3D printing xerox

Explained: What’s going on at Xerox Elem Additive?

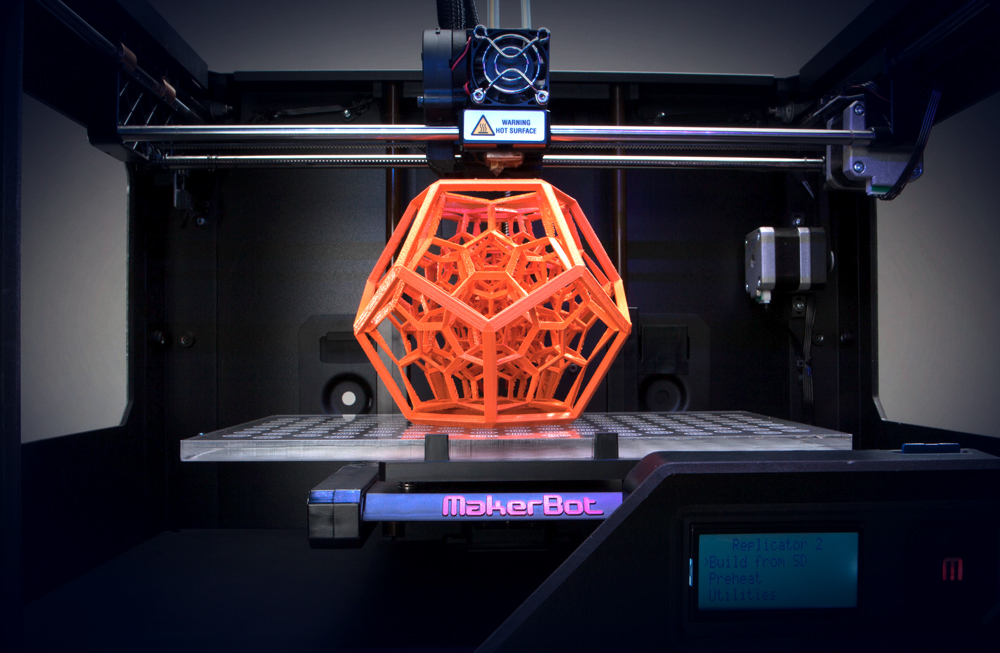

In 2019, Xerox made a big statement with its acquisition of Vader Systems, a New York-based start-up bringing to market a Liquid Metal additive manufacturing technology.

Liquid Metal was a development made by Scott and Zachary Vader, a father-son team, which uses wire feedstock to produce parts at ‘quick speed and low cost.’ Xerox saw it as a technology that could provide solutions to product development and supply chain, while also acknowledging it could harness its expertise in jetting, system design and product design to deliver robust 3D printing equipment to market.

Over three and a half years, Xerox commercialised the technology, hired the likes of Tali Rosman to lead the Elem Additive business unit, and installed the resulting ElemX printer in defence organisations, research labs and service bureaus.

Deployments of the ElemX were being announced at regular intervals, Xerox was still promoting the technology on socials as little as four weeks ago, and then news started to leak that there had been a significant shift in the business operations of Xerox Elem Additive.

Xerox has since confirmed that Elem Additive is being scaled back. But why?

What’s going on at Xerox Elem Additive?Well, less than a few weeks ago.

When Elem Additive General Manager Tali Rosman appeared on the TCT Additive Insight Innovators on Innovators podcast in August, all seemed well with the company. The discussion centred around how 3D printing technologies, like Elem Additive’s Liquid Metal process, could have an impact in industries such as defence. Rosman and her co-participant Mike Pecota touched on the work Xerox had been doing with the US Navy, while Xerox had also announced several additional users in other sectors.

Then, in early October, a flurry of posts on LinkedIn seemed to point to a significant change at the company. Activity on LinkedIn from several Xerox Elem Additive employees suggested the company had made the decision to lay-off a significant number of staff, including the ‘majority of R&D.’ A Xerox spokesperson has since confirmed that, “On September 30 [2022], Xerox scaled back its Elem Additive 3D business and is now solely focused on supporting current installations. ”

”

It comes just six months after Xerox stated in its annual financial report for the year 2021 that ‘we expect 3D to grow revenues rapidly in future years.’ As a publicly listed corporation, Xerox updates its shareholders regularly, with revenue and cash flow on a downward trend. As per its Q2 2022 financial results, revenue is down 2.6% year-over-year, while its operating cash flow is down 299m USD year-over-year to 85m USD, and its free cash flow is down 296m USD year-over-year to 98m USD. Since 2011, the company’s annual revenue has decreased by around 15 billion USD.

Xerox is not alone in making reductions to its workforce in the 3D printing space in recent months. Redundancies have been made at Nexa3D in recent weeks, Desktop Metal announced 12% of staff were to be laid off in June, and it has also been reported manufacturing service Fast Radius is to cut its workforce by up to 20%.

Among those to be let go by Xerox Elem Additive are Rosman, as well as Senior Product Managers, Mechanical Engineers, Senior Metallurgists, Quality Technicians and Supply Chain Analysts.

As Xerox’s spokesperson says, the focus is now on supporting current installations. These include ElemX machines deployed at the US Naval Postgraduate School, RIT, Siemens, Oak Ridge National Laboratory and Vertex Manufacturing. As per Rosman’s first appearance on the TCT Additive Insight podcast in February 2021, the wider Xerox Corporation is also an occasional user of Liquid Metal technology.

We are now in the process of looking and assessing all of these different businesses across the pipeline. Some of these will get through, and some of them will get rapidly shut down.

The departing R&D staff are also believed to have worked towards the development of IP around Liquid Metal technology, while Xerox had told shareholders in February that an ElemX2.0 was targeted for 'completion' in Q4 2022. This product was said to have the capacity to process Aluminium 6061, which would ‘increase the aperture of the industry verticals we’re going to get into at scale, which is the whole automotive and aeronautical industry. ’

’

With the subsequent ‘scaling back’ of Elem Additive, and with Xerox not having a presence at IMTS or Formnext, it is now not known whether the company still intends to introduce this capability to existing users of Liquid Metal.

When did Xerox enter the AM space and why?Xerox has had its toe in the additive manufacturing water for many years, contributing its printhead technology and capacity for materials and software development. In 2019, however, the company decided to submerge itself fully by acquiring the Vader Systems technology and pulling together various other assets and developments to form a ‘significant business.’

Speaking to TCT in June 2019, Kevin Lewis, Xerox’s Head of Business Strategy for 3D at the time, stressed that the ‘differentiation of the technology’ and that ‘Xerox’s expertise could be put towards helping that technology progress further,’ were among the key reasons for acquiring Vader Systems and its Liquid Metal technology. As noted by Vader Systems co-founder Scott Vader in the same interview, it was also important that the technology ‘supported true manufacturing.’ This element came up in Xerox’s 2019 Investors Day, when the acquisition was announced, as did the fact that Vader had already received ‘strong customer feedback from major manufacturers.’

As noted by Vader Systems co-founder Scott Vader in the same interview, it was also important that the technology ‘supported true manufacturing.’ This element came up in Xerox’s 2019 Investors Day, when the acquisition was announced, as did the fact that Vader had already received ‘strong customer feedback from major manufacturers.’

At the time, Xerox also stated the Liquid Metal technology would provide a new way for the company to deliver more value to customers.

And why has Xerox decided to scale back its additive activity?A Xerox spokesperson said: “As outlined at our Investor Day event earlier this year, the innovation studio model we have established enables us to quickly determine which businesses we continue moving forward with and which we scale down. This was a difficult, but necessary, decision.”

Xerox presentations at its Investor Day in February threw up many interesting titbits. Naresh K. Shanker, the Senior VP, CTO & Head of Palo Alto Research Center (PARC) at Xerox, spoke with much enthusiasm for additive manufacturing, suggesting the technology could enable distributed and localised manufacturing, as well as production on-demand. He also spoke in detail on the deployment of a Liquid Metal machine on a US Navy aircraft carrier, as well as software developments pertaining to its digital manufacturing endeavours and the aforementioned Aluminium 6061 capability.

He also spoke in detail on the deployment of a Liquid Metal machine on a US Navy aircraft carrier, as well as software developments pertaining to its digital manufacturing endeavours and the aforementioned Aluminium 6061 capability.

“This is really an exciting business,” he said. “We’ve got it off the ground and we’ve got a tremendous amount of launches coming up in the second half of this year. Our goal right now is to double and triple the number of machines this year that we are going to be launching.”

But he also mentioned the ‘venture studio’ established within PARC. This concept, “helps us very quickly accelerate even more businesses across the pipeline. And what we use is a customer-led innovation process. The focus is to test and validate problem, solution, fit and product market fit early in the life cycle, so we can put the capital structures early on.”

He went on: “And this also helps us determine very rapidly what businesses we will move along the pipeline and just as quickly, what businesses we will shut down […] We've talked about Elem and Eloque that we launched, including Novity, and we are now in the process of looking and assessing all of these different businesses across the pipeline. Some of these will get through, and some of them will get rapidly shut down. And what's important is to make sure that we are very efficient around the use of capital in terms of how we progress these entities.”

Some of these will get through, and some of them will get rapidly shut down. And what's important is to make sure that we are very efficient around the use of capital in terms of how we progress these entities.”

Somewhere between its 2022 Investor Day and September 30, Xerox has made the decision to significantly scale back the 'exciting business' that was Elem Additive. At this stage, there is no indication that Xerox will make the technology available to new users through other avenues, but Shanker did say back in February: “The second key business benefit that we’ve derived from [the venture studio concept] is that we now have vehicles to actually take these businesses to market in the form of spin-outs, joint ventures and even licensing opportunities with regards to the technology.”

What have former Xerox Elem Additive employees had to say?Those that have sought to update their employment status on LinkedIn have, in the main, expressed their disappointment at the decision and/or their pride at having successfully commercialised the Liquid Metal technology.

Bender Kutub, a Senior Product Manager at Xerox Elem Additive, noted, “it has been an amazing journey with the Elem Additive team, we accomplished a lot in [a] short period of time thanks to a great group of highly skilled and motivated individuals.”

Kevin Scofield, Director of Product Management at Xerox Elem Additive, said: “Xerox has made the unfortunate decision to cease all new development and sales of the Elem Additive product suite. While disappointing, it does not lessen the pride I have in bringing two new software apps (Navigator, Builder) from concept to launch in less that (sic) 18 months.”

Michael Lloyd, 3D Printing Quality Technician at Xerox Elem Additive, offered: “I was with many talented people [at Xerox] and I highly recommend, (sic) that any company pick them up.”

A Xerox spokesperson told TCT: “We are working to minimise the impact to the affected individuals and will provide transition assistance for those impacted.”

Want to discuss? Join the conversation on the Additive Manufacturing Global Community Discord.

Get your FREE print subscription to TCT Magazine.

3D Printing Layoffs Continue with Xerox Elem Additive Division - 3DPrint.com

The additive manufacturing (AM) industry has seen a number of companies contract as the larger economy struggles. This has included firms like Desktop Metal, Fast Radius, Nexa3D, and others. The latest is photocopier pioneer Xerox (Nasdaq: XRX), which has sought to revitalize its business by venturing into AM with an ambitious acquisition that led to the deployment of a unique, new metal 3D printer dubbed Elem X.

Now, like its colleagues in the space, Xerox, too, is performing layoffs in its additive division. Employees on LinkedIn have posted about their need to find new work after being let go from the company’s nascent 3D printing business. Elem Additive General Manager Tali Rosman also left the company. A Xerox spokesperson provided 3DPrint.com with the following comment:

“On September 30, Xerox scaled back its Elem Additive 3D business and is now solely focused on supporting current installations.

As outlined at our Investor Day event earlier this year, the innovation studio model we have established enables us to quickly determine which businesses we continue moving forward with and which we scale down. This was a difficult, but necessary, decision. We are working to minimize the impact to the affected individuals and will provide transition assistance for those impacted.”

Xerox’s Foray into 3D Printing

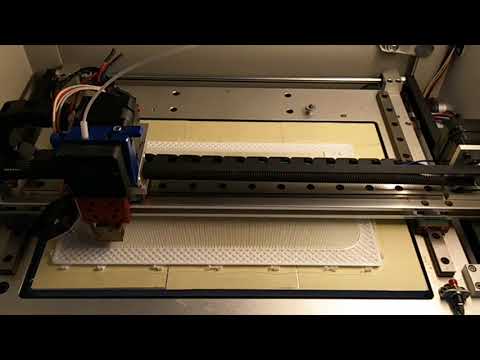

Xerox got into the 3D printing space in 2019 with the purchase of metal 3D printing startup Vader Systems. Vader’s process, which became the basis for the Elem X system, was capable of melting off-the-shelf metal wire in a ceramic crucible before using electromagnetic force to eject the molten metal onto a moving build plate.

Over the course of the next year, the company worked to commercialize the technology and build out a team that could successfully bring it to market. This included the hiring of Tali Rosman, who had previously worked at Stratasys for nearly four years as director of corporate development and head of product strategy and operations.

By February 2021, Xerox unveiled the Elem X and its first customer, the U.S. Navy. Other customers included Siemens, the U.S. Department of Energy’s Oak Ridge National Laboratory, and Vertex Manufacturing, led by GE Aerospace metal 3D printing veteran Greg Morris. These clients all sought the benefits of a technology capable of using low-cost materials to print solid parts in record time and with little post-processing.

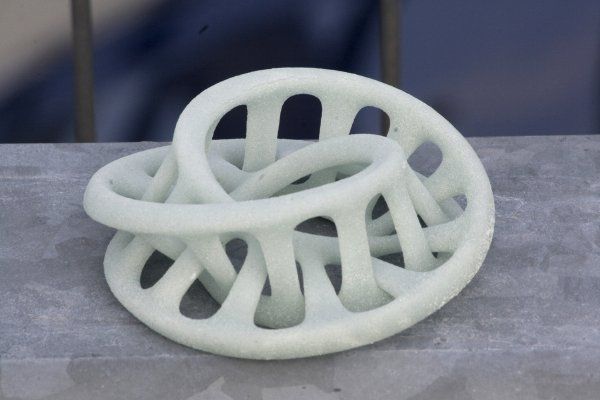

An example part that was 3D printed on the Xerox ElemX machine, powered by the SINUMERIK 840D sl control system from Siemens.Of course, selling metal 3D printers is a long game, with customers needing to validate the technology, justify the investment, and the orders for the equipment being fulfilled. However, in the case of Xerox, it seemed as though the business case for its additive division was a sound one. The Elem X was installed on a Naval vessel just this summer using a specialty ruggedized container, an event that surely garnered interest from potential customers looking for safe and rapid manufacturing of metal parts in possibly unstable environments. This means militaries of all types, particularly navies, as well as the marine and energy industries. Think 3D printing replace parts for offshore oil rigs, wind farms, or ships.

This means militaries of all types, particularly navies, as well as the marine and energy industries. Think 3D printing replace parts for offshore oil rigs, wind farms, or ships.

What Happened with Elem Additive at Xerox?

Xerox employees may be hesitant to speak on the record about the events that led to the layoffs, given the fact that it is a large, publicly traded company. Nevertheless, we don’t need comments from displaced workers to understand that the financial situation at the company has been dire for about a decade. Xerox generates revenues of $7 billion, a far cry from the $22 billion it was making circa 2011 and, still, its market cap is only $2 billion. The company has had four quarters of growth since 2012 and the stock itself has about halved since 2019.

Throughout this period, Xerox’s management has been tumultuous, with activist investor Carl Icahn thwarting a merger with Fujifilm in 2018. This was followed by an attempted hostile takeover of HP. After HP rejected two of Xerox’s unsolicited bids, Xerox announced a strategy to replace HP’s board. The most recent shakeup was the unexpected death of Xerox CEO John Visentin from an undisclosed illness in June 2022.

The most recent shakeup was the unexpected death of Xerox CEO John Visentin from an undisclosed illness in June 2022.

Xerox vs HP

While inopportune for the company, given its financial situation, the disruption in management and Xerox’s economic struggles could prove valuable to a potential competitor. On Xerox’s side, Icahn Associates Holding LLC is the largest shareholder with 22% of the company. Meanwhile, Warren Buffet’s Berkshire Hathaway, Inc. owns 10% of HP. Now could be the ideal time for HP to xerox Xerox’s own strategy and purchase its additive division. Here’s what 3DPrint.com Macro Analyst Matt Kremenetsky had to say:

“Given how crowded the space has become, Xerox may simply turn out to have been one legacy brand too many for the AM sector. At the same time, this doesn’t mean the company’s additive division is valueless—far from it! Rather, it suggests that the company’s AM portfolio could just hold much greater value as an acquisition for a company in better financial health than it ever has for Xerox itself.

Considering Warren Buffett’s penchant for buying out Carl Icahn — Buffett acquired Icahn’s entire stake in Occidental Petroleum earlier this year — combined with Berkshire’s simultaneously increasing stake in HP, the latter could be a perfect fit to take on Xerox’s AM operations.”

Elem Additive isn’t the only promising division that Xerox seems to be shedding. In 2021, Xerox created a joint venture with the state government of Victoria in Australia. Called Eloque, the business was focused on installing sensors in bridges for remote monitoring with the goal of repairing them and maintaining their longevity. Consultancy firm McKinsey & Company reported that “the technology works … as proven by extensive piloting done on five bridges in Victoria in 2019.” A rushed commercialization process saw Eloque’s product brought to market before it was ready, ultimately leading to the venture’s collapse.

In both the case of Elem Additive and Eloque, the products and the teams developing them seemed to be capable. For Elem Additive, the road map was promising and it had earned very established customers. Now that the Xerox is abandoning them, they may be ripe for acquisitions by others.

For Elem Additive, the road map was promising and it had earned very established customers. Now that the Xerox is abandoning them, they may be ripe for acquisitions by others.

Possible Buyers of Xerox’s 3D Printing Division

If we aren’t just watching two billionaires duke it out over turf at the end of the world, there are other contenders for purchasing Xerox’s promising AM division. Though it bought Xerox’s legacy printing business, Fujifilm has yet to make a real entrance into 3D printing, despite the fact that many other 2D printing companies are aiming to recover from losses made by the digital age.

Aside from HP, these legacy printing businesses include Mimaki, Ricoh, Sindoh, and Epson. Canon and Konica Minolta have long partnered with 3D Systems to sell its products. Canon in particular has explored the development of at least one 3D printer. More recently, Konica Minolta began selling 3D printing services with Markforged technology in Australia. One of these firms could firm up their commitment to the AM sector with the acquisition of Elem Additive.

The most obvious guess, given its current momentum, would be Mitsubishi via Nikon. Elem X technology would complement the variety of other metal 3D printing processes being developed at Mitsubishi, given its niche applications. Mitsubishi’s various businesses are ostensibly separate, so Xerox would have to work with whichever affiliated company that chose to buy it. For that reason, it could very well work within Nikon, which operates military and aerospace 3D printing bureau Morf3D.

The 3D Printing Workforce at Large

As 3DPrint.com has pointed out, the 3D printing market is experiencing a great deal of turmoil due to the larger recession. Many firms across the board have laid off employees, while the more financially stable ones are able to pick up the pieces. Alexander Daniels Global (ADG), a leader in 3D printing recruitment solutions, is in a keen position to understand the flow of the industry’s workforce. About the recent wave of layoffs, ADG Director Nick Pearce told 3DPrint. com:

com:

“The additive manufacturing industry is currently in something of a ‘transitory’ period. On the one hand we see a lot of demand still from companies looking to hire (ADG has seen a 35% increase in jobs between Q2 and Q3). However, hiring processes are taking longer and companies are sitting on candidate submissions. We have also seen some companies pulling back from hiring even where they have selected a candidate to offer.

“There is a lot of economic uncertainty surrounding the market as a whole which is driving this behavior. What I think is very short-sighted of businesses is the layoffs we are seeing. Companies simply haven’t learnt from COVID. There were similarly layoffs then, which at the time might have seemed reasonable. What these companies don’t take into account is how difficult they might find it to replace the talent they lose, when market conditions improve. There is also a hidden cost of goodwill. Often companies that make such layoffs lose the talent they wanted to keep, because the company they are working for is seen as less stable and less attractive to work for.

”

The good news for former Elem Additive employees, like many of those recently let go at other companies, is that many are extremely talented and capable individuals. Because the interest in AM remains and growth is projected to continue for the sector, they will certainly land in new positions, hopefully sooner rather than later.

Subscribe to Our Email Newsletter

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printing business news • Elem X • elemx • firings • hp • layoffs • metal 3d printing • Xerox • xerox elem additive

Please enable JavaScript to view the comments powered by Disqus.

3D Printing Technology

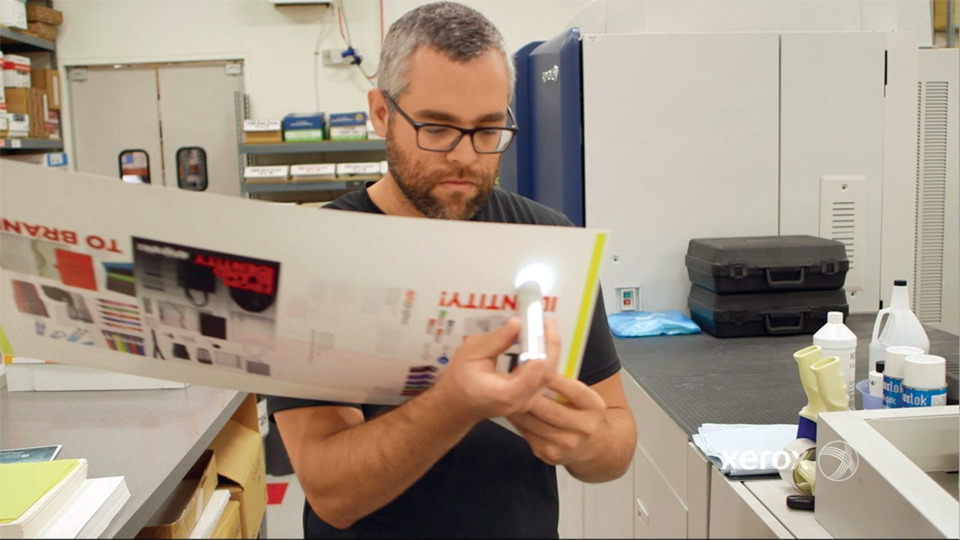

Wayne Buchar, Chief Engineer at Xerox, talks about the new industry of direct on-site printing.

Change Agents

Wayne Buchar: 3D Printing

"Applications in this area can only be limited by the imagination - it's a blue ocean, as no one has yet worked in this direction"

New industries outside the printed pages

Wayne Buchar is Xerox's chief engineer and project manager and has always been interested in inventions and problem solving. He is interested in how certain things work. So at the age of eight he built a transmitter to control model airplanes, in college he invented the award-winning ultrasonic microscope, and as an adult he developed direct-to-object printing technology. nine0003

He is interested in how certain things work. So at the age of eight he built a transmitter to control model airplanes, in college he invented the award-winning ultrasonic microscope, and as an adult he developed direct-to-object printing technology. nine0003

What is Direct Printing on Objects? Imagine a 3D object. For example, a cup, a water bottle or a ball. Now imagine that the image can be printed directly on the surface of these objects, even if the surface is uneven and curved. The Xerox® Direct to Objects Inkjet Printer, co-designed by Wayne Buchar, can print custom images on plastic, metal, glass and ceramic surfaces in just minutes. Direct on-site printing takes personalization to the next level and is a game-changer for retailers, print service providers and event planners. Read the interview with Wayne Buchar to learn more about his passion for innovation and how he came up with direct object printing. nine0003

Wayne, have you always been an inventor? Even as a child?

Yes it's true. I was fond of radio-controlled model aircraft. In all circles, I was always the youngest of the participants. In the aeromodelling club too. When I was eight, I built my own transmitter with my father. I have always been interested in electronics. In college, I received the National Technology Award for inventing the ultrasonic microscope. After that, I was invited for an interview at Xerox. Because I got a national award. nine0003

I was fond of radio-controlled model aircraft. In all circles, I was always the youngest of the participants. In the aeromodelling club too. When I was eight, I built my own transmitter with my father. I have always been interested in electronics. In college, I received the National Technology Award for inventing the ultrasonic microscope. After that, I was invited for an interview at Xerox. Because I got a national award. nine0003

Were your parents engineers?

Yes, my father was an engineer. He was in software. He started teaching me from a very young age. When I was eight, I helped him fix the car. He always took me with him and taught me everything he knew. He never gave things for repair to other people. Never. Therefore, when a color TV broke down, we repaired it together. I sat and watched him work. And he explained everything he did. I remember that at the age of 12 he explained to me what magnetic domain memory is. He then worked on the creation of such a memory at IBM. I was very lucky that my father liked to explain everything to me and allowed him to help. It has always been so. nine0003

I was very lucky that my father liked to explain everything to me and allowed him to help. It has always been so. nine0003

Tell us about your career at Xerox.

For many years I led the scanner development division. We created image processing technologies. I have always been very interested in innovation. Then I became the program manager and chief engineer of CiPress. When this product was ready, I went back to work on new ideas. I am referring to the NewStarts program led by Brendan Casey. That's when we got the idea to build the Brenva Industrial Inkjet Printing Machine. nine0003

At Xerox in Wilsonville, Oregon, there were several engineers who attended various inkjet conferences. They said, "Our printheads and our inkjet technologies can do a lot more than just print on paper." They came with burning eyes and said: “Listen, there is a huge opportunity in this! Why are we obsessed with only printing on paper?”

I called my friend David Tate, who worked in Wilsonville as director of business development. I told him, "Dave, have you ever been in a situation where a customer is completely satisfied with your printheads, and they need a team of engineers to create a new product based on these printheads?" He said, "Wayne, it happens all the time." Then I said, "Next time you have a client like that, ask him to call me." nine0003

I told him, "Dave, have you ever been in a situation where a customer is completely satisfied with your printheads, and they need a team of engineers to create a new product based on these printheads?" He said, "Wayne, it happens all the time." Then I said, "Next time you have a client like that, ask him to call me." nine0003

Three days later I got a call from Chuck Hull. He invented 3D printing. It was he who launched the production of 3D systems. He called me personally and said: “Wayne, I heard that you can help us. Together we can achieve amazing results. I saw your CiPress machine with all those printheads. Just imagine what you can do with a 3D printer.” It fascinated me. I called the project Engineering Services and said, "If we get people who need help integrating printheads, send them here." And we were getting calls. nine0003

How did you contribute to the development of direct object printing technology?

I put together a team and we had to overcome some technological difficulties. For example, learn to send drops of paint over a fairly long distance. Many people misunderstood the principle of inkjet printing. Even our inkjet specialists told me, "Nothing will come of this."

For example, learn to send drops of paint over a fairly long distance. Many people misunderstood the principle of inkjet printing. Even our inkjet specialists told me, "Nothing will come of this."

After many attempts and experiments, we still learned how to send ink drops at a distance of 5 to 7 mm. In normal printing, this distance is from 0.5 to 1 mm, sometimes even up to 2 mm. But 5-7 millimeters is almost a full-color digital airbrush. It was this achievement that formed the basis of the Xerox inkjet printer on objects. Now we are spraying ink not on a flat surface, but on a curved one, for this we need to correctly send drops to the surface and ensure that they hit accurately. nine0003

How do you see the future of this technology?

Yes, sure. This is just one of the new technology platforms we are working on. For example, we installed a print head on a robotic arm, and now we can print on buildings and airplanes. We are working on a wide variety of projects here. That is why I started working in the Engineering Services project. If you walk in and say, "We're Xerox engineering and we want to help you," you're getting all sorts of requests. nine0003

That is why I started working in the Engineering Services project. If you walk in and say, "We're Xerox engineering and we want to help you," you're getting all sorts of requests. nine0003

Our object inkjet printer was the first in the world. I think retailers will appreciate it. This is a completely new technology, so we are still trying to understand all the potential applications. And these spheres are countless, a whole ocean. After all, no one has done this before. Technology can develop in different directions.

Direct print printers can be useful in retail stores, distribution centers, and manufacturing plants. In addition, this technology, which can send ink droplets over such a distance, can be used on production lines for label printing. We are currently working to further improve this technology and make it cheaper. And to create such versions of the device that can be successfully introduced into production. nine0003

Right now, the main demand comes from graphics companies that want to showcase their work to clients. For example, they have created a series of new logos for a client and want the technology to print them on items. Today they have to go and order stamps. Labels, stencils, stamps - everything needs to be ordered.

For example, they have created a series of new logos for a client and want the technology to print them on items. Today they have to go and order stamps. Labels, stencils, stamps - everything needs to be ordered.

This is a rather long and expensive process. And then the client says: “Everything is fine, but I don’t quite like the color. And yet, let's add a couple of stars in the right corner, or something like that. And the process has to start all over again. The Xerox Inkjet Object Printer lets you simply place the desired object in the printer and the image is ready in two seconds. Graphic designers can immediately show clients what the created logo will look like and quickly make changes. And this is a very important difference. Most likely, this will completely change the way graphic designers work. nine0003

Sports grounds, such as baseball and football stadiums, are showing great interest in our invention. They like the idea that the device can be put on wheels and brought directly to the stadium or trade show. Several cruise ships were also interested in our printer. The idea is to install one or two printers on the ship that will help people capture their memorable moments. So far, there is nothing like it in the world, so we will learn more and more potential applications. nine0003

Several cruise ships were also interested in our printer. The idea is to install one or two printers on the ship that will help people capture their memorable moments. So far, there is nothing like it in the world, so we will learn more and more potential applications. nine0003

Could this device be the forerunner of 3D printing?

This could be a good addition. One of our clients is a large shopping center. When their people saw this printer, they said, “This makes a lot more sense than trying to 3D print things completely. In essence, this is printing on finished three-dimensional objects. And you can print an image in less than a minute, you don’t have to wait a whole day to create an item on a 3D printer. Then you need to remove the product from the mold. Often it is covered with wax. Then it must be placed in acid. That is why they told me so. nine0003

Xerox inkjet object printers use proprietary printhead technology. And our printheads are truly unique. They are made of stainless steel and plated with gold. Therefore, many people are interested in cooperation with us. Since there are no plastic components in the print heads that come into contact with the ink, we can use them to spray acid and various other liquids. None of the competitors can offer this. In addition, the heads were designed to work with molten solid ink, which resembles wax in structure. So they can be used at high temperatures. As the temperature rises, liquids become less viscous. One of the biggest challenges in inkjet printing is getting the ink through very thin holes. Therefore, the viscosity of the liquid must be minimal. And if you heat liquids, they become very fluid. nine0003

Therefore, many people are interested in cooperation with us. Since there are no plastic components in the print heads that come into contact with the ink, we can use them to spray acid and various other liquids. None of the competitors can offer this. In addition, the heads were designed to work with molten solid ink, which resembles wax in structure. So they can be used at high temperatures. As the temperature rises, liquids become less viscous. One of the biggest challenges in inkjet printing is getting the ink through very thin holes. Therefore, the viscosity of the liquid must be minimal. And if you heat liquids, they become very fluid. nine0003

We are not aware of any other manufacturers whose printheads can operate at 105 degrees Celsius. Now we can create specialized products, for example, for medicine. You can sterilize the items you print on because the head operates at a temperature above the boiling point. Who would even think of that when we discussed the idea of wax printing? Thanks to our learning to print with solid ink technology, we are now able to expand into other markets. nine0003

nine0003

We are changing the world together. Each of us. With every breath, our presence sets off a chain reaction in the world around us.

But only a few of us are able to change the lives of others for the better. And only a few do it day after day. Every day, Xerox R&D centers test new technologies that make a difference.

The company creates opportunities for them and gives them time to dream. And also resources to turn dreams into reality. Whether it's inventing new materials with incredible performance or using virtual reality to improve memory in people with Alzheimer's. nine0003

We are proud of our people who drive change at Xerox R&D centers around the world.

Xerox announces entry into the 3D printing market and buys out 3D printer developer Vader Systems

News

Xerox announced at the New York Investor’s Day 2019 conference its intention to enter the additive manufacturing market and backed up the statement with a deal to acquire startup Vader Systems, which develops unusual magnetohydrodynamic 3D printers for printing with molten metals and alloys.

nine0003

nine0003 Research and consulting company International Data Corporation (IDC) recently forecast that the global additive manufacturing market will be worth $13.8 billion by the end of this year, and the well-known US office equipment manufacturer is keen to take a bite. Xerox Corporation has not yet been engaged in the production of 3D printers or the manufacture of consumables for them, but intends to soon present its solutions for high-performance 3D printing with polymers and not only. nine0003

The corporation has not yet disclosed specific plans for the future, but it was not without a surprise: during the conference, Xerox representatives announced the purchase of a family startup Vader Systems. Founded by inventor Zachary Vader and supervised by his father, Scott Vader, the company has been developing relatively inexpensive MHD metal 3D printing technology over the past seven years.

The Polaris pilot system, demonstrated last spring at the RAPID + TCT show in Fort Worth, Texas, is capable of growing metal blanks up to 305 x 305 x 305 mm.