3D prototype printing services

Custom Online 3D Printing Service

CapabilitiesCustom Online 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Our 3D Printing ServicesMaterialsApplications and BenefitsSizes and TolerancesAbout 3D Printing3D Printing GuideXometry's Online 3D Printing Services: High-Quality Rapid Prototyping and Production Parts

Xometry offers an industry-leading 3D printing service online. Whether you need prototypes or production parts, we can make them for you on demand in as fast as a day. We are your one-stop-shop for accurate, precise, custom 3D printed parts at an affordable price. Upload your 3D CAD file to get an online quote and lead time within seconds. We print everything from single prototypes to thousands of production-grade parts.

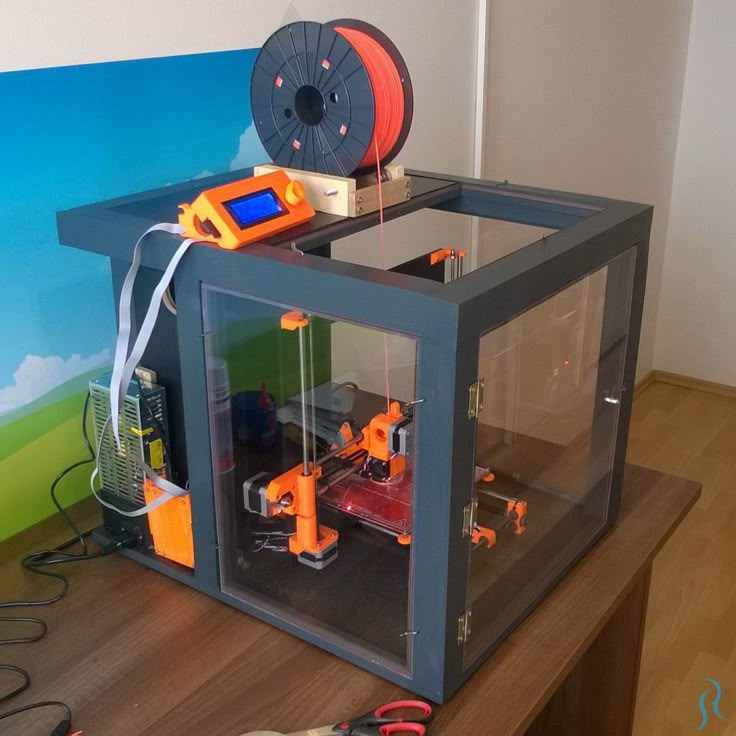

We use the latest additive manufacturing technology to build affordable functional parts in over 60 metals and plastics. Xometry offers eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more. For a great introduction to additive manufacturing, please visit our Complete Guide to 3D Printing.

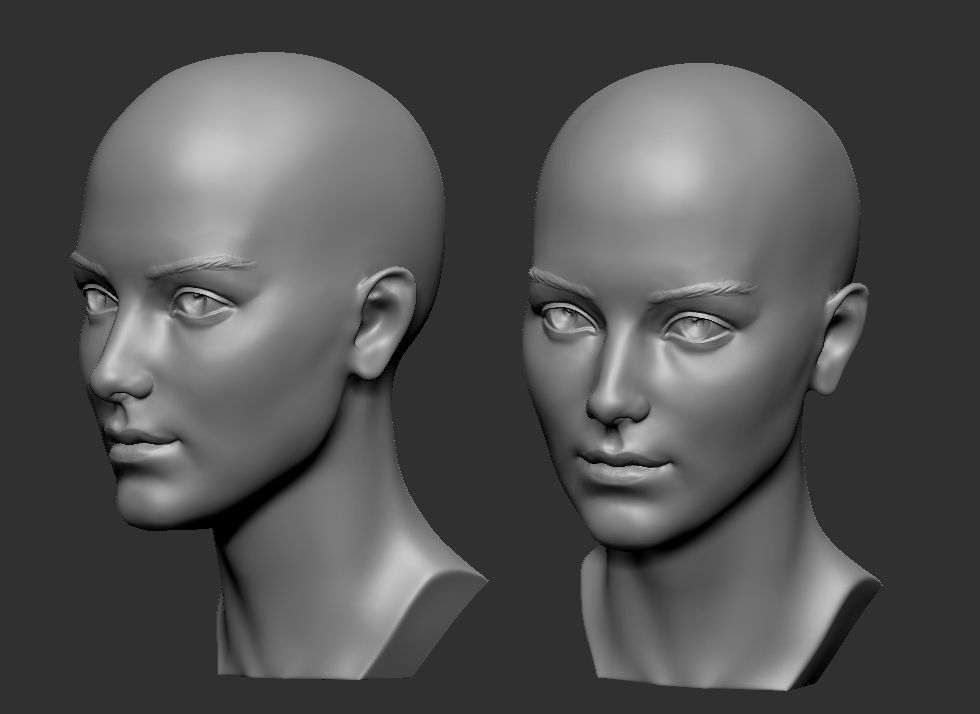

Use the 3D viewer above to preview Xometry’s part rendering features.

Thermoplastic 3D Printing

Selective Laser Sintering (SLS) 3D Printing Service

Upload your CAD file to get instant quotes on SLS parts. Parts ship in days. Free shipping on all US orders.

Selective Laser Sintering (SLS) 3D Printing Service

HP Multi Jet Fusion (MJF) 3D Printing Service

Quality prototypes and production parts. Free shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified.

Free shipping on all US orders. ISO 9001:2015, ISO 13485, and AS9100D certified.

HP Multi Jet Fusion (MJF) 3D Printing Service

Fused Deposition Modeling (FDM) 3D Printing Service

High Quality Large Format FDM 3D Printing Free Shipping on All US Orders

Fused Deposition Modeling (FDM) 3D Printing Service

Thermoset 3D Printing

Stereolithography (SLA) 3D Printing Service

High-Resolution Prototypes in Days Free Shipping on All US Orders

Stereolithography (SLA) 3D Printing Service

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

High-Performing Prototypes and Serialized Production Parts Free Shipping on All US Orders

Carbon Digital Light Synthesis™ (DLS™) 3D Printing Service

PolyJet 3D Printing Service

Prototypes, color concept models, and simulated overmold parts in days Free shipping on all US orders

PolyJet 3D Printing Service

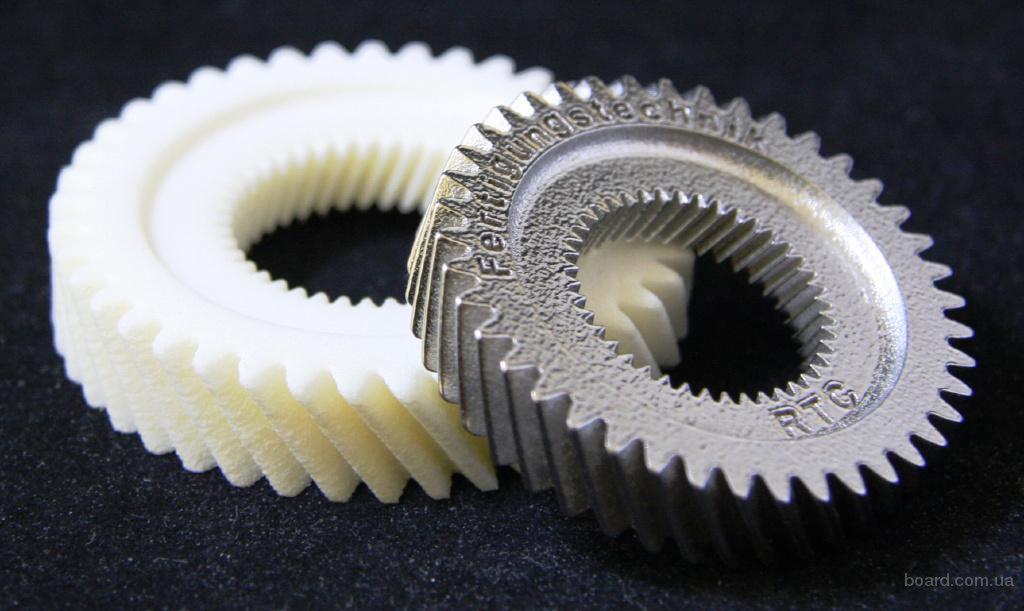

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Upload your CAD files to get an instant quote on metal prototypes and production parts. Free shipping on all US orders.

Free shipping on all US orders.

Direct Metal Laser Sintering (DMLS) 3D Printing Service

Metal Binder Jetting 3D Printing Service

Upload your CAD files to get an instant quote on parts. Free shipping on all US orders.

Metal Binder Jetting 3D Printing Service

Get flexible payment options for the parts your business needs.

The Best 3D Printing Material Selection

Durable Nylon

Nylon is one of the most versatile options for 3D printing with great feature detail and performance.

ABS and ASA

ABS and ASA 3D prints have a variety of colors and are a staple to 3D printed plastics.

ULTEM 9085 and ULTEM 1010

Tough, heat resistant, and durable ULTEM is engineered to withstand the most rigorous environments.

Elastomers and Rubber-like Materials

3D printed TPE and silicone-based elastomers give rubber parts without the need for tooling.

Metal 3D Prints

3D printed metal parts can achieve complex geometries without a sacrifice in performance.

Multi-Material Parts

PolyJet 3D can combine multiple properties in a single print for overmolds and other cosmetic features.

Materials for all Applications

Xometry has the widest variety of industrial 3D custom printing materials available for instant quoting.

Flame Retardant Plastic 3D Printing

Xometry's 3D Print Service offers a variety of polymers that are flame retardant and qualify for UL-94 V-0 and FAR 25.853 60 second burn test. This includes FDM ULTEM 9085, FDM ULTEM 1010, and SLS Nylon 12, Flame Retardant. These polymers are perfect for aviation and aerospace applications. Learn more about 3D Printed Flame Retardant Plastics.

Ready to start making custom 3D printed parts?

Free shipping on all 3D printing orders!

Applications of 3D Printing

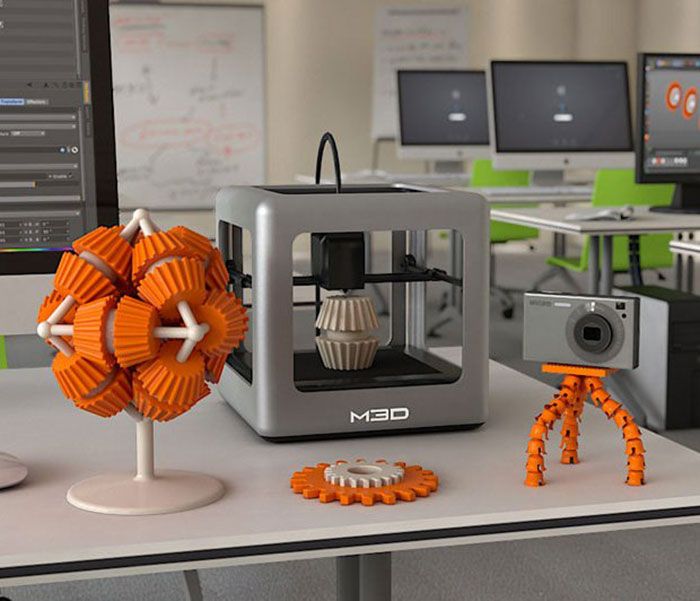

Concept Models

The speed and versatility of 3D Printing lets product developers create physical snapshots of their designs through the iterative process.

Rapid Prototyping

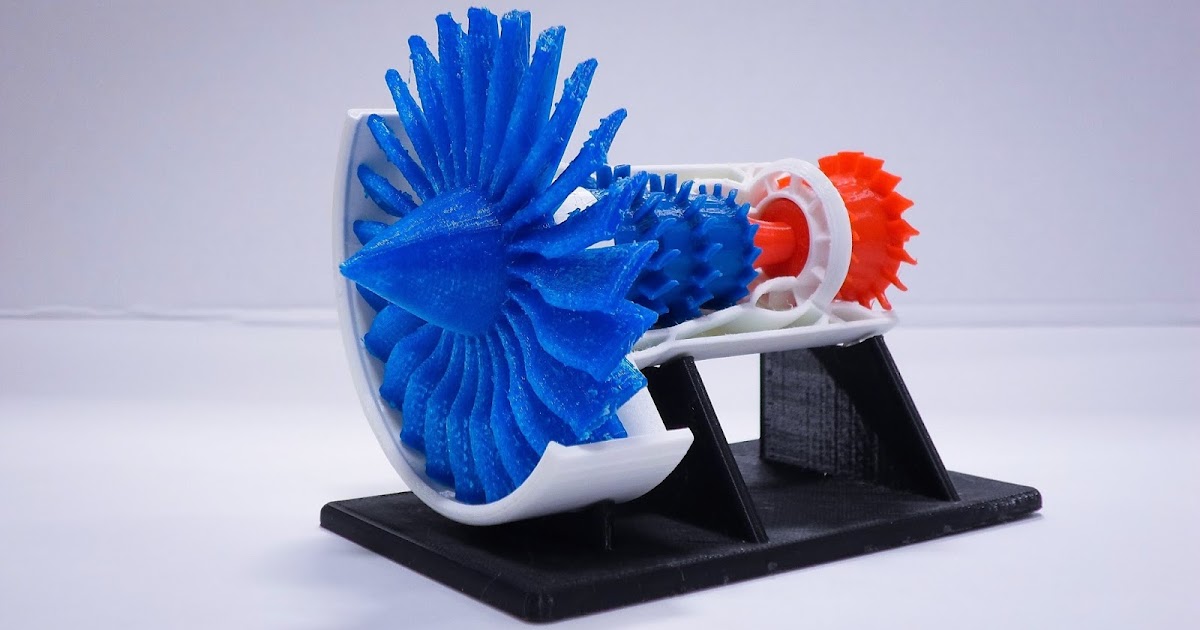

3D Printing can be used to create fully-functional prototypes, complete with moving parts, as well as all-in-one assemblies.

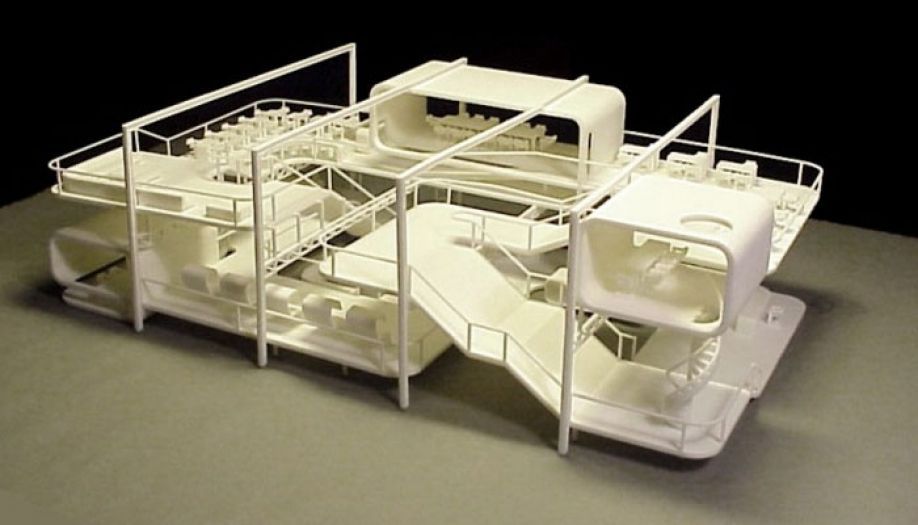

Direct Digital Manufacturing

The high accuracy and consistency of 3D printing makes it an ideal way to build production quantities of discrete or customized parts.

Advantages of 3D Printing

Rapid Turnaround

Parts can typically be shipped in as little as 1 day, allowing for faster design iterations and speed to market.

Durability

3D printing can offer great impact strength, medium flexibility, and high resistance to environmental factors.

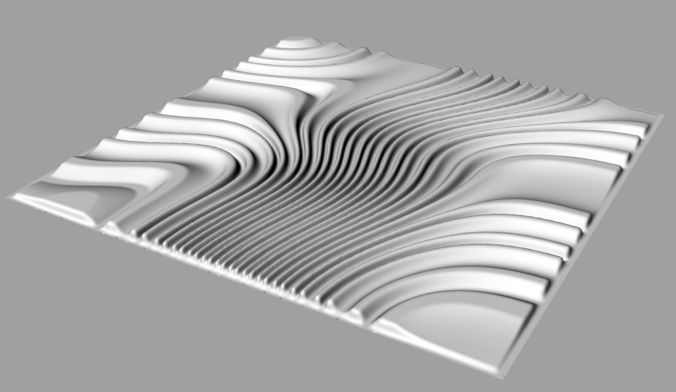

Complex Geometry

Geometries can be built more easily due to the 3D printing process, adding complexity without additional cost.

Precision

3D printing can achieve precise parts and feature details.

Part Production

3D printing with Xometry helps you produce end-use parts on-demand, increasing throughput.

Scalability

With 3D printing, you can make a single part or component as easily as dozens of production pieces.

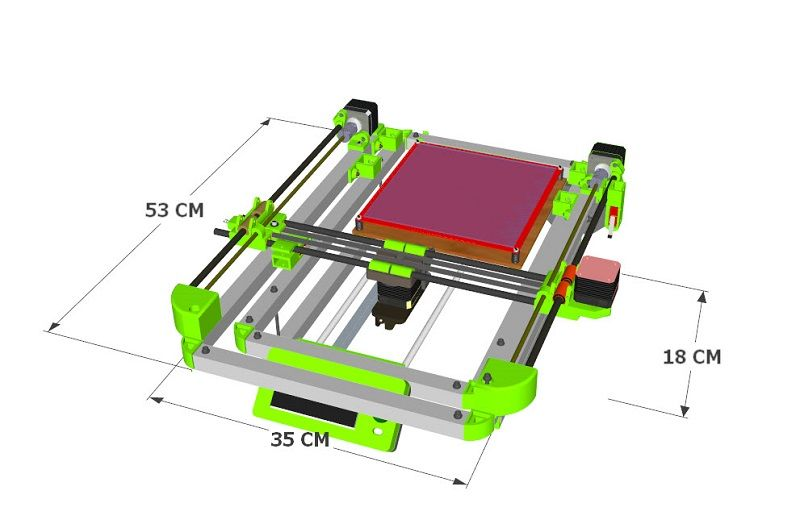

3D Printing General Tolerances

General Guidelines when Designing for 3D Printing

| Description | Tolerance Notes |

|---|---|

Description Part Size | Tolerance Notes Xometry can accommodate 3D printing up to 24" x 36" x 36" without the need to split and bond parts. |

Description Minimum Feature Size | Tolerance Notes 0.030" - 0.060" is typical. |

Description Minimum Wall Thickness | Tolerance Notes 0.020" - 0.060" is typical. |

Description Clearance Between Features | Tolerance Notes At least 0.030" |

General tolerances apply before secondary finishing or post-processing unless otherwise specified. Please check out Xometry's Manufacturing Standards for more information on tolerances per process.

What is 3D Printing?

What is 3D Printing?

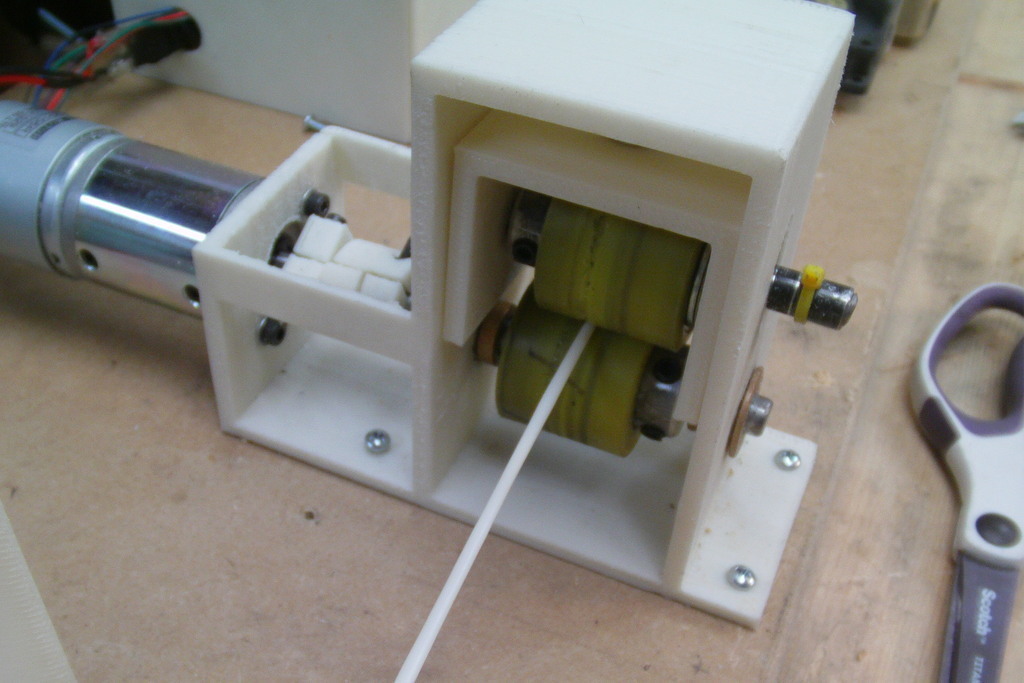

3D printing is an additive manufacturing process where materials are joined together to make objects from 3D model data (CAD). Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Typically, 3D printing is a layer-by-layer process where part geometries are “grown,” fusing with the previous layer. 3D printing processes can build objects in plastics, photopolymers, reaction polymers, composites, metal, glass, and other materials.

Instant Quote Demo

See how fast and simple it is to get a quote for 3D printing using the Xometry Instant Quoting Engine®.

Why Choose Xometry for 3D Printing?

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

We are ISO 9001:2015, ISO 13485 and AS9100D certified.

Become an additive expert with our Complete Guide to 3D Printing

3D Printing Services Available at Xometry

Bronze 3D Printing Service

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Bronze 3D Printing Service

Color 3D Printing Service by Xometry

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Color 3D Printing Service by Xometry

Large Scale 3D Printing Service on Xometry

Get instant online quotes on large scale 3D printed parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Large Scale 3D Printing Service on Xometry

Rubber 3D Printing Service on Xometry

Get instant online quotes on parts in over 70 metal and plastic materials. Free shipping on all US orders. ISO 9001:2015, ISO 13485 and AS9100D certified.

Rubber 3D Printing Service on Xometry

3D Printing Services Near You

AlabamaArizonaArkansasCaliforniaColoradoConnecticutDelawareFloridaGeorgiaIdahoIllinoisIndianaIowaKansasKentuckyLouisianaMaineMarylandMassachusettsMichiganMinnesotaMississippiMissouriMontanaNebraskaNevadaNew HampshireNew JerseyNew MexicoNew YorkNorth CarolinaNorth DakotaOhioOklahomaOregonPennsylvaniaRhode IslandSouth CarolinaSouth DakotaTennesseeTexasUtahVermontVirginiaWashingtonWest VirginiaWisconsinWyoming

Rapid Prototyping Services by Sculpteo and 3D Object Prototyping

If you are working on a new product or refining an existing one, rapid prototyping is ideal to test, iterate and adjust your concept. This is a way to speed up your designing process and bring your ideas and product to market faster.

This is a way to speed up your designing process and bring your ideas and product to market faster.

Do you need parts as quickly as possible to validate a project? We will manufacture your parts immediately in our factory-certified ISO 9001.

- ISO 9001

- Fast Turnaround

- Secure File Upload

Rapid prototyping: A quick and efficient way to give life to your ideas

Rapid prototyping allows you to create a physical model of your product or design a concept quickly and efficiently. 3D printing offers a range of technologies and materials adapted to rapid prototyping. You can then test and validate your ideas before committing to full-scale production. 3D Printing is the shortest path between your ideas and a functional prototype in your hands and it can be used at each stage of your manufacturing process. More specifically, 3D printing can be a strong ally at the early stages of your product development. With 3D printing technologies, make as many iterations as needed with a great precision and speed up your prototyping process.

More specifically, 3D printing can be a strong ally at the early stages of your product development. With 3D printing technologies, make as many iterations as needed with a great precision and speed up your prototyping process.

Benefit from the flexibility of Additive Manufacturing for your prototyping process!

3D Printing is the shortest path between your ideas and a functional prototype in your hands. 3D printing can be a strong ally at the early stages of your product development.

Prototype and iterate with Stereolithography (SLA), Selective Laser Sintering (SLS), or Fused Deposition Modeling (FDM) technologies.

Sculpteo was the partner we needed for producing Tundra, being able to 3D print parts made it possible to create a customizable drone. Our partnership with Sculpteo was an essential part in the creation of this machine.

Alexandre Labesse Hexadrone CEO

3D printing gives us the ability to get our parts quickly, compared to other manufacturing techniques. We can also manufacture complex parts with a finished appearance, which could not be machined. We have been working with Sculpteo since 2014 and the quality keeps improving. Our contacts with the team are regular in order to find the best compromises regarding our needs.

We can also manufacture complex parts with a finished appearance, which could not be machined. We have been working with Sculpteo since 2014 and the quality keeps improving. Our contacts with the team are regular in order to find the best compromises regarding our needs.

Nicolas RigauxMechanical engineer at Microfilms

At the small scale of the cargo projects we run, 3D printing is the only economical production method for the geometries we need. Using Sculpteo’s service allows us to produce a much more professional quality product than we could achieve in-house, at a much lower time investment.

Jürg GermannHead of Engineering at WeRobotics

We are always looking for performance for our robots, and this fundamentally involves reducing the weight of the various fittings linked to the robots such as their grippers. 3D printing is a solution for us to combine performance, rigidity and mass of these assemblies. We have been working with Sculpteo for 4 years, the quality of the prints has always been very satisfactory and the proximity of our account manager allows us to save time and improve our performance in the realization of our projects.

We have been working with Sculpteo for 4 years, the quality of the prints has always been very satisfactory and the proximity of our account manager allows us to save time and improve our performance in the realization of our projects.

Anthony MOUTEAU Designer / SAS I.D.E.C

3D printing is an opportunity to easily reproduce the structure of a robot. More and more robots are being produced thanks to 3D printing. Additive manufacturing is a long-term trend for the robotic market, just as it is for aeronautic and automobile businesses

Jérôme LAPLACEDirector, Génération Robots / HumaRobotics

Previous

Next

500 +

Parts printed per day

1000 +

Happy customers each year

0 +

Technologies and finishes

0 +

Industrial 3D Printers

Order your 3D printed parts in just a few clicks!

Upload 3D file30+ File formats accepted

Review PrintabilityAutomatic file analysis and repair

Instant Quote75+ material and finishing combinations

Receive Your PartsShipped to your door in just a few days

CUSTOMER STORY

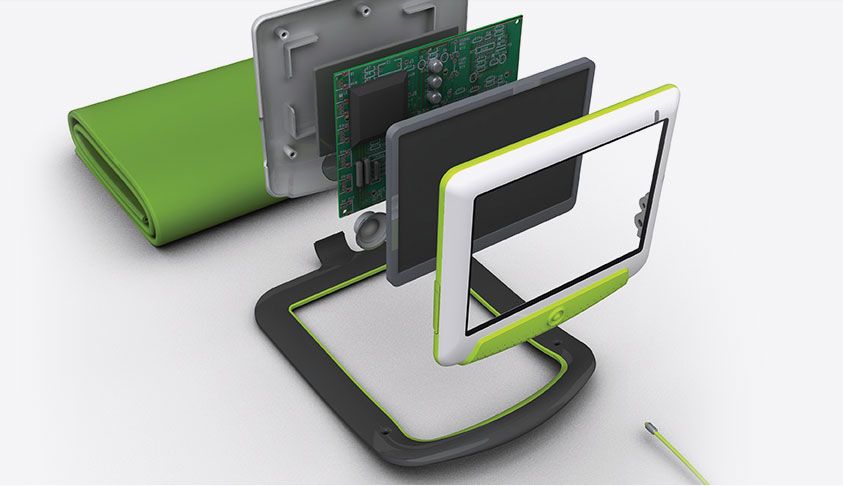

Koovea is a startup based in Montpellier, south of France, specializing in connected temperature monitoring for the logistics of temperature-sensitive products. Their challenges? Develop rapidly a sensor resistant to extreme temperatures and respond to their client’s needs faster by offering customized versions of their products.

Their challenges? Develop rapidly a sensor resistant to extreme temperatures and respond to their client’s needs faster by offering customized versions of their products.

Read more >

Materials Adapted To Prototyping

Benefit from an extensive catalog of 3D printing technologies, from Stereolithography to Selective Laser Sintering and HP Multi Jet Fusion. Using our online 3D printing service, you will access cost-effective and accurate 3D printing materials to give life to your proofs of concept and functional prototypes. Powder-based or resin options are available for your RP process.

Reasons to use 3D printing for rapid prototyping

Rapid prototyping with 3D printing will help you bring your project to the next level in no time, bringing your ideas to reality efficiently and reliably. Benefit from the rapid prototyping tools offered by additive manufacturing:

It can take months to create a prototype using traditional manufacturing techniques, which is quickly becoming expensive for your business. With rapid prototyping and 3D printing, it only takes days, which is a saving you time and money in the long run.

With rapid prototyping and 3D printing, it only takes days, which is a saving you time and money in the long run.

- Flexibility

Since you’re not committing to a large-scale production run, you can make changes and iterations easily. Flexibility is an incredible advantage when working on complex and innovative products requiring testing.

- Testing

Creating a physical model allows getting a better sense of your product, how it will look and how it will function. This is a way to get the feedback needed about your product. Making high-fidelity prototypes is a crucial step to making adjustments or improvements and making the perfect product meeting your needs and requirements.

- Cost-effectiveness

By catching mistakes early, and iterating in a reactive way, you will speed up the process and save money. Rapid prototyping with additive manufacturing is a cost-effective way to prototype your ideas.

Rapid prototyping with additive manufacturing is a cost-effective way to prototype your ideas.

Start your rapid prototyping process today with Sculpteo

Choose a prototyping partner with short lead times and experienced advice using our innovation-oriented point of view. Sculpteo is dedicated to helping you succeed and using additive manufacturing in a way adapted to your business's needs.

With 10+ years of expertise in additive manufacturing for production and prototyping, Sculpteo also offers rigorous quality control. With our online 3D printing service and our advanced platform, you get professional 3D printing at your fingertips. Create a free account, upload your 3D files, select your material, technology, and post-processing options, and order online.

We'll take care of the rest in our industrial ISO 9001 factory.

Stop wasting time, start your rapid prototyping process now

Prototypes are an essential step in your product development. Before a more costly step of production, you need to evaluate the design and functionality of your product. An excellent rapid prototyping technique is just what you need! Rapid prototyping allows engineers and designers to manufacture and test their products faster and iterate as much as necessary. Whether to create a scale model of a physical part to validate the shape or its visual aspect, try out an assembly, or build functional features and test them, rapid prototyping will help you achieve your goals in time. Some game-changing technologies, such as additive manufacturing, allows you to create your high-fidelity prototypes,

Before a more costly step of production, you need to evaluate the design and functionality of your product. An excellent rapid prototyping technique is just what you need! Rapid prototyping allows engineers and designers to manufacture and test their products faster and iterate as much as necessary. Whether to create a scale model of a physical part to validate the shape or its visual aspect, try out an assembly, or build functional features and test them, rapid prototyping will help you achieve your goals in time. Some game-changing technologies, such as additive manufacturing, allows you to create your high-fidelity prototypes,

concept models and functional prototypes with an excellent surface finish. Additive manufacturing technology can become your true ally, for all kinds of applications with advanced technologies such as SLS, MJF, Binder Jetting, Polyjet and other technologies. Get rid of the disadvantages of manufacturing technologies such as CNC machining and benefit from the flexibility you deserve to grow your projects.

Additive manufacturing can boost your company, not only thanks to rapid prototyping. Discover how you could benefit from a more scalable, flexible, and resilient manufacturing process for prototyping and production.

What is design for additive manufacturing (DfAM), and what are the benefits? We are going to see how this design could be a real asset for your business.

3D printing prototypes: what are the advantages? Discover how 3D printing can help you develop advanced prototypes thanks to a large variety of materials.

How to identify 3D printing opportunities for your business? Find out our 10 best tips and see how 3D printing could be a great asset for your business!

What are the advantages of rapid prototyping?

Rapid prototyping reduces design and time development, which leads to a reduction in product development costs. This is also offering more room for iteration and testing. Rapid prototyping has a beneficial impact on your overall manufacturing process.

This is also offering more room for iteration and testing. Rapid prototyping has a beneficial impact on your overall manufacturing process.

Is rapid prototyping the same as 3D printing?

Rapid prototyping is allowed by manufacturing techniques such as 3D printing. Rapid prototyping is the technique to create a prototype model from a 3D model. We can say that additive manufacturing is the process, and rapid prototyping is the end result.

Where is rapid prototyping used?

Rapid prototyping can be used by everyone, and by every kind of industry. Moreover, rapid prototyping can be used at any stage of the product development cycle for any product.

Moreover, rapid prototyping can be used at any stage of the product development cycle for any product.

Printing of ABS (ABS) plastic using FDM technology to order

Printing of ABS (ABS) plastic using FDM technology to orderPrinting ABS (ABS) with plastic using FDM technology to order

Technology: 3D PRINT

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Price

no more than 12 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 25 o/cm 3

Cost for processing

+ 50 o for processing 1 item

Printing time

We print on the day of order*

Calculate the cost

Price

no more than 25 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

+ 500 o for processing 1 item

Printing time

from 5 to 7 days

Calculate the cost

Price

no more than 25 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 12 o/cm 3

Cost per treatment

+ 50 o for processing 1 item

Printing time

from 1 to 3 days

Calculate the cost

Price

no more than 70 o/cm 3

Processing cost

+ 500 o for processing 1 item

Printing time

from 5 to 7 days

Calculate the cost

Price

no more than 25 o/cm 3

Cost per treatment

+ 50 o for processing 1 item

Printing time

We print on the day of order*

Calculate cost

Need an alternative?

More accurate

Photopolymer

Higher quality

Polyamide

Beneficial for series production

Molding plastic into silicone

Feedback form for calculating the cost of 3D printing

If you have a finished 3D model, upload it to the online form to calculate the cost of 3D printing.

If you do not have a 3D model or need a preliminary consultation, contact us by phone +7 (499) 390-03-77, send a 3D model with questions to our mail [email protected] or fill out an application, we will contact you and answer all your questions.

Fields marked with an asterisk (*) are required

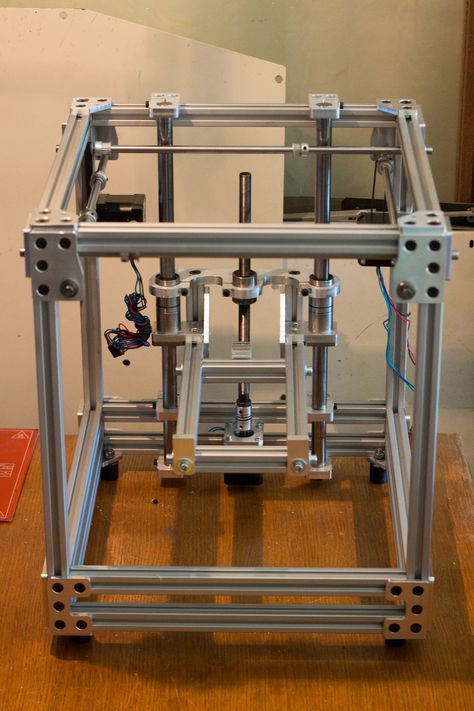

SLS printing with polyamide on a custom 3D printer

SLS printing with polyamide on a custom 3D printerSLS printing with polyamide on a 3D printer to order

Technology: 3D PRINT

Loading ...

Loading ...

Loading . ..

..

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Loading ...

Price

from 99 o/cm 3

Cost per treatment

+ 50 o for processing 1 item

Printing time

from 3 to 7 days

Calculate the cost

Price

Considered individually

Processing cost

Calculated individually

Printing time

from 10 to 15 days

Calculate the cost

Price

from 99 o/cm 3

Processing cost

+ 50 o for processing 1 item

Printing time

from 3 to 7 days

Calculate the cost

Price

Considered individually

Processing cost

Calculated individually

Printing time

from 10 to 15 days

Calculate the cost

Need an alternative?

More accurate

Photopolymer

Cheaper

ABS

Beneficial for series production

Molding plastic into silicone

Feedback form for calculating the cost of 3D printing

If you have a finished 3D model, upload it to the online form to calculate the cost of 3D printing.