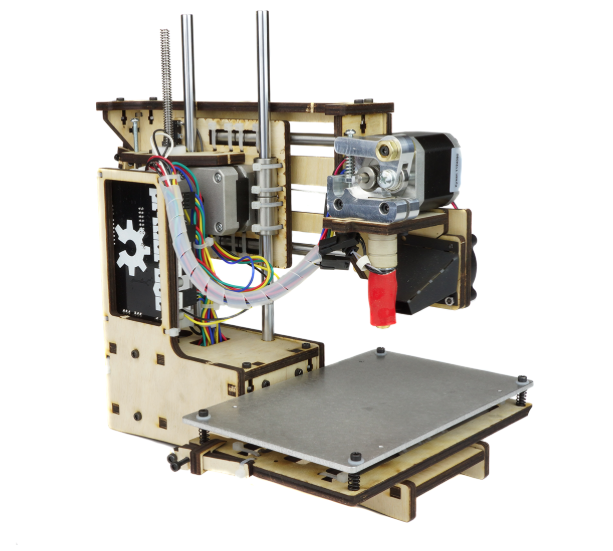

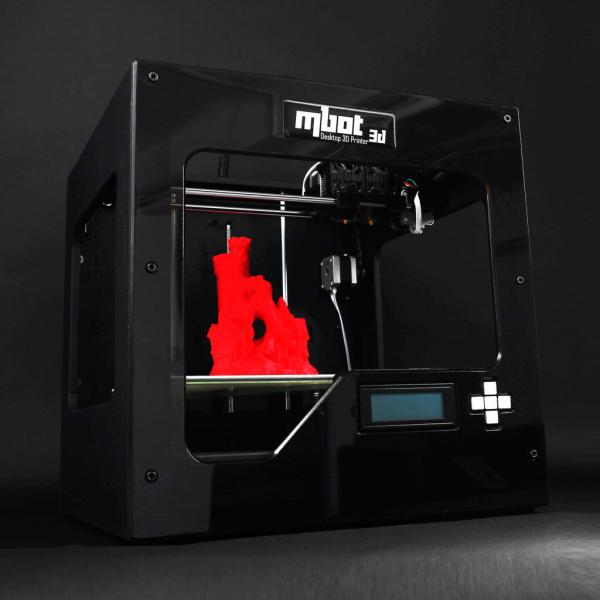

3D printer simple

Best 3D Printer for Beginners 2022 [The Ultimate 3D Printer Guide]

3D printing is a particularly difficult hobby to get into; there are confusing terms thrown around left and right, a million printers available, and enough specifications for each to make your head spin. It doesn’t have to be this, way, though!

Today’s article is dedicated to finding the 3D printers with the easiest operation and simplest configuration. We’ll examine each individually, highlight its strengths and weaknesses, and ultimately, say why it’s a good choice for novices. Take a look at the best 3D printers for beginners below:

Table of ContentsShow

The 10 Best 3D Printers For Beginners In 2022

Buyer’s Guide

Before we jump right into our reviews, it’s important for beginners to know what to look for in a 3D printer. That’s why we’ve created a short guide to some of the things that will have a large impact on your printing.

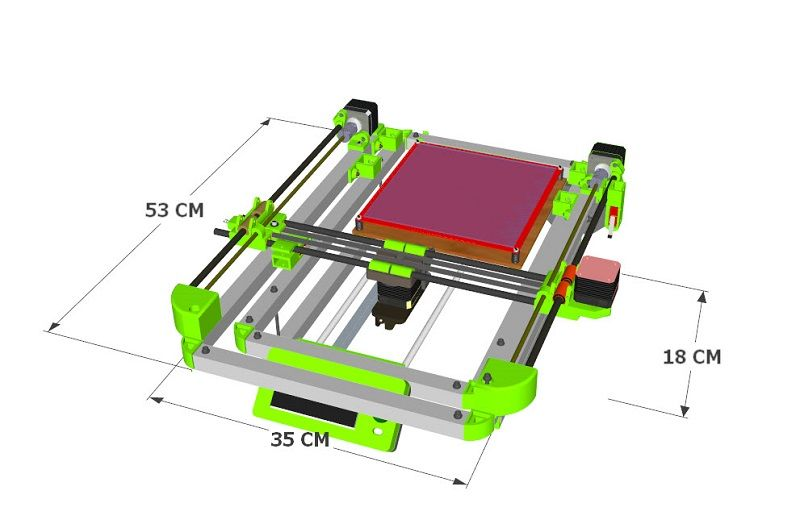

Build Area

The build area of your printer refers to the maximum allowable space for printing. You might see it listed as a series of dimensions (for instance, 5 x 5 x 5”) or it might be provided as a volume (such as 5”3 or five cubic inches). In these examples, both printers would have the exact same build area size.

Now, bear in mind that this doesn’t refer to the biggest items you can build. By including clips or other attachment mechanisms, you can combine several individual prints to create something far larger.

Printing Materials

While most basic, beginner-level 3D printers use PLA and ABS filament, more expensive models usually allow you to use a wider range of materials. For instance, you may be able to print with carbon-fiber or wooden filaments, water-soluble support materials, or even glass.

The problem is that these coarser materials can damage your extruder. That’s why if your printer supports these filaments, you’ll likely need to upgrade to a metal extruder head. These are available relatively cheaply, and help guarantee an identical print every time.

You may also want to consider different support materials. Some, like PVA, dissolve in water, leaving clean edges without any further processing. If your printer only supports PLA or ABS, however, you’ll be stuck using simple snap-off supports like those found in plastic model kits. For general printing, this isn’t an issue, but if you want a more professional end product, we recommend a printer with support for more filament types.

Print Speed

Often, you’ll see print head speed listed in millimeters (mm). This number lets you know how far the print head can move in a single second. Higher speeds are better, but this isn’t a true depiction of how quickly you’ll be able to print. For this, you’ll have to find the “print speed” listing.

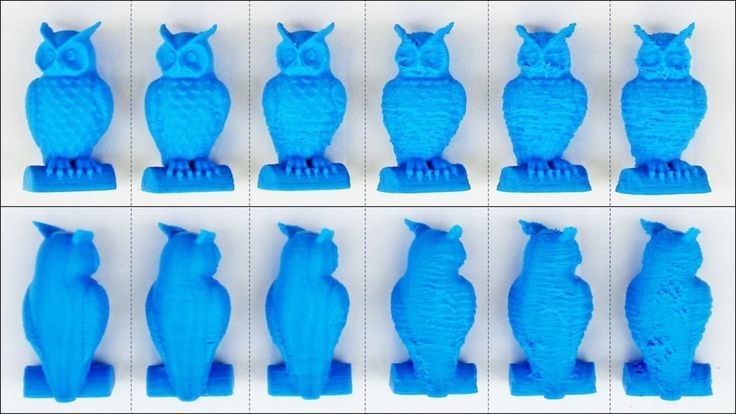

Now, it’s worth noting that the print speed listed will be the fastest that your printer allows. There are usually two settings: speed and quality. As you might expect, the faster you print, the lower the overall quality of the item. If precision and fine details are your number one priority, you’d be better off with a slower speed.

If precision and fine details are your number one priority, you’d be better off with a slower speed.

Layer Height

Usually, the printer’s supported layer heights will be listed in microns. The thinner the layer, the less obvious it will be, and the smoother the finish. On the other hand, with the thinnest layers, you can expect a print to take a lot longer to finish.

You’ll usually find the layer height that best allows you to compromise between speed and print quality early on. Afterward, you’ll know which setting works best for more detailed objects and which is best for everyday printing.

Calibration

Usually, before you can begin printing, you first have to calibrate the machine. There are various different components that require your attention: the print bed has to be leveled to ensure a perfectly flat surface, the print arm has to be perfectly positioned, and the step distance has to be set to avoid printing a far larger (or smaller) item than intended.

In recent years, printers have begun to automate these processes so you don’t have to. Some include automatic-leveling functionality, while others come pre-configured out of the box. Generally, you can expect to pay a little more such models, but as we’ll show below, it’s still possible to find them at a reasonable price.

Entry Level 3D Printers

In this section, we’ll be discussing low-cost 3D printers that are excellent for beginners. Without further ado, let’s begin with the XYZPrinting da Vinci Mini.

At around $180, the XYZPrinting da Vinci Mini as among the cheapest 3D printers on the market. This doesn’t mean it’s low-quality, though! In fact, it boasts wifi connectivity, a generous build area, and even an auto-leveling bed. You are limited to using PLA and PETG filaments but we think that’s a reasonable trade-off considering this model’s low price point.

This is about as simple as 3D printers come. You’ll find modeling software and starter filament included in the box, and since the da Vinci Mini calibrates itself, you can go from unpacking to printing in as little as 20 minutes. XYZPrinting even offers 30 free printing tutorials on their website to help novices out.

XYZPrinting even offers 30 free printing tutorials on their website to help novices out.

Even the interface is easy to use. Printing is performed with a single button, and various colored LEDs alert you to any errors as they occur. This product is designed for beginners, and it shows.

This printer retails for about $190 but has the smallest build area of any on our list. What gives? Well, the Monoprice Select Mini offers more freedom than most: thanks to its heated plate, you’re free to print with almost any material be it PLA, ABS, PVA, or even wood.

Sounds complicated right? It’s really not. This printer ships fully assembled and ready to go. It works with any PC or Mac, and even includes an SD card (and wifi support) so you can move your models across effortlessly. Sure, it’s a little slower than most, but it’s also far smaller, meaning you don’t need a dedicated space for it on your desk.

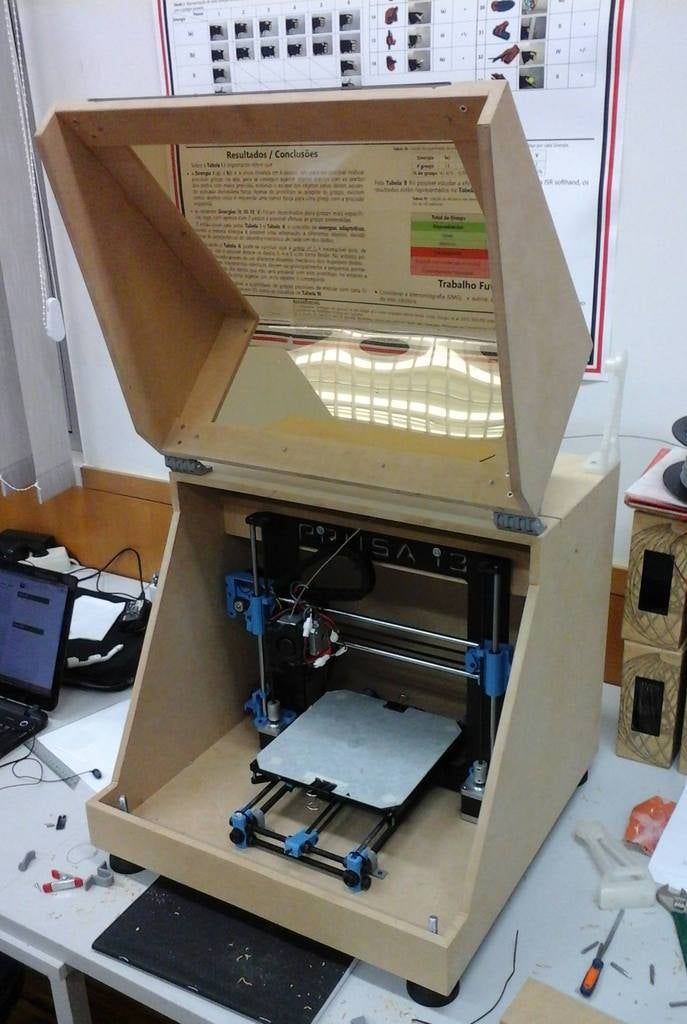

The only real problem with this printer is that some materials need an enclosure to print well, which this model doesn’t have. That said, it’s easy enough to create your own and in a pinch, even a plastic tub will work.

That said, it’s easy enough to create your own and in a pinch, even a plastic tub will work.

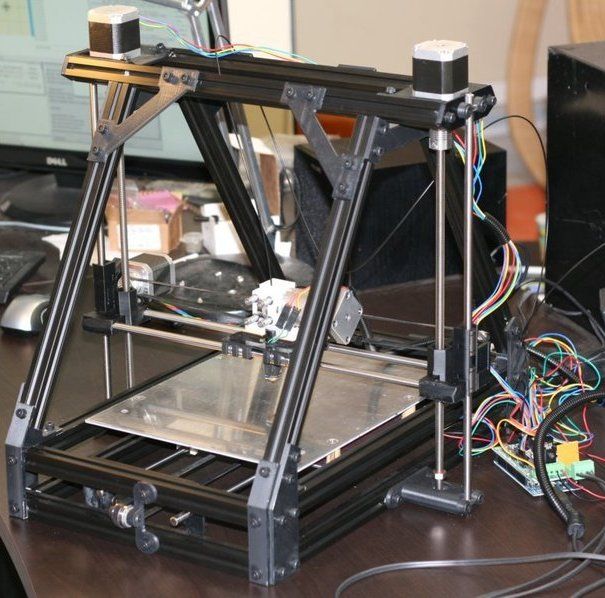

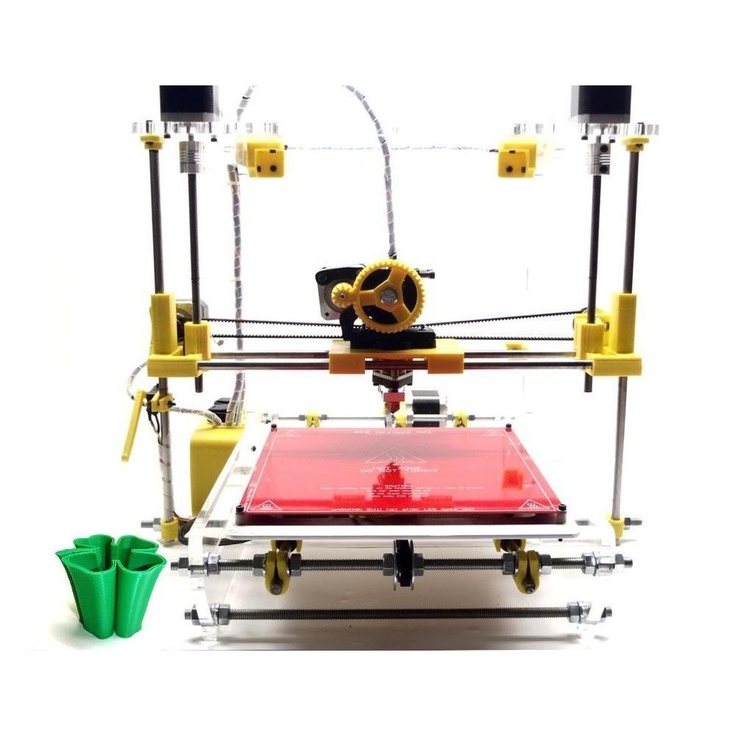

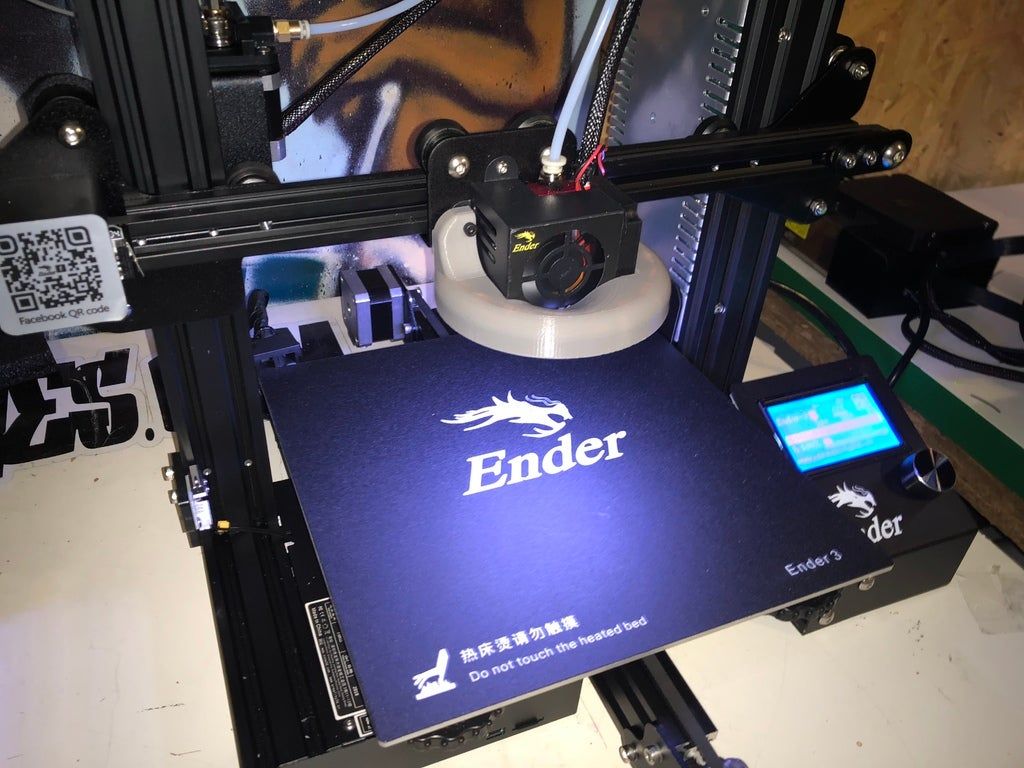

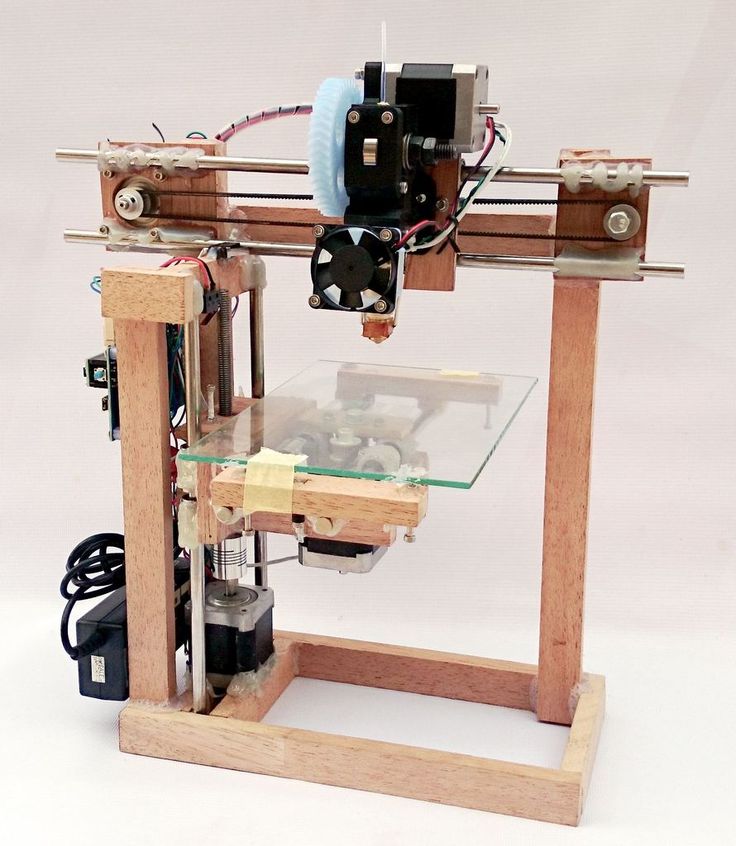

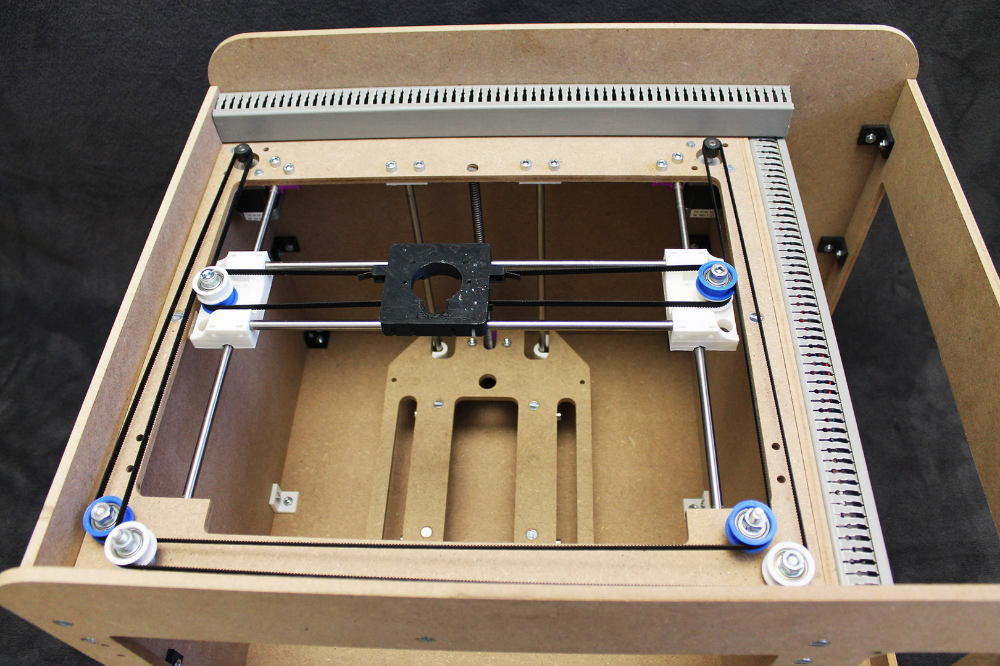

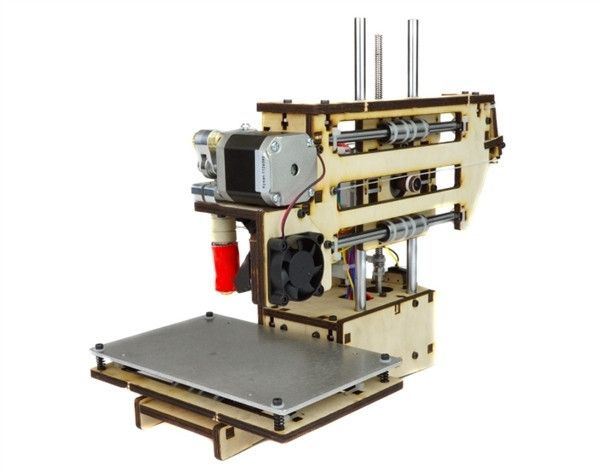

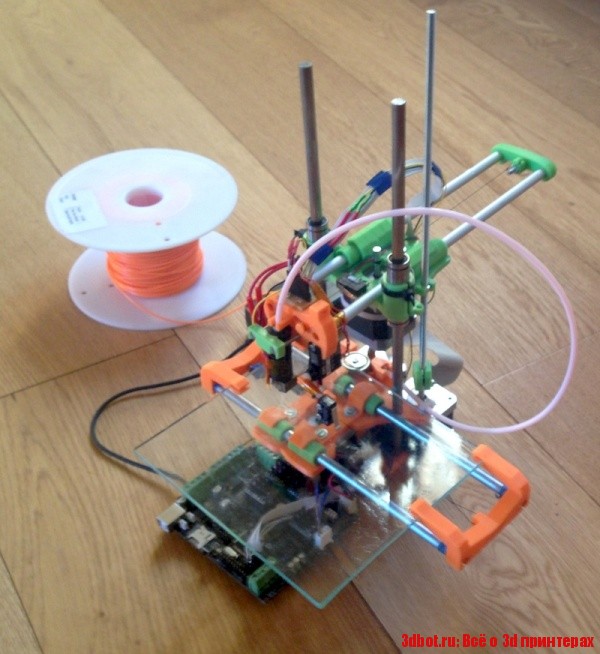

The Comgrow Creality Ender 3 is a printer that you build yourself. Wait, don’t leave! This model only takes about half an hour to assemble, and this is a large part of why such a high-quality printer can retail for about $239. This is a surprise in itself since the Ender 3 includes many traits most printers don’t, like the ability to resume a print after a power cut.

This printer has it all: wifi support, fast travel speeds, a colossal build area, and even a fast heat up time (around five minutes to reach 110°C). The downside is that you’re limited to using PLA filament, but this is the most beginner-friendly material of all, so it’s not really an issue.

There’s an advantage here too. By building your printer piece-by-piece, you’ll have a greater understanding of what exactly each component does. This makes maintenance easier in the long term, so while there’s undoubtedly a bit of a learning curve, the Creality Ender 3 might not be such a bad idea.

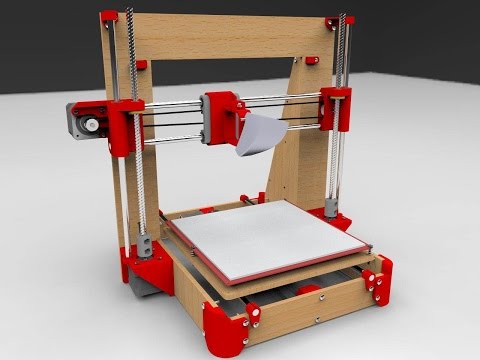

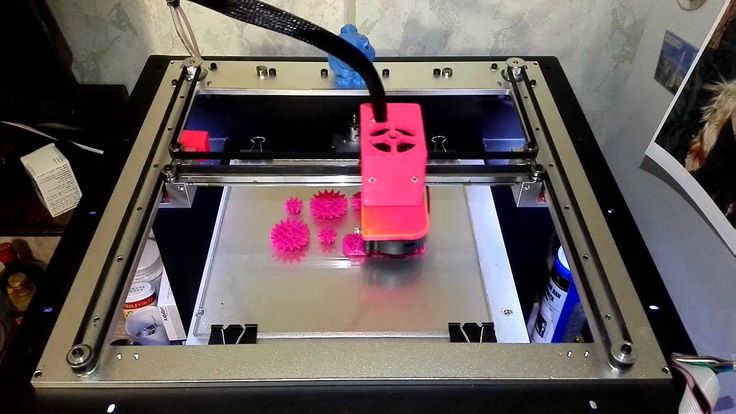

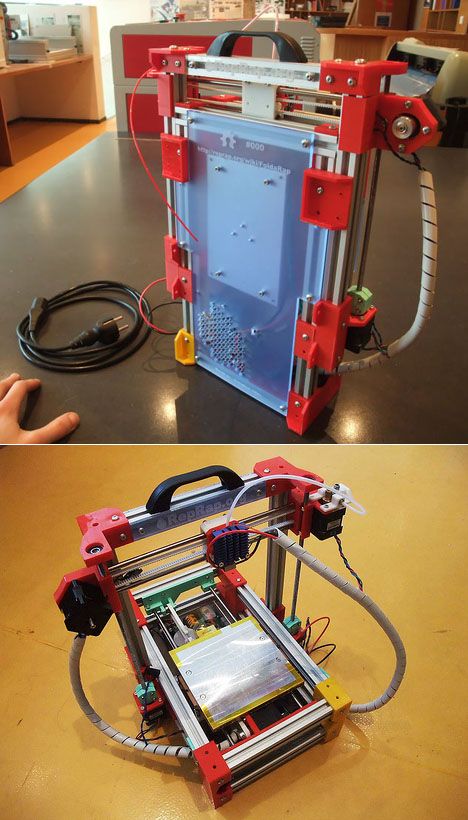

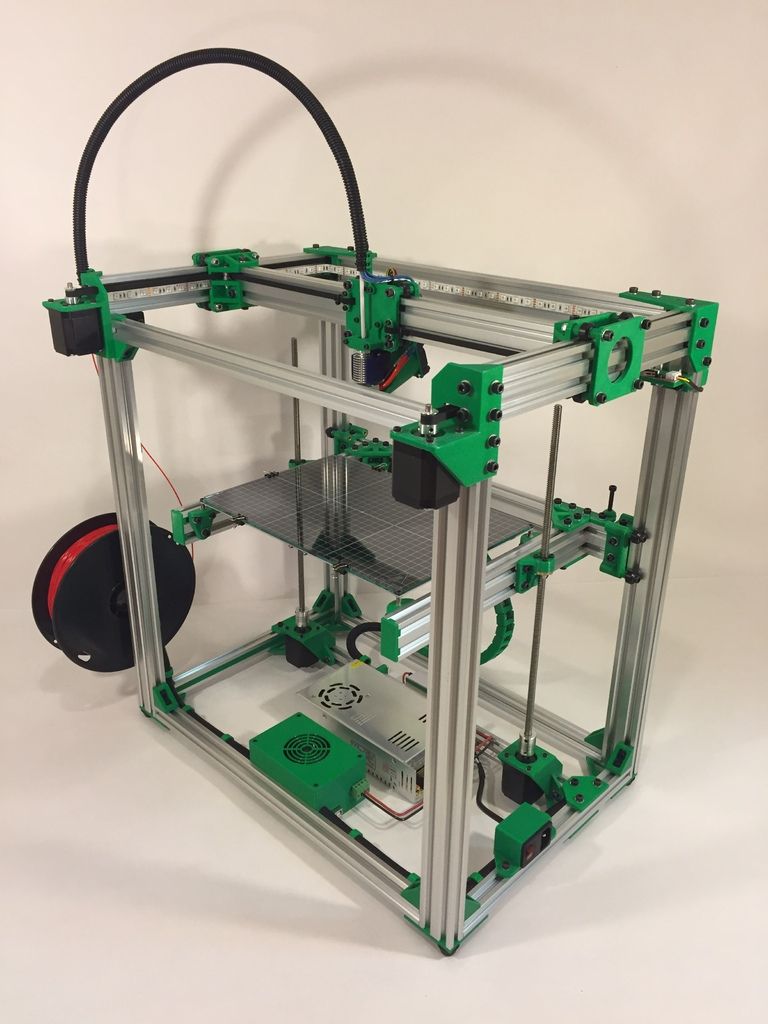

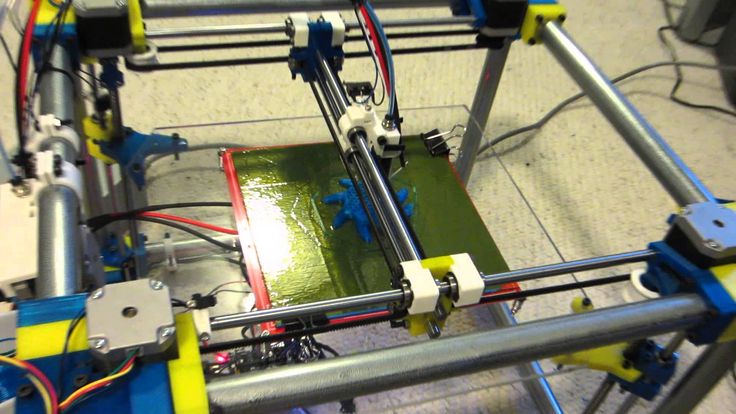

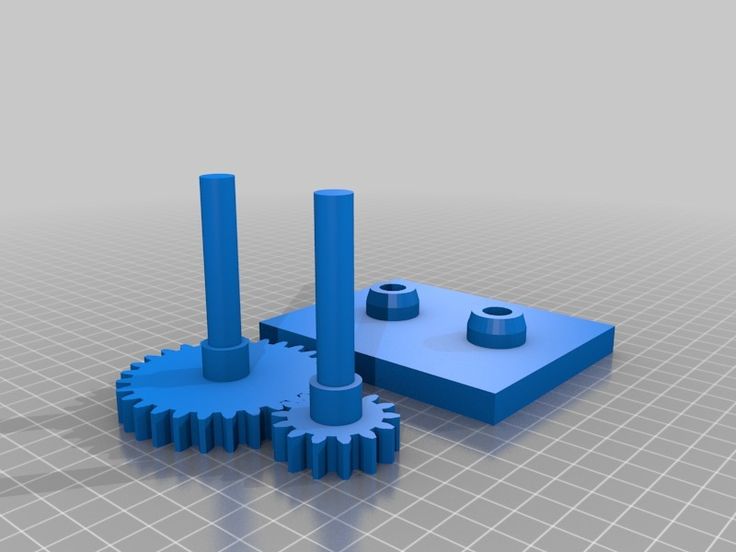

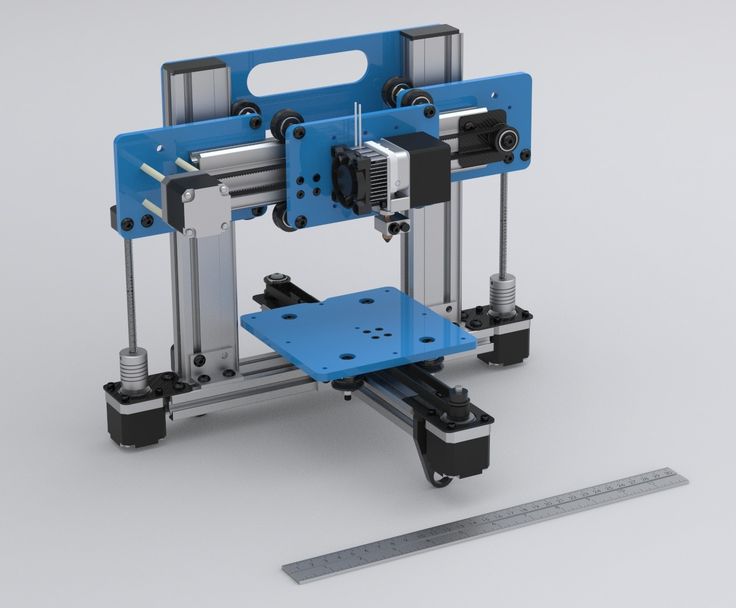

The Kossel Mini is another DIY printer, one that retails for about $260. Notice its unique shape: the circular build plate is perfect for those looking to build larger models like figurines or interlocking parts. Better still, it’s incredibly easy to upgrade thanks to its simplistic design.

Although it looks a little basic, there’s actually a good amount of functionality here. The bed is heated, so you won’t have issues with material sticking to it. It’s even capable of leveling itself, which means that there’s very little fuss or configuration required when you’d like to get started.

Again, you’re limited to using PLA filament. That said, with a little tweaking and upgrading, there’s no reason you shouldn’t be able to use other materials too. As a result, the Kossel Mini is an extraordinary choice not only for 3D printing newcomers but also those looking for a long-term project.

One of the great things about this printer is that it’s so modular. This means that if one part stops working, it’s a simple matter to order and install a replacement. This prevents lengthy warranty processes, and ensures your printer is never out of action for more than a few days at a time.

This prevents lengthy warranty processes, and ensures your printer is never out of action for more than a few days at a time.

Mid-Range 3D Printers

If you’re willing to spend a little more, you can greatly increase the functionality and ease of use that your 3D printer provides. Don’t believe us? Check out the products below to see for yourself!

The FlashForge Finder is one of the most popular 3D printers around, and for good reason. It offers a decent build volume, wifi connectivity, and even runs quieter than most, at around 50dB. You can only print with PLA, but as this is a beginner-friendly model, that’s to be expected.

Don’t understand calibration? No problem! The Finder makes it as easy as can be by simply telling you to tighten various screws until you hear a beep. This takes all the guesswork out of getting ready to print and allows you to focus on the fun part – the actual creation process.

This printer can be controlled via its 2.5” touchscreen or remotely on your PC. The menus are simplistic and easily understandable, written in plain English, so anyone can use them. Also included are various tools you might need, such as an unclogging tool and Allen wrenches.

The menus are simplistic and easily understandable, written in plain English, so anyone can use them. Also included are various tools you might need, such as an unclogging tool and Allen wrenches.

There’s no need to worry about safety, either. The non-heated build plate relies on adhesive surfaces to prevent sticking, and means you can’t burn yourself my mistake. With wifi compatibility, SD card and USB support, and even the ability to send models from cloud storage, the FlashForge Finder has everything you’ll ever need.

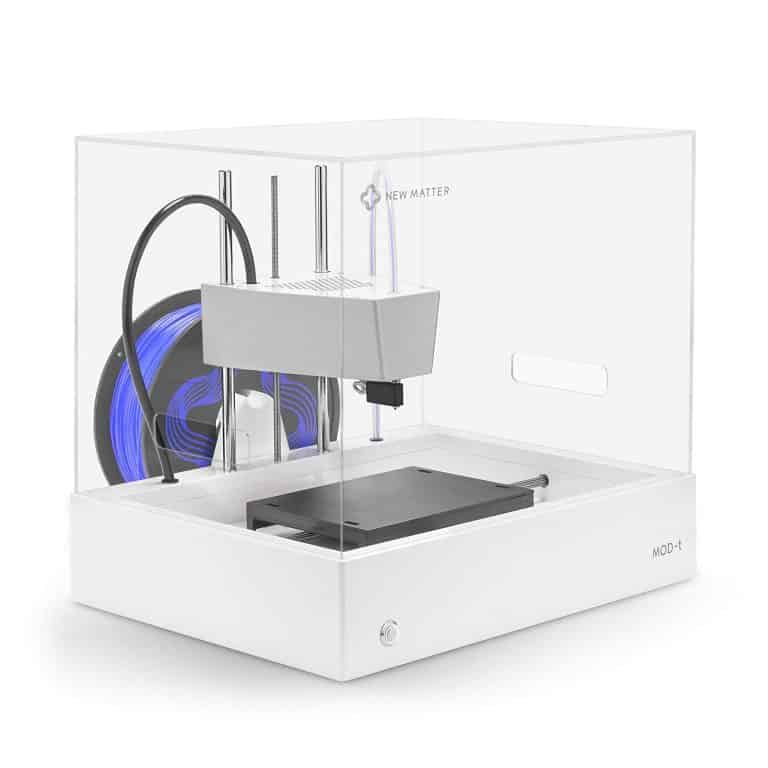

You’d be forgiven for thinking that this futuristic-looking printer cost more than it does! At around $230, the MOD-t is reasonably priced, but better yet, it’s also pretty strong. For instance, it boasts a 50-micron print layer; that’s half the size of numerous similarly-priced printers!

We really liked that this model can start printing right out of the box. Just import a model via wifi or SD card, add some PLA filament, and you’re good to go. The build area is a good size, although not cubic in shape. On the plus side, it is enclosed, meaning you’re less likely to see prints ruined by temperature fluctuation.

On the plus side, it is enclosed, meaning you’re less likely to see prints ruined by temperature fluctuation.

The print speed doesn’t seem that fast at first glance, but remember: this is an entry-level machine. Since you won’t be building massive items, the speed is less crucial. What really matters is getting the nicest finish, and luckily, the MOD-t makes this as easy as possible, even for inexperienced users.

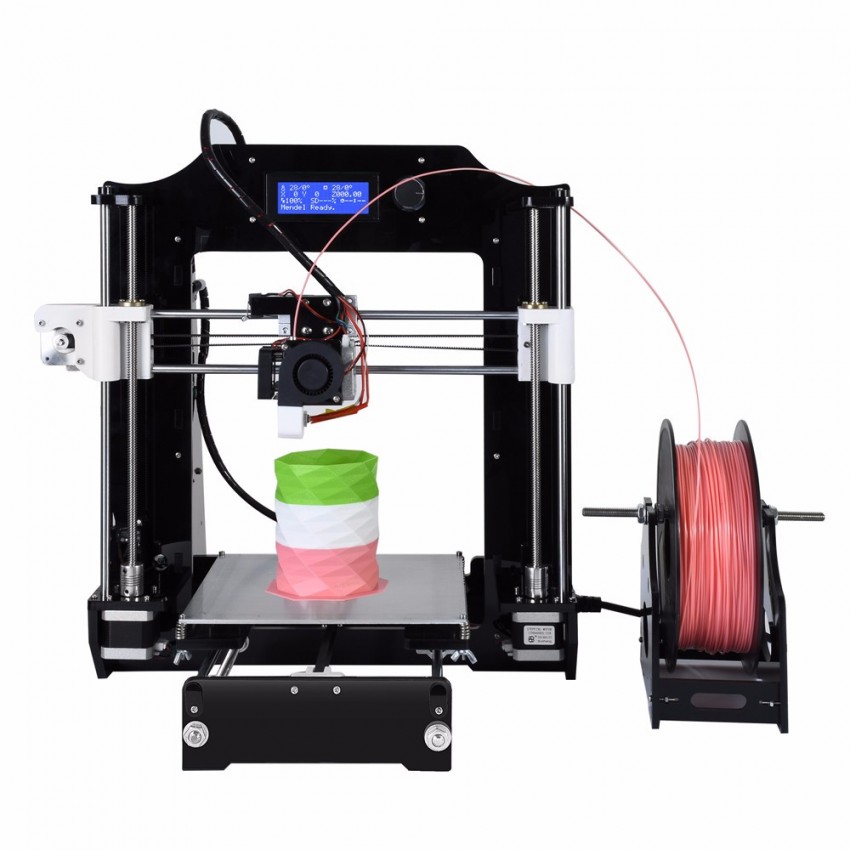

If the previous products seem a little too simplistic, the Anycubic I3 Mega might be just what you need. It requires you to connect a couple of cables before use, striking a balance between full-DIY printers and ready-to-go models. It includes additional helpful features too, like filament detection, print-resume tech, and a non-stick build plate.

You’re not limited to PLA either. This printer can use PLA, ABS, HIPS, and wood-based filaments, allowing you to plan and create far more imaginative pieces than most other beginner-oriented models. With 50 micron layers and a print speed of about 60mm/s, the I3 Mega offers the best of both worlds.

Note the massive build area: it absolutely dwarfs that of many of this printer’s rivals. For less than $400, you can find a 3D printer capable of printing almost anything you can imagine. Sure, the upfront cost is a little higher, but you won’t have to upgrade for several years at least.

If you want the most options, you want the Wanhao Duplicator i3 Plus. It supports more than 15 different filament types, offers a gargantuan build area, and features a 3.25” touchscreen for easy operation. The best part? This printer retails for around $420, far less than most models with similar functionality.

Most of the common stumbling blocks are already taken care of. For instance, the heated bed prevents sticking, the fan prevents overheating, and the steel frame provides more than enough stability. You’re limited to transferring files via USB or SD card, but that’s nothing too unusual, particularly in a mid-budget printer.

So what makes this a good choice for beginners? Simply, it makes printing as easy as possible. There’s very little manual configuration required, and as this is a popular model, you can easily find help on a Wanhao-dedicated forum. There’s no mess, no stress – just high-quality 3D prints.

There’s very little manual configuration required, and as this is a popular model, you can easily find help on a Wanhao-dedicated forum. There’s no mess, no stress – just high-quality 3D prints.

We were pleased to see that this printer comes with a one-year warranty. After all, while relatively inexpensive, it’s still a significant investment. Wanhao’s support affords you peace of mind, and if anything goes wrong, you can consult their FAQs or contact support via phone, email, or post.

Premium 3D Printers

While not everyone will be able to afford the following products, they offer additional functionality that lower-cost models don’t, while being easily accessible for people who’ve never used a 3D printer before.

Now, we know what you’re thinking: I don’t want to spend around $650 on my first 3D printer. Bear with us, though, because spending a bit more to get a high-quality product the first time means you’ll save money down the road. And believe us, the QIDI TECHNOLOGY 3DP is absolutely a high-quality printer.

The first thing which sets it apart is there are two extruders. This means you can either print twice as fast or use two different materials for a striking contrast. You could even mix ABS and PLA if you like since this model supports both.

Models not quite right? With this printer, you don’t necessarily need to fire up the CAD software. Instead, you can slice and edit your models directly using this printer’s minimalistic, easy-to-use onboard controls. With a heat-resistant, warp-resistant frame, you’ll get exceptional prints every time.

Finally, because you can choose an enclosed or ventilated build area, you’ll find that fewer prints fail. This, in turn, saves you money as you’re not wasting as much filament. Sure, these materials are fairly inexpensive, but the costs definitely start to build up, particularly if you plan to use the QIDI for several years.

The Dremel Digilab 3D20 puts user safety above everthing else. This model costs under $600 and features a fully-enclosed build area (which is particularly spacious), as well as a non-heated bed and third-party certification. Best of all, though, it places particular emphasis on consistency.

Best of all, though, it places particular emphasis on consistency.

In practice, this means that you’re limited to using proprietary PLA filament. You might be a little disappointed by this, but it does essentially guarantee that prints only fail very infrequently. Plus, this filament is guaranteed to be non-toxic, plant-based, and recyclable, so it’s safe for kids and pets.

There’s no assembly required, either. In fact, the Digilab 3D20 is ready to print straight out of the box. It even comes with a small spool of filament, although only enough for a couple of prints at most. Model manipulation is as simple as can be, thanks to this printer’s compatibility with popular software like Cura.

As if this wasn’t enough, the 3D20 also includes a one-year warranty and access to a responsive, US-based customer support line. Reliable, high-quality prints, safety as a top priority, and exceptional customer support? What more could you ask for? How about a full-color touchscreen? Oh wait, that’s included too.

Best 3D Printer for Beginners: The Verdict

While all of the printers mentioned above are excellent for beginners, you’re probably wondering which is the best overall, especially since you’ve seen how advanced some 3D printers can be. Well, it wasn’t easy but we finally came to the decision that the FlashForge Finder is better for most users.

Our reasoning is simple: it’s an inexpensive, reliable printer that offers a good degree of freedom without being overwhelming to novices. Not only that but with automatic calibration, it takes the busywork out of printing. This makes it more appealing to kids, but also helps prevent user frustration, which is never a bad thing.

The Best 3D Printers for Beginners in 2022

While 3D printing has been around for a while, it’s only recently become more accessible to the mainstream consumer market. Desktop 3D printers make it simple for hobbyists to take advantage of this innovative technology, but those dipping their toes in for the first time may be wary. There’s an enormous variety when it comes to the best 3D printers for beginners, making the process of setting up, printing, and finishing your models a simpler, more digestible process.

There’s an enormous variety when it comes to the best 3D printers for beginners, making the process of setting up, printing, and finishing your models a simpler, more digestible process.

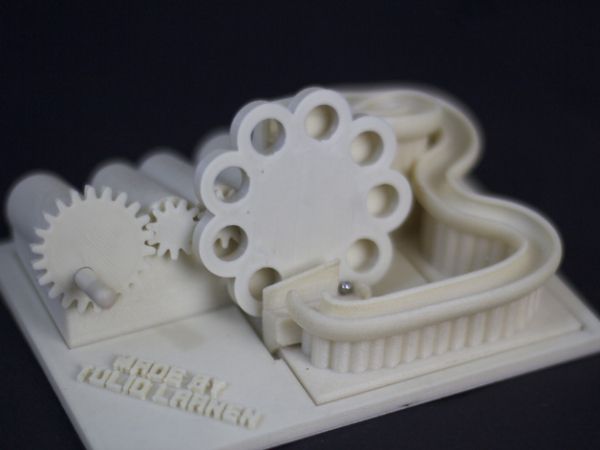

3D printers use a process called additive manufacturing to turn digital models into three-dimensional objects. Most often, 3D printers use small nozzles and materials like plastic, resin, polymers, or metal, depositing the material layer by layer, then fusing them with an adhesive or ultraviolet light to create a 3D model.

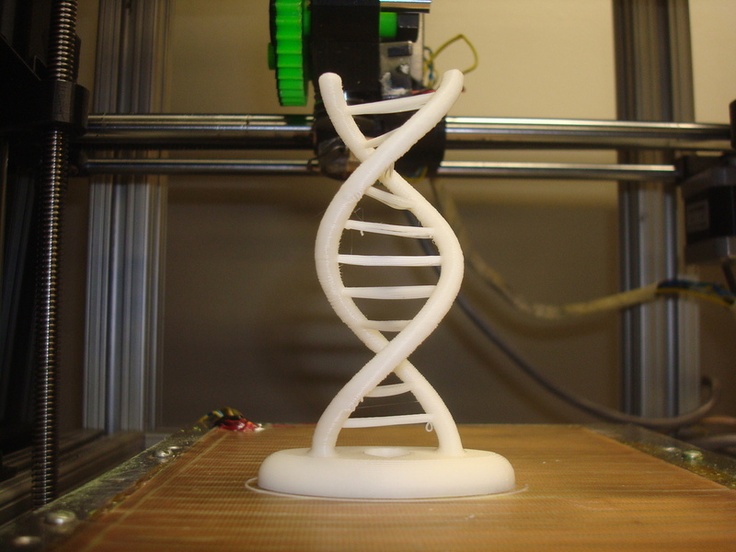

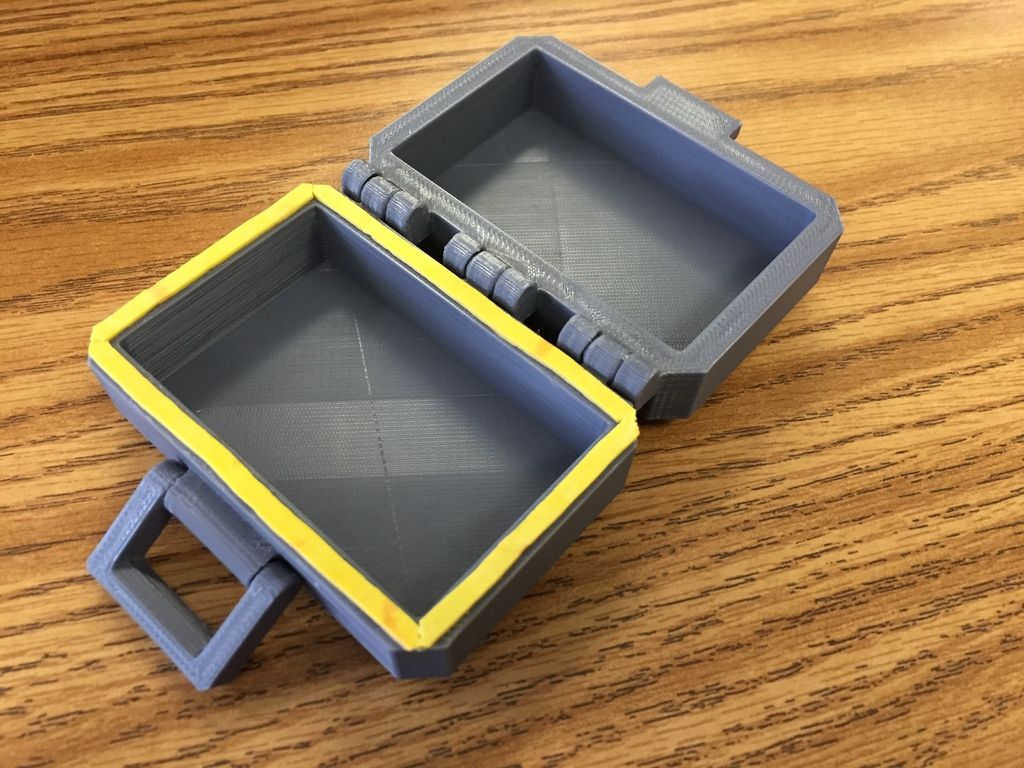

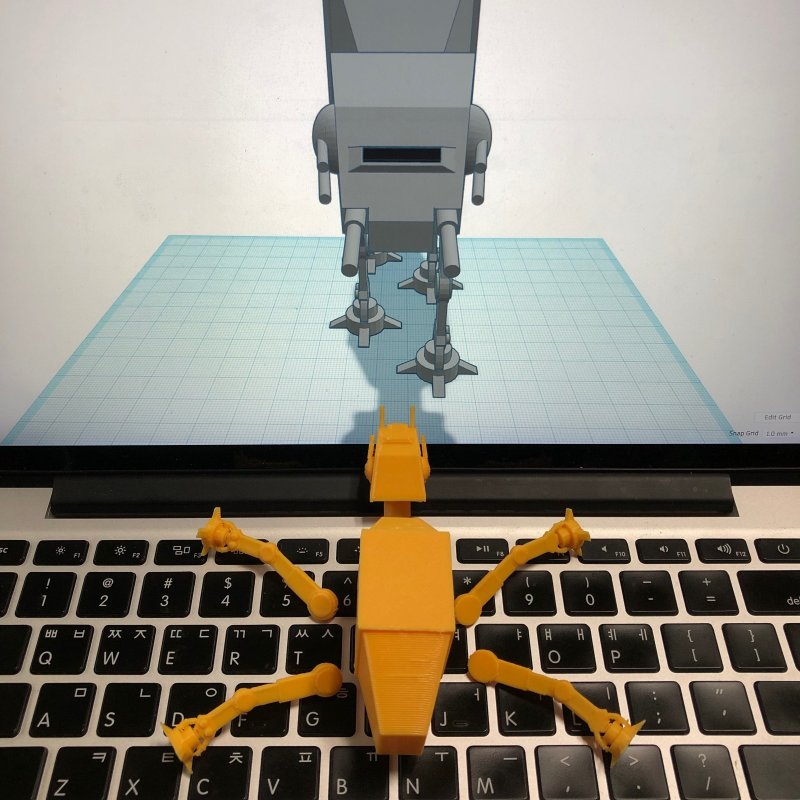

The things you can create with a 3D printer are almost endless. These desktop devices give you the power to harness your creativity and turn digital prototypes, 3D doodles, and much more into physical objects — all from the comfort of your home. The best 3D printers for beginners will bring your digital dreams to life.

— Best Overall: Creality Ender 3 Pro 3D Printer

— Best Budget: Monoprice Select Mini 3D Printer v2

— Best Resin: ELEGOO Saturn MSLA 3D Printer

— Best Multifunction: Snapmaker 2. 0 Modular 3-in-1 A350T 3D Printer

0 Modular 3-in-1 A350T 3D Printer

— Most User-Friendly: Monoprice Voxel 3D Printer

— Best Premium Pick: Robo E3 3D Printer

How 3D Printing Works

3D printers use a process called additive manufacturing (more colloquially known as 3D printing) to turn digital models into three-dimensional objects. Most often using small nozzles and materials like plastic, resin, polymers, or metal, the printer deposits the material layer by layer, then fuses them with an adhesive or ultraviolet light to create a 3D model.

The things you can create with a 3D printer are almost endless. These desktop devices give you the power to harness your creativity and turn digital prototypes, 3D doodles, and much more into physical objects—all from the comfort of your home. The best 3D printer for beginners will bring your digital dreams to life.

How We Selected the Best 3D Printers for BeginnersAs with any new consumer technology, 3D printing isn’t exactly cheap, so you’ll have to spend some money for a decent pick. We narrowed down our picks for the best 3D printer for beginners from dozens of 3D printers, paying attention to price, ease of use, and print quality.

We narrowed down our picks for the best 3D printer for beginners from dozens of 3D printers, paying attention to price, ease of use, and print quality.

Price: 3D printers start at a couple of hundred dollars and can range up to thousands of dollars. Most beginner hobbyists will want a budget-friendly option for testing the waters. We included several printers in a modest price range, skewing towards more affordable prices to appeal to novices.

Ease of Use: User friendliness is one of the most important features when it comes to picking the best 3D printer for beginners. We prioritized features like straightforward assembly and print material refilling, as well as a simple-to-use interface with less of a learning curve required to get started.

Print Quality: Through reviewing product specifications and consumer reviews, we chose 3D printers that create high-quality models, so your design looks exactly as intended. We prioritized 3D printers with good specifications and high user satisfaction. Get started with the best 3D printing software.

Get started with the best 3D printing software.

Why It Made The Cut: This beginner-friendly 3D printer is affordable, simple to use, and creates quality prints.

Specs:

— Build Volume: 8.7 inches L x 8.7 inches W x 9.8 inches H

— Weight: 19 pounds

— Compatible Materials: PLA (polylactic acid), ABS (acrylonitrile butadiene styrene), PETG (polyethylene terephthalate glycol) plastic

— Print Speed: Up to 180 mm/s (millimeters per second)

Pros:

— Easy to assemble

— Removable, flexible, and magnetic print bed

— Great print quality

Cons:

— Printing bed can be tricky to level

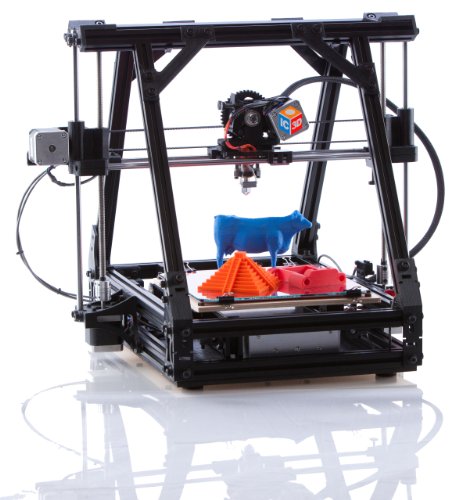

The Creality Ender 3 Pro 3D Printer is a popular 3D printer model for hobbyists, and for good reason. This printer is affordable, easy to use, and comes with several attractive features.

This printer is affordable, easy to use, and comes with several attractive features.

The printer arrives partially assembled with all the necessary tools included for easy setup. Loading the plastic filament is simple. Once assembled and switched on, the device is ready to print almost immediately, with a rapid heating feature that gets the printer ready to go in only five minutes. In case of any pauses in printing, it also has a handy ‘resume print’ function, which restarts the job where it left off.

The heated, removable, and flexible magnetic print bed makes it easier to remove completed models after they’re finished printing, although users will need to take care when re-installing the bed to make sure it’s level. Overall, this 3D printer delivers great print quality, and for its reasonable asking price, it’s our choice for the best 3D printer for beginners looking to dip their toes into 3D printing. For another great option, read out review of the Anycubic Vyper 3D Printer.

Why It Made The Cut: This printer may not have the fancy features of more expensive models, but it offers excellent value and versatility for its price.

Specs:

— Build Volume: 4.7 inches L x 4.7 inches W x 4.7 inches H

— Weight: 10 pounds

— Compatible Materials: All filament types including ABS, PLA, and wood and metal composites

— Print Speed: Up to 55 mm/s

Pros:

— Affordable

— Refurbished model cuts down on electronic waste

— Supports all filament types

Cons:

— Small build volume

— Relatively slow printing speed

The Monoprice Select Mini 3D Printer v2 is the best budget 3D printer available today. It’s also extremely easy to use for beginners. And since this model is refurbished, you can save even more money.

Once you have your first project off the ground, it’s easy to get more creative. With a heated build plate and wide extruder temperature range (maxing out at 482°F), this 3D printer can work with any 1.75mm filament type, including ABS, PLA, conductive PLA, wood and metal composites, and dissolvable PVA. This flexibility opens the door to a range of exciting new projects.

3D printer size is usually directly related to price, so this budget-friendly printer has a small build volume (about 4.7 inches cubed)—but that also means a compact enough size to fit on just about any desktop. Find other affordable options in our guide to the best budget 3D printers.

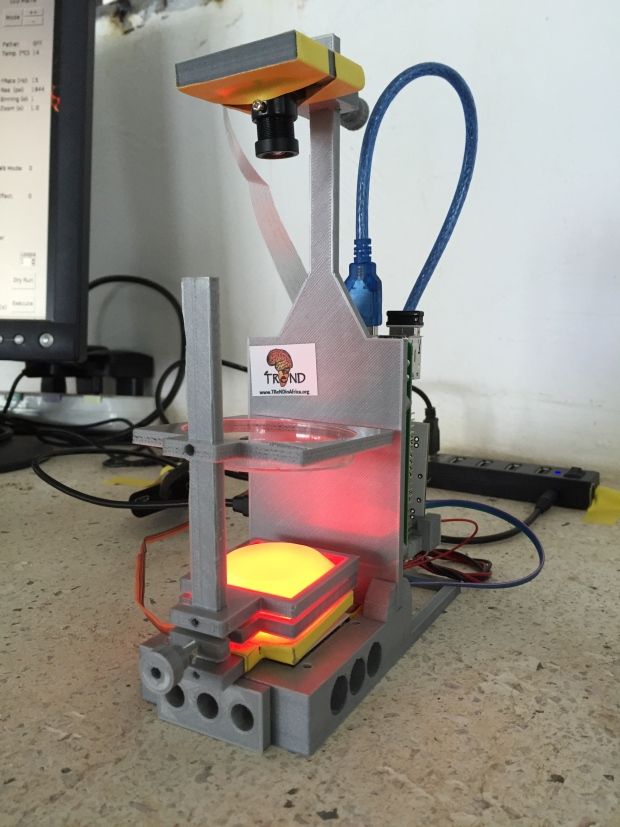

Best Resin: ELEGOO Saturn MSLA 3D Printer Resin Details. ELEGOOWhy It Made The Cut: This is the best resin 3D printer because it has a relatively large build volume and an accurate printing process to create detailed, sizable resin models.

Specs:

— Build Volume: 7. 6 inches L x 4.7 inches W x 7.9 inches H

6 inches L x 4.7 inches W x 7.9 inches H

— Weight: 30 pounds

— Compatible Materials: DLP photopolymer resin

— Print Speed: Up to 40mm/s

Pros:

— Accurate printing results

— Simple to assemble and easy to calibrate

— Large build volume for printer type and price

— Can print multiple miniature models simultaneously

Cons:

— Test model is difficult to remove from the build plate

Compared to FDM (fused deposition modeling) 3D printers, resin printers can print higher levels of detail, which is especially ideal for printing smaller models. Instead of injecting melted materials like plastic layer by layer, resin printers use light (like ultraviolet lights) to cure liquid resin into thin layers. This method allows for finer printing details and a smoother surface. Beginners who want to take advantage of resin 3D printing should consider the ELEGOO Saturn MSLA 3D Printer, a relatively affordable choice with several attractive features.

Resin printers tend to be smaller than FDM printers. For its entry-level price, this printer has a large build volume at 7.6 inches long by 4.7 inches wide by 7.8 inches high. This larger size gives the flexibility to create larger, but still very detailed models and miniatures. The ELEGOO also prints 60 percent faster than its predecessor (the smaller Elegoo Mars 2 Pro), while still delivering excellent printing results.

Setup is simple with this printer (although beginners should keep in mind that resin printing requires more post-processing than FDM printing). An easy-to-calibrate build plate and a uniform light source create great print results with few adjustments needed.

Best Multifunction: Snapmaker 2.0 Modular 3-in-1 A350T 3D PrinterPowerful Times Three. SnapmakerWhy It Made the Cut: This multifunction 3D printer lets you get everything done with one device, from printing, to laser engraving, cutting, and carving.

Specs:

— Build Volume: 12. 59 inches x 13.77 inches x 12.99 inches

59 inches x 13.77 inches x 12.99 inches

— Weight: 61.73 pounds

— Compatible Materials: PLA, Wood PLA, PTG, TPU

Pros:

— Several functions all in one machine

— Compatible with many materials

— Can create larger models with its bigger surface area

— Innovative, sturdy design that’s built to last

Cons:

— Incredibly heavy

— Not a very beginner-friendly price

With a wide array of uses, the Snapmaker 2.0 Modular 3-in-1 3D Printer is a fantastic machine to learn the basics of 3D printing on, and then keep around for the long haul as you master each function. An upgrade to Snapmaker’s previous models, the 2.0 A350T encompasses noise reduction for quieter printing, faster speeds, and precision down to .005 millimeters for a smoother finish.

This 3D printer is an absolute beast when it comes to material compatibility. Whether you’re printing with PLA, PTG, or TPU; engraving or cutting into plywood, paper, acrylic, fabric, or leather; or carving out shapes and textures with hardwood, PCB, acrylic, POM, carbon fiber sheets, or many more, the Snapmaker can handle the task. This is likely beyond the scope of what you’d be getting into as a beginner, but it opens up the possibilities as you broaden your knowledge and get more comfortable in the realm of 3D printing.

This is likely beyond the scope of what you’d be getting into as a beginner, but it opens up the possibilities as you broaden your knowledge and get more comfortable in the realm of 3D printing.

There’s a lot to applaud Snapmaker for, including its incorporation of auto-leveling, filament runout and power loss recovery, WiFi connectivity, and an all-metal, high-strength build that’s designed to last.

Most User-Friendly: Monoprice Voxel 3D Printer Smart and Easy to Use. MonopriceWhy It Made The Cut: A fully-enclosed design, auto-leveling platform, and auto-feeding filament feature make this printer an extra user-friendly choice.

Specs:

— Build Volume: 5.9 inches L x 5.9 inches W x 5.9 inches H

— Weight: 20 pounds

— Compatible Materials: ABS, PLA, wood fill, copper fill, steel fill, and bronze fill filaments

— Print Speed: Up to 100mm/s

Pros:

— Auto-levelling platform

— Full enclosure

— WiFi-enabled

— Built-in camera for print monitoring

Cons:

— Relatively small build volume

If you want to get into 3D printing without the steep learning curve, consider the Monoprice Voxel 3D Printer. This 3D printer features several automated functions that make it extra simple to use.

This 3D printer features several automated functions that make it extra simple to use.

The printer arrives fully calibrated and ready to print, right out of the box. An auto-leveling feature ensures that the build platform is in the right position, while an auto-feeding filament feature makes loading filament easy. The built-in filament sensor also recognizes low filament levels and pauses prints to notify you that it needs reloading. Once your creation is done printing, lift the heated, flexible, and removable build plate. With a bit of flexing, the model should pop off with ease.

This 3D printer features a closed design to keep hands (or paws) away from hot and moving parts while it’s printing. It is also Wi-Fi-enabled; its functions are controlled and monitored through its color touch screen or through your smartphone (through the Polar Cloud cloud-based platform), and you can check on printing progress through the window or with your phone via the built-in camera. If you're into making miniatures, you may also want to consider the best resin 3D printers.

Why It Made The Cut: Robo's E3 is the perfect 3D printer to get if you want to jump into making complex projects right away. It's compatible with over 20 materials, ranging from wood to metal to glass.

Specs:

— Build Volume: 5.9 inches L x 5.9 inches W x 5.9 inches H

— Weight: 19.8 pounds

— Compatible Materials: ABS, PLA, wood fill, copper fill, steel fill, brass fill, carbon fiber fill, magnetic iron, glass fill, bronze fill filaments, and more.

— Print Speed: Up to 100mm/s

Pros:

— Auto-calibrated print bed

— Can store up to 1,000 models on its internal storage

— WiFi-enabled

— Includes two spools of PLA filament.

Cons:

— Expensive

If you're serious about getting into 3D printing, and don't want to go through the process of buying an entry-level printer and then upgrading it in a year or two, Robo's E3 is the one to get. It's roughly the same size and weight as our other 3D printer recommendations, but it can work with a lot more materials.

It's roughly the same size and weight as our other 3D printer recommendations, but it can work with a lot more materials.

This gives you the freedom to create 3D prints that wouldn't be possible otherwise, especially if you're making objects that require different elements, like glass and metal. If you plan on printing the same objects over and over again, the E3's built-in storage will come in handy. That's doubly true if you accidentally delete a model on your computer.

While these features add to the E3's cost, but it's still a good machine for beginners because of its auto-calibrating print bed, which improves the odds of you ending up with a satisfying print rather than one that's lopsided. By reducing the number of prints you have to discard due to quality issues, the Robo E3 is more forgiving for new 3D printer users, and a lot less wasteful. Novice 3D printers will also benefit from the two-hour online training course that comes with this printer.

It's hard to overlook the Robo E3's up-front cost, but again, it's so capable relative to the other 3D printers we're recommending for beginners that it's well worth the price. This should be the only 3D printer you'll ever get, unless you start needing one for commercial use.

This should be the only 3D printer you'll ever get, unless you start needing one for commercial use.

The best 3D printers for beginners give you the power to create on-demand. But as more 3D printers flood the market, it can be hard to choose the best one for your needs. When shopping for the best beginner-friendly 3D printer, consider the printer dimensions, build volume, compatible materials, and ease of use.

Printer Size and WeightWhile consumer 3D printers are heavier than your standard all-purpose printer, they’re still a reasonably small size. Since they’re made for at-home use, most have a compact footprint to fit on a desktop or counter.

Consider the printer size and weight and how it will fit in your space. Keep in mind that the size of the printer is related to the build volume the printer is trying to accommodate; a larger printer will be able to create larger items, and a smaller one will be limited to smaller items.

3D printers can be used to create just about anything, from giant 3D models to tiny trinkets, but at-home 3D printers are much smaller than the ones you might find in a design studio.

To help shoppers make a suitable choice, consumer 3D printers include a build volume measurement that describes the maximum width, height, and length of the print area. The build volume roughly determines the maximum size model that the printer can create. Consider the type of items you are hoping to print and choose an appropriate build volume from there.

Compatible MaterialsMost consumer 3D printers available today use fused deposition modeling (FDM), where material (usually plastic filament) is melted and extruded through a nozzle to create thin layers that make up a model. Other 3D printers, like resin printers, use curing processes, like UV light, to harden materials by layer.

The compatible materials vary by 3D printing method, but can include plastics, metals, polymers, resin, ceramics, plaster, and glass. When shopping for a 3D printer, check whether the ones you’re considering allow you to build creations with your preferred materials.

When shopping for a 3D printer, check whether the ones you’re considering allow you to build creations with your preferred materials.

3D printing can get overwhelming for those who aren’t tech-savvy, so as a beginner, it’s important to find a 3D printer that is simple to use. A beginner-friendly 3D printer should have a simple setup process, easy refilling process, and intuitive controls.

Features like a touchscreen interface, print resume functions, robust safety features, and a heated bed (which can ensure a well-made model foundation) can make a 3D printer more user-friendly. Some printers also come with included printing materials, so you can get started right away.

3D printers can include other convenient perks, like quiet operation, built-in cameras to monitor printing, and Wi-Fi connectivity so you can print and monitor progress from anywhere. Buying from a company with easy-to-reach customer support or an active online community is also a nice perk, in case you need to do any troubleshooting down the road.

There’s no singular best brand when it comes to 3D printers. We’ve selected our top picks from several reputable brands in the 3D printing industry. The brands on this list create quality 3D printers with user-friendly features that will appeal to beginners.

Q: Does 3D printer size matter?Yes. On a basic level, you’ll want a 3D printer that fits in your space. More specifically, you’ll want a 3D printer with a suitable build volume (the maximum print area) for your needs. Of course, as build volume increases, so does the printer size (and price).

Q: How much does a 3d printer cost?3D printers start at around $200 and can range up to many thousands of dollars. For a decent entry-level 3D printer for beginners, expect to spend between $200 to $400 for a good printer with some user-friendly features. For newbies, it’s best to start with a more basic and budget-friendly printer and you can always upgrade down the line if you decide you need more features.

Compared to many hobbies, 3D printing is a relatively expensive one (although it is much more affordable than it once was). Budget-friendly 3D printers still come in at a couple hundred dollars, which is a somewhat high upfront cost for testing out a new pastime. Ongoing costs include refill printer materials and possible replacements or repairs when something goes amiss. That said, you’ll be able to make some pretty cool and useful stuff, so the hobby is often well worth the price.

Q: What is a good size 3D printer?It depends. Do you plan to print industrial-size parts or small baubles? A good printer size is subjective and will depend on your needs. Most at-home 3D printers are small enough to fit on a desk or counter, and so are often best for smaller projects. When shopping for a 3D printer, consider its build volume, which will give you a better idea of what size models the printer can produce.

Related: Looking for more options? Here's our roundup of the best 3D printers for every kind of project.

Final Thoughts on the Best 3D Printers for BeginnersThe Creality Ender 3 Pro 3D Printer is one of the most highly-rated and popular picks for beginners. It’s a solid, budget-friendly printer that is user-friendly and creates high-quality models.

This post was created by a non-news editorial team at Recurrent Media, Futurism’s owner. Futurism may receive a portion of sales on products linked within this post.

Share This Article

Top 20 Inexpensive 3D Printers ($199 to $1000)

3DPrintStory Reviews Top 20 Inexpensive 3D Printers ($199 to $1000)

Just 10 years ago, a 3D printer cost over $100,000. Today, you can easily find a cheap 3D printer for under $200. This is amazing. nine0005

Today, you can easily find a cheap 3D printer for under $200. This is amazing. nine0005

Naturally, the lower the price, the more restrictions. Some of the printers on our list will not have a heated bed and the workspace will be small. Naturally, the quality of most of the models presented below cannot compete with more expensive counterparts.

But with a little patience and diligence, it is quite possible to achieve high-quality 3D printing on a printer that costs half the price of a flagship smartphone. And it's really cool!

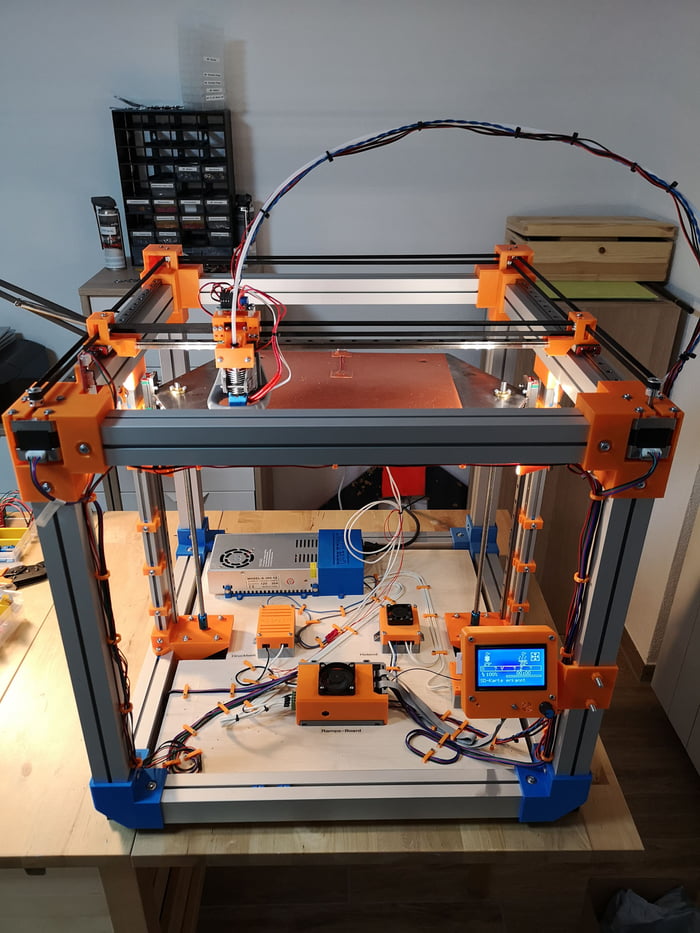

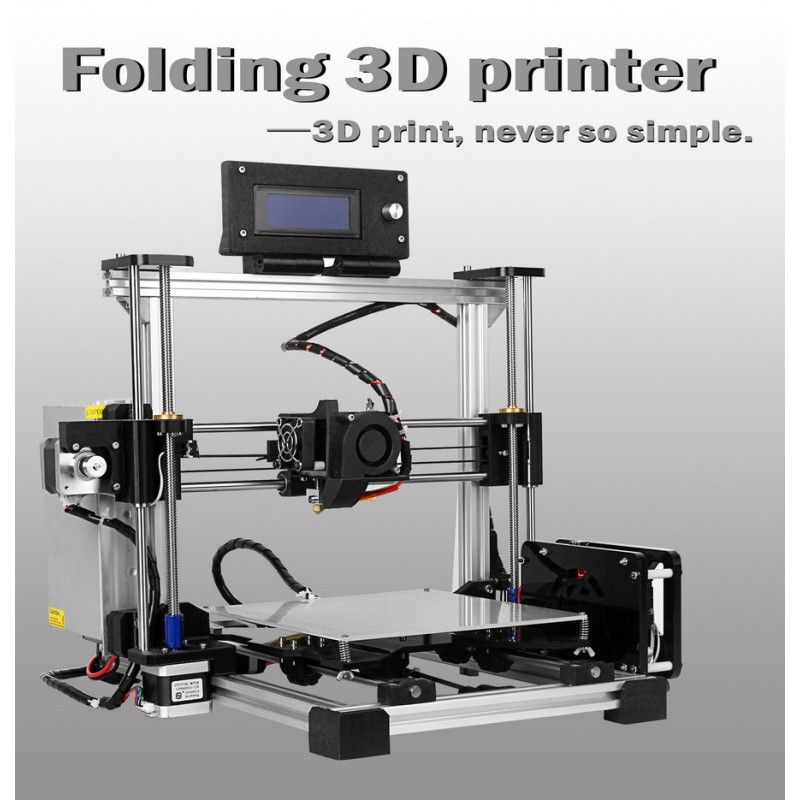

Important note : All 3D printers in this top are supplied assembled by the manufacturer. If you have free time and want to spend less money, you can buy DIY kits and assemble the 3D printer yourself according to the instructions.

List of the best cheap 3D printers in the price range from $ 200 to $ 1000

| 3D Printer | Material Material | Working space (mm) | Price | 459 |

|---|---|---|---|

| Flashforge Finder | PLA | 140 x 140 x 140 | 499 |

XYZPRINING DA vinci jr. 1.0 Pro 1.0 Pro | PLA | 150 x 150 x 150 | 499 |

| XYZprinting da Vinci Jr. Mix 2.0 | PLA | 150 x 150 x 150 | 599 |

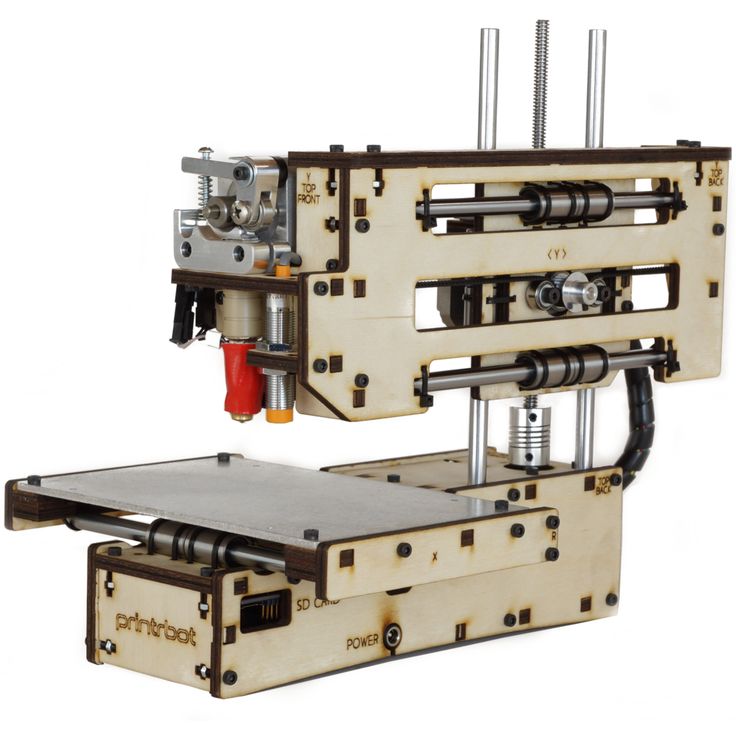

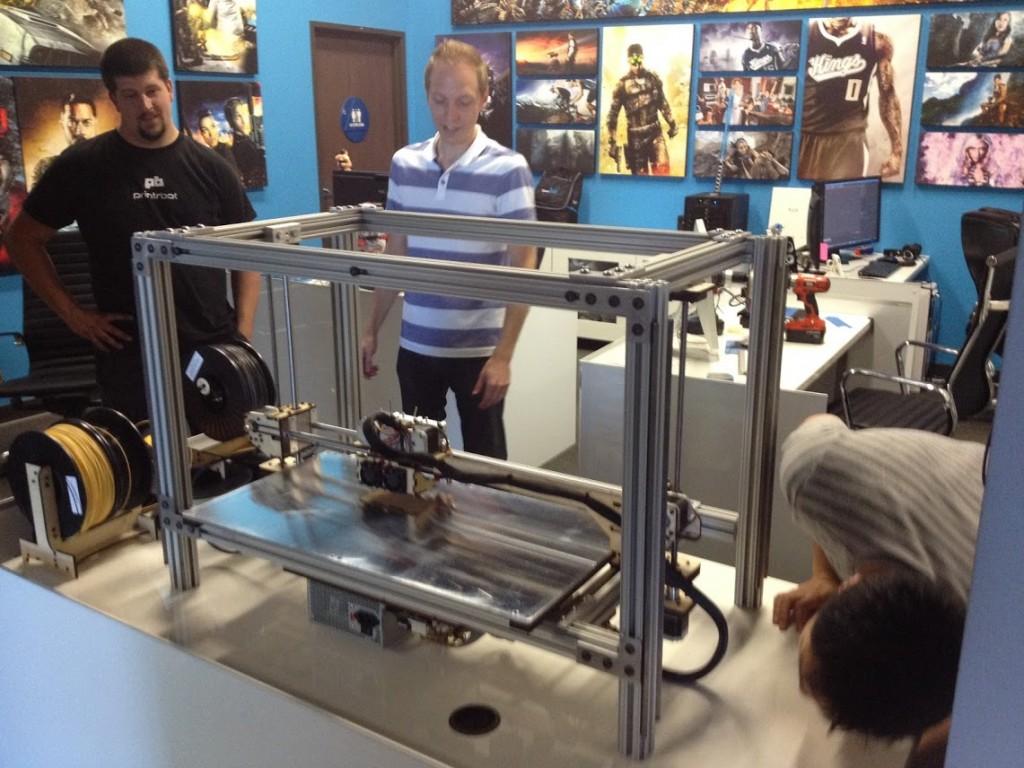

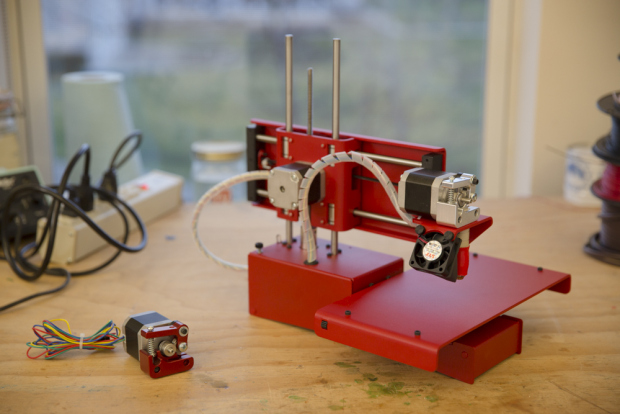

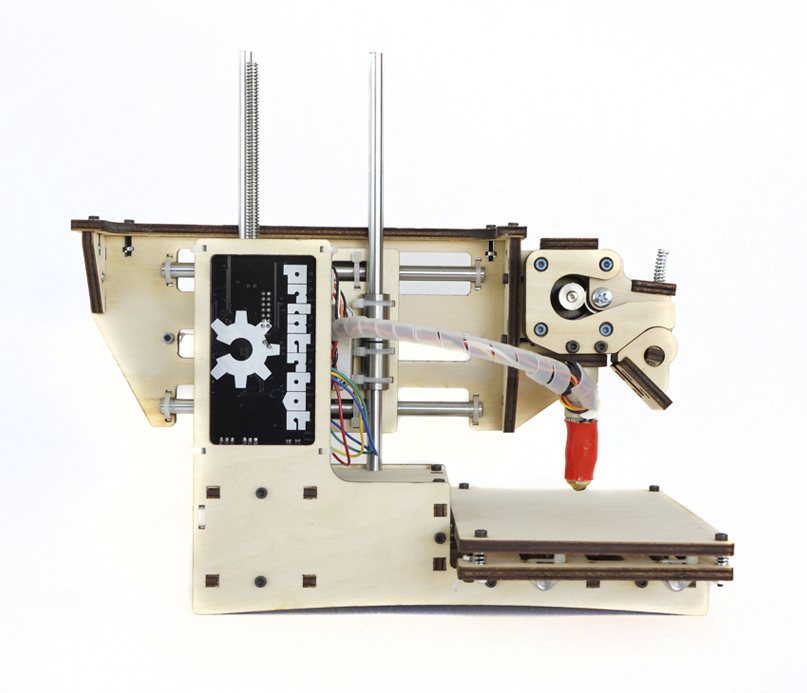

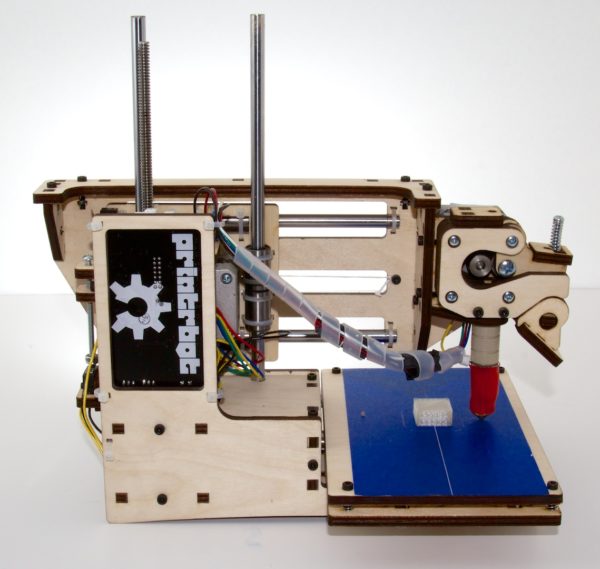

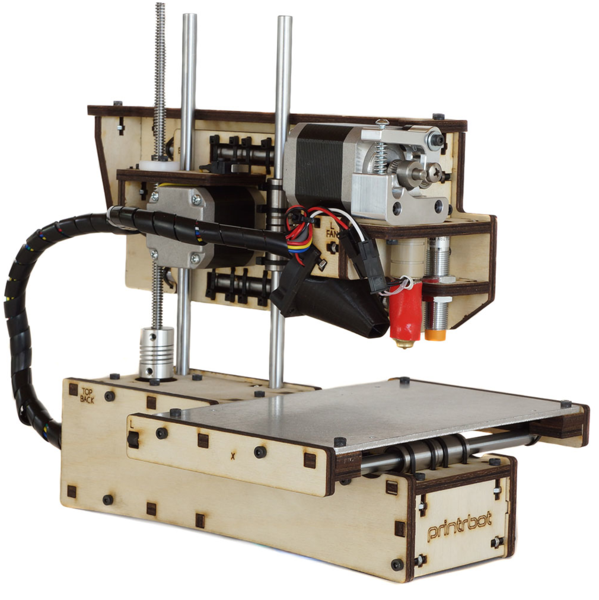

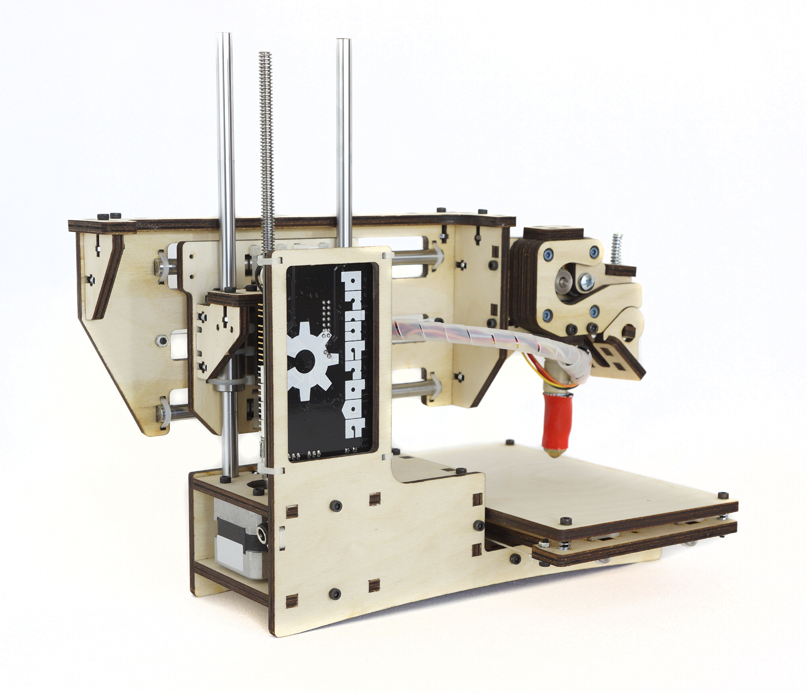

| Printrbot Simple | |||

| Dremel Idea Builder | PLA | 230 x 150 x 140 | 899 |

| Printrbot Simple Pro | PLA | 200 x 150 x 200 | 999 |

| Prusa i3 MK2 | PLA, ABS, exotic | 250 x 210 x 20022 | |

In the article we are considering unfinished, but high -quality 3D printers from AM etc. nine0005

If you want to buy them, even if you live in large cities such as Kyiv, Moscow, St. Petersburg, Minsk, it may turn out that these models will not be in the online stores of your city, or they may be with a decent mark-up relative to the cost that indicated in the article.

Since most of them are European / American, it is possible that they will not be in stores at all.

Therefore, before making a choice, I recommend looking directly at eBay, Amazon, Aliexpress, etc. - many sellers on these planforms deliver to the CIS countries within 1-4 weeks on average. nine0005

It is especially worth monitoring these platforms during the discount period - Black Friday or Chinese New Year (Aliexpress or Gearbest) - prices on such days can be 2 or more times lower than usual and it is worth waiting for a few weeks.

Monoprice MP Select Mini ($199)

Probably the best 3D printer on our list. Why? Because the Monoprice MP Select Mini is an impressive development with a thoughtful, compact design at a very low price. This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB. nine0005

nine0005

The heated bed and wide temperature range of the extruder are especially pleasing, because for such a small price you get the opportunity to print in different materials: from ABS B to PLA or exotic materials like conductive PLA plastic, wood, metal-based composites and PVA.

For those who are worried about the lack of a guarantee - for such a price it is possible without it. This model is upgradeable. For example, you can install a new nozzle, change the table and add WiFi connectivity. nine0005

Small working space - 120 x 120 x 120 mm. Over time, this will definitely not be enough for you.

Specifications of cheap 3D printer Monoprice MP Select Mini

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes; nine0346

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: SD card, USB.

Back to the list of 3D printers

M3D Micro Retail ($249)

The M3D Micro 3D printer hit the market thanks to Kickstarter. This model was presented with an incredible price of $349.

The working space of the M3D Micro is 109 x 113 x 166 mm. There are several body color options. The company has implemented "Micro Motion Technology" - a set of innovative solutions - thanks to which you get excellent quality 3D printing at a small price. nine0005

Today, this inexpensive 3D printer already costs even less than the price announced on Kickstarter. You can buy it for $249 with a 12 month warranty. By the way, it is already possible to pre-order the next "pro" version.

Specifications of cheap 3D printer M3D Micro Retail

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 116 x 109 x 113 mm;

- Minimum layer height: 50 microns; nine0346

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- XY accuracy: 15 microns;

- Open Source: no;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to 3D printer list

XYZprinting da Vinci Mini ($289)

Da Vinci Mini is a successful attempt to make the 3D printer user-friendly. This model has only one button and 5 multi-colored indicators that reflect the current status of 3D printing. In addition, this affordable 3D printer is WiFi capable so you can control it over a network in your home, office or lab.

Unfortunately, you can only use the manufacturer's own 3D materials. On average, they cost 20% more than usual. However, the company also argues that the materials used (PLA) will be 100% non-toxic. nine0005

Specifications of cheap 3D printer XYZprinting da Vinci Mini

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes; nine0346

- Connection: USB, WiFi.

Back to 3D printer list

Monoprice Maker Select V2($299)

The next cheap 3D printer with a good reputation is the Monoprice Maker Select V2.

This model is an analogue of the Wanhao Duplicator i3, which, in turn, borrowed the design from the Prusa i3. But this does not affect the quality, as the Monoprice Maker Select V2 is easy to use and gives excellent 3D printing results.

Monoprice Maker Select V2 design feature is that the power supply and control panel are placed outside the 3D printer. The working space of this model is 200 x 200 x 180 mm. And this is really a good indicator for the money. nine0005

Specifications of cheap 3D printer Monoprice Maker Select V2

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm; nine0346

75 mm; nine0346 - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

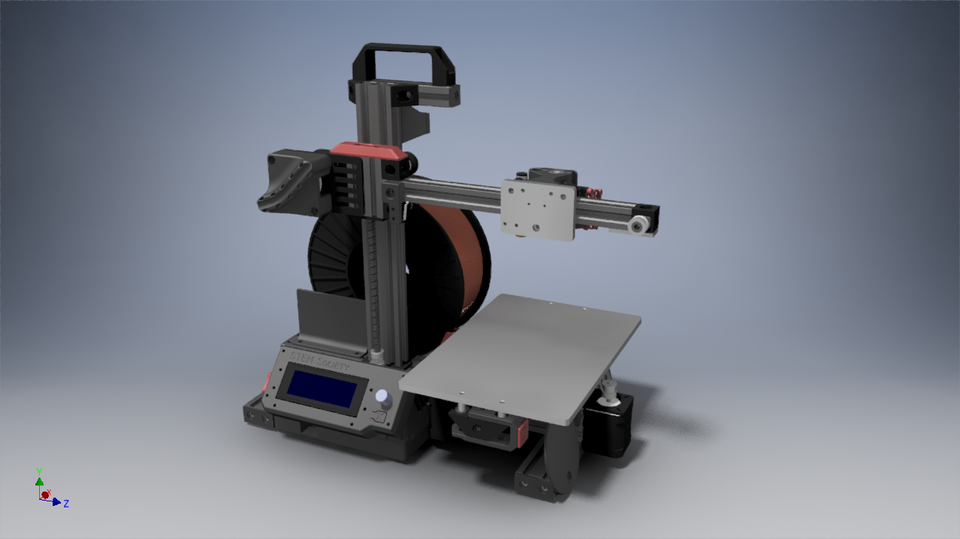

New Matter MOD-t ($299)

New Matter is a young startup that offers a 3D printer MOD-t - An interesting design with a minimalistic design. This cheap 3D printer is WiFi enabled so you can manage print settings and print from your computer, tablet or smartphone. The working space is 150 x 150 x 125 mm. Thanks to the case, the noise during its operation is reduced. But the most interesting and attractive thing about MOD-t is the price. Only $299. In general, this is an interesting, high-quality model.

Specifications of cheap 3D printer New Matter MOD-t

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 100 x 125 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm; nine0346

75 mm; nine0346 - Control panel on 3D printer: no;

- Connection: USB, WiFi.

Back to the list of 3D printers

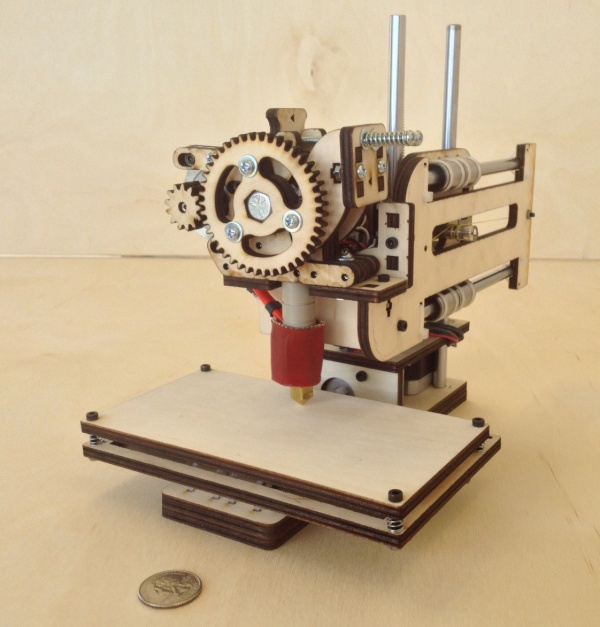

Printrbot Play ($399)

The Printbot Play is a very popular budget 3D printer that is often used in education. This inexpensive, reliable model, which is almost entirely made of metal.

The working space is 100 x 100 x 130 mm. Printbot Play has an extruder manufactured by the company itself - Alu Extruder v2. The body is made of powder coated steel and aluminium. SD slot provided. nine0005

You can upgrade the basic design of the Printrbot Play with a heated stand or increase the Y-axis stroke.

Back to 3D Printer List

Wanhao Duplicator i3 Plus ($459)

The Wanhao Duplicator i3 Plus is an upgraded version of the popular Wanhao Duplicator i3 (which in turn is based on the Prusa i3).

The main features of this cheap 3D printer are a large working space of 200 x 200 x 180 mm, a steel frame, electronics integrated into the design itself (previously it was taken out separately), a slot for a full-size SD card and a touchscreen display for control. nine0005

Wanhao Duplicator i3 Plus Cheap 3D Printer Specifications

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm; nine0346

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Flashforge Finder ($499)

FlashForge Finder is one of the newest 3D printers on our list. This affordable 3D printer offers an average working space of 140 x 140 x 140mm.

This Finder features a transparent sidewall design so you can view the 3D printing process from any angle. A color display is installed, it is possible to transfer data via WiFi network. The printer comes with some supplies and a USB flash drive, so you can start 3D printing almost immediately. nine0005

Specifications of cheap 3D printer FlashForge Finder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 140 x 140 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- XY accuracy: 11 microns;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm; nine0346

75 mm; nine0346 - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D printer list

XYZprinting da Vinci Jr. 1.0 Pro ($499)

What's so special about the da Vinci Jr. 1.0 pro? This is a new model from XYZPrinting, which includes many advanced features, such as support for printing materials from other manufacturers and increased speed of 3D printing.

Also features an auto-calibration mechanism, a closed chamber with a unique cooling system, and a 0.3mm nozzle option for high-quality printing of fine model details. All in all, this is a great 3D printer with a lot of useful features and at a low price. nine0005

Specifications for cheap 3D printer da Vinci Jr. 1.0 Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes; nine0346

- Connection: USB, SD card.

Back to 3D printer list

XYZprinting da Vinci Jr. Mix 2.0 ($599)

XYZprinting provides a wide range of low cost 3D printers. And paying attention to each model is quite difficult, although many of them are very interesting.

XYZprinting da Vinci Jr. Mix 2.0 stands out because it can print with two different materials and mix them to create multi-colored models. This dual-color 3D printing technology is rare in this price range ($500 to $1,000), so if you're interested in experimenting with multicolor printing, XYZprinting da Vinci Jr. Mix 2.0 is a great choice. nine0005

However, there is a drawback. This 3D printer is not compatible with materials from other manufacturers, so you will have to buy special materials from XYZprinting (as we mentioned above, they cost 20% more, but are not toxic).

Specifications of cheap 3D printer XYZprinting da Vinci Jr.

Mix 2.0

Mix 2.0 - Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 200 microns; nine0346

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card, WiFi.

Back to 3D printer list

Printrbot Simple ($599)

Printrbot Simple is the flagship of the Printbot empire. This model has a great open design with a solid aluminum frame and a working space of 150 x 150 x 150mm. This inexpensive 3D printer comes fully assembled at a very good price. As you need and want to experiment, you can add a heated table and expand the workspace in the horizontal plane. nine0005

Specifications of cheap 3D printer Printrbot Simple

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 80 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional; nine0346

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to the list of 3D printers

UP mini 2 ($599)

The UP mini 2 is a low cost 3D printer that packs in impressive design and functionality. For starters, it has a touch screen panel and the ability to connect via WiFi.

But the most interesting is further. Implemented power failure protection system. 3D printing will continue after the emergency stop. Built-in HEPA air filtration system. Automatic detection of the height of the extruder nozzle. A separate, closed container for the material, thanks to which it does not deteriorate under the influence of moisture from the environment. nine0005

Great 3D printer for a small price. The only thing that upsets me a little is the small working space - 120 x 120 x 120 mm.

Specifications of cheap UP mini 2 3D printer

- Printer type: FDM;

- 3D printing materials: PLA, ABS;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 150 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- Open source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D Printer List

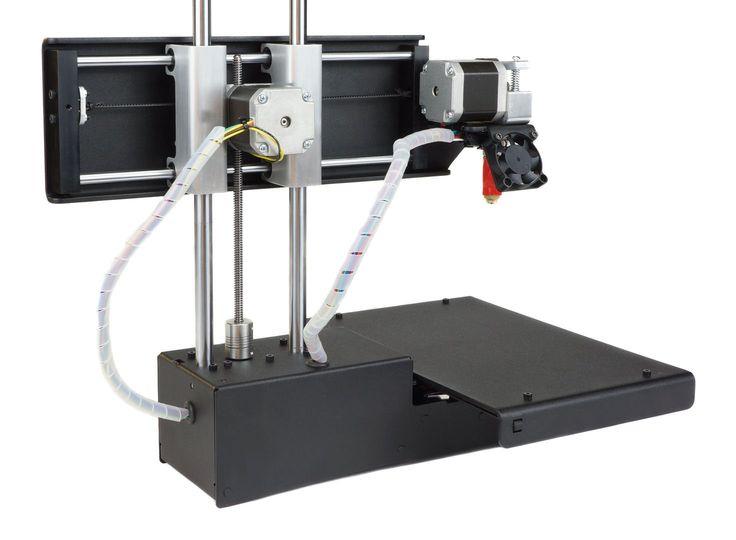

Monoprice Maker Select Ultimate ($699)

The Monoprice Maker Select Ultimate is an extraordinary beast that combines elements from two leaders in the world of 3D printing - Zortax and Ultimaker. The Monoprice Maker has an aluminum perforated printing table, which was offered in the Zortax M200 (thanks to this table, the grip of the base of the model with the table is much better), and the software part is almost identical to Ultimaker 2 (very user-friendly interface and functionality). nine0005

This model uses a "Bowden extruder", i.e. the feed units and nozzle are separated, unlike the direct feed. This improves reliability and reduces the likelihood of 3D printing errors (although, most likely, it was necessary to sacrifice printing speed, as the weight of the printing unit increases). Given the cost, this is a good model, the analogues of which are much more expensive.

Specifications of cheap UP mini 2 3D printer

- Printer type: FDM; nine0346

- 3D printing materials: PLA, ABS, exotic;

- Working space: 200 x 200 x 175 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Robo C2 ($799)

The Robo C2 is a small 3D printer with tons of connectivity options. Using a specialized application, you can monitor the status of 3D printing from your smartphone or tablet. It can be connected to a Chromebook. Thanks to the built-in slicing program, you do not need to install additional printing software.

Probably the most impressive is the integration with Amazon Alexa. Users can stop, cancel and check the status of 3D printing in real time using voice commands. nine0005

nine0005

What does this inexpensive 3D printer offer? Working space 127 x 127 x 150 mm. The 3D printing speed is 300 mm/s and the resolution is 20 microns. There is a built-in 3.5'' color touch screen, a system for monitoring the amount of remaining material for printing, automatic calibration and a removable self-aligning print platform. The only drawback is that the table is not heated, so you have to use PLA plastic.

Specifications of cheap 3D printer Robo C2

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 127 x 127 x 150 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to the list of 3D printers

Wanhao Duplicator 4S ($829)

The Duplicator 4S has 2 extruders. It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

One of the features of this model is a high-precision material feed wheel, which ensures the same filament feed speed. The Duplicator 4S is equipped with a 0.4mm precision nozzle. nine0005

Specifications of cheap 3D printer Duplicator 4S

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40 mm/s;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 0.4 mm;

- Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

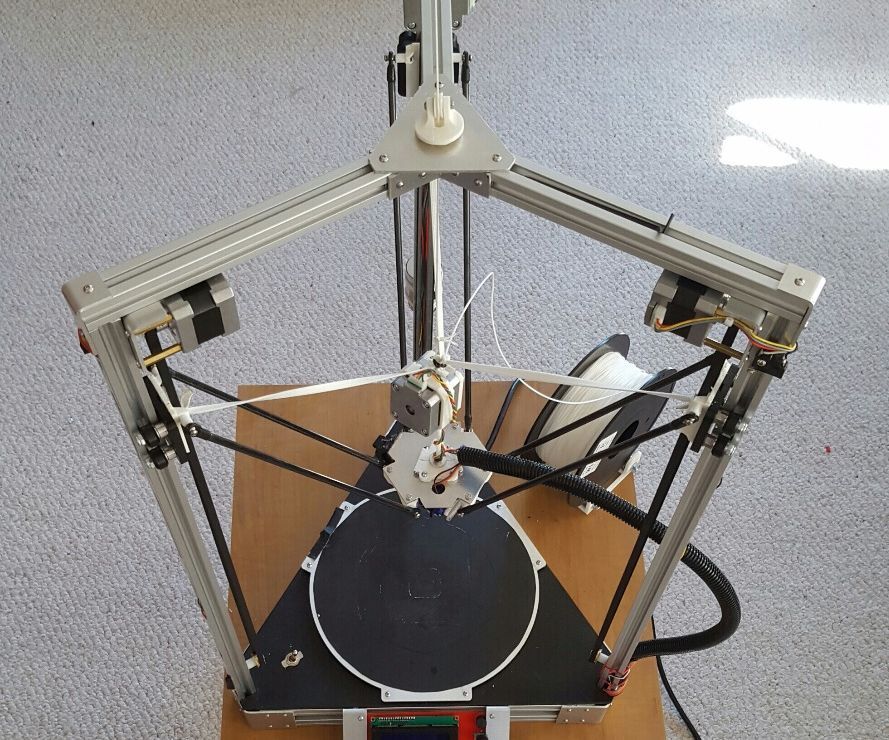

Polar 3D Printer ($899)

Polar 3D belongs to a separate category of 3D printers in this top, since this model implements the polar coordinate system. This causes the table to rotate and the print head to move up, down, right, and left. nine0005

Thanks to the polar coordinate system, this 3D printer is powered by two stepper motors, so it consumes less power. In addition, it turned out to realize a larger size of the working area: 203 (table diameter) x 152 (Z coordinate) mm.

Nominal price $899, but there are special discounts for educational institutions. The discounted price is only $599.

Specifications of cheap 3D printer Polar 3D

- Printer type: FDM;

- Materials for 3D printing: PLA;

- Working space: 203 (table diameter) x 152 (Z-coordinate) mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 400 microns;

- Number of extruders: 1;

- 3D printing speed: 40 mm/s;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no; nine0346

- Connection: USB, WiFi, SD card.

Back to 3D printer list

FlashForge Creator Pro ($899)

You've probably heard of this 3D printer. FlashForge Creator Pro is very similar to Makerbot Replicator 2X. This inexpensive 3D printer has 2 extruders, it has a steel closed body.

Other features include a table sizing system, and a guide screw that makes the guide system more stable and durable. The design is nothing special, but this model has earned positive reviews from the 3D community due to its reliability, versatility and ease of use. nine0005

Specifications of cheap 3D printer FlashForge Creator Pro

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40-100 mm/s;

- Open Source: design and software; nine0346

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: yes;

- Connection: USB, SD card.

Back to 3D Printer List

Dremel Idea Builder ($899)

The Idea Builder is plug and play. This 3D printer is designed by Dremel. It has a color touch screen display. Sufficiently large working space - 230 x 150 x 140 mm. Unfortunately, the table is not heated. On the other hand, since only PLA plastics can be used, this model is great for classrooms and teaching labs. nine0005

Specifications of cheap 3D printer Dremel Idea Builder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 230 x 150 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes; nine0346

- Connection: USB, SD card.

Back to the list of 3D printers

Printrbot Simple Pro ($999)

Printrbot Simple Pro is a significant upgrade from the original Simple. Same open design, no body. Like its predecessor, the Printrbot Simple Pro is compact and portable. All-metal construction for excellent vibration damping and shock resistance.

The main difference is the built-in color touch screen, the ability to connect via WiFi and free cloud service (optional), which greatly improves the 3D printing process. Simple Pro has a 32-bit processor, which ensures smooth and fast movements. And at the same time, this model is included in our top 20 cheap 3D printers, since its cost is $999.

Specifications of cheap 3D printer Printrbot Simple Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 200 x 150 x 200 mm;

- Minimum layer height: 50 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional;

- Nozzle diameter: 1.

75 mm; nine0346

75 mm; nine0346 - Control panel on 3D printer: yes;

- Connection: USB, WiFi.

Back to 3D printer list

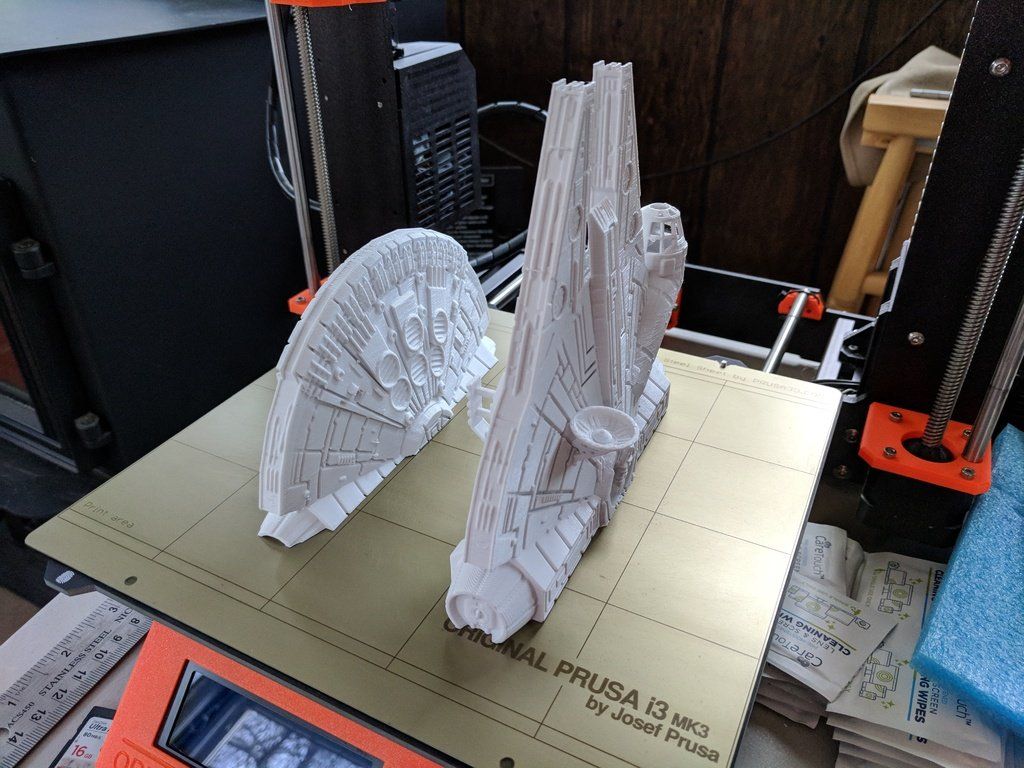

Prusa i3 Mk2 ($999)

This is one of the best 3D printers you can buy in this price range. All nodes are open-source licensed and part of the Rep-Rap project, so there are many copies around ... but all replicas are worse than the original.

The Prusa i3 Mk2 is equipped with a heated table that has technology to compensate for temperature differences in the center and corners. There is an automatic calibration system. And of course, amazing documentation. This is an extremely versatile 3D printer that you will 100% appreciate when you start printing with unusual materials such as PLA, PET, HIPS, Flex PP or Ninjaflex, etc. nine0005

The Prusa i3 Mk2 is a 3D printer that is constantly being developed and supported by the manufacturer. Its developer Josef Prusa regularly adds new features, software and design improvements (for example, the ability to color 3D print). If you look for quality competitors in the 3D printing market, then the cost of their equipment will be in the region of $2000 - $3000.

If you look for quality competitors in the 3D printing market, then the cost of their equipment will be in the region of $2000 - $3000.

The only drawback is that if you decide to buy a Prusa i3 Mk2, you will have to wait about 2 months, as the company cannot keep up with the high demand. nine0005

Specifications of cheap 3D printer Prusa i3 Mk2

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 250 x 210 x 200 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 50 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes; nine0346

- Nozzle diameter: 1.75 mm;

- Control panel on 3D printer: yes;

- Connection: SD card.

3D printing for dummies or "what is a 3D printer?"

- 1 3D printing term

- 2 3D printing methods

- 2.

1 Extrusion printing

1 Extrusion printing - 2.2 Melting, sintering or gluing

- 2.3 Stereolithography

- 2.4 Lamination

- 3 Fused Deposition Printing (FDM)

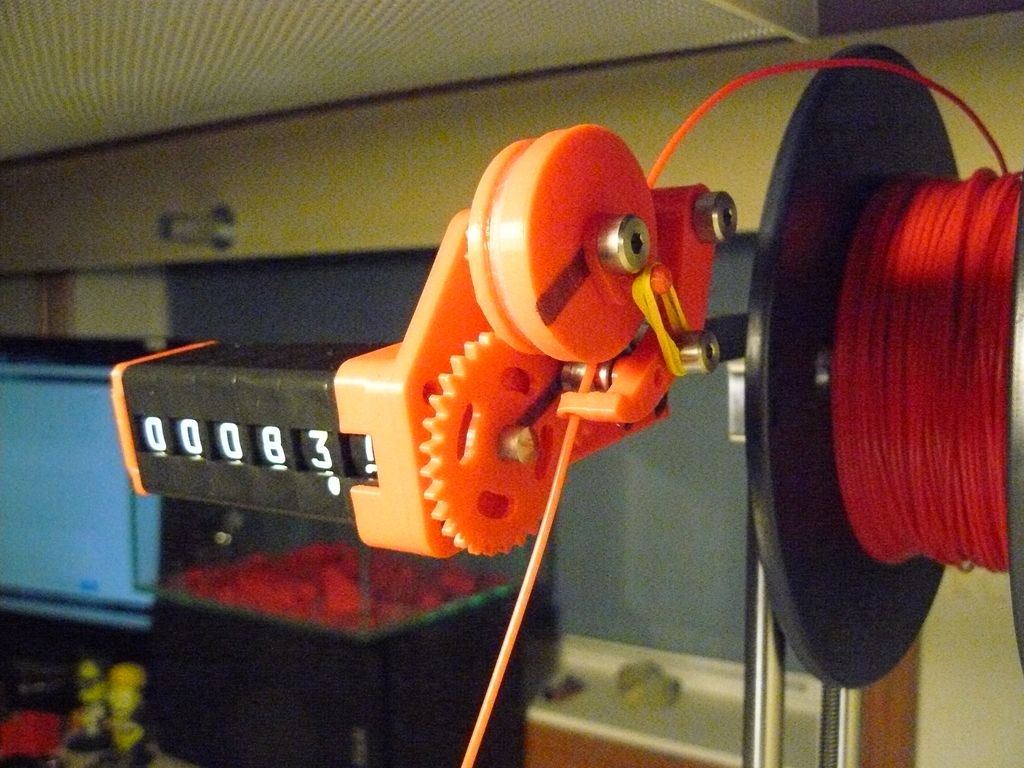

- 3.1 Consumables

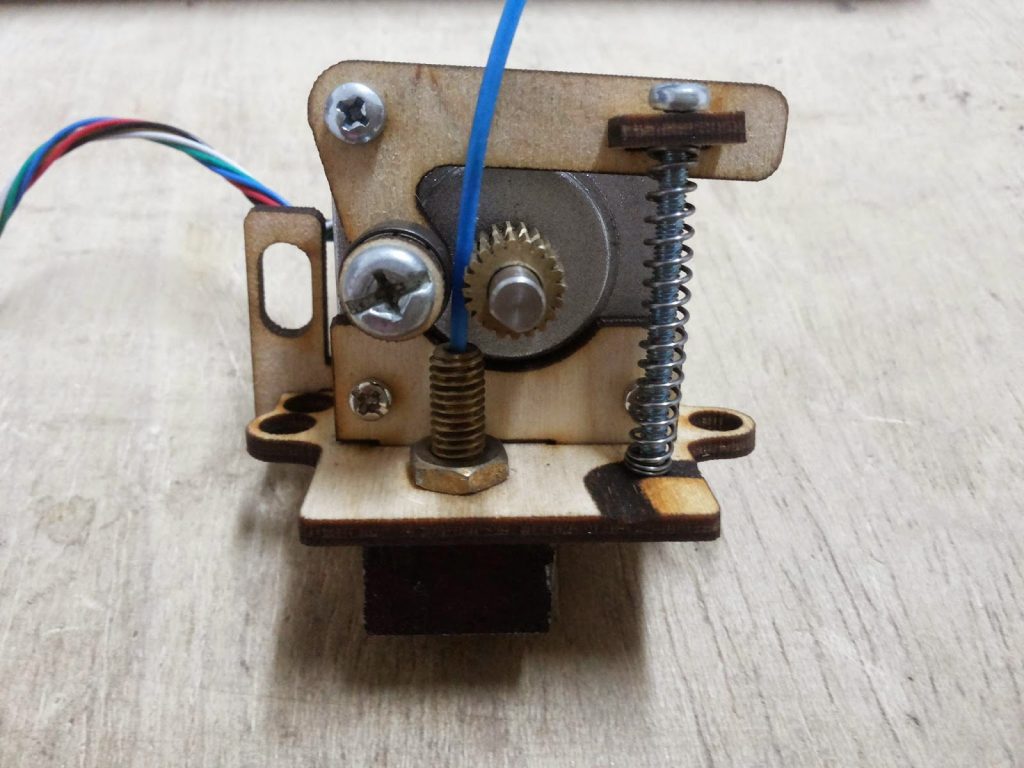

- 3.2 Extruder

- 3.3 Working platform

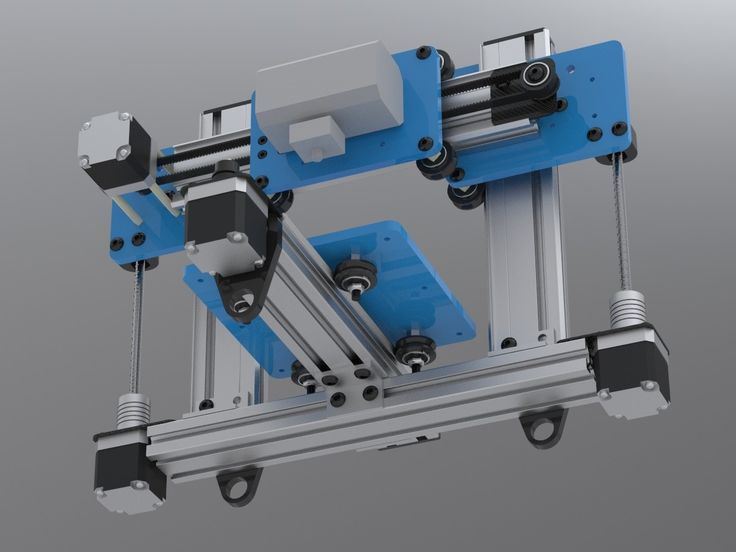

- 3.4 Positioners

- 3.5 Control

- 3.6 Varieties of FDM printers

- 4 Laser Stereolithography (SLA)

- 4.1 Lasers and projectors

- 4.2 Cuvette and resin

- 4.3 Varieties of Stereolithography Printers

The term 3D printing

The term 3D printing has several synonyms, one of which quite briefly and accurately characterizes the essence of the process - "additive manufacturing", that is, production by adding material. The term was not coined by chance, because this is the main difference between multiple 3D printing technologies and the usual methods of industrial production, which in turn received the name "subtractive technologies", that is, "subtractive". If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained. nine0005

If during milling, grinding, cutting and other similar procedures, excess material is removed from the workpiece, then in the case of additive manufacturing, material is gradually added until a solid model is obtained. nine0005

Soon 3D printing will even be tested on the International Space Station

Strictly speaking, many traditional methods could be classified as "additive" in the broad sense of the word - for example, casting or riveting. However, it should be borne in mind that in these cases, either the consumption of materials is required for the manufacture of specific tools used in the production of specific parts (as in the case of casting), or the whole process is reduced to joining ready-made parts (welding, riveting, etc.). In order for the technology to be classified as “3D printing”, the final product must be built from raw materials, not blanks, and the formation of objects must be arbitrary - that is, without the use of forms. The latter means that additive manufacturing requires a software component. Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive. nine0005

Roughly speaking, additive manufacturing requires computer control so that the shape of final products can be determined by building digital models. It was this factor that delayed the widespread adoption of 3D printing until the moment when numerical control and 3D design became widely available and highly productive. nine0005

3D printing methods

3D printing technologies are numerous, and there are even more names for them due to patent restrictions. However, you can try to divide technologies into main areas:

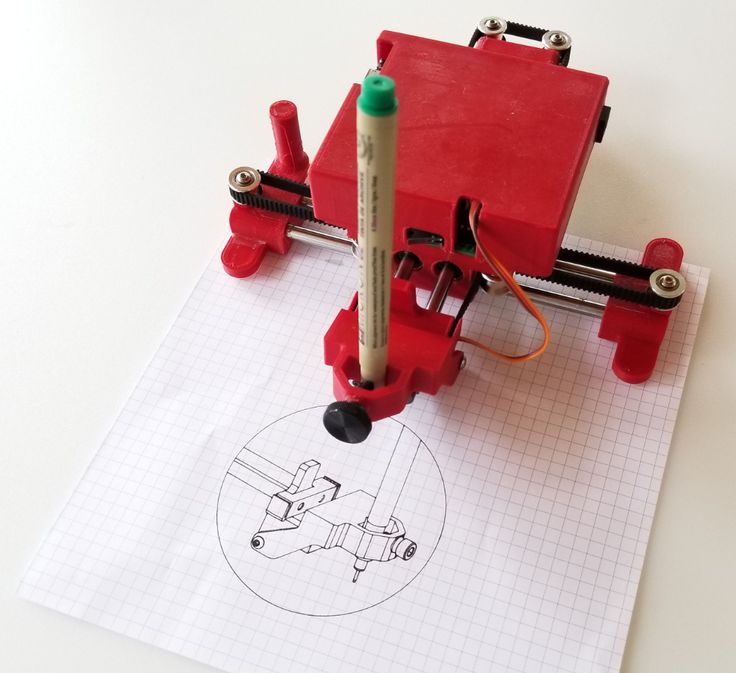

Extrusion printing

This includes methods such as deposition fusion (FDM) and multi-jet printing (MJM). This method is based on the extrusion (extrusion) of consumables with the sequential formation of the finished product. As a rule, consumables consist of thermoplastics or composite materials based on them. nine0005

Melting, sintering or bonding

This approach is based on bonding powdered material together. Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal. nine0005

Formation is done in different ways. The simplest is gluing, as is the case with 3D inkjet printing (3DP). Such printers deposit thin layers of powder onto the build platform, which are then selectively bonded with a binder. Powders can be made up of virtually any material that can be ground to a powder—plastic, wood, metal. nine0005

This model of James Bond's Aston Martin was successfully printed on a Voxeljet SLS printer and blown up just as successfully during the filming of Skyfall instead of the expensive original

sintering (SLS and DMLS) and smelting (SLM), which allow you to create all-metal parts. As with 3D inkjet printing, these devices apply thin layers of powder, but the material is not glued together, but sintered or melted using a laser. Laser sintering (SLS) is used to work with both plastic and metal powders, although metal pellets usually have a more fusible shell, and after printing they are additionally sintered in special ovens. DMLS is a variant of SLS installations with more powerful lasers that allow sintering metal powders directly without additives. SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium. nine0005

SLM printers provide not just sintering of particles, but their complete melting, which allows you to create monolithic models that do not suffer from the relative fragility caused by the porosity of the structure. As a rule, printers for working with metal powders are equipped with vacuum working chambers, or they replace air with inert gases. Such a complication of the design is caused by the need to work with metals and alloys subject to oxidation - for example, with titanium. nine0005

Stereolithography

How an SLA printer works

Stereolithography printers use special liquid materials called "photopolymer resins". The term "photopolymerization" refers to the ability of a material to harden when exposed to light. As a rule, such materials react to ultraviolet irradiation.

Resin is poured into a special container with a movable platform, which is installed in a position near the surface of the liquid. The layer of resin covering the platform corresponds to one layer of the digital model. Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again. nine0005

Then a thin layer of resin is processed by a laser beam, hardening at the points of contact. At the end of illumination, the platform together with the finished layer is immersed to the thickness of the next layer, and illumination is performed again. nine0005

Lamination

Laminating (LOM) 3D printers workflow

Some 3D printers build models using sheet materials - paper, foil, plastic film.

Layers of material are glued on top of each other and cut along the contours of the digital model using a laser or a blade.

These machines are well suited for prototyping and can use very cheap consumables, including regular office paper. However, the complexity and noise of these printers, coupled with the limitations of the models they produce, limit their popularity. nine0005

Fused deposition modeling (FDM) and laser stereolithography (SLA) have become the most popular 3D printing methods used in the home and office.

Let's take a closer look at these technologies.

Fused Deposition Printing (FDM)

FDM is perhaps the simplest and most affordable 3D construction method, which makes it very popular.

High demand for FDM printers is driving device and consumable prices down rapidly, along with technology advances towards ease of use and improved reliability. nine0005

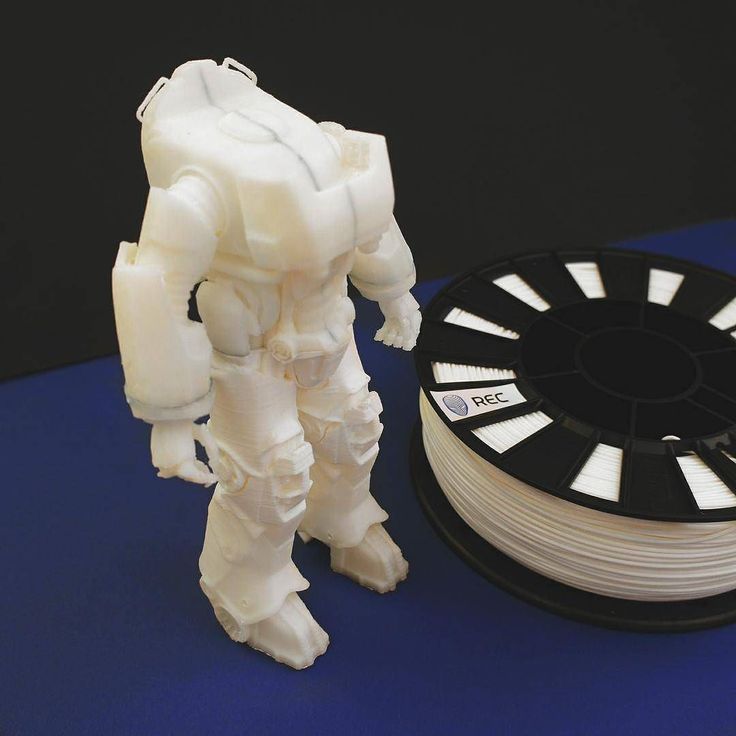

Consumables

ABS filament spool and finished model

FDM printers are designed to print with thermoplastics, which are usually supplied as thin filaments wound on spools. The range of "clean" plastics is very wide. One of the most popular materials is polylactide or "PLA plastic". This material is made from corn or sugar cane, which makes it non-toxic and environmentally friendly, but makes it relatively short-lived. ABS plastic, on the other hand, is very durable and wear-resistant, although it is susceptible to direct sunlight and can release small amounts of harmful fumes when heated. Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc. nine0005

Many plastic items that we use on a daily basis are made from this material: housings for household appliances, plumbing fixtures, plastic cards, toys, etc. nine0005

In addition to PLA and ABS, printing is possible with nylon, polycarbonate, polyethylene and many other thermoplastics that are widely used in modern industry. More exotic materials are also possible, such as polyvinyl alcohol, known as "PVA plastic". This material dissolves in water, which makes it very useful for printing complex geometric patterns. But more on that below.

Model made from Laywoo-D3. Changing the extrusion temperature allows you to achieve different shades and simulate annual rings

It is not necessary to print with homogeneous plastics. It is also possible to use composite materials imitating wood, metals, stone. Such materials use all the same thermoplastics, but with impurities of non-plastic materials.

So, Laywoo-D3 consists partly of natural wood dust, which allows you to print "wooden" products, including furniture.

The material called BronzeFill is filled with real bronze, and models made from it can be ground and polished, achieving a high similarity to products made from pure bronze. nine0005

One has only to remember that thermoplastics serve as a binding element in composite materials - they determine the thresholds of strength, thermal stability and other physical and chemical properties of finished models.

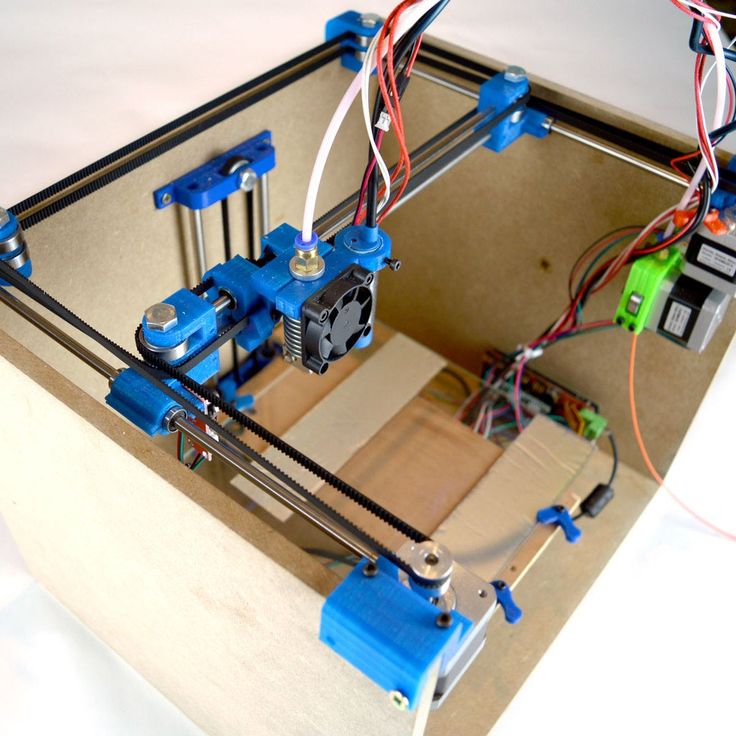

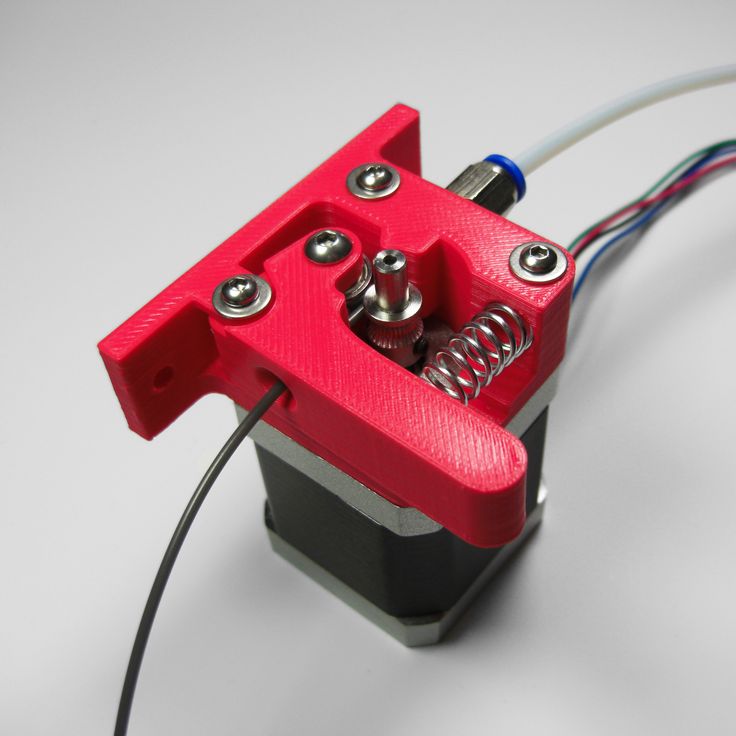

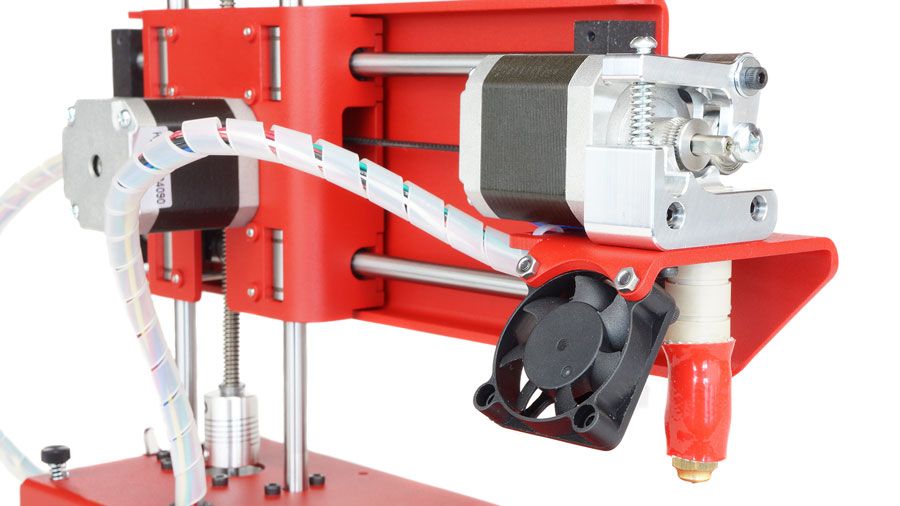

Extruder

Extruder - FDM print head. Strictly speaking, this is not entirely true, because the head consists of several parts, of which only the feed mechanism is directly "extruder". However, by tradition, the term "extruder" is commonly used as a synonym for the entire print assembly. nine0005

FDM extruder general design

The extruder is designed for melting and applying thermoplastic thread. The first component is the thread feed mechanism, which consists of rollers and gears driven by an electric motor. The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed. nine0005

The mechanism feeds the thread into a special heated metal tube with a small diameter nozzle, called a "hot end" or simply a "nozzle". The same mechanism is used to remove the thread if a change of material is needed. nine0005

The hot end is used to heat and melt the thread fed by the puller. As a rule, nozzles are made from brass or aluminum, although more heat-resistant, but also more expensive materials can be used. For printing with the most popular plastics, a brass nozzle is quite enough. The “nozzle” itself is attached to the end of the tube with a threaded connection and can be replaced with a new one in case of wear or if a change in diameter is necessary. The nozzle diameter determines the thickness of the molten filament and, as a result, affects the print resolution. The heating of the hot end is controlled by a thermistor. Temperature control is very important, because when the material is overheated, pyrolysis can occur, that is, the decomposition of plastic, which contributes both to the loss of the properties of the material itself and to clogging of the nozzle. nine0005

nine0005

PrintBox3D One FDM Printer Extruder

To prevent the filament from melting too early, the top of the hot end is cooled by heatsinks and fans. This point is of great importance, since thermoplastics that pass the glass transition temperature significantly expand in volume and increase the friction of the material with the walls of the hot end. If the length of such a section is too long, the pulling mechanism may not have enough strength to push the thread. nine0005

The number of extruders may vary depending on the purpose of the 3D printer. The simplest options use a single print head. The dual extruder greatly expands the capabilities of the device, allowing you to print one model in two different colors, as well as using different materials. The last point is important when building complex models with overhanging structural elements: FDM printers cannot print “over the air”, since the applied layers require support. In the case of hinged elements, temporary support structures have to be printed, which are removed after printing is completed. The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material. nine0005

The removal process is fraught with damage to the model itself and requires accuracy. In addition, if the model has a complex structure with internal cavities that are difficult to access, building conventional supports may not be practical due to the difficulty in removing excess material. nine0005

Finished model with PVA supports (white) before and after washing

In such cases, the same water-soluble polyvinyl alcohol (PVA) comes in handy. Using a dual extruder, you can build a model from waterproof thermoplastic using PVA to create supports.

After printing, PVA can simply be dissolved in water and a complex product of perfect quality can be obtained.

Some FDM printers can use three or even four extruders. nine0005

Work platform

Heated platform covered with removable glass work table