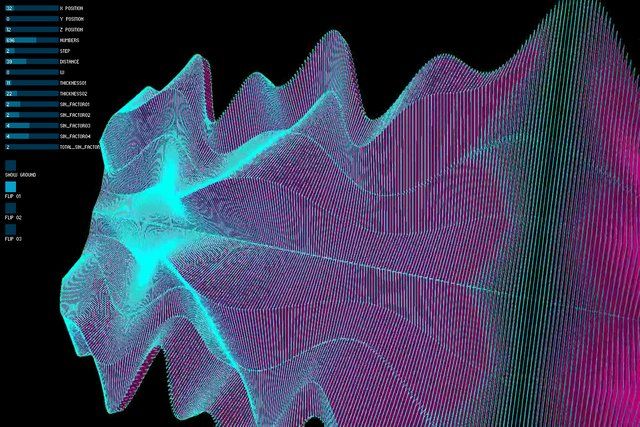

3D printing data visualization

Data Visualization Models Custom 3D Fabrication Services

Data Visualization 3D Models + Technology

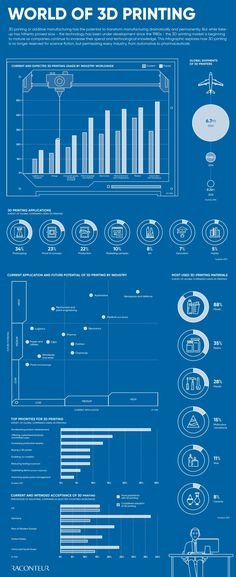

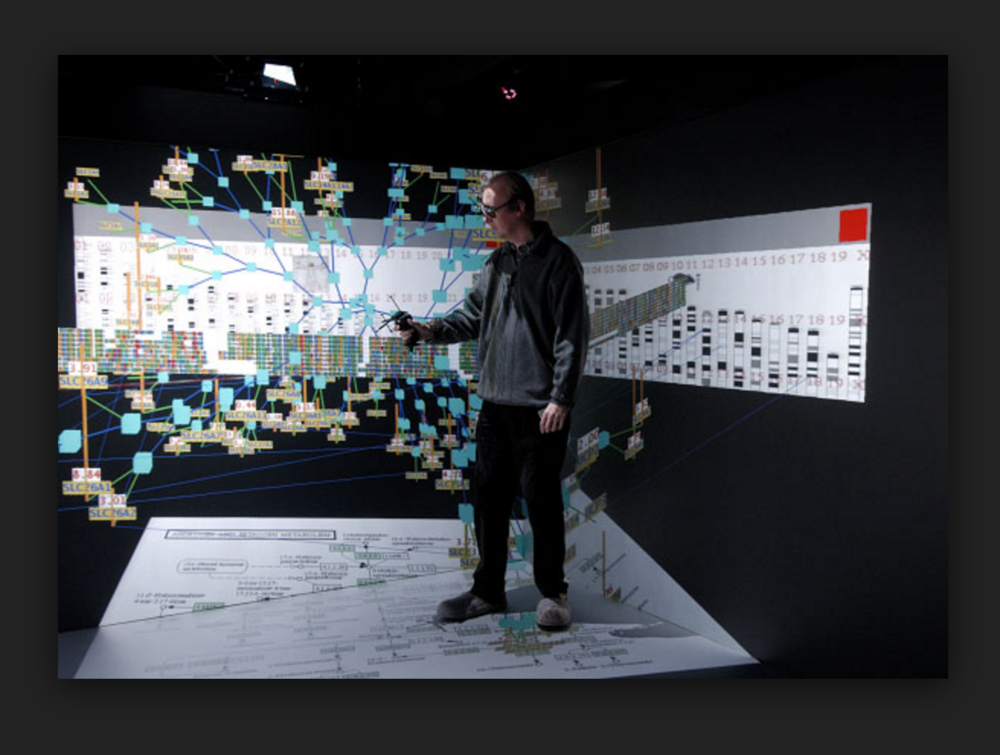

Everyone loves show and tell. That’s exactly what data visualization means. By showing a physical model of the data, rather than just telling others about it or reading it off your paper, you let the model do the explaining. When you can see what is trying to be conveyed, it’s much easier to comprehend than just reading about it or seeing an image on a flat 2D screen. 3D printed data visualization is improving communication all over the globe – visually.

Museums, art galleries, corporations, small companies, scientists, government agencies and educational institutions use data visualization through 3D printing to enhance presentations and communicate simple and complex data sets.

A majority of the population (approximately 65%) use visual learning, or a combination of visual learning & words as their preference.

This is a 3D diorama display of a underwater salt formation located in the Caribbean ocean.Features & Benefits

- Presentations and displays are more effective.

- Helps to avoid information dumps of data and makes it easier to understand.

- Enhances insight into the data.

- Allows for quicker understanding of data.

- Enables hands-on experiences and collaboration.

- Models can be displayed in a variety of places to benefit more people, i.e. boardroom, museum, home, office and classroom.

- People can experience the data visualization model together versus individually just looking at the data on a computer screen, tablet or mobile device.

Data Visualization Applications

Business

Many types of business data can be condensed into a single 3D printed data model that contains a multitude of data rather than having that same information on numerous slides, leading to a more memorable experience for the attendees. Audiences are more receptive to what’s being presented when they can see it up close.

Audiences are more receptive to what’s being presented when they can see it up close.

All areas of your business can benefit from models that include data like sales revenues/losses, growth, product sales and product comparisons. Here’s an engaging model for 2016 Fast Food Sales that measures the data in hamburgers, cups of coffee, donuts, and chicken legs.

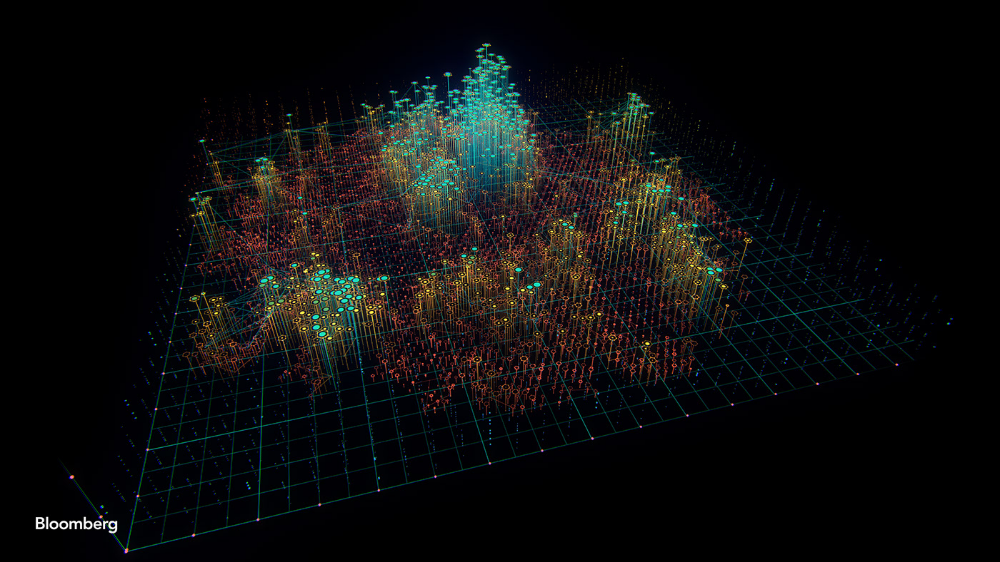

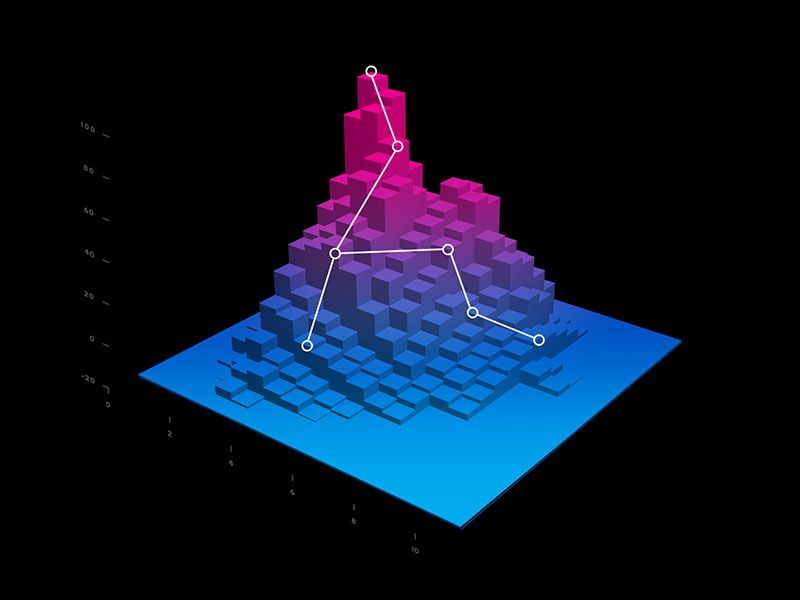

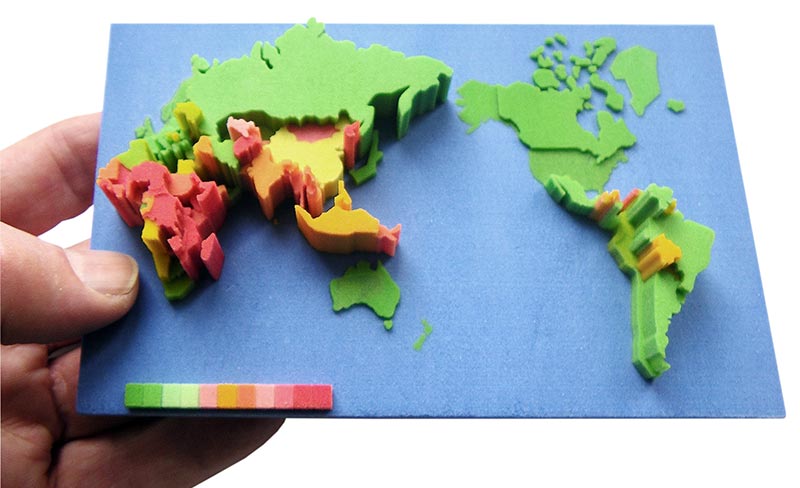

Another example is printing a 3D tangible data height map that can help make certain decisions easier for consumers. Some questions it may facilitate and answer: Is your area beneficial for pursuing solar? How much can you save? How long until it pays for itself? How much does it cost to install by state? What tax credits are involved by state?

All of these pieces of information can be included in a single 3D data model allowing you to quickly dissect the data visually as opposed to relying strictly on researching the words and numbers in a report. This also enables you get immediate feedback from your target audience.

Museums and Expos

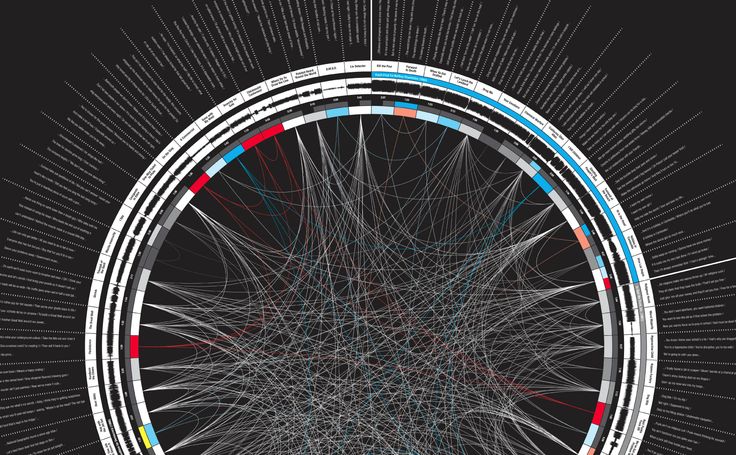

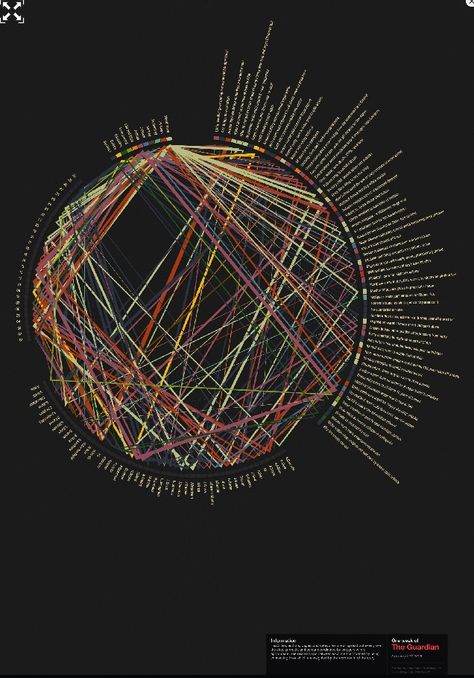

Museums and expos are using interactive sculptures like these data visualization models as fun and informative ways to display data. Timelines like this one are displayed when museums host exhibits on a particular theme. There are also tablets and computers with touchscreens available so visitors can interact and learn more about the subject.

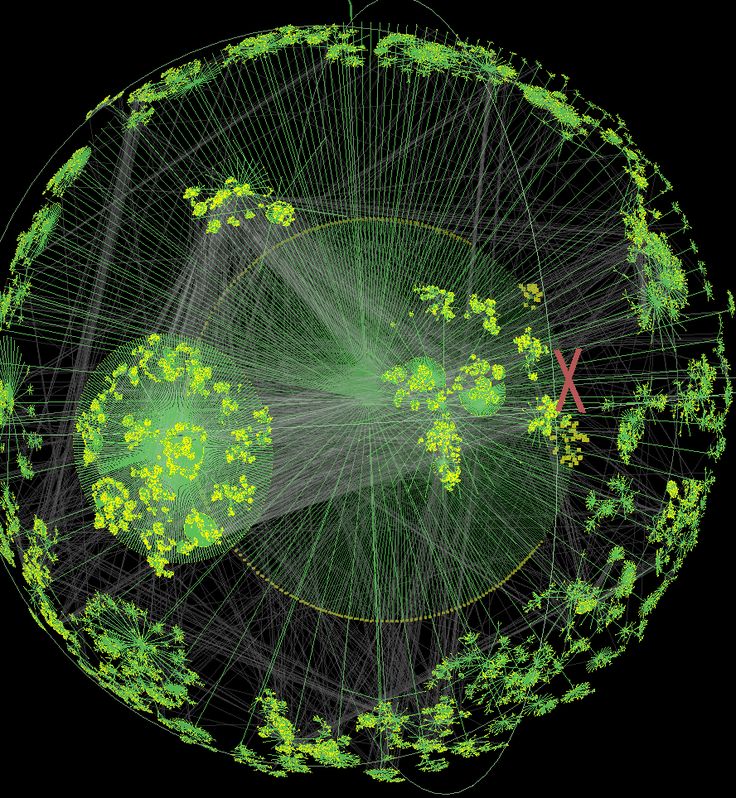

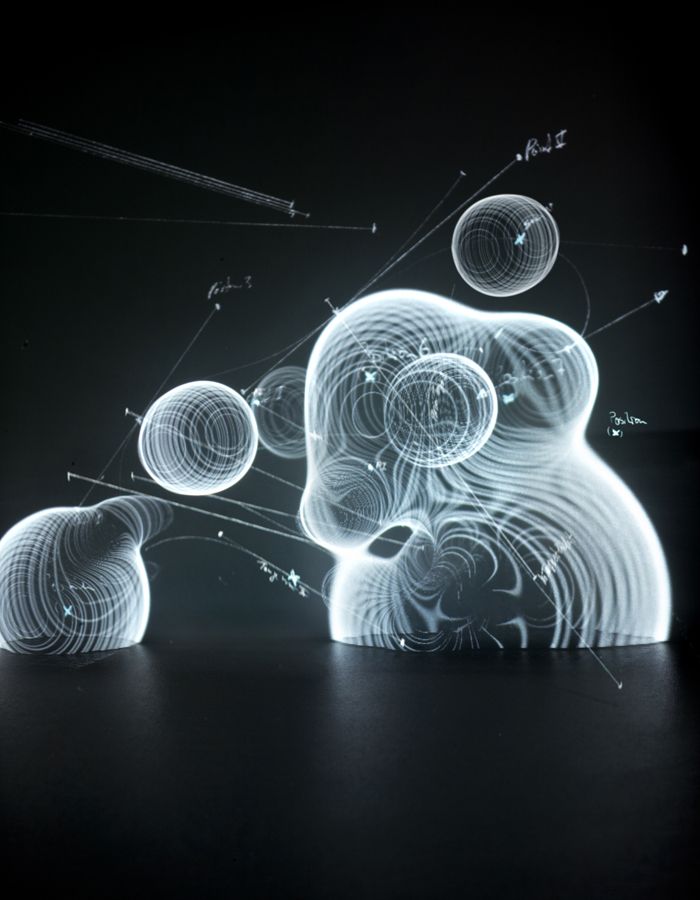

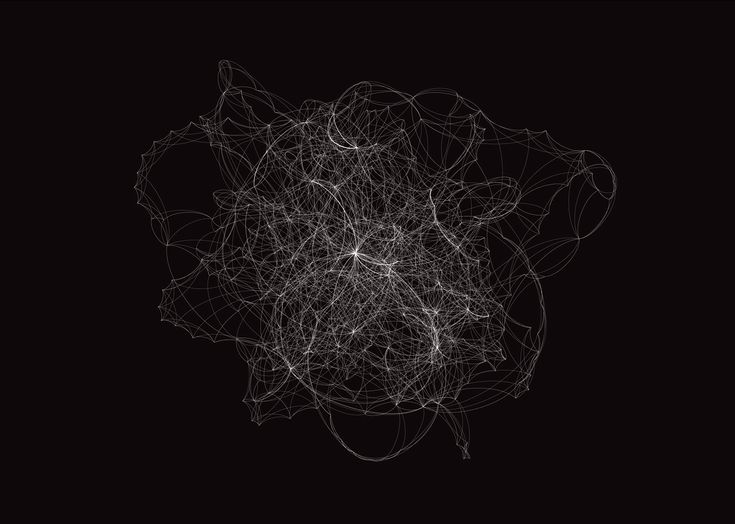

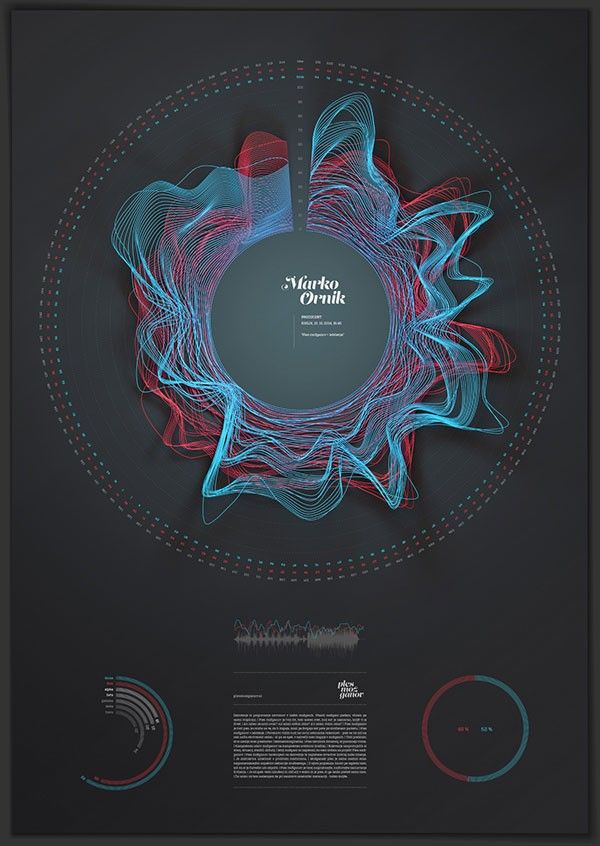

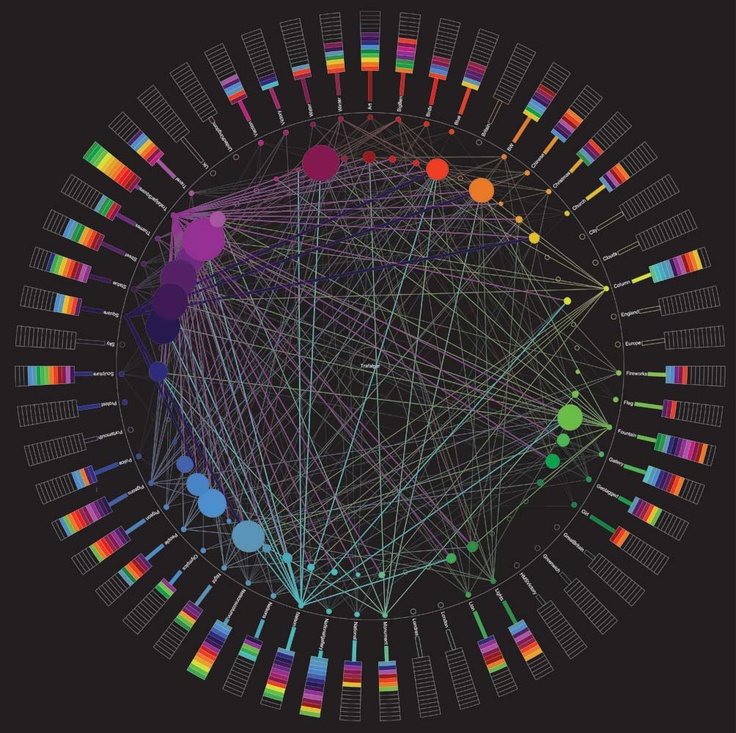

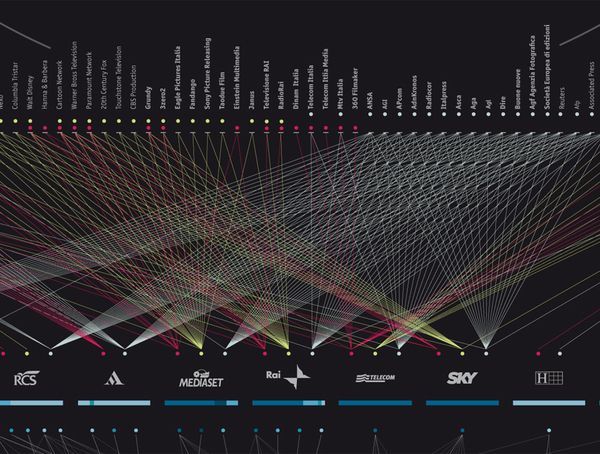

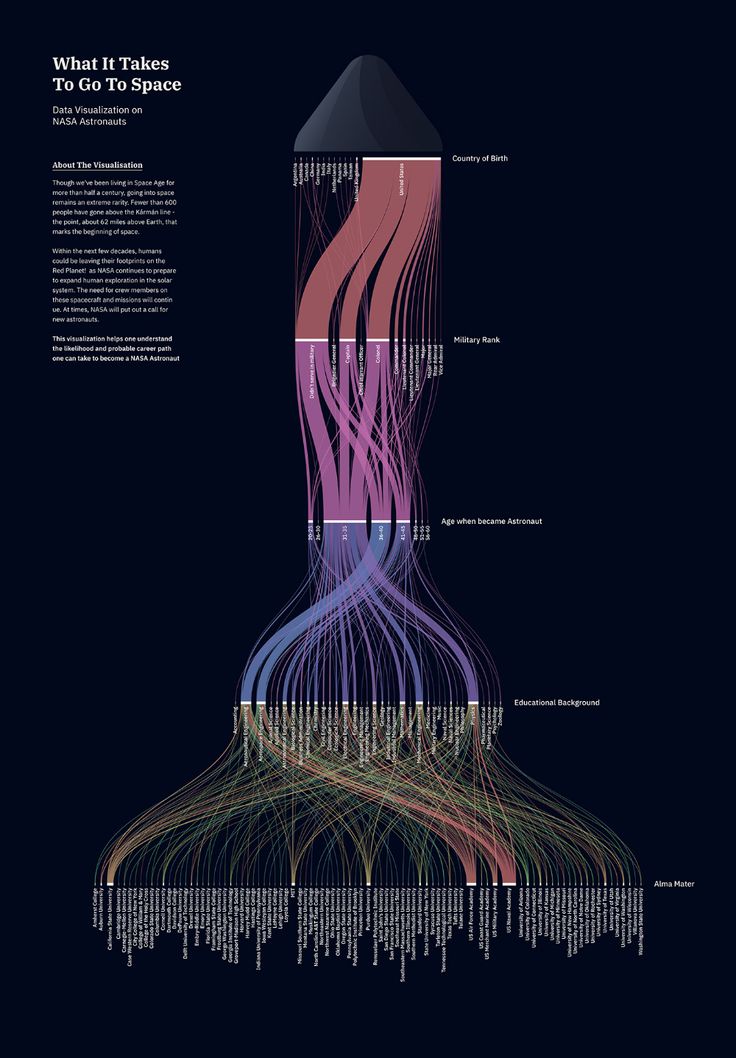

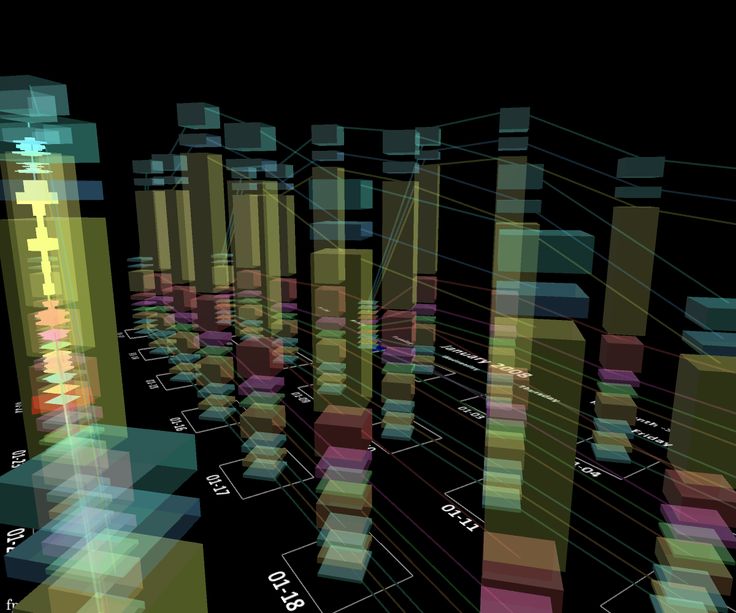

The emoto project (pictured below) captured and analyzed tweets in real time during the London 2012 Olympics and then created an interactive model that enabled users to see the tweets of the most interesting themes and who tweeted them at what time of the day.

Education

Statistics like graduates in a school district over the last decade or since the turn of the century. High school dropouts by district, state and country, test results comparisons, enrollment increase/decrease in any given time period, etc. can all be presented as a physical model along with interactive technology to increase awareness to issues facing education today.

Manipulatives, which are toys and tools used to teach math, can be 3D printed to enhance the learning environment. Many kids learn best if they play with blocks and tools they can touch. Customized manipulatives are generally cheaper to 3D print, so more kids can make use of them in the classroom.

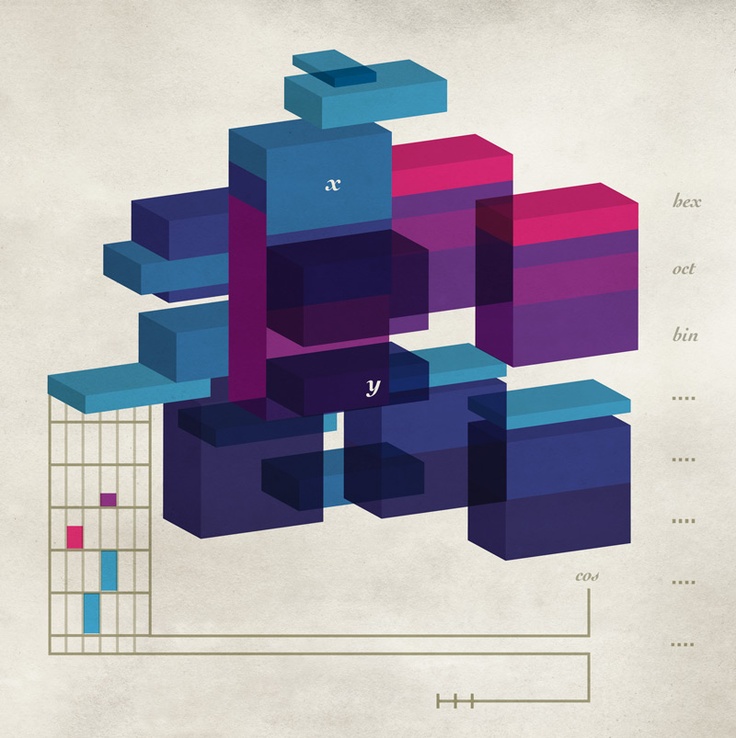

Classrooms are starting to implement 3D-printed models they can print themselves or externally printed 3D models in their lesson plans. The above image is a 3D-printed manipulative used to illustrate mathematic equations that can be operated by the student.

3D-printed manipulatives used to illustrate mathematic equationsManufacturing Process

Data models can also be applied by analyzing manufacturing and consumer data on how products are used, possible break points or areas of high stress, possible grip points and its impact on the structure itself through frequent usage. Parts and Prototype manufacturing such as structural integrity and damage prevention/reduction.

Parts and Prototype manufacturing such as structural integrity and damage prevention/reduction.

Taking data on how the consumer will or has used similar products in the past can visually show the designers where they might need to focus their attention more before they even start designing. This will save both time and money, allowing manufacturers to build products that are stronger, more durable with higher efficiency.

Memorialize Events

We each have fond memories of those we love, our accomplishments and major life events. Having a physical representation of that time is another way to use data visualization. We can also pay tribute to others like the brave people who survived, lost their lives, rescued others and all of us who were affected by the events at the World Trade Center on September 11, 2001.

3D-printed data of man-made and natural disasters enables research and understanding to help prevent or reduce these tragic events in the future.

This data visualization model of the 2014 San Francisco Earthquake was created by Doug McCune to see how it compared to earthquakes that hit San Francisco in 1906 and 1989. The US Geological Survey built models for the earlier earthquakes and he was able to get them all together for the side-by-side comparison.

On March 11, 2011, a 9.1 magnitude undersea megathrust earthquake hit Tōhoku Japan and the tsunami that followed was more than 131 feet tall. The quake struck offshore and had worldwide effects. Covering 11,000 miles, the tsunami waves traveled across the pacific to Alaska, Hawaii and Chile. They were nearly 7 feet high when they reached the shore in Chile and they tore a huge chunk of ice off of Antarctica.

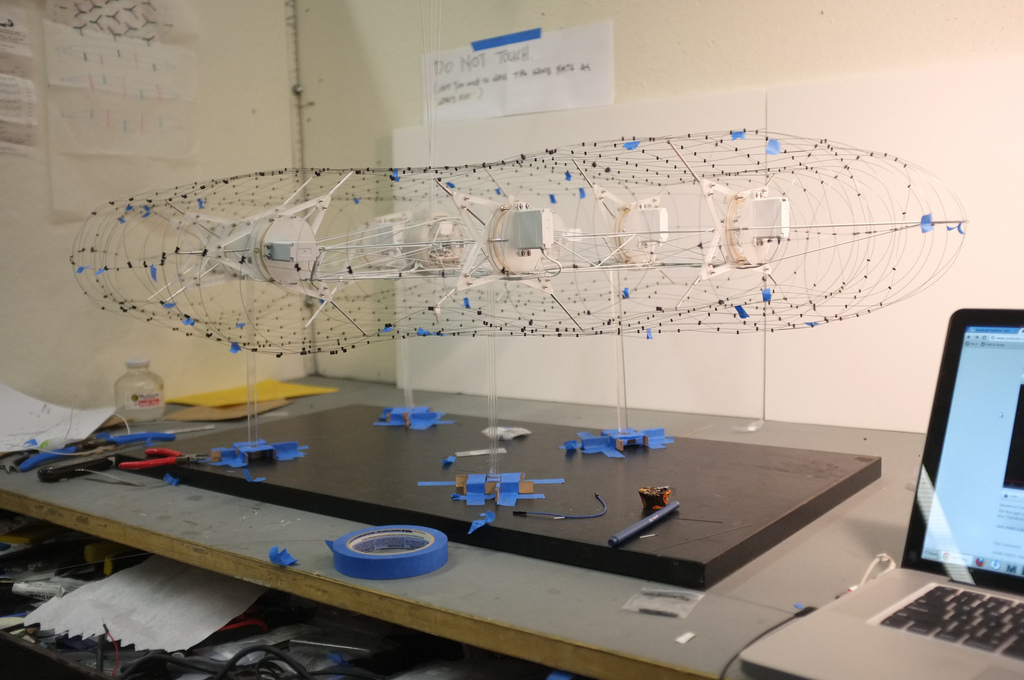

The 3D data sculpture below was created by Luke Jerram to explore how data is read, represented and interpreted. It measures 11 13/16 in x 7 7/8 in and represents the 9-minute duration of the quake. It’s amazing how a stunning piece of art can be created from an event so terrifying.

Science

Scientists in all fields use 3D printed data for training, assessing patterns, presentations and more. Meteorologists use physical three-dimensional models to show a plethora of data including tornado paths yearly, by decade and areas affected the most, rainfall by county, state, country and globally. NASA also uses topography models for educational purposes and to help scientists better understand the Earth and its solar system.

The data that can be 3D printed is endless but here are a few more possibilities: carbon emissions in big cities, the effects of weather on crops by region, molecules, atoms, land and water, pollution, population and census data, cityscapes, noise simulation, and sound waves.

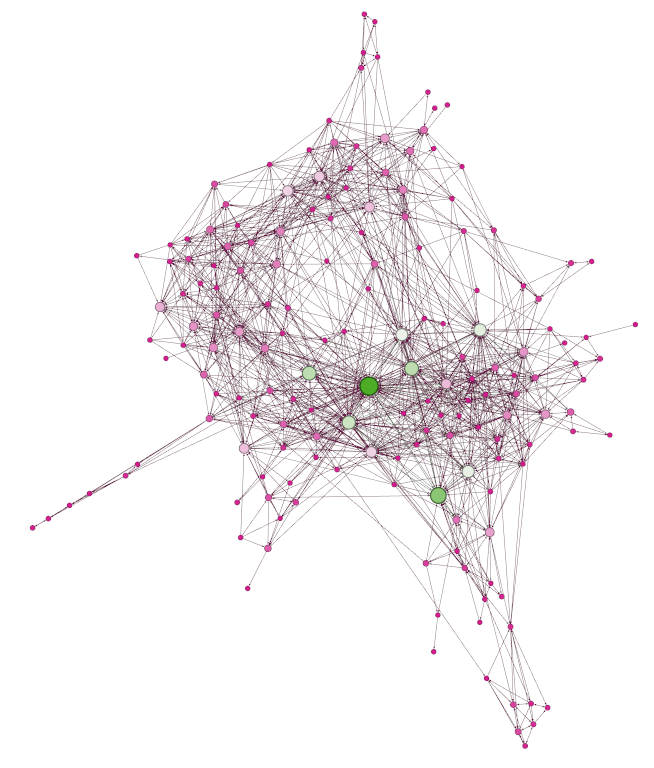

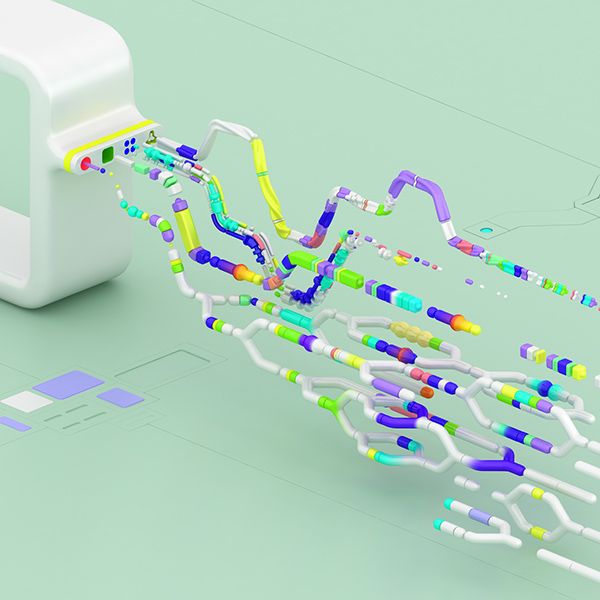

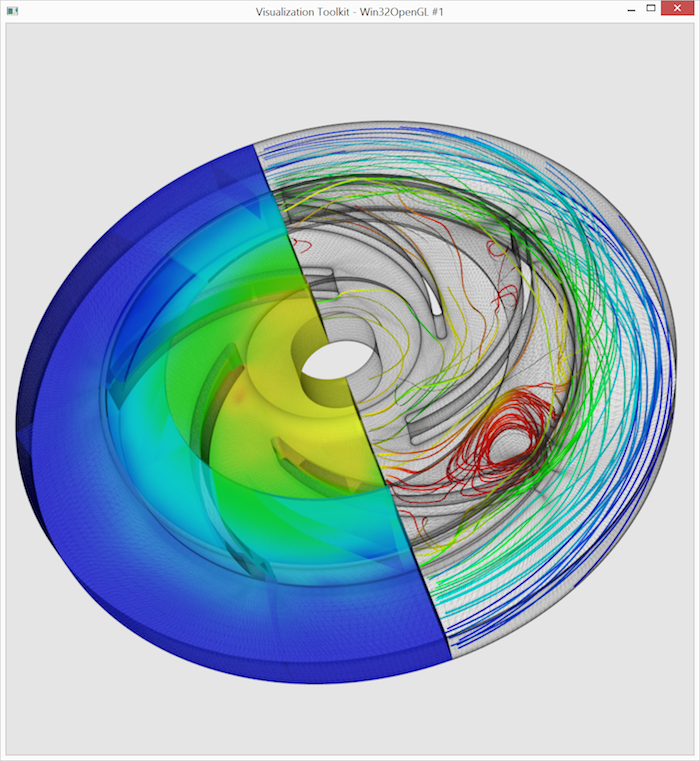

Tractography models are used for studying the brain and for preoperative planning for brain tumors and vascular malformations. The models visually represent the electrical impulses around the brain. The data used to create these physical models is collected by combining magnetic resonance imaging (MRI) and CT-Scans.

Government Agencies

City Planning also benefits from 3D-printed data visualization. Using housing DATA with geospatial overlays, physical models assist builders and city planners on how to best implement emergency plans and strategies to deal with natural disasters like floods, hurricanes, tornados, earthquakes (structure stability), mudslides.

Urban planning also benefits from data visualization and can include the effects of proposed construction on historical sites, impact of growth on rural communities, environmental planning like the shoreline changes due to global warming and the affect high-rise buildings have in downtown areas such as humidity, sunlight, temperature and wind tunnels. These models are useful for comparisons of past urban space, as it exists today and what it might look like in the future after new construction or developments are made.

Department of Defense could use this technology to assess 3d printed statistical information on terrorist cells’ location, population density, and movement for a given period of time. To better predict future movement, growth rate, and threat level.

To better predict future movement, growth rate, and threat level.

Creative Industry

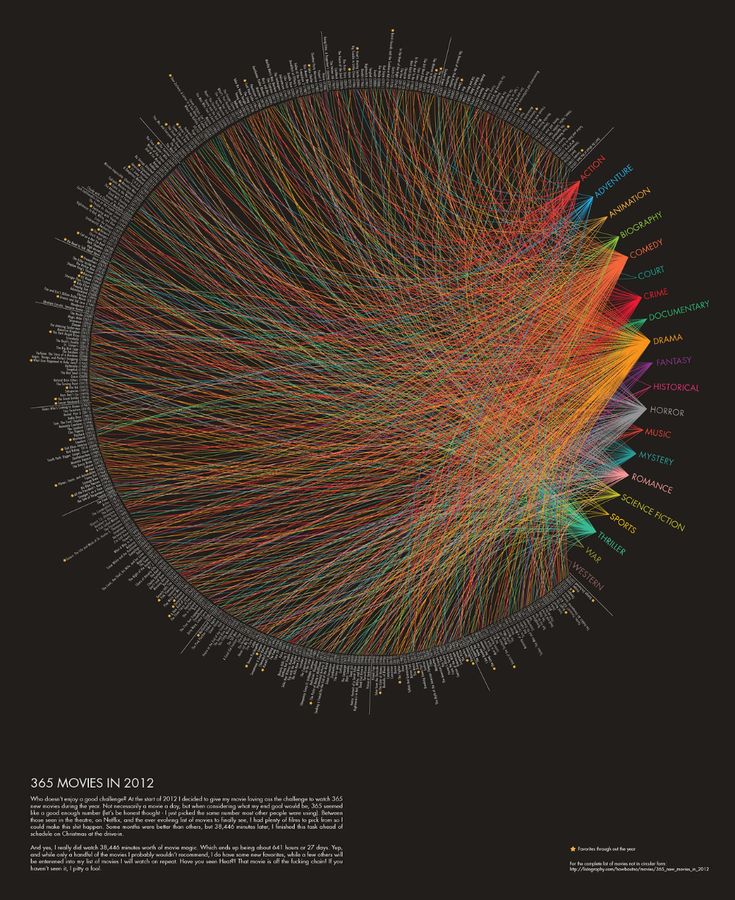

Some people refer to this technology as 3D printed data sculpture. Artists and sports enthusiasts take data from sporting events like the Super Bowl to create dynamic pieces of 3D art. The images below represent the passing stats of Super Bowl I in 1967 to Super Bowl 50 in 2016.

Below, the 3D-printed charts show shots made by NBA players. Each cell represents one square foot on the court. Collectively they show shot distribution for each player. Placing the data side-by-side you can compare each player’s strengths and where they’re lacking.

These data models can be 3D printed in a variety of materials including metal. Other sculptures created with 3D printed data, including furniture like this illuminated New York City landscape tabletop, add to the ambiance of a room.

Technology and Materials

- With 3D printing technology, you aren’t limited to straight lines and boxes.

A 3D printer can easily print jagged edges, curves, and intricate details. Other technologies include foam fabrication, hot wiring, CNC cutting, laser cutting, and welding.

A 3D printer can easily print jagged edges, curves, and intricate details. Other technologies include foam fabrication, hot wiring, CNC cutting, laser cutting, and welding. - We can 3D print data visualization models in different materials including UV-cured resin. The type of model you’re looking for determines which material will produce the best results. We can help you choose the material that is best for your project.

- 3D printed data visualization models show incredible detail. The resolution of our printers is finer than a human hair.

- Data visualization models can be 3D printed in full-color (over 750,000 variations of color) for awe-inspiring presentations and displays. No painting required!

Using translucent plastic, data can be programmed to light up from beneath the model with different colors via a projector that’s connected to a laptop or iPad. The program beams an image onto the model from below. This kind of model can facilitate multiple samples of data because it’s made of clear material. So all you need to do is pull other data from your device and project it from underneath the model.

So all you need to do is pull other data from your device and project it from underneath the model.

Pricing

The cost of a data visualization model is based on the volume of materials (size of the model), type of materials, the time it takes to create the 3D design, production labor, and installation time and materials, as well as other specific elements unique to the project. Each model is bid individually and the best way to determine cost is to email us, call us at 385-206-8700, or fill out the form below and let us bid on your project.

Get a Free Price Estimate for a Custom 3D Data Visualization Model

Custom Fabrication Workflow

Common Questions & Answers

-

What file type is required to make 3D-printed data visualization?

We work with all architectural CAD programs including AutoCAD, Revit, and Maya just to name a few. If you design in 3D, we will start with your 3D files. If you have 2D blueprints and elevations, or artist sketches, we can build a model from these files as well.

-

What technology do you use to fabricate/print 3D data visualization models?

It can be a number of different technologies, individually or combined. These range from 3D foam, 3D printing, CNC cutting, laser cutting, laser etching, casting, molding, sculpting, painting, airbrushing, laminating, vinyl printing, and woodworking – all meant to produce high quality models. -

What is the material used?

We match the correct material and fabrication process to your requirements in terms of presentation, size, and transportability. We fabricate in our model shop using different types of foam, wood, metal, resins, and acrylics. We can also 3D print in UV-cured resin, plastic, rubber-like acrylic, and nylon. -

What is the largest model you can 3D print?

There is no limit to the size of model. Transportability will be your only concern on an extremely large model. -

What is the turnaround time for a 3D-printed data visualization model?

This depends on the features of the design itself as well as the scale of the model. We usually ask for six to eight weeks from the time we take the order to when you will receive the model. Large projects can be four to six months or longer. We understand that sometimes deadlines are tight and we can accommodate rush orders.

We usually ask for six to eight weeks from the time we take the order to when you will receive the model. Large projects can be four to six months or longer. We understand that sometimes deadlines are tight and we can accommodate rush orders. -

If I want a second model, is it cheaper?

Our pricing is based on the fabrication costs and the time it takes to prepare your design. The second model is less money because the design portion is complete.

Do you have a question we didn’t answer? Don’t hesitate to contact us at 1-385-206-8700 or [email protected].

Shapeshifting Data Visualization Model Interactive Data Visualization Model Rearrangeable Data Visualization ModelWorldwide Delivery

WhiteClouds has delivered models around the world.

History of Data Visualization Models

For thousands of years, civilizations have made data visualizations with things they had on hand: clay, sticks, and other physical objects. Anciently, the Sumerians used pieces of clay to represent units of measure. Native Micronesians from the Marshall Islands used stick maps to show ocean swell patterns. Women from the Yakama Native American tribe used strings made of hemp as personal diaries of life events. Each being represented by a knot, bead or shell. It is called an Ititamat or time ball which grew in size as time passed.

Anciently, the Sumerians used pieces of clay to represent units of measure. Native Micronesians from the Marshall Islands used stick maps to show ocean swell patterns. Women from the Yakama Native American tribe used strings made of hemp as personal diaries of life events. Each being represented by a knot, bead or shell. It is called an Ititamat or time ball which grew in size as time passed.

And as early as 1812 when Napoleon marched to Moscow to conquer the city, charts were created to show others what happened. This campaign, charted by Charles Joseph Minard, was a disaster and the 470,000 soldiers Napoleon started out with, were reduced to just 10,000. He even included the winter temperatures the soldiers had to deal with along the way.

In 1854, John Snow – no, not the one from Game of Thrones – created a dot map visualization that showed the number of cholera deaths by household in a London neighborhood. Because of this data, they were able to find out that those dying all got their drinking water from the same well. Turns out it had been contaminated by sewage. This led to the solution of building sewage systems and protecting the wells from further contamination.

Turns out it had been contaminated by sewage. This led to the solution of building sewage systems and protecting the wells from further contamination.

Florence Nightingale used them in 1855 – 1856 to determine that the soldier mortality rates in the Crimean War were high and soaring higher due to the poor hospital practices, not just because of the battles that were going on. Her research was part of a Royal Commission. Her colleague, a statistician named William Farr, wasn’t a fan of including the visualization but she stood her ground. As a result, it’s one of the most famous records of data in the world.

In 1995, Mike Bailey created the San Diego Supercomputer Center’s TeleManufacturing Facility to help scientists visualize their data with a physical model. One of the first digitally-fabricated molecular models was created using laminated object manufacturing. This enabled biochemists to get insights not otherwise available from on-screen 3D models. Their conclusion was that physical models are important tools that greatly increase the understanding of data available from 3D computer graphical analysis. After moving the facility to Oregon State University, it was renamed the Center for 3D Hardcopy and uses a ZCorp Z406 3D printer to fabricate its physical models for the scientific community.

After moving the facility to Oregon State University, it was renamed the Center for 3D Hardcopy and uses a ZCorp Z406 3D printer to fabricate its physical models for the scientific community.

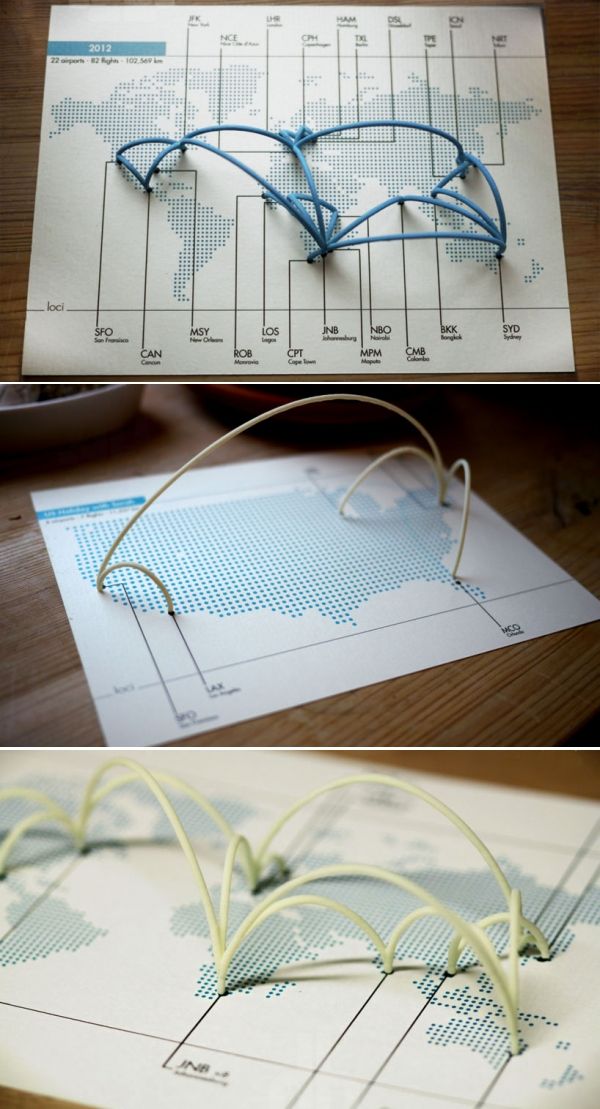

One of the pioneers of the data visualization concept, Volker Schweisfurth, took 3D printing technology further than building objects, models and prototypes. He developed a way to bring data to life via 3D printing or data physicalization. Others have followed suit and now there are myriad ways to display data.

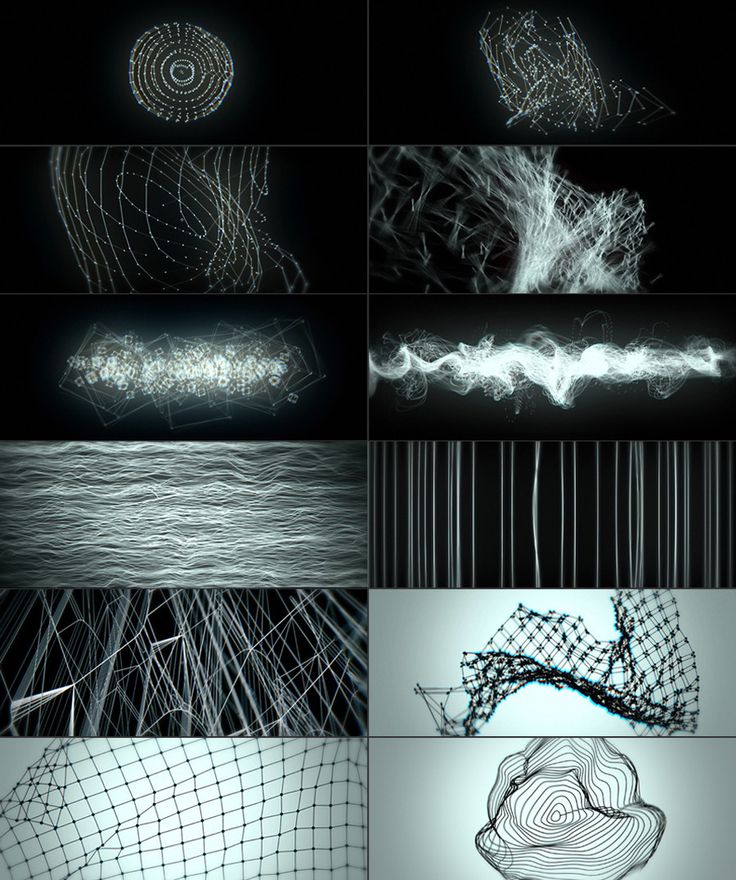

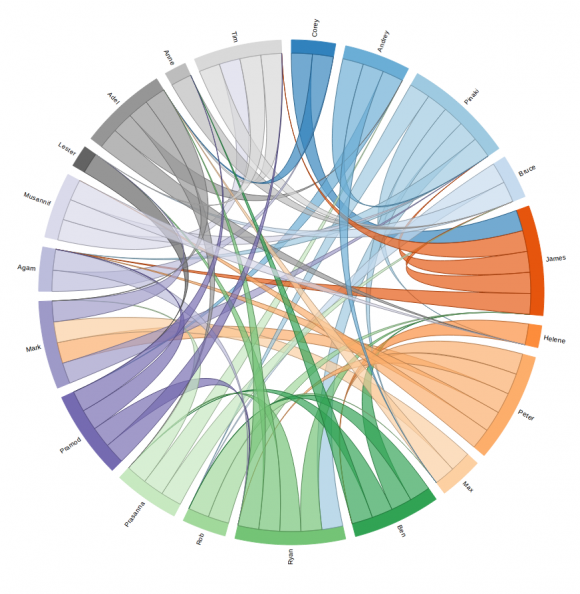

With computer technology, data visualization has evolved to include interactive and automated graphs and charts that rotate 360 degrees, enlarge key elements when you hover over them with your mouse, like this amazing 2013 budget visualization in the New York Times and move like an ocean wave, like this one by Pew Research Center that shows solar eclipses until the year 2080. However, this data is still only in the two-dimensional field.

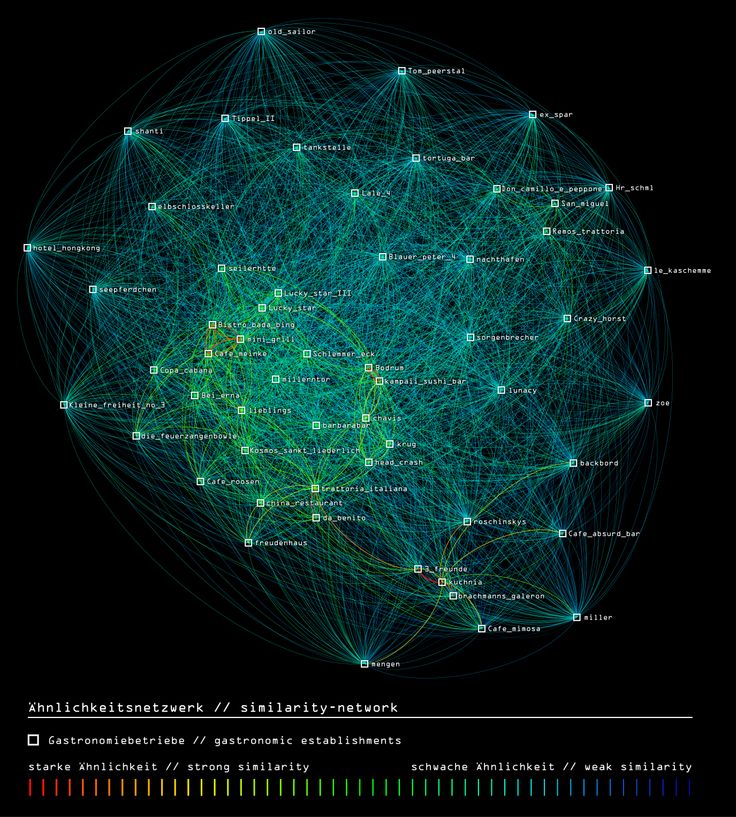

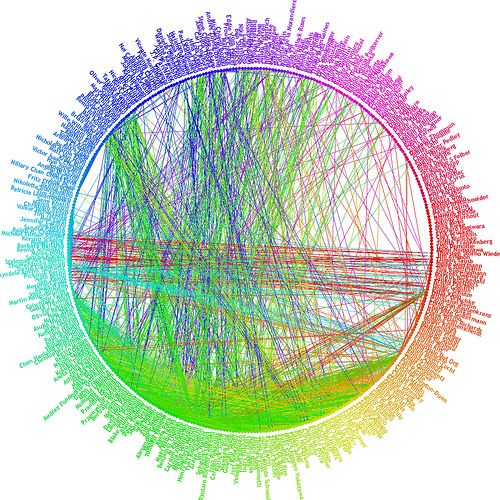

These data visualization models have been used to display data like this image of the Google Eye that was created by Andrej Boleslavský that shows the number of page visits for 2012. Other data that has been made into physical models represented marine trade, scientific research, electricity usage, engineering, genealogical and generational tracking, traffic flow, crime rates, sound waves, molecules, DNA, population, travel logging, weather patterns, finances (personal and business), food consumption, keyboard frequency, and sleep patterns. However, this list does not exhaust all the possibilities. Adding the physical 3D element data can really bring the WOW factor you’re looking for and create a data visual like no other.

Other data that has been made into physical models represented marine trade, scientific research, electricity usage, engineering, genealogical and generational tracking, traffic flow, crime rates, sound waves, molecules, DNA, population, travel logging, weather patterns, finances (personal and business), food consumption, keyboard frequency, and sleep patterns. However, this list does not exhaust all the possibilities. Adding the physical 3D element data can really bring the WOW factor you’re looking for and create a data visual like no other.

Making Data Matter: 3D printed data-sculptures

Technology

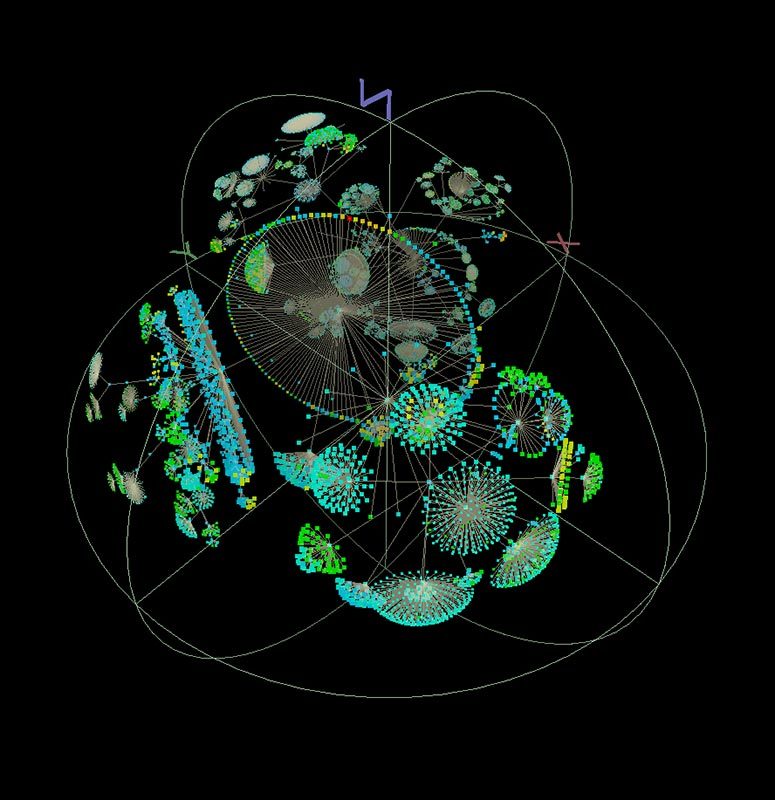

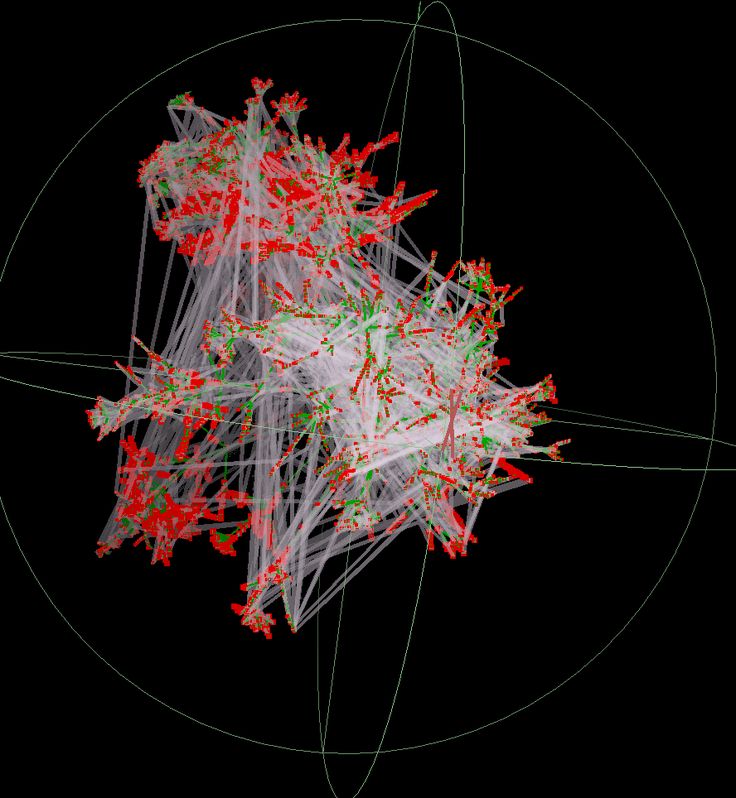

Building on existing additive manufacturing technologies, Making Data Matter offers a novel process that opens up new possibilities for presenting data in tangible form.

Until now, 3D data sets have typically been shown using two-dimensional methods, and either printed or displayed on screens. Making Data Matter is not about conceiving and designing new forms, but focuses on finding better ways to transform these existing data sets into visual form.

Why Making Data Matter? To harness 3D printing technologies for the physicalization of scientific data sets commonly associated with scientific imaging.Through this process, biological data like MRIs and geospatial data obtained using photogrammetry methods can be presented in ways that give the viewer more useful insights. The manifestation of data into such material forms has been coined either ‘data physicalization’ or ‘physical visualization’.

Making Data Matter focuses on using 3D printing technologies for the physicalization and better visualization of scientific data setsThe minds behind Making Data Matter – Mediated Matter research group and deskriptivThe processes in Making Data Matter come out of work in the Mediated Matter research group at the MIT Media Lab. It is a progressive and innovative group which focusses on digital fabrication, computational design, materials science and synthetic biology. Research is aimed at the creation of novel technologies informed by nature and biological processes, and applied across diverse fields from architecture and construction, to product design and fashion.

It is a progressive and innovative group which focusses on digital fabrication, computational design, materials science and synthetic biology. Research is aimed at the creation of novel technologies informed by nature and biological processes, and applied across diverse fields from architecture and construction, to product design and fashion.

Two of the key investigators of Making Data Matter, Christoph Bader and Dominik Kolb, have worked together as deskriptiv since 2010. Both completed their M.Sc. Media Arts and Sciences at MIT in 2017. Their work focuses on generative processes, specifically those which produce shapes. Bader is now a PhD candidate at MIT.

The models in Making Data Matter are made of light-activated resins called photopolymers and each model is built up in fine layers of resin which are constructed and hardened one layer at a time by a UV laserSeveral other researchers are also credited with working on the project, including Associate Professor Neri Oxman, the founder, and director of the Mediated Matter research group. Oxman’s work in generative design is widely recognized and it has attracted numerous awards.

Oxman’s work in generative design is widely recognized and it has attracted numerous awards.

Previous work completed by the Mediated Matter research group includes a distinctive series of masks for Icelandic singer Björk, called Rottlace. The masks investigated the idea of ‘a face without skin’, and were heavily informed by the musculoskeletal system and how it attenuates human vocals. Other series of exhibited projects informed by biology are Wanderers and Vespers.

Making Data Matter harnesses the capabilities of multi-material 3D printing, which is often employed commercially for prototyping and manufacturing products with complex geometries. Stratasys is one company making such 3D printers and several models in this project were completed with their machines.

Stratasys is one company making such 3D printers and several models in this project were completed with their machines.

The models are made of light-activated resins called photopolymers. Each model is built up in fine layers of resin which are constructed and hardened one layer at a time by a UV laser. Vibrant full-color models are produced by using several colors of resin in a manner reminiscent of traditional 2D printing. Cyan, magenta, yellow, black, white, and transparent resins are combined in various proportions to create very detailed and nuanced pieces with varying transparencies.

The detail, transparency, and sophisticated use of color all make this a significant advance on previous visualization methods, such as crystal laser engraving or powder-based 3D printing processes. Its physicality also fundamentally separates it from immersive experiences which are being created through virtual reality and augmented reality technologies.

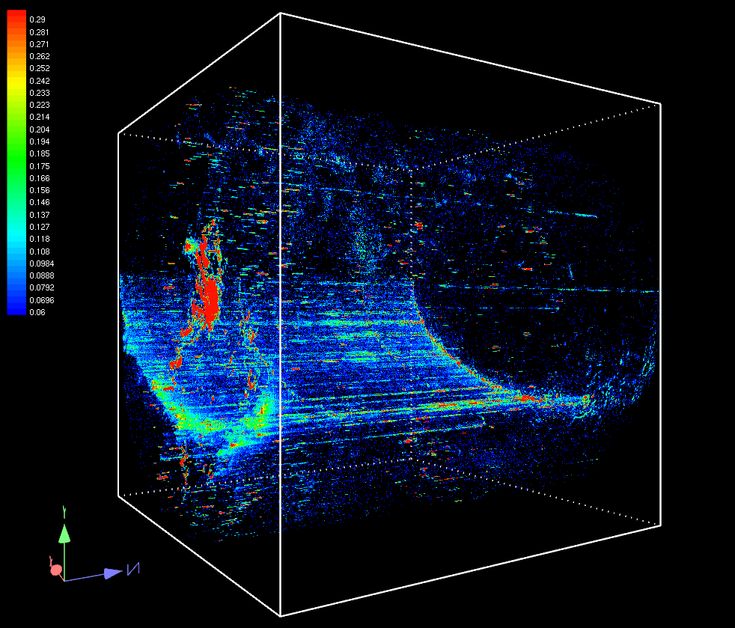

The resulting models are beautiful plastic resin pieces that show ‘opaque data’ suspended within a transparent block. Some are simply a rectangular form with straight sides, like a chunk of data has been isolated from a larger object. Others take on a shape which is representative of the original data container they come from—a human brain or a hand for example.

Can data be used as a visual expression of a brand? That’s what experience design agency HUSH did for the headquarters of United Therapeutics.

It is the ability to see and manipulate a physical visualization which is the key appeal of the process. Information can be more intuitively comprehended as our visual-spatial abilities kick in.

A voxel is basically the 3D equivalent of a pixel. In the same way that a higher number of pixels in a 2D image produce a more detailed image, the more voxels the better quality model you can print. The researchers note that commercially available multi-material 3D printers can have “929 billion individually addressable material droplet positions, or voxels”.

At each voxel, a precise mix of materials and colors can be defined and laid down by the printer. The method has been used to produce complex high-resolution models of things like anatomy, but only recently utilized for data visualization.

The method has been used to produce complex high-resolution models of things like anatomy, but only recently utilized for data visualization.

Making Data Matter rejects the established 3D printing workflow which is defined by polygon surfaces and discrete materiality. Instead, it creates a means to interface directly with the printing capabilities of the multi-material machines.

By utilizing voxels and delivering data in the printer’s native resolution, it avoids the need to post-process data—something which can cause alterations and loss of information. The researchers explain, that “by converting data sets into dithered material deposition descriptions, through modifications to rasterization processes, we demonstrate that data sets frequently visualized on screen can be converted into physical, materially heterogeneous objects”.

The method is ideally suited to visualize discontinuous data sets. That is, point clouds and data which don’t sit neatly together as a ‘single object’ but are instead an array of discrete points that need to be understood through the spatial relationships between each other.

As an area of research, data physicalization is still an emerging field. It is set to encourage cross-disciplinary interactions and support work in education, communication, problem-solving and decision making. The name of this project perhaps forms a succinct expression of the crux of the discipline as a whole—it is about finding ways of ‘Making Data Matter’.

The possibilities for different kinds of data sets to be physicalized in a more accurate and engaging way than ever before is what makes Making Data Matter such fascinating research. Ultimately, data matters more to people when they can see and understand it.

Ultimately, data matters more to people when they can see and understand it.

If you want to know more about the advances in 3D printing and how it is revolutionizing the design world, don’t miss how Nagami is redefining the concept of design, production, and consumption through 3D printing.

3D imaging session » Medvestnik

3D printing has the potential to transform the medical field in the near future, with many new possibilities for visualizing complex anatomical structures, creating models for training, templates for preparing for surgical interventions, or even creating prostheses. This branch is in the field of interest of many medical disciplines.

Wide front

3D printing found its first use in healthcare in cranioplasty, when parts were made using a 3D printer to close skull defects, says Nikolai Kulberg , Head of the Department for the Development of Medical Imaging Tools, Research and Development Center for Medical Radiology. Today, 3D printing has become widespread in dentistry, where, due to the use of modern technologies, the speed and quality of manufacturing prostheses, implants, and aligners are significantly increased. To do this, based on the scan results, a 3D model of the product is built, ideally suited to the patient, and, depending on the tasks, a sample is printed. In this case, such 3D printing technologies as layer-by-layer deposition, selective laser sintering, stereolithography can be used.

Today, 3D printing has become widespread in dentistry, where, due to the use of modern technologies, the speed and quality of manufacturing prostheses, implants, and aligners are significantly increased. To do this, based on the scan results, a 3D model of the product is built, ideally suited to the patient, and, depending on the tasks, a sample is printed. In this case, such 3D printing technologies as layer-by-layer deposition, selective laser sintering, stereolithography can be used.

In addition, 3D printing is also being used in other areas of healthcare, such as prosthetics, training models and preoperative planning models, as well as auxiliary elements such as drilling templates, the expert notes.

With the advent of consumer-grade 3D printers that cost less than 2,000 euros, many hospitals are starting to take a closer look at this area.

“3D printing has been developing very actively all over the world over the past 3-4 years, because printers themselves have become available,” explains the director of the Scientific and Practical Center for Medical Radiology, chief specialist in radiation diagnostics in Moscow, professor . - Companies have appeared, including in Russia, that offer services for printing 3D models for healthcare. It is important that X-ray diagnostics provides a link between visualization data and their printing, and a radiologist together with a medical physicist, an IT specialist can prepare the correct display of anatomical structures for their further printing. For his part, the surgeon who performs some kind of operation can express his wishes.

- Companies have appeared, including in Russia, that offer services for printing 3D models for healthcare. It is important that X-ray diagnostics provides a link between visualization data and their printing, and a radiologist together with a medical physicist, an IT specialist can prepare the correct display of anatomical structures for their further printing. For his part, the surgeon who performs some kind of operation can express his wishes.

CT vs MRI

“CT and MRI are the most suitable types of radiation diagnostics for modeling objects for 3D printing,” says Kristina Sergunova, head of the department for the development of control and technical monitoring tools at SPC Medical Radiology . - So, on the basis of the Department of Traumatology, Orthopedics and Disaster Surgery of the PMSMU. THEM. Sechenov in the GKB im. S.P. Botkin, since 2015, 3D printing technology has been used to plan primary and revision hip arthroplasty using images obtained on a computed tomograph and processed by an engineer.

According to her, stereolithographic templates are also made from CT data for planning the parameters and localization of dental implants, while the 3D model obtained from the results of computed tomography is combined with an optical scan of the silicone impression of the oral cavity. Based on the obtained images, bone models can be made for training and decision making in orthopedics.

MRI provides 3D isotropic data volumes that can be translated into a printable model. In addition, this type of radiation diagnostics also characterizes the physicochemical properties of the object under study, which expands the information content of the model. So, for example, the initial data obtained as a result of magnetic resonance angiography allows printing 3D objects for preoperative planning. However, MRI shows spatial distortions that are significantly greater than CT. They are usually due to the inhomogeneity of the magnetic field. In this regard, when constructing a 3D model from MR images, of greater interest is the relative contrast that shows the structural features of the organ. In addition, it is possible to share the results of CT and MRI, as happens when planning radiation therapy. In this case, the results of computed tomography allow you to build an anatomically accurate image, and the data of magnetic resonance imaging provide additional information about the structure of tissues, the expert adds.

In addition, it is possible to share the results of CT and MRI, as happens when planning radiation therapy. In this case, the results of computed tomography allow you to build an anatomically accurate image, and the data of magnetic resonance imaging provide additional information about the structure of tissues, the expert adds.

Simple and complex

Remember that in addition to buying a 3D printer for 3D printing in medicine, you need special software that allows you to segment data to build a 3D model that is compatible with the capabilities of the printer. This can often be done with open source x-ray imaging software or inexpensive commercial software. There is also open source software and programs available on the Internet.

Segmentation - conversion of two-dimensional images into 3D objects - can be performed automatically, semi-automatically (for example, according to the algorithms for drawing individual parts of the model) and manually. Depending on the structure of interest, this process can be quite simple (especially when there is significant contrast between adjacent objects—like between bones and muscles on a CT scan). In other cases, segmentation work is very difficult: for example, if you need to differentiate gray and white matter on a CT scan of the brain. Therefore, it is advisable to take a balanced approach to the choice of visualization methods and not to forget about the possibilities of contrasting.

In other cases, segmentation work is very difficult: for example, if you need to differentiate gray and white matter on a CT scan of the brain. Therefore, it is advisable to take a balanced approach to the choice of visualization methods and not to forget about the possibilities of contrasting.

When the desired structure is segmented, it is exported as an STL file (stereolithography) and further converted by the software into a 3D printer head movement algorithm. Another way is to send the model to an external supplier who specializes in 3D printing.

The key to success

It is noteworthy that the attitude of modern departments of various directions to 3D printing varies - in some it is actively developing, while the management of others notes that they do not see a special need for it. Therefore, the key to the successful implementation of this technology in hospital practice is a multidisciplinary approach. Abroad (for example, at the University Hospital in Basel, Switzerland) there are examples of fruitful cooperation between radiologists and maxillofacial surgeons, whose enthusiasm has allowed individual clinics to gain significant experience in the preparation, implementation and use of 3D printing in the treatment of patients.

At Basel University Hospital, the 3D Printing Lab is located in the Department of Radiology, as it is at the crossroads of many disciplines and is the best in information technology. Swiss doctors have debugged a simple process for creating 3D printing orders, which are sent from a common clinical information system to the lab's e-mail. Depending on the type of task, either the radiologist or the surgeon (in complex cases they work together) takes responsibility for the task. Cooperation with the Swiss University of Applied Sciences allows doctors to use modern biomedical 3D printers (they are able to create models from biocompatible materials).

According to the Swiss, the benefits of this collaboration became apparent immediately after the opening of the 3D lab in June 2016. During the first 6 months of her work, more than 250 3D models were created, and in many cases this improved the quality of diagnosis and treatment of patients. The number of requests to the laboratory continues to grow.

Another advantage of the introduction of 3D printing, Swiss doctors say, is the rethinking of the role of the radiologist, who, working on the creation of models, comes close to clinical practice (while the clinician becomes “a little bit of a radiologist”), which ultimately enriches both specialists from a professional point of view.

“One of the problems with the introduction of 3D printing in Russia is the unpreparedness of clinicians to use such opportunities – doctors are quite conservative,” says Professor Morozov. - The vast majority of surgeons continue to use the method of planning operations, which in English is called window glazing, that is, looking at pictures in front of a window. This gives very approximate information about the anatomical structures. Therefore, it is very important to create educational programs and disseminate information about the possibilities of using 3D printing. I hope that every year there will be more and more such projects.”

Data Visualization (Module 3, Lesson 5.

)

) Module 3. Lesson 5.

Data Visualization

Link to the Manual

Module 3. Lesson 5. Data Visualization

Discussion:

Using the

Visualization

Discussing the Process

did you perform data analysis

in the last lesson?

Discussion

Data analysis process steps already completed

?

Talk

How can you visualize data?

Data can be accessed

apply:

➔ graph

➔ diagram

➔ illustration

➔ video

➔ mental map

Discussion

Popular visualization methods

What is the visualization step for?

Talk

Can I skip it?

Which data is easier to understand?

Summer

6030

Spring

2261

Winter

1450

Autumn

1099

2

Discussion

1

Discussion

0008 effectively convey the main idea of

to the audience.

For us, this is the most physiological

way of perceiving information.

Discussion

Numerous studies

confirm that 90% of information

people receive through vision.

Module 3 Lesson 5 Data Visualization

New Topic:

Data Visualization in

Pandas

Data Visualization

Plotting and charting

the visualization step is one of the

most important tasks in data analysis.

Data visualization

What types of charts are there?

➔ circular;

➔ linear;

➔ columnar;

➔ bar graph;

➔ mustache box;

➔ and many more...

Data visualization

Types of charts

Data visualization

How to build a chart in Python?

Data visualization

To plot charts, we will

use the plot() method of the

Pandas library.

Data visualization

Matplotlib is a language 9 library0008 Python programming, using

which we will display

graphics on the screen.

Data visualization

From Matplotlib, we will import

the pyplot module to use the

show() method.

import pandas as pd

Data visualization

import matplotlib. pyplot as plt

pyplot as plt

➔ The method applies to both

Series and DataFrame objects.

➔ The method plots the

quantitative data.

Data visualization

The plot() method

By default, the method plots a line

import pandas as pd

import matplotlib.pyplot as plt

index = [1, 2, 3, 4, 5])

s.plot()

plt.show ()

Data visualization

s = pd.Series(data = [10, 5, 15, 20, 10],

Data visualization

Which data can be displayed with a line graph

?

➔ Line graph is used for

observation for changes in some

value over a certain period

.

Data visualization

Line graph

What information about applications can we

display with a line graph

?

Data visualization

Let's return to the dataset that stores

application data from the Google Play Store.

Filtering and

grouping must be applied to the data.

Data visualization

Without additional actions, the data

of this dataset cannot be demonstrated

in dynamics.

Everything will depend on the advanced

you hypotheses.

Data visualization

But that doesn't mean that in your projects

you won't be able to build a linear

graph!

The type of diagram can be set using the

kind parameter.

Data visualization

The plot() method can plot

different types of charts.

Data visualization

Consider what values the kind parameter can

take, and which charts

will be built depending on these values.

➔hist;

➔box;

➔scatter;

➔pie;

➔bar;

➔barh.

Data visualization

The kind parameter sets the chart type

➔ The chart shows the distribution

of the values of a particular feature between

the minimum and maximum values.

➔ By default, the distribution range

is divided into 10 intervals.

➔ kind = 'hist'.

Data visualization

Histogram

Application size histogram

How to change the number of

columns?

Data visualization

df['Size']. plot(kind = 'hist')

plot(kind = 'hist')

Application size histogram

Data visualization

df['Size'].plot(kind = 'hist', bins = 5)

Visualization

data

Why change the number of

columns?

Data visualization

By changing the number of columns, you can

see fluctuations in values

How to evaluate the distribution of values

in this case?

Data visualization

df[df['Type'] == 'Paid']['Price'].plot(kind = 'hist')

Data visualization

Data that stands out among the total

sample of values is called

outliers.

➔ Chart that simultaneously displays

median, lower and upper

quartiles, minimum and maximum

values and outliers.

➔ kind = 'box'.

Data visualization

Box with whiskers

Box with whiskers chart for app cost

Data visualization

df[df['Type'] == 'Paid']['Price'].plot(kind = 'box')

structure of the diagram

maximum

value

75th percentile

(third apartment)

Median

25th percentile

(first apartment)

Minimum

Visualization

Data

Diagram structure

Visualization

Data

Most of the meanings

is located in a box.

Chart structure

Outliers

Data visualization

If a value is not specific to a box and does not

fall into it, then it becomes an outlier.

Data visualization

Are outliers good,

bad or neutral?

➔ An outlier may occur due to data entry error

.

➔ The outlier distorts the results of statistical

calculations, for example, the

arithmetic mean.

➔ The presence of outliers indicates the heterogeneity of the

sample and casts doubt on the results of the

data analysis.

Data visualization

Dangers of emissions

What to do with emissions?

Data visualization

➔ Check if there were any errors

when entering data.

➔ If errors are found, correct them.

➔ Make a decision to remove row data containing outliers from dataset

.

➔ The decision to delete rows depends

on the purpose of the study and the amount of data.

Data visualization

What should I do if the data entered

is incorrect?

Case No. 1. We are a team of developers

1. We are a team of developers

mobile applications

Working conditions: to find your niche in the market,

it is important to have data on both expensive and budget

applications.

Output: Rows with outliers should be left.

Data visualization

Purpose of data analysis: to study the characteristics of the market,

target audience, popular genres, prices,

update frequency.

Case № 2. We want to advertise our

products in applications

Working conditions: our potential consumers

use only budget applications.

Output: Rows with outliers need to be deleted.

Data visualization

Purpose of data analysis: to select suitable

applications for advertising integration.

How to visually reflect the relationship between

two indicators?

Visualizing data

When we perform analysis, we study

relationships between data.

➔ The diagram shows the degree of association

between variables.

➔ kind = 'scatter'.

Data visualization

Scatterplot

Sample scatterplot

Data visualization

How to build a diagram of this kind?

Building a scatterplot

2. Mark on the coordinate plane the points whose coordinates

are the values of

selected features.

Data visualization

1. Select two features, the relationship between which

we want to visualize.

3. Assess the location of the points on the graph:

are they scattered evenly along the

coordinate plane, or are they collected around

an imaginary line?

4. If the dots are gathered around an imaginary

lines, there is a connection between the values, otherwise there is no connection in

.

Data visualization

Scatter plotting

Data visualization

Give an example of a hypothesis that can be tested

using a scatterplot

.

Expensive apps have

fewer installs than

cheap or free apps.

Data visualization

Hypothesis example

Scatterplot

df.plot(x = '

kind = 'scatter')

Data visualization

y = '

Scatterplot

Value relationship

confirmed.

The hypothesis is correct

Data visualization

df.plot(x = 'Price', y = 'Installs', kind = 'scatter')

Data visualization

What relationships between values can we see on the diagram

?

By strength

Visualization

data

1. Strong.

2. Weak.

3. None.

Directionality

Data visualization

1. Positive.

2. Negative.

3. Zero.

By type of graph

Visualization

data

1. Linear.

2. Nonlinear.

➔ The diagram shows

the distribution of values in

categories. Clearly displays

proportions and proportions.

➔ kind = 'pie'.

Data visualization

Pie chart

How to build a pie chart for

seasons if the information in this column is not

quantitative?

Data visualization

Suppose there is a column in the DataFrame with

the name of the season during which

the last update was made.

Step 2. Build a pie chart

based on the obtained Series.

Data visualization

Step 1. Count the number of

unique values of the column

using the value_counts() method.

Pie chart

Data visualization

df['Season'].value_counts().plot(kind = 'pie')

Visualization

data

How many parts of the diagram

are easy to read?

Visualize

data

Choose 5-6 categories, otherwise

the chart is hard to read

➔ The chart helps you compare

values with each other.

➔ kind = 'bar'. The columns are arranged

vertically.

➔ kind = 'barh'. The columns are arranged

horizontally.

Data visualization

Bar chart

Data visualization

Compare the number of applications in

different categories using

vertical bar chart.

Bar chart

List the cons

of this bar chart

Data visualization

df['Category'].value_counts(). plot(kind = 'bar')

plot(kind = 'bar')

Category names

are partially written and

overlap.

Data visualization

Bar chart

Add padding between the chart columns

and labels.

Data visualization

Change the chart type to

horizontal bar.

Parameter figsize

figsize = (8, 5)

Data visualization

➔ Allows you to set the width and height

of the chart.

➔ If the parameter is not specified, then the size is

by default (6.4, 4.8).

5

8

Bar chart

Data visualization

df['Category'].value_counts().plot(kind = 'barh', figsize = (8, 5))

Data visualization

What is missing from the chart, so that

is convenient to define the values of

categories?

Coordinate grid

Data visualization

df['Category'].value_counts().plot(kind = 'barh', figsize = (10, 10), grid = True)

Data visualization

How can you compare whether 90,008 average installs across 90,008 different target audiences for 90,008 paid and free apps?

First prepare data,

build charts

then

d1 = df[df['Type'] == 'Free']. pivot_table(index = 'Content Rating',

pivot_table(index = 'Content Rating',

columns = 'Type',

values = 'Installs',

d2 = df[df['Type'] == 'Paid'].pivot_table(index = 'Content Rating',

columns = 'Type',

values = 'Installs',

aggfunc = 'mean')

d1.plot(kind = 'barh')

d2.plot(kind = 'barh')

Data visualization

aggfunc = 'mean')

Two separate charts

Data visualization

Is it easy to compare values?

two

- Same column color.

- Different division value on the x-axis.

- Not all 9 listed for paid apps0008 target audience categories.

Data visualization

Disadvantages of using

separate charts

First we prepare the data,

we build one chart

then

d = df.pivot_table(index = 'Content Rating',

columns = 'Type',

aggfunc = 'mean')

Data visualization

values = 'Installs',

Two charts in the same coordinate grid

d.plot(kind = 'barh', subplots = True)

Data visualization

Allows plotting two

graphics under each other

Two charts in the same coordinate grid

The layout parameter allows you to set the layout of the charts.

➔ layout = (1, 2) - two in one line.

➔ layout = (2, 1) - two lines one at a time.

Data visualization

d.plot(kind = 'barh', subplots = True, layout = (1, 2))

Data visualization

Is it convenient to compare values?

- Signatures of values along the y-axis of the second chart

are superimposed on the first one.

- No grid to exactly

define values.

Data visualization

Chart minuses

The sharey parameter allows

not to duplicate labels along the y-axis

Data visualization

d.plot(kind = 'barh', subplots = True, layout = (1, 2), sharey = True, grid = True)

Data visualization

Is it possible to combine these two graphs

?

Stacked bar chart

Data visualization

➔ The chart shows the ratio of values

of two or more parameters.

Stacked Bar Chart

Data Visualization

d.plot(kind = 'barh', grid = True)

Module 3. Lesson 5. Data Visualization

Lesson 5. Data Visualization

Working on the Platform:

Data Visualization

Complete Activity

"Data Visualization"

Work

in VS Code

mars.algoritmika.org

Break

Module 3. Lesson 5. Data visualization

Discussion:

Work on an individual project

Discussion

The steps in the data analysis process that

already completed

Discussion

What needs to be done today?

Discussion

Graphs and charts are built

based on the data obtained in step

Explore.

Checklist

Complete the "Research" stage.

The results obtained in the course of these two stages

will need to be presented in the form of a presentation

at the next lesson.

Discussion

Run the "Render" step.

Talk

Don't forget to review the checklist and mind map you

was created in the last lesson.

➔

Matplotlib library not installed in VSC.

➔ You will need to install

yourself.

Learn more