3D printing prague

3D Printing Service Near You

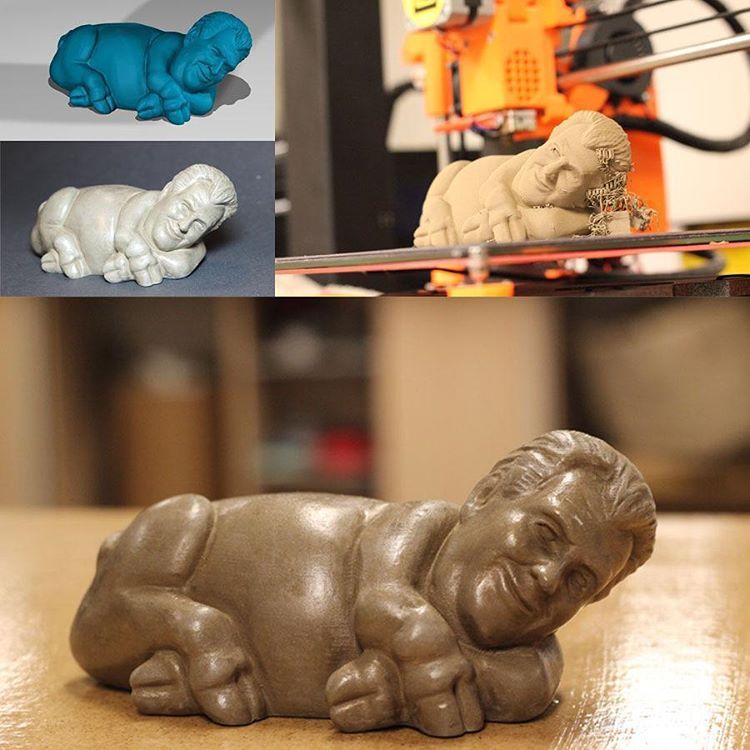

12 3D Printing Services are currently ready to take your order and deliver custom parts to Prague, Prague, Czech Republic. Through our platform, you can order 3D printed prototypes, replacement parts and many other custom projects without any minimal size or quantity requirements. If you have an idea of what technology, material or application suits your order, use filters to narrow down the search. You can also explore vendors’ portfolios with printed examples and customer ratings for a full perspective on their experience with different types of parts.

Upload files to compare instant quotes from local 3D printing services

Upload filesor contact us directly to get a volume discount.

If you’re looking to get something 3D printed and delivered to Prague, Prague, Czech Republic, you’re in the right place. All companies that provide prototyping and printing near you are listed above.

How much does it cost to 3D print my parts?

To check out the pricing instantly, choose a vendor and hit the “Instant order” button. From a 3D model file such as STL, PLY, OBJ or 3MF we are able to calculate the price automatically. If you aren’t sure which vendor to choose, you can “Get instant quote” at the very bottom of the page with the list of all available 3D printing bureaus.

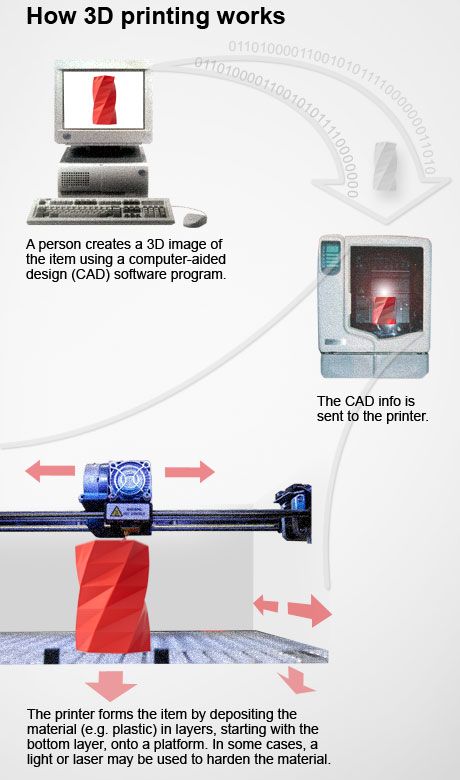

What if I don’t have a 3D file?

3D printing starts from a model, so it is necessary to have a file. Fortunately, many companies that provide additive manufacturing can help you design the parts. For more complex modeling tasks, consider hiring a professional 3D designer.

How do I choose a vendor?

Treatstock aims for transparent workflow between 3D printing companies and customers for great results. To make sure you have all the information needed to choose your manufacturing partner, we include a list of vendor’s machines and customer ratings for each service provider. The full list of their capabilities is included on their business page as well.

The full list of their capabilities is included on their business page as well.

How does it work?

- Upload a 3D file to instant order;

- Select specifications and fill in the delivery details;

- Finalize the order process;

- Monitor progress in your Purchases;

- Get your custom parts delivered to your door.

Our support team is always available for assistance. To learn more about 3D printing technologies, visit our manufacturing guide. And the material guides will help you find out more about all available manufacturing mediums.

Product Application

- Prototype

- HD Prototype

- Jewelry

- Dental

- Multi-color

- Metal

- Miniatures

Materials

- PLA

- ABS

- Nylon

- Wood PLA

- ASA

- Resin

- Rubber-like (TPU)

- PA12 Nylon

- PETG

Technology

- FDM (Fused Deposition Modeling)

- DMLS (Direct Metal Laser Sintering)

- SLS (Selective Laser Sintering)

- PolyJet and PolyJetMatrix

- SLA (Stereolithography)

- CJP (ColorJet Printing)

- DLP (Digital Light Processing)

- DUP (LCD-based Direct UV Printing)

Prague Receives its First 3D Printed Tram Shelter

Published on September 14, 2022 by Clemens M.

The infrastructure of the Czech capital Prague covers a length of 142 kilometers, on which about 991 vehicles are on the road every day, transporting both residents and tourists. Accordingly, the transport company of Prague, which operates the tramway and metro and keeps them instant, is in charge of all the stations and stops. At one such stop, which is named Stromovka and located in Prague 7, a 3D printed bench ,including a lining was produced in just 36 hours, was unveiled last weekend. The exciting thing here is the fact that the tram shelter is the first of its kind in the Czech Republic to have been produced by additive manufacturing.

The innovative bus stop shelter was manufactured and built by the Prague-based company So Concrete, which provided the bench and shelter to the city of Prague free of charge. The prototype, which will now offer passers-by a place to sit while they wait for the next tram, was made of concrete that has a very special property: it is ten times stronger than conventional concrete and is therefore characterized as ultra-strong. Prague’s politician in charge of transport, Adam Scheinherr, is overjoyed with the benefits that 3D printing brings to Prague explaining, “Combining this kind of concrete with 3D printing is a way to use concrete only where it is absolutely necessary […] This is a change in approach to projects and sets a course that meets conditions for sustainable development. Don’t waste energy and resources, which are becoming rarer and rarer.”

Prague’s politician in charge of transport, Adam Scheinherr, is overjoyed with the benefits that 3D printing brings to Prague explaining, “Combining this kind of concrete with 3D printing is a way to use concrete only where it is absolutely necessary […] This is a change in approach to projects and sets a course that meets conditions for sustainable development. Don’t waste energy and resources, which are becoming rarer and rarer.”

Passers-by can sit under cover at the additively manufactured tram station

Details About the 3D Printed Streetcar Station in Prague

Thanks to the use of this 3D printing manufacturing method, the city of Prague can not only enjoy a new and sustainable way of construction. Additionally, in economic terms, the construction allows for higher efficiency. In this case, just 60% of the materials were used and also in terms of human labor, it was possible to reduce it to a minimum. After the 3D printing was completed, So Concrete took care of the transport of the individual parts printed in concrete, where they were subsequently assembled and now represent a completely new type of streetcar stop. However, 3D printing was not used for all of the construction,. Instead, the entire design was optimized with the help of artificial intelligence, with human labor only being used for modification at the end.

However, 3D printing was not used for all of the construction,. Instead, the entire design was optimized with the help of artificial intelligence, with human labor only being used for modification at the end.

Regarding the maintenance of the new tram shelter, So Concrete states that the roofing will not require any maintenance because the material used for it is enormously long-lasting. Estimating it to last 100 years or even longer, Federico Diaz, managing director of So Concrete, gives further specifics about the material and its applications: “The lifetime of the material is extreme, it is used, for example, for water dams.” Since the bus shelter has already welcomed numerous guests, the city is sure that this will not be the last construction produced by using 3D printing. Furthermore, they are already planning other projects, such as the construction of the Štvanická pedestrian bridge, the reconstruction of the Barrandov Bridge and the Libeň Bridge.

The tram house is made by 3D printing and AI designed

What do you think of the additively manufactured tramway waiting house in Prague? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

3D printed houses grow in the Czech Republic

Photo: Patrik Salát, Český rozhlas

Sounds like science fiction? In Tršest, in the Jihlava region, one prototype of the house design has already been printed. A local engineering and construction company has been developing a unique 3D printer for four years together with specialists from the Czech Technical University in Prague. Although it is of considerable size, according to the creators, it can be moved almost anywhere and printed a concrete house on site in a matter of hours. nine0003

“The test print of this design, on which we studied, lasted about 35 hours. This printer is different from other 3D printers. In fact, it looks like a gantry crane. The difference is that we have a moving platform on this portal, on which our printhead moves,” says Marek Stadler from the Faculty of Mechanical Engineering of the Czech Technical University.

Photo: Patrik Salát, Český rozhlas

Next to the portal of the 3D printer in Tršest is the first prototype of the printed house. nine0003

nine0003

The print head models an angle pattern, but makes it, not like similar machines, round, but square, because the printer does not use a classic robotic “hand”, but just its own print head. The dimensions of the printer are significant, and it can turn around 122 square meters of area. In height, the structure can reach a height of five meters. So, all that is needed to start construction is a pre-prepared project on a computer. Thanks to this, with the help of 3D printing, houses can be built in a matter of days and replace a number of craftsmen of various professions. nine0003

Photo: Patrik Salát, Český rozhlas

“It operates in the same way as conventional CNC machining centres. This means that it is controlled by G-code. If we already have the code ready, then two people are enough to work, one of whom takes care of the preparation of the mixture, and the other manages and controls the printing process.

The vision of a more robotic construction process that would solve the shortage of workers in the construction industry inspired Podzimek four years ago to start developing a 3D printer together with experts from the Czech Technical University. nine0003

nine0003

Photo: Patrik Salát, Český rozhlas

“If I assume that there will be no workers at all, we will have no choice but to completely robotize the construction process,” says company director Martin Podzimek.

According to him, sooner or later robotization will still prevail in construction.

Therefore, his company wants to continue developing the 3D printer. If investors are interested, the firm plans to print more houses in the future.

Photo: Daniela Brychtová, Český rozhlas

However, one should not think that this case in the Czech Republic is unique and still really resembles lines from science fiction. In the Vysočina region, trial testing of house printing on a 3D printer is currently underway. If everything goes smoothly, in two years the firm plans to print... an entire school!

“We started with 3D printing of various benches, flower pots, urban furniture, but at the moment this is not enough for us, so we would like to move on to something more,” says ICE Managing Director Dominik Stupka. nine0003

nine0003

It is in ICE's production facility, which is equipped with three giant 3D printers, that parts of houses are made.

Photo: Daniela Brychtová, Český rozhlas

“The working title of this facility is a bicycle garage. But in fact, this is a house about 3 x 8 meters in size, it consists of several segments, and we are making one of them here.”

But before the house could be printed, the company had to build the 3D printing machine itself. The goal is to improve the machine so that it can be operated by a non-specialist. In the future, the company wants to move from a small home to larger projects. According to Tomasz Vranek, director of the company, the first printed school building in the northern hemisphere will be built exactly in Zdar nad Sazavou. nine0003

Photo: Daniela Brychtová, Český rozhlas

“We have set ourselves a huge task, but we want the school to be ready in the summer of 2023 so that children can start the 2023/2024 school year in the new building.

This is an alternative Montessori school in Ždiar nad Sázavou in the Radost district,” shares Tomasz Vranek. According to Tomasz Vranek, 3D printing technology should save time and money, as well as fill the shortage of masons in the market. Most of the development effort is planned to be focused on developing a material that will be comparable in price to existing conventional concrete, thus saving up to 70% of material and human labor, as 10 masons can be replaced by one robot In the near future in Ždiar nad Sazavou the first cafe printed on a 3D printer will also appear. nine0003

The first 3D-printed house is presented in Prague

Until the end of August, a 3D-printed house can be seen on Streletsky Island in Prague. It was made in České Budějovice and is the first in the world. Its authors hope that construction companies will begin to take this technology seriously. However, this is hindered by high prices.

The price of building materials remains a serious problem. “A kilogram of our mixture costs about 16 crowns, which is several times more than concrete from a concrete plant. In the future, we would like to print, for example, from recycled materials and local concrete mixes, to which additives will only be added during printing,” says one of the creators of the house. nine0003

“A kilogram of our mixture costs about 16 crowns, which is several times more than concrete from a concrete plant. In the future, we would like to print, for example, from recycled materials and local concrete mixes, to which additives will only be added during printing,” says one of the creators of the house. nine0003

The mixture is enriched, for example, with so-called plasticizers, thanks to which it is possible to form organic forms, or hardening accelerators. Concrete partially hardens already during application.

Calculations show that such a house is built on average 7 times faster than an ordinary building, and creates several times less construction waste. Unlike conventional construction, 3D printing is not so limited to shapes, builders can easily choose round wall shapes, for example. “In conventional construction, it would be necessary to make complex shapes into which concrete would be poured. It will take longer and be much more expensive than in this case,” say the creators. nine0057 Another advantage is that not many people are involved in the construction itself. “If we take only 3D printing, theoretically two people can handle it. One controls the robot and the other controls whether there is enough mixture in the mixer and pump,” they explain.

nine0057 Another advantage is that not many people are involved in the construction itself. “If we take only 3D printing, theoretically two people can handle it. One controls the robot and the other controls whether there is enough mixture in the mixer and pump,” they explain.

The house weighing 30 tons and 13 meters long was transported to Prague on Monday evening. The "element", as the house was called, had to be divided into three parts during transportation so that it could be transported. On the way, he had to overcome 150 km, and also go through three locks. nine0003

According to the creators, the entire house was printed in 32 hours of pure time. However, a number of finishing works followed, for example, the installation of a roof. In addition, it took some time for the applied layers of concrete to dry to their final shape, so the whole process took two months.

A building with a total weight of 30 tons should last more than a century. According to the authors, its walls withstood a pressure of 50 tons during static tests.