Southington library 3d printer

3D Printing - Southington Public Library

3-D Printing Procedures & Guidelines

- The Library owns a Creality Ender 3 3D printer for patron use.

- The Library’s 3D printer may be used only for lawful purposes. The public will not be permitted to use the Library’s 3D printers to create material that is: Prohibited by local, state or federal law; unsafe, harmful, dangerous or poses an immediate threat to the well-being of others; obscene or otherwise inappropriate for the Library environment, including weapons; in violation of another’s intellectual property rights, for example, the printer may not be used to reproduce material that is subject to copyright, patent or trademark protection.

- The Library reserves the right to refuse any 3D print request.

- You will need basic understanding of Computer Assisted Drawing (CAD) and use of a 3D printer. See the library’s website for links to helpful websites.

3D model designs must be saved as STL, OBJ or STEP files. Digital designs also are available from various file-sharing databases such as thingiverse.com. You can print or modify designs that are not protected by copyright.

- The Library provides a limited amount of filament. You may provide your own filament.

Scheduling a 3D Print Session

- The Maker Space is open during normal library operating hours. All Maker Space use must be completed 30 minutes prior to Library closing. The Southington Public Library Maker Space is reserved for patrons using Maker Space equipment or for patrons attending a library program.

- In order to use the makerspace, you must have a valid Library card from a Connecticut public library.

- Appointments are required. Contact the Reference Desk 860-328-0947 x5 if you would like to use the 3D printer, located in our Maker Space.

- Read and submit a completed liability waiver.

For Children under 18, a parent or legal guardian must complete the minor liability waiver. Waivers may be obtained from the Reference Desk.

For Children under 18, a parent or legal guardian must complete the minor liability waiver. Waivers may be obtained from the Reference Desk. - Children under the age of 12 must be accompanied by an adult at all times when using the Maker Space.

- Food and drinks are prohibited in the Maker Space.

- There is a first come, first serve policy when it comes to utilizing tools and equipment. Please be courteous and share equipment when others are waiting.

- Library equipment cannot be removed from the Maker Space.

- Library equipment should be used in a manner consistent with the proper use of each device. Equipment should not be mishandled or used in a way that can cause damage. Staff have the right to end the use of equipment if deemed necessary.

- Tools used must be returned to their original location in a clean state. The workspace also needs to be cleaned before the maker leaves.

- The Library provides free consumable materials on a limited basis.

The maker agrees to avoid wasting supplies and materials.

The maker agrees to avoid wasting supplies and materials. - The Library does not accept responsibility if a project is destroyed, does not print correctly, or does not work.

- The Library is not responsible for equipment or files left behind.

- The Library reserves the right to halt, delete, or disallow the creation of items that violate Library policy, including the creation of weapons, pornography, or illegal items.

- The Library Code of Conduct and Internet Use Policy also apply to the Maker Space.

- Library staff can provide very limited assistance in using the equipment and software.

Maker Space Safety Guidelines

- Some tools require specific safety gear. All safety gear must be worn as appropriate.

- Certain items may require hair and any dangling items, like jewelry, to be secured or covered before use.

- If a maker sees that any tool or piece of equipment is unsafe or in a state of disrepair, the maker must immediately discontinue use of the tool and notify Library staff.

- The maker must report to a staff member any accident or incident that occurs and if unsafe behavior is witnessed, that behavior should be reported to a staff member at the time of the incident.

- Projects and materials may be subject to approval by staff prior to use of machinery.

Related Resources (click to open)

Thingiverse

Find lots of Things to Print

3Dtin

Start designing your own 3D object with this simple 3D design software

Tinkercad

With Tinkercad you can quickly turn your idea into a CAD model for a 3D printer

Wings 3D

An advanced subdivision modeler

Sculptris

A digital sculpting program

Bringing Art to Life: Southington Library Boasts New 3D Printer

Skip to main content

- Berlin, CT

- Meriden, CT

- Cheshire, CT

- Farmington, CT

- Newington, CT

- Wallingford, CT

- Rocky Hill, CT

- Naugatuck, CT

- Middletown, CT

- Wethersfield, CT

- Connecticut

- Top National News

- See All Communities

Community Corner

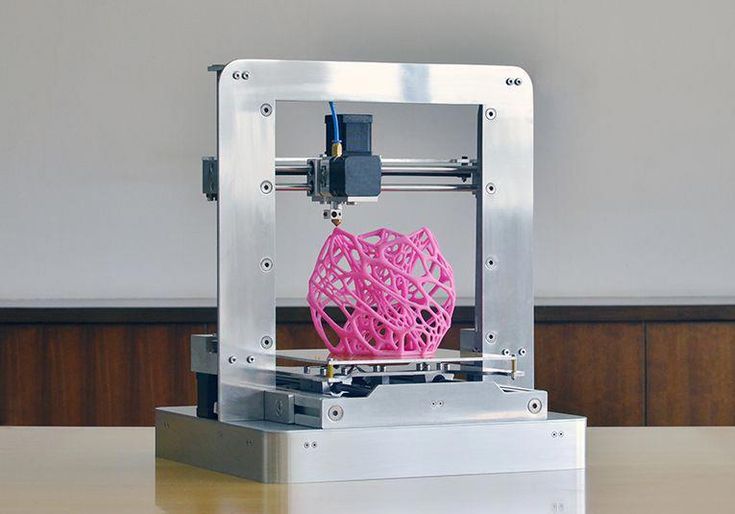

A grant from the Community Foundation of Greater New Britain has allowed Southington Public Library to purchase a 3D printer now in action – and it's opening a whole new world of opportunities for local residents.

Jason Vallee, Patch Staff

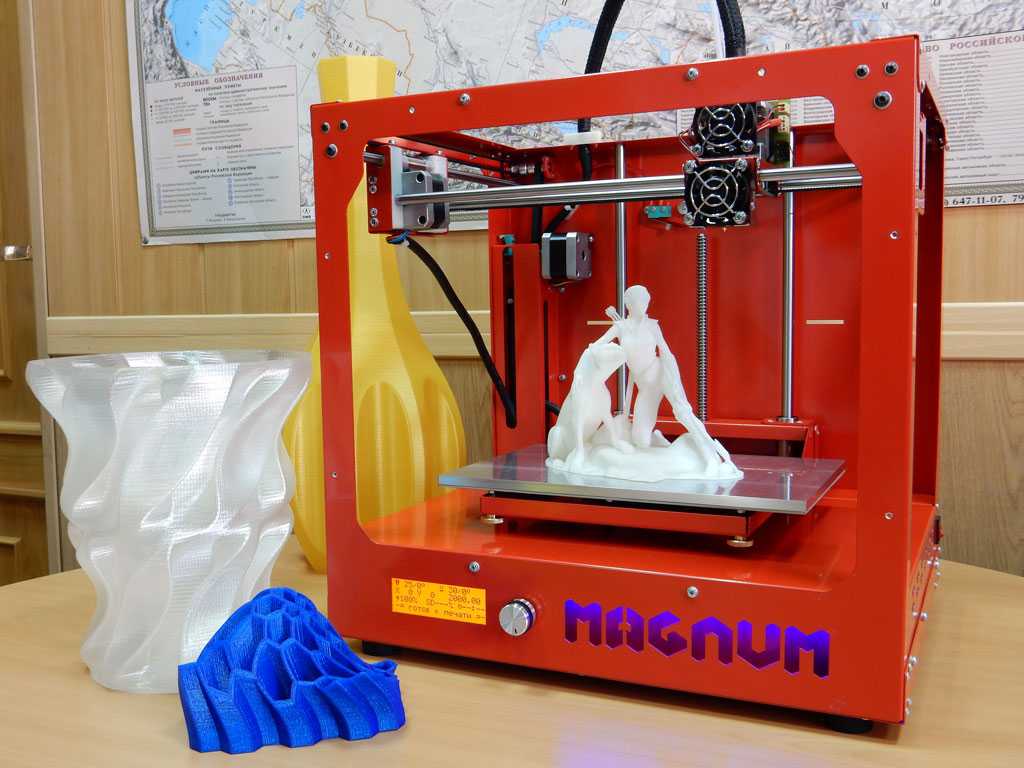

Jewelry, iPhone covers, figurines and building replicas are all coming to life these days at Southington Public Library.

It’s not the imagination sparked by the countless books or other media bringing these projects to life, however, but a new state-of-the-art 3D printer recently acquired as part of a grant from the Community Foundation of Greater New Britain.

“This opens a world of new opportunities for us,” said Sue Smayda, director of the Southington Public Library. “This gives us something that is not readily available for most artists and gives people a chance to come to the library and physically make something.”

The 3D printer, a Makerbot Replicator 2, was acquired recently using a $4,000 grant and will provide a unique summer opportunity for local students as part of the Science, Technology, Engineering, Arts and Math (STEAM) program, according to a press release from the Community Foundation of Greater New Britain.

The program is designed to open STEAM opportunities to students in local communities, the foundation’s website states.

Southington Public Library is now just the second library in the state to offer use of a 3D printer. Wesport Public Library also has a section dedicated to 3D printing and is available to library members.

Smayda said over the summer, students in middle school and high school will be part of an integrated production project that will involve middle school students developing stop motion films using iPads. High school students, including several that currently work with the Southington Cyber Knights robotics team, will then use the 3D printer to bring the stories to life, she said.

“It’s a program designed to create a partnership with our schools and help bring new opportunities to some of the town’s most talented students,” she said.

Once the program is complete, the 3D printer will be made available for public use beginning in September 2013. Residents will need to sign-up for certain times and remain at the station while conducting their work. Materials will be available free of charge, Smayda said.

Residents will need to sign-up for certain times and remain at the station while conducting their work. Materials will be available free of charge, Smayda said.

The technology works by using programmed SD cards that allow users to design and select the work they wish to print, according to Makerbot Industries, LLC. The printer uses polylactic acid, or PLAs, made from dyed cornstarch to produce a plastic product, according to the company’s website.

In a demonstration Tuesday, Smayda offered a wide variety of finished products that included figurines of Santa Claus and animals, iPhone 4 covers, bracelets, building replicas, chains and more.

Smayda said she hopes the latest acquisition is just the start of an effort to make libraries not just a place of information, but a destination to make things.

“This kind of technology is something the public is now seeking and libraries are going through a change to be a place to make things, not just a place holding media materials,” Smayda said. “We are certainly hoping to use this as a starting point to make the library a destination with something for everyone.”

“We are certainly hoping to use this as a starting point to make the library a destination with something for everyone.”

Make sure to like Southington Patch on Facebook and follow on Twitter for breaking news, daily updates and more!

Get more local news delivered straight to your inbox. Sign up for free Patch newsletters and alerts.

The rules of replying:

Crime & Safety|

Crime & Safety|

Business|

REC Wiki » Best 3D printing software in 2022

3D printing is a multi-step process, as you first need to design a 3D model, check it for errors, convert it to machine code, and only then the 3D printer goes into business . In this article, we will share examples of programs that can help at every stage of preparatory work and directly during 3D printing.

Contents:

1. 3D modeling software:

- Tinkercad

- ZBrushCoreMini

- 3D Builder

- SketchUp Free

- Fusion 360

- FreeCAD

- Blender

2. Editing and repairing STL files:

Editing and repairing STL files:

- Meshmixer

- MeshLab

3. Slicers:

- Cura

- PrusaSlicer

- ideaMaker

- ChiTuBox Basic

- Lychee Slicer

- Kiri:Moto

- IceSL

4. Control programs:

- OctoPrint

- MatterControl 2.0

- AstroPrint

5. G-code Visualizers

- UVTools

- WebPrinter

- Gcode Analyzer

- Design Software

1. 3D modeling software

If you are ready to create from scratch, you will have to learn special 3D modeling software. Many of them, especially professional computer-aided design systems, can be expensive investments, but on the other hand, there are plenty of quite capable and at the same time free offers on the market.

Tinkercad

Tinkercad is a browser-based application from Autodesk that is great for no-experience users, even kids, because of its simplicity. In this program, 3D models are built on the basis of basic blocks - simple geometric shapes that are joined together and then "filed" to the finished look. You can also convert 2D vector images into 3D models. Of course, you have to pay for simplicity - in the case of Tinkercad, rather primitive functionality that makes it difficult to create truly complex models. But such a task is not worth it: having gained basic skills on Tinkercad, you can always move on to more complex and more capable programs on our list. nine0003

In this program, 3D models are built on the basis of basic blocks - simple geometric shapes that are joined together and then "filed" to the finished look. You can also convert 2D vector images into 3D models. Of course, you have to pay for simplicity - in the case of Tinkercad, rather primitive functionality that makes it difficult to create truly complex models. But such a task is not worth it: having gained basic skills on Tinkercad, you can always move on to more complex and more capable programs on our list. nine0003

Official website

ZBrushCoreMini

ZBrushCoreMini is primarily a 3D sculpting tool, especially popular among those who create human and animal figures, computer game characters, comics, and the like. This software is mainly aimed at beginners and users with moderate experience, but at the same time, it is full of impressive features that make the work easier. For example, dynamic tessellation algorithms constantly analyze the surface of the working model and automatically add polygons so that detail is not violated. nine0003

nine0003

ZbrushCoreMini is offered free of charge and is positioned as an entry-level program for learning and gradually moving to more capable and complex options - ZBrush and ZbrushCore.

Official website

3D Builder

This program was developed by Microsoft and was included with Windows 10 for some time, although now it needs to be downloaded and installed separately. 3D Builder allows you to edit models in STL, OBJ, and 3MF formats, as well as create models from scratch. In this regard, the program is quite primitive, but it is simple and understandable even for novice modelers. nine0003

One of the interesting features of 3D Builder is the ability to simplify meshes by reducing the number of polygons, file weight and processing time in the slicer - useful in cases where the original designer obviously went too far with polygons. Additionally, you can import models from the library and even use Kinect sensors to 3D scan and import models of physical objects.

Official website

SketchUp

SketchUp is a web application with a great combination of simplicity and functionality. The user-friendly interface is intuitive and greatly facilitates learning, and the set of tools is quite diverse even for advanced users - hence the wide popularity of this program. nine0003

The free version was formerly called SketchUp Make, but is now simply called SketchUp Free. It includes everything you need for 3D modeling for 3D printing, just don't forget to download the module for exporting STL files - it's also free. The kit comes with 10 GB of storage for projects in the cloud and access to the 3D Warehouse, a repository with open source user-generated content.

Official site

Fusion 360

Professional CAD developed by Autodesk and famous for its ease of use and advanced functionality. This includes parametric modeling and mesh analysis and load distribution tools, including through generative design with topological optimization. The program is great for those who are engaged in 3D printing of functional products, for example, for industrial applications. nine0003

The program is great for those who are engaged in 3D printing of functional products, for example, for industrial applications. nine0003

Some versions of Fusion 360, such as hobby and student versions, are even available free of charge. FreeCAD FreeCAD The program relies on a parametric approach: at any point in history, you can scroll back and make changes to the parameters. The program even includes finite element analysis and a robotic system simulator. nine0003

Official site

Blender

One of the most popular 3D modeling programs, but quite difficult to master. Not the best choice for a novice designer, but a great tool for those who have already gotten their hands on simpler editors. Fortunately, the popularity of Blender has led to a huge number of guides, tutorials, and visual examples published by experienced users for beginner colleagues.

Developers are trying to make the program more convenient without sacrificing functionality: the interface has recently been updated, rendering has been improved, and 3D design and animation capabilities have been expanded. And yes, it's open source and freeware, so you don't risk anything. nine0003

And yes, it's open source and freeware, so you don't risk anything. nine0003

Official site

2. Editing and repairing STL files

If you find an interesting 3D model on the Internet, this does not mean that it can be immediately sent to a 3D printer. Many models are created for completely different needs, such as animations or video games, and in principle are not intended for 3D printing. But there is a solution: before processing such models into G-code, they must first be repaired so that the slicer can do its job well. The following programs on our list will help you cope with the repair. nine0003

Meshmixer

Meshmixer is an advanced and free program from Autodesk that allows you to view and check 3D models for errors in polygonal meshes that can ruin 3D printing. If such problems are detected, the program can automatically repair meshes. One example of an application is finishing 3D scans to a state suitable for 3D printing.

Additional functionality includes mesh blending, 3D sculpting, surface writing, cavity creation, support branching, mesh smoothing, and more. nine0003

nine0003

Official website

MeshLab

MeshLab is another open source program for editing polygonal meshes. MeshLab has the necessary tools for editing, checking, cleaning and converting meshes with the ability to combine meshes into one model and patch holes that can lead to incorrect processing of models into G-code.

Official website

3. Slicers

After receiving a 3D model, it must be converted into machine code - a series of commands understandable to CNC machines, including 3D printers. Slicers are responsible for this task - programs that accept digital models (usually in the form of files with STL, OBJ or 3MF extensions), analyze their structure, and then compile lists of actions for 3D printers, called G-code (Gcode). Such lists contain all the information necessary for the equipment: to what temperature to warm up the extruders and tables, whether to use airflow, along what trajectory and at what pace to lay the plastic. nine0003

nine0003

Cura

Cura is a slicer from the Dutch company Ultimaker, designed primarily for proprietary 3D printers, but open source and compatible with most other FDM/FFF systems. The program is easily customizable with various plugins. Since this is a very popular program, the chances are that it already has a profile with optimal settings for your 3D printer. If not, then nothing prevents you from creating a profile manually or using profiles prepared by other users. nine0003

The program has several levels of difficulty depending on the level of training - basic, advanced, expert and complete. The higher the level, the more access to customizable options. At a basic level, the program takes the bulk of the work on itself, helping inexperienced users.

Cura is constantly being developed and improved through regular updates and is also offered free of charge, although a paid version of Cura Enterprise is available to professional users with licensed plug-ins from the Ultimaker Marketplace, technical support and additional security measures. nine0003

nine0003

In addition to converting 3D models to G-code, Cura can also take on the role of a control program, but this will require a constant connection between the 3D printer and the computer throughout the 3D printing. Professionals appreciate another feature of Cura - seamless integration with professional computer-aided design systems such as SolidWorks and Siemens NX.

In general, Сura is suitable even for novice users, especially since a huge number of training videos and step-by-step guides are available for this program, both from developers and enthusiasts. nine0003

Official website

PrusaSlicer

3D printer manufacturer Prusa Research, under the leadership of the legendary Czech engineer Josef Prusa, whose designs are copied and refined around the world, has developed its own open source software based on the Slic3r slicer. PrusaSlicer quickly gained popularity as it not only retains the original program's extensive customizations, but also adds a number of useful features not found in Slic3r. nine0003

nine0003

A redesigned interface, support for Original Prusa branded 3D printers, and profiles with settings to work with many common polymers are just some of the improvements. Additionally, algorithms for generating support structures have been improved, support for multimaterial 3D printing and the ability to dynamically adjust the layer thickness have been added.

PrusaSlicer can process models not only for FDM 3D printers, but also for stereolithographic systems printing with photopolymers. As with Cura, the user can select a difficulty level with appropriate access to fine-tuning. nine0003

Official website

ideaMaker

Raise3D's slicer is optimized for branded additive hardware in the same way that PrusaSlicer is optimized for Original Prusa 3D printers, and Cura is optimized for Ultimaker 3D printers, but this does not mean that it cannot be use with third party systems. The organization of workflows and the interface is somewhat more complicated than in Cura and PrusaSlicer, but on the other hand, ideaMaker allows you to set up individual layers and apply textures for product customization. nine0003

nine0003

ideaMaker users can connect to the cloud platform and access hundreds of 3D printer profiles and materials created by other operators, or create their own library of settings.

Add the ability to customize support structures, split models for more efficient 3D printing of large parts, integrated mesh repair tools, and OctoPrint compatibility, and you have a flexible, versatile program to suit the needs of most 3D printers. nine0003

Official website

ChiTuBox Basic

This is a specialized slicer for those who use stereolithographic 3D printers that print with photopolymer resins. Most budget LCD masked stereolithography (MSLA) 3D printers rely on motherboards and firmware from ChiTu Systems, which also developed this software.

Users gain control over technology-specific parameters such as layer exposure time, as well as access to predefined profiles with settings for many popular 3D printers. The slicer takes into account such moments as the orientation of the model and the automatic construction of support structures with the possibility of manual optimization. nine0003

nine0003

Official website

Lychee Slicer

A program from the independent Franco-Belgian team Mango 3D, not associated with 3D printer manufacturers, but with support for many popular stereolithographic 3D printers, including those from Elegoo, Anycubic, Phrozen and Creality.

One of the features of this program is the high level of automation. If you wish, you can simply click on the "magic" button (it's called Magic), and the slicer will do everything by itself: it will orient the model on the platform, generate supports, and so on. Although, here you are lucky: the results are not always optimal, but usually adequate for relatively simple models. Otherwise, everything can be configured manually. nine0003

The program is offered in free and paid versions. The functionality of the free version is slightly reduced, but it has everything you need.

Official site

Kiri:Moto

Browser solution for those who lack computing power. Kiri:Moto can prepare 3D models for both 3D printing and laser engraving or milling. The settings are somewhat more primitive than in locally installed slicers, but are sufficient for most users. nine0003

Kiri:Moto can prepare 3D models for both 3D printing and laser engraving or milling. The settings are somewhat more primitive than in locally installed slicers, but are sufficient for most users. nine0003

Official website

IceSL

IceSL is a combination software that combines slicing with 3D modeling. In the left window, you can edit 3D models using scripts in the Lua language, which makes it possible to perform parametric modeling. On the right side, the 3D printing settings are displayed. For beginners, pre-configured settings are available, while experienced users can take advantage of features such as specific adjustment of parameters for individual layers with automatic gradation of intermediate areas. For example, this allows you to gradually reduce or, conversely, increase the filling density of the product as it is built, or gradually change the thickness of the layers. nine0003

Official website

4. Control programs

Control programs are designed for exactly this - managing workflows during 3D printing. Although you can insert a G-code drive into almost any 3D printer and press the start button, this is not always convenient, especially when you have to work with several 3D printers at the same time, and even more so when you do it remotely. This is where control programs come to the rescue. In addition, some of them offer additional functionality, including slicing and even editing 3D models. nine0003

OctoPrint

A web-based appliance that requires connection to a 3D printer via a microcomputer such as a Raspberry Pi equipped with a Wi-Fi module. This system allows you to control 3D printers remotely. OctoPrint accepts G-code from almost any slicer and provides the ability to visualize - view files before and during 3D printing. Alternatively, STL files can be loaded and processed directly in OctoPrint.

OctoPrint not only provides all the necessary tools for remote management, but also allows you to track the work in progress using notifications via various instant messengers. nine0003

This is a completely free, open source program with many plug-ins created by enthusiasts and available on the official website.

Official website

MatterControl

MatterHackers offers its own control program, slicer and 3D editor in one package. MatterControl allows you to directly control and observe 3D printing, slice, export G-code to SD cards for offline printing, and even create 3D models from scratch. The 3D printer will need a Wi-Fi or USB connection to run MatterControl. nine0003

The interface is well structured: on the left side there is a file browser and a library of simple geometric shapes. Interestingly, these shapes can be dragged into the 3D model and used as support structures.

Basic functionality is available in the free basic version, advanced users can pay to upgrade to MatterControl Pro.

Official website

AstroPrint

AstroPrint is a cloud-based management platform that allows you to remotely monitor and control multiple 3D printers simultaneously, store files, convert 3D models to G-code, and track workflow statistics. The functionality ranges from basic in the free version to advanced with different levels of paid subscriptions. nine0003

The 3D printer will require a Wi-Fi module to fully work with AstroPrint. In conjunction with the Raspberry Pi, the system is similar in functionality to OctoPrint: you can process models and send the finished code to a 3D printer via a web interface without the need for additional software. Another plus is integration with popular repositories of 3D models Thingiverse and MyMiniFactory, as well as 3D editors 3D Slash and Leopoly.

Official website

5. Programs for visualizing G-code

What if you find an old file with a G-code, but you have no idea what it is and why - maybe garbage, or maybe an excellent, but long-forgotten model without a clear marking in the file name? The programs in this section will help you visualize the contents of such files.

UVTools

This program combines file browsing with layer editing and even model repair for stereolithographic 3D printing. The program can also be used as a plug-in for PrusaSlicer, adding support for third-party photopolymer 3D printers - although PrusaSlicer is open source, support for stereolithographic systems is still limited to branded equipment. At the same time, UVTools allows you to print calibration samples to check the exposure time and other parameters, which can be useful, for example, when working with new photopolymers that have not yet been tested. nine0003

Official website

WebPrinter

A simple browser tool for quick G-code preview, developed by the same team that created the IceSL slicer and 3D editor. The application works very simply: follow the link, upload the file with the G-code and see how the 3D printer will grow the model according to the commands provided. Unfortunately, the functionality is limited: for example, the application does not provide information about temperature settings. On the other hand, you can quickly figure out what kind of model is hidden in a file with an incomprehensible name. nine0003

Official website

Gcode Analyzer

An old but still very capable and popular G-code analysis web application. The 3D simulation doesn't work very well, but the 2D and G-code previews work great. In 2D mode, you can conveniently view individual layers, moving from layer to layer and following the construction path step by step using two sliders. G-code viewer displays a complete list of commands, allowing you to see what a particular line of code is doing. nine0003

Official website

Adapted translation of The Best Free 3D Printing Software of 2022 article.

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability. nine0003

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

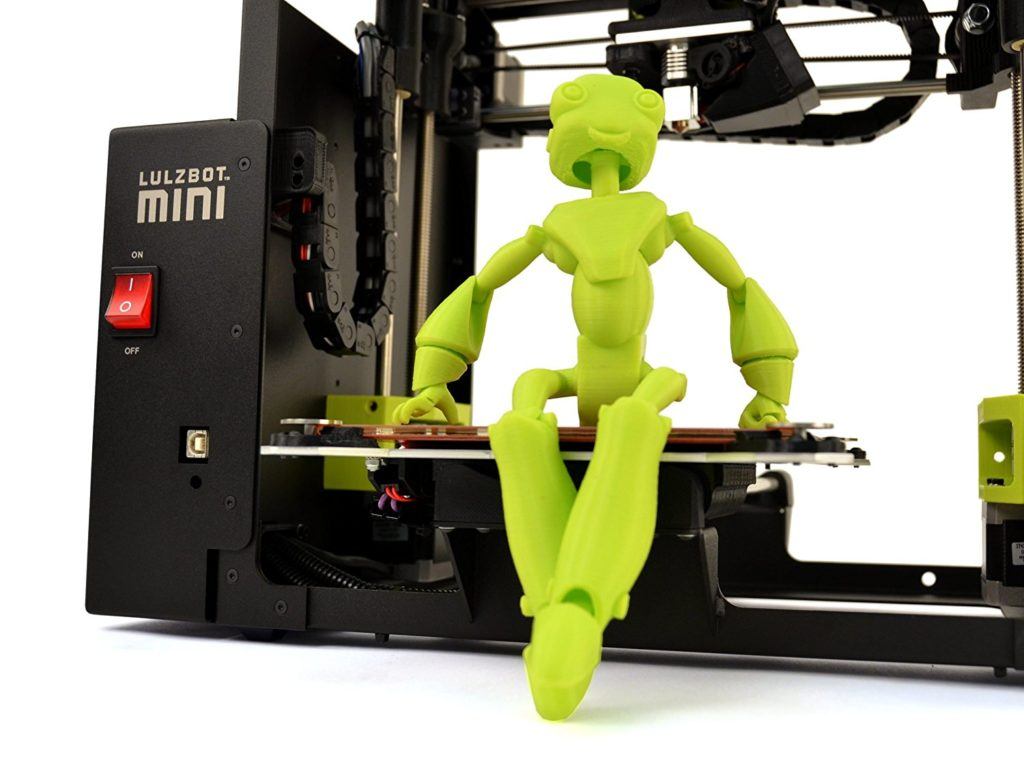

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc. nine0003

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

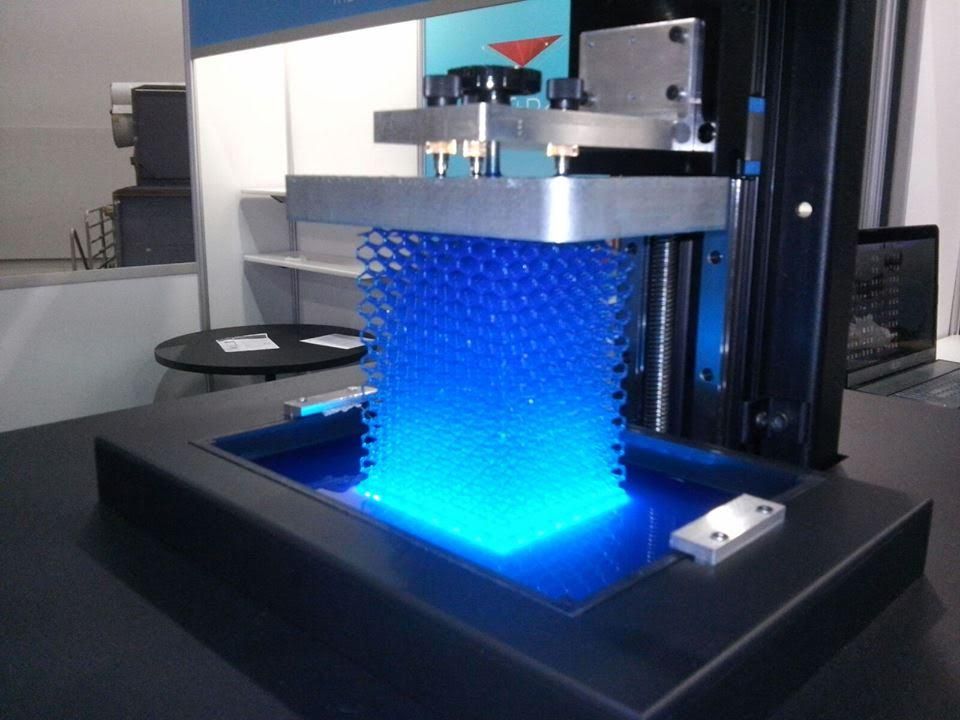

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp. nine0003

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

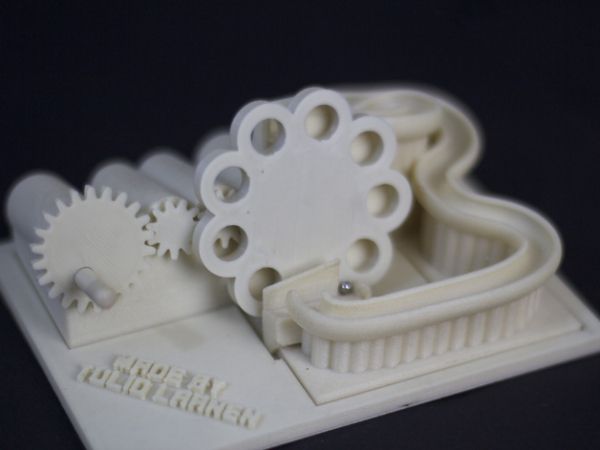

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used. nine0003

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powder materials.

The youngest technology, but with great potential for use in large-scale production. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas. nine0003

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model. nine0003

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive. nine0003

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size. nine0381

Custom Heads for LEGO Men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed. nine0003

3D Printed Chaplain

Chaplain 3D model from Warhammer 40k

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes. nine0003

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail. nine0003

DC Universe Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Weapon Seal

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire. nine0003

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer. nine0003

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a rather weak .380 ACP cartridge and could withstand a maximum of ten shots.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan. nine0003

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip. nine0003

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker. nine0003

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0385

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez. nine0003

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer. nine0003

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle. nine0003

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing. nine0003

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over the classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

nine0384 Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts model and make models and detailed instructions for assembling traction prosthetic hands and fingers publicly available so that any user can print and make a prosthesis at home. nine0003

Simple Traction Hand Model

Production

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer. nine0003

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased. nine0003

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality. nine0003

Prototyping

Gas turbine prototyping.

Prototyping by traditional methods is often time-consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing. nine0003

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.