3D printing props

3D Printing Courses - 3D PRINTED PROPS

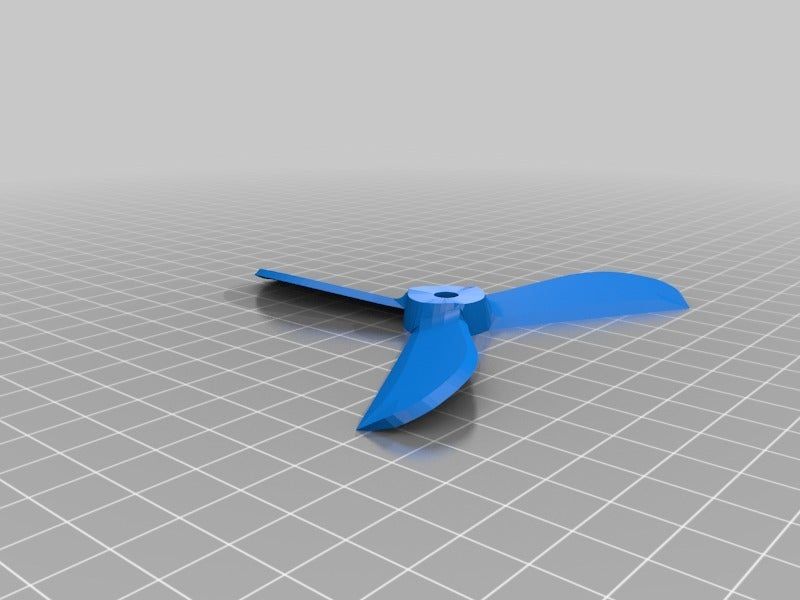

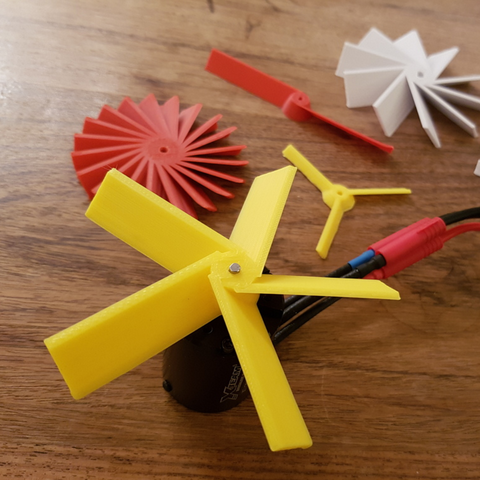

3D Printing Courses3D printing is magical! You take a file, or create your own, send it to your printer and after some time you have an actual solid object. It reminds me of something from the Jetsons. In this course you will learn all stages of 3D printing, from its history, ways to get the best print, using slicers and even finishing your prints.

Yes, 3D printing is magical, but there is also a lot of technical parts to the process, and this course will help you navigate the challenges 3D printer enthusiasts encounter when they start out. This was a fun class to create and I hope you enjoy it and learn how to make great prints!

cHECK OUT COURSE

Have you been wanting to learn about 3D resin printing? Then this is the course for you!

3D resin printing is becoming increasingly popular for good reason. Over the past few years, resin printers and materials have gotten more and more affordable, opening up a whole new world of 3D printing to enthusiasts.

In this course, I will walk you through every part of the 3D resin printing process. We will cover:

- The different types of 3D resin printers

- Factors involved in deciding which resin printer is right for you

- Different resins you can use when printing

- How to prepare your files for printing using the leading 3D resin slicer, Chitubox

- How to properly post-process your files: removing them from the print bed, removing supports, cleaning and curing

- Finishing your prints: Sanding, priming and painting

cHECK oUT COURSE

Do you want to learn how to make money with your 3D printer? Then this course is for you!

I currently run a successful YouTube channel with thousands of subscribers and have a successful website and Etsy shop where I sell hundreds of dollars a month in 3D files and physical prints. I love 3D printing and sharing what I know through my YouTube channel and in courses like this. That’s why I created this course to show 3D-printer enthusiasts like you how you can start earning money through your hobby.

That’s why I created this course to show 3D-printer enthusiasts like you how you can start earning money through your hobby.

In this course, we will cover 7 ways you can use your 3D printer to make money. After covering the basics, I will share details from my own revenue streams and show how much my files cost to commission and print, and how those costs inform the selling price.

We will then look at 3 case studies of other successful Makers who are using their 3D printers to earn money, and I will cover details behind how they print and price their products.

CHECK OUT COURSE

OTHER COURSESWhen you have completed this course and practiced, you will be able to pick up and grade any comic, whether it’s one in your collection or that grail book you finally found at a con.

The Learn to Grade Comic Books course is the most comprehensive course of its kind. In it, I walk you step by step through 27 comics at every grade level from 0. 1 to 10.0, explaining in detail why they received that grade. For the 25 grade levels from 0.5 to 10.0, I bought and cracked professionally graded books just for these videos so that we would have a solid baseline for understanding the criteria at each grade level.

1 to 10.0, explaining in detail why they received that grade. For the 25 grade levels from 0.5 to 10.0, I bought and cracked professionally graded books just for these videos so that we would have a solid baseline for understanding the criteria at each grade level.

In each video, we move up the grading scale, first examining the CGC graded comic, and then we look at two different comics with the same grade to compare and contrast their differences, because even though they are the same grade, they can look quite different.

cHECK OUT cOURSE

This course will teach you graphic design fundamentals and how to employ them to create awesome social media graphics using the FREE design tool CANVA.

- Do you need to create professional looking social media graphics for your side-hustles, but don’t know where to start?

- Have you tried to piece information together from various sources around the web but end up even more confused?

- Don’t have the money to hire expensive graphic designers for your projects.

,..who does right?

,..who does right?

If you answered yes, to any or all of these questions, then you have found the right course for you.

The life of a content creator is already stressful, having to produce on a daily, weekly or monthly basis. Just spent 3hrs. editing a new youtube video, but remember, you aren’t done till you create that eye catching thumbnail. It can seem overwhelming.

We will use the Fundamentals of Design to create a brand and all the graphics we create in the course will be for an imaginary entrepreneur who has started a travel blog and Youtube channel. This way you also learn how to not only create the images, but why and how they fit into a cohesive brand.

Start creating more professional and eye catching social media graphics and make your brand stand out on the web!

cHECK OUT COURSE

This course will teach you graphic design fundamentals and how to employ them to create awesome classroom handouts, posters, lesson plans and other deliverables’ using the FREE design tool CANVA.

-

Do you want to create fun and interesting handouts for your classroom, but don’t know where to start?

-

Have you tried to piece information together from various sources around the web but end up even more confused?

-

Don’t have the money to hire expensive graphic designers for your projects.,..who does right?

If you answered yes, to any or all of these questions, then you have found the right course for you.

Teaching is hard. Creating handouts that are fun and help your students learn take time to create and can be difficult without the right tools. Using the free online tool Canva is all you need to create everything you need for your class.

This is where this class will help. Anyone can learn how to use the free design tool CANVA. In this class you will learn not only to use CANVA, but before we start creating real-world classroom projects we cover the fundamentals of graphic design that will evaluate your classroom to another level.

We will use the Fundamentals of Design to create a brand and all the graphics we create in the course will be for an imaginary classroom.

cHECK OUT COURSE

Are you struggling with suddenly having to take your classroom teaching online in response to the new way we have to teach? It can be intimidating to make this move – not to mention technology challenges – and hard to know where to start!

This concise one-hour intro course is designed to ease your shift to online teaching and help you be successful delivering online learning to your students.

You’ll learn easy-to-implement techniques and tips from a seasoned instructional technologist and online instructor.

Kevin Volo holds a Masters in Instructional Design and is working on his PhD dissertation in Educational Practice & Theory. He has worked for most of the past decade “in the online trenches” at a State University of New York (SUNY) school, helping faculty engage students in online courses.

It drills down to the most important things you need to know and will leave you feeling comfortable and confident making the shift to online and virtual teaching.

Register today and take your teaching online with confidence and poise!

CHECK OUT COURSE

In this course you will learn to take awesome and memorable travel pictures. We start with lessons on how to use your camera properly so you get the bet possible exposure. We then move on to photographic composition so that your photos are not only exposed well, but are composed well.

We Also Cover Travel Topics Such As:

- Best camera options

- What camera equipment to pack

- What else should you pack to make your trip easier

- Travel safety, and much more

Photography Basics You’ll Learn:

- Exposure

- ISO

- Shutter Speed

- Aperture

- Depth of Field

- Composition Basics

- White Balance

- Lighting

I’ve been a photographer my whole life and have taught traditional and digital photography classes for 20 years. I love everything about photography and hope you will enjoy the course and learn about the joys of travel photography.

I love everything about photography and hope you will enjoy the course and learn about the joys of travel photography.

CHECK OUT COURSE

3d Printed Prop - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

( 1,000+ relevant results, with Ads Sellers looking to grow their business and reach more interested buyers can use Etsy’s advertising platform to promote their items. You’ll see ad results based on factors like relevancy, and the amount sellers pay per click. Learn more. )

3D printing in the film industry | 3D Print Expo

3D printing is changing the film industry. Shooting props, mock-ups, and even parts of character costumes can now be made faster, more accurately, and cheaper. Of course, this does not mean that props and designers were left without work: on the contrary, they received a new tool that is in many ways superior to the usual ones.

Shooting props, mock-ups, and even parts of character costumes can now be made faster, more accurately, and cheaper. Of course, this does not mean that props and designers were left without work: on the contrary, they received a new tool that is in many ways superior to the usual ones.

It's cheaper to blow up a printed car than a real one

In adventure films, we often see spectacular explosions of vehicles: cars, planes, helicopters. If you use real vehicles for filming, the budget of the film will grow noticeably. And what if it doesn’t come out to shoot from the first take? Then the costs must be multiplied by two, or even by three.

3D printed models made in real scale (eg 1:3 or less) fly just as spectacularly but save the crew thousands of dollars. And they can always be reproduced at a lower cost, because the most difficult part of the work is drawing a digital model on a computer. It only needs to be done once. Next will be printing, assembly of modules and finishing of models. This also takes time and effort, but in the end it is cheaper than buying a real car. Or make a model in traditional analog ways.

This also takes time and effort, but in the end it is cheaper than buying a real car. Or make a model in traditional analog ways.

It was 3D printing that was used by the filmmakers of Skyfall 007 for the Bond car explosion scene. They assembled a 1:3 scale model of a car from 18 printed parts. And the labor was justified, because today this legendary premium car, Aston Martin DB5, costs over $400,000. Previously, layout decorators worked with cardboard, plaster, plywood and wood; now they have a universal material - plastic for 3D printing.

Night props

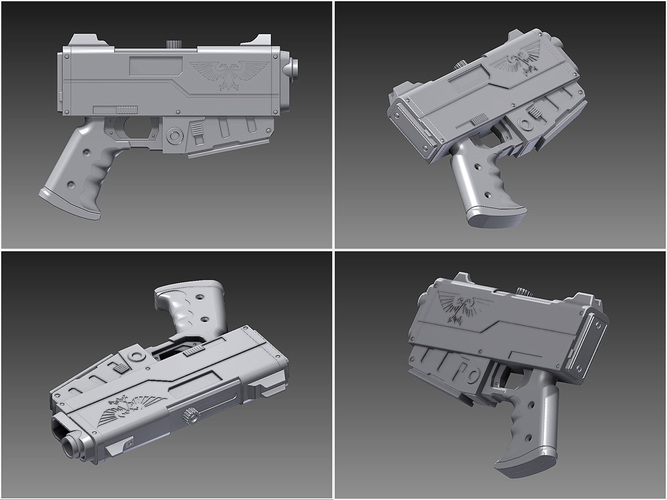

3D printers have revolutionized props making. Now unique items and artifacts, unusual dishes, weapons, armor and interior items can simply be printed. This saves time, especially if you need to make several identical things. Now even the most caustic blooper hunter will not find the difference between the two swords in different scenes: objects made on a 3D printer from the same model are always identical in shape.

Plastic in the film industry is often used to print “secondary” props that appear only briefly in the frame: for example, filling the shelves in the heroes’ room; table setting in the background. They require minimal finishing and can be printed faster due to their poor surface quality.

More time is spent on props of the first plan. After printing, it needs to be painted, varnished; apply texture. But still, 3D printers save props a lot of time and money.

There are printed objects in films that are included in the golden fund of world cinema: for example, in The Hobbit, elven swords, artifacts (the key to Erebor), parts of armor (bracers, helmets) and even parts of plastic makeup: ears and noses are made in this way orcs. In "Harry Potter" they printed a spider for one of the scenes. And in Iron Man 2013 - a superhero costume: for a perfect fit, the creators of the model scanned the body of Robert Downey Jr.

Creative space

Since 3D printers have become available not only to film studios, but also to ordinary people, they have also been used in amateur cinema. For example, in the movie Jurassic Park: Origin , which fans are making based on the famous blockbuster movie about dinosaurs, all prehistoric animals are 3D printed models. Volumetric printing allows you to take non-professional films to a new level, making them more complex and spectacular.

For example, in the movie Jurassic Park: Origin , which fans are making based on the famous blockbuster movie about dinosaurs, all prehistoric animals are 3D printed models. Volumetric printing allows you to take non-professional films to a new level, making them more complex and spectacular.

Learn more about the possibilities of modern 3D printing at exhibition 3D Print Expo in Sokolniki! 3D printing workshops, demonstrations of the latest printer models and the opportunity to meet manufacturers are waiting for you.

3D printing applications

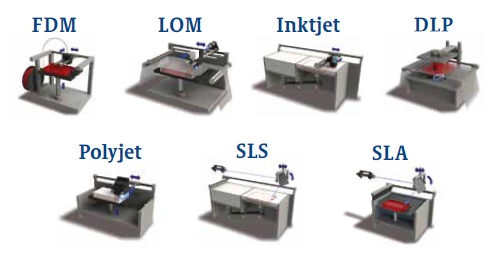

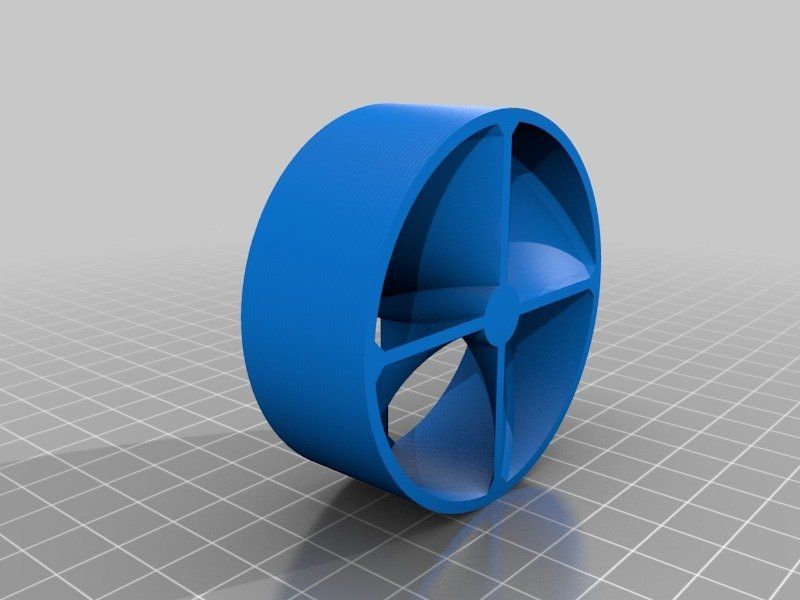

Aerospace engineers use 3D printing to produce high quality products. Now the most popular printing methods are being actively introduced: stereolithography (SLA), deposition method (FDM), selective laser sintering (SLS) and printing with metals.

The technology enables the creation of topologically optimized structures with a high strength-to-weight ratio and the ability to combine multiple components into a single part.

Optisys is a supplier of micro antennas to the aerospace and defense industries. They used metal 3D printing to reduce the number of individual pieces of tracking antenna arrays from 100 to 1. With this, Optisys was able to reduce the lead time from 11 months to 2 months, while achieving a weight reduction of 95%.

There are also 3D printed parts in the systems that propel the aircraft. As a rule, these are metal products made by laser metal sintering. So, in the Boeing 777, the compressor is connected to the temperature sensor using a 3D-printed adapter. In the F-15K Slam Eagle military aircraft, 3D printing is used to make the casing of the turbines, reducing the cost of the part from $34,000 to $2,550 and cutting its production time in half.

Automotive

3D printing is taking over the automotive industry with its speed and ease of change.

Volkswagen has traditionally used CNC machining to create custom fixtures and tools. But using CNC machines usually means longer production times and higher costs. The same fixtures can be printed within hours and tested on the assembly line. The test results will be instantly taken into account and the engineers will make adjustments to the 3D model of fixtures the very next day.

But using CNC machines usually means longer production times and higher costs. The same fixtures can be printed within hours and tested on the assembly line. The test results will be instantly taken into account and the engineers will make adjustments to the 3D model of fixtures the very next day.

Robotics

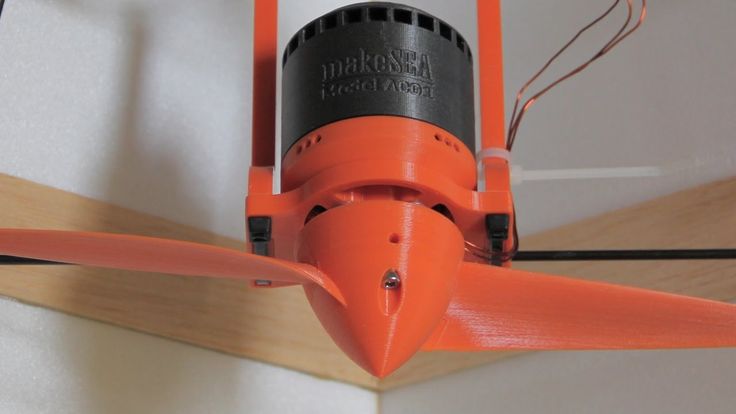

In the field of robotics and automation, non-standard parts are often required to develop new mechanisms. 3D printing has become one of the main manufacturing technologies in this industry due to its speed, great design freedom and ease of making adjustments to the product.

A team of engineering students from the University of Antwerp have created a robotic arm that can translate speech into sign language. They used 3D printing to produce most of the custom parts for their robot.

Industrial tools

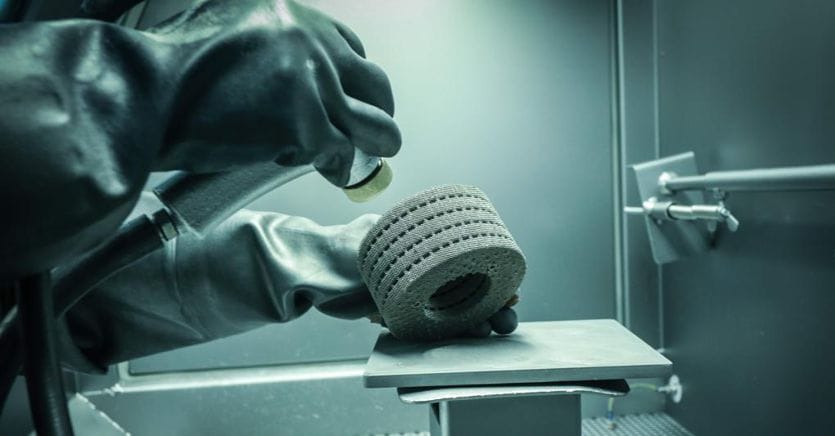

The emergence of new materials with high heat resistance and rigidity in the 3D printing market, combined with the ability to quickly and inexpensively create custom geometries, has pushed manufacturers to widely use the technology to create industrial tools.

For example, today 3D printing is used to make injection molds for the production of short run products. These molds are used to make several hundred parts (compared to 10,000+ using metal molds), but they cost less than "traditional" molds and can be made in a day. This makes them ideal for low volume, low cost production or testing before full scale production.

Health

The use of 3D printing technology in global healthcare began in the 2000s. Since then, the use of 3D printing for medical purposes has evolved significantly.

The first area in which products printed on a 3D printer were involved was dentistry. Dental prostheses, for obvious reasons, are the easiest to replace with products made of plastic and similar materials. To date, there are examples of implantation of whole jaws made of titanium. The first such operation was carried out in 2012 by the private dental company LayerWise.

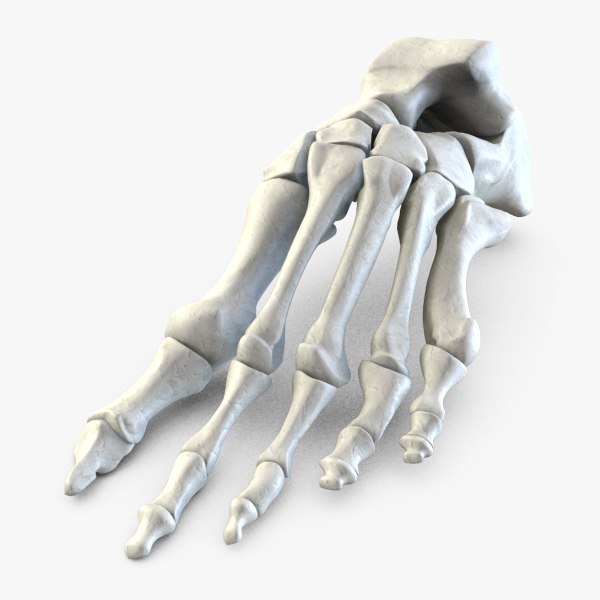

3D printing has proven to be extremely effective in creating prosthetic bones. In addition to high speed, modern technologies help to ensure the desired weight, and most importantly, the porosity of the product. The latter is extremely important for reducing the duration and improving the quality of osseointegration. There are many examples of successful pelvis, scapula, collarbone and other commonly operated bones performed around the world.

In addition to high speed, modern technologies help to ensure the desired weight, and most importantly, the porosity of the product. The latter is extremely important for reducing the duration and improving the quality of osseointegration. There are many examples of successful pelvis, scapula, collarbone and other commonly operated bones performed around the world.

Product design

3D printing allows designers to easily make changes to the product they are developing at no additional cost. They can also create high quality functional prototypes to test new concepts. The use of 3D printing speeds up the design cycle and reduces risks before the product is introduced into full-scale, high-cost production.

Paul Kohlhaussen designed and built a functional prototype of his latest camera. He combined camera parts from different models under one printed body.

Entertainment

3D printing has found widespread use in cinematography due to its ability to create believable props. The near-limitless possibilities of 3D printing to create intricate designs allow entertainment professionals to bring objects from their imagination to life. Thanks to technology, this can be done quickly and at a much lower cost than in the past.

The near-limitless possibilities of 3D printing to create intricate designs allow entertainment professionals to bring objects from their imagination to life. Thanks to technology, this can be done quickly and at a much lower cost than in the past.

One example is Vitaly Bulgarov, a concept designer whose resume includes work with film studios such as Paramount and Dreamworks. He used 3D printing to quickly turn his computer sketches into props for a movie he was working on.

Education

3D printing technology can be widely used for training specialists, for example, to create copies and mock-ups necessary for understanding. Such a visual aid gives students a practical and very valuable experience.

Aerospace engineering students at the University of Glasgow collaborated with Rolls Royce to create a functional model of a jet engine using 3D printing. The model gives instant feedback to students about the changes they make as they work.

Developers

For developers who are constantly exploring new ideas, 3D printing is the perfect tool.