3D printing supplies wholesale

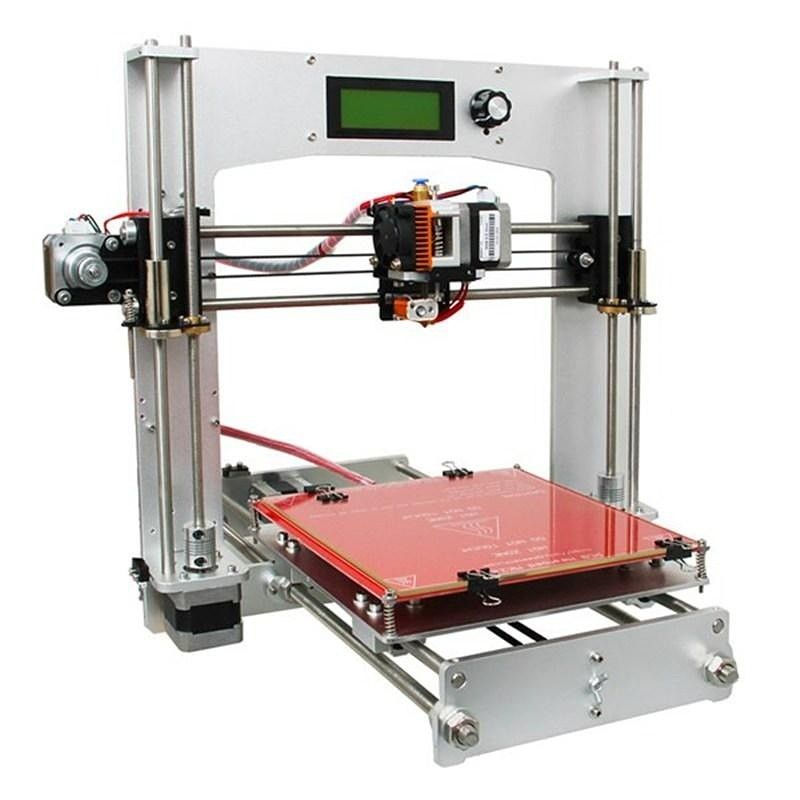

3D printers

Filters

- In stock (46)

- Out of stock (25)

- 3D Printer (65)

- 3D Printer with Curriculum (1)

- 3D printer (2)

- Artillery 3D (3)

- Creality 3D (5)

- Creatbot (9)

- FlashForge (13)

- Flsun (3)

- Kywoo3D (3)

- Lotmaxx (1)

- MakerBot (9)

- Mingda (1)

- Peopoly (1)

- Phrozen (6)

- Shining 3D (5)

- SnapMaker (3)

- ZMorph (3)

- Zortrax (3)

Showing 1 - 24 of 68 products

View

Filters

- In stock (46)

- Out of stock (25)

- 3D Printer (65)

- 3D Printer with Curriculum (1)

- 3D printer (2)

- Artillery 3D (3)

- Creality 3D (5)

- Creatbot (9)

- FlashForge (13)

- Flsun (3)

- Kywoo3D (3)

- Lotmaxx (1)

- MakerBot (9)

- Mingda (1)

- Peopoly (1)

- Phrozen (6)

- Shining 3D (5)

- SnapMaker (3)

- ZMorph (3)

- Zortrax (3)

Matte Black

Sky Gray

3D laser printers from the top brands | Lowest prices

Filters

- In stock (22)

- Out of stock (7)

- 3 in 1 3D Printer (1)

- 3D Printer (5)

- Laser Cutter/Engraver (19)

- Comgrow (2)

- Flux (4)

- Gweike Laser (3)

- Lotmaxx (2)

- Makeblock (1)

- Ortur (2)

- Sculpfun (4)

- SnapMaker (3)

- ZMorph (1)

- xTool (3)

Showing 1 - 24 of 25 products

View

Filters

- In stock (22)

- Out of stock (7)

- 3 in 1 3D Printer (1)

- 3D Printer (5)

- Laser Cutter/Engraver (19)

- Comgrow (2)

- Flux (4)

- Gweike Laser (3)

- Lotmaxx (2)

- Makeblock (1)

- Ortur (2)

- Sculpfun (4)

- SnapMaker (3)

- ZMorph (1)

- xTool (3)

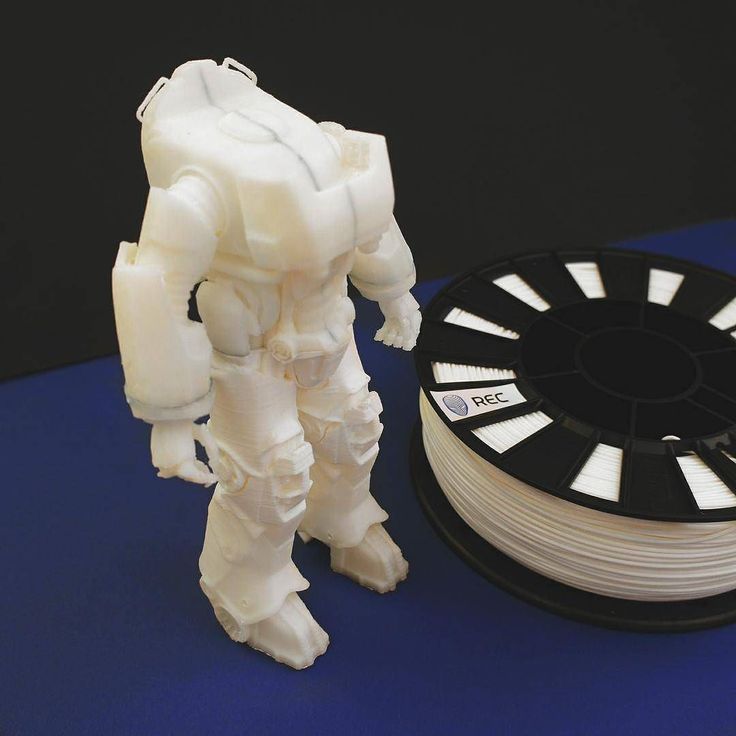

FDM/FFF Consumables

FFF technology has many advantages, including the relative simplicity of the design of printers and the affordability of both devices and consumables. Moreover, the range of materials is perhaps the widest among all available technologies. As a rule, thermoplastics are used for printing, but there are exceptions - composite materials containing various additives, but based, again, on thermoplastics. In this section, we will try to talk about the most widely used materials in more detail, starting with the most popular types. nine0003

- 1 Polylactide (PLA, PLA)

- 2 Acrylonitrile butadiene styrene (ABS)

- 3 Polyvinyl alcohol (PVA)

- 4 Nylon

- 5 Polycarbonate (PC)

- 6 High density polyethylene (HDPE)

- 7 Polypropylene (PP, PP)

- 8 Polycaprolactone (PCL)

- 9 Polyphenylsulfone (PPSU)

- 10 Polymethyl methacrylate (Acrylic, plexiglass, acrylic, PMMA)

- 11 Polyethylene terephthalate (PET, PET)

- 12 High impact polystyrene (HIPS)

- 13 Wood Simulators (LAYWOO-D3, BambooFill)

- 14 Sandstone Simulators (Laybrick)

- 15 Metal Simulators (BronzeFill)

Polylactide (PLA, PLA)

Polylactide is one of the most widely used thermoplastics due to several factors. Let's start with the fact that PLA is known for its environmental friendliness. This material is a lactic acid polymer, which makes PLA a completely biodegradable material. The raw materials for the production of polylactide are corn and sugar cane. At the same time, the environmental friendliness of polylactide causes its fragility. Plastic easily absorbs water and is relatively soft. As a rule, PLA models are not intended for functional use, but serve as designer models, souvenirs and toys. Few practical industrial applications include the production of food packaging, drug containers and surgical sutures, as well as use in bearings that do not carry high mechanical loads (for example, in modeling), which is possible due to the material's excellent slip coefficient. nine0003

Let's start with the fact that PLA is known for its environmental friendliness. This material is a lactic acid polymer, which makes PLA a completely biodegradable material. The raw materials for the production of polylactide are corn and sugar cane. At the same time, the environmental friendliness of polylactide causes its fragility. Plastic easily absorbs water and is relatively soft. As a rule, PLA models are not intended for functional use, but serve as designer models, souvenirs and toys. Few practical industrial applications include the production of food packaging, drug containers and surgical sutures, as well as use in bearings that do not carry high mechanical loads (for example, in modeling), which is possible due to the material's excellent slip coefficient. nine0003

One of the most important factors for 3D printing applications is the low melting temperature of only 170-180°C, which contributes to relatively low power consumption and the use of inexpensive brass and aluminum nozzles. As a rule, extrusion is carried out at 160-170°C. At the same time, PLA solidifies quite slowly (glass transition temperature is about 50°C), which should be taken into account when choosing a 3D printer. The best option is a device with an open case, a heated work platform (to avoid deformation of large models) and, preferably, additional fans to cool the fresh layers of the model. nine0003

As a rule, extrusion is carried out at 160-170°C. At the same time, PLA solidifies quite slowly (glass transition temperature is about 50°C), which should be taken into account when choosing a 3D printer. The best option is a device with an open case, a heated work platform (to avoid deformation of large models) and, preferably, additional fans to cool the fresh layers of the model. nine0003

PLA has low shrinkage, i.e. loss of volume on cooling, which helps prevent warping. However, shrinkage has a cumulative effect as the dimensions of printed models increase. In the latter case, the build platform may need to be heated to evenly cool the printed objects.

The cost of PLA is relatively low, which adds to the popularity of this material.

Acrylonitrile Butadiene Styrene (ABS)

ABS is perhaps the most popular thermoplastic used in 3D printing, but not the most common. This contradiction is explained by certain technical difficulties that arise when printing ABS. The desire of craftsmen to use ABS is determined by the excellent mechanical properties, durability and low cost of this material. In the industry, ABS plastic is already widely used: the production of car parts, cases of various devices, containers, souvenirs, various household accessories, etc. nine0003

The desire of craftsmen to use ABS is determined by the excellent mechanical properties, durability and low cost of this material. In the industry, ABS plastic is already widely used: the production of car parts, cases of various devices, containers, souvenirs, various household accessories, etc. nine0003

ABS plastic is resistant to moisture, acids and oil, has a fairly high temperature resistance - from 90°C to 110°C. Unfortunately, some types of material are destroyed by direct sunlight, which somewhat limits the application. At the same time, ABS plastic is easy to paint, which allows you to apply protective coatings on non-mechanical elements.

Despite a relatively high glass transition temperature of around 100°C, ABS has a relatively low melting point. Actually, due to the amorphous nature of the material, ABS does not have a melting point, as such, but 180 ° C is considered an acceptable temperature for extrusion, which is on the same level as the above-described PLA. The lower temperature spread between extrusion and glass transition allows ABS to cure faster than PLA. nine0003

The lower temperature spread between extrusion and glass transition allows ABS to cure faster than PLA. nine0003

The main disadvantage of ABS plastic can be considered a high degree of shrinkage during cooling - the material can lose up to 0.8% of its volume. This effect can lead to significant deformations of the model, twisting of the first layers and cracking. To combat these unpleasant phenomena, two main solutions are used. First, heated work platforms are used to help reduce the temperature gradient between the lower and upper layers of the model. Secondly, ABS 3D printers often use closed housings and control of the background temperature of the working chamber. This makes it possible to maintain the temperature of the applied layers at a level just below the glass transition threshold, reducing the degree of shrinkage. Full cooling is carried out after receiving the finished model. nine0003

The relatively low stickiness of ABS may require additional bonding aids such as adhesive tape, polyimide film, or applying an acetone solution of the ABS to the platform just prior to printing. For more information on how to avoid warping, see How to Avoid Warping 3D Printed Models.

For more information on how to avoid warping, see How to Avoid Warping 3D Printed Models.

While ABS is not a health hazard at room temperature, heated plastic releases acrylonitrile fumes, a poisonous compound that can irritate mucous membranes and cause poisoning. Although the amount of Acrylonitrate produced in small scale printing is negligible, it is recommended that you print in a well ventilated area or use an exhaust hood. It is not recommended to use ABS plastic for the production of food containers and utensils (especially for storing hot food or alcoholic beverages) or toys for small children. nine0003

The good solubility of ABS in acetone is very useful as it allows large models to be produced piece by piece and glued together, greatly expanding the capabilities of inexpensive desktop printers.

Polyvinyl alcohol (PVA)

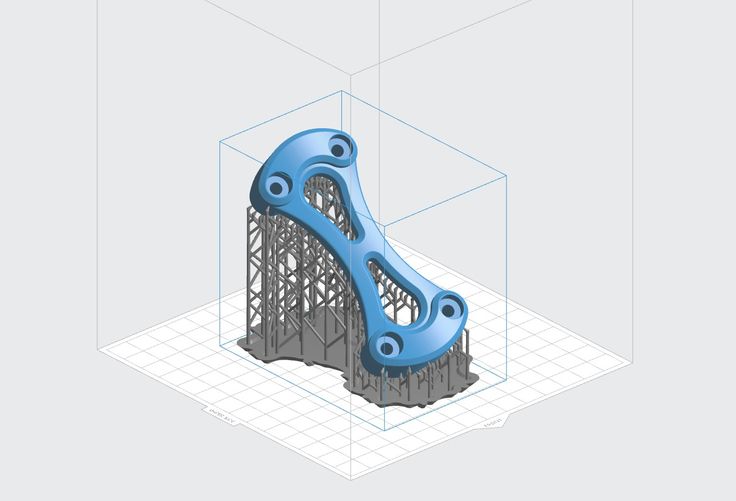

Polyvinyl alcohol is a material with unique properties and special applications. The main feature of PVA is its water solubility. 3D printers equipped with dual extruders have the ability to print models with PVA support structures. Upon completion of printing, the supports can be dissolved in water, leaving a finished model that does not require mechanical or chemical roughening. Similarly, PVA can be used to create water-soluble master patterns for molds and molds themselves. nine0003

The main feature of PVA is its water solubility. 3D printers equipped with dual extruders have the ability to print models with PVA support structures. Upon completion of printing, the supports can be dissolved in water, leaving a finished model that does not require mechanical or chemical roughening. Similarly, PVA can be used to create water-soluble master patterns for molds and molds themselves. nine0003

The mechanical properties of PVA are quite interesting. At low humidity, plastic has high tensile strength. With increasing humidity, strength decreases, but elasticity increases. The extrusion temperature is 160-175°C, which allows the use of PVA in printers designed for printing with ABS and PLA plastics.

Since the material easily absorbs moisture, it is recommended to store PVA plastic in dry packaging and, if necessary, dry before use. Drying can be done in a pottery kiln or an ordinary oven. As a rule, drying of standard coils takes 6-8 hours at a temperature of 60-80°C. Exceeding 220°C will cause the plastic to decompose, which should be taken into account when printing. nine0036

Exceeding 220°C will cause the plastic to decompose, which should be taken into account when printing. nine0036

Nylon

Nylon is attractive due to its high wear resistance and low coefficient of friction. Thus, nylon is often used to coat friction parts, which improves their performance and often allows them to function without lubrication. Following the widespread use of nylon in industry, additive manufacturing has also become interested in the material. Attempts to print with nylon have been made almost since the early days of FDM/FFF technology. nine0003

In reality, there are several types of nylon produced by different methods and with slightly different characteristics. The most famous is nylon-66, created by the American company DuPont in 1935. The second most popular option is nylon-6, developed by BASF to circumvent the DuPont patent. These two options are very similar. In terms of 3D printing, the main difference is the melting point: Nylon-6 melts at 220°C, while Nylon-66 melts at 265°C. nine0003

nine0003

Many hobbyists prefer to use commercially available nylon threads such as trimmer wire. The diameter of such materials often corresponds to the diameter of standard FFF materials, which makes their use tempting. At the same time, these products are usually not pure nylon. In the case of trimmer rods, the material consists of nylon and fiberglass for an optimal combination of flexibility and rigidity.

Fiberglass has a high melting point, and therefore printing with such materials is fraught with high nozzle wear and plugging. nine0003

Recently there have been attempts to commercially develop nylon-based printing materials specifically for FDM/FFF applications, including Nylon-PA6 and Taulman 680. These grades are extrudable at 230-260°C.

Since nylon easily absorbs moisture, store consumables in vacuum packaging or at least in a container with water-absorbing materials. A sign of excessively damp media will be steam escaping from the nozzle during printing, which is not dangerous, but may degrade the quality of the model. nine0003

nine0003

When printing with nylon, it is not recommended to use a polyimide desktop coating as the two materials fuse together. As a coating, you can use adhesive tape with wax impregnation (masking tape). The use of a heated bed will help reduce the possibility of deformation of the model, similar to printing with ABS plastic. Due to the low coefficient of friction of nylon, extruders with studded feeders should be used.

The nylon layers have excellent adhesion, minimizing the chance of delamination. nine0003

Nylon is difficult to bond, making it difficult to print large multi-piece models. Alternatively, fusion of parts is possible.

Because nylon can release toxic fumes when heated, we recommend that you print in a well-ventilated area or use an exhaust fan.

Polycarbonate (PC)

Polycarbonates are attractive due to their high strength and toughness, as well as resistance to high and low temperatures. nine0003

nine0003

The potential health risk of printing is worth noting: the toxic and potentially carcinogenic compound bisphenol A is often used as a raw material. .

The extrusion temperature depends on the printing speed to avoid cracking, but the minimum temperature at 30mm/s can be considered as 265°C. When printing, the use of polyimide film is recommended for better adhesion to the desktop surface. The high susceptibility of polycarbonate to deformation requires the use of a heated platform and, if possible, a closed housing with heating of the working chamber. nine0003

Polycarbonate is highly hygroscopic (easily absorbs moisture), which requires storage in dry conditions to avoid the formation of bubbles in the applied layers. For extended printing in humid climates, even the print spool may need to be stored in a moisture-proof container.

High Density Polyethylene (HDPE)

Arguably the most common plastic in the world, polyethylene is relatively rare among 3D printed materials. The reason for this is the difficulty in layer-by-layer manufacturing of models. nine0003

The reason for this is the difficulty in layer-by-layer manufacturing of models. nine0003

Polyethylene melts easily (130-145°C) and hardens quickly (100-120°C), as a result of which the applied layers often do not have time to set. In addition, polyethylene is characterized by high shrinkage, which provokes the twisting of the first layers and the deformation of the models as a whole during uneven solidification. Printing with polyethylene requires the use of a heated platform and a working chamber with accurate temperature control to slow down the cooling of the applied layers. In addition, you will need to print at high speed. nine0003

Difficulties in use are more than offset by the cheapness and availability of this material. Recently, several devices have been developed for processing plastic waste from HDPE (bottles, food packaging, etc.) into standard filaments for printing on FDM/FFF printers. Examples are FilaBot and RecycleBot. Due to the simplicity of design, RecycleBot devices are often assembled by 3D craftsmen.

Melting polyethylene releases harmful vapors, so it is recommended to print in well-ventilated areas. nine0036

Polypropylene (PP, PP)

Polypropylene is a widely used plastic used in the manufacture of packaging materials, utensils, syringes, pipes, etc. The material has a low specific gravity, is non-toxic, has good chemical resistance, is resistant to moisture and wear, and cheap enough. Among the disadvantages of polypropylene, one can note the vulnerability to temperatures below -5 ° C and to direct sunlight.

The main difficulty in printing with polypropylene is the high shrinkage of the material during cooling - up to 2.4%. For comparison, the shrinkage of the popular but already problematic ABS plastic reaches 0.8%. Although polypropylene adheres well to cold surfaces, it is recommended to print on a heated platform to avoid deformation of models. The minimum recommended extrusion temperature is 220°C. nine0003

nine0003

Polypropylene printing filaments are sold by Orbi-Tech, German RepRap, Qingdao TSD Plastic. Stratasys has developed a polypropylene simulant optimized for 3D printing called Endur.

Polycaprolactone (PCL)

Polycaprolactone (aka Hand Moldable Plastic, Mold-Your-Own Grips, InstaMorph, Shapelock, Friendly Plastic, Polymorph, Polymorphus, Ecoformax) - biodegradable polyester, characterized by an extremely low melting point of about 60 ° C . In practice, this property creates certain problems in 3D printing, since not all 3D printers can be configured to work at such low temperatures. Heating polycaprolactone to the usual extrusion temperatures (about 200°C) causes a loss of mechanical properties and may lead to breakage of the extruder. nine0003

Polycaprolactone is non-toxic, making it suitable for use in the medical industry, and biodegradable. When ingested, polycaprolactone breaks down, which makes printing with this material safe. Due to the low melting point, there is no danger of burns when touching fresh models. The high plasticity of the material makes it possible to reuse.

Due to the low melting point, there is no danger of burns when touching fresh models. The high plasticity of the material makes it possible to reuse.

Polycaprolactone is of little use for creating functional mechanical models due to its viscosity (glass transition temperature is -60°C) and low heat resistance (melting point is 60°C). On the other hand, this material is perfect for the production of mock-ups and food containers. nine0003

The material sticks easily to the surface of even a cold working table and is easy to paint.

Polyphenylsulfone (PPSU)

Polyphenylsulfone is a high strength thermoplastic used extensively in the aviation industry. The material has excellent chemical and thermal stability and practically does not burn. Polyphenylsulfone is biologically inert, which makes it possible to use this material for the production of tableware and food containers. Operating temperature range is -50°С - 180°С. Plastic is resistant to solvents and fuels and lubricants. nine0003

Plastic is resistant to solvents and fuels and lubricants. nine0003

For all its merits, polyphenylsulfone is rarely used in 3D printing due to its high melting point, reaching 370°C. Such extrusion temperatures are beyond the power of most desktop printers, although printing is theoretically possible using ceramic nozzles. Currently, the only active user of the material is Stratasys, which offers industrial Fortus installations.

Polymethyl methacrylate (Acrylic, plexiglass, acrylic, PMMA)

Polymethyl methacrylate is a well-known organic glass. The material is durable, moisture resistant, environmentally friendly, easy to glue, plastic enough and resistant to direct sunlight.

Unfortunately, acrylic is not suitable for FDM/FFF printing for a number of reasons. Acrylic is poorly stored in the form of spools of thread, as constant mechanical stress leads to the gradual destruction of the material. To avoid bubbles, the print resolution must be high, with a precision almost impossible for home printers. Acrylic's rapid curing requires strict environmental control of the working chamber and high print speeds. Again, the print speeds of FDM/FFF printers are inversely related to print resolution, which exacerbates the problem. nine0003

Acrylic's rapid curing requires strict environmental control of the working chamber and high print speeds. Again, the print speeds of FDM/FFF printers are inversely related to print resolution, which exacerbates the problem. nine0003

However, attempts are being made to print with acrylic, and some of them are producing relatively positive results. However, when creating sufficiently strong models, it is not yet possible to avoid the formation of bubbles and achieve the usual transparency of the material. At the moment, the best results with acrylic are shown by another printing technology - multi-jet modeling (MJM) from 3D Systems. In this case, a photopolymer version of acrylic is used. Stratasys has also made significant progress using its own photopolymer acrylic simulant VeroClear on Objet Eden printers. It is hoped that the high demand for acrylic will lead to the emergence of composite materials based on polymethyl methacrylate, designed specifically for FDM/FFF printing. nine0036

nine0036

Polyethylene terephthalate (PET, PET)

Polyethylene terephthalate - this complex name hides a material used for the production of plastic bottles and other food and medical containers.

The material has a high chemical resistance to acids, alkalis and organic solvents. The physical properties of PET are also impressive with high wear resistance and tolerance to a wide temperature range from -40°C to 75°C. Among other things, the material is easily machined. nine0003

Printing with PET is somewhat problematic due to the relatively high melting point of up to 260°C and significant cooling shrinkage of up to 2%. Using PET as a consumable requires approximately the same conditions as printing with ABS.

Achieving transparency of models requires rapid cooling to pass the glass transition threshold of 70°C - 80°C.

The material has become the focus of interest for 3D craftsmen using used containers as raw materials for the home production of 3D printing consumables. Recycling devices such as FilaBot or RecycleBot are used to make threads. nine0036

Recycling devices such as FilaBot or RecycleBot are used to make threads. nine0036

High impact polystyrene (HIPS)

High impact polystyrene is widely used in industry for the production of various household products, building materials, disposable tableware, toys, medical instruments, etc.

When 3D printed, polystyrene exhibits physical properties very similar to the popular ABS plastic, making it an increasingly popular material among 3D crafters. The most attractive feature of polystyrene is the difference from ABS in terms of chemical properties: polystyrene is quite easily amenable to the organic solvent Limonen. Since Limonene has no effect on ABS plastic, it is possible to use polystyrene as a material for building soluble support structures, which is extremely useful when building complex, interlaced models with internal supports. Compared to the convenient, water-soluble polyvinyl alcohol (PVA) plastic, polystyrene compares favorably with relatively low cost and resistance to humid climates that make PVA difficult to work with. nine0003

nine0003

It's worth bearing in mind that some ABS manufacturers mix slightly cheaper polystyrene into their consumables. Accordingly, models made from such materials can be dissolved in Limonene along with supporting structures.

When polystyrene is heated to extrusion temperature, toxic fumes can be released, so printing in a well-ventilated area is recommended.

Wood simulants (LAYWOO-D3, BambooFill)

LAYWOO-D3 is a recent development for printing wood-like models. The material consists of 40% natural wood chips of microscopic size and 60% binder polymer. The LAYWOO-D3 is very easy to handle, being virtually warp-free and does not require the use of a heated platform. According to the manufacturers, the polymer is non-toxic and completely safe.

The unique material properties allow for different visual results when printing with different nozzle temperatures. The operating temperature range is 180°C-250°C. As the extrusion temperature increases, the shade of the material becomes progressively darker, allowing it to simulate different types of wood or annual rings. nine0003

As the extrusion temperature increases, the shade of the material becomes progressively darker, allowing it to simulate different types of wood or annual rings. nine0003

Finished models are excellent for mechanical processing - grinding, drilling, etc. In addition, the products are easily painted, and unpainted models even have a characteristic woody smell.

Unfortunately, the cost of the material is almost four times higher than the price of popular materials such as PLA and ABS plastics. As popularity is projected to grow, the material should become more accessible.

Alternative materials are currently being developed and tested, such as BambooFill from the Dutch company ColorFabb. nine0036

Sandstone simulants (Laybrick)

Composite material from the inventor Kai Parti, responsible for the revolutionary wood simulant LAYWOO-D3. This time, Kai set his sights on sandstone imitation, using a tried and tested method of mixing a binder with a filler, in this case mineral.

Laybrick allows you to produce objects with different surface textures. At low extrusion temperatures of the order of 165°C-190°C, the finished products have a smooth surface. Increasing the printing temperature makes the material rougher, up to a high degree of resemblance to natural sandstone at extrusion temperatures above 210°C. nine0003

The material is easy to work with no need to heat the work platform, does not show significant deformation when shrinking and does not produce toxic fumes when heated. The only drawback can be considered a rather high cost of the material, which is largely due to limited production.

Metal Simulators (BronzeFill)

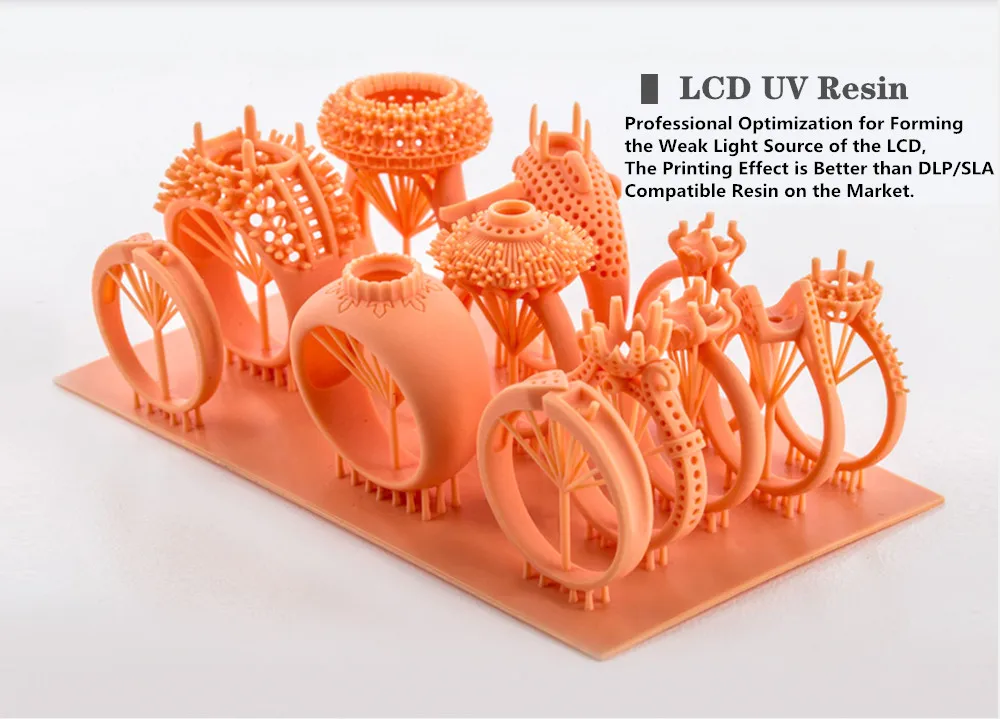

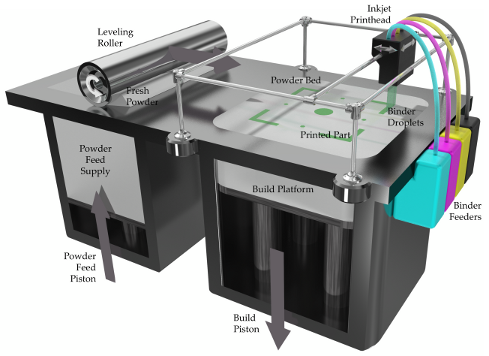

Metals have attracted additive manufacturing enthusiasts since the early days of 3D printing technology. Unfortunately, printing with pure metals and alloys causes a lot of difficulties that are insurmountable for most 3D printing methods. Fully functional metal products can only be produced using technologies such as SLS, DLMS or EBM, which require the use of industrial plants that cost hundreds of thousands of dollars. At the same time, metal imitators are successfully used in 3D inkjet printing (3DP), where products are formed from metal powders, the particles of which are held together by an applied binder material. In FDM/FFF printing, metal simulants are just emerging. nine0003

At the same time, metal imitators are successfully used in 3D inkjet printing (3DP), where products are formed from metal powders, the particles of which are held together by an applied binder material. In FDM/FFF printing, metal simulants are just emerging. nine0003

An interesting example is BronzeFill, which is actually a transparent PLA plastic filled with bronze microparticles. The material, currently in beta testing, must prove suitability for use in any printer designed to work with polylactide.

Finished products are easy to polish, achieving a high external resemblance to all-metal products. At the same time, it should be taken into account that the binding element of the material is thermoplastic, with appropriate mechanical and temperature limitations. nine0003

Go to the main page of the 3D Printing Encyclopedia

3D printing, 3D printers, 3D pens, 3D plastic in Ukraine

3D PRINTING

_____________

We embody Your Ideas

Qualitatively. Fast. Available.

Fast. Available.

ORDER 3D PRINTING

3D PRINTERS

Universal.

Reliable.

Accurate.

BUY

3D pens

Original

Warranty

Service

BUY

ENGINEERING APPROACH

Qualified specialists of 3D4U.com.ua will help you choose a 3D printer and consumables to solve your problems. Do you need a 3D printer? Then we will optimize your model for 3D printing and print with an accuracy of 20 microns.

COMPLETE SOLUTIONS

High quality materials for 3D printing (ABS, PLA, PET, HIPS, TPU, PRIMALLOY...), accessories and spare parts for 3D equipment, 3D printers, 3D pens. Modeling according to your drawings, sketches, photos. All this you can order right now! nine0003

QUALITY SERVICE

Pre-sales equipment testing. Consultations on the choice of 3D materials. Warranty and service maintenance during operation. Selection of 3D printing parameters according to your criteria. Focus on results.

FAST DELIVERY

Fast delivery across Ukraine by transport company New mail. Payment by VISA, MasterCard, cash upon receipt or by bank transfer. Up to 14 days return with 100% money back. Sending products on the day of order. nine0003

Popular use 3D Press

3D Printed Prototypes

3D printing

3D Seal of spare parts

Drying and optimization of the model free of charge !!!

ORDER 3D PRINTING

Send an order for 3D printing

Our achievements

Equipment

%

Satisfied customers

5000+

Completed orders

Feedback from our clients

We have not had a single complaint in two years of cooperation! An extremely responsible partner, with a great assortment. I recommend!

Grigory

Irpin

Very pleasant and competent employees. I asked a lot of questions, brought my 'stamps', asked for tips on improvements, inquired about upgrades to my printer - and always received direct and clear answers. Yes, I buy plastic from them. The only wish is to 'shift' the working hours on weekdays :), otherwise I also work until 18:00 and it is rarely possible to be in time before the store closes. In general, I am very satisfied with the company and the employees. Good luck to you! nine0003

Yes, I buy plastic from them. The only wish is to 'shift' the working hours on weekdays :), otherwise I also work until 18:00 and it is rarely possible to be in time before the store closes. In general, I am very satisfied with the company and the employees. Good luck to you! nine0003

Dmitry

Odessa

I have been working with the 3d4u.com.ua company for a year and a half, I bought a printer, components and plastic from them, everything works, consultations are at the highest level, the terms of sending plastic and components are the same day. I will continue to work further, I advise everyone.

Evgeny Shevchenko

Dnipro

The work of consultants, efficiency, order picking - everything is at the highest level! Thank you. Keep it up!

Valery

Kyiv

I have been working with this store for a year now. Great service! Great plastic!

Igor

Ternopil

Thanks to the store for the wonderful service! Zamovil pen called back literally through 5 hvilin. They gave a report consultation. They corrected it on the day of the appointment. The set includes a 3D pen, rich plastic, stencils and instructions. everything is as stated on the website. Vikonano all bezdoganno. thanks again. Daughter in captivity

They gave a report consultation. They corrected it on the day of the appointment. The set includes a 3D pen, rich plastic, stencils and instructions. everything is as stated on the website. Vikonano all bezdoganno. thanks again. Daughter in captivity

Lyudmila

Lviv

I ordered 3D printing at 100 and 200 microns + modeling, everything was done within a day + sending. I am very satisfied with the quality, not a single flaw, I will use again! nine0003

Maxim

Kharkiv

Kharkiv

I ordered 3D printing at 100 and 200 microns + modeling, everything was done within a day + sending. I am very satisfied with the quality, not a single flaw, I will use again!

Maxim2019-05-07

Lviv

Thanks to the store for the wonderful service! Zamovil pen called back literally through 5 hvilin. They gave a report consultation. They corrected it on the day of the appointment. The set includes a 3D pen, rich plastic, stencils and instructions. everything is as stated on the website. Vikonano all bezdoganno. thanks again. Daughter in capture

everything is as stated on the website. Vikonano all bezdoganno. thanks again. Daughter in capture

Lyudmila2019-05-07

Ternopil

I have been working with this store for a year now. Great service! Great plastic!

Igor2019-05-07

Kyiv

The work of consultants, efficiency, order picking - everything is at the highest level! Thank you. Keep it up!

Valery2019-05-07

Odessa

Very nice and competent employees. I asked a lot of questions, brought my 'stamps', asked for tips on improvements, inquired about upgrades to my printer - and always received direct and clear answers. Yes, I buy plastic from them. The only wish is to 'shift' the working hours on weekdays :), otherwise I also work until 18:00 and it is rarely possible to be in time before the store closes. In general, I am very satisfied with the company and the employees. Good luck to you! nine0003

Dmitry 2019-02-02

Irpin

For two years of cooperation, not a single complaint! An extremely responsible partner, with a great assortment. I recommend!

I recommend!

Grigory 2018-03-30

Dnipro

I have been working with 3d4u.com.ua for a year and a half, I bought a printer, accessories and plastic from them, everything works, consultations are at the highest level, the terms of sending plastic and components are a day in a day. I will continue to work further, I advise everyone. nine0003

Evgeny Shevchenko 2018-01-12

Welcome to the 3D4U online store - the place where you will find everything you need for 3D printing. We can buy for 3D :

- equipment;

- accessories for printers;

- handles;

- plastics;

- any materials needed to maintain 3D printers and more.

Along with sales, we provide 3D modeling and 3D printing services for prototypes, jewelry, souvenirs, auto parts, structural parts, and more. We often arrange promotions and interesting sales. Follow our news to not miss the opportunity to save. nine0003

The company operates throughout Ukraine. Both private entrepreneurs and large enterprises throughout the country have been cooperating with us for several years now. And they always receive the highest standard of service. Join those who have discovered for themselves (and their business) the world of high-tech 3D printing, know how to save wisely and get the most out of their hobby or professional work.

Both private entrepreneurs and large enterprises throughout the country have been cooperating with us for several years now. And they always receive the highest standard of service. Join those who have discovered for themselves (and their business) the world of high-tech 3D printing, know how to save wisely and get the most out of their hobby or professional work.

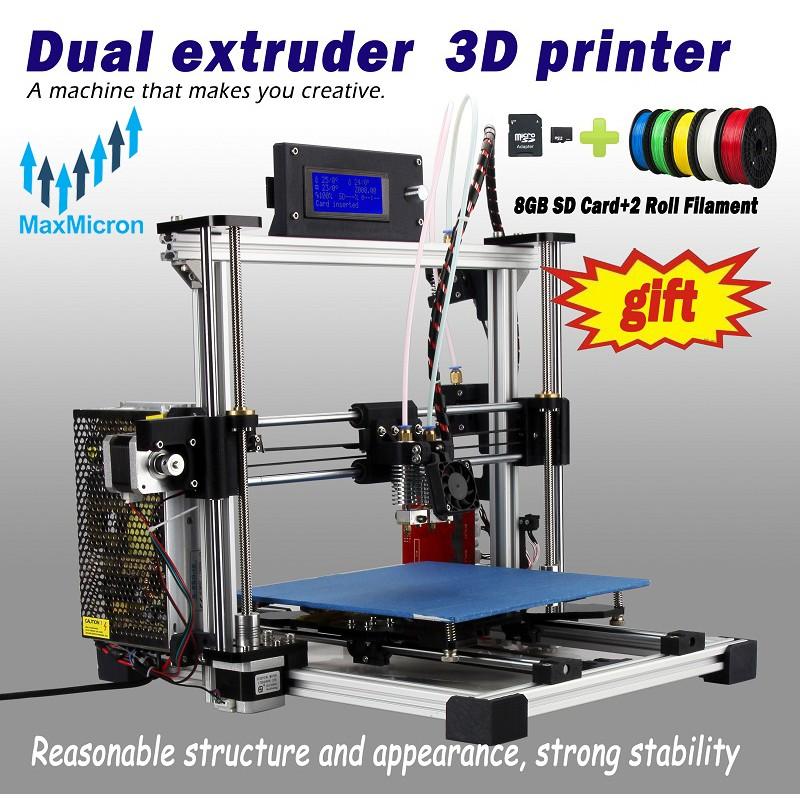

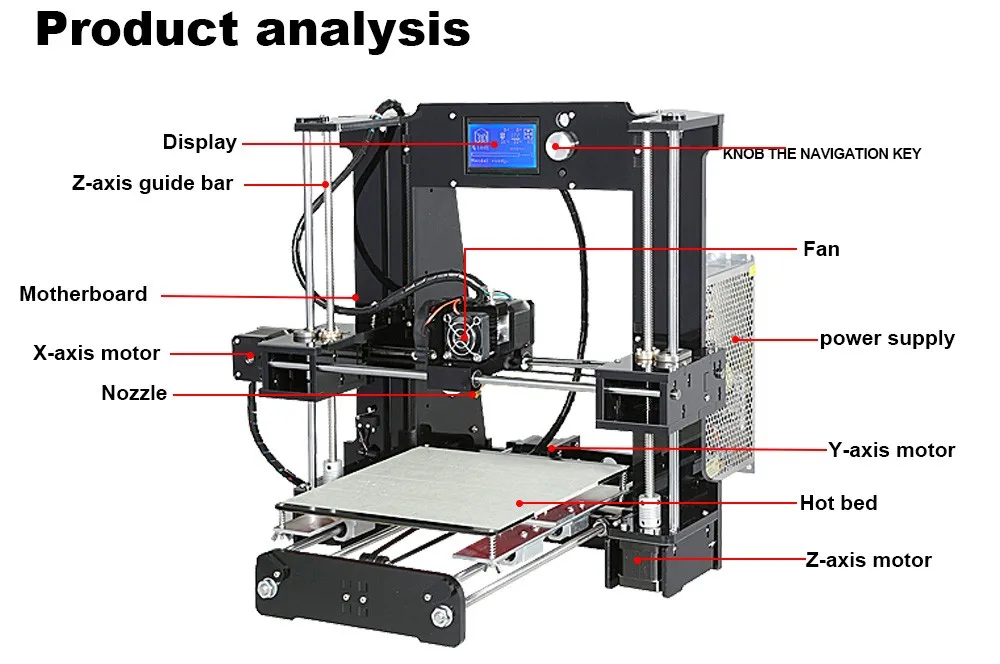

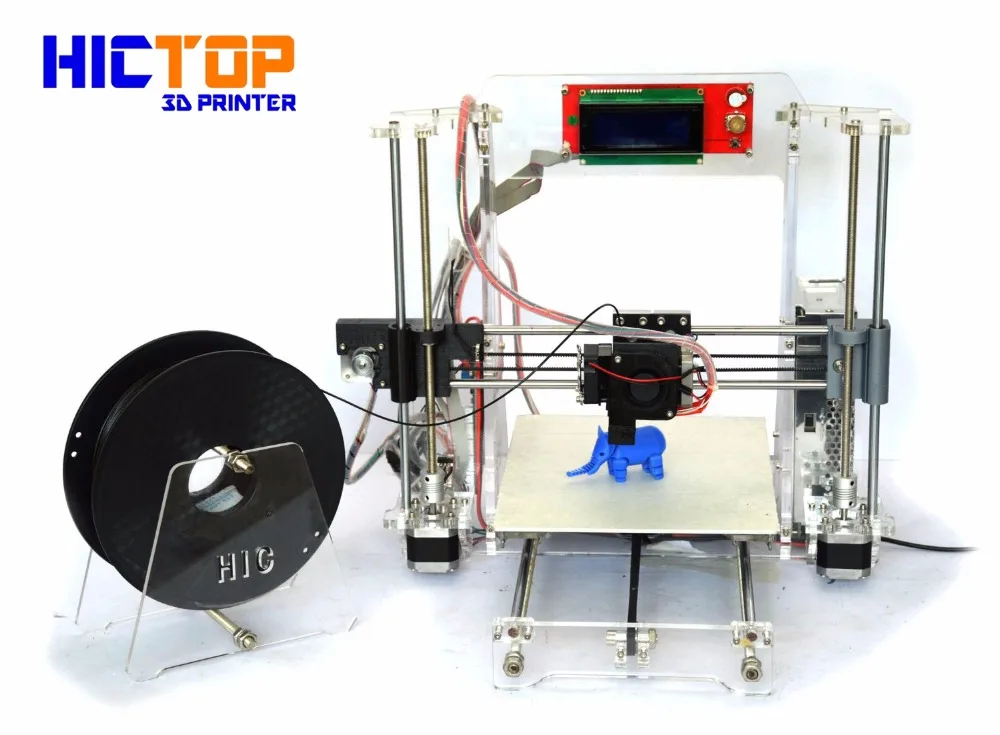

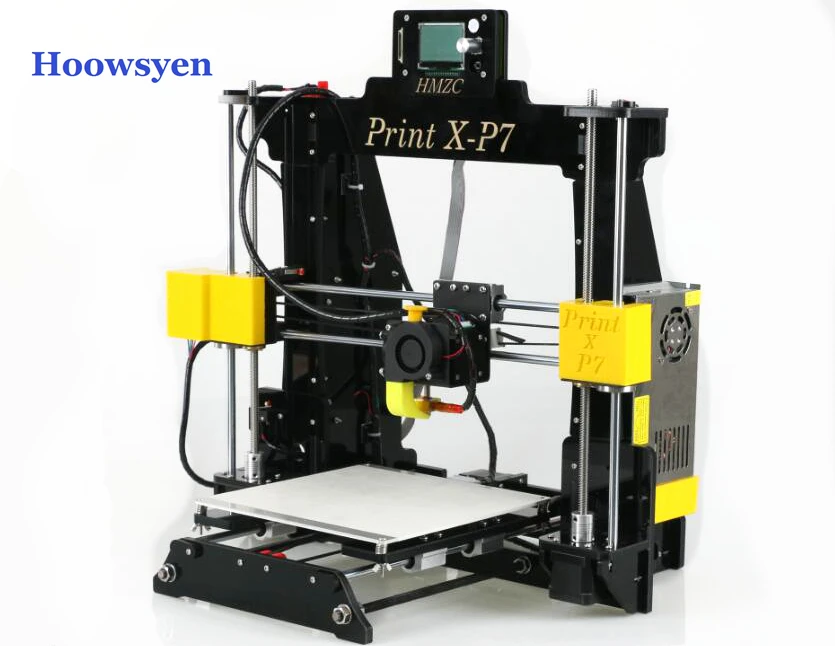

3D printers from trusted brands with delivery in Ukraine

You can buy 3D from us printers of recognized brands. The range includes models of open and closed type. There are devices for business and home, children and novice 3D printers.

We have carefully monitored the market, selected the most reliable manufacturers who make good equipment and offer it at affordable prices. Now we can offer you a really profitable purchase:

- assembly printers (KIT) from the well-known company Creality 3D;

- Flashforge premium professional 3D printers; nine0006

- Robust open Two Trees models with large area and Core XY system;

- convenient Voxelab technology devices.

Original branded 3D pens at affordable prices

Add dimension to your ideas and original sketches with high quality 3D pens. This accessory is a relative novelty in our country, but its popularity is already breaking all records.

Do not overpay for unique features, you can buy 3D in Ukraine from us at the most affordable prices. Handles from trusted manufacturers with official service and guarantees are our specialty.

3D materials for all types of equipment

You can always find high-quality 3D printing materials in our assortment: soluble and insoluble plastics, including those compatible for 3D printers with two extruders. If you order consumables for the first time, our consultants will tell you what is better and cheaper to choose.

3D4U is your correct answer to question where to buy everything for 3D . Here you will find:

- cheap types of PLA with a diameter of 1.75 and 2.

85 mm;

85 mm; - ABS and ABS+ professional products;

- durable HIPS plastic;

- PETG plastic for 3D printer;

- SILK;

- TPU and other popular consumables in a wide range of colors.

3D Modeling & 3D Printing Services

Do you need high precision parts or models but are not yet ready to equip your workshop with a 3D printer? Then we will model and print products for you. From sketches, photographs, slides. nine0003

If you already have a model, we will optimize it ourselves and implement it in volumetric form. Or we will perform modeling and print the desired batch. Pleasant prices, exact observance of deadlines and the result above expectations - our corporate identity in the provision of 3D services .

3D4U customer privileges

Why is it profitable to cooperate with us?

- 3D4U is the official distributor of the presented brands.

- We offer original products (no fakes) with full documentary support.