Buy 3d printing materials

Fillamentum 3D Printing Filament | MatterHackers

Technical Specifications

- Filament Diameters available: 1.75mm and 3.00mm

- ASA filament is very similar to ABS, but with greater UV resistance

- Timberfill filament is potentially abrasive, so a High Performance nozzle is necessary

Fillamentum

Fillamentum ASA Series

A rugged weather-resistant material that is much more resistant to UV light.

Fillamentum ExtraFill Series

An excellent baseline PLA that prints amazingly well.

Fillamentum FlexFill Series

Flexfill is rubbery and elastic, making it impact, oil and abrasion-resistant.

Fillamentum Crystal Clear Series

An incredible line of semi-transparent, colored materials.

Fillamentum TimberFill Series

Made from a PLA base with wood particulate, Timberfill gives you 3D prints that look like they were carved from wood.

Fillamentum Vertigo Series

Vertigo PLA series reflect light and create awesome, eye-catching prints with flecks of gold, silver and blue.

Fillamentum Extrafill ABS Filament

Premium ABS Filament with a wide variety of vibrant colors.

Fillamentum PVC Vinyl Filament

Fillamentum PVC Vinyl Filament

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

Ultimate Materials Guide - Tips for 3D Printing with PETG

Overview

PETG is a Glycol Modified version of Polyethylene Terephthalate (PET), which is commonly used to manufacture water bottles. It is a semi-rigid material with good impact resistance, but it has a slightly softer surface which makes it prone to wear. The material also benefits from great thermal characteristics, allowing the plastic to cool efficiently with almost negligible warpage. There are several variations of this material in the market including PETG, PETE, and PETT. The tips in this article will apply to all of these PET-based filaments.

The tips in this article will apply to all of these PET-based filaments.

- Glossy and smooth surface finish

- Adheres well to the bed with negligible warping

- Mostly odorless while printing

- Poor bridging characteristics

- Can produce thin hairs on the surface from stringing

Hardware Requirements

Before 3D printing with PET / PETG make sure your 3D printer meets the hardware requirements listed below to ensure the best print quality.

Bed

Temperature: 75-90 °C

Heated Bed Recommended

Enclosure Not Required

Build Surface

Glue Stick

Painter’s tape

Extruder

Temperature: 230-250 °C

No special hot-end required

Cooling

Part Cooling Fan Required

Best Practices

These tips will help you reduce the chances of common 3D printing issues associated with PET / PETG such as stringing, oozing, and poor bed adhesion.

Invest In a Good Build Surface

Some 3D printers come with a glass bed or blue painter’s tape installed on the bed. Although these surfaces might work fine for PETG, we recommend using a heated build platform for best results. The heated bed can significantly improve the first layer adhesion, making things much easier for future prints. Many of these heated beds come with a glass surface, allowing you to print directly on the bed without needing to apply any additional layers of tape or glue.

Although these surfaces might work fine for PETG, we recommend using a heated build platform for best results. The heated bed can significantly improve the first layer adhesion, making things much easier for future prints. Many of these heated beds come with a glass surface, allowing you to print directly on the bed without needing to apply any additional layers of tape or glue.

Calibrate Retraction Settings to Reduce Stringing

One of the few common issues that we see with PETG is stringing. These strings are thin hairs, similar to a spider web, that run between the different surface of your 3D print. Preventing these strings requires precisely calibrated retraction settings, so make sure to adjust your retraction distance and speed for the best results. Simplify3D also includes several useful features that can further reduce stringing. The first is called Coasting, which works by reducing the pressure in the nozzle right before the end of a segment. This way, when moving to the next segment, there is less pressure in the nozzle, so you are less likely to see stringing and oozing during that move. Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model. If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

Another great option can be found on the Advanced tab of your Simplify3D process settings. By enabling the “avoid crossing outline for travel movements” option, the software will automatically adjust the travel movements of your print to stay on top of the interior of your model as much as possible. This means that the strings stay inside of your part where no one can see them, instead of being on the outside of your model. If you are looking for more tips to reduce stringing, we have an entire section dedicated to this issue on our Print Quality Guide: How to Reduce Stringing and Oozing.

Optimize Extruder Settings to Prevent Blobs and Zits

When 3D printing at higher temperatures associated with PETG, you may notice small blobs or zits on the surface of your model. These print defects typically occur at the beginning or end of each segment, where the extruder has to suddenly start or stop extruding plastic. There are several ways to eliminate these print defects such as enabling “Extra Restart Distance” or “Coasting” options located in the Extruder tab. Simplify3D also includes an option to perform a dynamic retraction, where the filament is retracted while the extruder is still moving. This completely eliminates blobs that are typically formed from a stationary retraction. To learn more about these features and other tips for reducing blobs on the surface of your print, please refer to our Print Quality Guide.

Simplify3D also includes an option to perform a dynamic retraction, where the filament is retracted while the extruder is still moving. This completely eliminates blobs that are typically formed from a stationary retraction. To learn more about these features and other tips for reducing blobs on the surface of your print, please refer to our Print Quality Guide.

Pro-Tips

- The glossy surface of PETG is especially useful when using rafts. The part separates easily from the raft and maintains a clean surface finish.

- Try disabling your part cooling fan for the first few layers of the print to prevent warping. This trick especially works well for larger prints.

Get Started with PET / PETG

Now that you are ready to start printing with PET / PETG, here are a few ideas to help you get started – from common applications to popular filament brands.

Common Applications

- Water proof applications

- Snap fit components

- Planter Pot

Sample Projects

- Self-watering Planter

- Water Bottle

- Snap Fit Parts

Popular Brands

- ColorFabb PETG

- eSun PETG

- E3D Spoolworks Edge

- Hatchbox PETG

- HobbyKing PETG

Consumables for 3D printers.

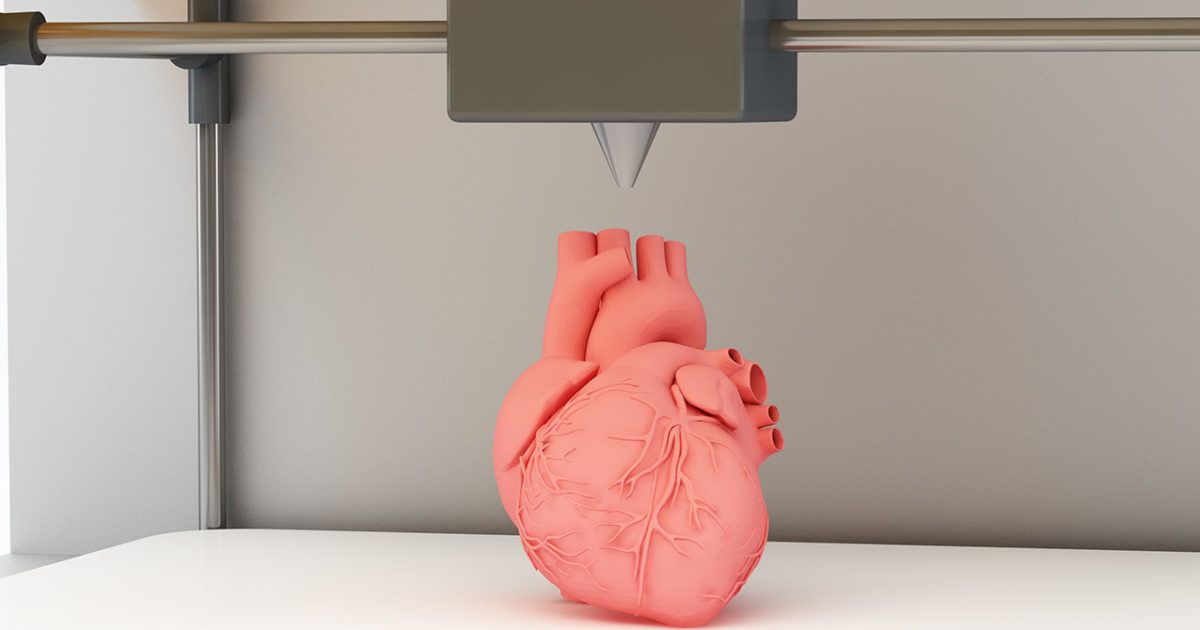

What and how to print.

What and how to print. Consumables for 3D printers: What and how to print? Here you will find answers to this question, as well as information about the latest materials available and in development.

brtv

Loading

12/11/2022

1670

Consumables

23

Follow author

Follow

Don't want to

This attribute of women's clothing looks exciting...

Today I will try to make some things out of this material by heat treatment and 3D printing. I had 10 tights at my disposal.

I thought this product was made of nylon, but it wasn't there.

The product has seams. I don’t know what threads they are sewn with, but what if something like cotton that does not melt. This will inevitably clog the nozzle. I'll have to cut them out....

I'll have to cut them out....

Read more

Consumables

38

Subscribe to the author

Subscribe

Don't want

At the 3Dtoday Fest "Volgobots" talked about the magic filament, which is cooler and more convenient than your polyamides. And you don't have to dry it. Brews "Nit" and calls it "NIT-ING". Of course, it is impossible to print on ordinary printers, because an active thermal camera and a table 150+ are required. Became interesting. nine0003

Read more

Consumables

eleven

Subscribe to the author

Subscribe

Don't want

Good day everyone!

Got a new product from Eryone - Duocolor Crystal Washable Resin for 3D printing. I heard about it about a year ago and was really looking forward to when the Chinese would start deliveries to Russia. This photopolymer resin is produced by the Chinese manufacturer Eryone, supplied from a warehouse in Moscow. Suitable for almost any SLA printer with a wavelength of 395-405nm.

I heard about it about a year ago and was really looking forward to when the Chinese would start deliveries to Russia. This photopolymer resin is produced by the Chinese manufacturer Eryone, supplied from a warehouse in Moscow. Suitable for almost any SLA printer with a wavelength of 395-405nm.

This photopolymer resin is based on a water washable resin and the model made from it is...

Read more

Consumables

twenty

Subscribe to the author

Subscribe

Don't want

After reading a few reviews from Ilya and Alexander on the budget composite rPETG GF from REC, I decided to personally familiarize myself with this filament and ordered a black spool. As a result, I was very pleased with the plastic with its ease of printing, the chic surface of the printed parts, and in general - it is pleasant to work with the material. nine0003

nine0003

Read more

xolodny

Loading

11/17/2022

956

Consumables

4

Subscribe to the author

Subscribe

Don't want

As a preface:

- You ate everything again!

- I'm very sorry, I'm very hungry ...

Somehow they sent me some spools of various SolidFilament plastics for tests and reviews. nine0003

Here, here, I immediately went into "production" with ABS, but my hands reached TPU only now, after almost 3 years.

Stosh.

I have never printed with pure TPU before, and all experience with "flex" is limited so far...

Read more

Consumables

eighteen

Subscribe author

Subscribe

Don't want

I remember all your cracks, ePA-CF!

Until some time, my acquaintance with composites of different grades was easy and cloudless. Materials always have their own specifics, but I found my own niche for each of them without any problems. There were also unsuccessful materials, but the one that will be discussed today is different. He's not bad, really. It simply should not be a composite - all this filling only harms it. However, first things first.

Materials always have their own specifics, but I found my own niche for each of them without any problems. There were also unsuccessful materials, but the one that will be discussed today is different. He's not bad, really. It simply should not be a composite - all this filling only harms it. However, first things first.

When in one...

Read more

nine0002 Consumables23

Subscribe to the author

Subscribe

Don't want

Hairy glass and children's pool

As you could see from the previous article, I am often asked to print something, if possible, designed for a direct hit by a nuclear warhead. For children, as a rule - they have comparable destructive power. So the acquaintance with the Filamentarno Total Pro GF-30 composite began with the same request. nine0003

They asked me to print the corners for the nets of an old children's pool table to replace the dead celluloid ones. At the same time setting...

At the same time setting...

Read more

Consumables

five

Subscribe to the author

Subscribe

Don't want

About two weeks ago I received new items - three-color PLA plastic from Eryone.

The manufacturer continues to increase the number of colors in the bar, and although we recently considered a two-color filament, a three-color filament is now available for sale. It gives a smoother gradient on the finished product. The basis of plastic is PLA, silk shades. nine0003

Four varieties:

• Red blue green

• Golden silver copper...

Read more

Consumables

28

Subscribe to author

Subscribe

Don't want to

Buttermilk for a catapult, or fluffy carbon fiber

My next foray into researching printing with composites began with a simple request from a little boy to fix his toy catapult. Purchased original was injection molded from ABS. It was dropped from the second floor, then ridden over with a scooter and apparently hit a couple of times with a hammer or something else hard in an attempt to repair the crack that had formed. In general, the catapult was destroyed, and in the formulation of the task, the emperor sounded ...

Purchased original was injection molded from ABS. It was dropped from the second floor, then ridden over with a scooter and apparently hit a couple of times with a hammer or something else hard in an attempt to repair the crack that had formed. In general, the catapult was destroyed, and in the formulation of the task, the emperor sounded ...

Read more

Consumables

42

Subscribe to the author

Subscribe

Don't want to

Trying out a pen: not a child's toy

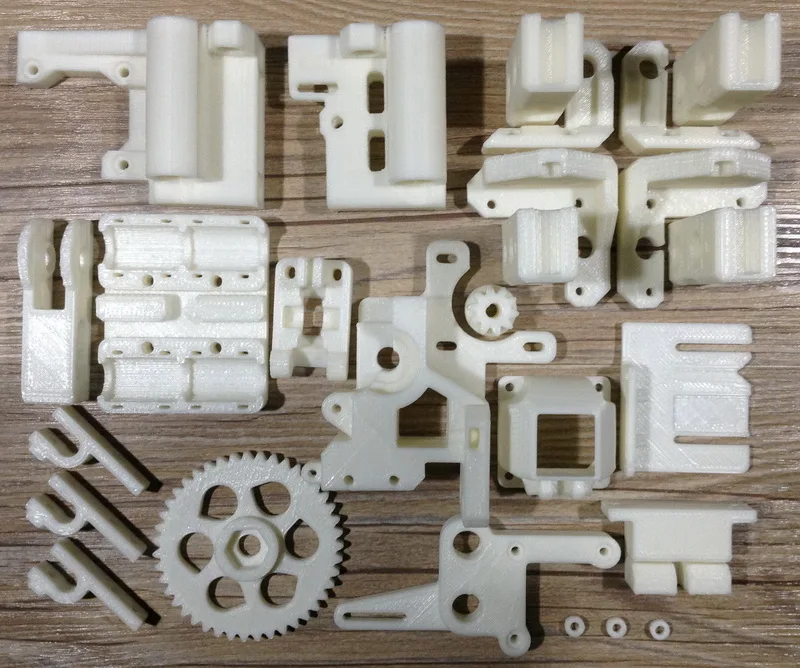

My acquaintance with composites began with the fact that the existing Qidi I-mate S printer ceased to satisfy me. Mainly in the head and extruder parts. There is Mk10 on a Teflon tube, and printing at temperatures above 260 is impossible. In practice, this temperature is limited to rather 250 - I changed the clogged tube several times when I printed at higher temperatures. In other words, I learned to print with composites in order to print with composites - well ...

In other words, I learned to print with composites in order to print with composites - well ...

Read more

- 1

- 2

- ... nine0209 103

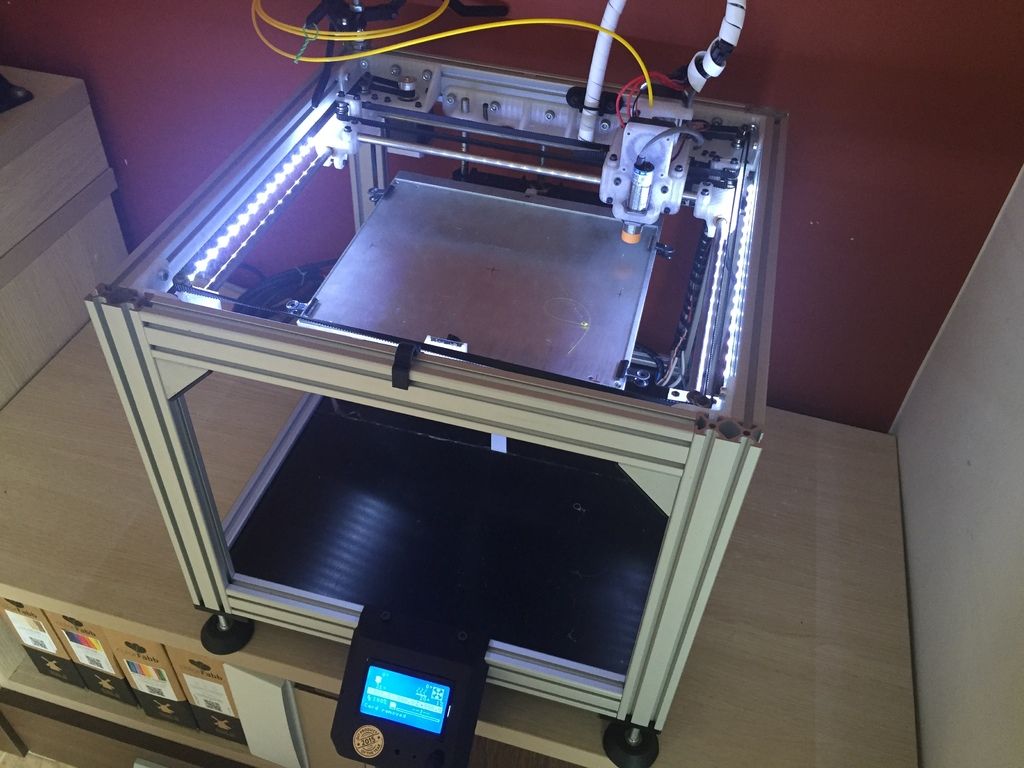

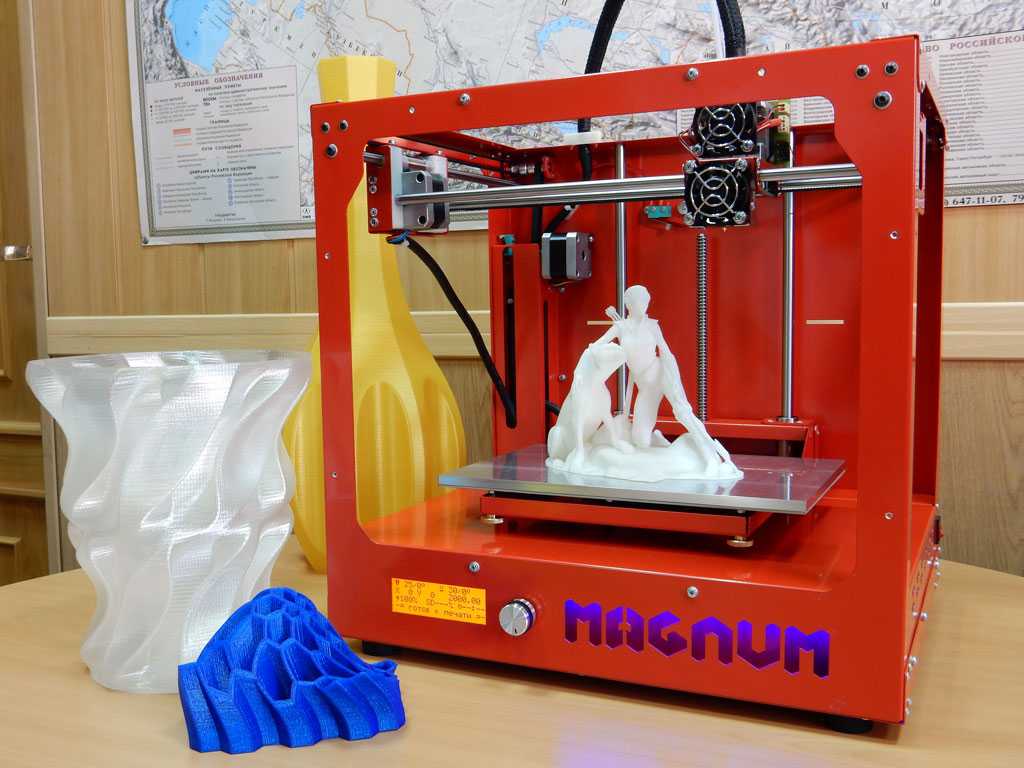

What is a 3D printer?

What is the best plastic for 3D printing? Let's figure it out together!

Plastic for 3D printing

After purchasing your own FDM 3D printer, as well as in the course of choosing it, it becomes necessary to choose the right plastic for 3D printing. But how to do this if you are new to 3D printing and have little to no understanding of this issue? Plastic for printing on a 3D printer is in most cases the main component of successful product reproduction. Therefore, we will not save on knowledge, and will tell you how to choose the best plastic for 3D printing. nine0003

But how to do this if you are new to 3D printing and have little to no understanding of this issue? Plastic for printing on a 3D printer is in most cases the main component of successful product reproduction. Therefore, we will not save on knowledge, and will tell you how to choose the best plastic for 3D printing. nine0003

Types of plastic for a 3D printer

First of all, you need to consider the types of plastic for a 3D printer. Plastic for 3D printing, or filament, is produced in the form of a thin thread with a diameter of 1.75 mm and 3 mm. Most often, filaments with a thickness of 1.75 mm are used in the basic configuration, but some manufacturers of 3D printers provide the ability to install a 3 mm plastic feed system. Plastic for 3D printing has many varieties, among which the most common are ABS and PLA plastic. nine0003

Plastic for 3D printing: varieties

By popularity in the Ukrainian market, the following types of plastic for 3D printing can be distinguished:

- PLA (PLA) or polylactide.

Organic and short lived. Suitable for 3D printing of decorative products, but not able to withstand high mechanical loads;

Organic and short lived. Suitable for 3D printing of decorative products, but not able to withstand high mechanical loads; - ABS (ABS) or acrylonitrile butadiene styrene. It has a long life and excellent mechanical properties. Heat-resistant and used for industrial purposes. Shrinks on cooling. It is recommended to print in ventilated areas; nine0210

- PVA (PVA) or polyvinyl alcohol. A water-soluble material that is used as a support;

- Nylone (Nylon). An alternative to ABS plastic, suitable for many engineering structures. When printing with nylon, it is recommended to ventilate the room;

- HIPS (High Impact Polystyrene). In terms of physical properties, it is a cross between PLA and ABS. May also emit toxic fumes when printed.

Other questions and answers about 3D printers and 3D printing:

What is the best plastic for a 3D printer?

In fact, there are many more types of plastic for 3D printing. This can include flexible, fluorescent and luminescent filament, wood and metallized materials. But in practice, such consumables are rarely used and are needed for narrowly specific purposes. Metallized plastics are interesting in their own right, but they are at the initial stage of development and are inferior in performance to ordinary reinforced materials. “And what plastic is best for a 3D printer?” - you ask. You should choose based on specific goals. If you intend to print decorative elements that will not be subject to payload, you can look at PLA plastic. If your goal is to print gears, structural parts and other things, look at reinforced materials for 3D printing. nine0003

But in practice, such consumables are rarely used and are needed for narrowly specific purposes. Metallized plastics are interesting in their own right, but they are at the initial stage of development and are inferior in performance to ordinary reinforced materials. “And what plastic is best for a 3D printer?” - you ask. You should choose based on specific goals. If you intend to print decorative elements that will not be subject to payload, you can look at PLA plastic. If your goal is to print gears, structural parts and other things, look at reinforced materials for 3D printing. nine0003

What kind of plastic to print with?

Please note that not every printer supports the full range of 3D printing materials. Before buying a specific filament, check the specifications of your own device to avoid wasting money. The rest is up to you and your imagination. A huge range of colors and shades of plastic is available for sale, matte and glossy, semi- and fully transparent materials.