3D scanner room

How to scan a room with a 3D scanner | Professional 3D scanning solutions

A long-range laser scanner is one way to get your scan. With Artec Ray, for example, the laser technology makes its way around the room, creating a point cloud. To capture the room in its entirety, you may need to place the scanner in several points. With Ray, this ensures that everything you’re scanning within 110 meters (and even if you’re trying to digitize the great hall of a medieval castle, this is likely the case) will be included in the scan. A preview takes as little as two minutes, while the actual scan is dependent on various factors, including how much detail is required.

Another benefit of a fast laser scanner such as Ray is that it has submillimeter precision for accurate measurements, and high 3D resolution to capture not only a precise outline of the area you’re scanning, but the smaller details as well.

If what you need is to capture parts of a room in higher 3D resolution or in areas that are difficult to access, we recommend using more than one scanner. For example, using Artec Leo in combination with Artec Ray allows you to utilize the best of both: A Leo scan’s texture and resolution paired with your Ray scan as a backbone, providing context for the item you need to highlight.

If you’re an interior designer demonstrating how furniture would look in the room, a full scan provides the setting, while targeted scanning of furniture added to the room allows the detail, color, and texture that sells the concept.

With a long-range scanner such as Ray, the scanner does much of the work for you, and can largely stay in place while the laser technology scans its way around the room. For a handheld scanner such as Artec Leo or Artec Eva, you manually take it with you throughout different parts of the space you’re in, or in targeted locations.

For any scanner, blank surfaces and unmarked walls can be difficult to scan. With Ray, the ability to cover large areas in one scan decreases the need for aligning several smaller scans together.

If you’re using Artec Ray for your room scan, we’ve got good news: Artec Studio can align Ray scans without targets. Just ensure that there’s sufficient overlap between your scans, with different items that can be used as reference points during post-scan processing. Geometrical features such as a table or a curtain could be your answer to successful alignment and registration.

If you do need to use targets and spheres, here’s what you should know.

Creating the right conditionsSure, it goes without saying that you’re going to need a room if you want to scan a room. But, there are some things to keep in mind before you get scanning. First, you need the right lighting. Sufficient lighting and uniform conditions are key to a good scan.

Another possible setback in your scanning project may come in the form of objects that are shiny, transparent, or reflective. As you already know, items like these don’t typically scan well. In this case, it’s best to spray them with a coating spray or with paint, or to remove them from the room altogether.

In this case, it’s best to spray them with a coating spray or with paint, or to remove them from the room altogether.

Take as many scans as necessary if you’re scanning from different angles.

The right angles/floor space

We’re willing to bet that your home isn’t made up of symmetrical rooms with only flat surfaces, no angles and no turns. In the case of split levels or steps, you’ll need to position your scanner in numerous locations. Same goes if you’re trying to scan around a corner, or beyond a cabinet.

In some cases, you’ll need to combine several scans. If you’re scanning a room from different angles, distances, or spaces, you’ll need to take as many scans as necessary to capture every bit of the room, and then piece them together during post-processing. If you’re using several scanners, their respective data may need to be combined – to fill a backbone scan of the room with furniture and other details captured separately, for example.

Artec Studio allows you to combine the scan data from the Artec 3D scanner range.

Canvas FAQ

Canvas FAQ- What device should I use with Canvas?

- What kind of accuracy can I expect from Canvas?

- What is Scan To CAD?

- Can I use Canvas with an iPad or iPhone without LiDAR?

- Can I do Scan To CAD myself?

- How big of a space can I scan?

- What file formats and programs does Scan To CAD support?

- Getting Started with Canvas

- Can I submit multiple scans of an entire home?

- What units does Canvas use, and how can I change this?

Getting Started

18 articles

Use Cases

11 articles

About Scan To CAD

24 articles

About Compatible Devices

4 articles

About 3D Scanning

15 articles

About Your Account and Account Portal

6 articles

About Occipital

5 articles

Troubleshooting and Technical Support

15 articles

General Information

4 articles

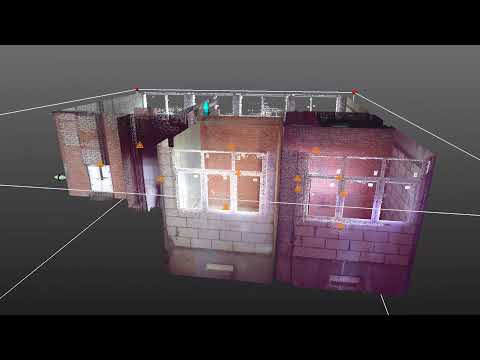

3D Scan Room at the Hyundai Motor Manufacturing Rus plant

In February, a new quality control laboratory, the 3D Scan Room, was launched at the Hyundai Motor Manufacturing Rus plant (hereinafter referred to as XMMR) in the welding shop. In this article, we will talk about how it works and how it helps to optimize the production process. Ilya Goryachev, Head of the Quality Control Department, and Roman Vinokurov, Leading Welding Quality Engineer, helped us figure out the answers to these and other questions. nine0003

In this article, we will talk about how it works and how it helps to optimize the production process. Ilya Goryachev, Head of the Quality Control Department, and Roman Vinokurov, Leading Welding Quality Engineer, helped us figure out the answers to these and other questions. nine0003

We thank the PR Department of Hyundai Motor Manufacturing Rus for providing this material.

The robot-mounted 3D laser scanner works in conjunction with a laser tracker.

All the most interesting and unique we publish in almanac "Production Management" . 300+ powerful cases, ready-to-use checklists and other useful materials are waiting for you in a complete set of numbers. Subscribe and get the best!

3D scanning technology

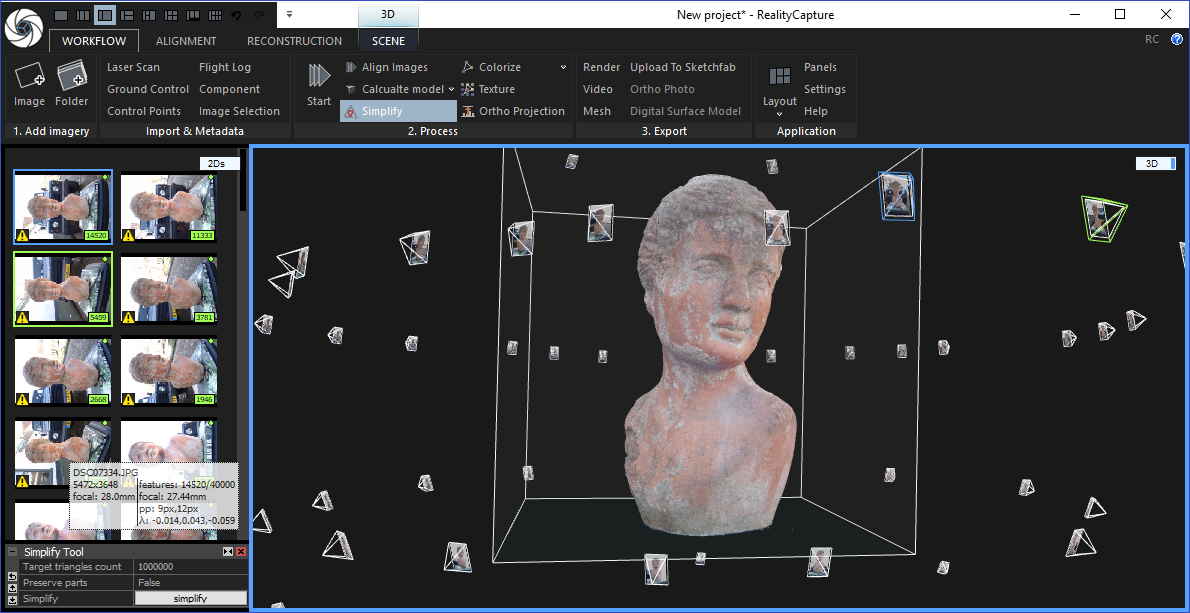

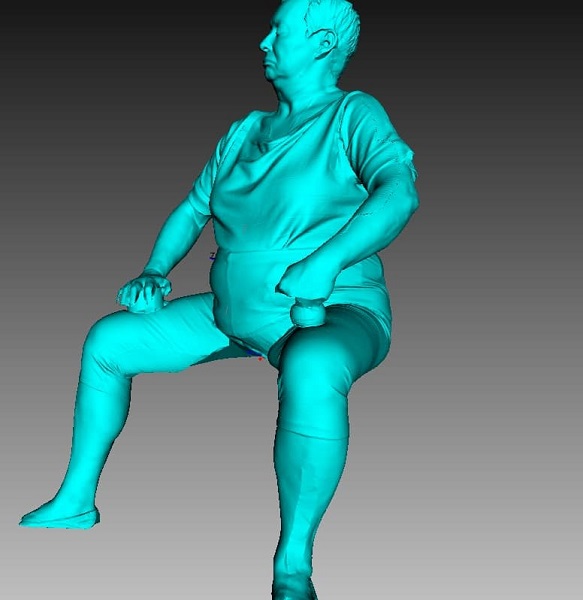

3D scanning technology, which is widely used in the automotive industry and many other areas, allows you to create a three-dimensional virtual copy of a real object based on the analysis of the shape of a real object. Depending on the type of interaction with the object under study, 3D scanners are divided into two types: contact, which create a 3D model by direct contact with the object, and non-contact. The latter include, for example, a laser scanner - this is the one used at our plant. With 3D laser scanning, a three-dimensional digital model consisting of many points is obtained by measuring an object by scanning the reflection of laser beams from its different parts. nine0003

Depending on the type of interaction with the object under study, 3D scanners are divided into two types: contact, which create a 3D model by direct contact with the object, and non-contact. The latter include, for example, a laser scanner - this is the one used at our plant. With 3D laser scanning, a three-dimensional digital model consisting of many points is obtained by measuring an object by scanning the reflection of laser beams from its different parts. nine0003

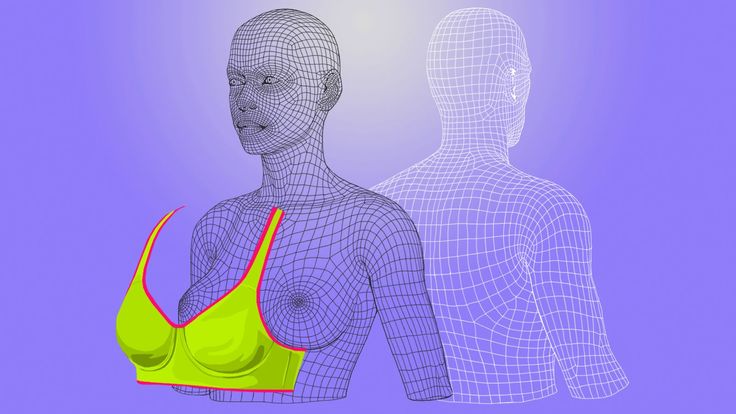

In the automotive industry, 3D scanning is used for design and simulation, product quality control and reverse engineering. At our enterprise, 3D scanning technology is needed primarily to control the geometry of the body and improve product quality. How does this technology help improve quality? When we get a 3D model of a measured body or other object, we can compare it with the original designed model - that is, with the "ideal model". Thus, you can see and understand how the real object differs from the reference one, what are the deviations in size and shape, at what stage of production the equipment should be reconfigured, and so on. Such measurements are made constantly and are necessary both for launching new models and for monitoring the status of those that are already being produced. Previously, only a contact machine (Coordinate Measuring Machine, CMM) was used for this purpose at the plant, later a hand-held 3D laser scanner appeared. nine0003

Such measurements are made constantly and are necessary both for launching new models and for monitoring the status of those that are already being produced. Previously, only a contact machine (Coordinate Measuring Machine, CMM) was used for this purpose at the plant, later a hand-held 3D laser scanner appeared. nine0003

Only one person is needed to manage the whole process. Currently, the training of employees of the quality control department and engineers of the welding shop continues.

How it works

In fact, the 3D Scan Room is a laboratory where measurements are made using the same scanner, only automatically, not manually. The idea of creating such a laboratory, according to Ilya Goryachev, appeared at the beginning of 2020, work on the project implementation began in April. Ilya himself oversaw the project as a key project for the division and the plant as a whole. In turn, Roman Vinokurov, according to the head of the quality control department, took upon himself "the main burden of creating the terms of reference and directly solving important work issues. " “Actually, I managed this project for 90% through him, and he did an excellent job,” said Ilya Goryachev.

" “Actually, I managed this project for 90% through him, and he did an excellent job,” said Ilya Goryachev.

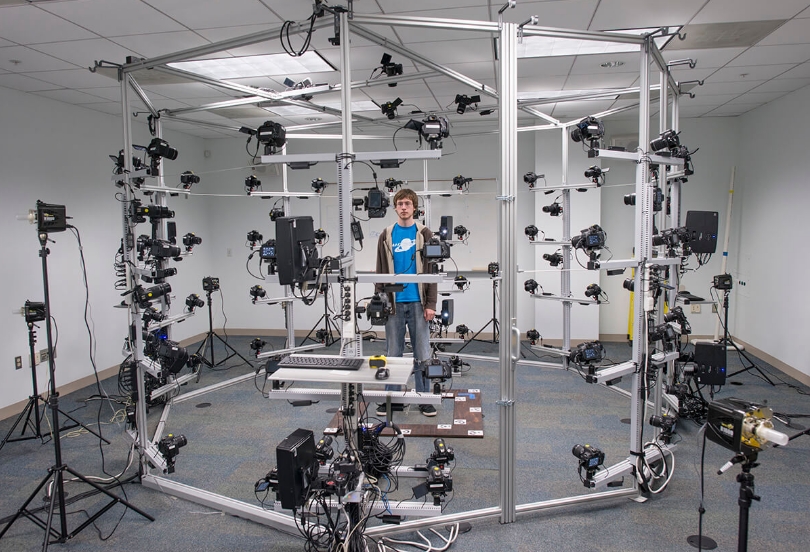

The project was based on the laboratory at the Hyundai plant in Turkey. The room is divided into two parts: the operator's room and the measurement area. In the measurement area, a Leica scanner is mounted on a robot that controls it using special software. The scanner works in conjunction with a laser tracker. The tracker tracks the position of the scanner in space and understands what position it is in relative to the body. Computers with software for offline programming are installed behind glass in the operator's room. Here sits an employee who controls the process. This room is spacious and comfortable, unlike the Turkish factory. “We understand that in order for a person to concentrate on such work, he needs normal conditions,” Ilya Goryachev emphasized. Soundproofing also serves this purpose - despite the work of the workshop, it is very quiet in the laboratory. nine0003

To measure the body, it is placed on a special measuring platform using a crane beam. This platform is easily customizable to measure any model that is produced in our factory. The process of installing the body is done manually, and the measurement bindings are made automatically using a pre-written measurement program. Nearby there is a separate small stand for measuring attachments. To scan the interior of the body, hinged elements are removed from it. nine0003

This platform is easily customizable to measure any model that is produced in our factory. The process of installing the body is done manually, and the measurement bindings are made automatically using a pre-written measurement program. Nearby there is a separate small stand for measuring attachments. To scan the interior of the body, hinged elements are removed from it. nine0003

Because there is only one robot in the lab, it can only measure one side of the body, and the front and rear. To measure the second side, the platform on which the body is placed must be rotated - this is done manually. When the body is fixed, you just need to start the scanning process. As a result, you will get a detailed high-resolution three-dimensional virtual model of the object under study, which you can work with on a computer. The received image of the PSL format is processed in the PolyWorks program. While processing is in progress, the robot is ready to measure a new object. nine0003

The 3D model of the measured object obtained as a result of scanning is processed in the PolyWorks program.

Better, faster, more precise

As already mentioned, XMMR measurements were previously carried out using a contact machine. A hand scanner appeared at the factory also quite a long time ago. All this is still used, however, both the CMM and the handheld scanner are inferior to the 3D Scan Room in a number of ways. First, it's speed. CMM analyzes the object slowly, point by point. It takes about eight hours to fully measure one body using a contact machine, that is, only three bodies can be measured per day. nine0003

Second is the ease of use. CMM requires direct contact with the surface of the object, which not only slows down, but also complicates the measurement process. The same applies to a handheld scanner: it takes a lot of time and effort to manually measure all areas of the body surface. 3D Scan Room saves these resources. The whole process of measuring the body at the start of the project should take a maximum of three hours according to the plan. At the same time, there is the potential to increase speed - this can be achieved by accelerating the work of the robot, as well as by optimizing the measurement program. nine0003

At the same time, there is the potential to increase speed - this can be achieved by accelerating the work of the robot, as well as by optimizing the measurement program. nine0003

Only one person is needed to manage the entire process. Currently, the training of employees of the quality control department and engineers of the welding shop, who used to work with SMM, and now in the laboratory, including with measurement programs, continues. Training is conducted by invited Korean specialists. “This is high-level programming – you don’t just write a program for a robot, you write a measurement program, you teach a robot to measure. It's complicated. This is done by a special remote control in conjunction with the scanner control system,” explained Ilya Goryachev. According to him, the department is faced with the task of launching the 3D Scan Room in three shifts so that measurements are carried out without interruption, since the higher the number of measured objects (models), the more data for more detailed analysis and more efficient equipment settings. nine0003

nine0003

The process of measuring the body at the start of the project, according to the plan, should take up to three hours.

Another advantage of 3D Scan Room is the measurement accuracy. Although the contact machine also gives a fairly accurate result, the 3D scanner also wins in this indicator: the metrological accuracy of the device in 3D Scan Room is 75 microns, and the measurement error fluctuates at the level of 0.015 mm. At the same time, the accuracy of a 3D scanner is not affected by such external factors as, for example, floor vibrations, which cannot be said about a contact machine. To avoid such vibrations and, accordingly, distortion of the results, the SMM is installed on a thick steel plate, under which a special foundation is poured, untied from the general foundation of the welding shop. Due to this, vibration is not transmitted along the floor. It does not matter for the operation of the equipment in the 3D Scan Room. According to the head of the quality control department, “if you put this machine in a stamping shop where the floor is shaking, it will still cope, but the CMM will not. ” nine0003

” nine0003

Currently, the 3D Scan Room project is at the start, the quality control department is planning a number of improvements. Nevertheless, we can already say with confidence that the launch of 3D Scan Room is an important step in the process of optimizing production, which will make quality control of cars faster, more accurate and more economical, and an important step towards the implementation of the concept of smart production - Smart factory.

iPhone LiDAR 3D Scan | arvr.media

nine0002 As you probably know, the latest generation of iPhone (12 Pro and 12 Pro Max) is equipped with a lidar camera. 3D photography for me is a natural evolution of photography and I have been waiting for this day for almost 10 years. Several 3D shooting applications have recently been released that take full advantage of this new capability. I have tested almost all of them available, and for the last 3 months I have been actively involved in 3D scanning. I am often asked what apps I recommend and how to get beautiful shots. Here is information about the apps that I love about each, as well as some general tips for using LiDAR on iPhone. nine0003

I am often asked what apps I recommend and how to get beautiful shots. Here is information about the apps that I love about each, as well as some general tips for using LiDAR on iPhone. nine0003

So here are my 6 scanning apps, all of which support exporting directly to Sketchfab:

Scaniverse

Scaniverse generally works well, is fast and easy to use, creates great textures, and does a good job of eliminating voids. Make sure you are working with your shots in ultra mode. This tool is very good for scanning things like cars. This frozen Mini is one of my best lidar shots. All my scanner shots are here, and the application is here. nine0003

Polycam

Polycam is fast and handles textures well. You can process the image in HD mode and get instant scan results. Very good for scanning things like rooms or murals and street art. You can see my Polycam shots here, and the app itself is here.

3D scanner app

The 3D scanner app offers a host of options that give you total control. For example, you can easily separate or trim excess space in an application. You can cut even with the help of a sphere. I think the app is especially good for small things like this dollar bill. Make sure you are using HD mode. Here you can see all my 3D scanner app images, and the application can be downloaded here. nine0003

For example, you can easily separate or trim excess space in an application. You can cut even with the help of a sphere. I think the app is especially good for small things like this dollar bill. Make sure you are using HD mode. Here you can see all my 3D scanner app images, and the application can be downloaded here. nine0003

Record3D

Record3D allows you to shoot 3D video, also known as 4D content, i.e. 3D scanning per frame of video. Here are my daughter's first steps. Keep in mind that this format ends up with very heavy files, so you only need to shoot for a few seconds to be able to upload the video to Sketchfab. Here you can find all my recordings in Record3D format, and the application is here.

SiteScape

SiteScape is great for quickly creating accurate point clouds. You can adjust the density and size of dots. I like to use it for complex and intricate scenes or structures. Also can be great for cars. This is where all my SiteScape snapshots are located. The application can be found here. nine0003

The application can be found here. nine0003

Everypoint

Everypoint is great for large point clouds like this subway mosaic. The developers are teasing us about the upcoming app update combining lidar and photogrammetry, looking forward to trying it out. You can find all my Everypoint shots here, and the app is here.

General tips

Here are some general tips for lidar scanning on the iPhone:

- Remember that you can scan. People often get frustrated when scanning on the iPhone, usually scanning things that don't stand a good chance on their own. The most important thing to remember is that the scanner does not work with small things and objects. For example, a regular boot is often too small. Also, iPhone lidar does not work well with shiny/reflective elements

- Avoid rescanning an area already covered, this will most likely create misalignment issues and create artifacts in your image

- Scanning around something small/thin - like a statue, chair, or wall - generally doesn't work well

- Make sure that every part of the scanned area is well scanned to avoid gaps and voids.

To do this, I usually use something like a spray gesture, a bit like if I were painting with spray paint

To do this, I usually use something like a spray gesture, a bit like if I were painting with spray paint - Walk slowly and carefully. Don't flinch

- A beautiful and neat 3D image significantly affects the overall perception. 3Dscannerapp, Polycam and Scaniverse offer cropping directly in the app

- Sketchfab offers many options to help turn a bad scan into a normal one. I like to add shadows (2nd editor tab) and then post-process effects like sharpening, depth of field, saturation

- Adding 3D annotations to Sketchfab is a great way to turn a scan into a mini story

3D photo for sale

Sketchfab shop allows you to monetize your 3D creations. It seems to me that most of my iPhone lidar shots are still a little behind in quality in order to put them in the store. That being said, I put 2 of them up for sale (mini and doctor's office) because users actually asked me how they could buy them. The bottom line is that you never know how someone might use your scans, and it's often more about setting an appropriate price based on the quality and limitations of the content.