3D printing pellet extruder

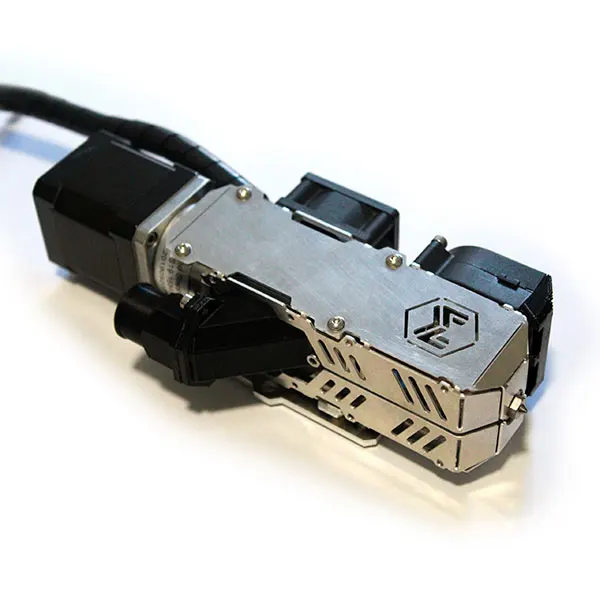

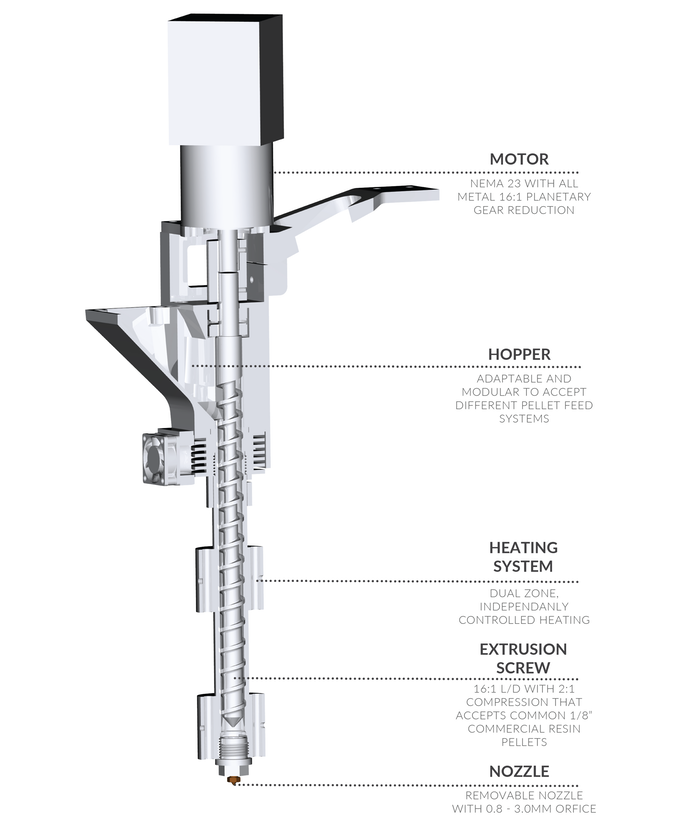

Pulsar™ Pellet Extruder: Industrial High Flow Extruder

Save time.

Save costs.

Pulsar™ is a state-of-the-art large-scale and high flow plastic pellet extruder.

It was designed with one purpose in mind: 3D printing of parts of one m³ and more as quickly and as cost-effective as possible.

Pulsar™ is compatible with any large-scale 3d printer or even robotic arms and is able to output as much as 500mm³/s (2.5kg/h) of materials.

Get a quote

Name*

Business Email*

Company

Phone*

Address*

Industry

MaritimeMedicalAerospaceResearchConstruction / ArchitechtureAutomotiveOther

Application

—Please choose an option—Robotic 3D PrintingCartesian 3D PrintingOther

Quantity

Voltage

110V220V

Nozzle Size

1.0mm3.0mm5.0mm

Auxiliary systems

Liquid-Cooling SystemAutomated Pellets Feeding System

Other information

Welcome to the Industrial 3D Printing Era

Ultra High Flow

The Pulsar can output up to 500 mm³/s (2. 5kg/h). It is our highest output flow solution and one of the fastest portable pellet extruder on the market.

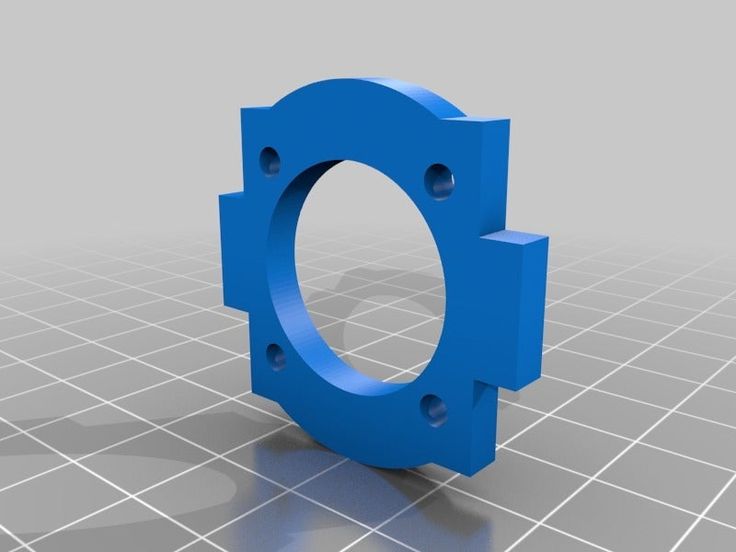

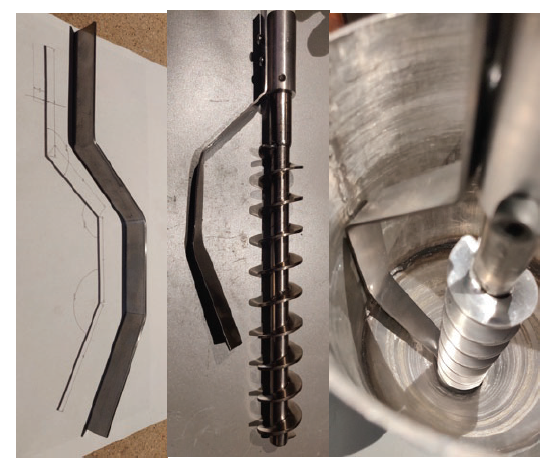

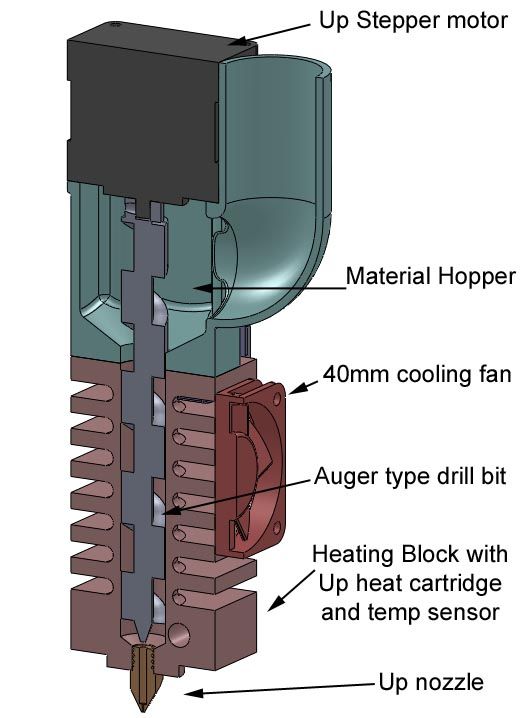

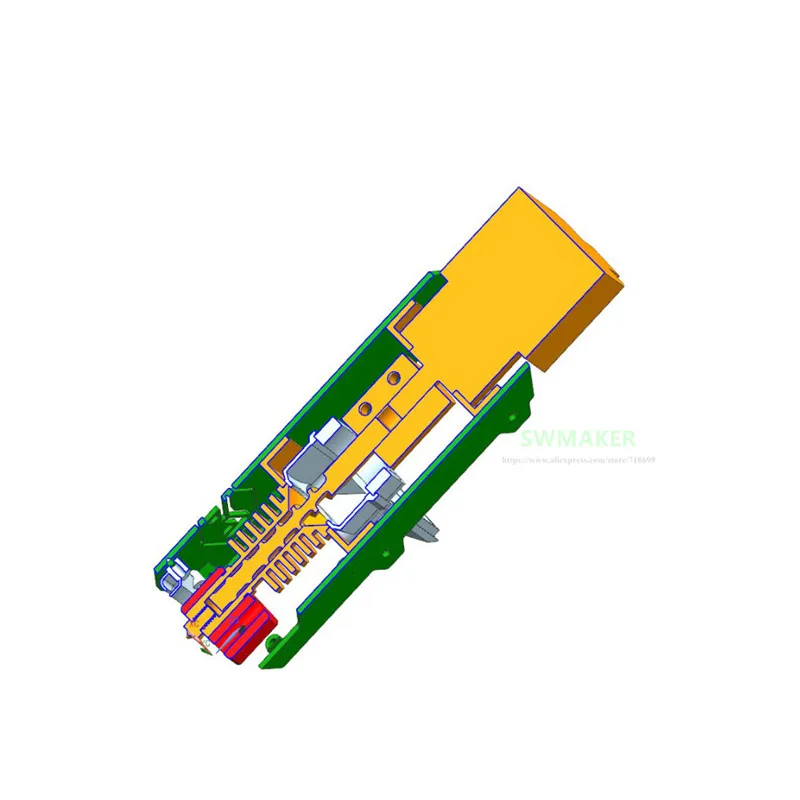

Customized Extrusion Screw

The customized screw design is optimized for 3D printing with high resolution.

Tri-zone Heating Control

The triple heat zone design ensures the polymer is at a constant temperature. The top section receives cold pellets and generates more heat to melt them. Then, the middle zone stabilizes the polymer at a precise temperature. Finally, the nozzle heater ensures an even flow.

Automatic Feeding System

The Pulsar can come with an optional feeding system which detects the pellets level. Pellets can be delivered from a bulk source.

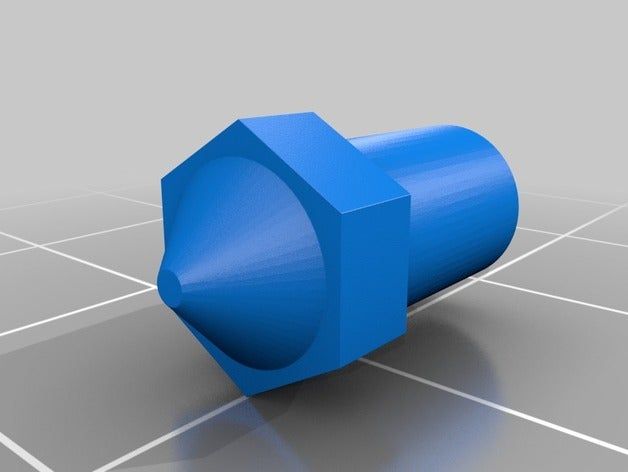

Multiple Nozzle Size

Pulsar can be used with large nozzles from 1.00mm up to 5.00mm.

Uniform Heating

The spiral heaters are wrapping the whole heated cylinder and ensure uniform temperature all the way through the end of the extrusion.

Melting Zone Sensor

The temperature sensors are placed 0. 50mm from the molten polymer. Readings are reliable and accurate.

50mm from the molten polymer. Readings are reliable and accurate.

Tool Steel Nozzle

The super abrasive resistant steel nozzle avoid any change in nozzle size and height during large prints with abrasive material.

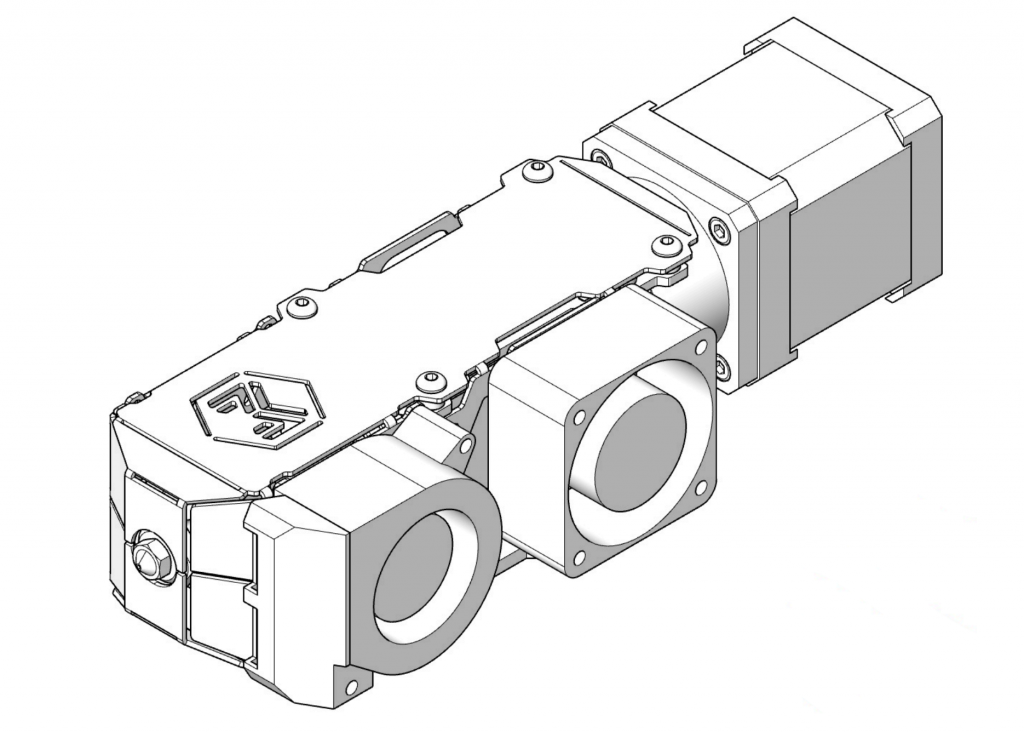

Strong NEMA23 Motor

The Geared NEMA23 motor can handle high flow without a sweat.

Precise Temperature Control

The three PT100 sensors are class A, high precision sensors. The circuit has been designed to use the best resolution between 0°C and 500°C.

Ultra Rugged

The all-metal frame is made from aluminum alloy and is designed to withstand high stresses in tough conditions.

Liquid-cooled

The Pulsar is ready for any environmental conditions. Due to the powerful heating zones, the water-cooling loop ensures the system is at a constant temperature

Anti-Oozing Mechanism

As the screw can’t pull molten plastic, an anti-oozing mechanism ensures nice looking prints without any flaws.

High-Temperature Materials: PEEK, Ultem, PSU

The high-temperature heaters, temperature sensors, and extrusion components enable printing up to 500°C.

1100 Watts Heating Power

High flow means high energy. The 1100 Watts heating system ensures stable temperature in high-speed 3D printing conditions.

Print any plastics

The Pulsar is able to print every single type of plastic pellets currently manufactured on the market

- Standard

- Flexible

- Support

- Advanced

- Engineering

- Other

Standard

- PLA

- ABS

Flexible

- TPE

- TPU

Support

- PVA

- HIPS

Advanced

- PC

- PET

- PETG

- NYLON

Engineering

- PEEK

- PEI

Other

- Metal Powder Filled

- Wood Filled

- Carbon Fiber Filled

Technical Information

|

Parameter

|

Value

|

Units

|

|---|---|---|

| Weight | 7000 | g |

| Screw diameter | 19. 3 3 | mm |

| Maximum screw operating speed | 60 | RPM |

| Max temperature | 500 | °C |

| Available nozzle sizes | 1.00 3.00 5.00 | mm |

| Max flow* | 500 3 | mm3/s kg/h |

| Total length | 500 | mm |

| Screw length | 348 | mm |

| Heating power | 1100 | W |

*With 3D700 PLA at 200 °C

Download CAD & Drawing

Pellet Extruders for 3D printing - Why Use Them and Which Ones Should I Buy

Print directly with pellets, without having to use filament?

It can be done with a pellet extruder.

A new world of possibilities to print large format pieces, with any material and with wholesale plastic prices.

📖 What do you want to read?

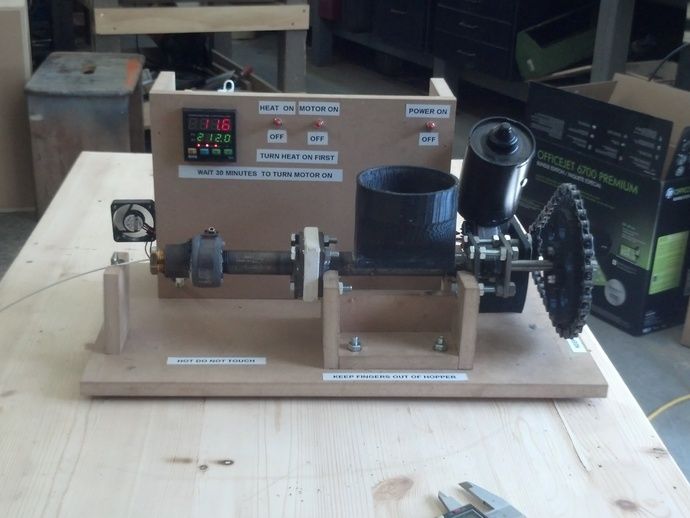

What is a pellet extruder?

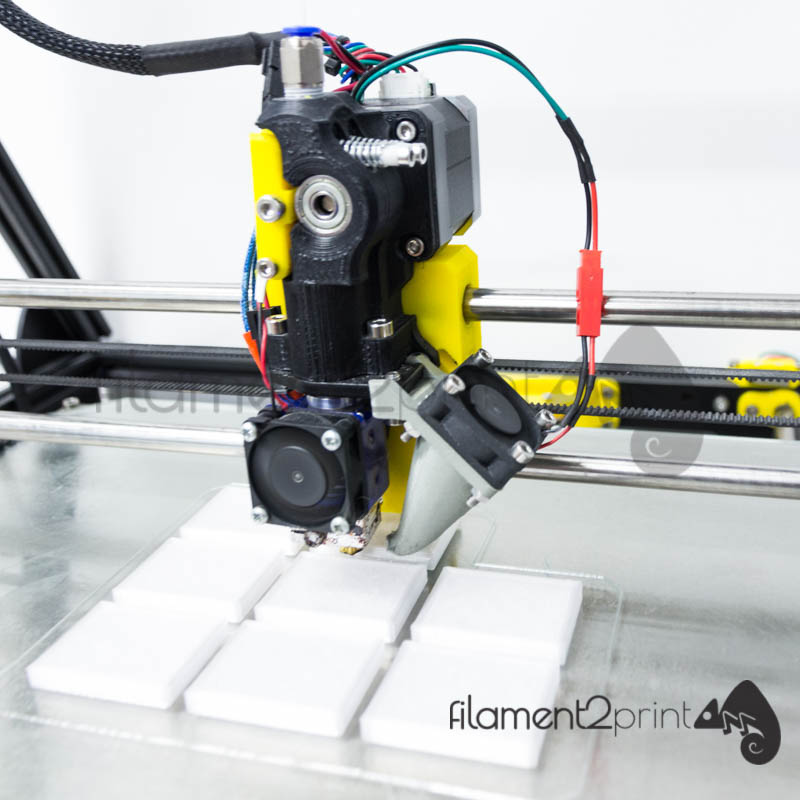

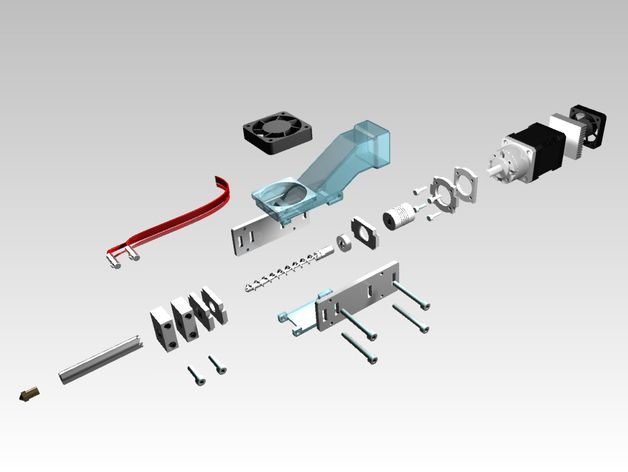

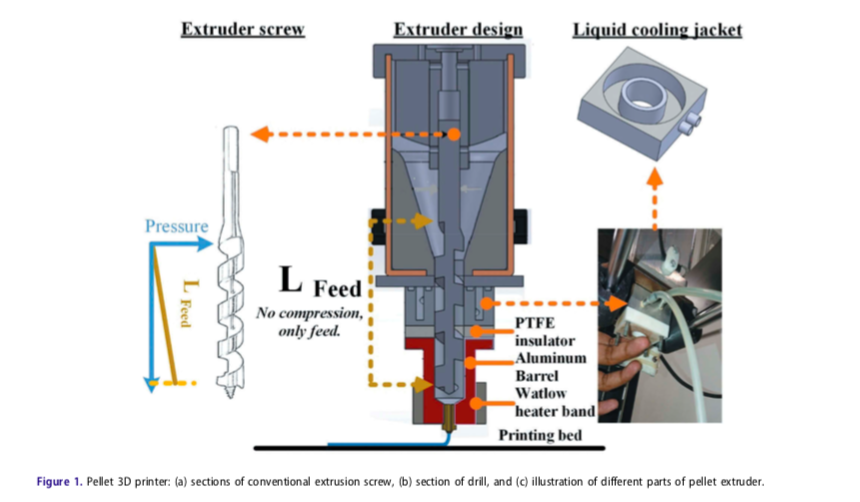

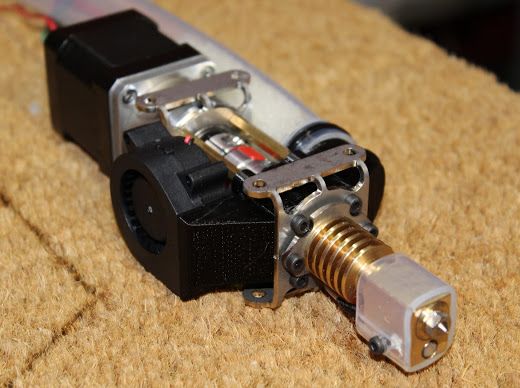

A pellet extruder is basically a part that combines a pellet melter and a pushing mechanism in one device. In this way they replace the extruder-melter assembly in our printer, so we must replace both elements by one of these pellet extruders.

In this way they replace the extruder-melter assembly in our printer, so we must replace both elements by one of these pellet extruders.

The new extruder uses pellets instead of filament to work. Pellets are small beads in which manufacturers sell the plastic in bulk. In fact, the filament is made from pellets, so we are saving an intermediate step in the process (and a lot of money).

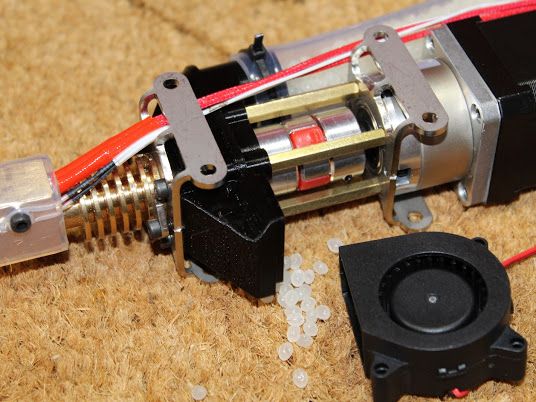

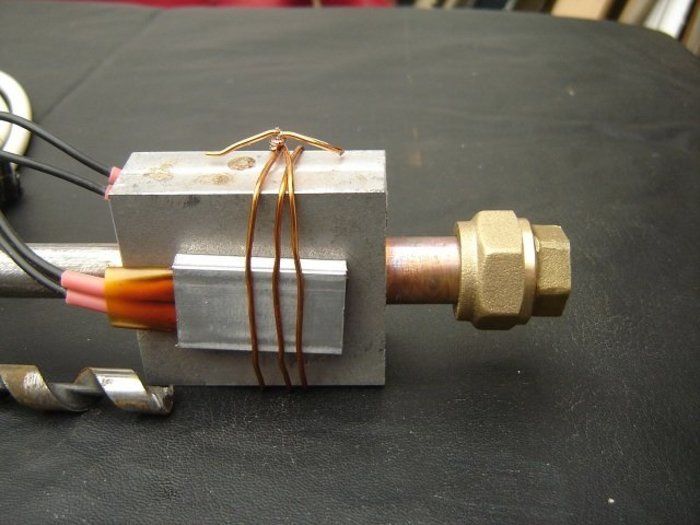

When replacing the extruder-melter assembly, a pellet extruder has to include all the functionalities that these comprise: material loading, pushing the material towards the melter, heater, thermal shock to avoid jamming, thermistor, nozzle… As a user, you only have to know that, once a pellet extruder is installed, your printer will work exactly as before, only now you will feed it with pellets instead of a filament coil (and change the steps per millimeter of the extruder).

What are the advantages of a pellet extruder?

Now that you know what a pellet extruder is, you most certainly can imagine several possible advantages. We are going to tell you about the ones we consider most relevant.

We are going to tell you about the ones we consider most relevant.

Final cost of the part

When we use a pellet extruder, the cost per part is greatly reduced, making 3D printing a quite valid option for long series of parts or very large parts that would normally not be profitable. There are two main reasons that will help us save costs: reduction in material cost and reduction in printing time.

Reduction in material cost

The material we use for 3D printing, whether PLA, ABS or other more technical material, sees its cost increased due to the industrial process needed to transform pellets into the filament we use. If we can skip this step and buy the pellets directly, we can buy the material much cheaper.

As you can see and as an example, PLA pellets (virgin, not recycled) from Smart Materials would cost us 8.95 euros per kilo. Smart Materials is not a brand that is known for being cheap, since the material they sell is of very good quality. Even so, 1 kilo of PLA in pellet format would cost us less than 1 kilo of the cheapest PLA filament you can find. This same material, if you decide to buy it in its 1.75mm filament format will see its price multiplied by 2.5, saving 14.5 euros per kilo of purchased material.

This same material, if you decide to buy it in its 1.75mm filament format will see its price multiplied by 2.5, saving 14.5 euros per kilo of purchased material.

There are much cheaper alternatives and we can lower the price by buying in large quantities. Good quality PLA pellets can be obtained for about 5 or 6 euros per kilo or even less.

Reduction of printing time

By printing on such inexpensive materials and on which we can precisely control how they are melted, we can print using very large nozzles. With large format printers and pellet extruders it makes perfect sense to print using a 1mm nozzle, depositing about 300 grams of material per hour depending on the model. To give you an idea, here is an example:

Tiempo de impresión usando un nozzle de 0.4mm y altura de capa de 0.2mmTiempo de impresión usando un nozzle de 1mm y una altura de capa de 0.6mmAs you can see, the time is reduced significantly, also reducing the printer depreciation cost, electricity, rent of the premises, the number of machines needed…

Ability to print large parts

As we have already explained, with a pellet printer we can drastically increase the printing flow, being able to print much larger parts in a much shorter time and using a more economical material. This means that we can print in 3D things like furniture or decorative elements such as vases and sculptures. Industrial grade and large volume parts are also possible with a pellet extruder, since we can make them in a reduced time and we can also use a totally customizable material (more about this below).

This means that we can print in 3D things like furniture or decorative elements such as vases and sculptures. Industrial grade and large volume parts are also possible with a pellet extruder, since we can make them in a reduced time and we can also use a totally customizable material (more about this below).

Larger printers often use pellet extruders directly, as with very high material flows such as those required by larger nozzles, the filament can be difficult to operate. And the material costs of larger parts also justify the investment in a pellet extruder to save per kilo of printed plastic.

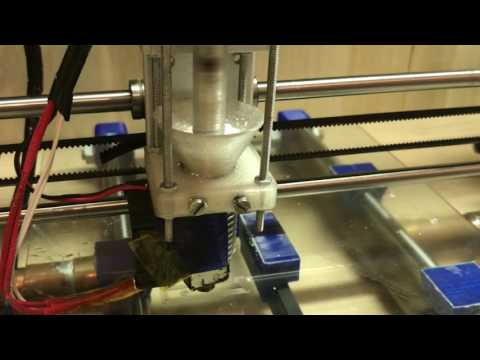

Here’s a video of the extruder in action:

Wide range of materials

With a pellet extruder you can print practically any material you can think of, from the basic ones like PLA to the more technical ones like polycarbonate (PC), TPU, EVA or even biomedical materials like PCL (polycaprolactone). These materials, besides being much cheaper than if we bought them in filament format, give us an added advantage: we can mix them or add loads of other material.

These materials, besides being much cheaper than if we bought them in filament format, give us an added advantage: we can mix them or add loads of other material.

Just imagine your extruder pellet as a small filament factory, only this time you are the one who decides exactly how much of what material will be melted to create the polymer that has the best properties. In addition, there is the possibility of creating materials filled with fiberglass, carbon fiber, kevlar… For professional makers, this option is incredible because it allows you to have your own material factory at home.

Finally, you can also create materials with the exact color you want, adding effects such as glitter or metallic highlights.

Recycling

By having a pellet extruder you can print using recycled plastic. You can buy pellets made from recycled plastic or recycle them yourself using a solution such as a plastic shredder. We have already talked more about this in our article on recycling in 3D printing.

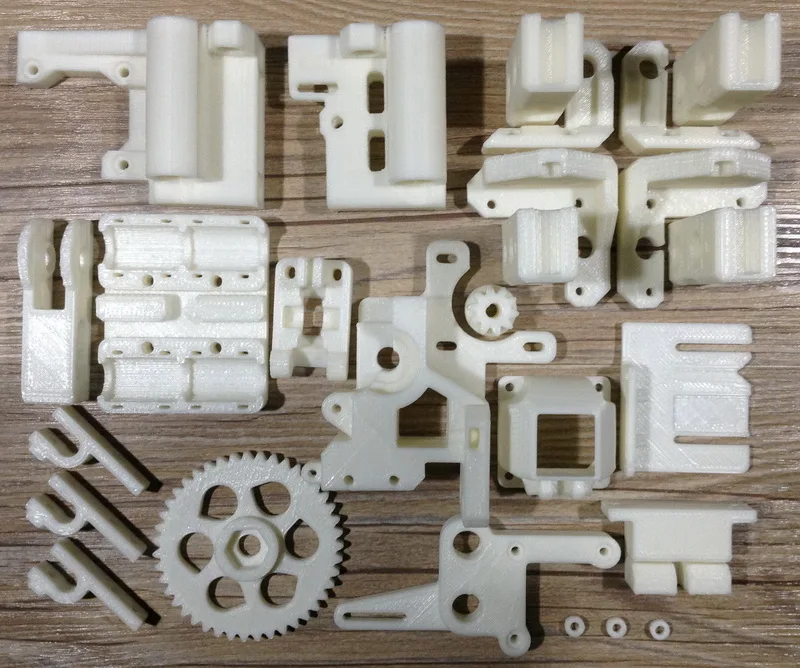

What projects are there?

There are not many pellet extruder projects today. As you know, our favorite (and almost the only one relatively known) is the Mahor XYZ pellet extruder. This extruder has been quite tested by the Spanish maker community and there are many reviews in Youtube. In their website you have all the information about it and you can buy it starting from 329 euros.

In the specific case of our favorite pellet extruder, the MahorXYZ, many improvements are included to ensure maximum reliability, such as:

- High torque motor

- High-powered heating block with adjustable position to ensure optimal flow for each material and avoid clogging

- Specially designed and machined spindle for the extruder

Low Flow

High Flow

It is a quality tool for companies and professional manufacturers who are going to use exotic materials or print large format parts.

Ask for a quote at Bitfab

In Bitfab we are up to date and we work with the best so, if you are interested in printing your parts using pellet extruders or looking to incorporate this technology in your workshop, we can help you. Do not hesitate to contact us and we will find the best solution for your specific problem.

Do not hesitate to contact us and we will find the best solution for your specific problem.

Contact Bitfab

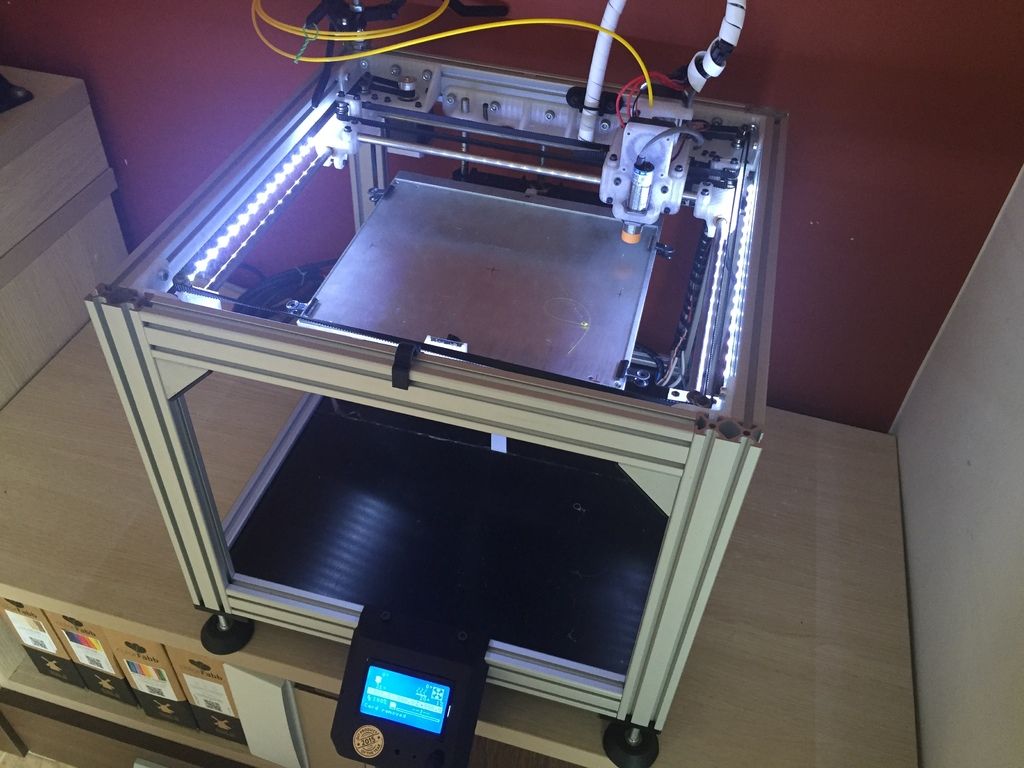

Discovery 3D Printer: printing big Experts argue that the pandemic will bring the Fourth Industrial Revolution closer, and many businesses today see digital technologies as a means of survival, and not just to increase competitiveness in the market.

iQB Technologies continues to expand its product portfolio and is now the exclusive distributor in Russia of industrial 3D printers Discovery 3D Printer by the Spanish manufacturer CNC Barcenas. For the first time, we present equipment for 3D printing of large-sized products and prototypes based on FFF/FDM technology. nine0003

CNC Barcenas is a fairly young business, just over ten years old. Since 2009, the company has been specializing in the production of CNC machines (milling, engraving and laser cutting), and in 2014 it expanded its capacity by starting the development, design and production of unique industrial 3D printers.

CNC Barcenas continues its pioneering work and is now one of the leaders in the European large format 3D printing market with many large scale projects to its credit.

Key Benefits of Discovery 3D Printer

-

Much lower cost printers than competitors offering the same technology and quality.

-

Continuous development of technology and experience in 3D printing and machine tools.

-

All equipment is completely designed and manufactured by CNC Barcenas in Spain.

-

Ability to customize the printer for the needs of each individual client.

-

The best drive and motor components for quality and fast printing.

-

Correction of irregularities during printing (calibration of nozzles and platform).

-

Debugging equipment to 100% result.

-

The open material system reduces operating costs significantly.

-

Internal cameras in printers that allow remote monitoring of the production process from any device. nine0003

-

Easy to use hardware and intuitive Simplify 3D software.

Technology and features of the 3D printing process - a complete analogue of FDM (Fused Deposition Modeling - modeling by layer-by-layer deposition). This is the most accessible and popular additive technology, it is familiar to all users of home 3D printers, but it is also widely used to solve serious production problems.

Its undoubted advantages include high productivity, the ability to produce large-sized products and the relatively low cost of equipment and consumables. nine0003

Its undoubted advantages include high productivity, the ability to produce large-sized products and the relatively low cost of equipment and consumables. nine0003 The disadvantages of this method are the highest degree of surface roughness among all additive technologies (the quality depends on the nozzle diameter and materials), the risk of plastic spreading and increased sensitivity to temperature changes. Note that the Super Discovery 3D Printer model equipped with a cutter will immediately correct the roughness and post-process the product right in the printer chamber.

As consumables, thermoplastics or composites are used in the form of threads wound on spools (so-called filaments), or granules. Their range is very diverse and allows you to choose the most suitable materials for the tasks to be solved in terms of physical and mechanical properties - ABS, PLA, nylon, polycarbonates, polyamides, polystyrene, polyethylene and many others. nine0003 Building an object in Discovery 3D Printer

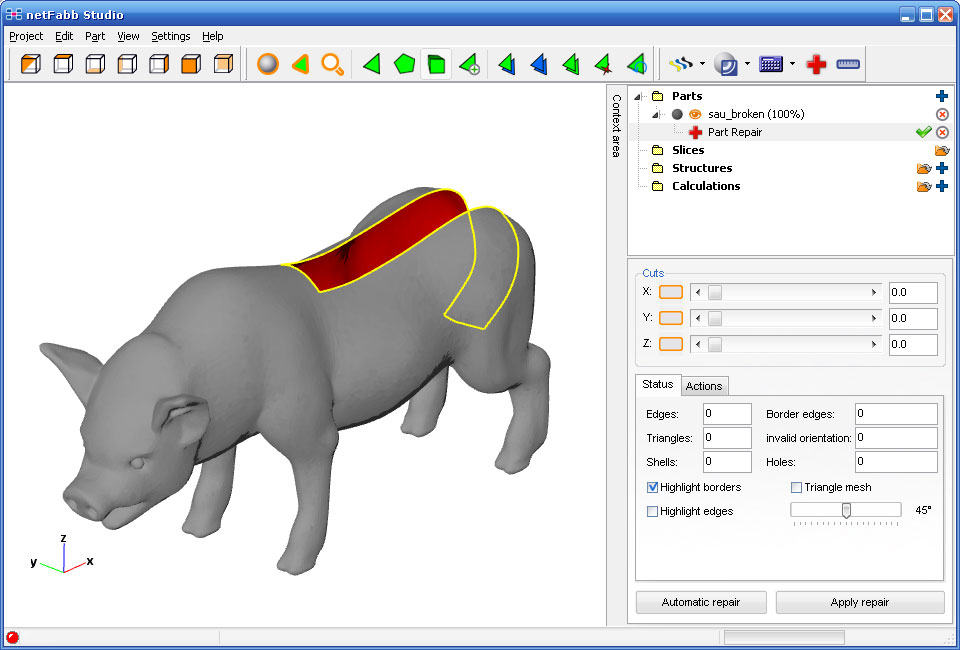

The process of creating a product using FDM/FFF technology includes the following steps:

-

Exporting a 3D model to the 3D printer software in .

stl format.

stl format. -

Preparation for printing: division of the model into layers and orientation on the build platform, if necessary, creation of supports. The result is a G-code containing all print settings.

-

Printing process by layer-by-layer extrusion (extrusion) of molten material. The extruder (print head) moves from bottom to top along the X and Y axes, the working platform moves along the Z axis. nine0003

-

Extraction of the printed object from the 3D printer, removal of supports, post-processing.

The filament printing method is used in the junior model of the Discovery 3D Printer line. The Super Discovery 3D Printer and Super Discovery 3D Printer Workstation implement the innovative Direct Extrusion of Pellet technology. The difference from standard FDM is that the consumables are in the form of granules rather than filaments. This method makes it possible to speed up and make more economical the production of large objects. nine0003 Helicopter seat Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 120 x 70 x 45 cm, weight: 20 kg A statue Equipment: Super Discovery 3D Printer, material: ABS with cellulose fiber, height: 1.87 m, weight: 45 kg

nine0003 Helicopter seat Equipment: Super Discovery 3D Printer, material: ABS with carbon fiber, dimensions: 120 x 70 x 45 cm, weight: 20 kg A statue Equipment: Super Discovery 3D Printer, material: ABS with cellulose fiber, height: 1.87 m, weight: 45 kg

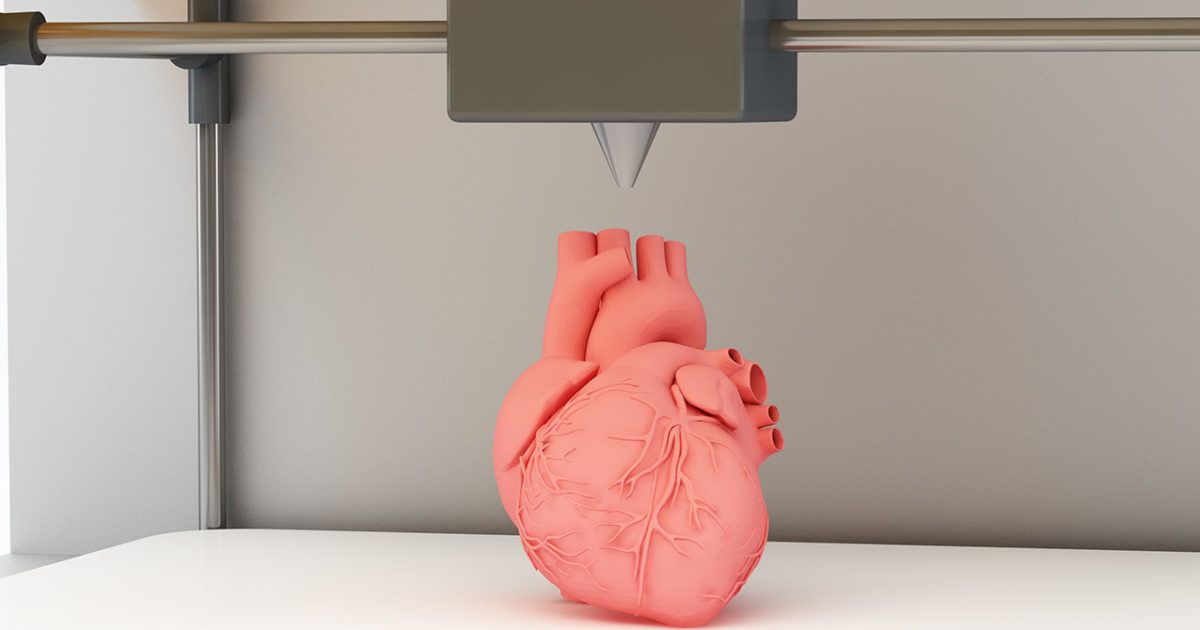

Discovery 3D Printer Applications

Each industry has its own specifics, which is why CNC Barcenas adapts the 3D printers produced to the requirements of specific tasks and projects where rapid prototyping or rapid production of final products is required. Discovery 3D Printer can be successfully used in the following industries:

-

automotive industry;

-

aerospace industry;

-

shipbuilding;

-

defense sector;

-

railway industry;

-

household goods and appliances;

-

furniture industry;

-

architecture;

-

medicine;

-

education;

-

industrial design; nine0003

-

3D printing services.

"We printed large parts and saved about 70% of the costs that usually go to subcontracting prototypes"

- Juan Galindo Pérez, Prototyping Manager at BSH Spain.

Product Line

Discovery 3D Printer 2021

Industrial FFF 3D Printer designed to produce large technical plastic parts for complex and long-term projects. As consumables, all filaments available on the market that conform to the standard 1.75 mm format can be used. The printer is equipped with a built-in dual extrusion system that can be used to create supports and parts from different materials in different colors. Discovery 3D Printer is one of the most attractive solutions on the market in terms of price and quality, given the dimensions of the printed products. nine0003

-

Works with ULTEM, PLA, ASA, ABS, PA, HIPS, 3D850, PETG, ABS Medical, ABS Hi and many more

- Automatic Leveling that automatically compensates for minor irregularities during printing

-

Build chamber size (W x D x H): 1150 x 800 x 500 mm

-

Printer size: 1150 x 800 x 500 mm

3

0015 -

Extruder (max.

Temperature): 450 ° C

Temperature): 450 ° C -

Workload: 80-140 g/h

-

Print speed: up to 400 mm/s

-

thickness thickness thickness layer (minimum): 0.1 mm

-

Software: Simplify 3D

Weight: 300 kg

Super Discovery 3D Printer

The machine was designed as an all-in-one solution for Industry 4.0 to produce large format parts up to 2.5m The Super Discovery 3D Printer is based on direct polymer bead extrusion technology to reduce cost per part, increase productivity and significantly reduce overall costs. Individual configuration is possible for any needs of large industry. nine0003

-

Works with all thermoplastics e.g. ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and heated platform (up to 175°C) with automatic leveling for the most demanding materials

-

Automatic feeding of granules, no restrictions on the amount of material and, as a result, on the weight of the product.

-

Build chamber size (W x D x H): factory standard 1300 x 2500 x 1000 mm, custom configuration possible

-

The dimensions of the printer with a loading funnel and an electric cabinet: 2000 x 3590 x 3000 mm 3000 mm

-

Weight: 1200 kg

-

Extruder (max. Temperature): 450 ° C

-

Workload: <6 kg/h

-

Print speed: up to 200 mm/s

-

layer thickness (minimum): 0.5 mm

-

according to: Simplify 3D

SUPER DISCOVERY 3D PRINTER COMPACT

9000 high-performance industrial-grade 3D printer for pellet extrusion printing. The machine is designed to create small and medium-sized products up to 1100 x 800 x 500 mm, and at the same time has all the advantages of the previous model Super Discovery 3D Printer, allowing you to reduce costs and increase print speed. nine0003-

Fully enclosed chamber and platform heated (up to 150°C)

-

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Direct resin pellet extrusion technology

-

Build chamber size: 1100 x 800 x 500 mm (modifiable)

-

Automatic pellet feed and no material limit

-

Weight: 450 kg

-

Extruder (max.

temperature): 410°C

temperature): 410°C -

Working load: 2 kg/h

-

Printing speed: up to 100 mm/s mm

-

Software: Simplify 3D

Super Discovery 3D Printer Hybrid

Combined solution that implements two additive technologies at once - filament printing method and direct extrusion of polymer granules, which can also be used separately. The innovative 3D printer works with any thermoplastics and has a build chamber up to 1100 x 800 x 500 mm, which can be modified to suit your individual needs if desired. nine0003

-

Combined filament and bead extrusion printing solution

-

Fully enclosed chamber and heated bed (up to 150°C)

-

Works with all thermoplastics including ABS, PC CF, ABS CF PPE CF, 3D850, ASA

-

Build chamber size: 1100 x 800 x 500 mm

-

Automatic granule feed and no material limit

-

Weight: 300 kg

-

Extruder (max.

temperature): 410 °C

temperature): 410 °C -

Working load: pellets - 2 kg/h, filaments - 80-100 g/h

- 9002 printing speed: pellets

- 9002 - up to 100 mm/s, filaments - up to 400 mm/s

-

Layer thickness (minimum): granules - 0.5 mm, filaments - 0.1 mm

-

Software: Simplify 3D

9015 9015 Discovery 3D Printer Workstation -

Works with all thermoplastics including ABS, ABS CF, PC CF, PPE CF, 3D850, ASA

-

Fully enclosed chamber and platform heated (up to 175°C) with auto leveling for the most demanding materials

-

Automatic pellet feeding, no restrictions on the amount of material and, as a result, on the weight of the product

-

Build chamber size (W x D x H): factory standard - 1500 x 2000 x 1000 mm, custom configuration possible

-

Printer size: 2000 x 3590 x 3000 mm

-

Weight: 1500 kg

-

Extruder (max. Temperature): 450 ° C

-

Workload: <6 kg

-

Speed: up to 200 mm/s

-

Layer thickness (minimum): 0.5 mm

-

Milling motor: high frequency brushless motor with air-cooled ceramic bearings, speed 4500-18000 rpm. nine0003

-

Software: Simplify 3D + CNC software

-

to modernize the production process and increase productivity;

-

reduce production and assembly time; nine0003

-

reduce labor costs;

-

reduce the amount of work on processing and painting;

-

increase the energy efficiency of production;

-

improve product quality.

The perfect combination of large format industrial 3D printer and milling system. The plant is designed for the production of large batches of large parts and prototypes. The principle of operation, just like that of the Super Discovery 3D Printer model, is based on the direct extrusion of granules. The special design allows the entire production process to be carried out, including post-processing, since both the extruder and the milling motor are present on the working platform. Super Discovery 3D Printer Workstation is capable of large-scale post-processing jobs, as well as cutting, punching or 3D engraving on plastic, photopolymer, foam, wood and other materials. nine0003

nine0003

Implementation history: FDM printing for the navy

At the request of the Spanish Navy, the state-owned shipyard Navantia developed and implemented the Shipyard 4. 0 strategy (“ Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of things, etc.

0 strategy (“ Shipyard 4.0”). The goal of the new business model is to optimize the production process using Industry 4.0 technologies, including 3D printing, robotization, digital twins, big data, artificial intelligence, the Internet of things, etc.

CNC Barcenas has been involved in two R&D projects for additive manufacturing. The first of these is called 3DCABINS and involves the production of fully equipped ship cabins through research and selection of the most suitable materials. For example, on the Discovery 3D Printer and Super Discovery 3D Printer installations, prototypes of a modular toilet for a naval ship were made. Compared to traditional production methods, the weight of the products has been reduced by almost 50% and their cost has been greatly reduced. The second project, ADIBUQUE, uses 3D printers to manufacture complex components for the navy sector, which are installed and tested on ships under construction. nine0003 Objects printed on the Super Discovery 3D Printer for the 3DCABINS project: – modular toilet, material: fireproof ABS, dimensions: 2200 x 1700 x 1200 mm, weight: 250 kg – ventilation grille, material: ABS with carbon fiber, dimensions: 59 x 89 x 4. 5 cm, weight: 3500 g

5 cm, weight: 3500 g

The use of Discovery 3D Printer has allowed Navantia:

Summary

Discovery 3D Printer is a range of additive machines made in Spain with an excellent price/performance ratio for creating large-scale products and prototypes.

The main features of the printers are large print format (up to 2.5 m), affordable FFF/FDM technology, ease of operation and unique technological solutions, such as the built-in dual extrusion system, correction of bumps during printing, individual configuration of printers, consolidation 3D printing and post-processing in one system. nine0003

All these advantages will allow enterprises of various industries to optimize production - from the automotive industry and shipbuilding to medicine and household appliances. Discovery 3D Printer will suit both large industrial productions and innovative companies in the small and medium business segment.

Discovery 3D Printer will suit both large industrial productions and innovative companies in the small and medium business segment.

F2 Pro Pellet 3D printer

Hybrid production

Possibility to post-process the resulting product (milling, turning)

Printing with recycled materials

Printable with recycled plastic pellets PET, PP, ABS, HDPE, LDPE, etc.

Ideal for printing moulds, punches, dies for laying out composites F2 Pro, own production and development by F2 innovations.

| Order now |

| Get detailed specifications |

F2 Pro Pellet combines the benefits of the Pro

printer with fast pellet technology. The

F2 Pro Pellet is an industrial 3D pellet printer ideal for high-speed 3D printing. The technology of three-zone heating of granules inside the extruder ensures a uniform supply of material and high quality of the resulting product.

In addition to standard print pellets (ABS, PLA, PP, PE, etc.), the printer allows printing with recycled plastic pellets PET, PP, ABS, HDPE, LDPE, etc.

Pellets are much cheaper than classic filament yarn, and the resulting products are perfectly post-processed - turning, milling, etc., which allows the introduction of additive technologies into the production chain of the enterprise.

The technology is suitable for creating disposable molds, punches, dies for laying out composites, prototyping, making mockups, etc.0003

Press Camera

Heated to 100 ° C with convection

Press area

1000*600*1000 mm

Plant Plot

Pacific Heater to 160 ° C. Printing Plant with

User Interface

own electronics and intuitive interface

Screw extruder

screw extruder (up to 500°C) allows you to quickly create large-sized products

(production up to 3 kg / h)

High -quality mechatronics

Precision guides and SHVP provide high accuracy of movement and repeatability of the products

Print camera

Heated to 100 ° C Camera

Press area

1000*1000 mm 9000 mm 9000 mm 9000 9000

160°C quick-change print platform with auto-calibration

User Interface

own electronics and intuitive interface

Screw extruder

screw extruder (up to 500°C) allows you to quickly create large-sized products

(capacity up to 3 kg / h)

Order

User Interface

Own electronics

For printer 9001 3 intuitive interface minimal training is required, by looking at the interface, you will immediately understand how to manage it.

User Interface

Own

electronics and intuitive interface

Minimal training is required to operate the printer, by looking at the interface, you will immediately understand how to operate it.

Print chamber

Heated chamber with convection up to 100°C

Forced convection of the chamber and uniform warm-up allows printing high details with good adhesion between layers. Details do not delaminate or deform.

Print chamber

Heated chamber with convection up to 100°C

Forced convection of the chamber and uniform warm-up allows printing high details with good adhesion between layers. Details do not delaminate or deform. nine0003

Extruders

Pellet extruder

The technology of three-zone heating of the pellets inside the extruder ensures uniform material supply and high quality of the resulting product.

Extruders

Pellet extruder

The technology of three-zone heating of the pellets inside the extruder ensures uniform material supply and high quality of the resulting product.

Built-in filters

Built-in air filtration system traps all unwanted particles

When heated, some plastics can release harmful substances, such as vapors from styrene derivatives, hydrocyanic acid, acetaldehyde.

Built-in high temperature filters not only block harmful particles but also odors.

Built-in filters

Built-in air filtration system traps all unwanted particles

When heated, some plastics can release harmful substances, such as fumes from styrene derivatives, hydrocyanic acid, acetaldehyde. nine0003

Built-in high temperature filters not only block harmful particles but also unpleasant odours.

Print platform

Quick change print platform

heated to 160°C

Quick release print platform makes printing quick and easy.

This avoids damage to larger models and allows the printer to be used almost without interruption between print runs.