Ups 3d printing stores

3D Printing | 3D Print Services

Find a 3D Printing Location

Print Functional Prototypes

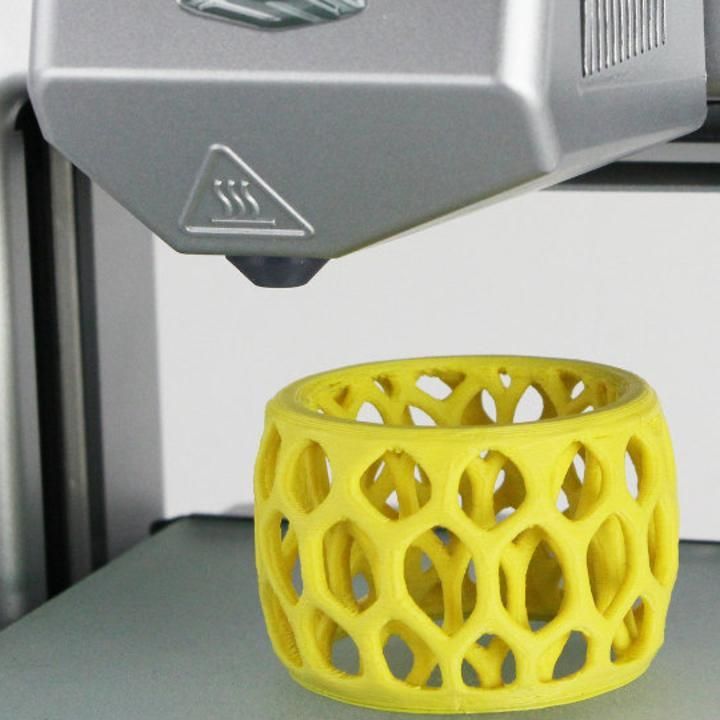

You can use 3D printing for prototypes or one-of-a-kind items. Let The UPS Store® bring your ideas to life. We can even use your 3D CAD file.

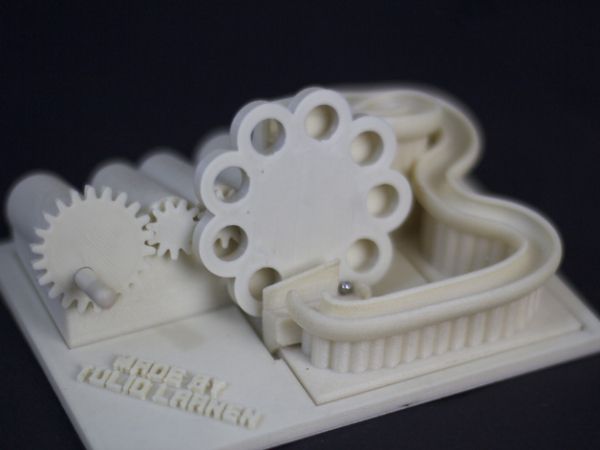

Construct Manufacturing Jigs and Fixtures

We understand when you do your own manufacturing, jigs and fixtures are critical for insuring high-quality and efficiency during assembly and testing. Our 3D printer can create complex parts so you are not dependent on a CNC machine.

Create Custom Accessories

Want to design your own smartphone case or money clip? Most items that are smaller than a breadbox and can be made out of single color of plastic are perfect for 3D printing.

Build Architectural Models

You can work in just about any 3D architectural design program and then export to common 3D CAD file types. The finished product is ready to show off or you can sand and paint your building to give it just the right look.

3D Printing Services Expanded Across Nation

The UPS Store continues to expand 3D printing services nationwide to meet the growing demands of its small business customers. 3D printing now available at approximately 20 The UPS Store locations. Use the interactive map below to find a participating location near you, or check out the full list of all The UPS Store locations offering 3D printing services.

3D CAD and 3D Scanning Services

The UPS Store 3D print locations can now also offer you 3D CAD and 3D scanning services through HoneyPoint3D. Getting a custom 3D print has never been easier - you dream it, HoneyPoint3D designs it, The UPS Store prints it. Enjoy the HoneyPoint3D benefits of an easy quoting process, affordable and quality engineering, online viewing of your 3D files, and efficient turn-around times. Get your 3D CAD or scan quote today!

Netfabb® at The UPS Store®

Participating The UPS Store 3D print locations are utilizing Netfabb software for 3D print file preparation and customization. Services available at these locations include:

Services available at these locations include:

- File fixing

- Text labeling

- Logo labeling

- Cutting

Contact or visit these Netfabb locations to learn more about their advanced 3D offerings.

3D Printing Frequently Asked Questions

Here a few questions we frequently hear about 3D Printing.

Please feel free to contact your local The UPS Store for any other questions you may have

-

What is 3D printing?

-

3D Printing is a manufacturing process that uses a digital file to create three-dimensional objects one layer at a time. We run a system that uses ABS plastic and soluble supports to create realistic prototypes and marketing models.

-

What kinds of things can I 3D print?

-

Small business owners and aspiring entrepreneurs will have the opportunity to print prototypes as part of the new product development process. With this printer, The UPS Store locations will be equipped to produce items like engineering parts, functional prototypes, acting props, architectural models, fixtures for cameras, lights and cables.

-

How long does it take to print?

-

The time it takes to print an object will depend on the complexity of the design. A simple object may take 4-5 hours, while a complex object may take 24 hours.

-

Which UPS Store locations are offering 3D printing?

-

The UPS Store is in the process of rolling out nearly 100 3D printing locations across the country. Visit /print/3d-printing/locations for more information.

More Than Logistics: UPS is Using 3D Printing to Completely Transform Their Industry and Business Model - 3DPrint.com

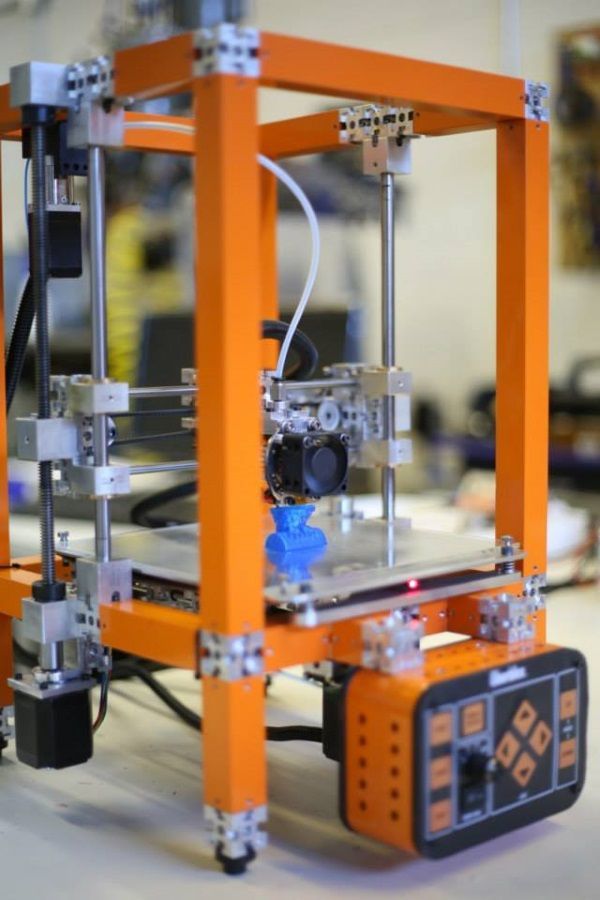

The thing that has always struck me as disruptive about 3D printing is the unpredictability of who and how it is going to be used. The fact is, you just never know where it’s going to show up, and who is going to be using it. 3D printing seems a natural extension of services for companies like Staples or Home Depot, as they have already been in the market of providing small business services to their customers. But who exactly could have predicted that a shipping company like UPS would be one of the fastest growing 3D printing service providers in the country, through The UPS Store?

But who exactly could have predicted that a shipping company like UPS would be one of the fastest growing 3D printing service providers in the country, through The UPS Store?

A growing number of The UPS Store locations are offering 3D printing services.

It started small of course, a handful of their physical locations started including a 3D printer on-site to offer customers an additional service while they stopped in to ship a package. But now, barely a year later and that additional service has spread to more than a hundred locations all over the country. But on-site 3D printing services are only part of the future of one of the largest private shipping companies in the world, and it is becoming evident than in a few years it may not even be accurate to call them a shipping company any longer.

It is important to remember that UPS has always referred to themselves primarily as a logistics company, and now, according to UPS vice president of marketing for global logistics and distribution Alan Amling, that is going to include light product assembly and manufacturing. In a conversation with InformationWeek, Amling detailed exactly how 3D printing is going to factor into the future of the company, and how they’re going to do it.

In a conversation with InformationWeek, Amling detailed exactly how 3D printing is going to factor into the future of the company, and how they’re going to do it.

“Excuse me sir, can you 3D print this small house that I have already 3D printed?”

For a company that sells customized golf clubs like Hopkins Golf the ability for UPS to store individual components, assemble them together when an order is placed and ship directly to the customer is a key part of their business plan. What is sort of brilliant about this particular partnership is the benefits that the relationship offers both companies. For Hopkins Golf they only need to source the parts and make sure that UPS is fully stocked, there is no need to assemble the clubs themselves, package them up and ship them off to customers. Not only does that save them time and allow for faster fulfilment in the age of Amazon Prime, but it reduces the amount of staff that they need as well as virtually eliminates the need for packaging or shipping materials.

UPS benefits by saving on the manpower required to physically pick up Hopkins Golf’s products from their shipping location and physically transport them to a UPS distribution hub. By having the products already in their central shipping facility, where staff can pick and ship what is needed, they can almost instantly be sent directly into their shipping network. This is a service that is already being implemented successfully and has proven itself to be viable. And according to Amling, light manufacturing using 3D printers is simply the next step of this type of service.

“You’d never want to make and store all the possible combinations [of Hopkins Golf clubs]. UPS stores shafts and heads and puts them together to order — this is light assembly that’s already being done. 3D printing coupled with pre-manufactured parts is the next evolution,” Amling told InformationWeek.

The new bank of CloudDDM 3D printers inside of the UPS facility.

UPS recently invested heavily in a 3D printing services company called CloudDDM, who set up a large bank of about a hundred industrial 3D printers inside of the massive UPS facility in Louisville, Kentucky. The workflow is pretty simple, a company offers 3D printable products, or products that need light assembly with 3D printable components. When a customer places an order, it is sent over to UPS and any parts that need to be 3D printed are sent directly to CloudDDM. Once the product is printed and assembled, it is immediately shipped out to the customer. CloudDDM founder Rick Smith sees his new partnership with UPS as a way to set his company apart from his competitors.

The workflow is pretty simple, a company offers 3D printable products, or products that need light assembly with 3D printable components. When a customer places an order, it is sent over to UPS and any parts that need to be 3D printed are sent directly to CloudDDM. Once the product is printed and assembled, it is immediately shipped out to the customer. CloudDDM founder Rick Smith sees his new partnership with UPS as a way to set his company apart from his competitors.

“Most of the service companies in the space are mom and pop, but CloudDDM is trying to be a manufacturer with some scale. The target parts are things like low-volume replacement parts that might fall below the minimum order from a manufacturer,” explains Smith. “We talked about this huge disruptive tech over a 50 year span. UPS is a supply chain management company. They want to go to customers and tell them this is how to think about additive manufacturing.”

While it is still early days for this type of service, and both UPS and their customers have a lot of logistical issues to work out, creative logistics is what UPS is known for. Not only is this an evolution of the 3D printing service provider market, but it’s a complete disruption of the light manufacturing, shipping and fulfilment markets as well. UPS has a huge network of customers all over the country, and a sizable staff of people who manage them. If anyone can successfully proselytize the benefits of using this type of business model to their clients it is going to be UPS.

Not only is this an evolution of the 3D printing service provider market, but it’s a complete disruption of the light manufacturing, shipping and fulfilment markets as well. UPS has a huge network of customers all over the country, and a sizable staff of people who manage them. If anyone can successfully proselytize the benefits of using this type of business model to their clients it is going to be UPS.

According to Amling, the goal of their new light manufacturing and digital reordering business model will require the use of every resource that UPS has available to them. That means using both the CloudDDM printer farm in Kentucky and the 3D printing capabilities of local UPS Stores to to the work. They just need to put a system in place to figure out what can be done where, and how much time will it save them. UPS is a global company, so the plan is to put this new model into place everywhere, however the company is currently restricting it to the US until they get the new model just right. But honestly it is only a matter of time before they do, and I fully expect to see similar fulfilment models implemented by other large online retailers like Amazon (which already offers something similar without the 3D printing) and Wal-Mart.com.

But honestly it is only a matter of time before they do, and I fully expect to see similar fulfilment models implemented by other large online retailers like Amazon (which already offers something similar without the 3D printing) and Wal-Mart.com.

Soon to be more than logistics.

At a previous job I worked closely with UPS for several years, and the few times that I was able to look into their logistics network it was sort of like walking into an Escher painting come to life. Nothing seemed to make sense to me, but for some reason it all seemed to work both quickly and efficiently. With the plans that UPS has for 3D printing, it’s pretty clear that logistics is just another industry that is being transformed by 3D printing. Discuss this story in the UPS 3D Printing forum on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printing services • 3D printing UPS • Alan Amling • cloudddm • fulfilment • light manufacturing • logistics • printer farm • Rick Smith • the ups store • ups

Please enable JavaScript to view the comments powered by Disqus.

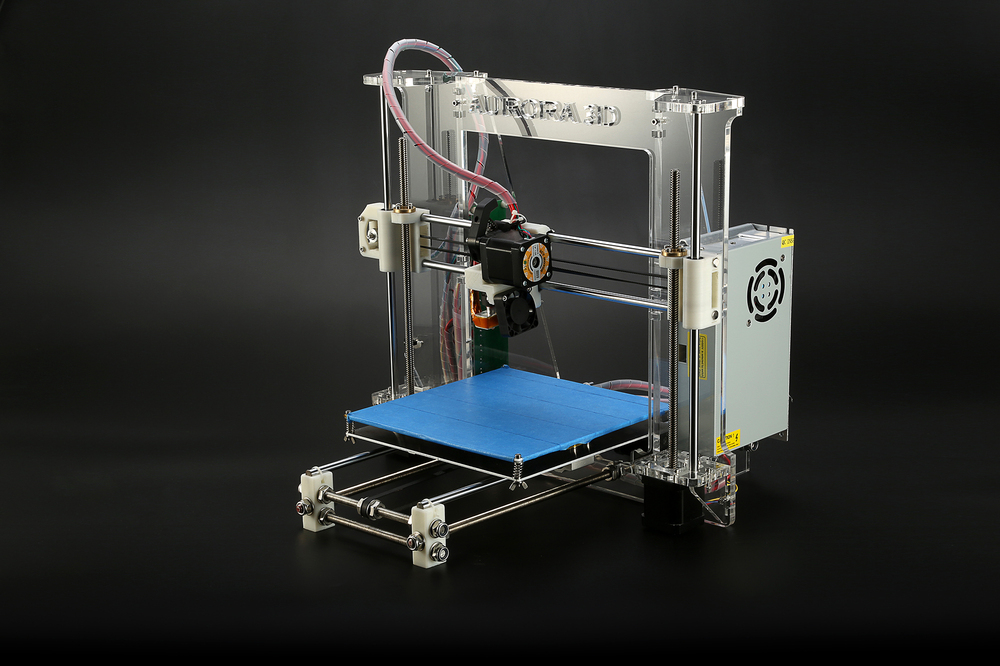

UP Box+

3D Printer PartsAvailability

In stock

Manufacturer

Country of origin

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China | nine0020

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! | nine0020

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go nine0003

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

Add to compare

Product added to compare Go nine0003

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Add to Compare

Product added to comparison Go

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go nine0003

| Manufacturer | UP! |

| Country of origin | China |

Add to compare

Product added to compare Go

| Manufacturer | UP! |

| Country of origin | China |

Manufacturer direct

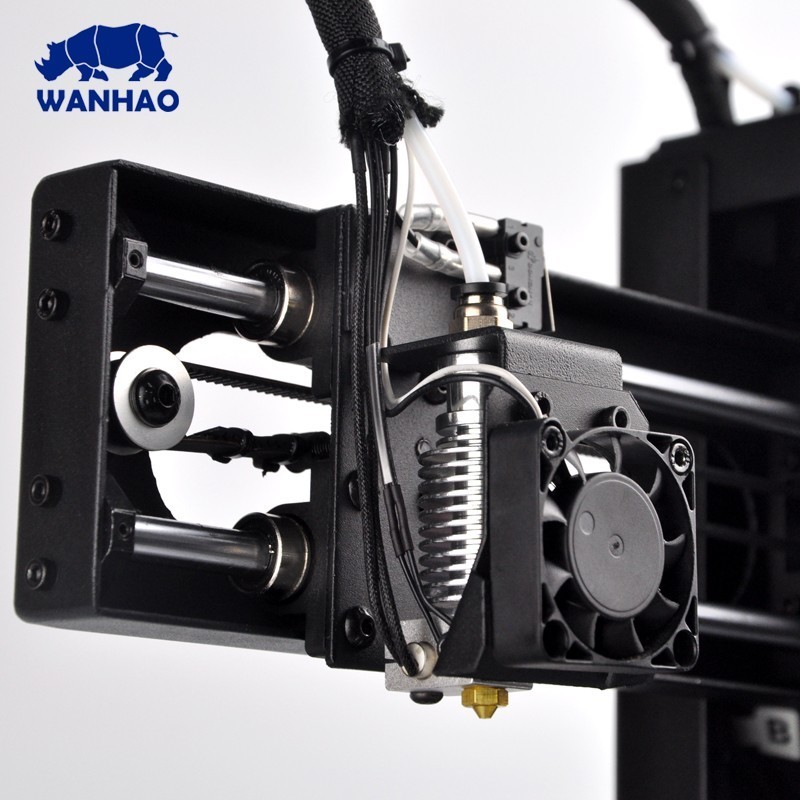

Our company is the official distributor of leading manufacturers of desktop and industrial 3D equipment (3D printers, 3D scanners, 3D manipulators) - Raise3D, FlashForge, Anycubic, Formlabs, Creality3D, PICASO 3D, Phrozen, Wanhao, CreatBot, QIDI, etc.

Own warranty service

We provide professional services for the selection, configuration, training, warranty and post-warranty maintenance of 3D equipment. nine0003

Pre-Purchase Demo

Before buying a 3D printer or scanner, you will be able to evaluate the functionality of the model you like in practice in the company's showroom in Moscow, get an online consultation on choosing the optimal equipment model for your tasks.

Free delivery within Russia

We work with the most reliable transport companies and courier services. Delivery of 3D printers is FREE of charge to all regions of the country! nine0003

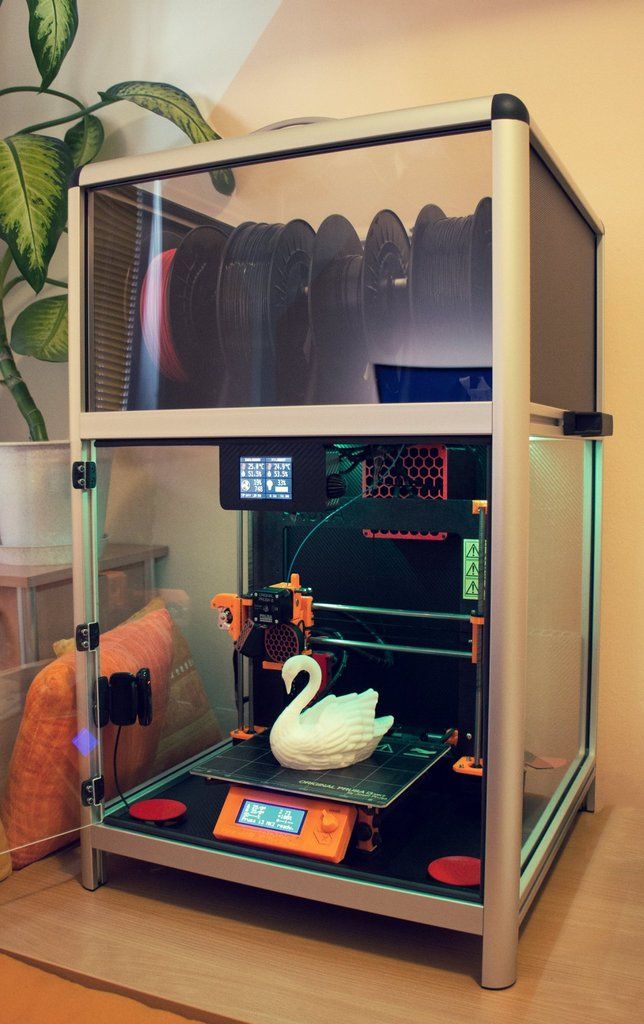

3D Printer Overview UP! Mini

3D printers have long ceased to be expensive, bulky and noisy devices used only in industrial production, various institutions and large companies. Printing and modeling three-dimensional objects at home no longer requires high costs and in-depth knowledge. There are many types of 3D printers now: self-assembly kits, expensive European and American 3D printers, high-precision 3D printers with a large print area, for jewelers and dentistry, etc. But among all the models available and with stable high print quality, there are not so many. One of them, compact and elegant - 3D printer UP! mini. nine0003

But among all the models available and with stable high print quality, there are not so many. One of them, compact and elegant - 3D printer UP! mini. nine0003

The Mini has been on the market since 2013 and is still one of the best compact 3d printers around. Model UP! Mini - developed by PP3DP. Because Since PP3DP is part of Tiertime, a large Chinese corporation that produces industrial 3D printers, you don’t have to worry about build quality and reliability. Serious production control and the absence of marriage are confirmed by numerous world awards, including the authoritative MAKE magazine for the best printer in the "get it and print" class. nine0003

Design

UP! Mini is a closed chamber 3D printer that has a positive effect on print quality, filters possible unpleasant odors, reduces the noise of moving parts inside the printer, and protects you and your children from burns if you accidentally touch the nozzle or 3D printer platform. With a modern design, UP! The Mini looks more like a coffee machine or something like that, rather than a modern machine that prints three-dimensional models from plastic. nine0003

With a modern design, UP! The Mini looks more like a coffee machine or something like that, rather than a modern machine that prints three-dimensional models from plastic. nine0003

Another advantage of this model is the patented Teflon-coated perforated working surface of the platform. Thanks to it, grip increases, stability and a stable position of the printed model increase. You do not need to spend money and time on the purchase of special coatings: adhesive tape, glue, varnish, special film, etc. which are widely used on many 3D printers from other manufacturers.

Getting Started

UP! Mini does not require you to seriously and deeply study the instructions for assembly, configuration and calibration. All you need to start printing is to take the printer out of the box, install the spool of plastic and the build platform, and start printing. Everything you need to run your 3D printer smoothly is included. Together with the device you get: a spare platform, a plastic coil and special tools for setting up and maintaining the device.

Sizes UP! The Mini is only 240 x 340 x 355 mm and weighs 6 kg. As mentioned above, according to these parameters, the device rather resembles an elegant and stylish household appliance that will complement and decorate your interior. With this in mind, you can safely place it anywhere in your home or office. nine0003

UP! Mini uses its own software, which any user can understand, the program is simple and intuitive, fully Russified and allows you to change and customize:

- Print speed

- Material type

- Percentage of material filling of the internal cavities of the model

- Scaling and rotation of the model

- The operating temperature of the extruder and platform.

- Size, type of supports and rafts

Or just select the type of plastic and start printing, all other values recommended for this type of plastic, the program will change on its own. All current operating systems are supported - Windows from XP to 8.1, and Mac OS X.

One of the main advantages of the UP 3d printer! Mini - is the presence of the "Pause" function, when during operation you can pause printing, replace the material and continue printing with a different color, which allows you to create bright and multi-colored models.

Getting started

So, you have connected the printer, loaded the model into the program and start printing. After sending the model for printing, the printer will need some time to load and prepare the virtual model for printing, the extruder and platform heat up, the layers of the model are calculated programmatically. After starting printing, you can safely disconnect the computer from the printer, then the printer will work autonomously. nine0003

Worktop size UP! Mini - 120x120x120mm. very good figure for such a small 3d printer. And don't let those numbers scare you, you can always print a large multi-part model. Special programs allow you to divide your virtual model into components already prepared and configured for 3D printing, print, and then glue. We recommend this method due to the fact that when printing on devices with a large print volume, any power outage, power surges, or suddenly running out of plastic will stop the printer and printing, which took several hours, will have to start over. nine0003

We recommend this method due to the fact that when printing on devices with a large print volume, any power outage, power surges, or suddenly running out of plastic will stop the printer and printing, which took several hours, will have to start over. nine0003

Maximum print resolution UP! Mini - 200 microns, or 0.2 mm. On our own, we add that due to the special closed design, uniform heating of the surface and the extruder, visually the models look comparable to those produced on 3D printers with a higher resolution (for example, 150 microns) and an open circuit. And do not forget that the higher the resolution, the longer it will take to print. For example, printing a model on printers with a resolution of 20 microns will take 10 times longer. nine0003

UP! Mini uses the most common consumables ABS (Acrylonitrile Butadiene Styrene) or PLA (Polyactide). But thanks to the heated bed and high extruder temperature, you can print flexible, engineering and decorative plastics. The printer comes with branded plastic, but you can use third-party plastics without loss of warranty and quality, the only condition is a diameter of 1.75 mm.

The printer comes with branded plastic, but you can use third-party plastics without loss of warranty and quality, the only condition is a diameter of 1.75 mm.

When UP! The Mini emits a short, rather loud and unpleasant squeak, but this is where all the unpleasant things from the printer end - both in terms of smell and noise from it, as expected, no problems. The printing process is monitored visually by the color of a single button. The backlight of the button changes color depending on the stage. And thanks to the backlight inside the case, you can observe the printing process without opening the printer door. nine0003

Output

UP! Mini is a full-fledged and serious device, perfect for both a beginner and an experienced professional. If you don't want to tinker with assembling, setting up, modifying the device, adding additional components, then the UP! Mini just for you.