3D print chain

Chain best 3D printer files・Cults

2023 Keyholder

Free

Chain Track and Machine Gun for Clim T206 Tank

Free

Mario Mushroom Keychain

€0.71 -10% €0.63

Chain_Print In Place_V1

€2.20

Chain cover tensioner 125 rotax

€1

Coffee Bean Chain

€1.85

Kingdom Hearts Keyblade

Free

KEYCHAIN AFA 3 STARS ARGENTINA

€0.81

world champion argentina fifa keychain

€1.43

Makima Chainsaw Man

€7. -25% €5.72 62

Key Rack Thing

Free

Happy 2023 Key chain - Crex

Free

Cable guide chain

€10.18

Chain attachment for diamond tool head

Free

Mario - PENGUIN KING / PENGUIN KING / key chain

€1.86

DEEZ NUTS - Gag Christmas Tree Ornament | Keychain

€0.99

POCHITA CAPIBARA CAPOCHITA

€1.52

Volvo S60/V60 keychain

€1

EMILLY KEY CHAIN

€0.68

WILLIAM KEY CHAIN

€0. 68

68

Jacob Key Chain

€0.68

Issabelle Key Chain

€0.68

Doris Key chain

€0.68

Cat

Free

Xbox key chain

Free

MESSI

Free

PRINCESS KEY CHAIN

€0.68

GEORGE KEY CHAIN

€0.68

MADISON KEY CHAIN

€0.68

ELLIE KEY CHAIN

€0.68

Chain Octopus

Free

LOVE YOU KEY CHAIN

€0.91

Xdesign logo keychain

Free

KEY CHAIN

€0. 68

68

Aprilia key chain

€0.50

JW.org Ear saver - Deluxe version

Free

Que mira bobo, anda pa ya - MESSI - Llavero + Mate

€1.87

Bow tie for buttplug keychain

€0.99

Chinese hat for buttplug keychain

€0.99

Cowboy hat for buttplug keychain

€0.99

Chain Chomp Mario Based

€3.76

Pochita chainsaw man

€5

The ClipBox Keychain

€0.61

Pull Chain Redirector

Free

Sprocket cover XR 150

€2. -10% €1.95 16

16

Harry Potter Heart Key Chain

€0.50

Platform 9 3/4 harry potter key chain

€0.50

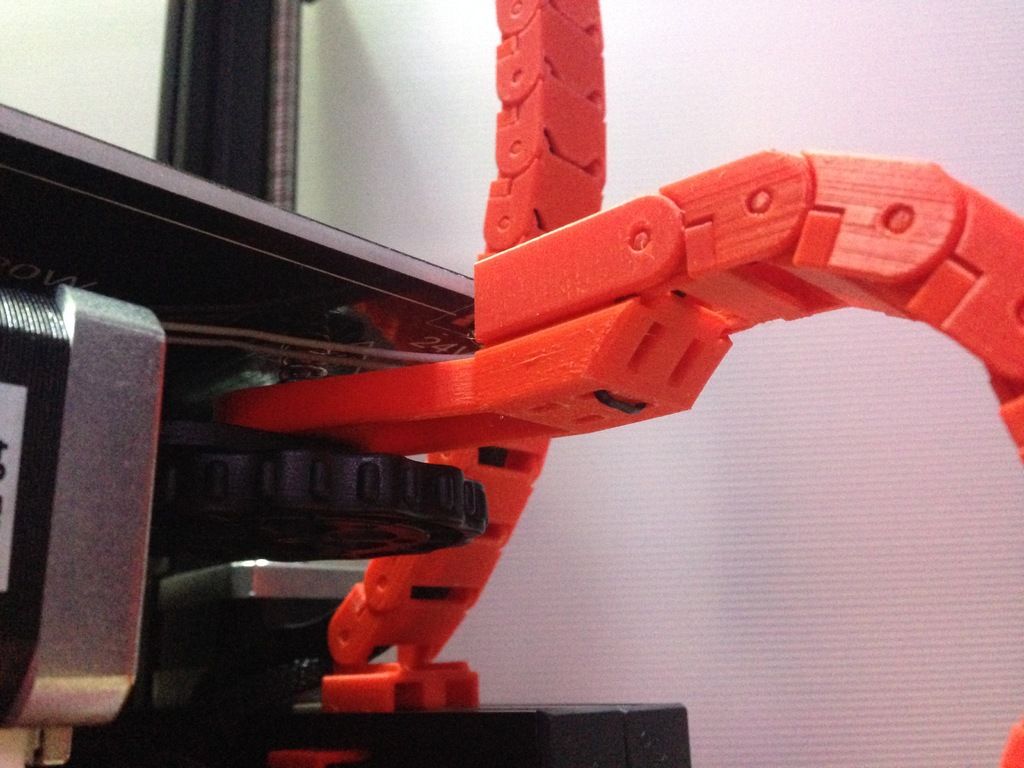

Cable Chain 15x30mm Flexible Drag

Free

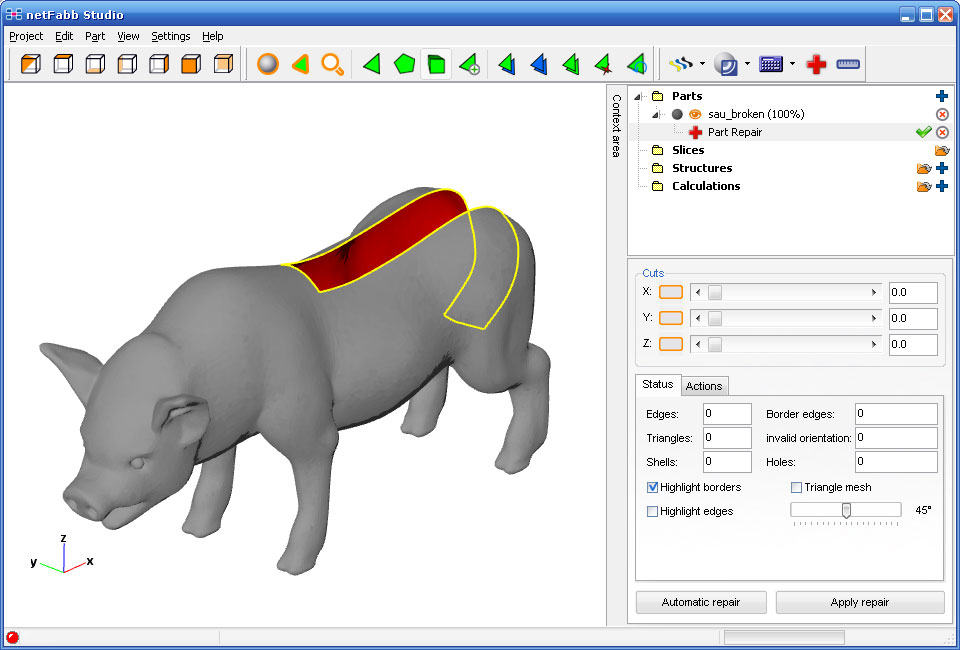

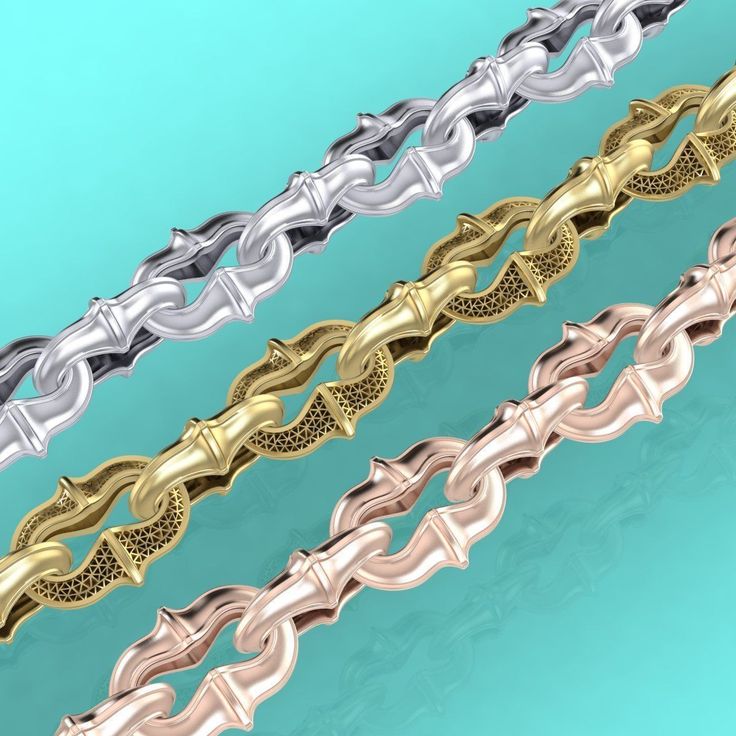

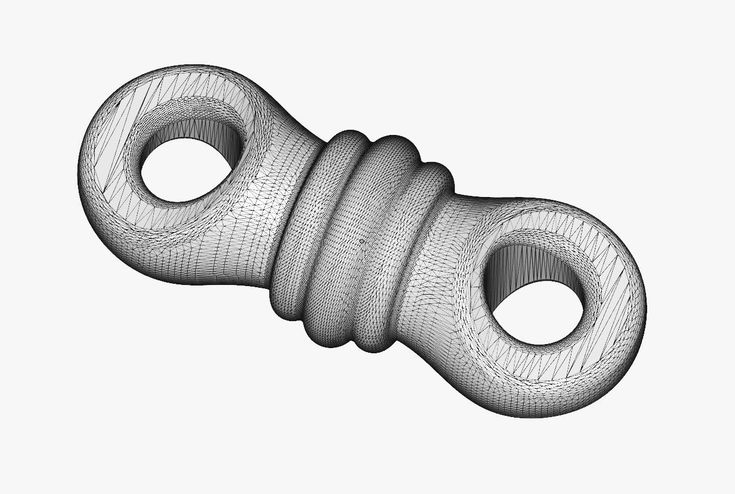

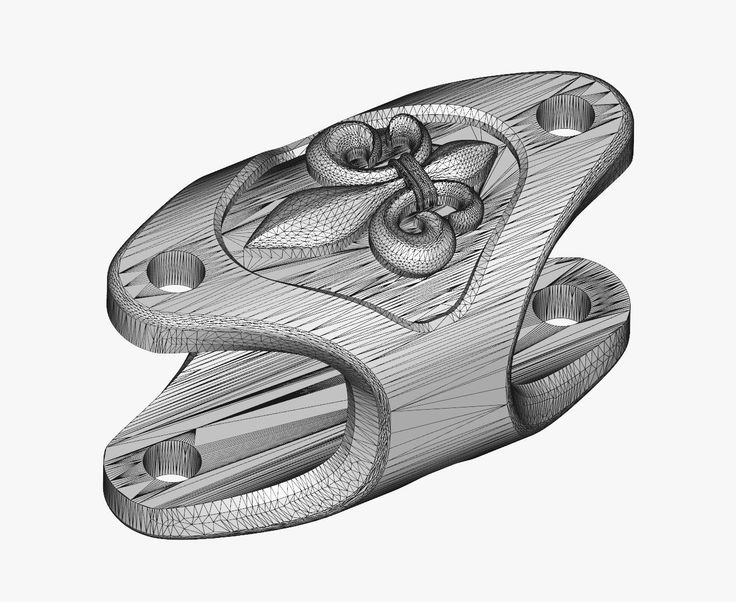

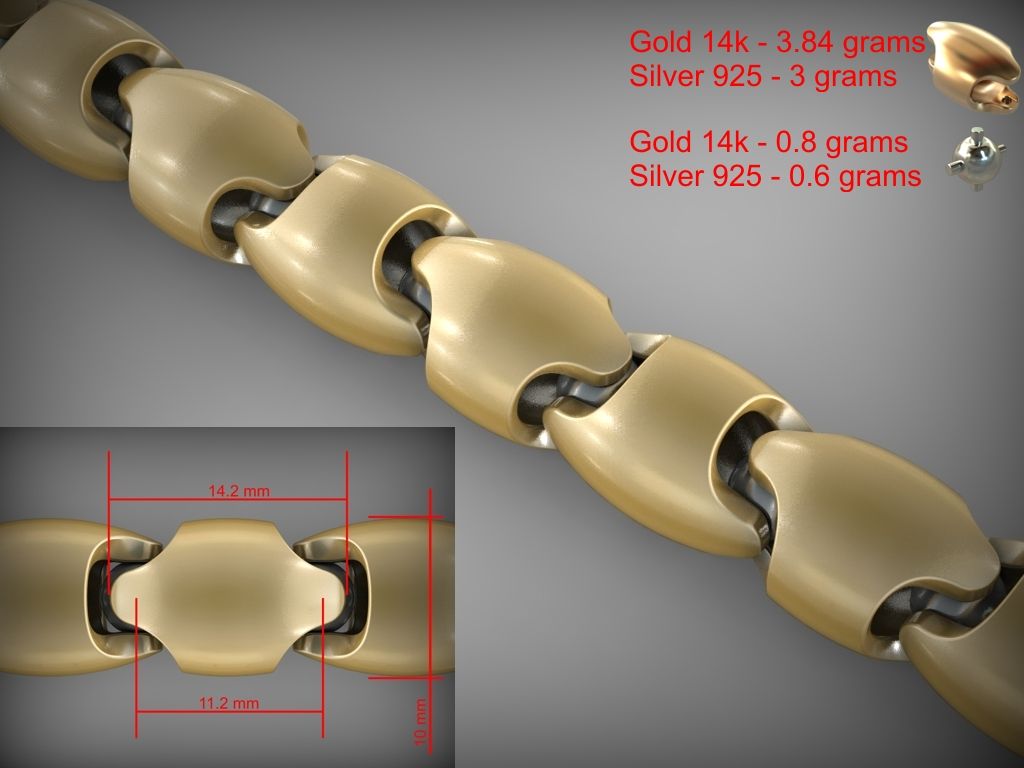

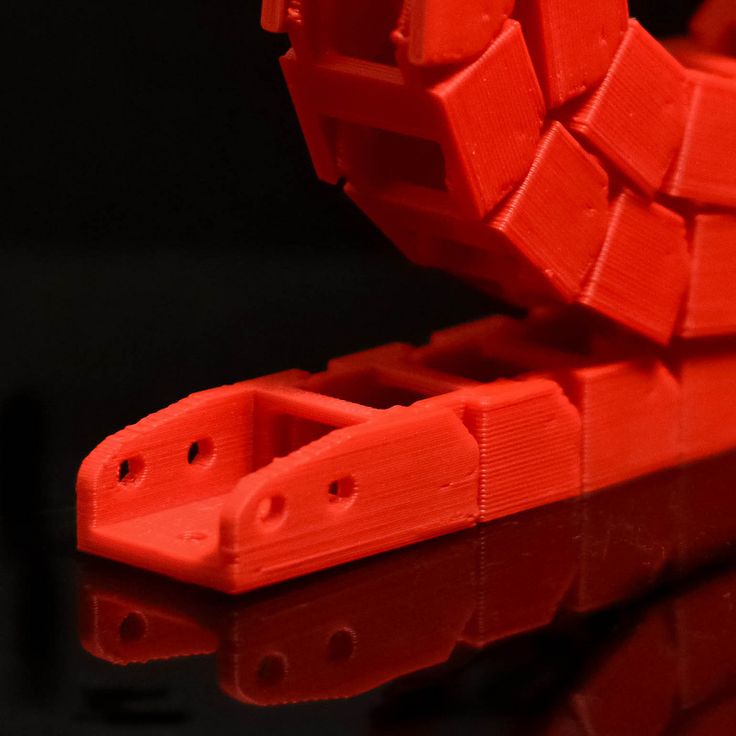

3D Printed Interlocking Designs

Interlocking links are a versatile design that is often difficult to produce with traditional manufacturing. Interlocking links essentially means a chain that connects together. Usually, each individual link has to be created separately, but with 3D printing, this process is much faster and the whole chain can be created together thanks to proper 3D printing design and unpacking technology.

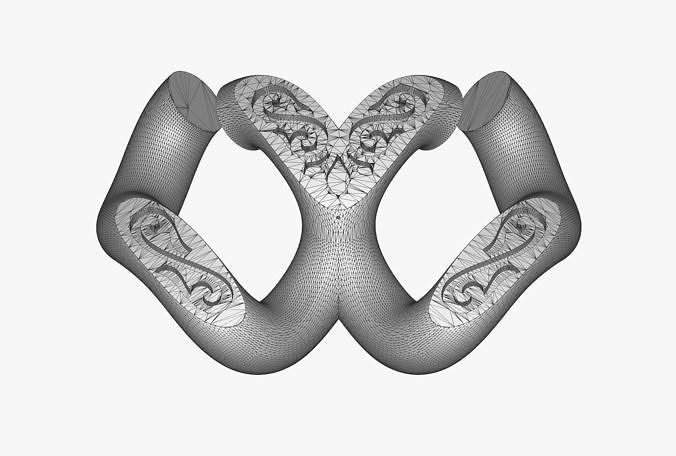

One of the most interesting uses for interlocking links is creating chainmail, which is essentially a fabric made by linking loops together. Visually, it is very striking and might be a popular choice for any fabric product. Practically, it is flexible and pretty tear-proof.

Practically, it is flexible and pretty tear-proof.

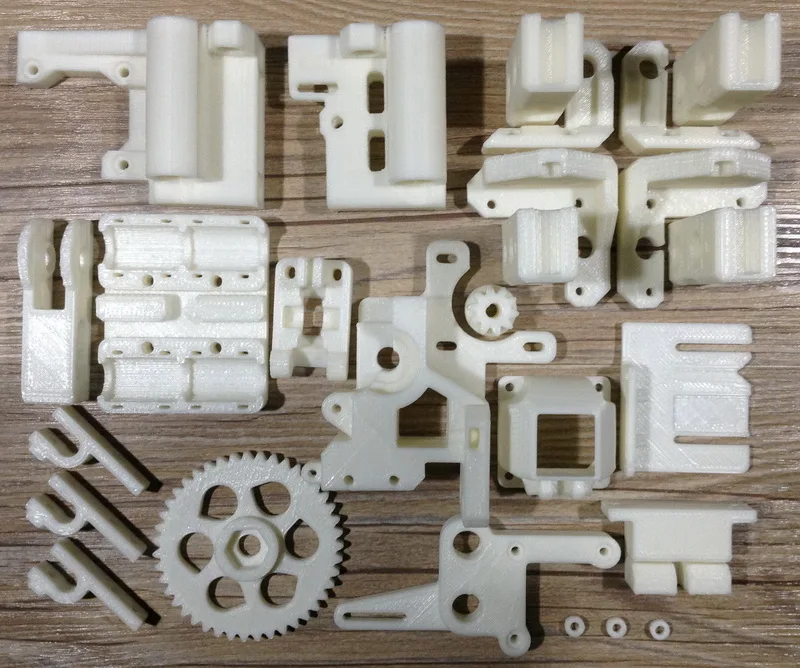

Desktop 3D printers can create links separately. These designs should be created with gaps that allow the links to be snapped together later. There is a lot of diversity that can be added to these 3D printed chain links. You can change the shape and texture. Regardless of the modifications, it is likely you will have to put these links together by hand after printing.

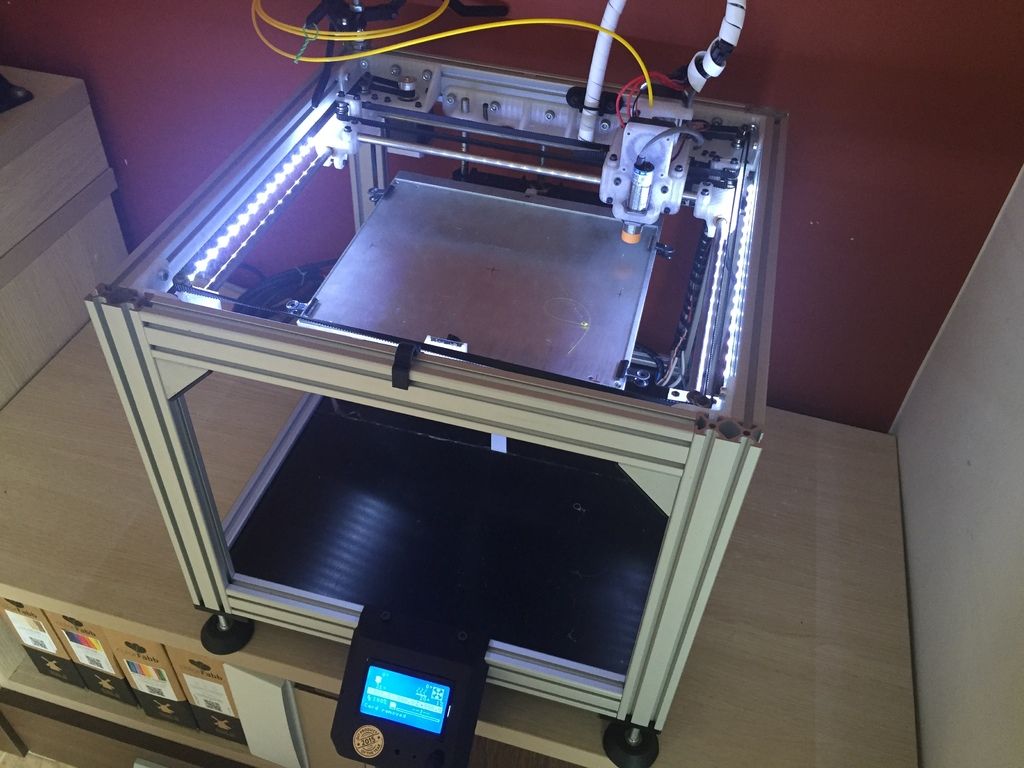

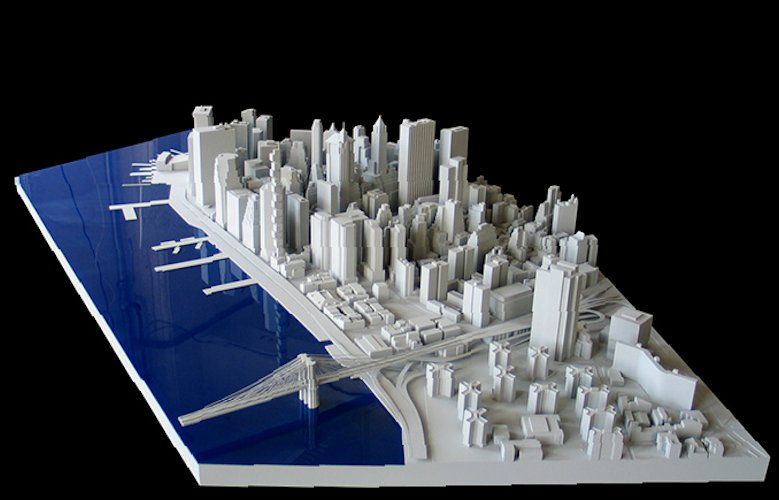

With industrial printers, 3D interlocking patterns become much simpler and interesting to print. The size of products and level of detail that an industrial 3D printer can create open a host of options for creating interlocking link patterns.

With the right industrial 3D printer and careful design, links can be printed already linked and in place. A flat sheet of links can be printed up to the size of the print area, or an even larger area can be printed by folding the sheets over each other in a configuration something like a folded towel. This also applies to ordinary chains as well; with careful folding, a chain longer than the printing bed can be easily printed.

Chainmail is all based upon one pattern of links. There are many different options out there (check out some of the designs found on https://www.mailleartisans.org/) but the most common and basic is a set of five links with four of them linked to a central one in a four-in-one design. These links are commonly basic round shapes, but you can opt to design any shape or texture you like or need.

This common design is not the limit, however, not by a long shot. Print link designs that interlock or complex patterns bound together by links. Use flat central links to create a flat yet flexible surface that you can add raised “pixelated” designs to. Add designs that cover the gaps to create a unique visual effect. Mix and match designs, even, to make something truly unique. The key is ensuring that the design has enough space between the links to print properly and that the links are thick enough to prevent fusing.

A common design approach for 3D printing is optimizing the design to be fully functional with as little material as possible. This can be done for chain links as well to create products that are more economical with their use of printing material and have a unique continuous look.

This can be done for chain links as well to create products that are more economical with their use of printing material and have a unique continuous look.

Link design can also be modified for flexibility and drape. Depending on the shape of the links and their organization, the resulting chain or chainmail can be more flexible or more stiff. Tile-like hexagon designs in particular allow for simple customization depending on the details of their design.

3D printed interlocking designs have an immense amount of creative potential, especially when combined with other aspects of design. If you’re looking for something different for your product, 3D printed chainmail or chains can be just the touch it needs.

JawsTec is more than happy to help you create the perfect 3D interlocking design. Our state-of-the-art 3D printers are perfect for creating large or small linking patterns and our team of experts is more than happy to work with you to take advantage of versatile 3D printed links.

Contact us today for a 3D printing quote!

STL file Printed Cuban Link Chain・3D Printer Design Download・Cults

Best 3D Printer Files in the Fashion Category

Wallet Card Organizer

Free

Tiny Wallet

Free

Knitting needle number 4 mm 5 mm / Örgü Şişi 4 MM 5MM KAFA

0.50 €

Plague doctor mask

Free

Skull badge

Free

Thunder Clip for Apple Pencil 1&2 | iPad

Free

Heart Button

Free

Heart Rate Watch

Free

Bestsellers in the Fashion category

Nike Air Jordan Colorized MMU Multi Material

1,87 €

Croc nuts

0. 95 €

95 €

Messi, what are you looking at, you fool.

2.03 €

FLORK WORLD CUP ARGENTINA 9 KEY RINGS0008

2.11 €

NIKE SHOES

3,50 €

Camera keyring

1.19 €

Harry Styles

2.16 €

Back panel for masks

4.56 €

MAGIC SNAKE, CONNECTED, IN SITE, RIGID, REVITALIZABLE, REPAIRABLE

3.75 €

Cat skull mask ARTICULATED

6 € -34% 3.96 €

Elf ears for Halloween or cosplay - 3 sizes

2. 26 €

26 €

BATCAT HELMET

3,57 €

nine0007 CASH AND CARD HOLDER0,75 €

Curved cap band

1.22 €

Keychain with skull

1.22 €

Gyro-motor factory / Clock factory

2.50 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments of . Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

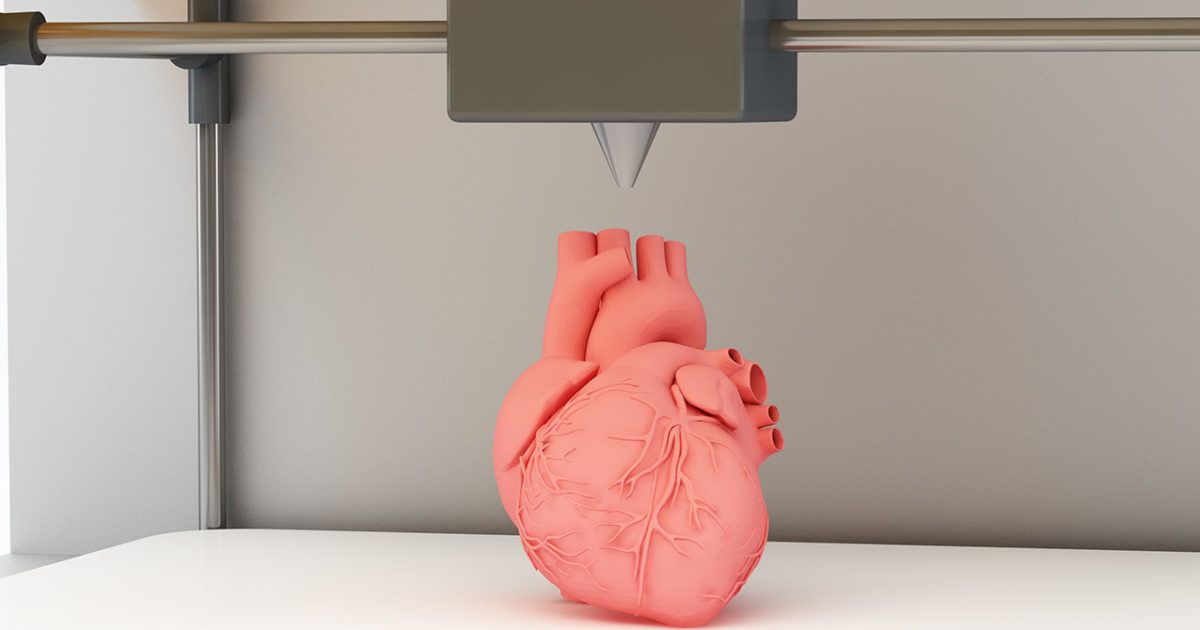

The impact of 3D printing on supply chains

Many industries today rely heavily on manufacturing and supply from China and Southeast Asia, especially in sectors such as manufacturing and logistics. During the global pandemic, disrupted supply chains have affected companies in many industries. Over 94% of FORTUNE 1000 companies said the crisis had severely affected their supply chains. Thus, the pandemic has highlighted the limitations of traditional methods, in particular their lack of flexibility.

Can 3D printing add flexibility to existing supply chains?

In the first few months of the pandemic, 3D printing became an important sector. This has been particularly noticeable in the medical sector, where it has been used to produce emergency equipment for medical personnel and patients worldwide. In a matter of days, 3D printers have managed to create critical devices for the healthcare sector, from masks to ventilator kits, to save lives. nine0006

In a matter of days, 3D printers have managed to create critical devices for the healthcare sector, from masks to ventilator kits, to save lives. nine0006

In the medical sector, 3D printing has been used to urgently produce face shields to protect healthcare workers.

At the same time, manufacturers from all industries also suffered from the limitations of existing supply chains. Particularly due to the lack of local production and long lead times.

So, could 3D printing be part of the solution? nine0115

One of the main advantages of additive manufacturing is its portability. This allows businesses to bring products to local markets faster. Instead of giving preference to mass production in other countries, manufacturers could give preference to developing it locally. Other benefits include greater product customization, less complexity, and faster time to market. For example, imagine a supply chain where the customer will be more involved in the design and production processes (because the price per unit of the part does not change). In fact, every detail can be personalized for the client at no additional cost. nine0006

In fact, every detail can be personalized for the client at no additional cost. nine0006

In addition, additive manufacturing is a much faster way. By combining the components and processes required for manufacturing, complexity, manufacturing costs can be reduced and therefore lead times and time to market can be reduced. While traditional parts need to be prefabricated to exist, 3D printed parts only need a digital file. What's more, shifting to on-demand production could become the norm. This will mean that the need to transport physical goods across countries and continents will decrease, which will have a major impact on warehousing and logistics. nine0006

Manufacturers can increase local production with AM CNC, will always be more competitive. Thus, additive manufacturing has the ability to optimize existing supply chains and close some of the gaps that exist today, but not replace traditional methods. nine0006 How are manufacturers embracing 3D printing? Many companies have not yet integrated 3D printers into their supply chains. Recently, many solutions have emerged to facilitate the adoption of 3D printing, including communication with suppliers. For example, Dassault Systèmes' Make service, part of the 3DEXPERIENCE Marketplace, connects shoppers with over 200 manufacturers in Europe and the US, offering 3D printing, CNC machining, cutting, injection molding, and more. Benoît Schildknecht, Marketing Director at Dassault Systèmes, comments: “ Dassault Systèmes' on-demand manufacturing solution, 3DEXPERIENCE Marketplace Make, enables you to rebuild a more agile supply chain, securely and closer to you, to meet your long-term needs and short-term needs. For a long time, barriers to market entry have been a lack of know-how and initial investment in equipment. This partly explains why 3D printing service providers have grown in volume in recent years. In 2017, Research and Markets predicted in its " 3D Printing Services Market - Global Overview and Forecast 2017-2022" " that the market will exceed $13 billion, with a CAGR of over 28% during 2016-2022. Service providers are able to overcome the barriers that companies face in the early stages of integration, when they have not yet figured out how they will invest in 3D printing in the long term.

For a long time, barriers to market entry have been a lack of know-how and initial investment in equipment. This partly explains why 3D printing service providers have grown in volume in recent years. In 2017, Research and Markets predicted in its " 3D Printing Services Market - Global Overview and Forecast 2017-2022" " that the market will exceed $13 billion, with a CAGR of over 28% during 2016-2022. Service providers are able to overcome the barriers that companies face in the early stages of integration, when they have not yet figured out how they will invest in 3D printing in the long term.

Learn more