Canal house 3d print

The World's First 3D Printed Canal House

The World's First 3D Printed Canal House - IGNANT3D printing is without said a step into the future of adapting without human hands, however this is the first time it’s been used in large beneficial scale – a home.

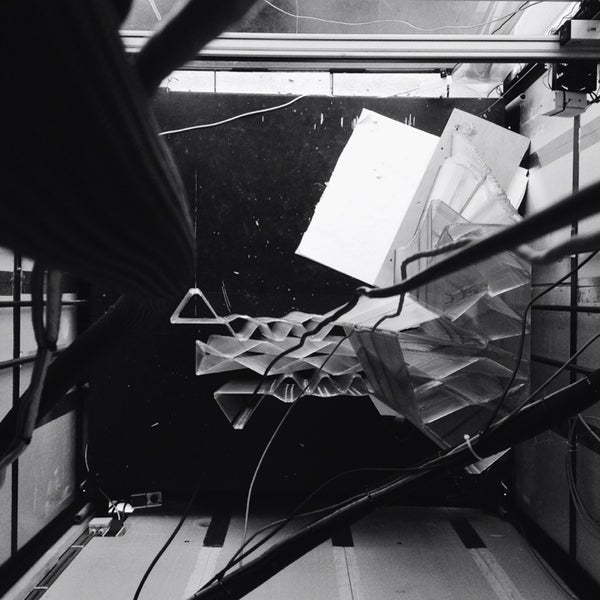

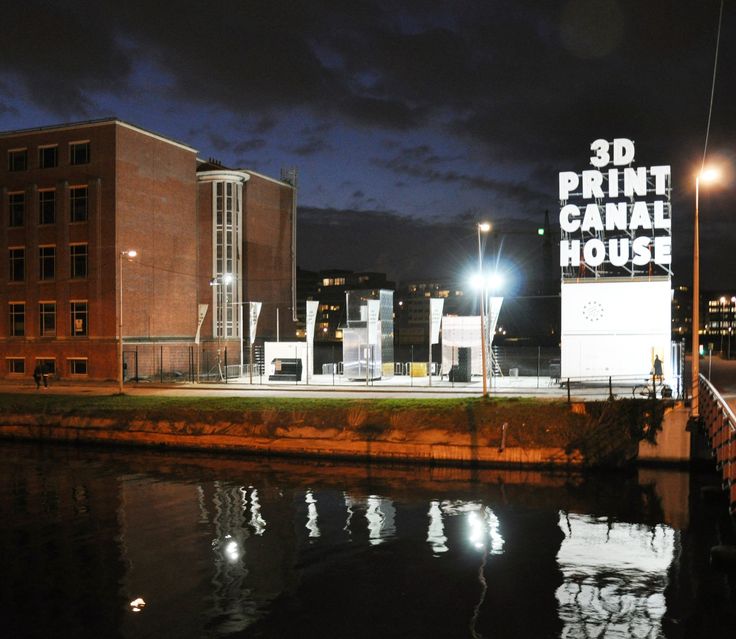

Originally launching in early 2014 at an expo-site in Amsterdam North, Amsterdam based DUS architects and contributing partners have made the 13 room project reality. To fabricate 3D printing in a larger scale for a 8 square-meter house the team developed a jumbo size printer named ‘KamerMaker’, printing matter up to 2 x 2 x 3,5 meters. The canal house will be open to public until 2017.

All images © Ossip & Sophia Van den Hoeck

Latest Articles

Load more

IGNANT uses cookies to improve your user experience on our website, to store the choices you make when you use our website, and to help us make ongoing improvements in the content and functions you encounter on our website. We also use cookies to target our marketing to your need and to generate usage statistics for our website. If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. You can revoke or adjust your selection at any time under Settings.

- Essential

- Statistics

- External Media

Accept all

Save

Individual Privacy Preferences

Cookie Details Privacy Policy Imprint

Cookie declaration

If you are under 16 and wish to give consent to optional services, you must ask your legal guardians for permission. We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. IGNANT uses cookies to offer you the best possible experience when you visit our website. A cookie is a small text file that is placed on your computer hard disk, smartphone or other IT equipment.

We use cookies and other technologies on our website. Some of them are essential, while others help us to improve this website and your experience. Personal data may be processed (e.g. IP addresses), for example for personalized ads and content or ad and content measurement. You can find more information about the use of your data in our privacy policy. IGNANT uses cookies to offer you the best possible experience when you visit our website. A cookie is a small text file that is placed on your computer hard disk, smartphone or other IT equipment.

The cookie makes it possible to recognize your computer/IP-address and to personalize content and your site experience and analyze traffic on our website.

If you do not want to accept cookies from us, you can disable all or specific categories of cookies by clicking here.

Accept all Save

Cookie declarationEssential (2)

Essential cookies enable basic functions and are necessary for the proper function of the website.

Show Cookie Information Hide Cookie Information

| Name | Borlabs Cookie |

|---|---|

| Provider | Owner of this website, Imprint |

| Purpose | Saves the visitors preferences selected in the Cookie Box of Borlabs Cookie. |

| Cookie Name | borlabs-cookie |

| Cookie Expiry | 1 Year |

| Name | WooCommerce |

|---|---|

| Provider | Owner of this website |

| Purpose | Helps WooCommerce determine when cart contents/data changes. Contains a unique code for each customer so that it knows where to find the cart data in the database for each customer. Allows customers to dismiss the store notifications. Contains a unique code for each customer so that it knows where to find the cart data in the database for each customer. Allows customers to dismiss the store notifications. |

| Cookie Name | woocommerce_cart_hash, woocommerce_items_in_cart, wp_woocommerce_session_, woocommerce_recently_viewed, store_notice[notice id] |

| Cookie Expiry | Session / 2 Days |

Statistics (1)

Statistics

Statistics cookies collect information anonymously. This information helps us to understand how our visitors use our website.

This information helps us to understand how our visitors use our website.

Show Cookie Information Hide Cookie Information

| Accept | Google Analytics |

|---|---|

| Name | Google Analytics |

| Provider | Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland |

| Purpose | Cookie by Google used for website analytics. Generates statistical data on how the visitor uses the website. Generates statistical data on how the visitor uses the website. |

| Privacy Policy | https://policies.google.com/privacy?hl=en |

| Cookie Name | _ga,_gat,_gid |

| Cookie Expiry | 2 Years |

External Media (4)

External Media

Content from video platforms and social media platforms is blocked by default. If External Media cookies are accepted, access to those contents no longer requires manual consent.

If External Media cookies are accepted, access to those contents no longer requires manual consent.

Show Cookie Information Hide Cookie Information

| Accept | Google Maps |

|---|---|

| Name | Google Maps |

| Provider | Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland |

| Purpose | Used to unblock Google Maps content. |

| Privacy Policy | https://policies.google.com/privacy?hl=en&gl=en |

| Host(s) | .google.com |

| Cookie Name | NID |

| Cookie Expiry | 6 Month |

| Accept | |

|---|---|

| Name | |

| Provider | Meta Platforms Ireland Limited, 4 Grand Canal Square, Dublin 2, Ireland |

| Purpose | Used to unblock Instagram content. |

| Privacy Policy | https://www.instagram.com/legal/privacy/ |

| Host(s) | .instagram.com |

| Cookie Name | pigeon_state |

| Cookie Expiry | Session |

| Accept | Vimeo |

|---|---|

| Name | Vimeo |

| Provider | Vimeo Inc. , 555 West 18th Street, New York, New York 10011, USA , 555 West 18th Street, New York, New York 10011, USA |

| Purpose | Used to unblock Vimeo content. |

| Privacy Policy | https://vimeo.com/privacy |

| Host(s) | player.vimeo.com |

| Cookie Name | vuid |

| Cookie Expiry | 2 Years |

| Accept | YouTube |

|---|---|

| Name | YouTube |

| Provider | Google Ireland Limited, Gordon House, Barrow Street, Dublin 4, Ireland |

| Purpose | Used to unblock YouTube content. |

| Privacy Policy | https://policies.google.com/privacy?hl=en&gl=en |

| Host(s) | google.com |

| Cookie Name | NID |

| Cookie Expiry | 6 Month |

Privacy Policy Imprint

Amsterdam architects plan 3D-printed canal house

Emilie Chalcraft | 6 comments

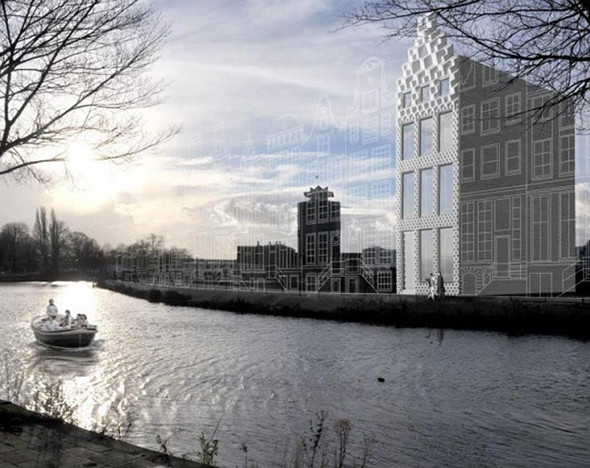

News: Dutch studio DUS Architects has joined the race to build the first 3D-printed house with plans to print a full-size canal house in Amsterdam.

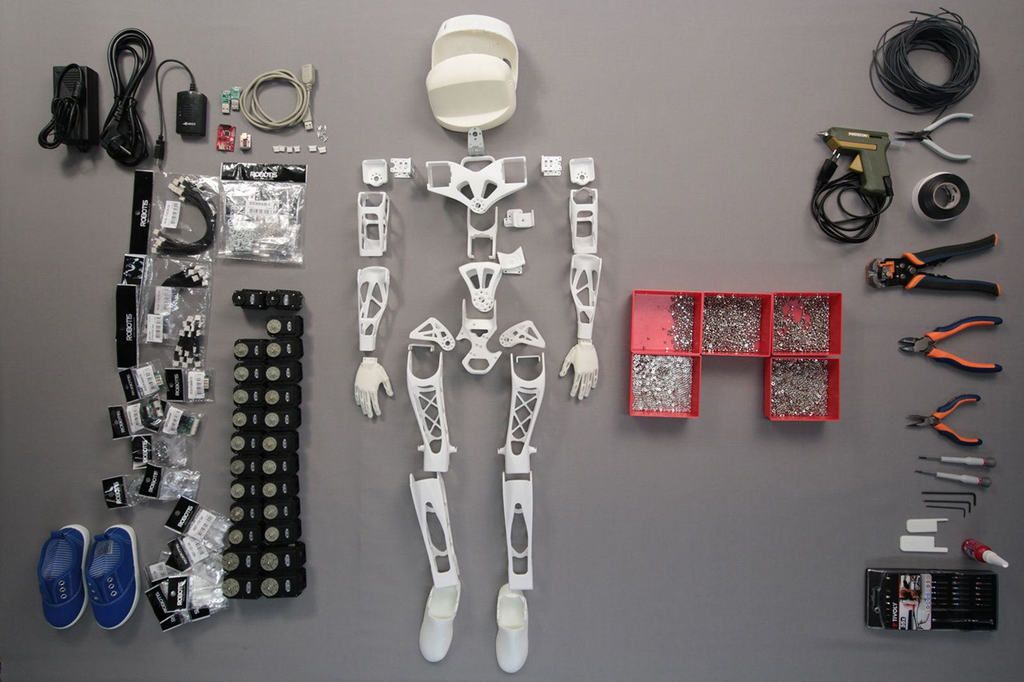

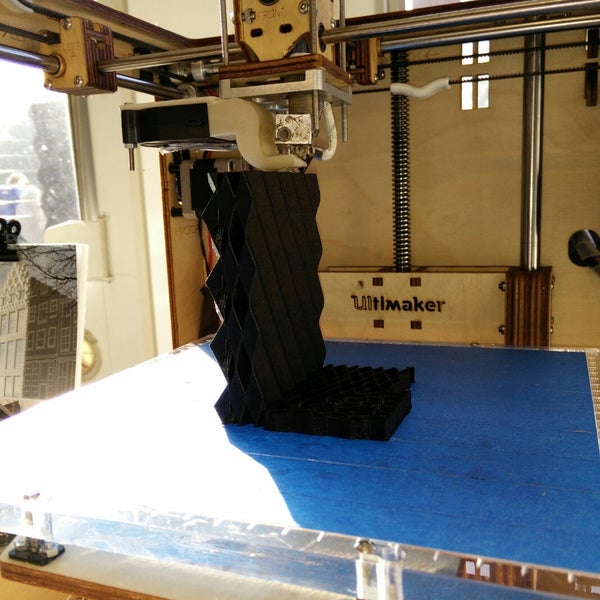

DUS Architects will print components for the house on-site using a purpose-built printer called the KamerMaker (above and below) and plan to start work in the next six months.

"This year we want to print the entire facade and the first room bit by bit," architect Hedwig Heinsman told Dezeen. "Then in the following months and years we will print other rooms."

The KamerMaker, which is Dutch for "room maker", is 3.5 metres high and sits inside a shipping container. Each building component will be printed and tested at a scale of 1:20 before being printed at a 1:1 scale with the KamerMaker.

Above: a round window frame printed with the KamerMaker

The house will be built in a developing area alongside the Buiksloter-canal in the north of the city, where it will act as a hub for research into 3D-printed architecture. "We want to build a construction site as an event space," sais Heinsman. "We'll have the printer there and every print we make will be exhibited. It's very much about testing and learning."

It's very much about testing and learning."

The first floors and facades of the house will be printed from polypropylene, but the architects hope to eventually use bioplastics and plastic recycled on-site.

Once the first part of the canal house is complete, it will be put to use as a "welcoming room" while the architects design and print additional rooms.

Each room will be dedicated to a specific research theme, such as the "cook room" where researchers will explore 3D printing with potato starch and the "policy room" where they'll consider how to obtain permits for printed structures.

Other rooms will include a workshop to test and repair designs and a "recycle room" where used items like plastic bottles will be shredded into printing material for the KamerMaker.

"We have the building grounds for three years, so I'm pretty confident it will last for that long, but of course our aim is for longer," said Heinsman. "We also had the idea that if at one moment we had to relocate it, we would just shred all the pieces and build it anew somewhere. "

"

The race to complete the first 3D-printed house is already well underway, with London collective Softkill Design recently announcing plans for a plastic dwelling that could be printed in three weeks and assembled in a day, while Dutch firm Universe Architecture intends to print a house based on a Möbius strip.

DUS Architects' previous projects include a pavilion made of bubbles and a pop-up bar made of umbrellas, both on the streets of Rotterdam.

Other 3D-printed designs we've featured lately include a floor-length nylon gown designed for burlesque dancer Dita Von Teese and a fuel-efficient three-wheeled car – see all 3D printing news.

Read more about the project on DUS Architects' website.

Subscribe to our newsletters

Your email addressDezeen Debate

Our most popular newsletter, formerly known as Dezeen Weekly. Sent every Thursday and featuring a selection of the best reader comments and most talked-about stories. Plus occasional updates on Dezeen’s services and breaking news.

Plus occasional updates on Dezeen’s services and breaking news.

Sent every Tuesday and containing a selection of the most important news highlights. Plus occasional updates on Dezeen’s services and breaking news.

Dezeen DailyA daily newsletter containing the latest stories from Dezeen.

New! Dezeen In DepthSent on the last Friday of every month, Dezeen in Depth features original feature articles, interviews and opinion pieces that delve deeper into the major stories shaping architecture and design.

Dezeen JobsDaily updates on the latest design and architecture vacancies advertised on Dezeen Jobs. Plus occasional news.

Dezeen AwardsNews about our Dezeen Awards programme, including entry deadlines and announcements. Plus occasional updates.

Dezeen Events GuideNews from Dezeen Events Guide, a listings guide covering the leading design-related events taking place around the world. Plus occasional updates.

Plus occasional updates.

We will only use your email address to send you the newsletters you have requested. We will never give your details to anyone else without your consent. You can unsubscribe at any time by clicking on the unsubscribe link at the bottom of every email, or by emailing us at [email protected].

For more details, please see our privacy notice.

Thank you!

You will shortly receive a welcome email so please check your inbox.

You can unsubscribe at any time by clicking the link at the bottom of every newsletter.

Reportage about construction 3D printing in Russia

News

and a manufacturer of construction 3D printers based in Yaroslavl and successfully operating in the Russian and foreign markets. The narrator is the head of the enterprise Alexander Maslov.

In already completed projects, AMT-Spetsavia printed houses both on top of the foundation and in blocks in workshop conditions. In the video, Alexander clarifies this point, which is related, among other things, to weather conditions.

“If we print a prefab in the shop, then [the process] does not depend on weather conditions in any way. Both winter and summer are about the same temperature, which is good. When you print on a foundation (which everyone loves because it eliminates the assembly step, which is quite a lot of time and money), then of course the weather conditions come into play. The construction season is usually from spring to autumn. It's hard to print in very hot weather because the long, thin concrete walls start to crack. To do this, various additives are introduced into the concrete or the printing is transferred to a more convenient night time. Comfortable temperatures are from spring to autumn, from about 5°C to 25°C. Of course, precipitation and strong winds have a very strong influence - the structure still has windage, and there is a slight shift in the printed layers. Light rain is not a hindrance, in heavy rain the wet concrete will erode, so you need to keep an eye on the weather. As a rule, an hour and a half before the approach of a thunderstorm, we stop printing, wash the equipment and wait. There is another option to close it with some kind of canopy or a greenhouse, but it’s actually easier to miss two hours of printing than to fence the roof, ”said Alexander. nine0003

As a rule, an hour and a half before the approach of a thunderstorm, we stop printing, wash the equipment and wait. There is another option to close it with some kind of canopy or a greenhouse, but it’s actually easier to miss two hours of printing than to fence the roof, ”said Alexander. nine0003

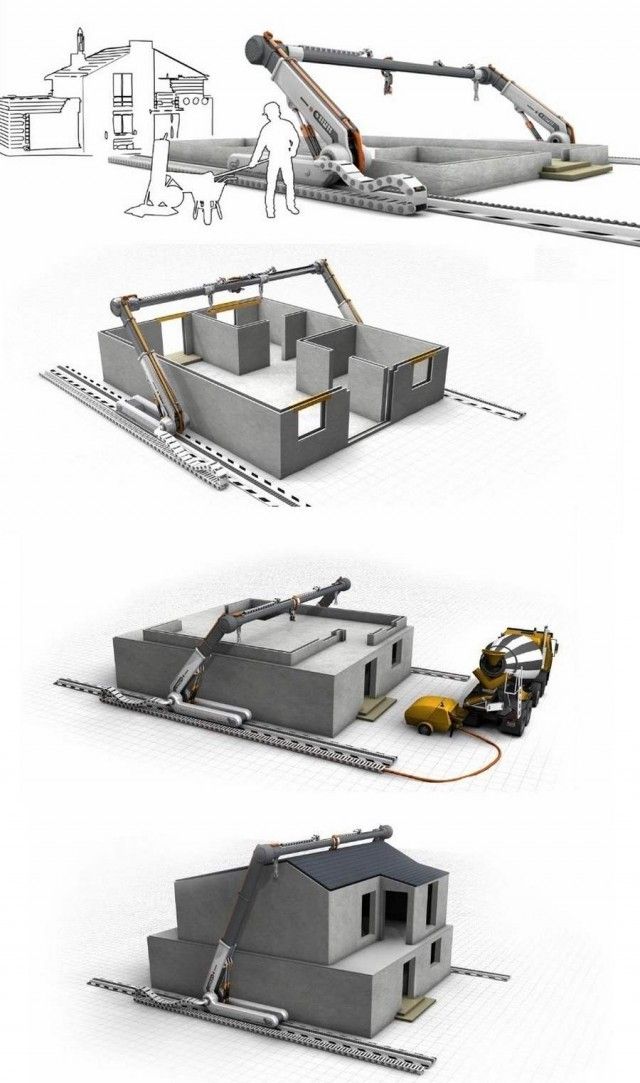

A 100 square meter 3D printed box takes thirty to thirty five hours to build. Fixed formwork is printed, which can be poured with foam compounds after one or several days, depending on the brand of concrete.

Alexander did not dare to give an exact figure, since the pace of work for each team is different, but in general, a small house can be built in about a month, including pouring the foundation and curing, 3D printing of formwork, inserting windows, doors, and so on. nine0003

According to Alexander, about forty companies are currently operating in the global market for 3D construction printing — some are engaged in the development and production of equipment, some directly in construction, some combine them. According to Alexander, AMT-Spetsavia accounts for 70% of the world production of construction 3D printers, with half of them going to Russian customers. In six years, the company has sold two hundred and forty pieces of equipment to sixteen countries. nine0003

According to Alexander, AMT-Spetsavia accounts for 70% of the world production of construction 3D printers, with half of them going to Russian customers. In six years, the company has sold two hundred and forty pieces of equipment to sixteen countries. nine0003

AMT-Spetsavia produces portal 3D printers of two main types - workshop systems and larger options for outdoor work. The former are used in 3D printing of small architectural forms and building blocks, while the latter are installed on construction sites and print formwork directly on top of foundations.

The working area of such large-scale systems varies from one hundred and twenty square meters with the possibility of erecting two-story structures up to four hundred and twenty square meters. The latter can theoretically build buildings up to twenty-six stories high, although in practice such grandiose projects have not yet been implemented. nine0003

Details in the report of the channel "Low-Rise Country":

What Europe's first fully 3D printed house looks like

Trends

TV channel

Pro

Investments

Events

RBC+ nine0003

New economy

Trends

Real estate

Sport

Style

National projects

Town

Crypto

Debating Club nine0003

Research

Credit ratings

Franchises

Newspaper

Special projects St. Petersburg

Petersburg

Conferences St. Petersburg

Special projects

Checking counterparties

RBC Library nine0003

Podcasts

ESG index

Policy

Economy

Business

Technology and media

Finance

RBC CompanyRBC Life

RBC Trends

Photo: Project Milestone

Europe's first 100% 3D printed home welcomes its new occupants, a couple from Amsterdam

What's going on

What it means 3D printer is just the beginning of a new stage in the industry.

Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs. nine0003

Residential buildings built using 3D printing technology have a number of significant advantages over "classic" buildings. Firstly, the speed of the project, the first house was printed in five days, but going forward, the company plans to produce concrete elements on site, as well as use a 3D printer to create auxiliary installations, which will reduce construction time and costs. nine0003 In addition, in an era of global concern for the state of the environment, such "green" technologies help to reduce environmental damage to the environment - with 3D printing, the consumption of cement and waste of building materials is much less than with "traditional" construction.

Finally, with the help of a 3D printer, almost any design idea can be realized, which will allow you to move away from the concept of residential buildings in the form of "concrete boxes". The development of this technology makes it possible to erect buildings of such forms that are difficult and expensive to build using traditional methods.