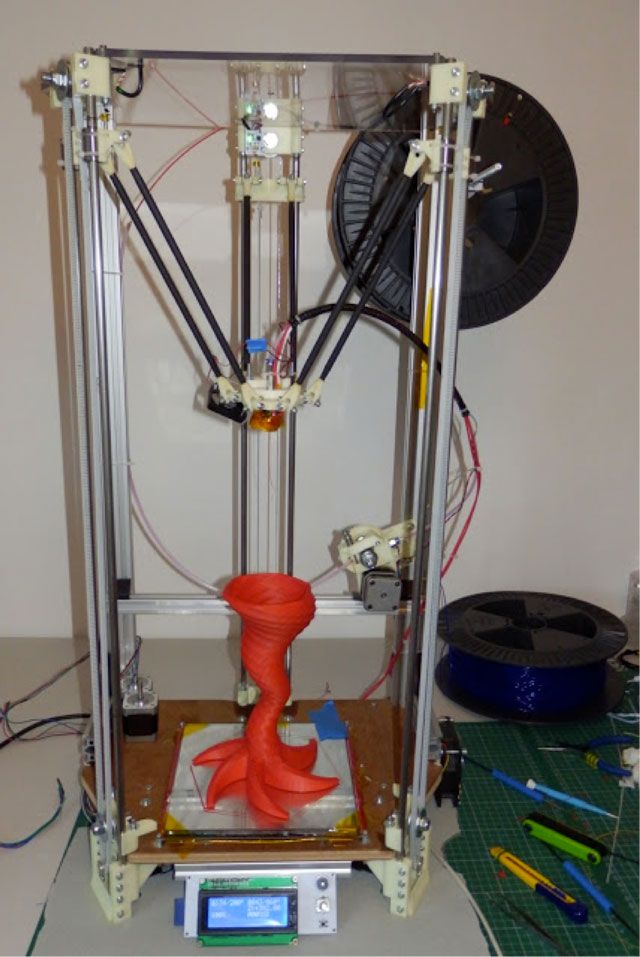

Netherlands 3d printer

3D printing in the Netherlands

3D printing in the Netherlands, hot or not? The cue in front of the RapidPro 3D fair in Veldhoven gives the answer: still hot. This year again more exhibitors and visitors participated in the fair. They presented a lot of information about new techniques and materials. However, the question remains: how big is the market for 3D printing in the Netherlands? It’s time to shed some light on this rising star.

Worldwide: growth of 17 billion euros in seven years

Several international research companies – Gartner, PwC, Canalys, IDC en Wohlers – have published estimations for the global market of 3D printing, now and in the future. The estimates are quite similar. For 2013, they assume a total market between 2 and 4 billion euros, increasing to 10 to 14 billion euros towards 2018. The increasing demand from the aerospace, automotive and medical markets stimulate this growth.

The analysis of Wohlers is substantiated best. In their report, they estimate the market for 3D printing in 2013 to be 2. 74 billion euros ($ 3.07 billion). A small quarter is earned with services, software, training and consultancy. The remaining revenue results from:

- printer sales (30%)

- products (30%)

- raw materials (17%)

In 2013, nearly 10,000 industrial 3D printing systems were sold worldwide, including 348 metal printers. Sales of home printers turned out to be approximately 72,500 units. The market forecast for this year is about 6 billion euros, with a rapid growth to nearly 20 billion in 2020.

The Netherlands accounts for 45 million euros

The exact size of the 3D printing market in the Netherlands is hard to determine. Public figures do not exist. Still, we can do more than just fortune telling. Based on our years of experience in this market and many discussions with various parties, ABN AMRO estimates the Dutch market revenue for 2015 around 45 million. This includes both the professional and the consumer market, for which we have looked at:

- sales of 3D printing systems

- printed products (with own machines and via Dutch service providers)

- software and services such as training, maintenance and advice

- raw materials

Professional market is just starting to develop

In the Netherlands, manufacturers of professional printers do not exist yet. Revenue from sales of printers is only the profit margin that distributors like Landré, Bender, Layertec, Brilliant, Palio en Kentie earn. Even though TNO and Additive Industries spend a lot of time in developing a new industrial printer, there are countries with a huge lead. Our Eastern neighbors, for example, with manufacturers as EOS and Envisiontec. Or the United States, with quoted market leaders 3D Systems and Stratasys. And what about large, traditional machine manufacturers as Trumpf, DMG Mori, Roland and Arburg. After long waiting to see what would happen, they also began last year to market 3D printing systems.

Revenue from sales of printers is only the profit margin that distributors like Landré, Bender, Layertec, Brilliant, Palio en Kentie earn. Even though TNO and Additive Industries spend a lot of time in developing a new industrial printer, there are countries with a huge lead. Our Eastern neighbors, for example, with manufacturers as EOS and Envisiontec. Or the United States, with quoted market leaders 3D Systems and Stratasys. And what about large, traditional machine manufacturers as Trumpf, DMG Mori, Roland and Arburg. After long waiting to see what would happen, they also began last year to market 3D printing systems.

Moreover, the Netherlands is missing big manufacturers of aircraft engines, such as GE, Rolls Royce and Pratt Whitney. They already print parts for turbines on a large scale. The Netherlands deals with smaller volumes. LUXeXceL in Goes only uses 3D printing technology for the production of lenses and ASML processes for some 3D printed parts in its machines. But most Dutch manufacturers use 3D printing for rapid prototyping only. And it is difficult to attach a direct value.

And it is difficult to attach a direct value.

Revenue service providers: approximately 14 million euros

There are currently approximately 160 professional 3D printing systems in the Netherlands. You can find them mostly in the R&D departments of Shell, Philips and NLR. SMEs as Mareco, 3D-Project, Cocu and Heijcon serve the market for prototypes and architects. Most of the nearly twenty SLS plastic printers can be found at the two largest Dutch service providers: Oceanz and Shapeways. They print for both the professional and the home market. Revenue from the German CNC Speed Form and the Belgian Materialise are not included in our calculation, even though these providers focus partially on the Dutch market.

Looking at industrial purposes, we see the greatest opportunities for 3D printed metal. The Netherlands has a dozen of this type of printers, again located at large companies such as Shell, Philips and more recently AAE. They also assist regional partnerships, such as AddLab (Eindhoven) and Civon (Doetinchem). The Dutch service providers Mundo and Amitek provide capacity for the dental, medical and precision industries.

The Dutch service providers Mundo and Amitek provide capacity for the dental, medical and precision industries.

We estimate the total revenue from the Dutch service providers at 11 to 14 million in 2015.

Revenue from filament, resins and powders still very small.

The Wohlers Report 2014 estimates the worldwide revenue from raw materials at nearly 475 million euros in 2013. It is a fact that the major printer manufacturers have a monopoly for the professional market. DSM has a very limited presence. The market for home printer filament is highly competitive. Innofil3D in Emmen is the market leader in the Netherlands. A very conservative estimate of the total raw material revenue in 2015 by Dutch manufacturers: 1 million euros.

Customization is upcoming

A few trends can be seen in 3D printing. Consumers want more attention, which means more personalized manufacturing. Factories need to change from mass production to small, customer-specific volumes. In addition, customers ask for fast delivery and set higher demands on sustainability. It is expected that local and decentralized production will eventually replace low-cost mass production in low-wage countries. 3D printing and extensive automation (robotics) make local production more affordable.

It is expected that local and decentralized production will eventually replace low-cost mass production in low-wage countries. 3D printing and extensive automation (robotics) make local production more affordable.

Conclusion: a dwarf with growing pains

Despite the tremendous hype around 3D printing, an estimated Dutch market revenue of 45 million euros in 2015 is still limited. A fraction of our total industrial production. Look for example at the income of machine builders, metal and plastics companies that are members of branche associations:

- FME-CWM 70 billion euros

- Metaalunie 22 billion euros

- Federatie NRK 8 billion euros

Adding these numbers up, makes a total revenue of 100 billion euros. The 3D printing industry only represents 0.045% of this total.

Too big to ignore

And still: a growth of over 30% per year and a disruptive character makes 3D printing a development to watch. I do not see it as a direct threat to the traditional manufacturing industry, but as a useful addition to the current production processes. The Wohlers Report 2014 estimates that, in the long run, more than 2% of industrial revenue will be earned with 3D printing. This would be a market of at least 2 billion euros in the Netherlands.

The Wohlers Report 2014 estimates that, in the long run, more than 2% of industrial revenue will be earned with 3D printing. This would be a market of at least 2 billion euros in the Netherlands.

As mentioned in the ABN AMRO report, Zie ginds komt de printer (2013), the initiative in the Netherlands is with the customer. But the industry will quickly take over, taking into account the rapid development on the side of the raw materials and the increasing speed and accuracy of printers.

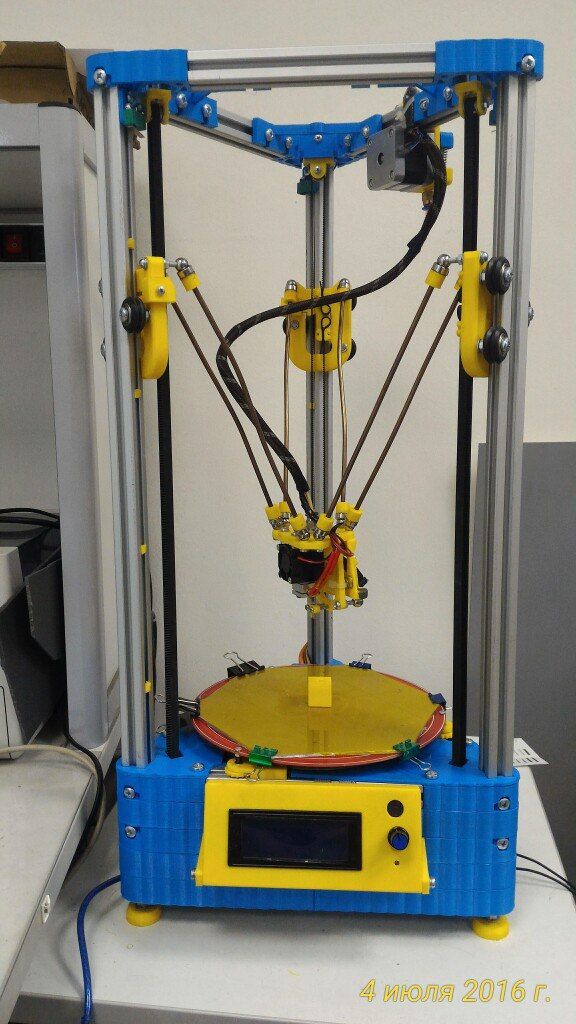

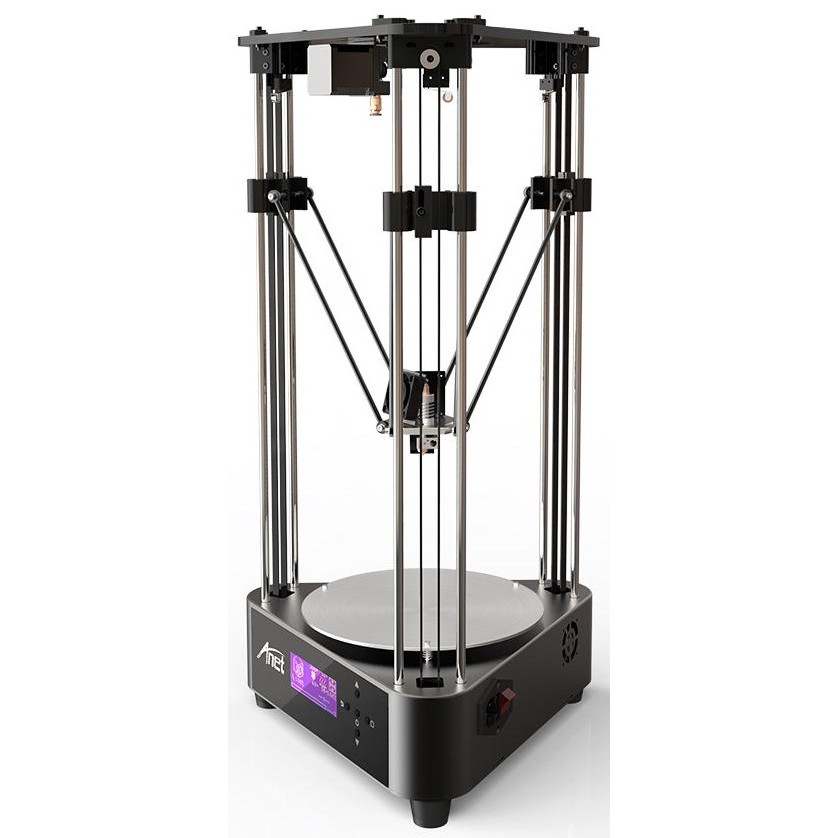

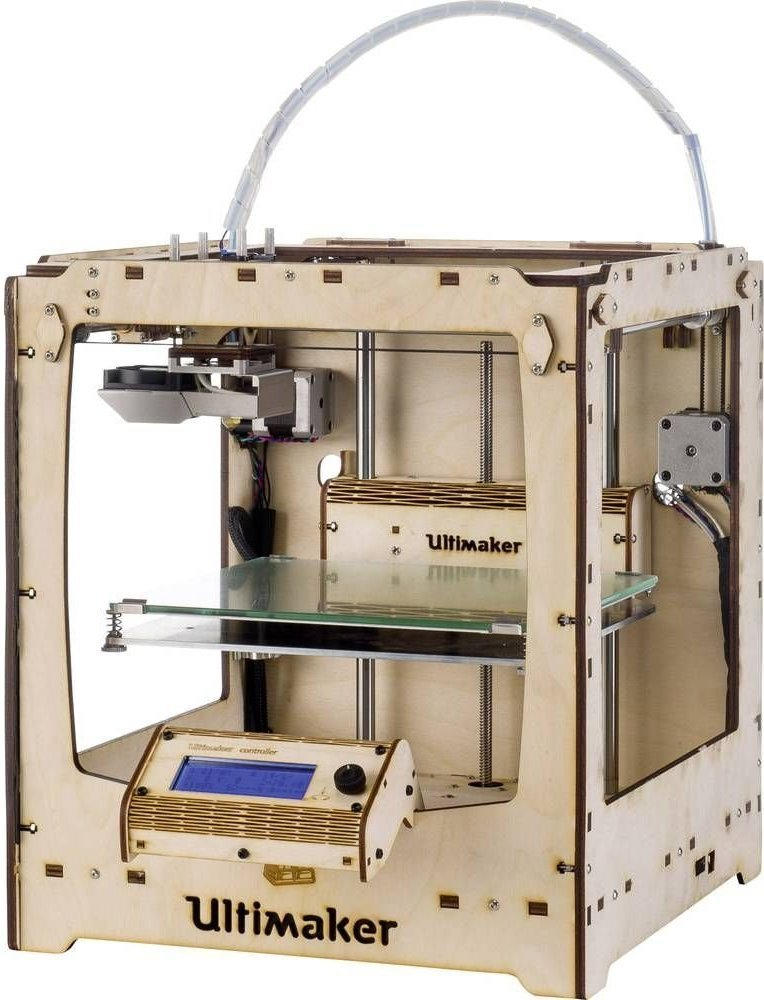

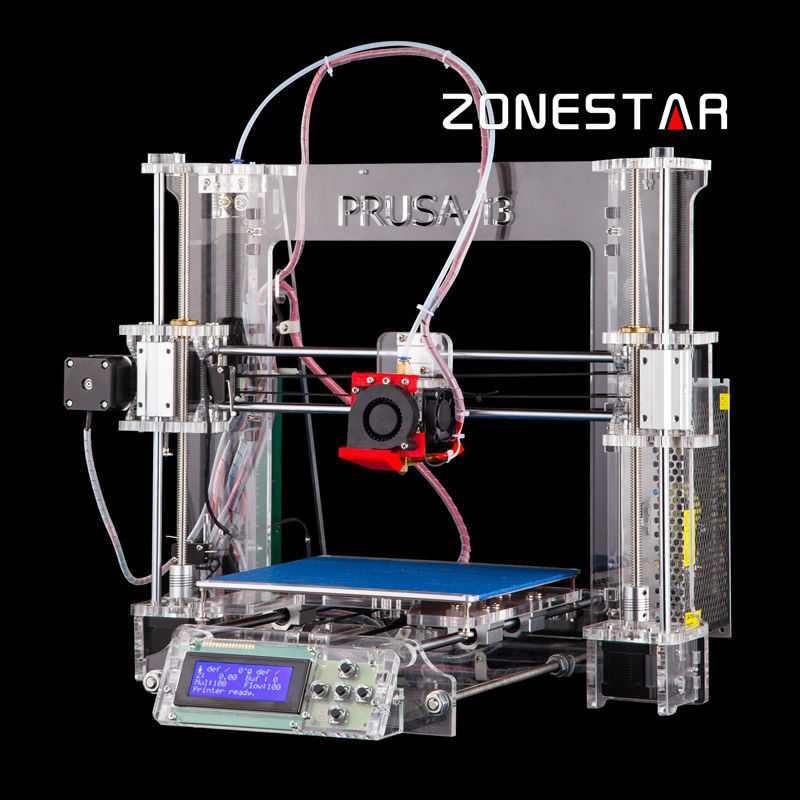

The Netherlands: home printing country

The consumer market looks very different. The Netherlands has a very active and enthusiastic home printing community with 45 Fablabs, 3D Hubs and rapidly growing printer manufacturers as Ultimaker, LeapFrog, Builder 3D and Felix. Together, these manufacturers sell more than 345 home printers per week. This results in an estimated revenue of 20 million euros in 2015.

3D Printing Service The Netherlands | Instant Quotes

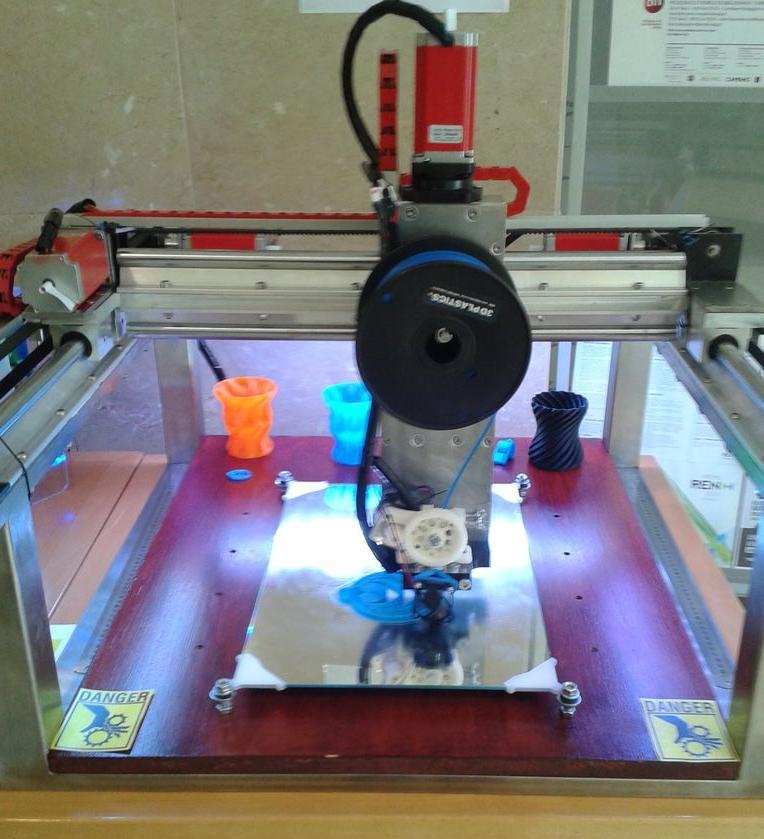

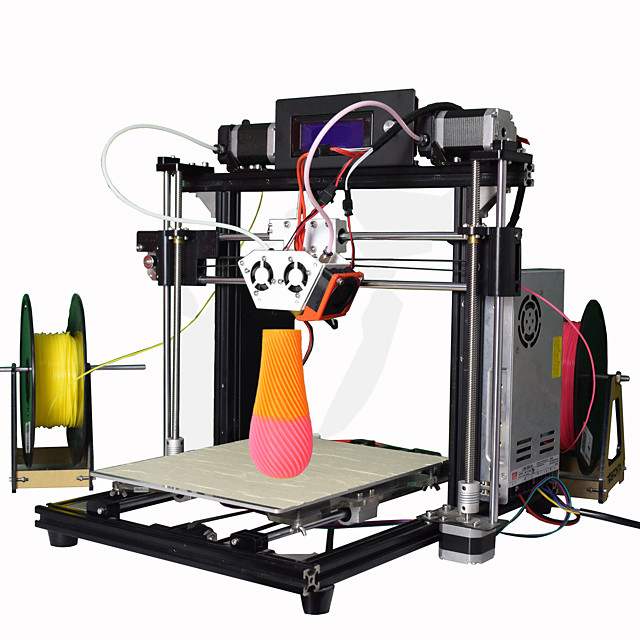

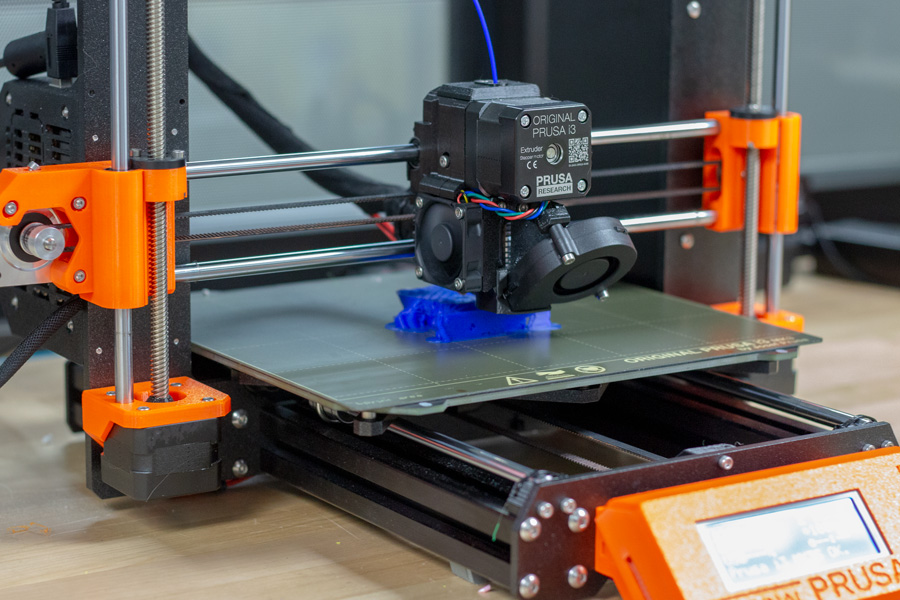

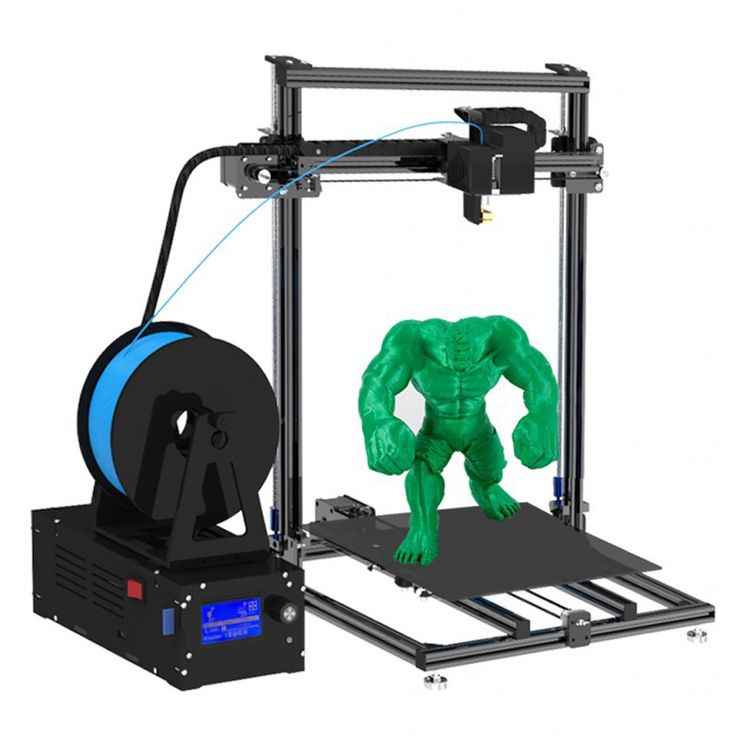

Our 3D printing capabilities

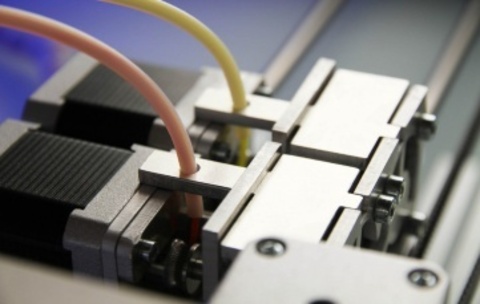

We have over 90 3D printing shops in our network and are well known for manufacturing high-quality parts at competitive prices, from rapid prototyping with Fused Deposition Modeling (FDM) to functional end parts made with Selective Laser Sintering (SLS) or Multi Jet Fusion (MJF).

Gallery of 3D printed parts manufactured by Hubs

With over 65,000 customers from every industry, including aerospace, defense, robotics, medical, machinery, automotive and electronics, we have extensive experience meeting a diverse range of 3D printing requirements, from prototyping to production: Visual aids, concept models, injection-molding prototypes, form-fit & function prototypes, tooling and casting patterns, jigs, grips and fixtures, and durable end parts.

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

HP PA 12 - Dyed Black

| Customer | True North Design |

| Purpose | Structural and vacuum EOAT components |

| Process | SLS / MJF |

| Unit price | $69.23 / $34.33 |

| Industry | Automotive |

Prototyping PLA

| Customer | Allision Conner |

| Purpose | End caps and cable strain relief for sheet metal enclosure |

| Process | FDM |

| Unit price | $7. 92 / $4.72 / $2.80 92 / $4.72 / $2.80 |

| Industry | Industrial Automation |

HP PA 12

| Customer | US Hammer |

| Description | A part for gasoline engine powered jackhammers |

| Process | MJF |

| Unit price | $22.18 |

| Industry | Construction |

Markforged Onyx - Black

| Customer | Autocom Manufacturing |

| Purpose | A production part for 3D printed lathe gantry gripper fingers |

| Process | FDM |

| Unit price | $48.86 |

| Industry | Automotive |

PC Stratasys - white

| Customer | Terumo medical corporation |

| Purpose | Prototyping parts used for a disposable electrical device |

| Process | FDM |

| Unit price | $55. 38 / $32.96 38 / $32.96 |

| Industry | Medical |

Formlabs Clear Resin

| Customer | Aversan Inc |

| Purpose | A prototyping part of an injection molded component for an automated door mechanism |

| Process | SLA |

| Unit price | $29.83 |

| Industry | Aerospace |

Instant, online 3D printing quotes

-

Upload a CAD to start (STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, STL, OBJ or X_T)

-

Price updates in real-time as you change materials, lead time, etc..

-

No hidden costs. Our instant quotes are not just indications, but the actual price, and include shipping and customs up front.

Learn about how our quoting algorithm works

Our ordering process

Receive instant quote

Upload your CAD to our online quoting platform

Confirm specs

Configure your part specifications and select a lead time that suits your schedule

Production

We select the best manufacturer for your order, and production begins immediately

Quality control

We take full responsibility for making sure your parts are manufactured according to our standards

Delivery

Our 3D printing service has been rated 4.9/5

Over 287 customers are satisfied with our 3D printing service.

“Betrouwbaar, professioneel en communicatief sterk.”

“Great service over many successive orders.”

“Denkt goed mee, duidelijk veel print expertise.”

“Good quallity,great service,friendly guy.”

“Great communication and easy to work with, will definitely order from again.”

“The prints were excellent, very fast completion and the overall service was top notch.”

“Great help and delivered product was exactly as expected”

“Had to get printed parts in a very short timeframe, hub helped me to achieve this by making the prints overnight and allow me to pick them up during the evening of saturday. ”

“Thank you so much, you were super helpful the entire way and very responsive!”

“Perfect. Goed persoonlijk contact, goed advies, goed resultaat.”

“Easy to do business with, good communication, fast delivery and perfect quality. Recommended!”

“Great first experience with 3D printing for me. Next time I need something printed I know who to go to! :) ”

“Very friendly and helpful! Result is a very nice quality print :) ”

“The print quality is amazing, really good service. Basically beyond happy with my 3DPrint!”

Basically beyond happy with my 3DPrint!”

“Again great job. If you need parts quickly and good quality.? ”

“Very helpful, fast communication and thinks along with you if there's anything that can be done better with your model. Highly recommended!”

“Snelle service en afhandeling en ook nog redelijk geprijsd”

“Everything was delivered as expected and it's looking great! Probably the smoothed service I've had so far on Hubs”

“Great service, got exactly what I wanted with regular updates and pictures during the process.”

“Nice print, in less than 24 hours (I picked it up).”

“Prima resultaat en meedenken voor een beter resultaat”

“Another great print, thanks guys!

One suggestion though: when shipping, please use stronger cartboard boxes. The box was pretty damaged upon arrival because the shipping guys stack boxes on top of each other. Heavier boxes had compressed mine/yours. Luckily, the model was unharmed. Four times five stars nonetheless. Keep up the good work!!”

Keep up the good work!!”

“Print was perfect as always ! Very very happy.”

“Very fast service, good quality printing. and fair prices and normal shipping costs”

“High quality, good communications, really quick: great value for money!”

Show more reviews

Show less reviews

Teams build better parts

Create your Hubs team and start collaborating

Read more

The Hubs Standard - consistent quality, every time

Hubs takes the stress out of manufacturing by guaranteeing the quality and consistency of every part. Each order is dimensionally and visually inspected to make sure it meets the Hubs Standard.

3D printing materials

We can generate instant 3D printing quotes for 25+ plastics. For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

For metal 3D-printed parts, you can request a quote from our parent company, Protolabs.

Available materials

SLS

PA 12 Glass filled PA 12

Desktop FDM

Prototyping PETG Prototyping ASA Prototyping TPU Prototyping ABS Prototyping PLA

Desktop SLA

Formlabs Standard Resin Formlabs Clear Resin Formlabs Tough Resin 2000 Formlabs Rigid Resin 4000 Formlabs Grey Pro Resin Formlabs Flexible Resin 80A Formlabs High Temp Resin Formlabs Durable Resin

MJF

HP PA 12 Glass filled HP PA 12

Industrial FDM

Markforged Onyx ABSplus Stratasys ULTEM 9085 Stratasys Stratasys ASA ABS M30 Stratasys ULTEM 1010 Stratasys

Industrial SLA

Accura 25 (PP-like) Accura ClearVue Accura Xtreme White 200 (ABS-like)

3D printing locations near The Netherlands

Nieuwegein Utrecht Zeist

Hilversum Amsterdam Dordrecht

Amersfoort Hoofddorp Tiel

Den Bosch

The 3D Printing Handbook

No one understands 3D printing like us - our founders literally wrote the book. Click here to download the sample chapters.

Click here to download the sample chapters.

Buy the book from Amazon

FAQ's

How much does your 3D printing service cost?

The cost of your 3D printed parts depends on factors such as part volume, part complexity, choice of material, which 3D printing technology is used, and if any post processing is required. For more details on these cost factors, see our article on the cost of 3d printing. To check the cost of your 3D printed part, simply upload a CAD (.STL) file and select your material and 3D printing technology to receive a quote within seconds.

How do you guarantee the quality of my prints?

Your parts are made by experienced 3D printing shops within our network. All facilities are regularly audited to ensure they consistently meet the Hubs quality standard. We include a standardized inspection report with every order and offer a First Article Inspection service on orders of 100+ units.

We have partners in our network with the following certifications, available on request: ISO9001, ISO13485 and AS9100.

Follow this link to read more about our quality assurance measures.

How do I select the right 3D printing process for my prints?

You can select the right 3D printing process by examining which materials suit your need and what your use case is.

By material: if you already know which material you would like to use, selecting a 3D printing process is relatively easy, as many materials are technology specific.

By use case: once you know whether you need a functional or visual part, choosing a process is easy.

For more help, read our guide to selecting the right 3D printing process. Find out more about Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF) and Stereolithography (SLA).

How can I reduce the cost of my 3D prints?

In order to reduce the cost of your 3D prints you need to understand the impact certain factors have on cost. The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

The main cost influencing factors are the material type, individual part volume, printing technology and post-processing requirements.

Once these have been decided, an easy way to further cut costs is to reduce the amount of material used. This can be done by decreasing the size of your model, hollowing it out, and eliminating the need for support structures.

To learn more, read our full guide on how to reduce the cost of 3D printing.

Where can I learn more about 3D printing?

Our knowledge base is full of in-depth design guidelines, explanations on process and surface finishes, and information on how to create and use CAD files. Our 3D printing content has been written by an expert team of engineers and technicians over the years.

See our complete engineering guide to 3D printing for a full breakdown of the different 3D printing technologies and materials. If you want even more 3D printing, then check out our acclaimed 3D printing handbook here.

We have an extensive range of online resources developed to help engineers improve their capabilities.

Introductory guides

Design guides

Material guides

Applications

CAD & file preparation

Post processing & finishing

Our other manufacturing capabilities

CNC machining

CNC machining

Milling (3-, 4- & full 5-axis), turning and post-processing

-

50+ metals and plastics & 10 surface finishes

-

Tolerances down to ±.0008” (0.020 mm)

-

Lead times from 5 business days

See our CNC machining services

Put your 3D printed parts into production today

Get an instant 3D printing quote

What the first 3D printed steel bridge looks like

Trends

TV channel

Pro

Investments

Events

RBC+

New economy

Trends

Real estate

Sport

Style

National projects

City

Crypto

Debating Club

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library

Podcasts

ESG index

Politics

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Mashable / YouTube

The world's first 3D printed steel bridge has been installed in Amsterdam. The project was ready three years ago, but the installation of the bridge was constantly delayed

What's happening

- On July 15, the world's first 3D printed steel bridge was opened in Amsterdam.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands.

It connects the embankments of the Oudesijds Achterburgwal canal. The grand opening was attended by Queen Maxima of the Netherlands. - The structure weighs 6 tons and is 12 meters long.

- The bridge was printed by four robots by welding layers of stainless steel wire, it took them 4.5 tons of steel and six months to make a span of 12 meters. Then coastal supports and decorative elements were made.

- This project was developed by the laboratory of Joris Laarmann and ABB, Air Liquide, ArcelorMittal, Autodesk, AMS Institute and Lenovo, while the Amsterdam-based company MX3D was fabricating and installing the structure.

- More than ten sensors are built into the bridge, with the help of which it will be possible to monitor its condition and deformation. Thus, he will himself indicate the need for repair. The sensors will also count the number of pedestrians crossing the bridge each day.

- The structure was installed for two years as a replacement for the conventional bridge, which will be under reconstruction at that time.

- This bridge was first presented at Dutch Design Week Eindhoven 2018, where the project won the Dutch Design Award and the Audience Award. After that, the finished bridge lay in storage for another three years: first, in anticipation of the reconstruction of the canal, then due to the coronavirus pandemic and lockdown.

What does it mean

In recent years, there has been an active development of 3D printing technology in construction. The Netherlands seems to be on a roll with this trend, with the first fully 3D-printed residential building in the EU populated in the suburbs of Eindhoven in early May, followed by the opening of the world's first 3D-printed steel bridge.

We have already said that 3D printing is the future of construction and design. Compared to classic buildings, 3D printing has a number of undeniable advantages, such as short construction times, reduced economic and environmental costs, and ease of execution of complex shapes.

“This is not just about reducing and optimizing construction costs, but about giving architects and designers a new tool, a very cool new tool, with which they can rethink the design of their architecture and their projects,” notes Tim Görtjens, co-founder of MX3D, a bridge builder.

Mika Mos, member of the council of the municipality of Amsterdam, expressed the hope that this construction will also help the city attract quality new tourists:

“This could attract a new type of visitor, those more interested in architecture and design, which will change the perception of the area (famous for nightclubs and noisy parties. — RBC Trends ).”

Updated on 10/18/2022

Text

Ksenia Yanushkevich

Top of the trend

Related materials

The future is here: 3D printed houses are starting to populate in the Netherlands

The future is here: 3D printed houses are starting to populate in the Netherlands

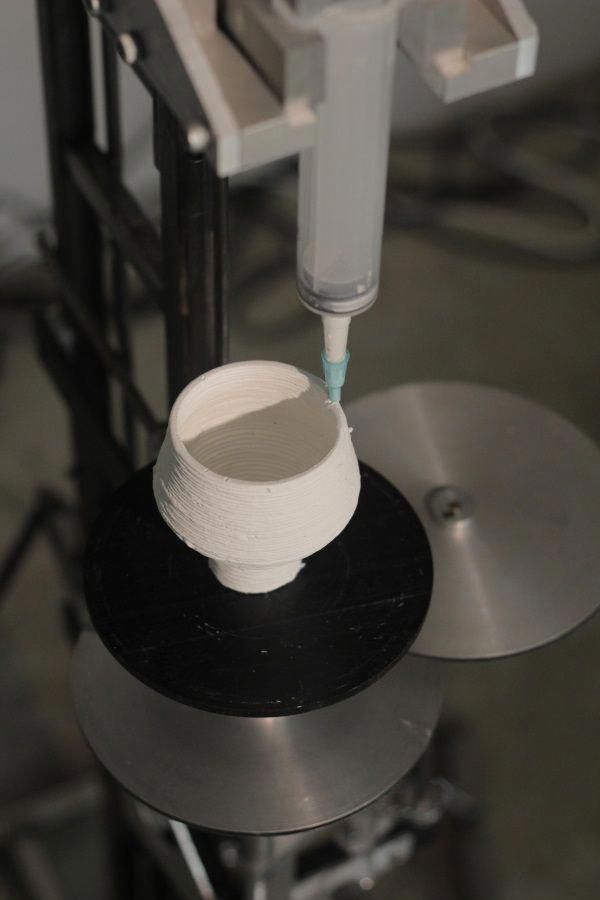

If just a few years ago 3D printing was considered a certain suspicion, then recent news has shown that this is actually a viable technology that is no good. On April 30, 2021, the tenants of the first 3D printed concrete house in the Netherlands received the keys. The Eindhoven home, the first of five under the Milestone Project, fully complies with all of the country's stringent building regulations.

On April 30, 2021, the tenants of the first 3D printed concrete house in the Netherlands received the keys. The Eindhoven home, the first of five under the Milestone Project, fully complies with all of the country's stringent building regulations.

One-story building with an area of 94 square meters, including a living room and two bedrooms. It follows the shape of a large stone that blends well with the natural landscape and demonstrates the freedom of form offered by 3D printing on concrete. Thanks to the very thick insulation and connection to the heating network, the house is very comfortable and energy efficient, with an energy efficiency factor of 0.25.

The house consists of 24 printed concrete elements, which were printed layer by layer at the factory in Eindhoven. The elements were then transported by truck to the construction site and placed on the foundation. Then the roof and window frames were installed in the house, followed by finishing.

The sloping walls of the building were particularly difficult to print, according to the team, but learning from the prototype helped them master the technique in the next 4 planned buildings. Concrete has been the most widely used building material in the world for decades and we are all familiar with it now; we know how and where to use it. Traditionally, we pour concrete into wood or metal formwork and end up using far more than is needed for construction. The more used, the greater the CO2 emissions of the building and the worse its greenhouse effect. One of the big advantages of 3D printing is that the concrete printer can only place concrete where it is needed without overloading the foundation or wasting materials.

In principle, printed houses can be built much faster, with more flexibility and potential for custom designs. Milestone Project partners are committed to making concrete 3D printing a sustainable construction method that helps address the housing shortage. According to Theo Salet, Professor of Concrete Construction at the Eindhoven University of Technology: “Today, this small building is the first important step in turning construction into a high-quality manufacturing industry. From design to implementation, digitization is leading to sustainable and affordable homes with occupants in mind.”

According to Theo Salet, Professor of Concrete Construction at the Eindhoven University of Technology: “Today, this small building is the first important step in turning construction into a high-quality manufacturing industry. From design to implementation, digitization is leading to sustainable and affordable homes with occupants in mind.”

The five Milestone Project houses are being built one after the other, so that each new round of construction can maximize learning opportunities compared to previous ones. Soon, the project partners will start designing the next building, which will be multi-storey and, therefore, will require technical improvements.

Peter Knauff, investment director at Vesteda, adds that “the freedom of form of 3D printing on concrete opens up huge new possibilities in the design and feel of a home. At the same time, this new technology contributes to providing the necessary sustainability in the construction industry, accelerating the production of buildings and controlling construction costs, which is very necessary to continue building affordable homes.