3D printing in biotechnology

What is 3D bioprinting? | 3D Bioprinting technology

The history of 3D bioprinting – where it all began?3D bioprinting is evolving rapidly since researchers have innovated and driven the field forward. However, as a technology, 3D printing is not a new invention. The first steps in 3D printing were taken in 1980s, when in 1984 Charles Hull filed a patent for the first commercial 3D printing technology. This has been a symbol of the birth of 3D printing, and it created the base for 3D bioprinting as well. Bioprinting came into picture in 1988, when Robert J. Klebe used inkjet printer for printing cells.1 After these first steps, the field has constantly evolved, and new methods and techniques have been discovered. The countless possibilities and opportunities to create something ground-breaking keep intriguing scientists, and thus bioprinting has become a popular technology.

What is 3D bioprinting and how does bioprinting work?

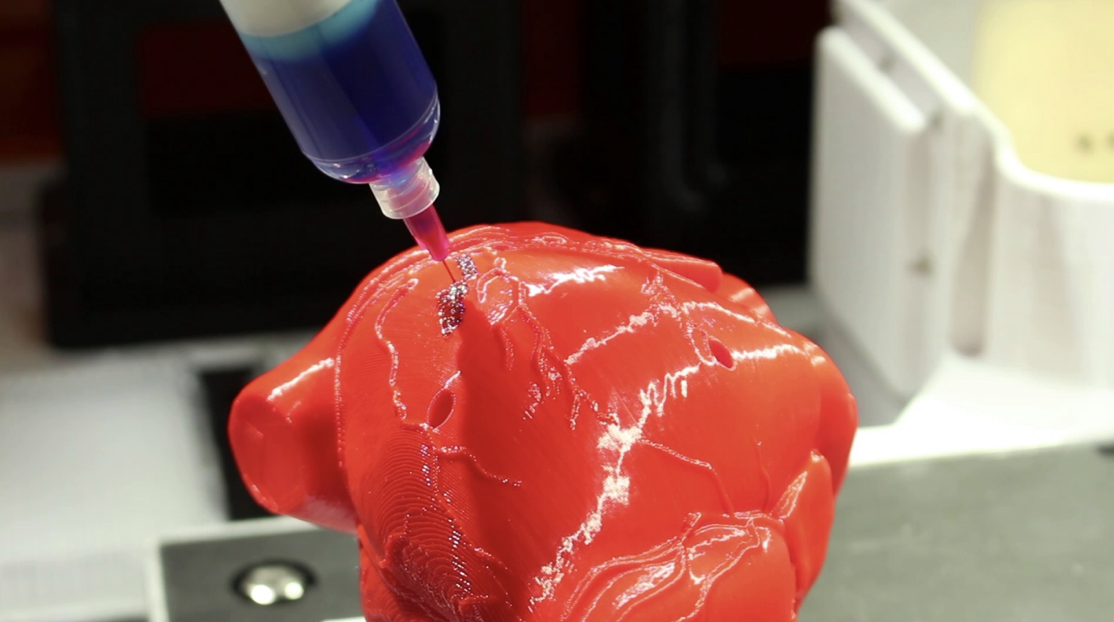

3D bioprinting is an additive manufacturing process that uses bioinks to print living cells developing structures layer-by-layer which imitate the behavior and structures of natural tissues. Bioinks, that are used as a material in bioprinting, are made of natural or synthetic biomaterials that can be mixed with living cells.

The technology and bioprinted structures enable researchers to study functions of the human body in vitro. 3D bioprinted structures are more biologically relevant compared to in vitro studies performed in 2D.

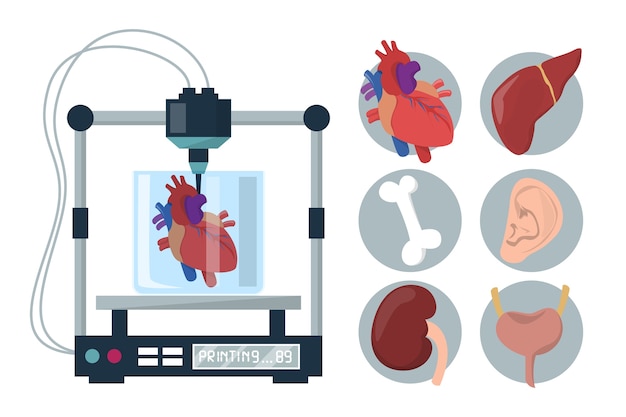

Mostly, 3D bioprinting can be used for several biological applications in the fields of tissue engineering, bioengineering and materials science. The technology is also increasingly used for pharmaceutical development and drug validation. Clinical settings such as 3D printed skin and bone grafts, implants and even full 3D printed organs are currently at the center of bioprinting research.

3D bioprinting of tissues and organs for regenerative medicine

Three-dimensional bioprinting plays an important role in tissue engineering which aims to fabricate functional tissue for applications in regenerative medicine and drug testing. Tissue regeneration and reconstruction could enable the possibility to repair or replace damaged tissues and organs.

Tissue regeneration and reconstruction could enable the possibility to repair or replace damaged tissues and organs.

Advantages and disadvantages of 3D bioprinting

Advantages of 3D bioprinting

- Allows mimicking the real structure of desired tissue/organ etc.

- Possibility to revolutionize future medical treatment capabilities

- Possible creation of patient-specific and organ-specific treatments

- Effects of drugs can be examined more accurately

- Decreases animal testing

- Biocompatibility with human cells and tissues

- Automating complex processes

- Consistency, less human errors

Disadvantages of 3D bioprinting

- Pricing, expensive technology

- Complexity

- Maintaining cell environment can be difficult

- Ethical concerns

- Energy consumption

3D bioprinting bioinks

Bioinks are used as the base material when bioprinting tissue-, organ-, or bone-like structures with bioprinters. 3D bioinks can be cell-laden, scaffold-free, or cell-free, like GrowInk™, which is an easily customizable hydrogel-based bioink made of nanofibrillar cellulose and water.

3D bioinks can be cell-laden, scaffold-free, or cell-free, like GrowInk™, which is an easily customizable hydrogel-based bioink made of nanofibrillar cellulose and water.

GrowInk’s cell-free form allows it to be tailored well to fit multiple research areas and purposes.

Choosing the right composition of bioink, and the bioink density can affect the cell viability and cell density, hence, selecting the most suitable bioink for each research purpose is essential.

Read more about GrowInk

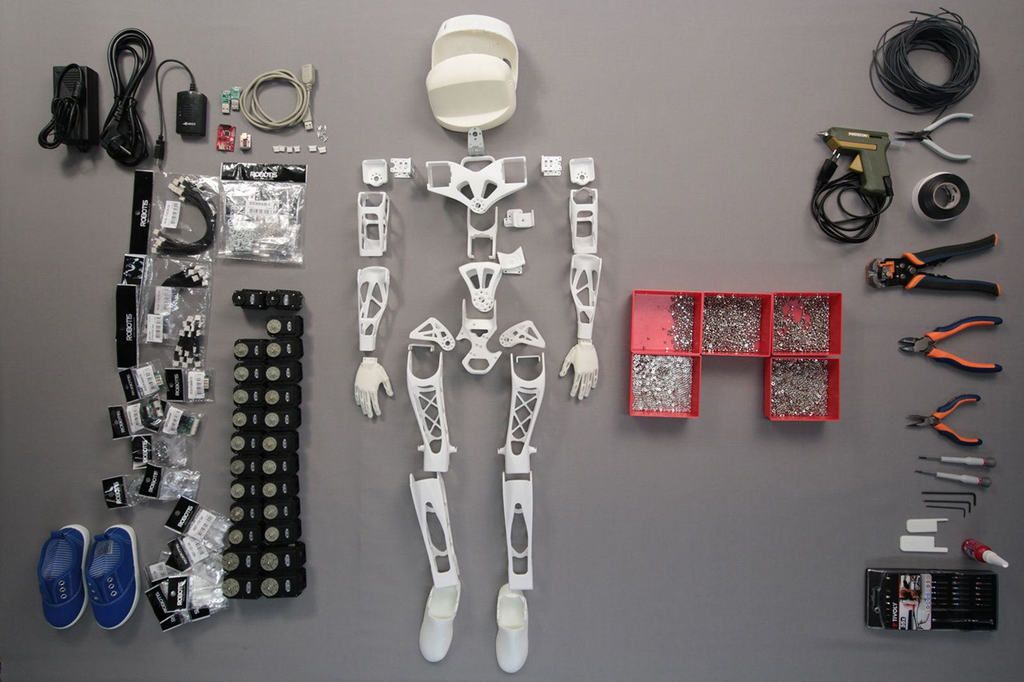

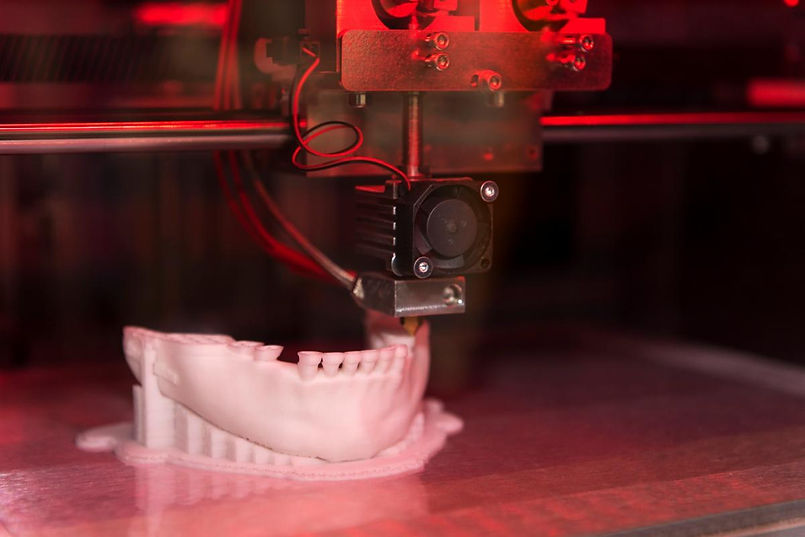

3D bioprinters

3D printers and 3D bioprinters are similar to each other, but 3D printers are designed to print solid materials, where 3D bioprinters are designed to print liquid or gel. 3D bioprinters are also designed to handle sensitive material that contain living cells, without creating too much damage on the end result. Bioprinters can be inkjet based, laser assisted, or extrusion based. Each printer type has its pros and cons when it comes to cost, cell viability, cell density, resolution, and so on. Bioprinters’ compatibility with bioinks also varies, and therefore it is important to ensure the bioprinter and bioink work well together.

Bioprinters’ compatibility with bioinks also varies, and therefore it is important to ensure the bioprinter and bioink work well together.

Commercially available cell printers

3D Bioprinting solutions – hints and tips for bioprinting

- Select the most suitable bioink for your research purpose and ensure the bioink you are using is compatible with the selected printing method and cell types

- Know what you are printing – create a new digital 3D model of the structure you want to print or get a license for an existing model

- Use fresh or new printer tips that are specifically fitted for your system

- Test different nozzle/needle sizes, printing speeds, and layer heights and optimize them based on the results

- Make sure the working temperature is suitable for the printer and the used materials

- Set an optimal printing pressure. A bit higher pressure is usually needed when printing with cells

Check out hints and tips when using GrowInk

Future of 3D bioprinting

The rapid development of technology can also be seen in the advancement of bioprinting. Three-dimensional bioprinting technology has the potential to solve numerous problems in areas such as healthcare. Functioning bladders, which have been grown using bioprinted tissue from patients’ own cells have already been transplanted into human body successfully2,3. Researchers are constantly researching the possibility of bioprinting other functioning organs.

Three-dimensional bioprinting technology has the potential to solve numerous problems in areas such as healthcare. Functioning bladders, which have been grown using bioprinted tissue from patients’ own cells have already been transplanted into human body successfully2,3. Researchers are constantly researching the possibility of bioprinting other functioning organs.

One future scenario of 3D bioprinting could be that no-more organ donors are needed, as personalized human organs can be printed using the patients’ own cells or stem cells as a base. This technology can be revolutionizing in preventing and fixing diseases. Eventually, it is hoped that bioprinting technology will enhance medical care and make it more efficient.

Applications of 3D bioprinting

3D printing of GrowInk

™-N and GrowInk™-T with Poietis NGB-R™ bioprinterHigh-throughput production of GrowInk

™-T models by drop-on-demand 3D bioprintingBioprinting publications

Wang, Q. , et al., (2021). Rheological and Printability Assessments on Biomaterial Inks of Nanocellulose/Photo-Crosslinkable Biopolymer in Light-Aided 3D Printing. Available from: https://doi.org/10.3389/fceng.2021.723429.

, et al., (2021). Rheological and Printability Assessments on Biomaterial Inks of Nanocellulose/Photo-Crosslinkable Biopolymer in Light-Aided 3D Printing. Available from: https://doi.org/10.3389/fceng.2021.723429.

Fonseca, A.C., et al., (2020). Emulating Human Tissues and Organs: A Bioprinting Perspective Toward Personalized Medicine. Chemical Reviews. Available from: https://doi.org/10.1021/acs.chemrev.0c00342.

Wang, X., Q. Wang, and C. Xu, (2020). Nanocellulose-Based Inks for 3D Bioprinting: Key Aspects in Research Development and Challenging Perspectives in Applications-A Mini Review. Bioengineering (Basel), 7(2). Available from: https://doi.org/10.3390/bioengineering7020040

Yadav, C., et al., (2020). Plant-based nanocellulose: A review of routine and recent preparation methods with current progress in its applications as rheology modifier and 3D bioprinting. International Journal of Biological Macromolecules. Available from: http://www.sciencedirect.com/science/article/pii/S0141813020349631.

Available from: http://www.sciencedirect.com/science/article/pii/S0141813020349631.

Ashammakhi, N., et al., (2019). Bioinks and bioprinting technologies to make heterogeneous and biomimetic tissue constructs. Materials Today Bio, 1: p. 100008. Available from: https://www.sciencedirect.com/science/article/pii/S2590006419300146.

Di Marzio, N., et al., (2020). Bio-Fabrication: Convergence of 3D Bioprinting and Nano-Biomaterials in Tissue Engineering and Regenerative Medicine. Frontiers in Bioengineering and Biotechnology, 8(326). Available from: https://www.frontiersin.org/article/10.3389/fbioe.2020.00326.

Jovic, T.H., et al., (2019). Plant-Derived Biomaterials: A Review of 3D Bioprinting and Biomedical Applications. Frontiers in Mechanical Engineering, 5(19). Available from: https://www.frontiersin.org/article/10.3389/fmech.2019.00019.

References

1Gu, Z., Fu, J., Lin, H. and He, Y., 2020. Development of 3D bioprinting: From printing methods to biomedical applications. Asian Journal of Pharmaceutical Sciences, 15(5), pp.529-557.

and He, Y., 2020. Development of 3D bioprinting: From printing methods to biomedical applications. Asian Journal of Pharmaceutical Sciences, 15(5), pp.529-557.

2Atala, A., Bauer, S., Soker, S., Yoo, J. and Retik, A., 2006. Tissue-engineered autologous bladders for patients needing cystoplasty. The Lancet, 367(9518), pp.1241-1246.

3 Belton, P., 2018. 'A new bladder made from my cells gave me my life back'. BBC, [online] Available at: <https://www.bbc.com/news/business-45470799> [Accessed 6 August 2021].

Bio printing - Bioprinting - Human tissue

3D bio printing of human tissue has been around since the early two-thousands. Nowadays scientists are in the midst of moving from printing tiny sheets of tissue to entire 3D organs. 3Dprinting.com will keep you informed of the latest developments in the bio printing industry.

Using AI and AM for Organoid Production

Living organs for medical experimentation are pretty hard to come by, on account of human beings actually using them on a day to. .. read more »

.. read more »

3 months ago

Bioprinting

Rabbit Gets Printed Cornea

Researchers from Hyderabad in India have successfully transplanted a 3D printed cornea onto a rabbit, which will pave the way for transplants onto... read more »

5 months ago

Bioprinting

3D Printed Lung Demos Gas Exchange in Animals

3D Systems and their collaborators at United Therapeutics have released an update on their 3D printed lungs at the LIFE ITSELF Conference in... read more »

7 months ago

3D Systems

Researchers Shape Matter with Sound

Researchers have figured out a way of fusing polymers using "sonochemical reactions". Unless you're a researcher in that field, or adjacent fields, it's... read more »

7 months ago

Bioprinting

3D Printed Living Ear Successfully Implanted on Patient

New York-based company 3DBio Therapeutics has announced the successful implant of a 3D printed ear onto a patient suffering from microtia, a condition. .. read more »

.. read more »

7 months ago

Bioprinting

Bioprinted Lymph Nodes Coming to an Immune System Near You?

It has been a while since we have covered anything in the domain of bioprinting. It’s not that we don’t like writing about... read more »

11 months ago

Bioprinting

Two Teams Win NASA’s Vascular Tissue Challenge Using 3D Printing

NASA started a competition in 2016 challenging entrants to “create thick, vascularized human organ tissue in an in-vitro environment to advance research and... read more »

1 year ago

Bioprinting

Benchtop Bioprinters: More Materials in Smaller Package

Last month, 3D Systems announced the acquisition of bioprinter manufacturer Allevi. It is the latest in a series of moves by the company. .. read more »

.. read more »

1 year ago

3D Systems

Industry Collaboration Highlights Path to 3D Printed Lungs

Earlier this year 3D Systems announced that they would be stepping up their efforts in the realm of bioprinting, in particular they intend... read more »

1 year ago

3D Systems

FRESH 2: Printing Heart Components From Collagen Bioinks

While many researchers have long been investigating a method for bioprinting a heart, this year has marked some stunning breakthroughs. Most notably scientists... read more »

3 years ago

Bioprinting

Mars Crew 3D Printing Skin & Bone Tissue in Space

While journeys through space require a lot of resources, there's only so much space missions can carry. This makes it especially difficult to. .. read more »

.. read more »

3 years ago

Aerospace

Ricoh Partners With Elixirgen Scientific to Develop 3D Bioprinted Products

Tokyo-headquartered digital technology company Ricoh has partnered with Baltimore-based stem cell research firm Elixirgen Scientific to develop new biomedical products and services that... read more »

3 years ago

Bioprinting

Aleph Objects & FluidForm Develop FRESH Bioprinting Tech

Aleph Objects, the makers of the LulzBot 3D printers is moving into a different sphere of additive manufacturing. In collaboration with Carnegie Melon... read more »

3 years ago

Bioprinting

SLA Organ Printing Yields Results Using Food Dye

Although the days of fully 3D printed organs are not here yet, every day medical researchers inch closer. Previously, Tel Aviv University developed... read more »

Previously, Tel Aviv University developed... read more »

3 years ago

Bioprinting

Cryolithography Device Bioprints Organs Faster

With all the advances in bioprinting, there are distinct limitations most researchers are facing. Even with advanced organ recreations like a functional 3D... read more »

3 years ago

Bioprinting

3D Printed Heart Marks a Breakthrough in Bioprinting

In a landmark achievement, Tel Aviv University have 3D printed a small heart using human tissue. While the organ itself is smaller than one... read more »

3 years ago

Bioprinting

3D Printed Bioreactor Can Grow Jawbones Using Ribs

Researchers at Rice, the University of Texas Health Science Center at Houston (UTHealth) and Baylor College of Medicine have developed a 3D printed. .. read more »

.. read more »

3 years ago

Bioprinting

Allevi Launches Bioink For Multi-layered Skin Printing

One of the most promising applications of bioprinting is that of printing skin for medical conditions and research. Researchers have long been trying... read more »

3 years ago

Bioprinting

Bioprinted Tubules Simulate Kidney Functions & Diseases

Harvard's Wyss Institute and their work with printed proximal bioprinted tubules help to reintroduce good molecules into the bloodstream. Aside from simulating the... read more »

3 years ago

Bioprinting

Spinal Cord Implant Promotes Nerve Cell Growth

Researchers at UC San Diego School of Medicine and Institute of Engineering in Medicine have developed a spinal cord implant that could potentially revolutionize. .. read more »

.. read more »

4 years ago

Bioprinting

How bones, vessels and organs are printed using 3D printers / Habr

In the early days of rapid prototyping, it was widely believed that 3D printing would transform all manufacturing, spurring a consumer revolution that would bring a printer into every home. This has not yet happened, however, as has happened with many of the latest technologies, rapid prototyping has found its application in a completely different area - in medicine.

Article from the Gizmodo website.

The research and projects below are some of the most interesting examples of the use of bioprinting and the use of computer-controlled machines to assemble biological matter using organic inks and ultra-strong thermoplastics. The range of application of bioprinting is very wide - from the reconstruction of the main parts of the human skull to the printing of scaffolds - scaffolds on which stem cells can develop into new bones. Read the details below. nine0009

Read the details below. nine0009

Skulls

Osteofab is a product of the company

Oxford Performance Materials. Initially, OPM entered the market by selling in its raw form a high-performance polymer often used in the manufacture of medical implants - a thermoplastic called polyetherketone ketone (PEKK), but over the past few years the company has become the first to master the use of this material, primarily in additive manufacturing . So, in February 2013, an American patient

installedFDA approved 3D skull implant. The casting and printing was carefully crafted to match the unique geometry of the patient's skull, of which 75% is now an implant.

Leather

The main problem with creating new skin using printing is the difficulty of recreating a specific shade from the entire possible spectrum. Given that our skin is unique, thin and subject to change, it is quite difficult to create an exact copy of it. There is a huge amount of interesting research on this topic, the essence of which cannot be put into a short story. nine0009

Given that our skin is unique, thin and subject to change, it is quite difficult to create an exact copy of it. There is a huge amount of interesting research on this topic, the essence of which cannot be put into a short story. nine0009

However, here are two of the most interesting: Scientist James Yoo of Wyke Forest University, with a grant funded by the US Department of Defense, is working on a machine that can print skin directly on burn victims. Another study is being carried out by scientists at the University of Liverpool, who are using carefully calibrated 3D scanners to obtain skin samples containing all of its finest nuances, which will allow more realistic implants to be printed later. nine0009

The research is still ongoing and the team plans to create a "skin sample database" of scanned samples that can be accessed from remote hospitals that do not have the cameras needed to scan a particular patient's skin. [ Gizmodo ; PhysOrg ]

Noses and ears

The creation of prosthetic ears, noses and chins is often a painful, expensive and time-consuming process for both the patient and the doctor himself. British industrial designer Tom Fripp has worked with scientists at the University of Sheffield over the past 5 years to develop a cheaper and easier-to-make 3D printed facial prosthesis. The process of creating such a prosthesis includes 3D scanning the patient's face (which is much less painful than casting it), modeling the replacement part and printing it, which uses pigment, starch and medical silicone. nine0009

British industrial designer Tom Fripp has worked with scientists at the University of Sheffield over the past 5 years to develop a cheaper and easier-to-make 3D printed facial prosthesis. The process of creating such a prosthesis includes 3D scanning the patient's face (which is much less painful than casting it), modeling the replacement part and printing it, which uses pigment, starch and medical silicone. nine0009

These prostheses have the added bonus that when they wear out (which they eventually will), they can be reprinted at a very low financial cost. [

The Guardian]

Prosthetic eyes

Fripp and a team at the University of Sheffield published the results of testing a similar process for making prosthetic eyes. Prosthetic eyes are expensive and, because they are hand-painted, can take months to make. Fripp Designs printers can produce 150 prosthetic eyes in an hour, and details such as iris color, size and number of blood vessels can be easily changed to suit the needs of the patient. [ nine0009 PhysOrg

[ nine0009 PhysOrg

]

Functional implants

As electronic devices — from drones to medical implants — get smaller, scientists are struggling to create batteries for them that are small enough, but with those could provide the necessary charge. However, a team of engineers from Harvard University is already printing microbatteries the size of a grain of sand using a 3D printer. Here's what the press release says:

“…researchers created an anode ink using nanoparticles of one lithium oxide compound, as well as a cathode ink made from nanoparticles of another kind of this compound. The printer applied ink to the teeth of two gold combs, thus creating a tightly connected structure of anodes and cathodes. The scientists then placed the electrodes in a tiny container and filled it with an electrolyte solution to make a battery."

Over time, they will be able to charge medical implants, which are held back due to charging problems. [ nine0006 Harvard ]

[ nine0006 Harvard ]

Bones

3D printed implants such as the jaw have been around for several years. However, a small group of researchers is conducting an experiment whose goal is to print real bones. For example, scientist Kevin Scheiksheff of the University of Nottingham invented a bioprinter that creates matrices from polylactic acid and gelatin alginate, which are then coated with stem cells.

The implanted matrices will gradually dissolve and be replaced by new growing bone: it will take approximately three months for the bone to completely transform. [ nine0006 Forbes ]

Blood vessels and cells

We can already print

organs, but there is a serious problem in creating a functioning circulatory system.

German scientist Günther Tovar, head of the Fraunhofer Institute for Interfacial Engineering and Biotechnology, is working on a project called BioRap. His task is to use a 3D printer to print blood vessels, which uses a mixture of synthetic polymers and biomolecules. The printed circulatory systems are being tested on animals - they are not yet ready for introduction into the human body. However, they will eventually make organ transplants possible. [ nine0006 Fraunhofer Institute ]

His task is to use a 3D printer to print blood vessels, which uses a mixture of synthetic polymers and biomolecules. The printed circulatory systems are being tested on animals - they are not yet ready for introduction into the human body. However, they will eventually make organ transplants possible. [ nine0006 Fraunhofer Institute ]

How do you see the future of 3D printing with living and substitute artificial materials for use in the human body? Will we soon be able to grow and replace full-fledged organs, such as the liver? Share your opinion in the comments.

| 3DNews Technologies and IT market. News at the forefront of science Scientists have learned how to quickly print complex... nine0103 The most interesting in the reviews 20. Chemically and thermally resistant glass is much preferred over plastic in industry, medicine and science. And if people have learned to cope well with the printing of plastic 3D models, then glass 3D printing could help develop many promising areas. Now it's possible. American and German scientists have learned how to quickly print micron-scale 3D glass models. nine0009 Image Source: Adam Lau/Berkeley Engineering The proposed technology is based on the Glassomer material invented by scientists at the University of Freiburg and a 3D printing method invented at the University of California at Berkeley called "Computer Axial Lithography" (CAL). The CAL method was introduced about four years ago. This is a photopolymer printing method in which a 2D model is projected into the thickness of a liquid polymer resin at different angles. Where the light intensity reaches a threshold value, the resin will harden rapidly. The glassomer material proposed by the Germans is a mixture of a transparent polymer with quartz glass powder. A model can also be projected into this transparent mixture, after which it hardens. After that, the model is placed in a furnace, where the plastic is burned out, and the quartz powder is sintered into one glass product. According to the scientists, who published the results of their work in the prestigious journal Science , for the first time, they were able to print glass with structures in the 50 micrometer range in just a few minutes, which is approximately the thickness of a human hair. In addition, the surfaces of the components are smoother than with conventional 3D printing processes. nine0009 A possible application of the innovative manufacturing process is seen in the creation of micro-optical sensor components, in the production of virtual reality headsets and modern microscopes. |

04.2022 [14:17], Gennady Detinich

04.2022 [14:17], Gennady Detinich  Then it is enough to wash the model in a solvent to remove the liquid composition and the model is ready, which takes a few minutes. nine0009

Then it is enough to wash the model in a solvent to remove the liquid composition and the model is ready, which takes a few minutes. nine0009