3D printing reno nv

Products – Dreaming In Print

Quick View

-

Quick View

- Buildings, GameScape 3D

- $124.99

- Create a more immersive experience with this 3 story home designed by GameScape 3D.

- Add to cart

Quick View

-

Quick View

- Buildings, GameScape 3D

- $99.99

- Create a more immersive experience with this 3 story home designed by GameScape 3D. Grand Total of 21 pieces to make this 3 Story House, Over 100 Hours of printing.

- Add to cart

Quick View

-

Quick View

- Cosplay

- $22.

99

- These smaller 3d printed pokeballs are perfect to round out any Pokémon cosplay. Measuring just over 2 inches in diameter, these fit perfectly in your hand when you are getting ready to catch 'em all with your cosplay. When purchasing you get a set of 3 of these pokeballs already put together.

- Add to cart

Quick View

-

Quick View

- Home Decor

- $24.99

- This is a set of 5 Patriotic Star and Stripes for your mantle, or table top decor. Items cut on 3mm thick Baltic Birch and hand painted. As the items are hand painted there will be variations in paint and colors depending on wood grain.

- Add to cart

Quick View

-

Quick View

- Jewelry

- $19.

99

99 - Need a gift idea? Or just want to get yourself something? Enjoy these laser cut acrylic 3mm Lotus Flower earrings. 925 Sterling Silver stamped earring fish hooks with silicone stopper.

- Select options

Quick View

-

Quick View

- The Dragons Rest

- $79.99 – $164.99

- Display your hero in this perfect rocky mountaintop ready for you camp and rest in between campaigns. It can easily be used as a terrain component as part of a tabletop campaign with a design aesthetic that fits a wide variety of Dungeons and Dragon or fantasy campaigns.

- Select options

Quick View

-

Quick View

- Misc.

Fun

Fun - $4.99

- Need a gift idea? Or just want to get yourself something? Laser cut on 3mm Baltic Birch to stay lightweight to avoid weighing down your keys. Acrylic painted faction colors to show off your choice.

- Add to cart

Quick View

-

Quick View

- Jewelry

- $15.99

- Show your love for your faction. Need a gift idea? Or just want to get yourself something? Enjoy these Alliance Lion laser cut on 3mm Baltic Birch to stay lightweight. 925 Sterling Silver stamped earring fish hooks with silicone stopper.

- Add to cart

Quick View

-

Quick View

- Misc. Fun

- $54.

99

99 - Incredible fully articulated 3D crystal dragon created by Cinderwing3D.

- Select options

Quick View

-

Quick View

- Misc. Fun

- $49.99

- Incredible fully articulated 3D woodland dragon created by Cinderwing3D.

- Add to cart

Quick View

-

Quick View

- Misc. Fun

- $49.99

- Yes this is made by the same creator as the articulating Crystal Dragon. This handsome void Octopus features multiple dodecahedron shapes inside his bulbous head. Super fun with his 8 tentacles swing freely as you hold him. Printed in Copper with more colors to come, so be on the look out.

- Add to cart

3D Printing

TEENS! We need your feedback. Please take our brief survey.

Visit covid19washoe.com for COVID-19 updates.

Narrow Your Search

- Books, Movies, Music

- Articles & Research

- Library Information

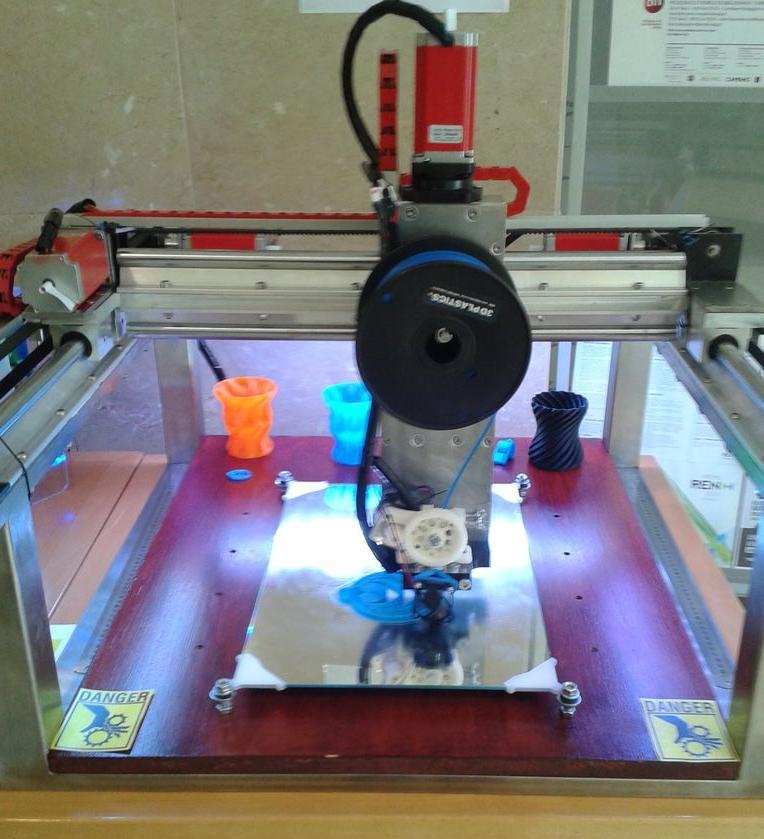

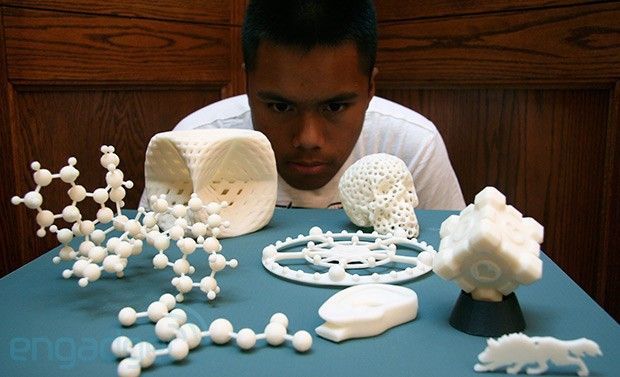

If you have never tried 3D printing before, here is your chance to try it out. You can submit a request and then select a Washoe County Library branch as your pickup location. Your object will be printed using PLA filament. Objects will be printed in whatever filament color is already in the printer.

3D printing at the library is free of charge and available to Washoe County Library cardholders. Each cardholder may request a maximum of 1 item per week. We do not print weapons or weapon parts (including guns and knives).

We do not print weapons or weapon parts (including guns and knives).

Your 3D printing file must be an .obj or .stl file. These are the only acceptable formats for the 3D printers used at the library. Print jobs are limited to one request per library card account per week.

The maximum total print time for each 3D item is limited to six hours. Anything requiring longer than six hours will not be printed. You item will be held for one month for you to pick up, then it will be discarded.

If your object is too big to fit on the printer, it will not be printed. Please see the FAQ page to see the maximum print size allowed per printer. We use the Lulzbot Mini 2, and the Lulzbot Taz printers.

Not sure where to start? Thingiverse, Tinkercad, and MyMiniFactory are all great sites to explore. While our printers can make a variety of things, they may not be ideal for highly detailed mini-figurines or similar print requests. If your item cannot be printed on a Washoe County Library 3D printer, you may want to explore other 3D printing services in the area, such as the University of Nevada, Reno's DeLaMare Library. Costs vary. There are also online printing services that you can use.

Costs vary. There are also online printing services that you can use.

Please browse the FAQs for more info.

Submit a Project 3D Printing FAQs

To Get Started

- You must have a Washoe County Library System library card account.

- You must have a Google/Gmail Account. Visit Google.com to create an account.

- Complete the Washoe County Library System 3D Print Request Form. You must be signed in to your Google account to use the form.

- Upload your print file (.obj or .stl only) and submit the form.

Once you submit your request, it will be added to the print queue, and you will be contacted as soon as the item is ready for pick up. Most print requests are completed in one to two weeks.

All 3D objects will be printed using a single filament color. Branches will use whatever filament color is already loaded in the printer. Each library patron is limited to printing a total of one 3D object per week. Print time per object must not exceed six hours. If your item cannot be printed, you will be notified by library staff. The library will not save or retain submitted files after printing objects. Printed items not picked up within one month after notification will be discarded. The Washoe County Library System's 3D printers may only be used for lawful purposes. They cannot be used to print material that is:

Print time per object must not exceed six hours. If your item cannot be printed, you will be notified by library staff. The library will not save or retain submitted files after printing objects. Printed items not picked up within one month after notification will be discarded. The Washoe County Library System's 3D printers may only be used for lawful purposes. They cannot be used to print material that is:

- Prohibited by local, state, or federal law

- Unsafe, harmful, or dangerous, or poses an immediate threat to the well-being of others

- We do not print weapons or weapon parts (including guns and knives)

- In violation of another’s intellectual property/copyright

The library reserves the right to:

- Review and approve all materials before printing

- Set a limit for the maximum amount of time a print job may take

- Refuse any 3D print request

Supervision of 3D printing by library staff or volunteers does not constitute knowledge or acknowledgement of any final use of the 3D product, and the library specifically disclaims any knowledge thereof.

Lulzbot Mini 2:

- Print Area Dimensions: 152 mm x 152 mm x 158 mm (6 in x 6 in x 6.2 in)

- Supported file formats: STL, OBJ, G, G-Code, 3MF, or X3D

- Layer Height: 0.25 mm

- Filament: PLA

- Infill default setting: 20 percent

- Available at: North Valleys Library, Northwest Reno Library, Sierra View Library, South Valleys Library, Spanish Springs Library, Sparks Library

Lulzbot Taz 6:

- Print Area Dimensions: 280 mm x 280 mm x 250 mm (11.02 in x 11.02 in x 9.8 in)

- Supported file formats: STL, OBJ, G, G-Code, 3MF, or X3D

- Layer Height: 0.25 mm

- Filament: PLA

- Infill default setting: 20 percent

- Available at: Downtown Reno Library, Incline Village Library

Download an Object to Print

Find and download 3D objects files created by others. Many sites offer files free of charge, and many site offer a 3D printing service:

Many sites offer files free of charge, and many site offer a 3D printing service:

- Thingiverse

- Pinshape

- Yeggi

- GrabCad

- Libre 3D

Design Your Own Object

There are lots of freely available lessons and software online. Here are a few we recommend:

TinkerCad

The interactive lessons are perfect for the first time user. This free, cloud-based 3D modeling software will have you creating your own designs in just a few lessons.

Blender

Open source 3D creation suite.

Sketchup

Think in 3D; draw in 3D. Start by drawing lines and shapes. Push and pull surfaces to turn them into 3D forms. Stretch, copy, and rotate to make anything you like.

Materials housed within the library as well as graphics or illustrations obtained by patrons may be protected by copyright. Patrons are responsible for abiding by copyright restrictions and obtaining any necessary permissions when using those resources.

The Wall Street Journal

Full access to the most recent issues of the Journal

Libby/OverDrive

Our main digital collection, with thousands of ebooks, audiobooks, and magazines

The New York Times

Complimentary digital access to The New York Times

Reading Challenges

Participate in all our reading challenges with the Beanstack app

Visit the Digital Library

TechBoomers

Learn popular technology, apps, and websites with a senior focus

Small Engine Repair Reference Center

Detailed, user-friendly repair guides for all manner of small engines

NoveList Plus

Reading recommendations, series information, and more tools for readers

Mango Languages

Easy access to language learning . More than 72 languages offered.

LinkedIn Learning

Creative, business, and technology courses for in-depth learning

Computer Skills Center

Video courses to learn popular software and computer basics

1,000 Miles Project

The first-hand account of a 1914 prospecting trip across Nevada provides an engaging way to study history

View all digital resouces

WorldBook Online

With activities and a suite of research tools, it's more than an encyclopedia

TumbleBook Library

A collection of talking, animated picture books and ebooks for kids

Teen Survey

Take our survey to help us better understand the types of events that interest you

Libby/OverDrive

Our main digital collection, with thousands of ebooks, audiobooks, and magazines

Teaching at Home

Help your child's education continue even when the schools are closed

1,000 Miles Project

The first-hand account of a 1914 prospecting trip across Nevada provides an engaging way to study history

View more resources by category

WorldBook Online

With activities and a suite of research tools, it's more than an encyclopedia

Teaching at Home

Help your child's education continue even when the schools are closed

Brainfuse HelpNow

Live homework help, writing lab, test prep, and other student resources

Explora

Research resources and tools for students and teachers

More Homework Help

STEAM

Science, technology, engineering, and art resources

Teaching at Home

Help your child's education continue even when the schools are closed

Family Engagement and Literacy

Cultural and educational resources for kids of all ages

Get a Card

Sign up for an instant digital card to get access to all our online resources.

Community Resources

Resources and support during the coronavirus outbreak

Back to Work Nevada

Links to resume help, unemployment insurance, and business loan providers

Apps and Tools

Many of our most popular resources have apps for easy use on mobile devices.

TumbleBiblioteca

Disfrute de más de 50 libros, libros de dibujos, y libros con audio para niños de todas las edades.

Referencia Latina

Texto completo cubre una amplia gama de temas dentro y fuera de la academia.

OverDrive

Colección de libros electrónicos y audiolibros descargables en inglés o español y revistas.

The New York Times

Acceso gratuito en línea al New York Times, tanto de forma remota como en la biblioteca.

HelpNow

Tutoría en vivo en español o inglés está disponible con Brainfuse HelpNow

Más en Español

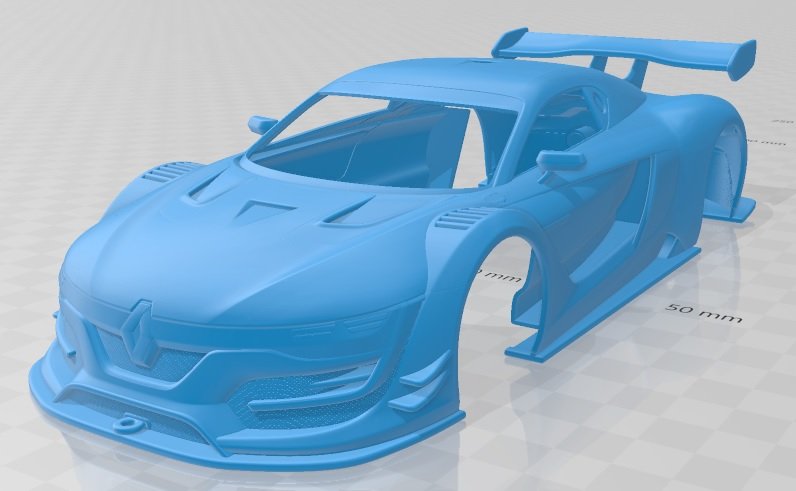

3D technologies in the Formula 1 project

Implementation stories

Automotive industry

Author: Yakov Bondarev

Author: Yakov Bondarev

R&D partnership | The ever-improving car | Quick design check | New possibilities of using wind tunnel | High speed and precision of parts manufacturing | New directions of development

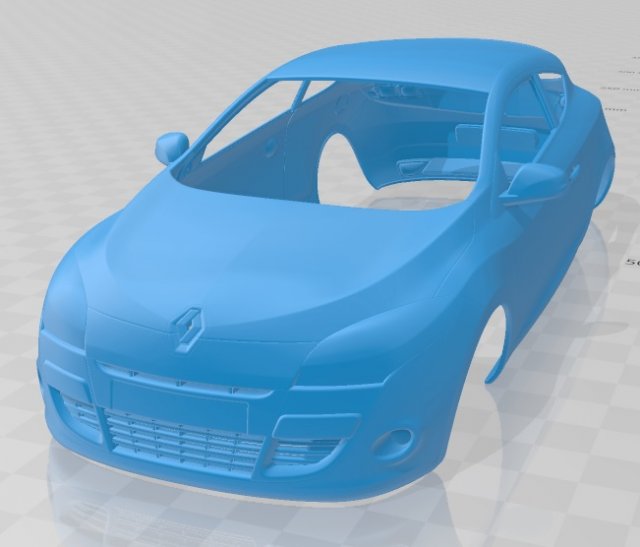

Formula 1 racing is a technical sport based on continuous innovation and requires high reliability from cars. Racing teams, including Renault Sport Formula One, are constantly striving to match and exceed the ever-improving results of the leaders. In this sport, the research and development process never stops, and technical partnerships are essential for an organization to achieve its goals. Renault Sport Formula One's collaboration with 3D Systems accelerates the development process and drives innovation at every stage, from wind tunnel and wind tunnel testing to the production of reliable finished parts.

Racing teams, including Renault Sport Formula One, are constantly striving to match and exceed the ever-improving results of the leaders. In this sport, the research and development process never stops, and technical partnerships are essential for an organization to achieve its goals. Renault Sport Formula One's collaboration with 3D Systems accelerates the development process and drives innovation at every stage, from wind tunnel and wind tunnel testing to the production of reliable finished parts.

Renault Sport Formula One team breaks new ground for innovation through R&D partnership with 3D Systems

“Race after race, more and more complex composites and aerospace alloys are being used, rigorously selected in research and development labs,” explains Renault Sport Formula One Technical Director Nick Chester. “At the end of every racing season, we expect our car to be more than a second per lap faster than it was at the beginning, and our technical partners are just as ruthlessly selected. We're not interested in relationships that don't help us improve our performance."

We're not interested in relationships that don't help us improve our performance."

The yardstick of ongoing innovation and strong collaboration explains the Renault Sport Formula One team's choice of 3D Systems and its 3D printing technology suite.

R&D partnership

Based in Enstone, UK, the Renault Sport Formula One team has been using 3D Systems technology since 1998. She was one of the first to use 3D printing for prototyping and closely monitored the development of this technology. Early on, the technology was used to test designed parts for functional and dimensional requirements, and to make jigs and fasteners for precise assembly. As the partnership between the two companies developed, 3D Systems engineers helped the Renault Sport Formula One team understand and use their existing capabilities, materials and methodologies. That the team was able to keep their wind tunnel loaded is a testament to the positive impact of the partnership with 3D Systems and the development of innovative automotive parts using 3D die-casting and 3D metal printing (DMP).

3D Systems laser stereolithography technology enables Renault Sport Formula One team to respond quickly to technical challenges

“The support provided by 3D Systems has also evolved as our collaboration has expanded,” explained Mr. Chester. “Looking back, as materials properties improved, the team sought to expand the range of applications for fast manufacturing materials to more complex engineering problems. The number of automotive components produced using additive manufacturing is increasing every year, bringing significant benefits to the team in terms of application flexibility and reduced production time and costs.”

Among the 3D Systems installations currently used by Renault Sport Formula One are six stereolithographic 3D printers and three selective laser sintering (SLS) machines. Materials are used ranging from Accura® for fixtures and fasteners, burnout models and wind tunnel parts to DuraForm® PA and DuraForm GF for car-mounted parts such as electrical junction boxes and air-cooling ducts. From material suitability testing to part design optimization, the partnership between Renault Sport Formula One and 3D Systems ensures the best possible results both on and off the race track.

From material suitability testing to part design optimization, the partnership between Renault Sport Formula One and 3D Systems ensures the best possible results both on and off the race track.

Continuous improvement car

Each year, the Renault Sport Formula One team designs and builds a new car that takes into account changes in the rules and follows a natural cycle of R&D to improve the performance of the car. As an example of the challenges that the changes to the Formula 1 rules entail, are the 2017 innovations allowing heavier larger tires, a wider front wing, a lower and wider rear wing and a taller diffuser. This means that parts from 2016 could not be reused in 2017.

As soon as the racing season begins, the tension only grows: sometimes there is only a week between races to make technical changes. From dedicated racetracks to rough and twisty street tracks, every race presents engineers with new challenges in terms of track architecture, climate and asphalt type.

The team prepares for the unique features of each track and uses all the time in the small gaps between races to bring the fruits of research into cars and equipment. Clearly, the speed and accuracy of 3D printing is of great value when preparing for new races. “The car is improving every day during the racing season,” says Patrick Warner, Lead Digital Manager for Renault Sport Formula One. “We need new components at every track, and the benefits of additive manufacturing are becoming ever more relevant.”

TASK

- Accelerate the R&D process in the automotive industry and promote innovation in a constantly changing environment.

SOLUTION

- 3D Systems complete solutions from printers and materials to application experience.

RESULTS

- Increased Efficiency: A small group of engineers were able to produce hundreds of parts a week for wind tunnel testing.

- Produce complex automotive parts in hours, not weeks, with SLA and SLS technologies.

- Making more innovative parts using 3D printed die-cast patterns.

- Assuring assembly quality by designing and manufacturing precision fixtures and fasteners that would not be possible or would be too time consuming with conventional technology.

- Opening new possibilities for the development of innovative 3D printed parts for testing and mounting on race cars.

Quick design check

Rapid prototyping using 3D printing was immediately demonstrated in Formula 1 racing, where the parts installed inside the car are densely packed and limited by the contours of the aerodynamic skin. The Renault Sport Formula One team's aerodynamicists quickly realized the potential of 3D printing to validate functional and dimensional requirements based on the complexity of parts produced by 3D Systems. As a result, the use of 3D technologies has grown rapidly, from rapid prototyping to the production of models for aerodynamic testing.

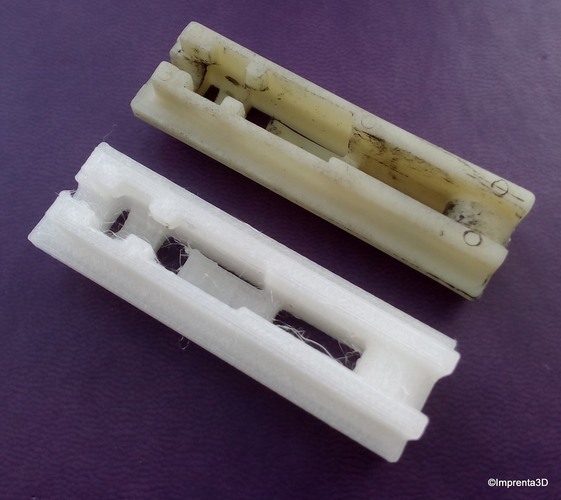

3D-printed burn-out casting patterns enable fast production of large metal parts of great complexity

Aerodynamic testing is an experience-based science,” Warner explains. “We develop and compare new ideas and identify future areas of work. The more ideas we can compare and evaluate, the more successful the races will be." In terms of parts quality, equipment life and performance, SLA technology has proven indispensable for the racing team.

New ways to use wind tunnel

In recent years, the aerodynamics group within the Renault Sport Formula One racing team has grown significantly and now has 120 employees, including aerodynamicists, technicians and modellers. According to Warner, the development of this area was largely due to the increased use of additive manufacturing technologies from 3D Systems. As one of the main advantages of 3D Systems technology, he points to the ability to build complex internal channels in aerodynamic test models, as well as the ability to collect more pressure readings.

“The model wind tunnel test car has a complex network of pressure sensors,” says Warner. “Before the advent of SLA technology, sensors were installed by drilling pressure tapping holes in metal and carbon fiber parts. The ability we now have to fabricate complex solids with extensive internal channels has revolutionized sensor placement and dramatically increased the number of sensors. It's an aerodynamicist's dream come true."

The wind tunnel test alone requires 600 parts per week to be 3D printed, Warner estimates, all of which is done by just five digital engineers.

“Using traditional technologies, we could not even dream of such a result,” notes Patrick Warner. “We would need a machine shop the size of a small town. Thanks to 3D Systems, we have a one-stop shop. We have the right equipment, the right materials, and the experience of application engineers who can get to work immediately.”

High speed and accuracy of parts manufacturing

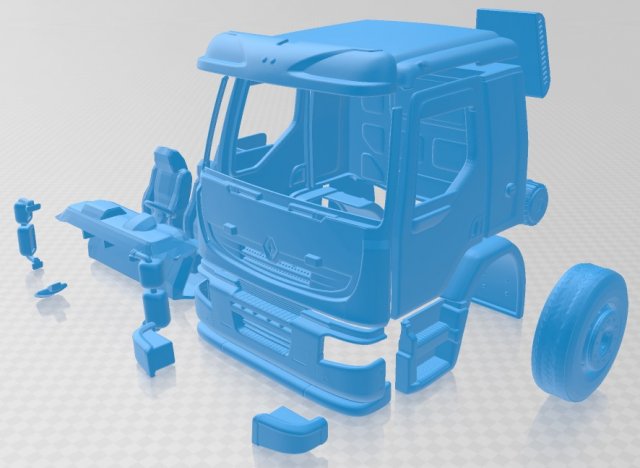

Metal 3D printing partnership with 3D Systems makes it possible to create innovative automotive components

In terms of performance and efficiency, 3D printing has greatly increased the Renault Sport Formula One racing team's ability to respond to the new challenges posed by the ever-changing rules of Formula One racing. With SLA and SLS technologies, complex fixtures and fasteners, fluid dynamic parts and automotive components can be produced in hours rather than weeks, making 3D technology ideal for solving Formula 1 racing logistical challenges.

With SLA and SLS technologies, complex fixtures and fasteners, fluid dynamic parts and automotive components can be produced in hours rather than weeks, making 3D technology ideal for solving Formula 1 racing logistical challenges.

In addition to the huge number of parts tested in the wind tunnel every month, the Renault Sport Formula One team manufactures a number of racing car parts directly. “3D Systems technologies have provided the foundation for a new, efficient manufacturing process that has enabled us to reduce both cycle times and costs, bringing invaluable benefits to the entire team,” said Rob White, CEO of Renault Sport Formula One. - On the one hand, we appreciate the opportunity to test several variants of the same part in a wind tunnel. On the other hand, we see how the number of parts in the car made by selective laser sintering is growing every year.”

3D printing helps the team create lighter parts that increase the speed and fuel efficiency of the car, as well as conduct accurate and informative consumption tests to improve engine performance and reduce wear. The finished design, along with the bill of materials, is sent to the digital technology team to manufacture the part. Thanks to SLA and SLS technologies, complex automotive components can be produced faster than ever, in some cases the part is ready for inspection even before the drawings are completed.

The finished design, along with the bill of materials, is sent to the digital technology team to manufacture the part. Thanks to SLA and SLS technologies, complex automotive components can be produced faster than ever, in some cases the part is ready for inspection even before the drawings are completed.

3D-printed diecast diecast models are also increasingly being used by the racing team for products such as transmission and suspension parts, removing restrictions on the level of complexity of parts and allowing the team's engineers to be more creative in their design. The accuracy of the SLA technology reduces the time required for the manufacture of casting patterns and machining of finished castings.

New directions of development

The benefits of 3D Systems technology, experience and services are closely linked to the key priorities of the Renault Sport Formula One team, such as innovation, efficiency, maximum precision and precision. For Bob Bell, CTO of Renault Sport Formula One, 3D Systems is more than just a technology provider: the two companies have developed a true partnership that delivers results today and creates huge potential for the future.

“Our partnership with 3D Systems over the past two decades has greatly increased productivity and efficiency,” says Bell. “It opened up new possibilities that I believe will only expand in the future.”

Translation from English. The original of this material is on the 3D Systems website.

iQB Technologies offers you to order one of the following services: expert advice, 3D training, test 3D printing/3D scanning, visiting your company, diagnostics or ordering 3D equipment.

Request a 3D expert consultation

Article published on 11/10/2017, updated on 05/14/2021

3Dcrafter.ru — 3D printing in Moscow on high-precision 3D printers

Materializer 24/7

We accept applications by e-mail around the clock!

Order

We accept applications by e-mail around the clock!

Order

Engineering and art

3D modeling

We accept applications by e-mail around the clock!

Order

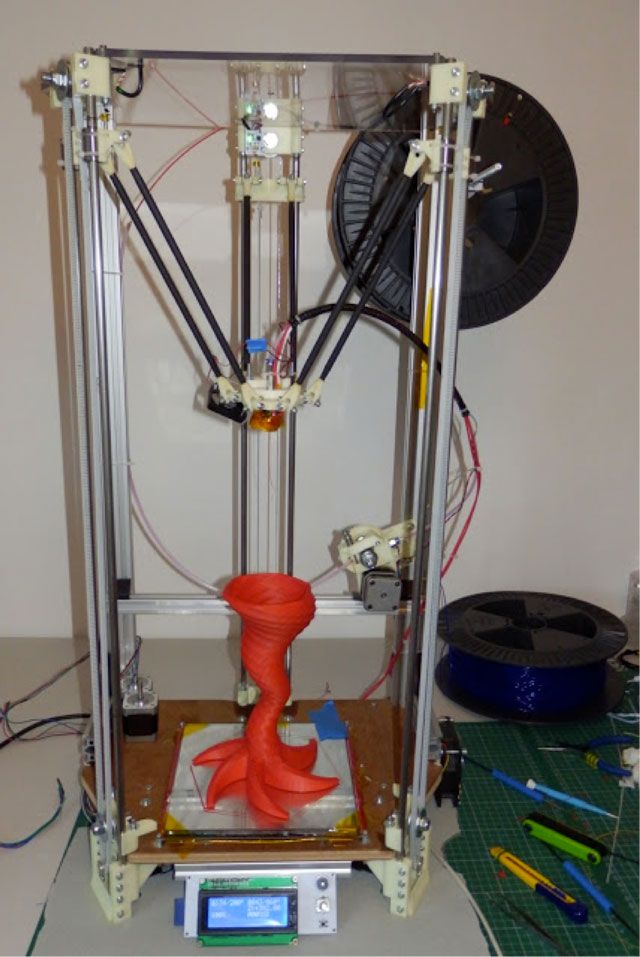

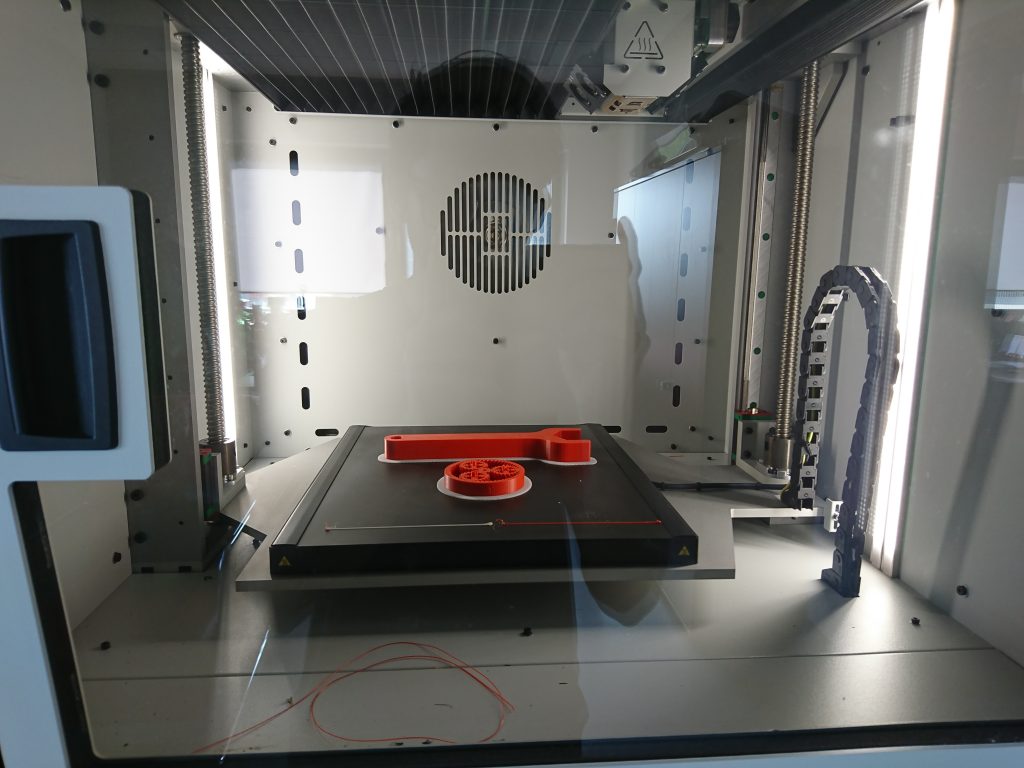

3D printing

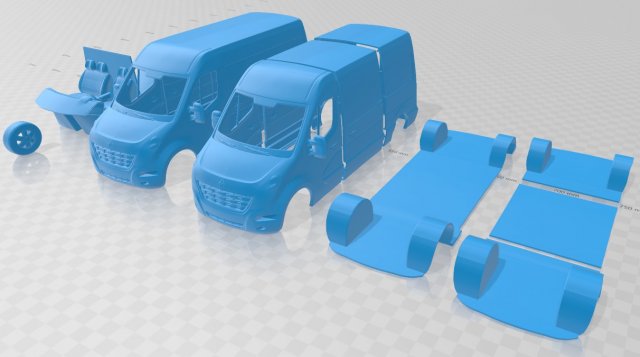

Creating an object from your 3D model

You can send us a 3D model for a detailed study, during which we will select the best manufacturing option.

Our consultants...

Use of advanced technologies

Several 3D printing technologies (FDM, SLS, SLA, MJM, CJP, etc.) are currently available, each of which is designed for...

Finished product post-processing

Thanks to the experience and practical skills, our specialists can carry out a complex of physical changes to the printed model...

Applications

3D printing technologies are gaining more and more popularity year after year, showing their practical advantages in ...

Technologies

FDM technology

The most popular 3D printing technology at the moment is Fused Deposition Modeling (FDM) or FDM technology...

SLS technology

Selective Laser Sintering (SLS) 3D printing technology based on the sintering of polyamide layers by means of a laser beam...

SLA technology

new properties.

MJP technology

3D printing technologies - Multi Jet Printing (MJP) is a multi-jet modeling method that closely resembles conventional inkjet printing. ..

..

BJ technology

3D printing technology - Binder Jetting (BJ) is based on successive bonding of layers of plastic powder with a special binder.

CJP Technology

Color Jet Printing (CJP) is the most popular full color 3D printing on the market right now. The technology is based on layer-by-layer bonding.

LaserCUSING technology

Additive manufacturing technology - LaserCUSING - is based on the method of selective laser melting of metal powder materials.

Case Studies

ABS, PLA, PVA, Carbon, Nylon (FDM)

Polyamide (SLS)

Photopolymer (SLA/MJP)

PMMA (BJ)

Plaster of Paris (CJP) 9014

3D printing cost

Material: ABS

Technology: FDM

Layer height: 0.05-0.40 mm

Detail: +++

Strength: ++++

Price (cm3): from eight

Material: PLA

Technology: FDM

Layer height: 0.05-0.40 mm

Detail: +++

Strength: +++

Price (cm3): from eight

Material: Carbon

Technology: FDM

Layer height: 0. 15-0.35 mm

15-0.35 mm

Detail: +++

Strength: +++++

Price (cm3): from fifteen

Material: Nylon

Technology: FDM

Layer height: 0.15-0.35 mm

Detail: ++

Strength: +++++

Price (cm3): from fifteen

Material: A.S.A.

Technology: FDM

Layer height: 0.05-0.40 mm

Detail: +++

Strength: ++++

Price (cm3): from fifteen

Material: PETG

Technology: FDM

Layer height: 0.05-0.40 mm

Detail: +++

Strength: ++++

Price (cm3): from ten

Material: FormaX

Technology: FDM

Layer height: 0.15-0.40 mm

Detail: +++

Strength: +++++

Price (cm3): from twenty

Material: PC

Technology: FDM

Layer height: 0.10-0.40 mm

Detail: +++

Strength: ++++

Price (cm3): from twenty

Material: TPU

Technology: FDM

Layer height: 0. 20-0.30 mm

20-0.30 mm

Detail: ++

Strength: +++++

Price (cm3): from 25

Material: Ultran

Technology: FDM

Accuracy: 0.15-0.25 mm

Detail: ++

Strength: +++++

Price (cm3): from 25

Material: Titan GF-12

Technology: FDM

Layer height: 0.15-0.40 mm

Detail: +++

Strength: ++++

Price (cm3): from 25

Material: SBS

Technology: FDM

Layer height: 0.15-0.35 mm

Detail: +++

Strength: ++++

Price (cm3): from fifteen

Material: Total CF-5

Technology: FDM

Layer height: 0.15-0.40 mm

Detail: +++

Strength: ++++

Price (cm3): from fifteen

Material: PVA

Technology: FDM

Layer height: 0.05-0.40 mm

Detail: +++

Strength: ++

Price (cm3): from 25

Material: HIPS

Technology: FDM

Layer height: 0.05-0.40 mm

Detail: +++

Strength: ++++

Price (cm3): from eight

Material: Polyamide

Technology: SLS

Layer height: 0. 10-0.15 mm

10-0.15 mm

Detail: ++++

Strength: ++++

Price (cm3): from 90

Material: Photopolymer

Technology: SLA

Layer height: 0.01-0.15 mm

Detail: +++++

Strength: +++

Price (cm3): from 90

Material: Photopolymer

Technology: MJP(MJM)

Layer height: 0.028-0.032 mm

Detail: +++++

Strength: +++

Price (cm3): from 750

Material: Wax

Technology: MJP(MJM)

Layer height: 0.02 mm

+++++

Strength: +

Price (cm3): from 900

Material: PMMA

Technology: BJ

Layer height: 0.15 mm

+++

Strength: +++

Price (cm3): from 70

3D Modeling and 3D Scanning

3D Engineering and Art Modeling

3D modeling is a combination of creativity and logic. What the eye perceives as volume, texture and ...

Preparing a 3D model for printing

Sometimes our clients come to us with a ready-made 3D model that they created themselves, downloaded from the Internet or received from . .. digital model. In fact, this is the next stage ...

.. digital model. In fact, this is the next stage ...

Unlimited base of

3D models

In two years of work, our company managed to collect a considerable number of 3D models that are widely used. In doing so, we can a little...

Case Studies

3D Engineering Modeling

3D Art Modeling

3D Scanning

Cost of 3D modeling and 3D scanning

Type: Engineering

File Format: *.stp, *.obj, *.stl

Price: from 1000

Note: ---

Type: Artistic

File Format: *.obj, *.stl

Price: from 1000

Note: ---

Type: 3D Scan

File Format: *.obj, *.stl

Price: from 2000

Note: ---

About us

Printing on

3D printers

Our specialists have extensive experience in working with models of both foreign companies and domestic brands...

Professionals in

3D printing and

3D modeling

Our specialists can create an object of almost any geometric shape, optimize it .