3D printing in san francisco

High quality 3D printing service in San Francisco

Get high quality 3D printed parts, prototypes and models in no time.

No signup required.

Contact us

What makes PrintAWorld different from the other San Francisco 3D printing companies out there

Get high quality parts

Our SLA 3d printer can print high resolution parts that other large format printers can only dream of.

Fast turnaround

On a tight deadline? Need it over the weekend? We can help you get your 3d printing project done in no time.

Get expert help

From fixing your 3D file to recommending the best material. We got you covered.

Some of the work that we did for our clients in San Francisco

How our 3D printing service in San Francisco works

0

1

.

Send us a few information

The material you need, quantities and a short description of your project.

If you're unsure, don't sweat it. We will guide you to the perfect solution!

0

2

.

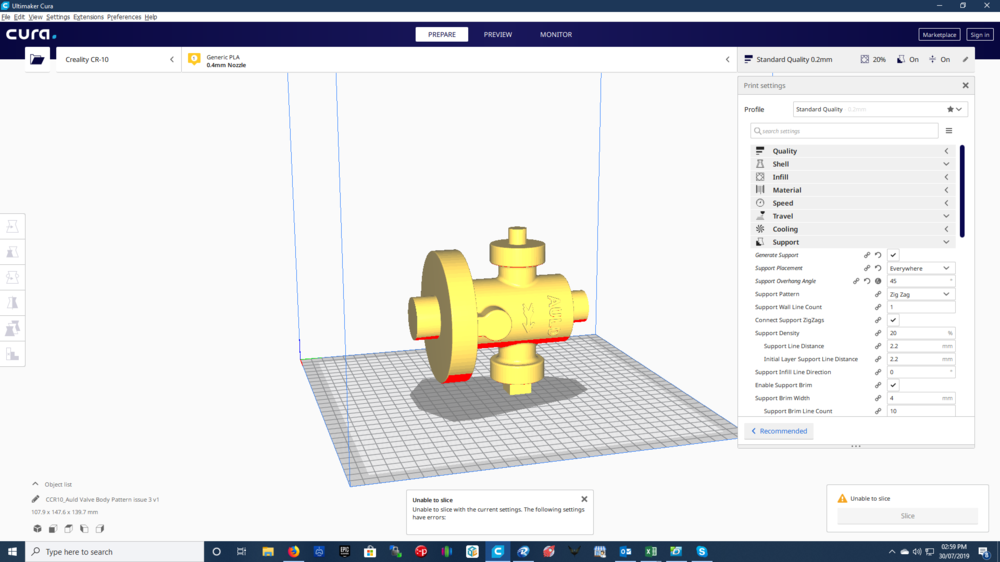

Upload a 3D File

Send us your.stl or .obj files. Don't have a file ready? We also provide a professional 3D modeling service.

0

3

.

Receive a quote

You'll get an email and a call from us immediately so we can talk about the best and most cost effective way to approach your project. No minimum order quantities!

0

4

.

Pay and print

Once the quote is approved we will start 3D printing your idea. We'll keep you updated and we'll make sure the result is exactly what you want or even more.

No minimum orders.

No minimum orders.0

5

.

Shipping or pickup

We offer nationwide delivery or you can pick it up from one of our local studios near you.

3D printing technologies that we use

These 3D printing technologies are what powers our 3D printing process

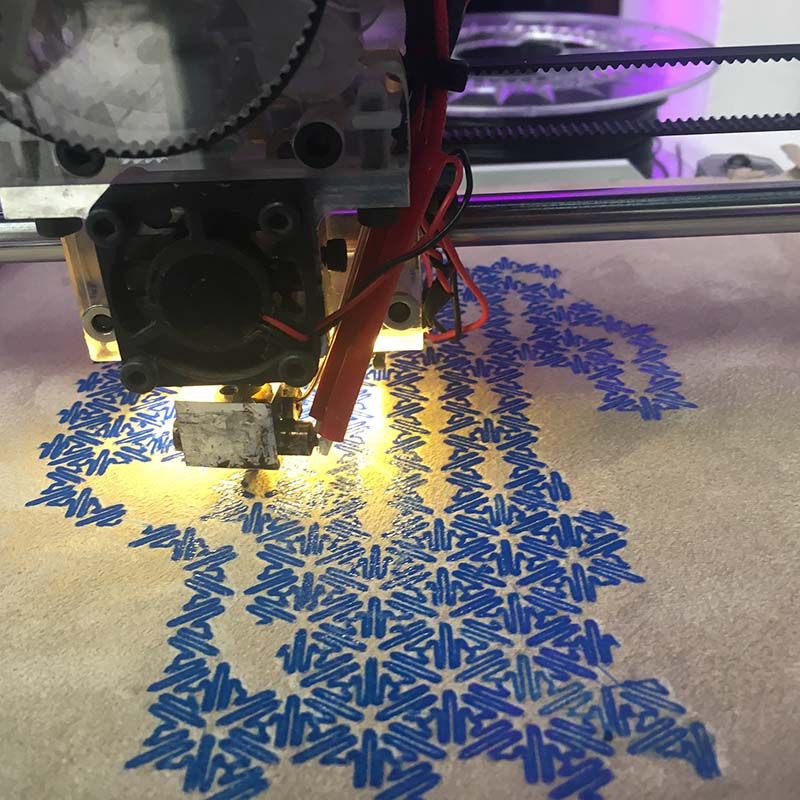

Fused Deposition Modeling (FDM)

We use Fused Deposition Modeling (FDM) for low-cost and simple 3d printed parts. We don't use this process as much because we find the quality lacking and the amount of post processing work involved negates the money you save from low material cost. This is good for prototyping but for manufacturing end products, they might not be cost effective as there are better printing methods. If you want to produce low-cost end use parts at a large volume, injection molding might be a better solution.

Selective Laser Sintering (SLS)

Selective laser sintering is another great additive manufacturing technology for rapid prototyping. SLS allows us to 3d print objects in different materials such as nylon and metal at large volume without the need for supports. SLS greatly reduces the time spent for post-processing.

SLS allows us to 3d print objects in different materials such as nylon and metal at large volume without the need for supports. SLS greatly reduces the time spent for post-processing.

Stereolithography (SLA)

Stereolithography allows us to 3d print accurate and high resolution prototypes . We us this process to create functional prototypes that are highly detailed. We recommend SLA for almost any 3d printing projects because we believe it produces the highest quality prints.

Multi-Jet Fusion (MJF)

Multi Jet Fusion is what helps us 3d print end-use production in 24 hours.

3D printing materials that we offer

Looking for a material that isn't listed here? Shoot us an email at [email protected]

ABS

ABS plastic is a strong and durable material. They're ideal for prototyping mechanical parts. For prototypes that require high-precision, consider CNC machining ABS or printing in other materials. For production parts, we suggest using injection molding instead.

Nylon PA12

Nylons is a strong and durable material that is also flexible. Ideal for live hinges and functional parts.

Standard Resin

Perfect for complex 3d models that require high details and smooth finishing.

SOMOS Resin

SOMOS resin is the industrial version of standard resin. It's perfect for almost any 3d that require smooth finishing and high details. We recommend this material for any projects such as high-detailed models, architecture, art sculptures and engineering prototypes.

SOMOS Waterclear 10122 Resin

Somos® WaterClear Ultra 10122 is a clear resin that produces colorless, functional and accurate parts that simulate an acrylic appearance. Parts produced from Somos® WaterClear Ultra 10122 exhibit excellent water and temperature resistance.

Other locations in CA where we offer our 3D printing services

Los Angeles

F.A.Q

How much does custom 3D printing cost?

Custom 3D printing can cost between $25 up to thousands of dollars depending on the size and volume of your 3D model. The 3D printing material used affects the price as well. At PrintAWorld, we use industrial SLA resin for our custom 3D printing as we believe it results in the best results for our clients. If you want to learn more, here's a breakdown of the cost of 3D printing.

The 3D printing material used affects the price as well. At PrintAWorld, we use industrial SLA resin for our custom 3D printing as we believe it results in the best results for our clients. If you want to learn more, here's a breakdown of the cost of 3D printing.

Do you offer shipping in San Francisco?

Yes. We offer shipping anywhere in San Francisco, CA. Due to the pandemic, we highly encourage contactless delivery with our clients in San Francisco.

3D Printing Service for San Francisco, California

CapabilitiesCustom Online 3D Printing ServiceCaliforniaSan Francisco

High Quality San Francisco, California 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your San Francisco, California 3D Printing Service: 3D Prototypes and Production Parts

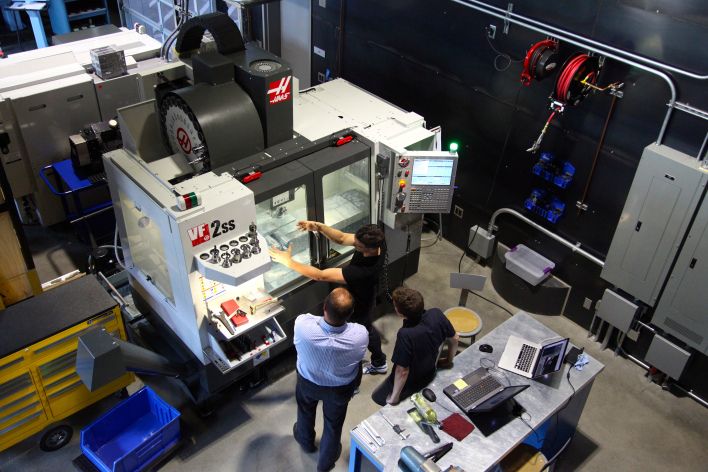

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near San Francisco, California

Oakland

CaliforniaBerkeley

CaliforniaBurlingame

CaliforniaPalo Alto

CaliforniaFremont

CaliforniaMountain View

CaliforniaSunnyvale

CaliforniaSanta Clara

CaliforniaSan Jose

CaliforniaStockton

CaliforniaElk Grove

CaliforniaSacramento

CaliforniaModesto

CaliforniaFresno

CaliforniaCarson City

NevadaReno

NevadaSparks

NevadaBakersfield

CaliforniaOxnard

CaliforniaSanta Clarita

California

Ready to start making custom 3D printed parts?

3D San Francisco! | High-quality 3D printing with high-precision plastic and nylon in Kyiv, Kharkov, Dnipro, Lvov, Odessa at the best price.

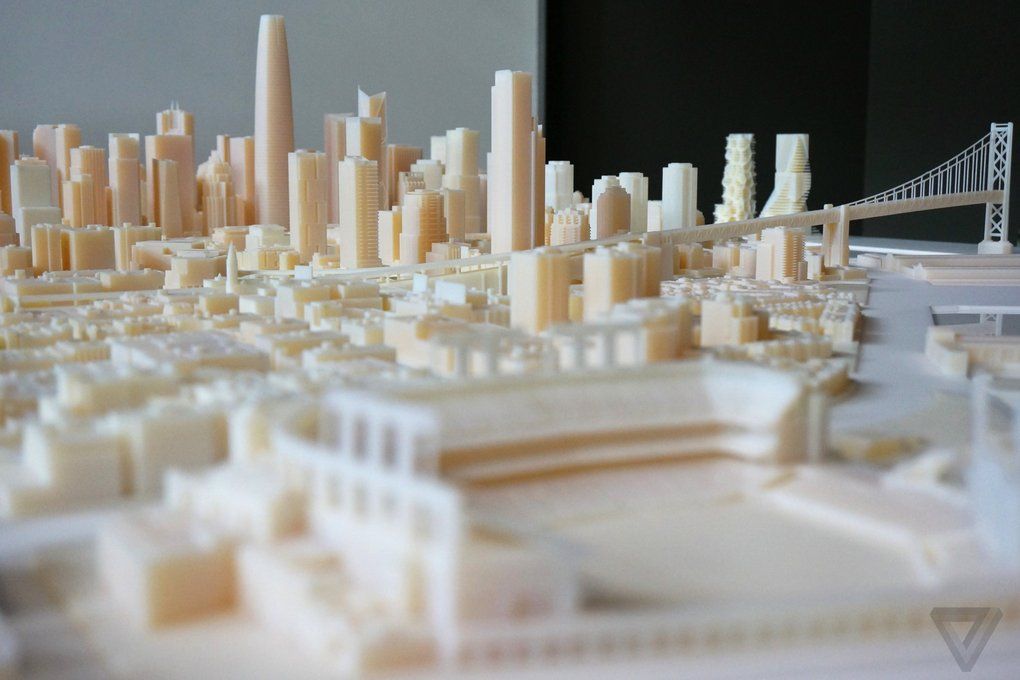

This 3D model of San Francisco is the result of a collaboration between Autodesk and SteelBlue and spans over 115 blocks, including the South of Market and the financial center of the city.

View of the financial center.

So what are the neighborhoods included in this 3D model? This includes AT&T Park, the Ferry Building, and the San Francisco Museum of Modern Art. The project was led by designers from Tishman Speyer and aimed to tell the story of the development of the city in a rapidly changing area of SoMa (South of Market ed.).

This copy of San Francisco can help in the field of urban planning, namely, to enable decision makers to get a better idea of the city as a whole. Compared to a digital copy, this model is presented physically, which means that it is much easier to work with such a model.

“In the work of designers, architects, urban planners, city officials and the general public, there is nothing better than a model city to scale. With the help of 3D printing, we get the possibility of rapid prototyping. We can change individual buildings or entire city blocks to explore urban design options and keep the model up to date in rapidly developing areas,” SteelBlue President O’Brien Chalmers said in a press statement. “The addition of data visualization layers gives us even more opportunities to understand and visualize how new buildings and infrastructure will affect the urban landscape and the people who live and work there.”

With the help of 3D printing, we get the possibility of rapid prototyping. We can change individual buildings or entire city blocks to explore urban design options and keep the model up to date in rapidly developing areas,” SteelBlue President O’Brien Chalmers said in a press statement. “The addition of data visualization layers gives us even more opportunities to understand and visualize how new buildings and infrastructure will affect the urban landscape and the people who live and work there.”

Embankment view.

The model also offers a fresh look at several projects under development, such as the Transbay Transit Center and many other new developments. The model provides a glimpse of what the “future of San Francisco” will look like, and includes buildings that are currently unfinished. Therefore, the model reflects what San Francisco will look like in 2017.

The team used two Objet Connex 500 printers with print accuracy as low as 16 microns to create this 3D model. The printers had to work for two months to print the entire model. Everything was based on a digital model made by the SteelBlue team.

The printers had to work for two months to print the entire model. Everything was based on a digital model made by the SteelBlue team.

More 3D cities are on the way! SteelBlue has shown that physical and digital city models provide great opportunities for city planning. The team is currently printing models of various cities at their headquarters in San Francisco. “We create digital 3D models of cities around the world,” says Autodesk Senior Manager Justin Lockitz. “They are quite useful for urban planning, but sometimes the tactile contact from a physical model gives a much greater insight and understanding that you can't get from a model on a monitor screen.”

You can watch a short video of the project below:

Photos credit: Autodesk / Steelblue / Tishman Speyers.

3D souvenir for yourself

Innovative technologies that until recently seemed like science fiction are becoming more and more commonplace: for example, 3D printing. Special printers are already used to create rocket engines, human organs and hi-tech buses for ordinary city streets. And in San Francisco, 3D printing technology has entered the broad tourist masses. Anyone can order a 3D copy of themselves, the whole family and even their dog. Roman Mamonov was impressed and… tested the technology on himself.

Special printers are already used to create rocket engines, human organs and hi-tech buses for ordinary city streets. And in San Francisco, 3D printing technology has entered the broad tourist masses. Anyone can order a 3D copy of themselves, the whole family and even their dog. Roman Mamonov was impressed and… tested the technology on himself.

San Francisco is one of the largest metropolitan areas in the United States. The intersection of tourist and high-tech flows. From here to Silicon Valley - half an hour by car. Innovation is almost a lifestyle. Among dozens of stores with the usual tourist knick-knacks in a fishing village on the bay, you won’t immediately notice this strange 3D printing studio. There are figurines of people in the shop window and on the shelves, in the center there is a strange design. All of this is a PocketMe start-up created by Ellis Saloner and her husband.

“We started our project back in Berkeley,” says Allison Saloner. – My husband and I have an engineering background in radio electronics, and my husband is passionate about photogrammetry technology. It involves the creation of a large number of photographs to build a three-dimensional model. He got into this technology and saw that people often make models of other people. So a year ago we opened in Berkeley, things were going really well. In December, we moved here to the Fisherman's Village area, and things got even better. Now we have clients from all over the world.”

It involves the creation of a large number of photographs to build a three-dimensional model. He got into this technology and saw that people often make models of other people. So a year ago we opened in Berkeley, things were going really well. In December, we moved here to the Fisherman's Village area, and things got even better. Now we have clients from all over the world.”

“Usually people come in and say they've never seen anything like it,” she continues. Some people say it's just incredible. So we see a lot of emotions. Many people say that it is frightening and very strange. But then they say: "I want the same." When a client comes in, he goes to our 3D pavilion, he stands there, we take a lot of photos, we can do several takes, different poses. After that, he decides what he likes best."

...I must say, the sensations are very unusual. The first thing that comes to mind is a scene from Luc Besson's film "Dancer", where the main character discovered new technologies for herself in approximately the same building - the Voice of America correspondent felt about the same.