Aircraft 3d printing

3D Printing for Aircrafts | EOS GmbH

As air traffic is steadily growing, the total volume is expected to roughly double over the next fifteen years. Even today, the industry is already under heavy load, as building and maintaining freight and passenger aircraft is a growing challenge. The CO2 emissions from operating flights also need to be reduced. And additive manufacturing paves the way for solutions.

In the aircraft construction sector, 3D printing makes faster production processes possible. Manufacturing can be performed precisely when needed. Another advantage: demand-driven additive manufacturing does not generate any of the excess or surplus that often occurs with series production. The process also allows lighter parts to be manufactured, which noticeably reduces the fuel consumption of the machines – the lower the weight, the less fuel is burned.

Additive manufacturing is perfectly suited to efficiently manufacture high-tech parts in the aviation sector that satisfy standard safety requirements.

63_lightweight_construction_solitaire_stroke_EOSGrey

By saving materials through design and engineering, you can successfully produce lightweight structures with 40-60 % less weight.

62_functional_integrationFunctionally optimized system components can be implemented in a single piece, which simplifies assembly and quality assurance processes.

28_calibrationAdditive manufacturing by EOS guarantees maximum flexibility in production planning. Modified components, upgrades and spare parts can be produced on demand, meaning that storage is not necessary.

Constructing engines and turbines means mastering challenges such as optimizing volume, performance and environmental friendliness. In these areas, 3D printing can make a significant contribution. It allows engines with sophisticated geometries, defined aerodynamic and fluid dynamic properties to be produced, as well as lightweight structures whose individual parts weigh up to 60 % less. Processing superalloys is also more cost-effective with 3D printing, since the material usage rate is lower. The results: significantly reduced environmental pollution over the lifetime of the aircraft. Parts made from a single piece are also more resilient and less susceptible to damage.

Processing superalloys is also more cost-effective with 3D printing, since the material usage rate is lower. The results: significantly reduced environmental pollution over the lifetime of the aircraft. Parts made from a single piece are also more resilient and less susceptible to damage.

The EOS technology is characterized by its great design freedom and the significantly shortened development, production and delivery times. In addition, development and production costs are drastically reduced. Components of lighter weight and greater complexity can be made a reality and production requires less material and minimal tools.

Dr. Karl-Heinz Dusel

|

MTU

The 3D printed valve block has proven that additive manufacturing with EOS technology is feasible for building critical primary flight components.

Alexander Altmann

|

Liebherr-Aerospace Lindenberg

Considering ecology and design taken together, optimized structures can also result in reduced CO2 emissions due to weight reduction. I see tremendous potential in DMLS technology for future aircraft generations, when it comes to both development and manufacturing.

I see tremendous potential in DMLS technology for future aircraft generations, when it comes to both development and manufacturing.

Jon Meyer

|

EADS

Our team has many years of experience in fluid-dynamic development as well as in the industry. We are driven by an entrepreneurial spirit that results in the continuous improvement and expansion of our product range, with innovative production methods playing a key role. We are absolutely convinced by EOS technology. It is revolutionary.

Katharina Kreitz

|

Vectoflow

Airbus is a global leader in the aerospace industry and related services. 3D printing technology by EOS helps Airbus to build a more cost- and resource-efficient aircraft. Additively manufacturing a locking shaft for aircraft doors achieved remarkable results:

Additively manufacturing a locking shaft for aircraft doors achieved remarkable results:

- 45 % weight reduction of the additively manufactured part, while keeping the same robustness

- 25 % savings in production costs by reducing material usage and assembly times

- Number of parts reduced from 10 to 1

- Weight reduction of more than 4 kg across 16 door shafts installed in an A350 aircraft

The component was made from titanium on the EOS system EOS M 400-4.

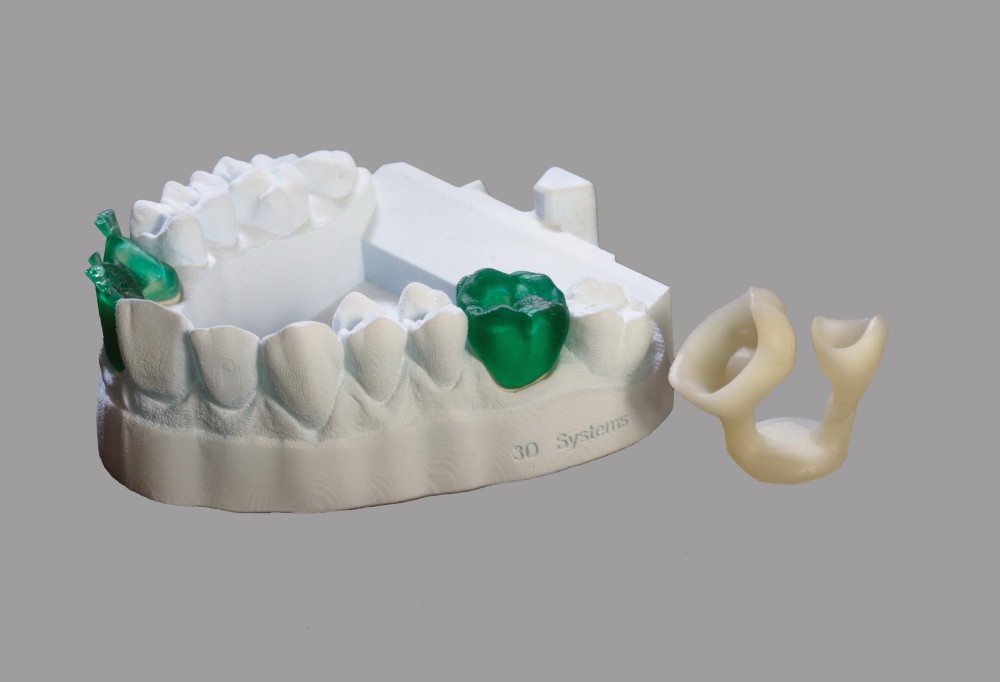

MTU Aero Engines, Germany’s leading engine manufacturer, has optimized its EOS machines to manufacture safe and cost-efficient parts in series. Using additive manufacturing, MTU builds borescope bosses for the geared turbofans of the new generation of PurePower® PW1100G-JM engines by Airbus A320neo. The low-pressure turbine in the A320neo turbofan is the first turbine ever to be equipped with additively manufactured borescope bosses by default. The cost benefits of EOS technology were one of the decisive factors for both production and development.

Fast: development, manufacturing and delivery times are significantly reduced

06_design_freedomFlexible: very high design freedom

03_cost_reductionCost-efficient: low material and tool usage, drastically reduce development and manufacturing costs

48_trusted_companyThe EOS system supports comprehensive quality assurance, including online monitoring and optical tomography.

Source: MTU | EOS

Additive manufacturing of borescope eyes for the geared turbofans of the new PurePower® PW1100G-JM engine generation of the Airbus A320neo.

download case study

The high safety requirements for approval are a major challenge in the aviation sector. Every part destined to fly has to be monitored continuously from raw material to end product, and there cannot be any defects. In collaboration with EOS, MTU Aero Engines developed an optical tomography technique for the build process into a serial product called EOSTATE Exposure OT. The parameterizable software allows detailed conclusions to be drawn about the quality of parts at every layer. In this way, optical tomography enables reproducibility to be verified, improves comparability between parts, build jobs and printing systems and creates the right conditions for cost-efficient quality assurance in series production applications.

In collaboration with EOS, MTU Aero Engines developed an optical tomography technique for the build process into a serial product called EOSTATE Exposure OT. The parameterizable software allows detailed conclusions to be drawn about the quality of parts at every layer. In this way, optical tomography enables reproducibility to be verified, improves comparability between parts, build jobs and printing systems and creates the right conditions for cost-efficient quality assurance in series production applications.

more about EOSTATE Exposure OT

Reduce cost drivers – a key factor to manufacture structural parts for the aviation sector more efficiently. Digitalized manufacturing processes offer wide-ranging opportunities. Thanks to additive manufacturing, multiple parts can be combined into a single component, eliminating production steps such as assembly. The process of storing spare parts, which currently ties up a lot of capital, is also becoming obsolete. Production only ever occurs when a part is needed, without requiring any preliminary processes. Additionally, additively manufactured structural parts are comparatively lighter, which helps to balance the CO2 footprint of aircraft.

Production only ever occurs when a part is needed, without requiring any preliminary processes. Additionally, additively manufactured structural parts are comparatively lighter, which helps to balance the CO2 footprint of aircraft.

Liebherr Aerospace is a leading supplier of systems for the aviation industry. With more than fifty years of experience, the company develops, manufactures and maintains a variety of aircraft instruments, including flight control and actuation systems, landing gears, air management systems and gearboxes.

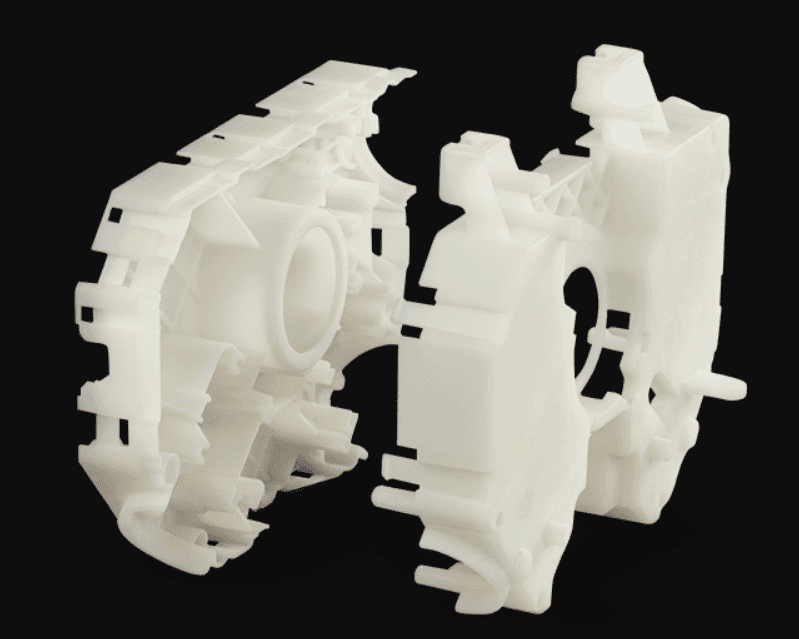

Using their metal 3D printer, the EOS M 400-4, Liebherr produced an innovative high-pressure hydraulic block for the Airbus A380. The new additively manufactured valve block achieves the same performance as the conventionally made part but is much lighter and contains fewer individual components. The part is made from a titanium alloy and satisfies all of the certification requirements needed for flight operations.

weight reduction

functional integration

find out more

Additive manufacturing with polymer technology is also becoming increasingly important for cabin interiors. There are several reasons: in this type of environment, high customization and flexible tool-free production are crucial. Materials used in the cabin also have to satisfy very strict requirements, e.g. in terms of flammability. The technology needs to be capable of processing these materials, especially when complex designs such as twisted strands are required. Finally, a consistent build process is necessary, with minimally complex post-processing, as well as a digital spare parts strategy and digital spare parts, with virtual inventories. Polymer technology for industrial 3D printing meets all of these criteria.

There are several reasons: in this type of environment, high customization and flexible tool-free production are crucial. Materials used in the cabin also have to satisfy very strict requirements, e.g. in terms of flammability. The technology needs to be capable of processing these materials, especially when complex designs such as twisted strands are required. Finally, a consistent build process is necessary, with minimally complex post-processing, as well as a digital spare parts strategy and digital spare parts, with virtual inventories. Polymer technology for industrial 3D printing meets all of these criteria.

Etihad Engineering is the largest service provider for aircraft maintenance, repair and operations (MRO) in the Middle East. As a subsidiary of the Etihad Aviation Group, the company offers around-the-clock maintenance services, including design, composite material repairs, cabin refitting and part-related services, in its modern facilities at Abu Dhabi International Airport.

Together with EOS, Etihad opened the first 3D printing manufacturing facility in the Middle East approved by the European Aviation Safety Agency (EASA) to design and manufacture aircraft parts.

Source: Etihad | EOS

Etihad Technicians at Work on an EOS P 396

The EOS P 396 system allows parts to be manufactured from polymer materials such as PA 2241 FR and can therefore be used to manufacture cabin parts that are replaced during the aircraft inspection process known as C-checks. Defects can also be remedied quickly by manufacturing any needed parts while performing maintenance during regular aircraft downtime (line maintenance).

Etihad and EOS are known for high-quality solutions and technological innovations and share the same mindset: “Together, we want to take the design and production of parts for aircraft interiors to the next level,” says Markus Glasser, Senior Vice President for the EMEA Region at EOS. “Additively manufactured cabin interior parts offer significant added value thanks to the simplified repairs, lightweight design, shorter lead times and flexible customization options. This tackles some of the key challenges of the aerospace industry.”

“Additively manufactured cabin interior parts offer significant added value thanks to the simplified repairs, lightweight design, shorter lead times and flexible customization options. This tackles some of the key challenges of the aerospace industry.”

Markus Glasser | Senior Vice President for the EMEA Region | EOS GmbH

Want to certify and scale your production? We can give you the know-how you need.

Our Additive Minds Consulting team makes it easier for you to implement robust processes that guarantee all-round stable industrial 3D printing production. In this way, you can generate detailed documentation to demonstrate that your production facilities and methods will operate smoothly, even in series production. We support you with certification for the standards you need.

more about Additive Minds

3D Printing Transforming Aircraft Interiors | Aerospace 3D Printing | Stratasys Direct

- February 05, 2019

Designing and manufacturing for aircraft interiors hinges on weight reduction. To reduce weight, cutting down on material and additives is key. 3D printing allows for the creation of continuous units, meaning all necessary features are consolidated into one part thereby reducing material usage, additional hardware and attachment features, and overall weight.

To reduce weight, cutting down on material and additives is key. 3D printing allows for the creation of continuous units, meaning all necessary features are consolidated into one part thereby reducing material usage, additional hardware and attachment features, and overall weight.

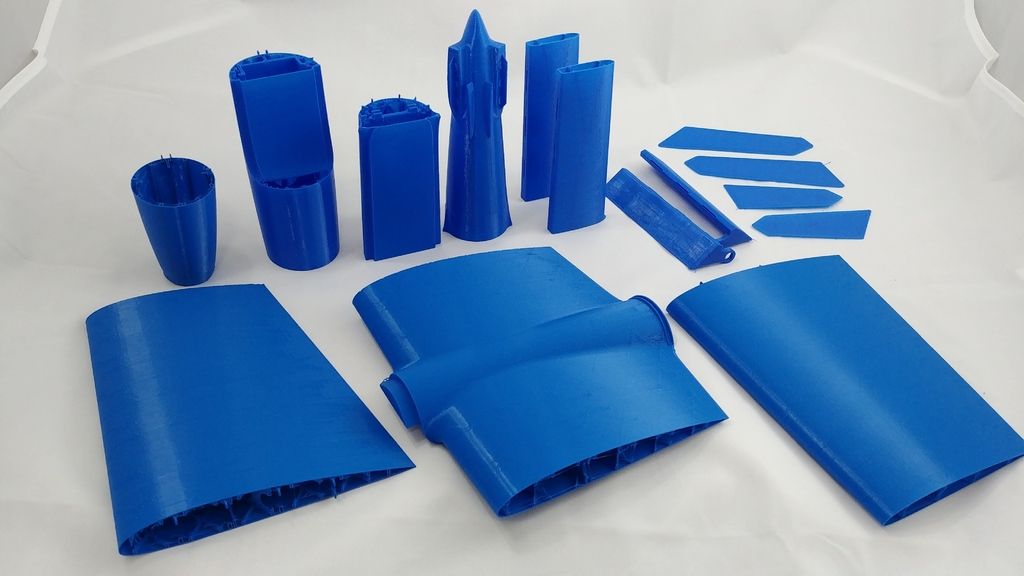

3D printing began factoring into the production of interior aircraft components over a decade ago. Air ducts, wall panels, and seat framework have all benefited from the ability to create complex geometries and organic shapes for reduced weight with 3D printing. As more and more airlines seek to add seats or increase passenger space, 3D printing offers a way to simplify parts and thin down panels, overhead compartments and seat components. Here are the top 3 ways we see 3D printing transforming aircraft interior manufacturing:

Less Material Usage

3D printing is an additive process, meaning it adds material layer by layer to build a final part rather than subtracting from a block of material. In a conventional process, a tool might be machined, then injected with material to pop out a final part. This scenario requires two tools for each side of the part, tool fixtures, machining with its inherent material consumption, discarded tool prototypes which have to be switched out as designs change, and finally fasteners to connect the injection molded part to the aircraft. By contrast, 3D printing goes from design file to printed part ready to plug into your aircraft – with attachment fittings and even movable features incorporated into the final 3D print, reducing overall material consumption and therefore material costs.

In a conventional process, a tool might be machined, then injected with material to pop out a final part. This scenario requires two tools for each side of the part, tool fixtures, machining with its inherent material consumption, discarded tool prototypes which have to be switched out as designs change, and finally fasteners to connect the injection molded part to the aircraft. By contrast, 3D printing goes from design file to printed part ready to plug into your aircraft – with attachment fittings and even movable features incorporated into the final 3D print, reducing overall material consumption and therefore material costs.

Complex, Consolidated Parts with High Strength

Paneling, seat trays, framework, overhead storage – these are items that rely on 3D printing both directly and indirectly. Fused Deposition Modeling (FDM) with ULTEM™ 9085 resin material directly impacts the production of aerospace parts. FDM with ULTEM™ 9085 resin has FST compliancy for aircraft interior applications. The resin provides excellent strength-to-weight ratio, which is why Airbus currently uses FDM with ULTEM™ 9085 resin to manufacturing 1,000s of parts for its aircraft.

The resin provides excellent strength-to-weight ratio, which is why Airbus currently uses FDM with ULTEM™ 9085 resin to manufacturing 1,000s of parts for its aircraft.

Aircraft production relies indirectly on 3D printing for larger volumes of units. Because 3D printing is faster and better equipped to build complex parts – which in turn makes it more cost-effective – it is often used as a master pattern in urethane casting for large interior components on aircraft. The 3D printed pattern is first used to consolidate multiple components into one fluid build, such as a three-part panel involving frame, wall and attachment, into a single unit. Then the 3D printed pattern creates a soft silicone tool for urethane casting. Urethane casting delivers FAR 25.853 flammability rated parts for volumes exceeding 50-100 parts. Today, urethane casting is used for many of the interior components involving luggage, armrests and seats on aircrafts.

part consolidationWeight Reduction & Cost Savings

It almost goes without saying: less material and consolidated designs that result in fewer components means overall weight reduction. But weight reduction also occurs from optimized, revolutionary designs only possible through 3D printing. 3D printing is a new way of thinking about aircraft components. That’s our challenge to designers: Think outside the box and find a new way of manufacturing that helps your bottom line. We know 3D printing can do all the heavy lifting, metaphorically and literally.

But weight reduction also occurs from optimized, revolutionary designs only possible through 3D printing. 3D printing is a new way of thinking about aircraft components. That’s our challenge to designers: Think outside the box and find a new way of manufacturing that helps your bottom line. We know 3D printing can do all the heavy lifting, metaphorically and literally.

✈️ Best Aircraft & Aircraft 3D Printing 3D Files ・Cults

✈️ Best Aircraft & Aircraft 3D Printing 3D Files

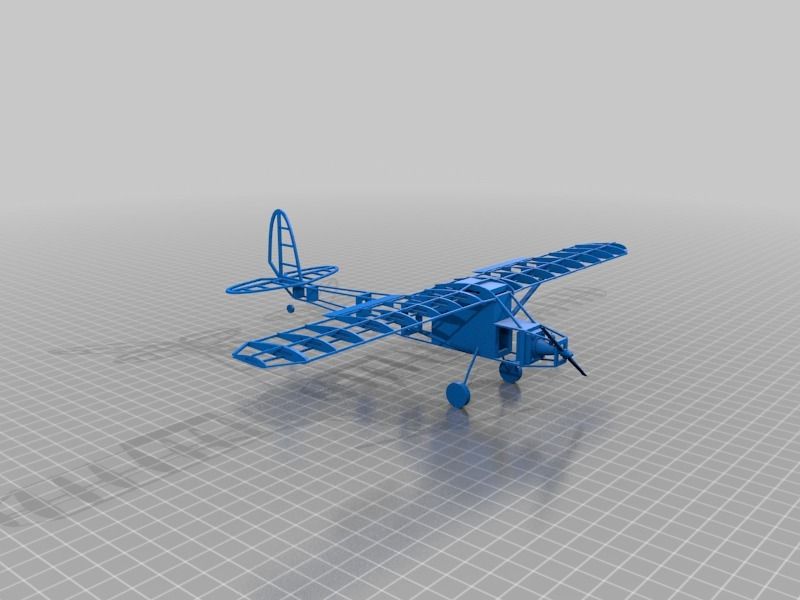

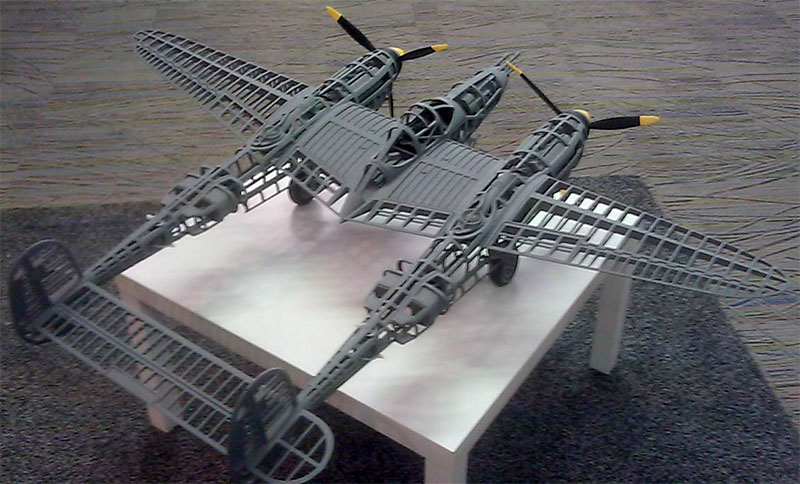

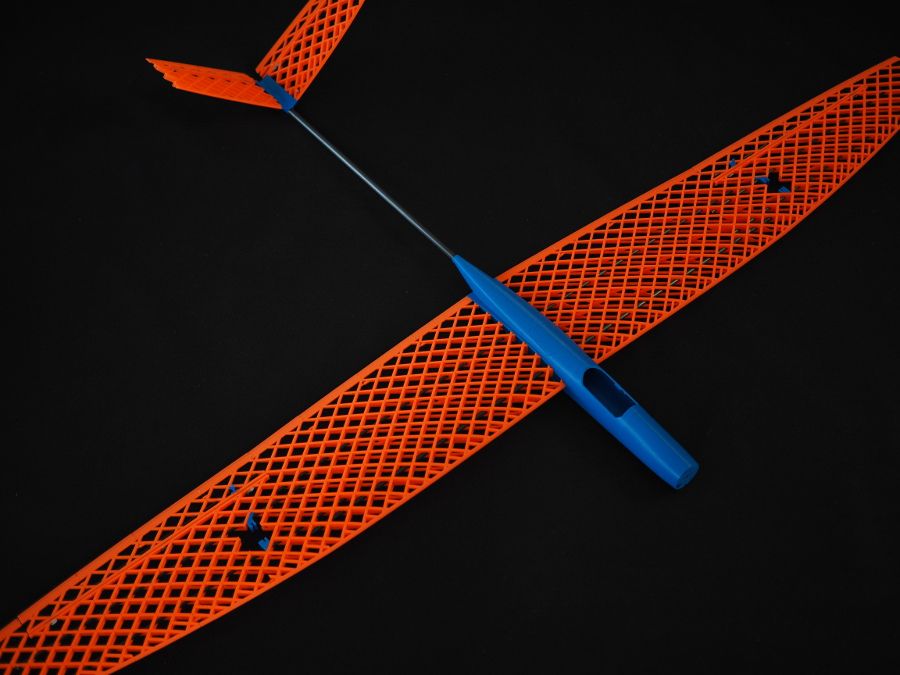

Climb with this collection of 3D files perfectly optimized for 3D printing. You can print beautiful airplane models to decorate your home or even do some modeling. As a result of 3D printing and connecting various parts, your aircraft can even fly for real. This is a great way to show your child how an airplane works and talk about the different models: CESSNA, Airbus, Boeing, etc.

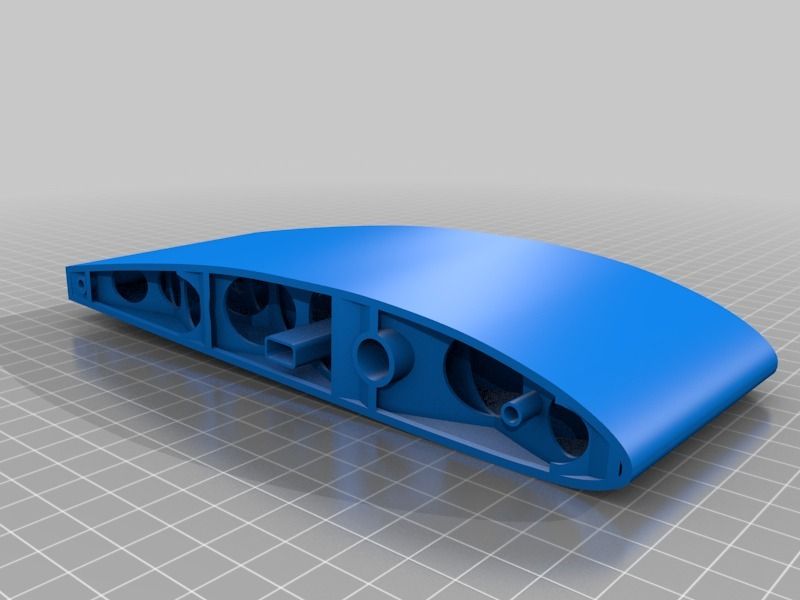

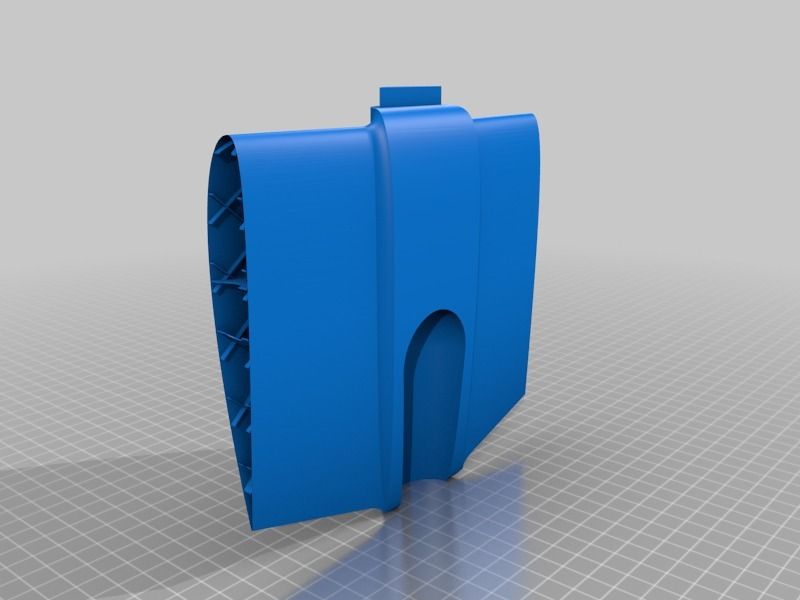

RC plane - Eclipson model A free version by Eclipson

Free

F5 Tiger 1/64 easy to print scale model

Free

Free RC Airplane

Free

Pilot Baby - 3D printed reproduction of a vintage RC sport model.

Free

Build your own aircraft engine

Free

RAF WW II Spitfire

Free

Easy to print T-38 Talon aircraft scale model (esc: 1/64)

Free

Plane

Free

RC airplane Wing - Eclipson Model Y

Free

F117 Nighthawk

Free

MD80 AIRCRAFT SCALE MODEL

Free

RC plane fuselage - Eclipson model Z

Free

Airbus A220-100 - 1:144 - Free

Free

Zlin Z-242 frame model (esc: 1/64) (No 3D print, CNC routing)

Free

Cessna 172 Skyhawk 1:72

2 €

Turboprop Engine

Free

Ultimate Biplane 10-300S

Free

Easy to print Cessna Citation SII 1/64 aircraft scale model

Free

Porco Rosso Savoia S.

21 Aircraft

21 Aircraft Free

Aero Commander 500S

Free

Model plane

Free

SOFIA, the Stratospheric Observatory for Infrared Astronomy

Free

Das Liddle Stik RC Airplane

Free

Antonov An-225

Free

Easy to print Aero L-39 Albatros aircraft scale model

Free

Aircraft

Free

Lancer B1 Bomber

Free

PIPE ECHAPEMENT SPITFIRE

Free

WW II RAF Spitfire Sliced

Free

A02 C-3D aircraft

Free

P-51D Mustang - Sally AURI

Free

First Take Off of a fully printed (FDM) sailplane.

Free

Ercoupe Golden Age Aircraft

Free

RAF Mosquito WW II

Free

Le Rhone spinning radial dummy engine for RC planes

Free

Little Jet Plane

Free

RAF Lightning

Free

Floonda - free 3d printed Freestyle Glider 1335mm Wingspan (Vasemode)

Free

Mobile device Barron Red

2.42 €

Transport Aircraft Toy Puzzle

Free

Speedy "Red Mini Wing" RC Plane

Free

"Red Swan" the biggest fully printed Flying Wing

Free

Antonov An-32

Free

Antonov An-124

Free

Touristic plane

Free

EL-39 - RC half-scale jet for 120 mm EDF

17. 01 €

01 €

Skewer Fighter Jet (F-86 Saber)

Free

Bi Plane

Free

Hawker Tempest V WW2 Fighter

Airbus A220-100 - 1:144 - Free

Airbus A220-100 - 1:144 - Free

Aichi D3A2

Here is our selection of best 3D aircraft files , all these great machines from the Cults and 3D file libraries are perfectly 3D printable for .

This collection includes free 3D files of all types of aircraft. There are many aircraft models of the most prestigious brands, such as Boeing , Airbus , Cessna or Antonov .

Professional 3D printing of has gained a lot of development in the world of aeronautics mainly for very specific applications. For example, this technology makes it possible to create very strong and much lighter parts compared to traditional manufacturing processes.

For example, this technology makes it possible to create very strong and much lighter parts compared to traditional manufacturing processes.

Of course, you won't find real aircraft parts here, but you will find lots of 3D aircraft models . For lovers of modeling, you can 3D print your own airplane or glider!

Aircraft 3D printing: An engineer's story Boeing

Each Boeing 787 passenger aircraft has about 30 3D printed parts. Combined, Boeing Commercial Airplanes (jet airliners and business jets) contain 25,000 printed parts. And military aircraft F-15 and F / A-18 - about 40,000. Most of the components are components of air ducts, but there are engine parts and parts of the interior of the cabins.

Boeing spokesman Bernardo Malfitano spoke at the EAA AirVenture Oshkosh forum of aviation enthusiasts and spoke about how 3D printing is being used in the aircraft industry today.

Mechanic, tester, aircraft builder and pilot

Bernardo Malfitano has been with Boeing since 2007. In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

In his career, he was engaged in the repair and maintenance of the air fleet, analyzed the wear and tear of aircraft. Now he is involved in the development of new aircraft.

According to the expert, all popular 3D printing methods are now used in the aerospace industry: laser stereolithography (SLA), deposition method (FDM), selective laser sintering (SLS) and direct metal deposition (DMD). Unlike traditional techniques, in which the cost of a part depends on the circulation (the higher it is, the lower the price for each spare part), 3D printed products cost the same: it doesn’t matter if you ordered 10 or 1000 pieces. Therefore, it is advantageous to use this technology for small circulations.

Where are printed parts on airplanes?

Air ducts are the part of the aircraft where 3D printed parts are most widely used today. In modern aircraft, circulating air maintains a comfortable temperature for a person and a safe pressure. 3D printed duct connections are used in the Boeing 787, F/A-18 and F-35 fighters, and Bell 429 helicopters.

3D printed duct connections are used in the Boeing 787, F/A-18 and F-35 fighters, and Bell 429 helicopters.

Power units. There are also 3D printed parts in the systems that propel the aircraft. As a rule, these are metal products made by laser sintering or metal deposition. So, in the Boeing 777, the compressor is connected to the temperature sensor using a 3D-printed adapter. And in the F-15K Slam Eagle military aircraft, casings for turbines were made using volumetric printing. This reduced the cost of the part from $34,000 to $2,550 and halved its production time.

Interior details . Shelves, brackets and various fixtures in passenger aircraft cabins are often printed in plastic. For example, the popular Boeing A350 has over 500 of these parts on board.

Small parts. End caps, parts of seats and instrument cases - all this can also be made using the 3D printing method. In the Boeing A300 passenger ship, brackets and seat belt buckles for crew seats are produced in this way.

Advantages of 3D printing for aircraft construction

Additive technologies attract aircraft designers not only because they are economical. They make it possible to optimize the shape at the model stage and significantly reduce the weight of the product. So, by replacing the cast metal bracket with a plastic one printed on a 3D printer, the designers managed to reduce its weight from 918 grams to 326. Of course, there is more than one bracket on the plane, so the total gain in weight is several kilograms. For passenger aircraft, lightening the design means reducing fuel consumption, which reduces not only the costs of the airline, but also environmental damage.

Parts with mesh and honeycomb structure are lighter than monolithic ones, but at the same time they do not lose strength. Each new sample introduced in the aircraft industry undergoes multi-stage tests, especially if it is a functional part.

Is it possible to print the entire aircraft?

If additive technologies are so good for 3D printing, is it possible to print an entire airplane? Bernardo Malfitano is sure that now it is impossible.

Today, 3D printing is successfully used to make drone bodies and working models of aircraft. At the Berlin Air Show in 2016, visitors saw the Airbus Thor, a remote-controlled aircraft about 2 meters long. All of its parts were 3D printed.

But to create the hulls of large aircraft - passenger liners, cargo planes, fighter jets - modern 3D printing technologies are not reliable enough.

Malfitano explained that the US has statutory manufacturing standards. The aircraft industry is governed by 14 CFR Part 25 (“Airworthiness Standards: Transport Category Aircraft”). It says that the structure of the materials must be strong, and the details must be reliable, which must be confirmed by certain tests. Meanwhile, testing parts created by 3D printing often reveals defects and inhomogeneities.

The second factor is the price. Aircraft manufacturing is mass production, so it is now more profitable to use traditional techniques at most nodes.

Bernardo Malfitano's entire presentation can be viewed here.

Learn more