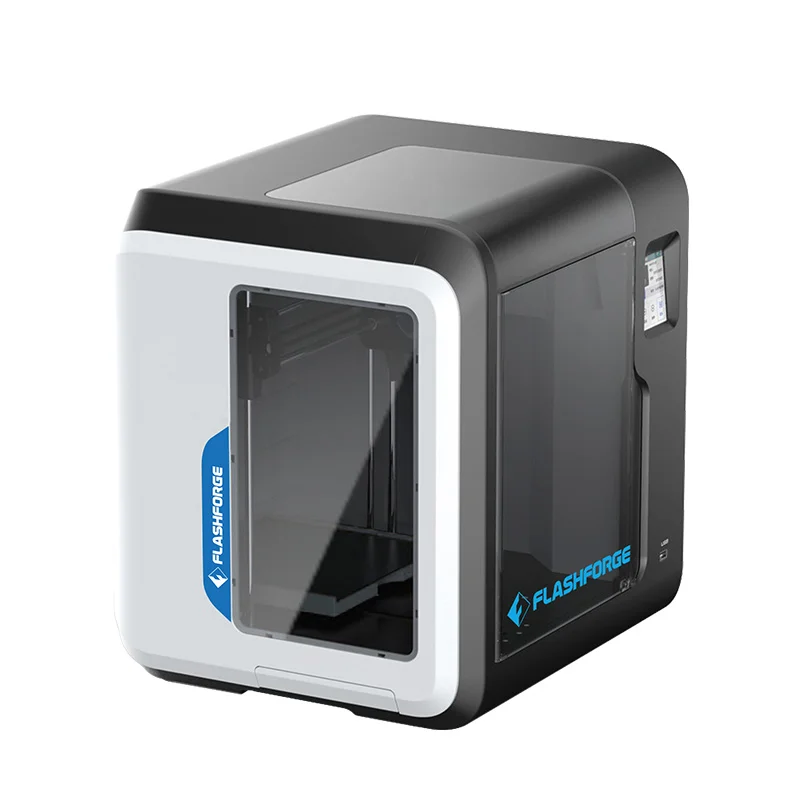

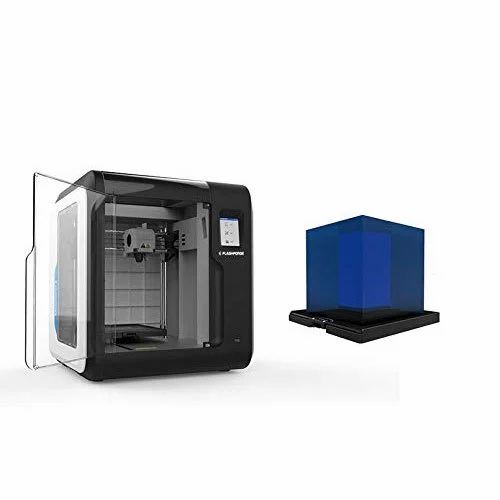

Adventurer 3d printer

Flashfore Adventurer 3 3D Printer

KEY FEATURES

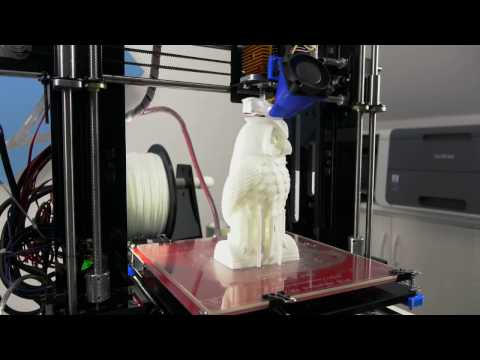

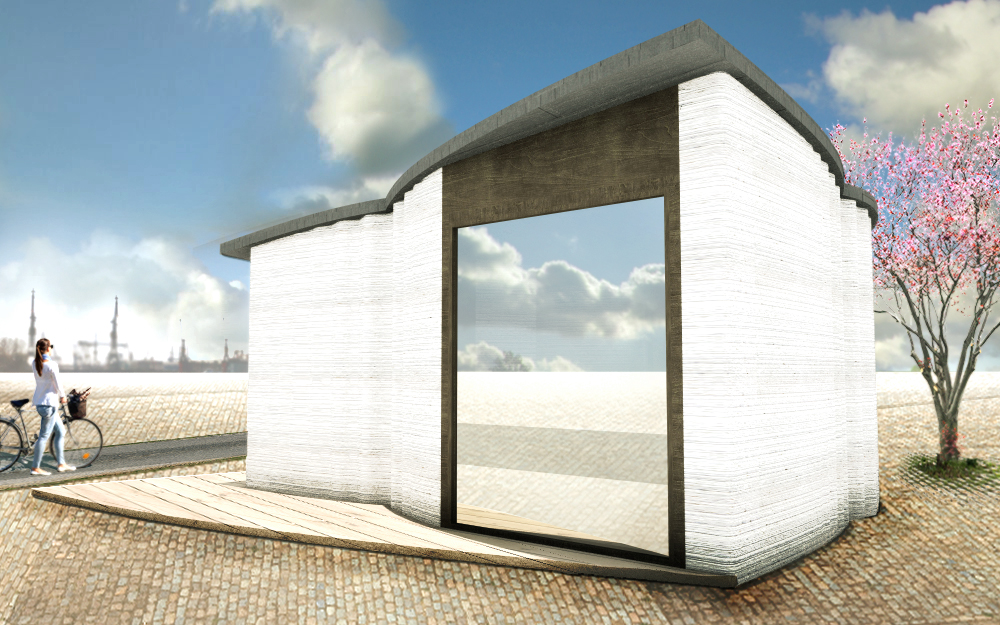

With a compacted and closed printed chamber, Adventurer3 is lightweight and portable. It is perfect for family and office users to use, which combines functionality and entertainment.

Adventurer3, Makes 3D Printing Easy

No more actions, just finish the unboxing and start your 3D printing journey.

Load & unload filament automatically

With the creative filament feeding design, just need to insert the filament into the inlet and wait for loading filament to the nozzle automatically. More loading and unloading action can be operated on the touchscreen.

Touchscreen interface

The 2.8-inch color touchscreen interface makes every action visible. The printing status is in real-time.

Detachable nozzle

Only three steps to finish all nozzle change processes. Simple and fast.

Heatable flexible platform for easy object removal

Adventurer3 is equipped with a heatable platform, which can reach 100℃. Whatever size model adheres to the platform easily. And flexible features enable the objects to be removed quickly just by bending the platform.

Multiple connections

Adventurer3 supports 5 connective ways to transfer print files quickly. It also supports wireless transmission via Wi-Fi.

Build-in camera

Through FlashCloud or PolarCloud, monitor the printing process without limitation of time and place.

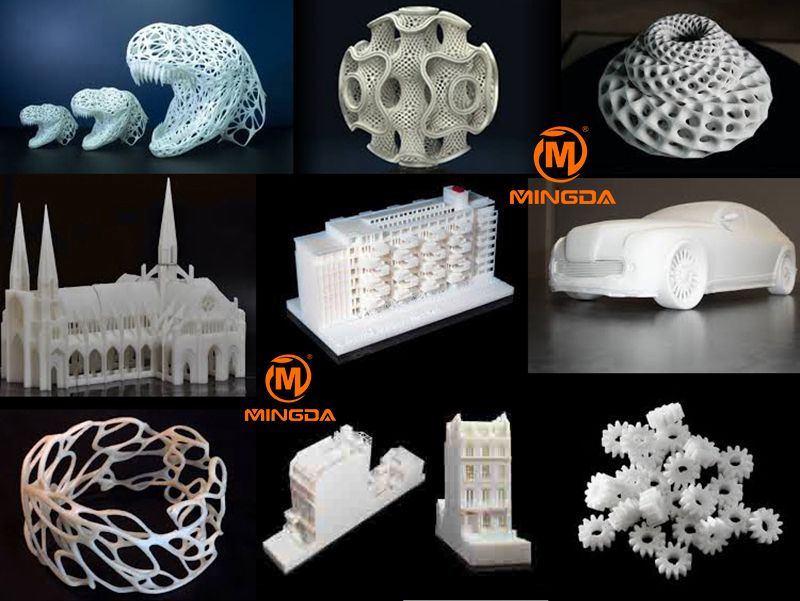

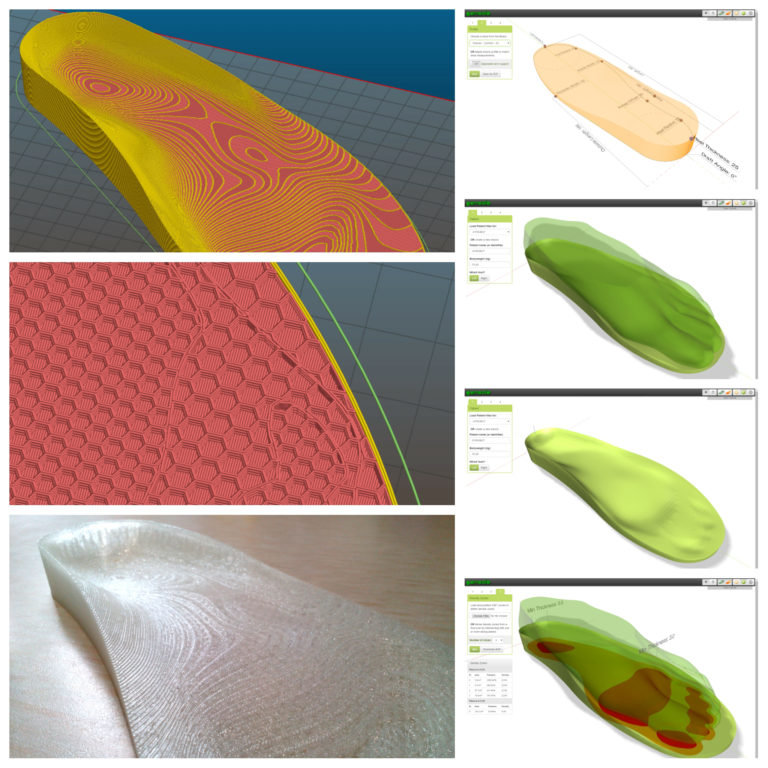

More than an entertaining device

Adventurer3 is a kind of productive tools for designers and engineers to realize creative designs.

Great printing result

Adventurer3 has excellent printing performance in PLA with a smooth printing surface. Dimensional accuracy of ±0.2 mm, which is the same precision standard with over $1000 FFF 3D printer in the market.

Note! Similar quality can not be guaranteed with the third-party filament use.

Support ABS

With the closed printing chamber and heatable platform, Adventurer3 supports ABS, which is often used in the industrial application.

A powerful ecosystem

FlashPrint offers standard and expert printing modes. Default parameters that have been tested countless times to ensure the great printing results. In the expert mode, it allows adjusting parameters easily with the third-party filament or under complex printing environment.

Adventurer3 printing form is possible with FlashCloud. Different print files can be transmitted to the corresponding machine via Wi-Fi, it also supports in monitoring the printing process.

Learn more about FlashCloud

Specification

Printing

- Extruder Quantity 1

- Nozzle Diameter 0.4mm

- Maximum Extruder Temperature 240℃ (464℉)

- Print Speed 30-100 mm/s

- Maximum platform Temperature 100℃ (212℉)

- Filament Compatibility PLA / ABS

- Filament Diameter 1.

75mm (0.069IN)

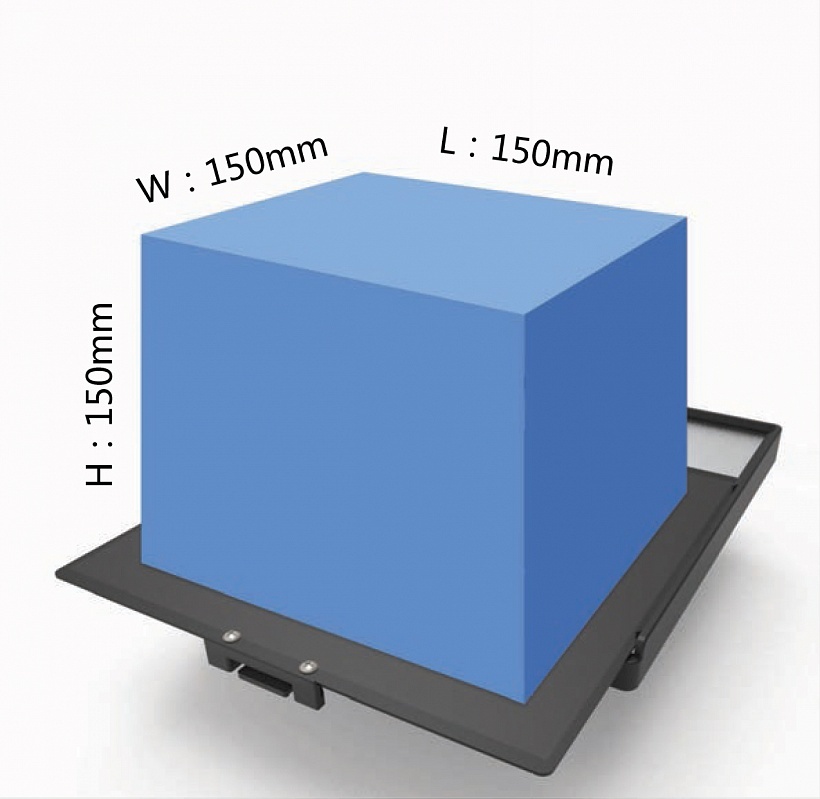

75mm (0.069IN) - Print Volume 150*150*150mm (5.9*5.9*5.9IN)

- Layer Thickness 0.1mm-0.4mm

- Print Precision ±0.2mm

Mechanical & Dimension

- Printer Dimension 388*340*405mm (15.3*13.4*16IN)

- Screen 2.8-inch touch screen

- Net Weight 9kg (19.85LBS)

- Gross Weight 13kg (28.7LBS)

- Internal Storage 8 G

- Spool External

- Running Noise <45dB

- Working Environment 15-30℃ (59-86℉)

Electrical

- Power Input AC100-240V, 47-63Hz

- Power 150W

- Power Output 24V, 6.25A

- Connectivity USB stick, Wi-Fi, Ethernet, FlashCloud, PolarCloud

Software

- Software FlashPrint

- File Input Format 3MF / STL / OBJ / FPP / BMP / PNG / JPG / JPEG files

- File Output Format GX/G

BUY NOW

Flashforge Adventurer 3 3D Printer, Auto-Level, Cloud Print, Super Quiet – FlashForge USA

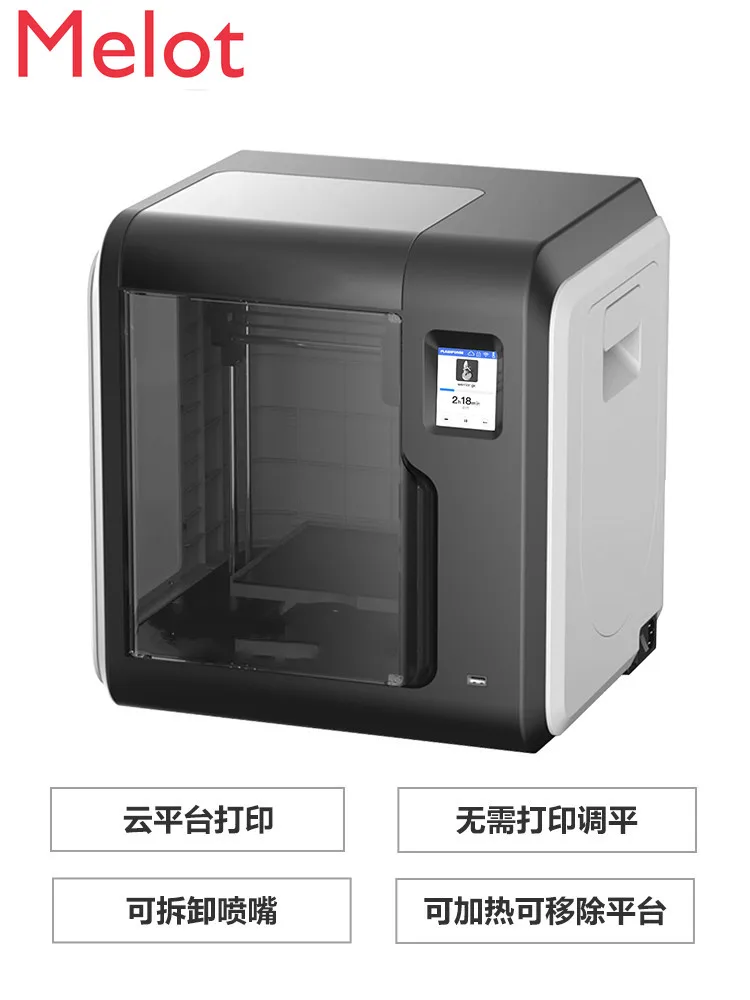

Skip to contentFlashForge Adventurer 3 3D Printer

Minimalist, Lightweight, and Compact Design

- Nozzle: remove nozzle just in one clip, stainless steel tube material, and fast heating up to 200°C (392°F) in 50 seconds

- Built-in HD Camera

- Maximum printing temperature at 240°C (464°F)

Detachable Nozzle

For ease of cleaning. Making removal and installation of nozzle easy

Removable and Flexible Heated Build Plate

Making removal of printed objects hassle free

Quick Heat Up Nozzle

Extremely quick heat up of nozzle to 200°C (392°F) in 50 seconds

No Leveling of Build Plate Required

Build plate is leveled at the factory level - calibration maybe required

Touchscreen Interface

An intuitive UI interface provides simple operation and ease of reading to printer's status

Built-in HD Camera

Built-in Wi-Fi HD camera for remote monitoring

Build Volume

150 x 150 x 150 mm (5. 9 x 5.9 x 5.9 in)

9 x 5.9 x 5.9 in)

Auto Filament Loading System

Printing will be suspended when filament is broken or run out, and printing will be resumed after filament is detected and loaded

Filament Compatibility

PLA, High-Speed PLA, PLA Color Change, Ultra Strong PLA, Metal-Filled, Wood, Polished PLA, ABS, ABS Pro

45 Decibel Noise Level

Ultra quiet printing operation providing pleasant printing experience in classrooms, homes, and offices

SPECIFICATIONS

Printing

Extruder Quantity: Single

Build Volume: 150 x 150 x 150 mm (5.9 x 5.9 x 5.9 in)

Layer Resolution: 0.1-0.4 mm

Nozzle Diameter: 0.4 mm (0.015 in)

Max. Printing Temperature: 240°C (464°F)

Max. Build Plate Temperature: 100°C (212°F)

Filament Diameter: 1. 75 MM (0.069 in)

75 MM (0.069 in)

Filament Compatibility: PLA, ABS, Ultra Strong PLA, PLA Color Change, Metal-Filled, Wood, Polished PLA, and High Speed PLA

Max. Print Speed: 100mm/s

Mechanical & Dimensions

Screen: 2.8-inch Touch Screen

Frame and Body: ABS and PC

Product Dimensions: 388 x 380 x 405 mm (15.3 x 15 x 16 in)

Net Weight: 19.85 LBS (9 kg)

Gross Weight: 28.7 LBS (13 kg)

Spool Hold Diameter: 52 MM (2.05 in)

Electrical

Power Input: 100-240 VAC, 47-63Hz

Power Output: 24 V, 6.25 A

Power: 150 W

Connectivity: USB Stick, Wi-Fi, Ethernet, and Cloud Printing

Software

Software: FlashPrint

File Input Format: .3mf / .stl / obj / .fpp

File Output Format: .gx / .g

Supports (OS): Windows XP/Vista/7/8/10, Mac OS X, and Linux

What's in the Box

Adventurer 3

One spool of filament (0. 25 kg)

25 kg)

Power Cable

After-sales Service Card

User Guide

Screwdriver

Unclogging Pin Tool

Allen Wrench

Grease

We Recommended

FlashForge Ultra Strong PLA Filament

Check it out

(There is a solution) Flashforge adventurer 3 filament feeder loud knocking noise, not enough filament extruded

print-quality pla extruder filament flashforge-adventurer-3

My Flashforge Adventurer 3 is not printing correctly. The filament feeder makes a repetitive loud thud and not enough filament is squeezed out. The resulting print (if completed) is not continuous.

Results vary by filament. PLA brand Flashforge (red) works best. Every other filament fails completely, unless I'm printing at high quality and a head temperature of 235 degrees. The nozzle did not clog repeatedly, but from the very beginning, when the filament was fed in, it did not flow properly.

I've already used the included extruder blockage clearing tool a few times, but after posting this question, I tried again. Normal use of the tool made no difference. So I applied more force, and pushed the filament by hand right into the extruder and used the pin to try and clear the extruder. Now it seems to work adequately, not perfectly. I can print with the default settings. It still knocks or ticks a little. I'm dismayed by the amount of force I had to use to clear the blockage in the extruder.

@Will Barrows, 👍4

Talk

9 answers

Best answer:

▲ 2

advice to clean feed mechanism on Bowden thoroughly. When I looked closely, there were plastic flakes all over the mechanism. I used compressed air and a brush to clean it up. I also discovered an expert mode in the FlashPrint software that allowed me to slow down the rate at which the fill fills. Now I have good print results with any filament.

Now I have good print results with any filament.

EDIT AND UPDATE:: I still had problems with PLA. I've been printing with ABS for most of the past year without any of these issues. I think PLA is just rougher, scratches more than ABS, and gets caught in the tube. I found a comment that applying olive oil to the filament fixes this. I used vaseline. For a while everything was fine, but the seller said that this would lead to other problems.

There is no permanent answer to this question yet.

, @ Will Barrows

▲ 1

PLA should not be printed at 235°C. If your printer requires such a high temperature to make the filament very fluid, there is too much friction in your system, for example, this could be caused by blockages or too low a layer height when printing the first few layers. Please note that such high temperatures are also a cause of obstruction, as the filament can be charred causing clogs. On the other hand, too low temperatures also cause too much friction or resistance.

On the other hand, too low temperatures also cause too much friction or resistance.

The sound you hear is often referred to as a "click" and can be caused by skipped steps or skipped extruder gearing due to friction/resistance.

Now that the click is in, please study this answer and this answer to answer your problem.

, @ 0scar

▲ 2

My Flashforge 3 adventurer had similar symptoms at the start of printing. I found that the z-axis went out of calibration, causing the print head to make contact with the bed, which meant the filament could not extrude. The solution was to calibrate by slipping a piece of paper under the extruder and adjusting the z-offset until it just touches. After that everything worked fine. Hope this helps.

, @ DaveA

▲ 1

I had an identical problem, flashforge provided a setting that helped (mostly ran much slower) but I still needed high heat and had a lot of crashes.

I eventually took apart the hotend of the extruder and found that there is a tiny metal tip that holds a plastic tube through which the filament passes to get to the hotend. It didn't work and got sucked into the pipe. The high temperatures and low speeds basically just softened the PLA enough to squeeze past the blockage.

I cut out a piece of metal from the side of the plastic tube and assembled it without it.

The printer now works great at high speeds and with any filament :)

I haven't seen the negative effect of removing this tip yet, I think the extruder may eventually fail, at which point at least i know i just need a new extruder.

There are four plastic clips that you need to insert with a screwdriver if you want to try this I was able to open it without causing any damage as the clips are quite strong.

, @ Oiff

▲ 0

I've been having a lot of bumps lately after I moved my printer location.

Turns out my printer wasn't level and the extruder was pushing harder (further down) in different places, causing bumps. It really shows because the calibration is only in 1 place.

I used printer paper and a bubble level and then readjusted. Since then, not a single hit.

, @ Josh L

▲ 2

After a couple hundred hours of (mostly) successful prints, I heard a strange feeder thud, and although it was feeding the filament, it didn't pull it all the way out to change the color. Tried several tricks to fix it without success. Then I read here about how easy it is to use compressed air to clean the wheels and feed channel. Voila! Success. Maybe next time it will not solve anything, but it cleared up this problem.

, @ Marvin Mallon

▲ 2

I had this problem and decided to post my solution here.

The nozzle (at least my nozzle) is not actually a 0.4 mm nozzle. You can tell just by comparing it next to another. I seem to have a 0.3mm nozzle despite being sold as 0.4mm.

As soon as I set toolpath width in FlashPrint to 0.3 mm, my knock (extruder skip) and subsequent underextrusion completely disappeared .

, @ harry_p_6

▲ 0

Your nozzle may be blocked. Check it.

My printer worked fine for the first ~500g of ABS. Then I started to hear clicks/pops when printing was high on media. The hose connector that attaches to the top of the extruder eventually gave up and it released the PTFE tube, creating spaghetti in the printer before I could stop it.

So I replaced the hose connector, but the printer still crackled when material flow was high. I followed the instructions for cleaning the nozzle. I wanted to clean it until I could see the light coming through the nozzle, so I removed the nozzle and used heated needles to pierce it. That's when I realized something was stuck in the nozzle...

That's when I realized something was stuck in the nozzle...

I looked at my broken hose connector and sure enough, the clamp/retaining ring inside the hose connector was broken and crushed. Looks like a piece of the ring got stuck in my snot. I couldn't figure out how to clean the nozzle so I just bought a new one.

, @ Dave Gage

▲ 0

I had the same problem with mine. And the click was really calibrating. When you make the paper part, I make sure to move the axis up one point from the table, leaving enough room for the thread to be laid and glued. If it's still thumping after that, check for a clogged nozzle (which you'll still have to do if you've tried countless failed prints due to miscalibration). I can guarantee there is a blockage at this point, it's just a given if you think about it. Also, I read above that someone tested the nozzle is actually . 3mm instead of .4mm.

3mm instead of .4mm.

I also believe this is true. All of their models seem to be the wrong size. So the path extrusion should also be adjusted when all is said and done. Good luck

, @ Shustine Mock

Free STL file "Adventurer Monk" Thumbnail・3D Printer Model Download・Cults

Desktop miniature of a human barbarian

0,95 €

Necromancer table miniature

0,94 €

Table miniature "Dwarf warrior"

0,94 €

Mini Shadow Fighter

Free

Wood Elf Ranger Miniature

Free

Miniature Half-Orc Barbarian

Free

First Strike Human Barbarian Miniature

Free

Goblin Tramp Miniature

Free

Best 3D printer files in Game category

Mario? Block Bank

Free

Toxic croc

3. 44 €

44 €

Double-sided formula 1

Free

Peg solitaire

Free

Helicopter Pull, Push, Downhill Toy

Free

FDM ready split Camel

Free

Arbok flex (articulated)

2,50 €

Pidgeot figurine with open wings

5 €

Bestsellers in the Game category

Voidwalker Exosuits Truescale

14.83 €

Enourmous Imperial Heavy Tank

10 €

Off-road vehicle

2 €

Heavy Imperial Fire Support Weapon [Preliminary Support]

5 €

Vodfolk Explorer

9. 62 €

62 €

Emberfolk Fighters

9.62 €

Imperial Heavy Weapons & Regimental Flags [OFFERED]

2 €

Dancing Skeleton

3.37 €

RC 1/10 Dodge Challenger

7,50 €

GIANT CROCODILE HINGED

4.19 €

CRAMER Truggy RC 4x4 Full 3D Printed

7,50 €

Lazy Cat

3.84 €

Exolotreftes Truescal

5 €

Iron Warrior Heads and Shoulders MK 3

€4.29 -fifteen% 3.