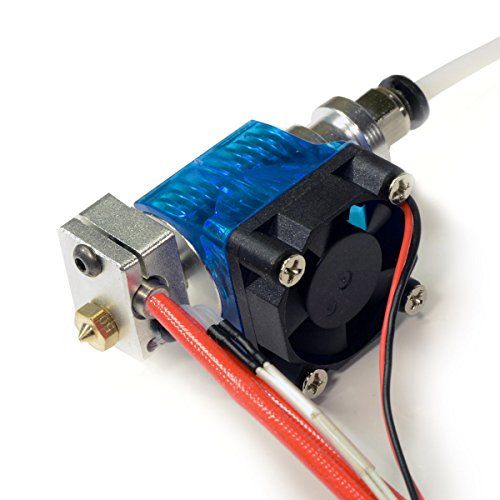

Overview of 3D printer extruders

Below are the most popular 3D printer extruders with detailed specifications.

MK8

This is the most popular direct extruder. It is easy to install and easy to use, suitable for most 3D printers. Costs approximately $15.

Device specifications:

- Thread diameter 1.75 mm;

- nozzle diameter can be from 0.2 to 0.5 mm; nine0080

- heater for 12 V and 40 W;

- operating speed - 4 cm per second;

- device weight - 450 g;

- operating temperature - from 190 to 250 degrees.

E3D TITAN AERO

Main features of E3D TITAN AERO:

- direct drive;

- all-metal thermal barrier;

- maximum temperature - 285 degrees;

- gear ratio - 3 to 1;

- is suitable for flexible plastics.

The device is easy to install and easy to use. The original costs about $170, but you can buy a Chinese equivalent for about $40.

Includes:

- standard or mirror housing;

- heat sink;

- mounting connectors;

- fan;

- heating block;

- nozzle;

- Teflon tube;

- thermal grease;

- idle lever; nine0080

- thermistor cable and cartridge.

About the dual extruder on the Ender 3 pro

The dual extruder allows you to print with two filaments at once. Thanks to this, you do not need to think about stopping work to replace the material.

Now such devices are used to print the model and supports in different materials. Supports are usually made from cheaper plastic, as they will be removed after the print is finished.