3D printed gun site

3D-printed guns are back, and this time they are unstoppable

Jake Hanrahan

Business

A decentralised network of gun-printing advocates is mobilising online, they're anonymously sharing blueprints, advice and building a community. There's no easy way they can be halted

A new network of 3D-printed gun advocates is growing in America – and this time things are different. Unlike previous attempts to popularise 3D-printed guns, this operation is entirely decentralised. There’s no headquarters, no trademarks, and no real leader. The people behind it reckon that this means they can’t be stopped by governments.

“If they [the government] were to come after me, they’d first have to find my identity,” says Ivan the Troll, a member of the group. “I’m one of many, many like-minded individuals who’re doing this sort of work.”

Known only by his online moniker, Ivan the Troll is the de facto spokesman of an underground wave of 3D-printing gunsmiths. Ivan says he knows of at least 100 people who are actively developing 3D-printed gun technology, and he claims there are thousands taking part in the network. This loose-knit community spans across the whole world.

They communicate across several digital platforms, including Signal, Twitter, IRC, and Discord. They critique each other's work, exchange 3D gun CAD files, offer advice, talk theory, and collaborate on future blueprints. These 3D-printed gun enthusiasts – who share similar ideas and political viewpoints on gun control – mostly found each other online via gun control subreddits and forums.

Ivan is just one small part of this network. He says he is from Illinois, and is of “college age”, but otherwise he remains mostly anonymous, to lie low. At the same time though, he’s launched bombastic PR videos demonstrating the new 3D-printed gun parts he’s created in his garage, including a Glock 17 handgun frame.

One of his most recent videos shows the polymer Glock 17 frame in various stages of production in his workshop. The footage is set to fast-paced synthwave music and is run through a trendy VHS filter – the aesthetics are important. Toward the end, Ivan fires several rounds with the fully built handgun, as text flashes up saying “ANYONE CAN MAKE IT”, “LIVE FREE OR DIE”, and “GO AHEAD TRY TO STOP THIS YOU FILTHY STATISTS”. He’s also uploaded the complete CAD reference model designs for a 3D-printed AR-15 assault rifle to his file-sharing space online. It’s clear Ivan is trying to provoke his detractors as much as possible.

In February of this year, Ivan and his group decided to name themselves “Deterrence Dispensed”, which is a tongue-in-cheek nod to the notorious Defence Distributed – a 3D-printing gun company formerly run by Texan crypto-anarchist Cody Wilson.

Most Popular

In September 2018, Wilson, 30, was arrested and charged with sexual assault against a minor. He is alleged to have paid $500 to have sex with a 16-year-old girl in his home city of Austin, Texas. Needless to say, this arrest effectively took Wilson out of the 3D-printed gun world entirely. Many of the people who looked up to him were either disgusted or realised that his time was up. He stepped down from Defence Distributed, which was before seen as the driving force behind 3D-printed guns since it launched in 2012. Wilson was released on a $150,000 bail, but has remained silent since.

He is alleged to have paid $500 to have sex with a 16-year-old girl in his home city of Austin, Texas. Needless to say, this arrest effectively took Wilson out of the 3D-printed gun world entirely. Many of the people who looked up to him were either disgusted or realised that his time was up. He stepped down from Defence Distributed, which was before seen as the driving force behind 3D-printed guns since it launched in 2012. Wilson was released on a $150,000 bail, but has remained silent since.

Defence Distributed has many other ongoing legal battles. Attorney generals from more than 20 US states are currently in the process of suing the company – which has countersued – in a bid to reverse a court win that momentarily allowed Defence Distributed to upload and share 3D-printed gun blueprints online. Their headaches are long, drawn out, and ongoing. (New York State has just passed a law to ban 3D-printed guns).

For Ivan’s group, Deterrence Dispensed, none of this is relevant. They’re uploading these files individually on services such as Spee.ch, a media-hosting site underpinned by the LBRY blockchain, and they aren’t waiting for anyone to give them permission. They’ve made their own 3D-printed gun designs, modified old ones, and are keeping all the Defence Distributed ones available for free too.

They’re uploading these files individually on services such as Spee.ch, a media-hosting site underpinned by the LBRY blockchain, and they aren’t waiting for anyone to give them permission. They’ve made their own 3D-printed gun designs, modified old ones, and are keeping all the Defence Distributed ones available for free too.

“Even if there was no government telling me I couldn’t do this, I think that I would still do it,” Ivan says. “Some people get a kick out of video games, I like spending hours and hours drawing stuff on CAD.”

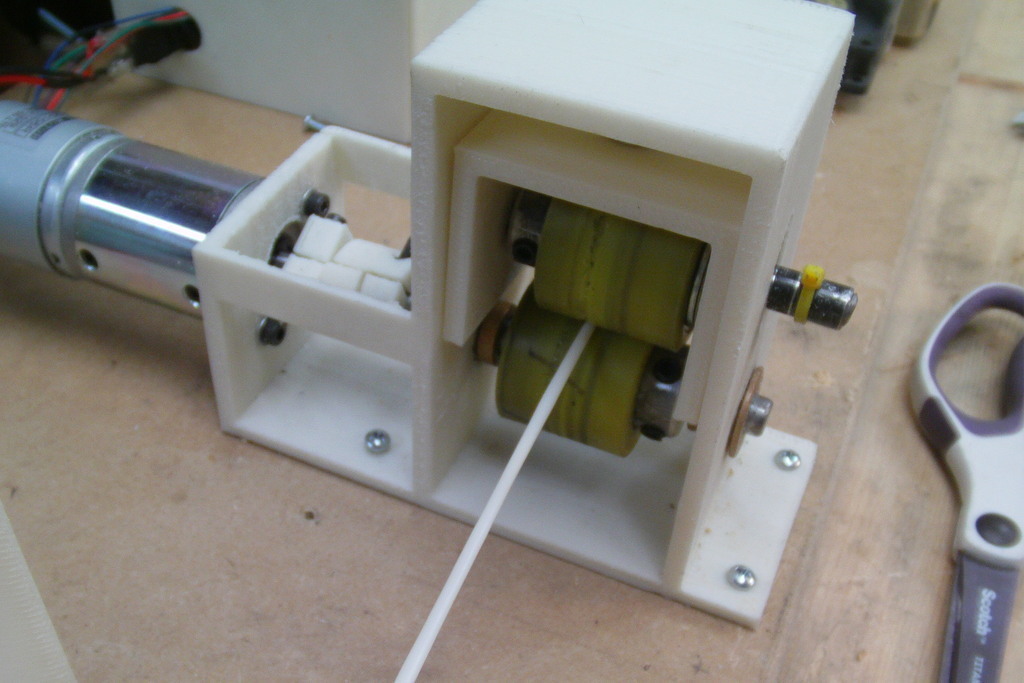

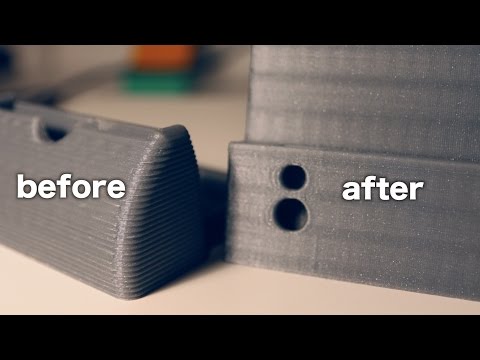

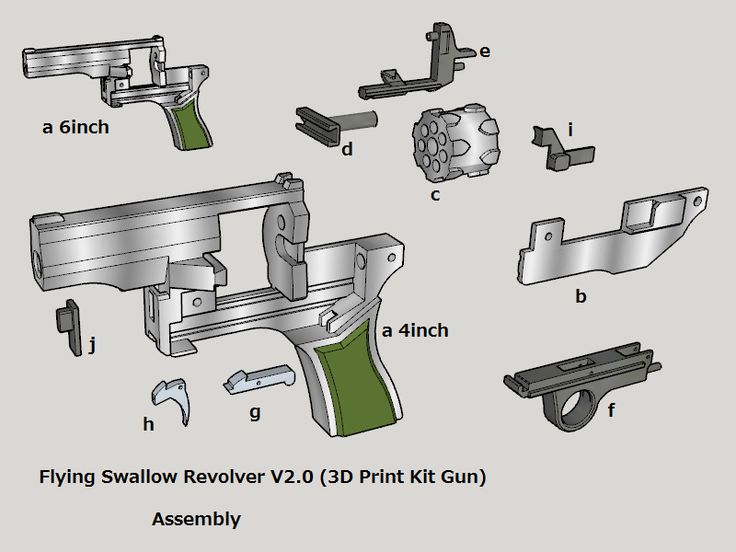

Ivan isn’t just “drawing stuff on CAD” though. He’s providing free files to help anyone with a half-decent FDM (Fused Deposition Modeling) 3D printer and some hand tools to make a workable handgun. Once the CAD file is downloaded, it’s opened in a “slicer” program that translates the CAD files into instructions that the 3D printer can understand. Once the 3D-printed gun parts are ready, they can be assembled into a fully workable gun.

The CAD gun designs put out by Deterrence Dispensed are so well-made, according to Ivan, that they’re not just “workable”, but superior. “Our AR15 CAD model is the best in the public domain without a doubt,” says Ivan.

“Our AR15 CAD model is the best in the public domain without a doubt,” says Ivan.

Most Popular

Despite being overtly antagonistic Ivan has had no real run-ins with the authorities so far. His Twitter account was permanently suspended after New Jersey state senator Bob Menendez lobbied for it to be taken down, but as far as the government and law enforcement goes, things have been mostly quiet.

Ivan sees himself, and other radical 3D-printing gun groups such as FOSSCAD (another decentralised group of 3D-printing enthusiasts who focus on firearms), simply as hobbyists who’ve chosen the “wrong” thing to build. He sees 3D-printed guns as somewhat of a paper tiger. He points out that while 3D-printed gun parts can be built to kill people, zip guns (homemade firearms built from crude materials) have been around for decades and are arguably more deadly. The hysteria and backlash, to Ivan at least, is completely misplaced.

“Take it from me as someone who’s printed a gun. Making a slam-fire shotgun is 100 times easier, 100 times quicker, and about 100 times cheaper than printing a [regular] gun. For eight dollars I can pop down to Home Depot and build a shotgun.”

Making a slam-fire shotgun is 100 times easier, 100 times quicker, and about 100 times cheaper than printing a [regular] gun. For eight dollars I can pop down to Home Depot and build a shotgun.”

Already in 2019, 156 people have already been killed in US mass shootings, and gun-related deaths are at a 20-year high. In March, a terrorist armed with two semi-automatic rifles and two shotguns killed 51 people in an anti-muslim attack in Christchurch, New Zealand. In such circumstances, do the US (and the world) really need more guns – zip gun, 3D-printed, or otherwise? Ivan thinks yes.

“The cops killed more people alone last year than all active shooter incidents in the last ten years,” he says. “We live in a society, in America, where you run the risk of a cop blowing your ass up for no specific reason. You don’t even have to present a threat to them. A cop can kill you and get away with it just because he really wanted to do it.”

He then went on to cite the many police shootings of unarmed black men in American, specifically mentioning Stephon Clark. Clark, 22, was shot to death by police in his own back garden while holding nothing but a mobile phone. “I believe it is inherently important that … you should be able to own a gun,” Ivan continued. “You should be able to own the same legal force that the cops are using to control you.”

Clark, 22, was shot to death by police in his own back garden while holding nothing but a mobile phone. “I believe it is inherently important that … you should be able to own a gun,” Ivan continued. “You should be able to own the same legal force that the cops are using to control you.”

Most Popular

But the facts are clear. The majority of gun deaths around the world come from just six countries – one of which is the US. And analysis from Harvard University shows where there are more guns, more murders happen.

Anti-gun campaigners, obviously, disagree with the notion of a downloadable gun. Avery Gardiner, the co-president of the Brady Campaign, has said 3D-printed guns present a "supreme threat to our safety and security". Speaking after a court decision in August Gardiner said: "Already, there have been a wave of dangerous actors seeking to illegally post the blueprints online".

A mix of a libertarian attitude and the rewarding hobby aspect of designing and creating something is often what drives members of these decentralised 3D-printed gun networks to do what they do – that is, uploading schematics, sharing them, improving designs, and making 3D-printed gun work more easily accessible while remaining largely under the radar. Ivan claims he does this for a love of freedom and “radical” belief in the US first and second amendment: free speech and the right to bear arms.

Ivan claims he does this for a love of freedom and “radical” belief in the US first and second amendment: free speech and the right to bear arms.

He takes this to such a radical degree though, that he even theorises he should technically be able to have his own Tomahawk Missiles, saying that they would be safer in his hands than in those of the US Military and its allies – given the country's track record for accidentally targeting civilians, including a wedding party in Afghanistan and a school bus in Yemen.

Referring to the mounting list of civilian killings carried about by US forces in foreign wars, Ivan sounds at times more like a radical leftist than the right wing “gun nut” many in America label him as. He claims not to have any specific ideology though, saying: “I get to be my own special snowflake.”

As of now, Ivan the Troll, Deterrence Dispensed, and the thousands many more 3D-printed gun enthusiasts connected to each other worldwide, have essentially let the cat out the bag. There is no way to stop the anonymous file sharing of 3D-printed guns online. Whether they’re just pretending to be doing this for reasons of liberty or otherwise, their message is clear: it’s already too late to stop.

There is no way to stop the anonymous file sharing of 3D-printed guns online. Whether they’re just pretending to be doing this for reasons of liberty or otherwise, their message is clear: it’s already too late to stop.

More great stories from WIRED

– Why parents should stop worrying about videogame addiction

– Why are we having less sex? Blame honesty

– Jeff Bezos wants to colonise space, but he's destroying Earth

– Why staff on the autism spectrum are a huge asset

– Why Tim Cook is a better Apple CEO than Steve Jobs

TopicsEngineeringPolitics

More from WIRED UKSecurity

Ring Is in a Standoff With Hackers

Plus: A SpaceX supplier ransom, critical vulnerabilities in dozens of Android phones, and more.

By Matt Burgess

Science

No One Knows If Decades-Old Nukes Would Actually Work

Atomic weapons are highly complex, surprisingly sensitive, and often pretty old. With testing banned, countries have to rely on good maintenance and simulations to trust their weapons work.

With testing banned, countries have to rely on good maintenance and simulations to trust their weapons work.

By Chris Baraniuk

Science

Russia Is Powering Up a Giant Laser to Test Its Nukes

To check that atomic weapons work, scientists run simulations of explosions using high-energy lasers—and Russia is building the strongest one of all.

By Andy Extance

Business

Conspiracy Theorists Are Coming for the 15-Minute City

A movement to promote neighborhoods with amenities within walking distance has enraged far-right activists, climate deniers, and extremists.

By Peter Guest

3D Printed Guns Archives - 3DPrint.com

OUTLAW3D: 3D Printing Fake Number Plates in Australia

License plate cloning is not uncommon. This type of vehicle identity theft which involves copying a car’s registration number and assigning it to another vehicle is typically used for illegal…

This type of vehicle identity theft which involves copying a car’s registration number and assigning it to another vehicle is typically used for illegal…

February 27, 2023 by Vanesa Listek

3DPrint.com’s Top 10 Stories of 2022

Surely like nearly every website, 3DPrint.com performs regular reports on traffic behavior and the like. And, like the rest of the internet, our most popular stories are generally the ones…

December 29, 2022 by Michael Molitch-Hou

Club Q Suspect May Have Explored 3D Printed Gun Parts in 2021, Relatives Say

In a new turn of events, the story behind the November 19, 2022 Club Q shootings that left five dead and 25 injured is becoming increasingly complicated. Now, an El…

December 14, 2022 by Vanesa Listek

Man Gets $21,000 for 3D Printed Guns in NY — What Does it Mean for Gun Buybacks?

Gun buybacks are turning into the perfect opportunity to sell 3D printed guns and gun parts. In the last several months, there have been such events in Philadelphia, Raleigh, Michigan,…

October 12, 2022 by Vanesa Listek

Law Enforcement in Australia, Spain, U.

S. and Canada Continue Targeting 3D Printed Guns

S. and Canada Continue Targeting 3D Printed Guns Earlier this year, a report by the Dutch police revealed signs that 3D printed guns were on the rise; then, the first International Conference on 3D Printed Firearms took place…

August 31, 2022 by Vanesa Listek

New US Federal Rule Treats 3D Printed Guns Like Any Other Firearm

In April 2022, President Biden expressed his determination to crack down on ghost guns, promising that “if you commit a crime with a ghost gun, expect federal prosecution.” Now, a…

August 30, 2022 by Vanesa Listek

3D Printing News Briefs, March 12, 2022: 3D Printed Car Parts, Heat Exchangers, & More

In today’s 3D Printing News Briefs, a Volkswagen subsidiary has invested in an SLM Solutions 3D printer, and Stratasys partnered with Radford to 3D print sports car parts. Then we…

March 12, 2022 by Sarah Saunders

3D Printing News Briefs, February 12, 2022: Business, Aerospace, Guns, & More

Business, post-processing, aviation, automotive, and guns—that’s what on the menu in today’s 3D Printing News Briefs! AMT appointed Magnus René as Chairman of the Board, Optomec announced major growth in…

February 12, 2022 by Sarah Saunders

3D Printing News Briefs, January 29, 2022: Magnets, Materials, & More

We’re starting with some interesting research on 3D printing molecular magnets in today’s 3D Printing News Briefs, and then moving on to materials, as the Lehvoss Group plans to present…

January 29, 2022 by Sarah Saunders

3D Printing News Briefs, October 6, 2021: Business, Guns, & Bridges

We’re starting with a little business in today’s 3D Printing News Briefs, as EPLUS 3D and Shining 3D have issued a joint declaration. Optomec received an order from an OEM…

Optomec received an order from an OEM…

October 6, 2021 by Sarah Saunders

3D Printing News Briefs, September 11, 2021: Rocket Nozzles, Ghost Guns, & More

In today’s 3D Printing News Briefs, Stratasys is the first founding partner of nFrontier’s Emerging Technologies Center in Berlin, which is looking to become one of Europe’s top facilities of…

September 11, 2021 by Sarah Saunders

3D Printing News Briefs, September 9, 2021: Events, Materials, & More

In today’s 3D Printing News Briefs, the first Formnext + PM South China finally opens this week. In materials news, a biomedical company introduced what it calls the first purified…

September 9, 2021 by Sarah Saunders

3D Printing News Briefs, August 19, 2021: Software Release, Medical Devices, & More

In today’s 3D Printing News Briefs, we’ve got an updated software release to tell you about, followed by news of a medical device startup using Nanofabrica’s Tera 250 micro AM…

August 19, 2021 by Sarah Saunders

Register to view and download proprietary industry data from SmarTech and 3DPrint. com

com

Questions? Contact [email protected]

Already have an account?

Log In

Best files for 3D printing

Glock .40 and .357 Sig Practice Barrel

Free

supfoil 6.3´ x 23 x 7 1/4 - 110L

30 €

Ford Focus RS MK3 2.3 EcoBoost Cylinder Head Gasket

Free

T-shirt with key ring Dibu 23 - Argentina

0,60 €

Basketball wall decoration Jordan

0,50 €

Silencer for MK23

2 €

Computer case

€30.50 -20% 24.40€

Р/К YF-23 Black Widow II

23. 21 €

21 €

YF-23 Black Widow II Assembly Manual

Free

case for samsung s23 ultra 6.8" case for samsung s23 ultra 6.8"

0,50 €

Michael Jordan lamp

2.50 €

CASE FOR SAMSUNG GALAXY S23 ULTRA

Free

Computer case

32 €

Kansas City YOUNG BATH BOMB

3.25 €

Kansas City Solid shampoo and soap pump mold

3.25 €

jordan 23 nba basketball lamp

6 €

ZSU-23-4V1 Gun top plate

Free

MAGPUL MLOK Angled Fore Grip

2€ -50% 1 €

FIFA 23 Controller Stand | Playstation PS4 PS5|Xbox

€4. -50% 2.13 €  25

25

ZSU-23-4V1 Front hull fairing

Free

PP-40E Extended magazine Glock .40 cal & 10mm

11.61 €

Fighter TC 97

6.25 €

Air Jordan LED

2.50 €

FIFA 23 logo

0.54 €

Ford Fiesta MK7 ST

0.50 €

Ford Fiesta MK7 4-door model

0,50 €

Modular rack/organizer/paint bottle holder - (12 bottles) 32 mm, Citadel

5,80 €

Modular Rack/Organizer/Holder for Paint Bottles - (6 Bottles) 23mm, Citadel, Hobby Paints, Model Paints

3,95 €

Maestro vs.

Logan

Logan 32.50 €

Fan art X-23

18.57 €

Ford Focus RS MK3 2.3 EcoBoost Cylinder Head Gasket

Free

Ford Focus RS MK3

0.50 €

Handwheel NEMA23

Free

double dragons play with pearls

1.35 €

seat 2.3 VR5

0.50 €

COOKIE KNIFE NEW YEAR 2023

0,50 €

SHOTGUN AIRSOFT - M870 Handguard

4 € -50% 2 €

Martinez pattern keychain / Martinez pattern keychain

0. 57 €

57 €

Dibu Martinez Funko

3.17 €

SSX23 slide adapter for Vector Frenzy 1x20x28

Free

Motor mount for t-slot 90x45 mm

Free

90x45 t-slot nema23 support

free

Space Core Captain

2.27 €

ZSU-23-4V1 AIR INTAKE COVER (EARLY)

0,56 €

WEDNESDAY Addams, Merlina

11.14 €

ZSU-23-4V1 Turret laying parts

1.42 €

R3D MK23 magazine opener

3.40 €

DG7YBN 5el Yagi antenna for 23 cm (1296 MHz)

Free

10 most unexpected directions of 3D printing

As professionals say, the main problem with 3D printing is that no one knows why it is needed. But the portal 3Dtoday knows. Therefore, they have prepared for us a cool material about the areas for which 3D printing is actively used in our time. So, the ten most striking applications of 3D printers in everyday life and industry are in front of you!

But the portal 3Dtoday knows. Therefore, they have prepared for us a cool material about the areas for which 3D printing is actively used in our time. So, the ten most striking applications of 3D printers in everyday life and industry are in front of you!

For most people, additive technologies are still something mysterious and incomprehensible, despite their growing popularity around the world. In fact, household 3D printers are quite easy to operate, and quite successfully produced by Russian companies at quite affordable prices. Industrial devices, in turn, are very expensive, but their potential cannot but impress. Go!

Do not self-medicate! In our articles, we collect the latest scientific data and the opinions of authoritative health experts. But remember: only a doctor can diagnose and prescribe treatment.

Medical

The most promising direction for 3D printing in general is piece or small-scale production. If consumer goods are easier and cheaper to cast and stamp, then customized products are more profitable to print, since 3D printing allows you to go from a digital model directly to production without requiring the manufacture of expensive tooling. Sometimes, one-piece production simply cannot be dispensed with. Children’s prostheses are great examples, and they need to be constantly replaced as the child grows. The idea of prosthetics has become widespread around the world, with some fully functional 3D printed mechanical versions costing as little as $50, while classic custom prostheses can cost as much as $50,000. Designers are being helped by 3D scanners used to obtain a three-dimensional drawing of a limb. Then the prosthesis is printed according to the obtained dimensions and outlines. The pioneer in this area was Aaron Brown and his project E-Nabling The Future. He came up with children's prostheses in the shape of the hands of superheroes - Wolverine, Iron Man, and so on. They play not only a mechanical, but also a serious psychological role in the rehabilitation of children who have lost limbs or were born without them.

Sometimes, one-piece production simply cannot be dispensed with. Children’s prostheses are great examples, and they need to be constantly replaced as the child grows. The idea of prosthetics has become widespread around the world, with some fully functional 3D printed mechanical versions costing as little as $50, while classic custom prostheses can cost as much as $50,000. Designers are being helped by 3D scanners used to obtain a three-dimensional drawing of a limb. Then the prosthesis is printed according to the obtained dimensions and outlines. The pioneer in this area was Aaron Brown and his project E-Nabling The Future. He came up with children's prostheses in the shape of the hands of superheroes - Wolverine, Iron Man, and so on. They play not only a mechanical, but also a serious psychological role in the rehabilitation of children who have lost limbs or were born without them.

But dentures are just the beginning. There is a special area in additive manufacturing called bioprinting. Its essence lies in the 3D printing of volumetric structures with living cells and biodegradable materials that serve as a scaffold or "matrix" for the cell mass. Of course, it is possible to grow a cell mass in a test tube, but only bioprinting can create a fully functional organ from several tissues and with a network of blood vessels, and even suitable for transplantation. Work in this direction is already underway, although complex organs have not yet been obtained. The most advanced example can be considered the experiments of the Russian company 3D Bioprinting Solutions, which printed the thyroid gland, which was then successfully implanted in an experimental mouse. But the American company Organovo already produces liver tissue used as samples for testing new drugs for efficacy, toxicity and side effects without the participation of bipedal test subjects.

Its essence lies in the 3D printing of volumetric structures with living cells and biodegradable materials that serve as a scaffold or "matrix" for the cell mass. Of course, it is possible to grow a cell mass in a test tube, but only bioprinting can create a fully functional organ from several tissues and with a network of blood vessels, and even suitable for transplantation. Work in this direction is already underway, although complex organs have not yet been obtained. The most advanced example can be considered the experiments of the Russian company 3D Bioprinting Solutions, which printed the thyroid gland, which was then successfully implanted in an experimental mouse. But the American company Organovo already produces liver tissue used as samples for testing new drugs for efficacy, toxicity and side effects without the participation of bipedal test subjects.

ADVERTISING - CONTINUED BELOW

Sometimes it is not necessary to print a new organ to save a life. You can fix an existing one. A vivid example was the operation performed by surgeons of the St. Petersburg State Pediatric Medical University. Doctors had to save a baby born with a complicated heart defect. In order to understand the structure of the defect, the doctors printed an exact model of the heart from tomographic images and worked out all the details before proceeding with two complex operations. The story ended happily: the boy went to a quick recovery.

You can fix an existing one. A vivid example was the operation performed by surgeons of the St. Petersburg State Pediatric Medical University. Doctors had to save a baby born with a complicated heart defect. In order to understand the structure of the defect, the doctors printed an exact model of the heart from tomographic images and worked out all the details before proceeding with two complex operations. The story ended happily: the boy went to a quick recovery.

Robotics

We already mentioned prostheses, but what about full-fledged robots? Easily. There are actually a lot of options, but the development of Siemens is interesting because it is based on 3D printed robots that act as 3D printers! As conceived by the creators, such devices should act as a production swarm like ants or bees. A group of machines follows common algorithms by printing new objects using onboard 3D printers.

These "robo-spiders" work on batteries, remembering their position in space and relative to each other. When the batteries are low, the spider robot calls a fully charged shifter, and he goes to rest and recharge. The developers believe that the industrial version of such a swarm will be able to produce truly large-sized objects like buildings or ship hulls.

When the batteries are low, the spider robot calls a fully charged shifter, and he goes to rest and recharge. The developers believe that the industrial version of such a swarm will be able to produce truly large-sized objects like buildings or ship hulls.

Construction

Buildings, however, can be printed now. There are still few construction 3D printers, but they show very interesting results. The essence of the process, as a rule, comes down to layer-by-layer printing of walls from a specially formulated cement mixture. The recipe for the mix is very important as it needs to set fast enough to not get crushed by subsequent layers. On the other hand, drying too quickly will prevent the layers from setting to each other. The resulting hollow walls serve as a kind of non-removable formwork, into which you can insert insulation, reinforcement, conduct communications, and for greater strength, fill the remaining cavities with concrete and get a monolithic structure. The advantage of this technology over the usual formwork is the ability to create all sorts of hitherto unthinkable shapes - rounded, spiral, etc.

The advantage of this technology over the usual formwork is the ability to create all sorts of hitherto unthinkable shapes - rounded, spiral, etc.

An excellent example is the work of Andrey Rudenko, who printed a miniature castle on an illustration. Andrey recently took on a serious project by printing an extension to a hotel complex in the Philippines. And the dexterous Chinese from WinSun have already printed a five-story building, although they carried out this project in parts, assembling the printed panels at the construction site.

Automotive

In just a few years, you'll notice a new car pulling out of your neighbor's garage every time. How can this be? The answer is simple: he prints them. The production of spare parts for automobiles quickly became one of the favorite directions among do-it-yourself printers or "makers". Is it worth waiting for delivery or scouring the shops in search of a broken handle or a hood ornament torn off by a bully when they can be printed? At the same time, printed products cost mere pennies, while spare parts from dealers can be quite expensive. For printing, you can use ABS plastic - the same one from which most plastic trim elements are made. But the automotive 3D printing career didn't end there.

For printing, you can use ABS plastic - the same one from which most plastic trim elements are made. But the automotive 3D printing career didn't end there.

When MarkForged introduced a special 3D printer that allows printing with plastic and carbon fiber composites, 3D printed parts began to appear even on Formula 1 cars. And the American company Local Motors went even further and created a car with a 3D printed body. Now even Toyota is working on its own version of a 3D printed machine.

Space

Those born to fly should not crawl, and astronauts love high-tech gadgets. A space 3D printer suggests itself! The first such device, similar to bar desktop machines available on Earth to anyone, was launched into orbit in September 2014. The Made in Space 3D printer has been successfully tested in zero gravity and has already returned to its home planet, and it has been replaced by a more advanced version.

And yes, like motorists, astronauts intend to use 3D printing to produce spare parts. The logic here is simple: why carry a full set of parts and tools into orbit when they can be printed as needed from a relatively small stock of materials on board the station? The latest Made in Space project, which is still conceptual, involves 3D printing of engines and onboard equipment on asteroids using improvised materials. For what? To deliver a huge block of valuable raw materials to near-Earth orbit, where it can be used to build new orbital structures or lowered to Earth.

The logic here is simple: why carry a full set of parts and tools into orbit when they can be printed as needed from a relatively small stock of materials on board the station? The latest Made in Space project, which is still conceptual, involves 3D printing of engines and onboard equipment on asteroids using improvised materials. For what? To deliver a huge block of valuable raw materials to near-Earth orbit, where it can be used to build new orbital structures or lowered to Earth.

Although everyone has their own worries: Italian astronauts do not start their day without a cup of espresso brewed using a special coffee machine. And in order to prevent the drink from spreading throughout the station, 3D-printed cups of a special shape are used to hold the liquid due to surface tension. And quite recently, a Russian satellite manufactured by specialists from the Tomsk Polytechnic University arrived on board the ISS. The design of the satellite is partially made using 3D printing.

Aircraft

Wait, what other 3D printed engines? Is it possible? Quite, and additive manufacturing is successfully used in many areas of mechanical engineering, including the aviation and space industries, where 3D printed engine parts are quickly becoming commonplace. It's all about 3D printing methods such as selective laser sintering (SLS) and deposition welding (SLM). These methods allow you to create high-precision parts consisting entirely of metals and alloys.

Fine powders are used as raw materials, which are heated almost to the melting point and then sintered or alloyed along predetermined contours using ultra-precise lasers. Although there were initially certain doubts about the strength of such products, numerous experiments dispelled fears: the density of the parts obtained is almost similar to cast counterparts, and the ability to manufacture the most complex components as a whole makes it possible to avoid the formation of weak zones that usually appear at the site of welding seams.

3D printed engine parts, up to nozzles, are already being used on SpaceX devices, Airbus is actively and successfully testing 3D printed engine parts and supporting structures of airliners, and 3D printed swirlers created by the All-Russian Scientific Research Institute of Aviation materials (VIAM) for advanced PD-14 engines currently undergoing flight tests.

Industrial design

Although complex, expensive metal-printing systems are used to manufacture engines, 3D printers that print plastics are the most used in the industry. They are used not so much for the manufacture of finished products as for prototypes. Initially, 3D printing technology was called that - rapid prototyping. 3D printers make it possible to produce high-precision prototype parts, gadget cases, architectural models, and even shoes. Finished products not only serve for visual visualization, but also allow you to try on the components to be assembled. The latter option is used by the developers of the Armata tanks. Because prototyping requires no custom tooling, and the design itself can be quickly digitally modified and reprinted, 3D printing for prototyping results in significant time and cost savings for R&D.

Because prototyping requires no custom tooling, and the design itself can be quickly digitally modified and reprinted, 3D printing for prototyping results in significant time and cost savings for R&D.

At the same time, 3D printing is for all ages. While serious engineers are designing tanks and aircraft, their young colleagues are increasingly using 3D printing to teach modeling and design skills. Inexpensive user-level 3D printers are increasingly being used in schools and circles, and youth creativity centers are being created throughout Russia, where future engineers can try out additive manufacturing technologies on their own experience.

Weapons

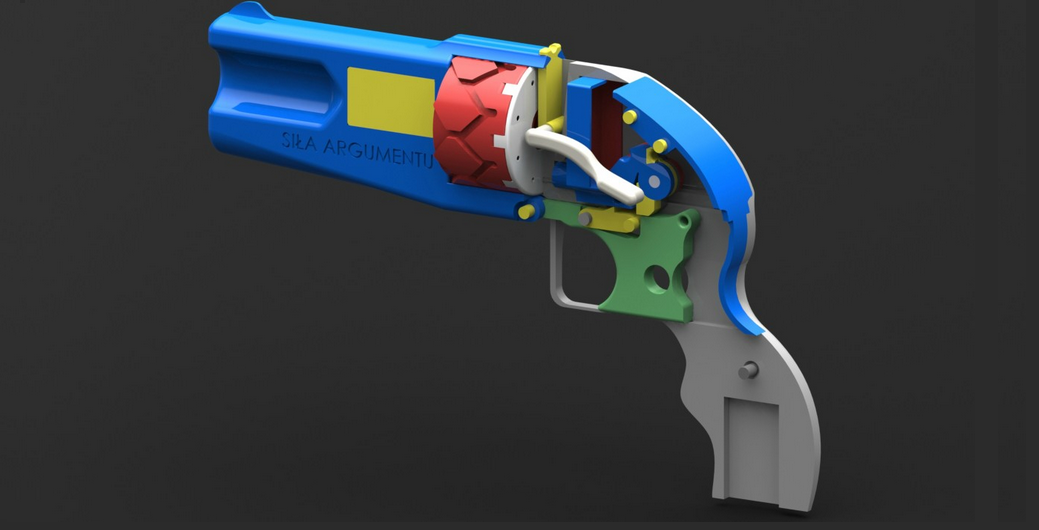

Naturally, 3D printing has also caught on with gun enthusiasts, causing a lot of headaches for regulators around the world. It all started with the Liberator project by an American gun fighter named Cody Wilson. A simple plastic gun can be printed on any home 3D printer, the only metal element is a nail used as a striker, and the probability of an explosion and resulting injury to the shooter is higher than the chance of a successful shot.

It turned out to be almost impossible to fight the distribution of free files with a 3D model of a pistol, but these were just flowers. Berries followed in the form of a 3D-printed receiver for AR-15 automatic carbines, the actual analogues of the M-16 assault rifle, which is in service with the United States and many other countries of the world. The fact is that it is the lower part of the receiver that is subject to registration and accounting, since the serial number is stamped on it, and all other parts can be bought at any weapons store. The box, on the other hand, does not carry high loads, and it is quite possible to print it from plastic, and then assemble an unaccounted, unregistered rifle. Gun printing quickly fell under a local ban, and the aforementioned MarkForged company even refused to sell Cody their printer that prints with high-strength composites.

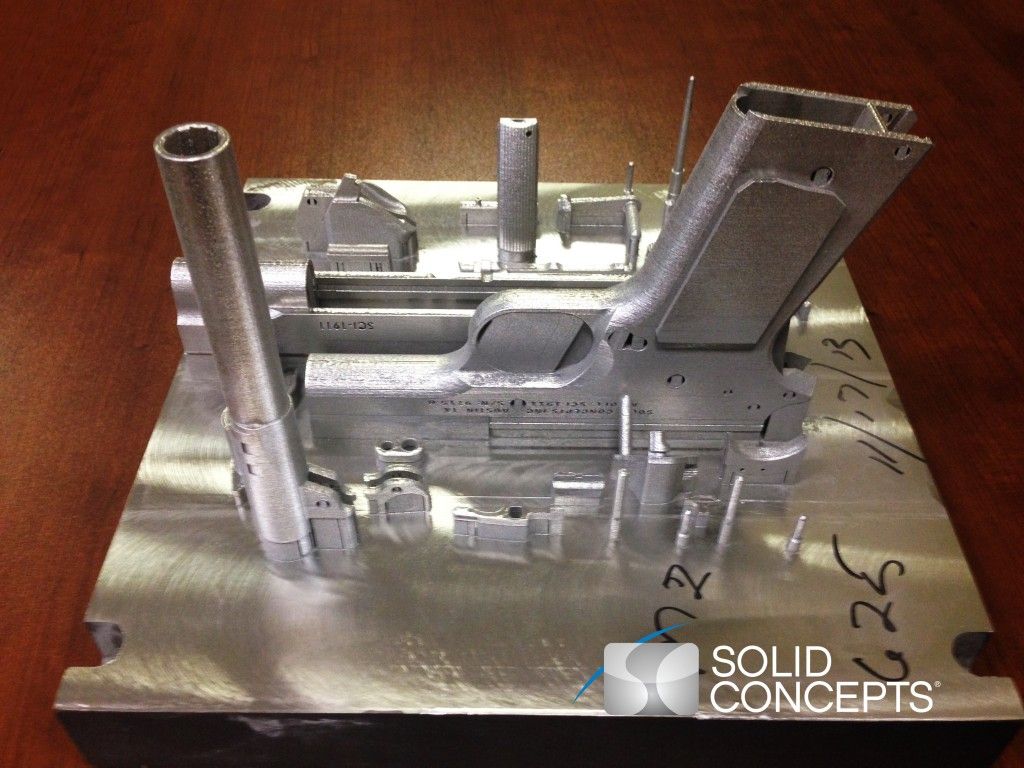

Although, sometimes there are quite legal projects, such as fully functional 3D printed replicas of the Colt 1911 pistol, released in a limited edition by the California arms company Solid Concepts. Be that as it may, 3D printing of weapons in Russia will result in at least a criminal article for illegal storage and distribution, and therefore the experience of Cody Wilson should not be adopted.

Be that as it may, 3D printing of weapons in Russia will result in at least a criminal article for illegal storage and distribution, and therefore the experience of Cody Wilson should not be adopted.

Jewelry

What about fake weapons? This option is allowed by law and is quite available even on consumer 3D printers. And not only weapons, but also all kinds of armor, jewelry and accessories. From the glowing "plasma" swords from the popular game Halo to full-fledged Star Wars stormtrooper costumes, cosplay fans create the most colorful examples illustrating the possibilities of 3D printing.

In fact, MakerBot founder Bree Pettis demonstrated the feasibility of large-scale 3D printing with the Replicator Z18 3D printer in the most graphic way possible by wearing a fully printed helmet on his head in front of an enthusiastic audience of printers.

But with the help of 3D printing, you can create not only toy decorations, but also real ones. Jewelers around the world are increasingly turning to 3D modeling and printing blanks, which are used to make molds for casting precious metal jewelry.