3D printing gloves

Gloves best STL files for 3D printer・Cults

Glove dryer

Free

FIGURE, RALLY, CHAMPION POSE WITH CAP, DRIVER, F1, WRC

€10

CHAMPION POSE WITH CAP, SITTING, DRIVER, FIGURE, RALLY, SCALE, F1

€11

CHAMPION POSE WITH CAP, DRIVER, FIGURE, RALLY, SCALE, F1

€14

DIBU MARTINEZ

€6.34

deku air force gloves

€14.15

Boxing Gloves

€5.70

Clip système gants étanches TED - 23mm

Free

Wool Gloves Christmas Candles

€3.77

Motorcycle helmet glove dryer

€11

helmet and gloves dryer

€8

Marvel glove lamp

€6. 25

FIGURE CHAMPIONS CUP WRC DAKAR RACING SCALE

€13

Big Boa Kit for Action Figures

€15

Santa 3d model

€0.57

Bakugo's Grenade Gauntlets - My Hero Academia

€5

Water tap Kitchen gloves holder

Free

Christmas gloves

€1.56

Boxing Gloves - LED LAMP

€5

Giant Mechanical Cyberpunk Hands

€21.59

F1 SUIT 80', HELMET, GLOVES, F1 MASK

€15

F1 SUIT 80', HELMET, GLOVES

€12

F1 POSE GLOVES, HELMET, SUIT F1 80

€10

F1 FIGURE, HELMET, SUIT MODERN F1

€12

F1 CHAMPION, POSE BIRD, HELMET F1

€10

F1 POSE GLOVES, HELMET, HELMET, HANS, F1 MODERN

€10

Articulated fingers Hand harnesses

Free

Disposable glove wall mount

Free

Alien Articulated Fingers

€5. 17

17

Canelo Glove Earrings

€2.83

Vi’s Atlas Gloves – Arcane / League of Legends

€22.74

Drying rack for gloves

Free

christmas set x6

€1.50

Hulk hands (gloves)

Free

BOXING GLOVES DRYER

€1

Daft Punk Gloves 3D print model

€14.15

Cosplay Paws

€4.72

Cartoon Hand 5 Fingers Fuck

€7.78

Cartoon Hand 5 Fingers

€7.78

Turtle Ninja Hand Fuck

€7.78

Turtle Ninja Hand

€7. 78

78

Mickey Hand One

€7.78

Mickey hand Index

€7.78

Mickey hand Fist

€7.78

GLOVE CLIPS, GUARD, HOLDER

€0.77

Peace was never an option meme

Free

3D print ready Pilot Rally race car male Racing Driver

€7

Cosplay Naruto gloves and head 2 colors

€1.25

Glove best 3D printing files・Cults

PEET DRYER ACCESSORIES

€0.62

Glove dryer

Free

Clawd Wolf Ghoul Sports Glove, Bat, Ball and Gum replacements

€8

Glove compartment lock jetta mk3

€7. 38

38

GOLDEN GLOVE FIFA WORLD CUP QATAR 2022 - DIBU MARTINEZ

€7.97

Qatar 2022 Trophy Key Ring

€0.68

DIBU MARTINEZ

€6.37

Christmas | New Year cookie cutters - #47 - santa's glove (style 2)

€0.90

Seat Glove for Golf MK6

Free

DOOM Slayer Glove improved and scaled

Free

Nightmare Glove STL FILE FOR 3D PRINTING - LASER CNC ROUTER - 3D PRINTABLE MODEL STL MODEL STL DOWNLOAD BATH BOMB/SOAP

€3.56

Winter Glove Cookie Cutter (Personal Use Only)

€2.38

Wool Gloves Christmas Candles

€3.80

Christmas | New Year cookie cutters - #30 - santa's glove (style 1)

€0. 60

60

Baseball/Softball Caddy

Free

Marvel glove lamp

€6.25

Lightning claw attachment for TYRANT TYPE

Free

German soldiers 3D print model

€33

German soldier 3D print model

€38

Gen 2&3 Powerfist Arms (Tyrant type)

€8.08

german drivers soldiers 3D print model

€37

soldiers 3D print model

€33

German soldiers rest 3D print model

€36

christmas glove

€0.50

GLOVE CLAMPING RING FOR SANDBLASTING MACHINE

€0. 53

53

FREE Key holder and baseball keychain, glove and ball.

Free

MICKEY INFINITY GAUNTLET

€5.41

The Infinity Gauntlet - Wearable Replica

€25

The Infinity Gauntlet - Wearable DnD Dice Holder

€29

Christmas glove - Polymer Cutter (Clay Cutter)

€2.64

Glovebox Hook

Free

Gen 6 Powerfist Arms (Tyrant type)

€8.08

Freddy Krueger's glove (easy to print for Halloween)

Free

Polymer Clay Cutter Christmas Glove

€6.04

heart towel holder

€0. 50

50

Ford Escort Cosworth Glove Box Handle

€5

Glove - MOLD BATH BOMB, SOLID SHAMPOO

€2.85

VW New Beetle Cups OPEN Glove Box

€1.50

Glove Holder for Dental Revealer

€3.98

homer simpson keyholder

€1.25

Drying rack for gloves

Free

Hulk hands (gloves)

Free

CAN'T TOUCH THIS BAKING GLOVE WALL ART 2D

€0.62

Hand pen holder

€2.50

Airsoft 40mm Gauntlet (Arm Grenade Launcher)

€4.99

Audi TT 8J Fixing handle, glove box

Free

Hockey Glove

€1. 31

31

Cosplay Paws

€4.75

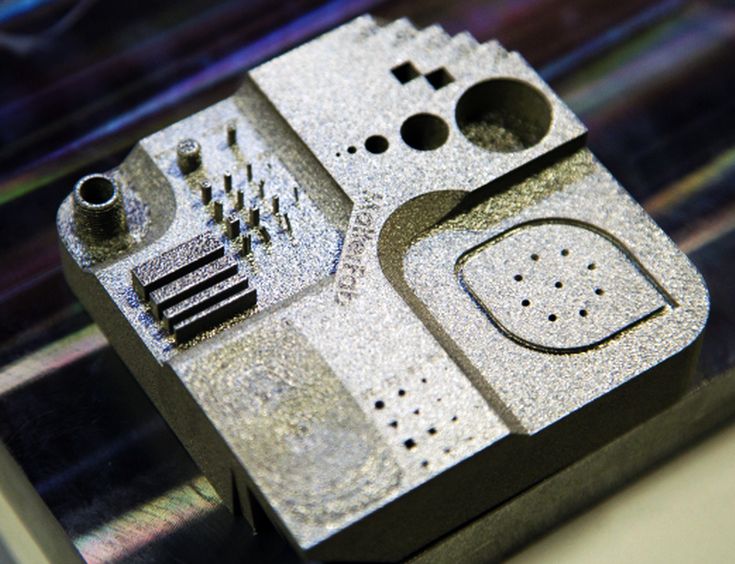

Helpful Tips for 3D Printing at Home

You, like many people around the world, may have had to quickly change from working in a workshop or office with many tools at hand to working at home where resources are more limited . During this difficult period, the ability to adapt to new circumstances and challenges helps to reduce production disruptions and avoid disruptions in the organization of the development cycle.

Formlabs desktop stereolithography (SLA) 3D printers are compact in size and can be used from home or outside the office environment. In addition, the ability to use over 30 different materials that mimic everything from silicone and polypropylene to ABS and more increases flexibility, expands the scope and makes it easy to adapt to new tasks as they arise. nine0003

Introducing 3D printing technology in-house will help you cut costs and keep your feet on the ground during times of uncertainty, especially if you have previously used or currently use third-party 3D printed models. Our customers are using home 3D printing to reduce costs, improve manufacturing process efficiency, continue developing critical products, and help overcome the COVID-19 crisis..

Our customers are using home 3D printing to reduce costs, improve manufacturing process efficiency, continue developing critical products, and help overcome the COVID-19 crisis..

Dan Kirchgessner, Communications Specialist, and Jake Kapusta, Senior Maintenance Specialist share practical tips for printing at home.

Before the 3D printer is delivered to your home, you need to organize your space and workspace so that you can print, post-process, and finish everything you need. You will need space to house the printer(s), post-processing stations such as Form Wash and Form Cure, workspace to separate and finish parts, and short-term storage space for items such as spare wash solvent, resin reservoirs, cartridges for resins, gloves, post-processing tools, etc.

Alexis Hope, designer and researcher at MIT's Media Lab and MIT's Center for Social Interaction Tools, says that in setting up her home workshop, “getting the printer home was a great incentive to reorganize the workplace. Space is required for flushing and curing systems, as well as space for storing models, so proper organization of space is necessary for productive work. ”

Space is required for flushing and curing systems, as well as space for storing models, so proper organization of space is necessary for productive work. ”

Alexis Hope's home workshop. nine0010

Some of the most frequently asked questions about 3D printing at home have to do with environmental factors such as sounds and smells. To account for sensitivity to odors, we advise placing the post-processing station in a well-ventilated area or near an open window. Although the Form 3 is relatively quiet - it produces a noise comparable to that of a microwave oven - you may prefer to place it away from those areas of your home where you don't want to disturb the silence. nine0003

Woody Hedberg, Formlabs Print Process Engineer, recently hosted a Form 3L in his apartment for material testing purposes. “As a protective measure, I installed thick cardboard on the floor and walls of the room,” says Hedberg. In addition, for the workplace, he chose a space near an open window and behind a closed door to reduce the penetration of potential smells and sounds.

After preparing the workspace, lay out the items needed for 3D printing, such as wash containers, baskets and bottles, tweezers, spatula, detach tool, wire cutters, disposable nitrile gloves, and any additional tools that you may need during the work 3D printing process. nine0003

If you already have a 3D printer, the first thing you should consider is transporting it from your office or workplace to your home. When preparing your Formlabs 3D printer for shipping, first remove the resin cartridge, then remove and clean the platform, and finally remove the resin reservoir and close the lid before placing it in its storage case. Ensure that all accessories containing polymers are securely closed before transport.

Before shipping the Form 3 printer, secure the Light Processing Unit (LPU) with wing screws and latch. Failure to lock the LPU may damage the printer. Contact us if you can't find the screws. nine0003

Carefully wrap the printer in protective material and, if possible, place it in the original packaging. Be sure to pack all the accessories you may need for 3D printing and post-processing: Form Wash and Form Cure or post-processing kit and an alternative curing solution and consumables such as resin reservoirs and cartridges, gloves, tools for post-processing, isopropyl alcohol, etc.

Be sure to pack all the accessories you may need for 3D printing and post-processing: Form Wash and Form Cure or post-processing kit and an alternative curing solution and consumables such as resin reservoirs and cartridges, gloves, tools for post-processing, isopropyl alcohol, etc.

After unpacking 3D printing supplies at home and before printing, be sure to check that the printer is level and stable in the new location. nine0003

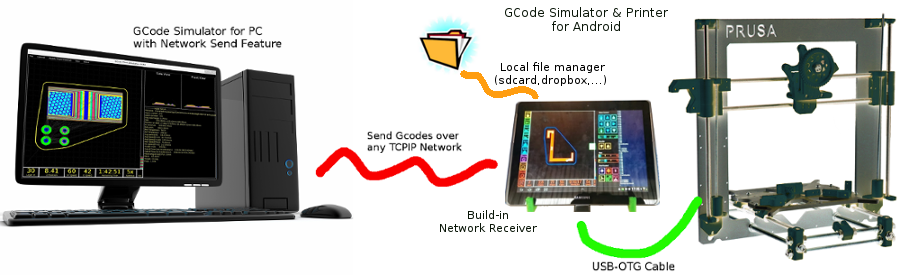

Now that your printer is ready to use at home, there are several ways to improve and streamline your workflow.

Schedule the start and end times for printing to fit your work schedule. This way you can load the printer to the maximum. You can schedule the start of your next print using PreForm's Estimated Print Duration feature. Print time-consuming models while you're away from your workspace so you can print while you're away so you can start the next one when you get back. nine0003

Kevin Gauthier, Business Development Specialist at Formlabs, found that when working remotely, his team sent models to each other more often: "Never forget to print an instance of an object for yourself so you can refer to it later. "

"

Kevin Gauthier's home workspace.

Continuing the same line, Hedberg suggests documenting and photographing every 3D printed model in detail, especially if your storage space is limited. “Now that we are working remotely, we need a proper documentation system. This does not mean that every 3D printed model should be saved, but carefully documenting the printed models and keeping records for my colleagues, yes,” he says. nine0003

Use the Dashboard to monitor the printing process in real time, as well as tank usage and resin usage. You'll also be able to track quality prints and scrap rates so you know which designs are the best and use them for future iterations.

“Do all the design work you can and prioritize critical physical prototyping tasks for different teams,” says Zach Frew, Formlabs Technical Specialist. Frew says you need to prioritize these tasks, especially when work resources are limited, and share them with your team members. nine0003

Follow safety guidelines when using Formlabs products. Handle IPS with nitrile gloves in a well-ventilated area. Keep the IPS away from heat, sparks and open flames. Isopropyl alcohol evaporates quickly, so keep containers covered if possible. For detailed safety information, contact the manufacturer or supplier of this chemical.

Handle IPS with nitrile gloves in a well-ventilated area. Keep the IPS away from heat, sparks and open flames. Isopropyl alcohol evaporates quickly, so keep containers covered if possible. For detailed safety information, contact the manufacturer or supplier of this chemical.

As Formlabs Materials Expert Zak Zguris says, “You have to practice good chemical hygiene. Keep everything clean. Wipe up any drops or spilled liquids immediately. To avoid sticky residue, use acetone or isopropyl alcohol. When washing in the IRS, ventilation of the working space with fresh air should be provided. The cabinet is not at all suitable for the active use of a 3D printer or a washing station in an IRS.” nine0003

Always wear gloves to protect your skin when handling resin cartridges and containers. Store ink cartridges upright, out of direct sunlight, in a well-ventilated area. Close the cartridge outlet cap to prevent resin leakage.

Liquid or partially cured polymers must not be poured down the drain or disposed of with household waste. Do not pour isopropyl alcohol (IPA) with the polymer dissolved in it down the drain or dispose of it with household waste. All solvents and polymers should, as always, be disposed of in accordance with local regulations and the supplier's MSP. More information about security measures can be found on our technical support website. nine0003

Do not pour isopropyl alcohol (IPA) with the polymer dissolved in it down the drain or dispose of it with household waste. All solvents and polymers should, as always, be disposed of in accordance with local regulations and the supplier's MSP. More information about security measures can be found on our technical support website. nine0003

Do you have any helpful tips or advice that you could share based on your experience of transitioning to working from home? We'd love to hear about them. We invite you to share them on social media with the tag @formlabs or #EngineeringFromHome or by commenting on our forums.

3D printing helps Paralympic athletes improve their performance / +1

Society

Technology makes assistive devices more accessible

Photo: iStock Athletes with various disabilities participate in the Paralympic Games. Many of them use assistive devices: prostheses, wheelchairs, special gloves. 3D printing technology is increasingly being used to manufacture these devices. University of Queensland and University of Technology Sydney researchers James Novak and Andrew Novak note that this is an affordable way to improve athletic performance and keep athletes safe. Scientists warn that some competitors have access to more advanced tools, and this gives them a certain advantage. nine0003

3D printing technology is increasingly being used to manufacture these devices. University of Queensland and University of Technology Sydney researchers James Novak and Andrew Novak note that this is an affordable way to improve athletic performance and keep athletes safe. Scientists warn that some competitors have access to more advanced tools, and this gives them a certain advantage. nine0003

Even during the Paralympic Games in Rio de Janeiro in 2016, German cyclist Denise Schindler performed with a 3D-printed prosthetic leg. She lost the lower part of her right leg as a child in a car accident and started playing sports at 18. The custom-made prosthesis was made by the American company Autodesk, which develops solutions for 3D design, design, graphics and animation. The cyclist and her team interacted with the company using the Fusion 360 cloud product modeling software. The developers came up with over 50 prosthetic designs before it was printed. nine0003

The product is made of polycarbonate (polymer plastic. — Approx. Plus-one.ru) and weighs less than 1 kg, while its carbon fiber counterpart is 1.5 kg. The production of a prosthesis can take from five days to ten weeks, the cost is from £ 3.5 thousand to 12 thousand. This year at her third Paralympic Games in Tokyo, 35-year-old Denise Schindler, who is called Killerbiene (from German - “bee killer"), won a bronze medal in the 3,000 m individual pursuit in classes C1-3. nine0003

— Approx. Plus-one.ru) and weighs less than 1 kg, while its carbon fiber counterpart is 1.5 kg. The production of a prosthesis can take from five days to ten weeks, the cost is from £ 3.5 thousand to 12 thousand. This year at her third Paralympic Games in Tokyo, 35-year-old Denise Schindler, who is called Killerbiene (from German - “bee killer"), won a bronze medal in the 3,000 m individual pursuit in classes C1-3. nine0003

New Zealand athlete Anna Grimaldi wears a 3D printed prosthesis. A girl who was born without an arm won first place in the long jump competition at the Paralympics in Tokyo. The prosthesis was made for her by Zenith Tecnica, a company based in Auckland, which specializes in titanium 3D printing and manufactures products for the medical, aerospace and other industries. The company said that the production process of the prosthesis, including the processing of digital models and printing itself, took only a few hours. Anna Grimaldi received the product thanks to High Performance Sport NZ. It is funded by the New Zealand government and works with national sports organizations to improve the performance of competitors. nine0003

It is funded by the New Zealand government and works with national sports organizations to improve the performance of competitors. nine0003

From sports to manufacturing

James Novak and Andrew Novak also talk about athletes who have started making their own assistive devices. One of them is American track and field athlete, wheelchair racer Ariel Rauzin. In 2003, at the age of 10, she was paralyzed as a result of a spinal cord injury sustained in a car accident. In 2012, Ariel started wheelchair racing, and in 2016 she founded Ingenium Manufacturing, a company that 3D printed gloves for wheelchair athletes. The girl came up with an idea for a business as part of one of the tasks while studying at the University of Illinois at Urbana-Champaign. The company's website emphasizes that the gloves made of plastic are comfortable to use and strong enough to withstand serious force. The company produces gloves not only for professional athletes, but also for beginners. They cost $150, but buyers under the age of 18 can get a discount: Ariel Rauzin is sure that the high cost of equipment can be an obstacle to starting a sports career. In 2019In 2018, the track and field athlete reported that over 4,000 pairs of gloves had been sold to athletes from 31 countries in three years.

In 2019In 2018, the track and field athlete reported that over 4,000 pairs of gloves had been sold to athletes from 31 countries in three years.

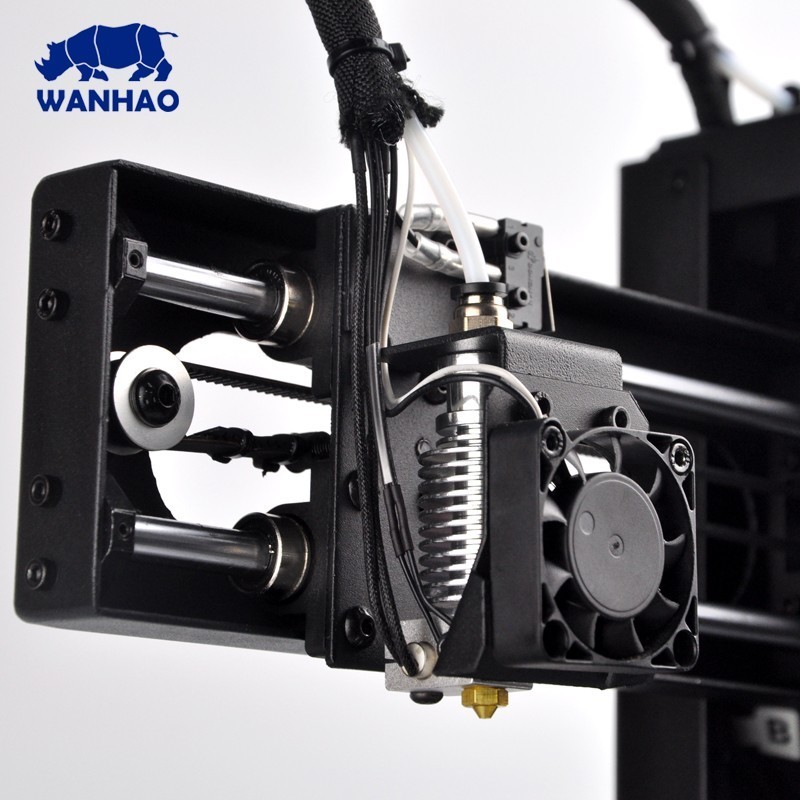

Another athlete who decided to launch his own production of various auxiliary products is the British paratriathlete, participant in the Paralympic Games, World Championships, and Ironman races (long-distance triathlon competitions. — Approx. Plus-one.ru) Joe Townsend. The man served in the British Royal Marines and lost both legs in 2008 in an explosion in Afghanistan. He started triathlon in 2011. At some point, Townsend discovered that there was practically no equipment on the market with optimal performance for athletes at an affordable price. One of the products that Joe Townsend decided to focus on was a bicycle crank that transmits power from the pedals to the wheels. Parts are made from composite compounds, such as MarkForged's Onyx material, which consists of nylon and chopped carbon fiber. They are printed on a Markforged Mark Two printer and reinforced with continuous fibers. Products are lightweight, durable and impact resistant. Their design can be adapted to the individual needs of each athlete - both amateur and professional. nine0003

Products are lightweight, durable and impact resistant. Their design can be adapted to the individual needs of each athlete - both amateur and professional. nine0003

Joe Townsend also 3D-prints other items, such as gloves and special handles (one of the parts of hand-operated bicycles. — Approx. Plus-one.ru). Gloves come in different stiffness: for example, a tough athlete uses during competitions to improve results, and more comfortable soft ones during training. Handles are made to order. The buyer receives plastic granules, which can be turned into a prototype of the desired shape with the help of hot water. The hardened part is sent to the manufacturer, who will print the desired component. nine0003 Ingenium Manufacturing gloves for wheelchair athletes

Photo: Instagram / @ingenium_manufacturing

3D scanning and technology ethics

3D scanning is also used to manufacture assistive devices for paraathletes. It allows you to create three-dimensional models of various parts of the athlete's body and make equipment that is exactly the right size and shape. Back in 2016, the design studio of the German car, motorcycle and engine manufacturer BMW Designworks used 3D scanning technology to produce gloves for wheelchair athletes. The studio made 3D models of the athletes' accessories and then printed them on a 3D printer. This made the gloves lighter and more accurate. nine0003

Back in 2016, the design studio of the German car, motorcycle and engine manufacturer BMW Designworks used 3D scanning technology to produce gloves for wheelchair athletes. The studio made 3D models of the athletes' accessories and then printed them on a 3D printer. This made the gloves lighter and more accurate. nine0003

3D-scanned Australian basketball and tennis player Dylan Olcott's wheelchair has also been created. It is made of carbon fiber and follows the body shape of a parasportsman. The seat, like other parts of the stroller, including the aluminum frame, was developed at the Australian Institute of Sport (Australian Institute of Sport, an educational and scientific institution. — Approx. Plus-one.ru). Compared to analogues, the stroller weighs less, has great maneuverability and is easy to repair. nine0003

James Novak and Andrew Novak note that these technologies are becoming more accessible. Already now, everyone can buy surf fins, various bicycle accessories, including bottle cages, bicycle chain guides, coasters, as well as sneakers with printed soles.