3D printer board 32bit

The 6 Best 3D Printer Controller Boards in 2022 – Clever Creations

Our site is reader-supported. When you buy via the affiliate links on this site, we will receive a commission at no cost to you. All opinions remain our own. Learn more

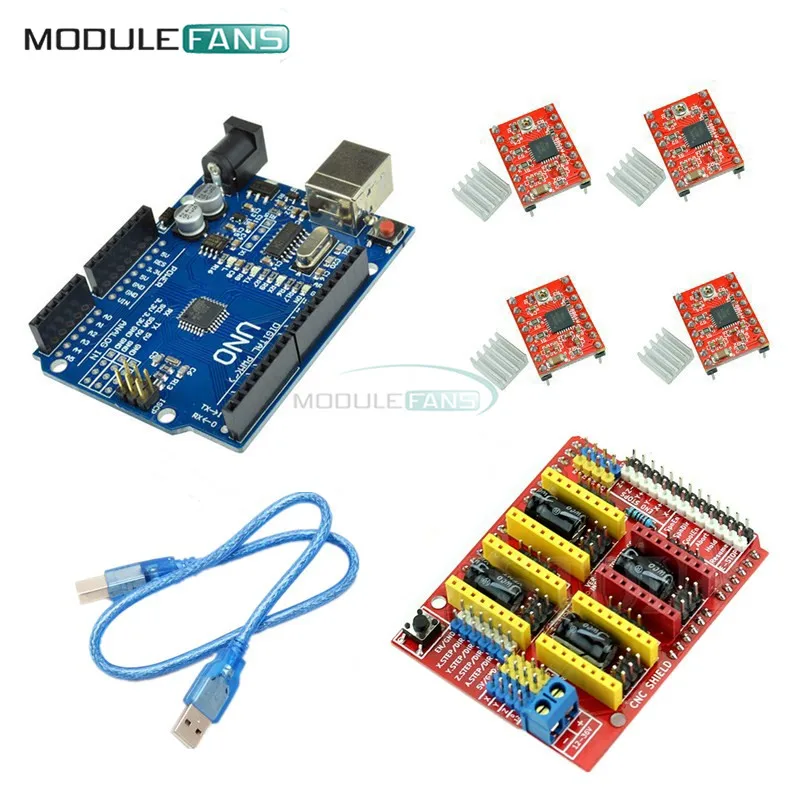

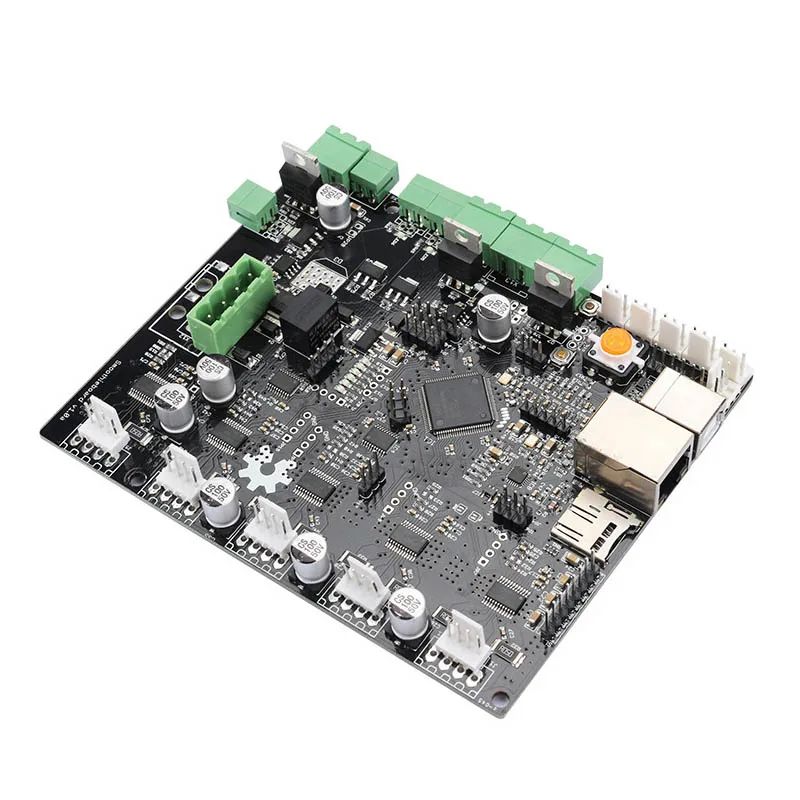

From using Arduinos with CNC shields to now having a full-fledged WiFi-equipped circuit, 3D printer controller boards have come a long way. They’re the brains of any 3D printing setup and are responsible for controlling, coordinating, and executing all of a printer’s functions.

If you’ve bought a fully assembled 3D printer that you are happy with, it’s doubtful that you ever had to think about the controller board. But if you’re someone who wants to upgrade his 3D printer or build a DIY printer from scratch, you probably understand how important it is to select the best 3D printer controller board for your needs.

To help you with getting the best control board for your 3D printer, we’ve compiled a list of the six best motherboard options that you can buy right now.

| 3D Printer Controller | Summary | Input | Processor | Price | Best Offer |

|---|---|---|---|---|---|

| Duet 2 WiFi | Best overall | 11-25V | 32-bit | $170 | MatterHackers |

| Duet 3 6HC | Best high-end | 11-32V | 32-bit | $255 | MatterHackers |

| BTT SKR Mini E3 V2.0 | Best on a budget | 12/24V | 32-bit | $65 | Amazon |

| Creality 3D 4.2.7 | Best for Ender 3 | 24V | 32-bit | $50 | Creality3D |

| BIGTREETECH Octopus | Most stepper drivers | 4.75-36V | 32-bit | $52 | Amazon |

| BIGTREETECH TFT35 V3.0 | Best LCD add-on | 5V | 32-bit | $45 | Amazon |

Best 3D Printer Motherboards in 2022

Duet 2 WiFi

Best overall

Check price at

AmazonMatterHackersE3D

The Duet 2 Wi-Fi features a 32-bit ARM-based processor specifically designed for industrial automation projects. As-is, the Duet 2 Wi-Fi can support up to five unique stepper motors. This, however, can be extended to support up to five extra stepper motors and extruders with the Duex 5 expansion board.

As-is, the Duet 2 Wi-Fi can support up to five unique stepper motors. This, however, can be extended to support up to five extra stepper motors and extruders with the Duex 5 expansion board.

All stepper drivers used on the Duet 2 Wi-Fi are TMC2660s, which have a high current rating of 2.4A and are able to run the stepper motors quietly in up to 1/256 micro-stepping. The board runs on the well-documented and feature-rich RepRap firmware.

The great thing about the Duet 2 Wi-Fi is its compatibility with different Duet expansion boards and accessories. You can connect a PanelDue board to get a full-color graphic touch screen, temperature sensing daughterboards, the Duex 5 for additional steppers, servos, fans, and heaters. It even has the option to use a smart effector for delta 3D printers for bed leveling.

The many features and ability to use it with practically any 3D printer make the Duet 2 Wifi the overall best 3D printer controller board that you can get right now. It definitely costs more than your typical board, but you get what you pay for.

Standout Features

- Wi-Fi connectivity

- External stepper driver support

- Quiet 1/256 microstepping

Technical Details | |

|---|---|

| Input voltage | 11V - 25V |

| Stepper drivers | 5x TMC 2660 |

| Microstepping | Up to 256 |

| Microprocessor | ARM Cortex M4F, 32-bit |

| Connections | 2.4GHz WiFi, USB serial port |

| SD card slot | Yes |

What We Like

- Powerful

- Many I/O ports

- Built-in Wi-Fi

Could Be Better

- High price

Find Duet 2 WiFi at

AmazonMatterHackersE3D

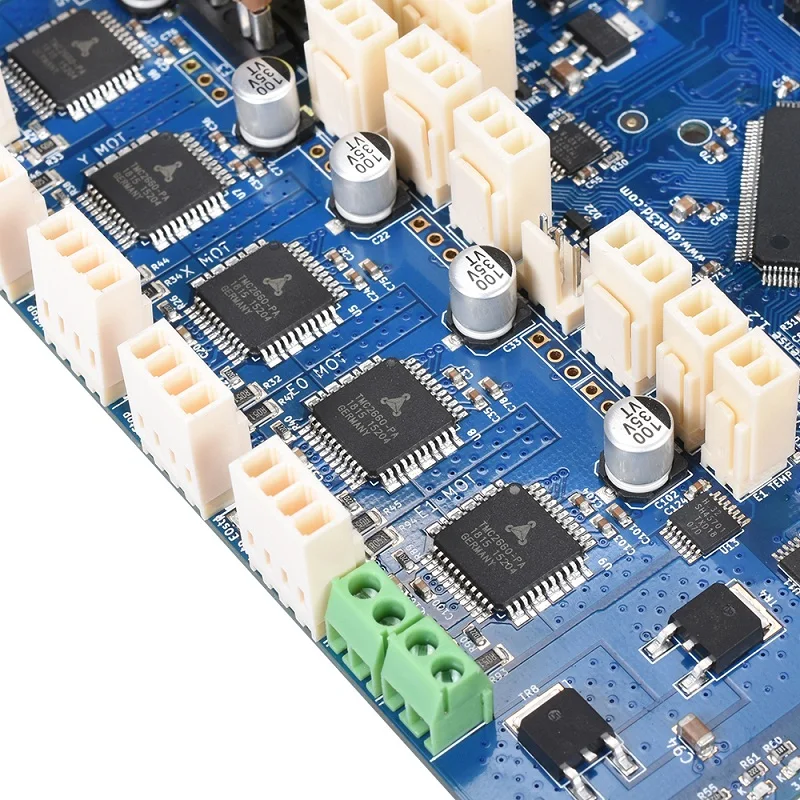

Duet 3 6HC

Best high-end

Check price at

AmazonMatterHackersE3D

The Duet 3 6HC is the latest release from Duet 3D. The 6HC in the name stands for 6 High Current stepper motors. The board uses a faster 300 MHz 32-bit ARM processor, allowing for high-speed calculations. The Duet 3 features six Trinamic 5160 stepper motor drivers rated at a 6.3 A peak current.

The 6HC in the name stands for 6 High Current stepper motors. The board uses a faster 300 MHz 32-bit ARM processor, allowing for high-speed calculations. The Duet 3 features six Trinamic 5160 stepper motor drivers rated at a 6.3 A peak current.

Other than this, you get 10 PWM outputs for the heated beds, extruders, and fans. It has 9 I/O ports for end-stops, Z probes, filament sensors, and other peripherals. These allow you to decorate your 3D printer with many sensors, fans, and accessories and still have room left for more.

The CAN-FD buses will let you connect other Duet boards, smart tools, and custom add-ons, thus ensuring upgradability. There’s a dedicated high-speed SPI bus to a single board computer (SBC) to let you connect SBCs like Raspberry Pi’s.

The Duet 3 6HC is expensive and aimed at professionals that require a versatile high-end 3D printer controller. However, the RepRap community’s ample amount of documentation and support means that if you want one, you can easily configure it to work with any off-the-shelf 3D printer as well.

Aside from being more than powerful enough to drive nearly any 3D printer, the Duet 3 is an equally attractive option for a home CNC machine or laser engraver.

Standout Features

- High-speed ARM processor

- High current stepper drivers

- Numerous i/o options

Technical Details | |

|---|---|

| Input voltage | 11V to 32V |

| Stepper drivers | 6x TMC2160 or TMC5160 |

| Microstepping | Up to 256 |

| Microprocessor | ARM Cortex M7, 32-bit |

| Connections | Ethernet and USB Serial port |

| SD card slot | Yes |

What We Like

- Wide stepper motor compatibility

- Suitable for high-end 3D printers

- Lots of expansion options

Could Be Better

- High price

- Requires technical expertise

Find Duet 3 6HC at

AmazonMatterHackersE3D

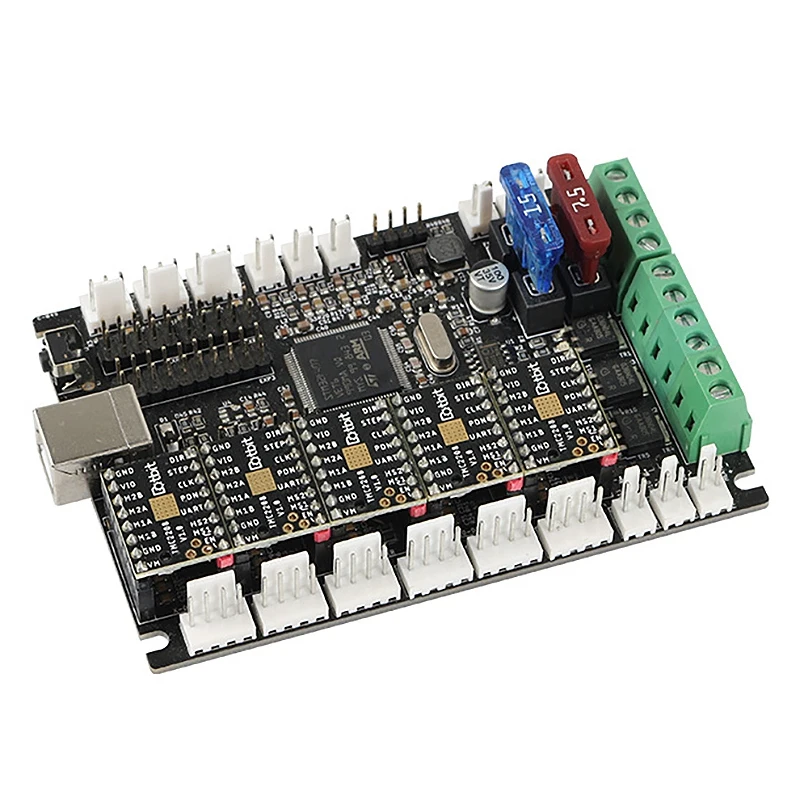

BIGTREETECH SKR Mini E3 V2.

0

0 Best on a budget

Check price at

AmazonBigtreetechGeekbuying

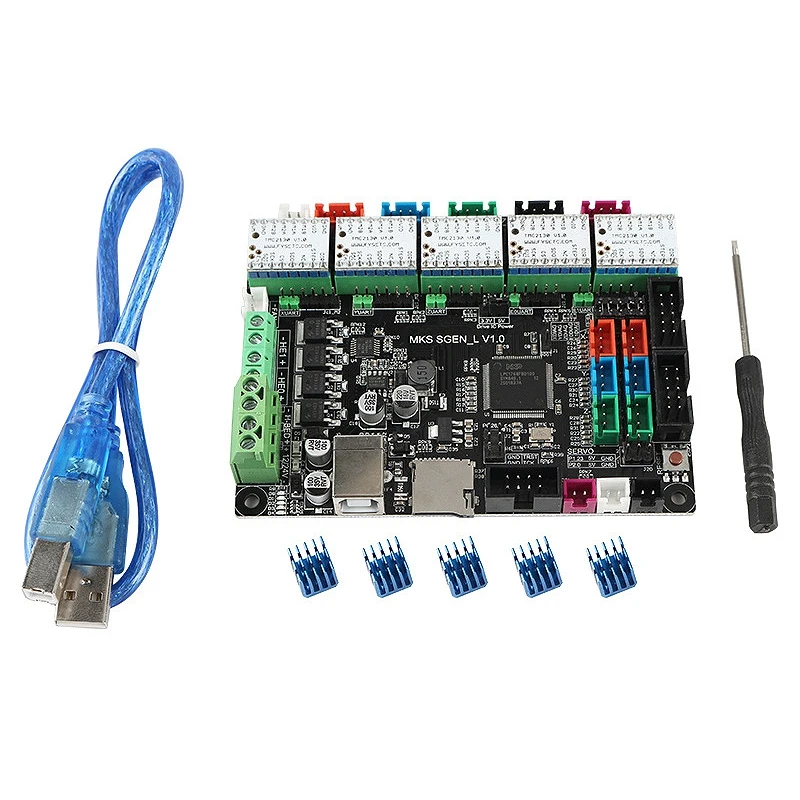

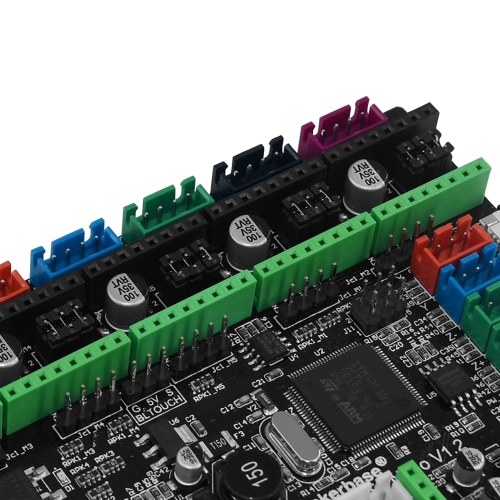

The SKR Mini E3 V2.0 is the successor to the original E3, designed explicitly for the Ender 3 3D printers. With the SKR Mini E3 V2.0, Bigtreetech offers support for more Creality machines like the CR-10, CR-10S5, and Ender 3 3D printers.

The V2.0 is a 32-bit 3D printer controller board that features ultra-silent, TMC 2209 stepper motor drivers and can handle 2A RMS current. It also comes with two Z-axis ports, so that you can drive dual Z-axis stepper motors.

Aside from the excellent stepper drivers, the SKR Mini E3 V2.0 also comes with support for BLTouch and filament detection sensors. This gives you the option to install additional Ender 3 upgrades and Ender 5 upgrades that reduce the chance of failed 3D prints.

The Mini E3 V2.0 supports the open-source Marlin firmware. It offers a variety of additional features like the power resume function, automatic shutdown, and onboard sensorless homing functions.

If you’re on a budget and want to upgrade your Creality 3D printer, the SKR Mini E3 V2.0 is likely the best 3D printer controller for you.

Standout Features

- Parallel Z-axis interface

- BLTouch and filament detection ports

- Improved thermal performance

Technical Details | |

|---|---|

| Input voltage | 12/24V |

| Stepper drivers | 4x TMC2209 |

| Microstepping | 256 |

| Microprocessor | ARM Cortex-M3, 32-bit |

| Connections | Mini-USB-B type |

| SD card slot | Yes |

What We Like

- Low price

- Easy to use

- Silent stepper drivers

Could Be Better

- Limited upgradability

Find BIGTREETECH SKR Mini E3 V2. 0 at

0 at

AmazonBigtreetechGeekbuying

Creality 3D 4.2.7

Best for Ender 3

Check price at

AmazonCreality3D

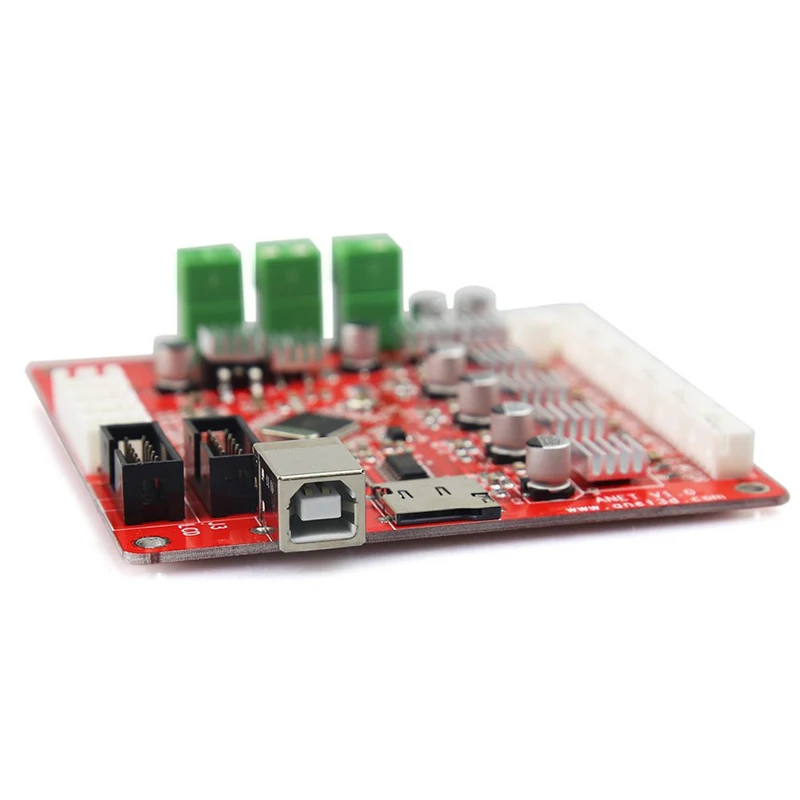

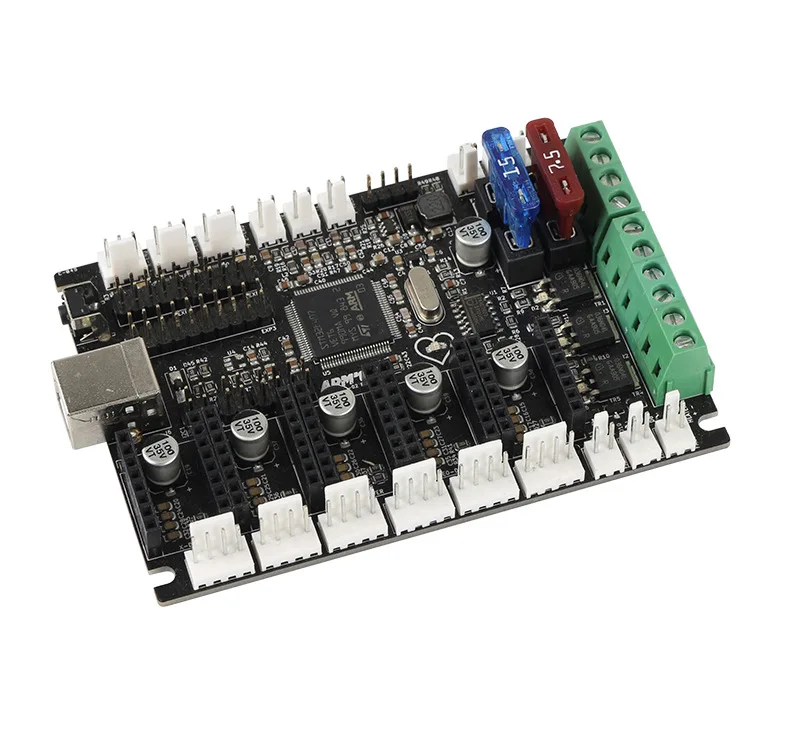

The Ender 3 is still one of the best budget Creality 3D printers. But it has aged in terms of its features and capabilities. The latest version of the 3D printer controller board from Creality – 4.2.7 aims to bring the Ender 3 to the current 3D printing trends.

The Creality 3D 4.2.7 controller board features a 32-bit ARM processor with increased flash storage that lets you run more firmware features faster, and with this supporting the latest Marlin 2.0 firmware. Creality calls this controller board the “silent mainboard” due to the TMC 2225 stepper motor drivers that keep your 3D printer’s motors silent.

This 4.2.7 now comes with a pre-installed bootloader, which means that you can update the firmware by merely inserting the SD card with the firmware BIN file. It also has ports for the BLTouch auto leveling sensor and filament sensors that remove the need for any previously needed extenders.

The Marlin 2.0 comes pre-installed with the board, and with a little bit of configuration, you can directly use it with your Ender 3. It is an excellent upgrade for the Ender 3 3D printers, considering that you get an officially supported board with the latest features.

Standout Features

- 32-bit processor

- Pre-installed bootloader

- Silent TMC 2225 stepper drivers

Technical Details | |

|---|---|

| Input voltage | 24V |

| Stepper drivers | 4x TMC2225 |

| Microstepping | Up to 256 |

| Microprocessor | ARM Cortex-M3, 32-Bit |

| Connections | Micro-USB port |

| SD card slot | Yes |

What We Like

- Easy to install and use

- Official company support

- Affordable

Could Be Better

- No UART control

- Poor quality control

Find Creality 3D 4. 2.7 at

2.7 at

AmazonCreality3D

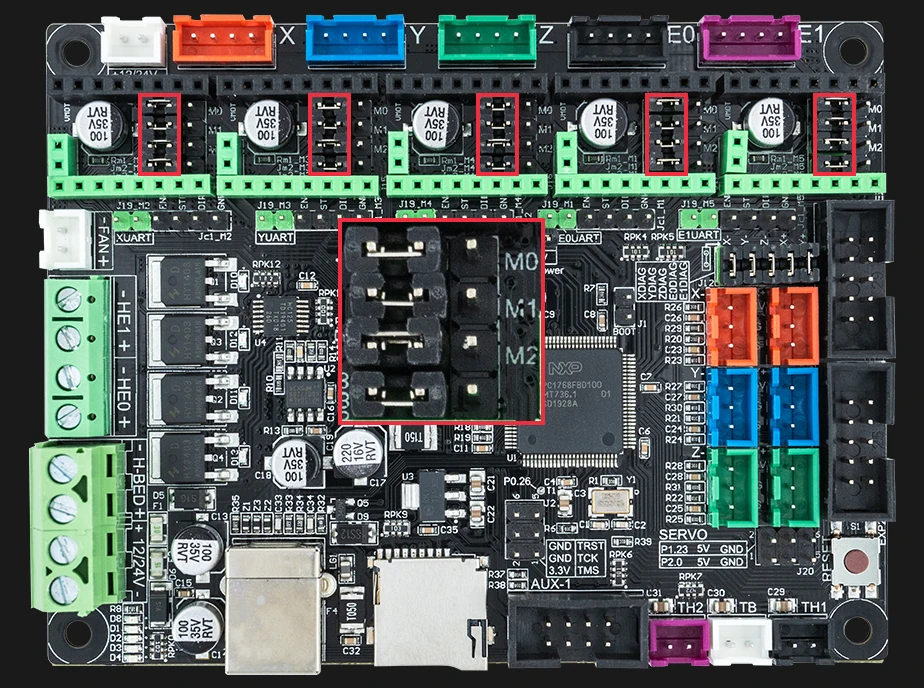

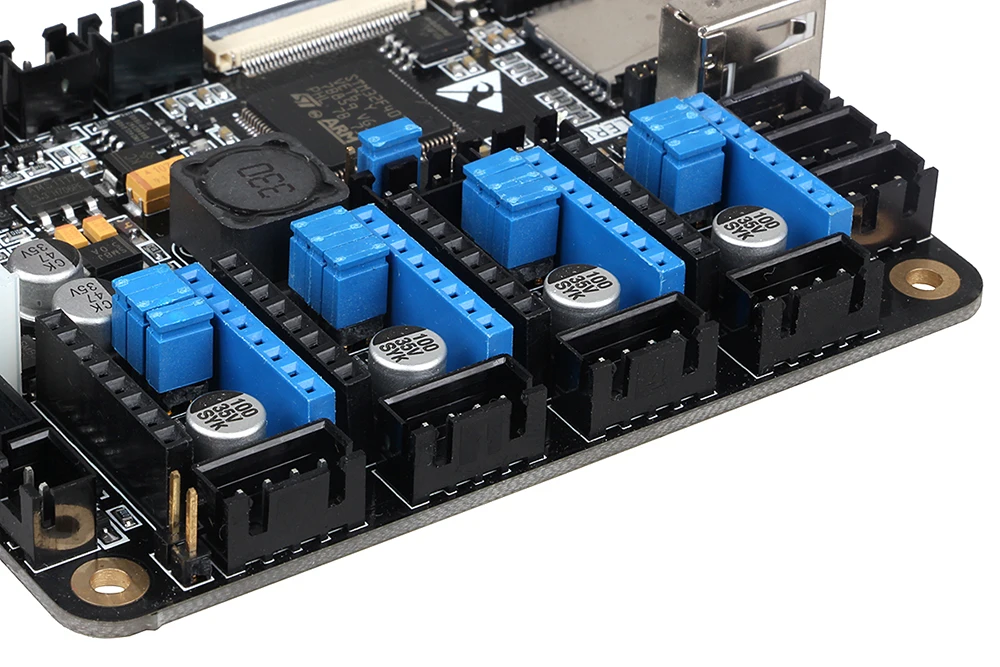

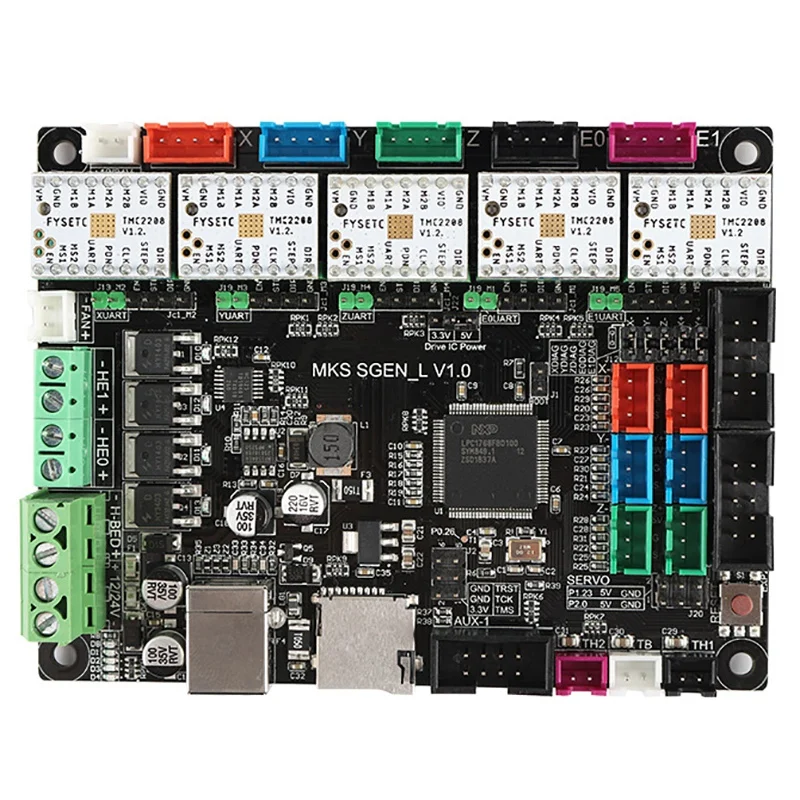

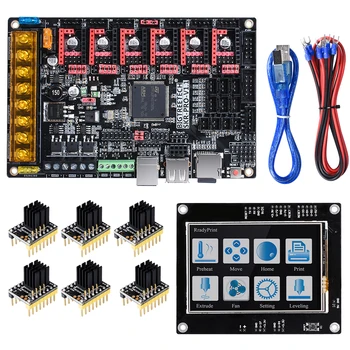

BIGTREETECH Octopus

Most stepper drivers

Check price at

AmazonBigtreetechGeekbuyingBanggood

The BIGTREETECH Octopus controller board natively supports eight stepper motors. You can choose your stepper motor drivers and the mode in which you want to run them, and this makes the board a beast in terms of sheer stepper motor support.

This 3D printer controller board supports up to four hot-end heaters. Then there are six PWM controllable fan interfaces, six end-stop switches, and two inputs for filament detection sensors. You even get a CAN bus interface if you decide to upgrade further and a USB-A port that can interface with a Raspberry Pi using emulated serial over USB.

Another expansive feature of the Octopus board is the support for a dual Z-axis drive. This can come in handy if you’re building a large cartesian or even a Core XY-type 3D printer. There are many other features too, and the sheer number of connectivity options make it one of the best 3d printer controllers if you’re planning to build something like a Voron 3D printer that needs many stepper motors.

Standout Features

- Supports up to 8 stepper motors

- Interfaces with Raspberry Pi

- Marlin and Klipper firmware support

Technical Details | |

|---|---|

| Input voltage | 4.75V - 36V |

| Stepper drivers | 8 pluggable stepper driver support |

| Microstepping | Up to 256 |

| Microprocessor | ARM Cortex-M4, 32-bit |

| Connections | USB type C port |

| SD card slot | Yes |

What We Like

- Suitable for large 3D printers

- Lots of expansions ports

- USB-C interface for easy compatibility

Could Be Better

- Complex wiring

- Limited community support

Find BIGTREETECH Octopus at

AmazonBigtreetechGeekbuyingBanggood

BIGTREETECH TFT35 V3.

0

0 Best LCD add-on

Check price at

AmazonBigtreetechBanggood

The BIGTREETECH TFT35 V3.0 is an LCD touch screen upgrade designed for the Ender 3 and CR-10 3D printers. The V3.0 stands out because of its dual nature. You can use it as a regular LCD screen with the knob or use the touch screen to navigate the menu quickly.

It gives you the best of both worlds without the hassles of either. Additionally, you get a port for an external Wi-Fi module, a full-sized SD card slot, and a USB 2.0 port, giving you plenty of options in terms of connectivity.

However, the touch screen is not plug-n-play, and you need to tweak some firmware settings to get it working with your 3D printer. Teaching Tech on YouTube has a comprehensive guide covering everything you need to get the TFT35 working.

The BIGTREETECH TFT35 V3.0 is not meant as a completely new overhaul for your 3D printer but rather is aimed to improve the functionality of interfacing with it. The touch screen combined with the knob is suitable for many users. And considering the price, it is a worthwhile upgrade to make.

And considering the price, it is a worthwhile upgrade to make.

Standout Features

- Dual-mode use

- Pre-installed bootloader

- Wi-Fi module and filament detection ports

Technical Details | |

|---|---|

| Input voltage | 5V |

| Microprocessor | ARM Cortex-M3 series 32-bit |

| Connections | USB A port and external Wi-Fi module support |

| SD card slot | Yes |

What We Like

- Easy to use

- Compatible with many 3D printers

- Lots of configuration options

Could Be Better

- Firmware can be buggy

- Technical expertise required

Find BIGTREETECH TFT35 V3.0 at

AmazonBigtreetechBanggood

Buyer’s Guide

Above we have listed some of the best 3D printer controller boards available. But what if you want to look for more boards? What exactly do you look for in a 3D printer motherboard, and how do you select one for yourself? Here are a few pointers that you need to keep in mind.

But what if you want to look for more boards? What exactly do you look for in a 3D printer motherboard, and how do you select one for yourself? Here are a few pointers that you need to keep in mind.

Firmware Compatibility

Firmware is the software on the 3D printer controller board that is responsible for all calculations and commands to the printer hardware. There are many different types available, for example, Repetier, Prusa, Klipper, and Smoothieware.

Each one is designed for a slightly different purpose, and you need to keep in mind your goals with the machine. For example, if you want a high-speed 3D printer, Klipper is the best choice for you. Marlin and RepRap are the go-to options if you want well-documented and widely used firmware.

You need to consider the choice of your firmware beforehand to select the best suitable controller board for yourself. Make sure there’s enough documentation and support available with your combo so that if you run into any issues, you can quickly sort it out.

Processor

3D printers either have an 8-bit controller board or a 32-bit board. An 8-bit board is cheap to manufacture and provides all the basic functionalities you would expect from a 3D printer. However, it comes with low onboard memory, and the lower number of bits means that it can process fewer calculations at a time, thus significantly affecting its speed.

32-bit motherboards operate at a higher clock speed, have a slightly greater onboard memory, and execute calculations at a much higher rate. They’re compatible with more I/O ports and communication interfaces, and all of these translate to a more feature-rich 3D printer motherboard.

If you want a basic 3D printer with limited functionalities, 8-bit boards are an option. They’ll save a bit of money, and you won’t have to pay for things you won’t use. However, if you want your 3D printer to be future-proof, have advanced functions, and print faster, a controller board with a 32-bit processor is vastly superior.

In our list with the best 3D printer controller boards above, we have only added 32-bit controllers. We believe that an 8-bit board is not worth buying and a 32-bit board is always the better option.

Communication methods

The most basic method of communication on a 3D printer motherboard is a USB port. A USB serial port allows you to control your 3D printer via a USB connection with a computer.

Wi-Fi and Ethernet ports are other methods of communicating with your 3D printer. An ethernet port would allow you to control your 3D printer over a local wired network.

Wi-Fi connectivity would allow you to control your printer wirelessly. One benefit of Wi-Fi is that you don’t even have to be present in the same room as your 3D printer, and you can control it remotely from anywhere.

Low-end controller boards don’t come with Wi-Fi and Ethernet ports; some might have pins for attaching external Wi-Fi modules, though. A USB serial port is enough if you want a basic 3D printer. If you want wireless 3D printing or operate many 3D printers simultaneously, you should consider getting a Wi-Fi-equipped controller board.

If you want wireless 3D printing or operate many 3D printers simultaneously, you should consider getting a Wi-Fi-equipped controller board.

Connectors

Aside from a USB port, there are many other connectors (or headers) on the controller board. These are used for a wide variety of purposes. Endstop connectors, hot end heaters, stepper motor connectors, bed leveling, and filament runout detection sensors are some of the few.

A well-specced-out controller board like the Duet 2 Wi-Fi or the Duet 3 6HC will have almost all of these connectors and then some more. Connectors allow you to interface various devices with your 3D printer, providing additional functionality.

The more connectors your controller board has, the more expensive it will be and take a lot of space. You need to know what features you want in your 3D printer and select the board with the particular connectors to get the maximum benefit.

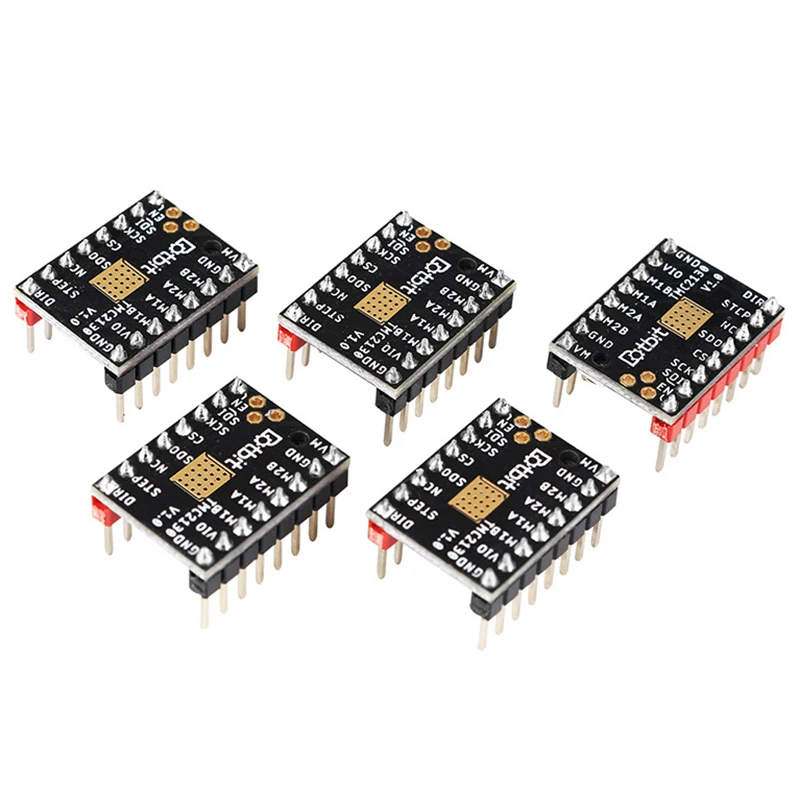

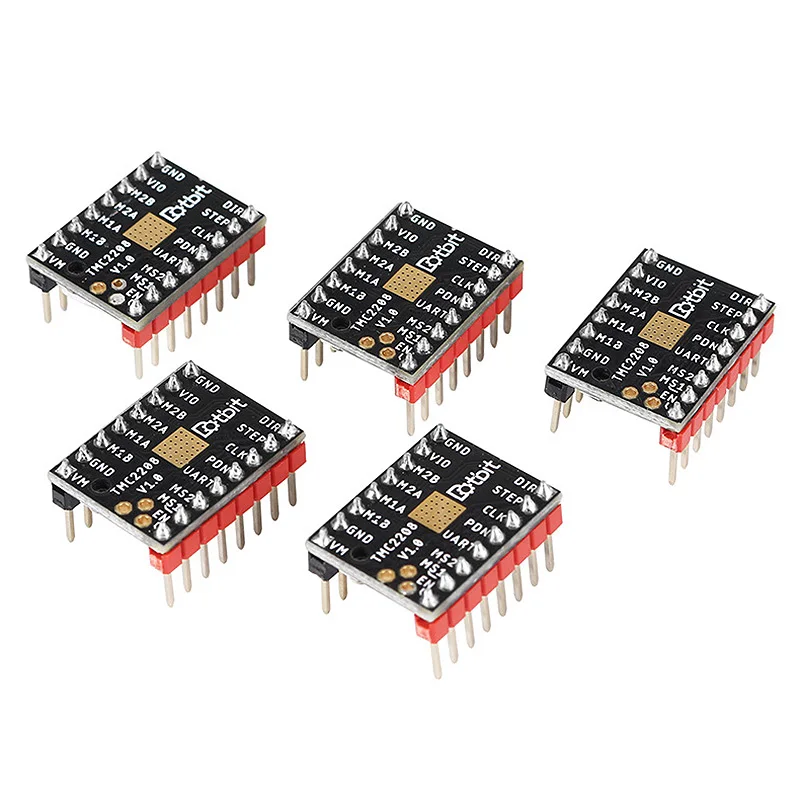

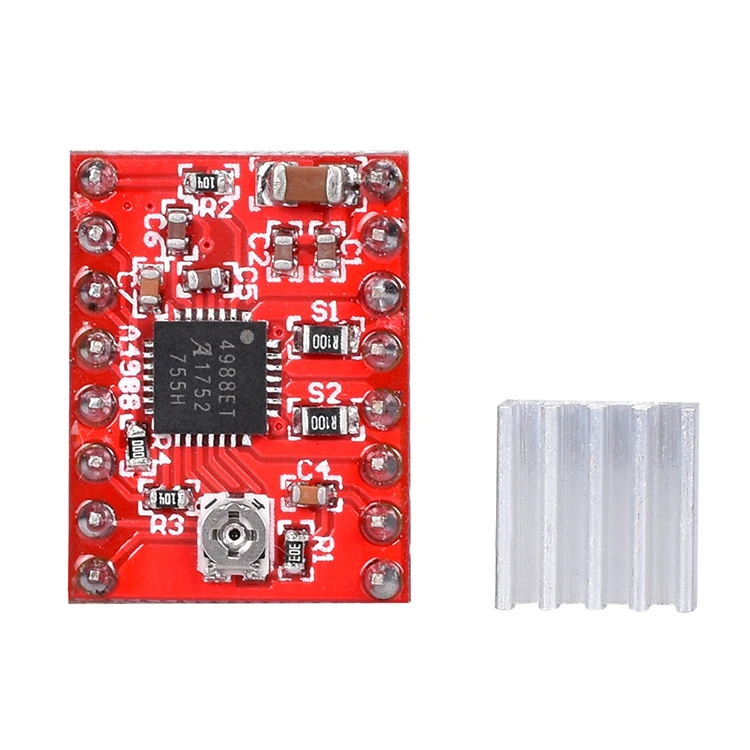

Stepper Drivers

Stepper motor drivers affect the size of the stepper motors you can drive in your 3D printer and the sound levels you hear in the process. On most 3D printer controller boards, stepper drivers can’t easily be swapped out. Therefore, selecting the right kind of controller board with the right stepper driver is essential.

On most 3D printer controller boards, stepper drivers can’t easily be swapped out. Therefore, selecting the right kind of controller board with the right stepper driver is essential.

Basic stepper drivers like the A4988 are cheap, easily accessible, and provide a relatively good experience for basic 3D printers. They do drive stepper motors loud, are unreliable, and can only provide the steppers with limited current.

TMC drivers, on the other hand, are known for their silent operation and current-carrying capacities. The TMC 2xxx series are rated at 2A peak current, while the TMC 5160 typically offers 3A to 4.4A on 3D printer controller boards.

You need to consider the microstepping capabilities of the stepper motor drivers as well. Microstepping divides a full step into smaller steps. The smaller the step, the higher the resolution and the smoother the vibration. As a minimum, you want 1/16 step microstepping, but the best 3D printer controller options offer up to 1/256 step

Touch screen support

A touch screen enhances the functionality and ease of use of a 3D printer by making navigating the menu and dialing in the various features easier.

Not all controller boards have touch screen support built-in. While choosing a controller board, look at the connectivity options and the compatible touch screens. You need to make sure that the board’s firmware supports it, and there is at least a little bit of documentation on how to interface the controller with the touch screen.

FAQ

What is a 3D printer controller board?

A 3D printer controller board is a piece of hardware that controls all electronic components in a 3D printer. It is responsible for motion, temperature control, and reading all commands from GCode files.

Why upgrade your printer’s stock controller board?

As time passes, the current features in your 3D printer start to seem obsolete. A controller board upgrade will give you access to many advanced features, allow for added functionalities and enhance your overall 3D printing experience.

Is a 3D printer controller board the same as a 3D printer motherboard?

Yes, in the context of 3D printing, the terms ‘controller board’ and ‘motherboard’ are used interchangeably. They mean exactly the same thing.

They mean exactly the same thing.

Conclusion

The best 3D printer controller boards are the ones you’re able to afford and will work with your 3D printer. With so many options on the market, it can be tough to choose just one. The important thing is figuring out which one of these top-rated controllers would be right for you.

In our opinion, the Duet 2 Wi-Fi is the overall best 3D printer controller board that you can get right now. Despite its high price, the Duet 2 Wi-Fi ticks all the boxes in terms of features, connectivity, upgrades, and ports. It is designed to be a universal solution for all types of 3D printers and can serve as an effective replacement for practically any board.

Let us know what you think about it, and if you have anything else to add, feel free to comment below.

Scroll to Top

Minitronics v2.0 - 32-bit all-in-one controller board | 3D printing experts

Overview Description Content Documentation Specifications

Compact, affordable, single-board solution with on-board stepper drivers.

Stock - NL: >100

$ 41 excl VAT In stock

Dispatches same business day!

Product description

Compact, affordable, single-board solution with on-board stepper drivers. 32-bit SAMD21 Microprocessor running at 40Mhz, well capable of running even Delta printers at decend speeds.

Minitronics is the slim but powerful electronics line. It's designed to be an easy to use, compact and smart solution to fit 90% of the 3D-printers. Unlike the Megatronics, which targets at the advanced range of usages, the Minitronics is plug and play, which will fit the needs of the average user better.

Minitronics has a powerful SAMD21J18 32-bit microprocessor with 256KB memory, running at 48Mhz. The board can be connected to a PC using a normal USB cable and can run stand-alone from 12V power supply. The board is compatible with Arduino and will therefor be easily programmed from the Arduino IDE.

The board comes with four DRV8825 on-board stepper drivers, which can be configured to different micro-stepping settings. To enable dual-head support an external stepper driver may be hooked up to the EXTSTEP header.

To enable dual-head support an external stepper driver may be hooked up to the EXTSTEP header.

Version 2.0 of the Minitronics gives you more features, while maintaining the same small form-factor of the version 1.1. Mounting hole positions, USB connector and reset button are placed at the same positions making an upgrade easy.

The boards comes with a 40mm fan, to cool the back of the board, allowing the stepper drivers better performance. Also a power connector is provided, but you may wish to add wiring yourself

Documentation

Minitronics v2.0 datasheet Minitronics v2.0 User Manual Test firmware, source files, examples MK4Duo firmware

What's in the box?

This is a kit of the following items.

| 1x | Axial Fan 40x40x10mm ( 12 V ) | |

| 1x | Minitronics v2. 0 - 32-bit all-in-one controller board (board only) 0 - 32-bit all-in-one controller board (board only) |

Specifications

| sku | MINITRONICS20K |

|---|---|

| gtin | 8719345201387 |

| Processor | |

| Technology | SAMD |

| Type | ATSAMD21J18 |

| Frequency | 48 MHz |

| Dimensions | |

| Length | 93. 9 mm 9 mm |

| Depth | 56.8 mm |

| Height | 19 mm |

| Features | |

| Thermistors | 3 |

| Endstops | 3 |

| Stepper drivers | 4 |

| Sound | |

| LCD | |

| External SD card | |

| External stepper drivers | 1 |

| Ethernet | |

| WIFI | |

| Seperated heated bed input | |

| MOSFETs | 4 |

| Dimensions | |

| Product Dimensions | 94x57x19 mm |

Price breaks

| 1 - 9: | excl $ 41 |

| 10 - 29: | excl $ 39 |

| 30 - : | excl $ 36. 75 75 |

| Need a larger quantity? Contact our Sales department. | |

32-bit 3D printer boards

32-bit 3D printer boards

The controller board is the heart of any 3D printer and controls components such as the extruder, heated bed, motors and sensors. The rapidly evolving 3D printer controller boards are expanding to offer incredible possibilities.

Duet Wifi

These 3D printer boards are usually powered by RepRapFirmware. The entire Duet family can be controlled through the Duet Web Control , but they also support the PanelDue touch screen. All of them have a slot for an expansion board. drives 5 independent stepper motors with built-in Trinamic TMC2660 drivers and I/O circuit - DueX4 for Duet 0.6 and 0.8.5, and DueX2 and DueX5 for Duet WiFi and Duet Ethernet.

The firmware for the Duet board family is open source, but most users do not need to modify the firmware itself, only working with settings stored on the internal SD card. However, it's a good idea to update your Duet to the latest stable firmware.

However, it's a good idea to update your Duet to the latest stable firmware.

Replicape BeagleBone Black

Replicape is a fast 3D printer board. It works with a BeagleBone Black, with a 1GHz processor and two 200MHz PRUs.

It is extremely versatile. The control can support two to five 2A stepper motors, two servos and four fans. Uses the best TMC 2100 stepper motor drivers, which have an incredibly low noise level. And also interacts with the printer through the browser, while printing.

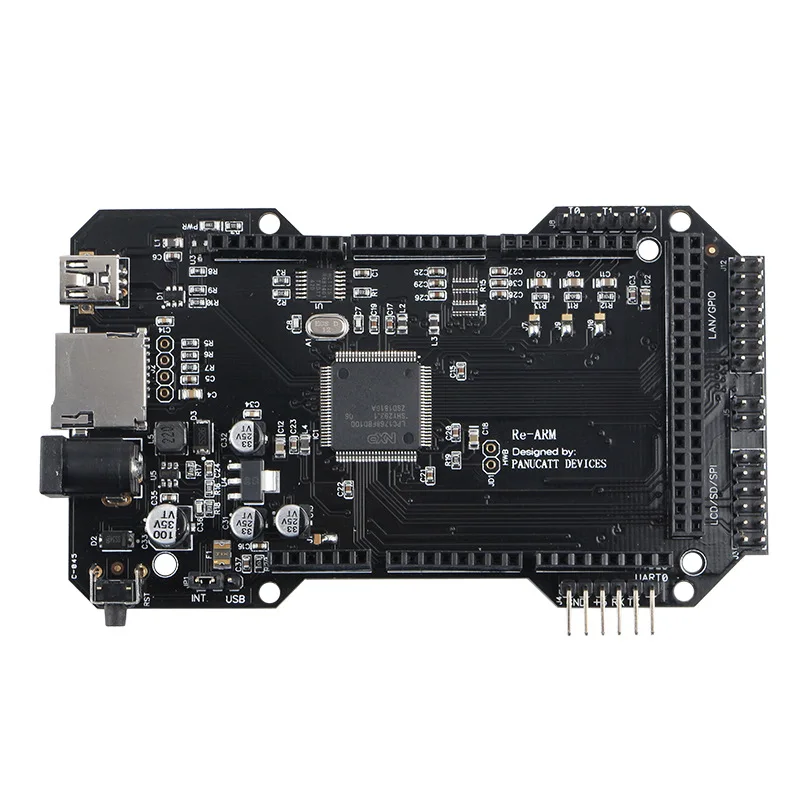

Re-ARM for RAMPS, simple 32-bit upgrade

The Re-Arm microcontroller board is more powerful and equipped with a faster 100MHz processor, which provides a high feed rate for the 3D printer. The board has an SD card slot for firmware and configuration files, but a second SD card is also supported, connected via the LCD screen for file uploads. Having a separate configuration file outside of the firmware makes setting changes much easier than other boards that require new firmware for any setting changes. The configuration is a text file that allows you to easily and quickly make changes from your computer.

The configuration is a text file that allows you to easily and quickly make changes from your computer.

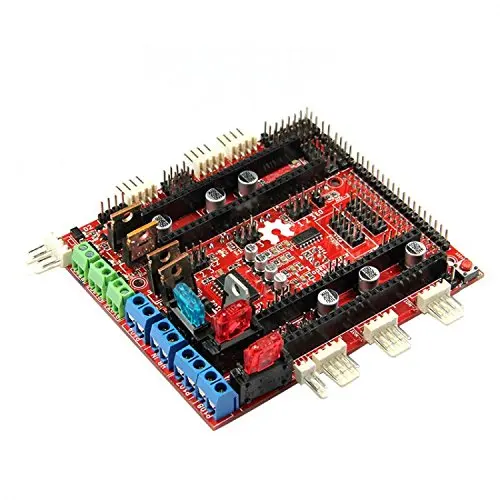

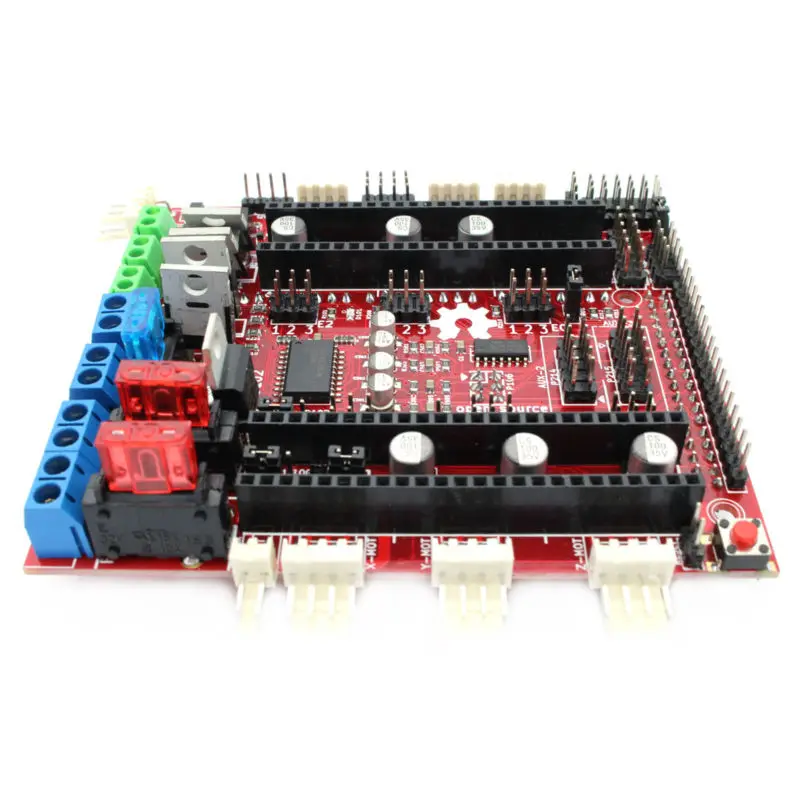

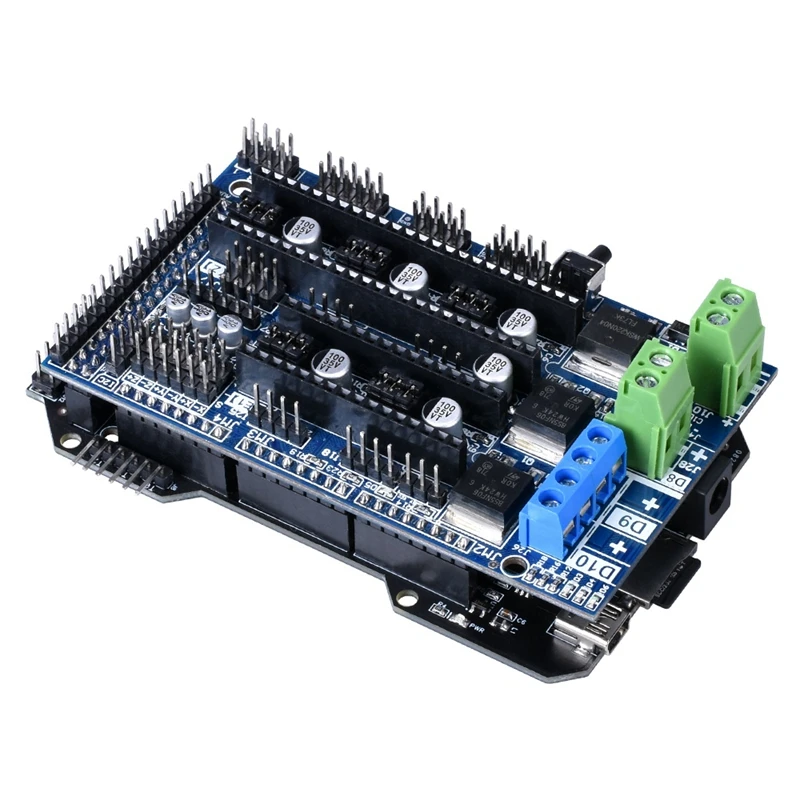

Arduino DUE with RADDS 1.5

The RepRap Arduino-Due Driver Shield is a daughterboard for the 32-bit Arduino Due. Although it looks like an 8-bit RAMPS board, it provides much more processing power and allows your 3D printer to print faster and with greater accuracy.

The 12-bit ADC (analogue-to-digital converter) has been upgraded from 10 to 12 bits. The temperature calculation is now performed over 4096 measurement points instead of 1024. This gives 4 times better temperature resolution and improves the accuracy of temperature readings.

In addition to better temperature resolution, the new firmware includes an algorithm that uses 660 measurement points to extrapolate results. This takes RADDS to the next level of temperature control for RepRap 3D printing.

Smoothieboards 4x

Smoothieboards is a controller board for digital machines. It is designed for use in 3D printers ( Reprap ), laser engravers and CNC machines, developed by a community of volunteers to run the open source Smoothieware firmware They come in many varieties, with different sets of features and benefits.

It is designed for use in 3D printers ( Reprap ), laser engravers and CNC machines, developed by a community of volunteers to run the open source Smoothieware firmware They come in many varieties, with different sets of features and benefits.

All Smoothieboards are designed to run on the most powerful machines in their price range. They are designed to be easily extended, developed and used by general users.

Smoothieboard v1 was the first Smoothieboard released and received several updates. It has gone from a pilot project to a widely used and recognized system. The board comes in 3 versions, 3X, 4X and 5X, with different sets of peripherals.

Archim 1.0

This is Archim v1.0a. The Archim Rambo 1.0 board is a versatile 3D printer motherboard. This is an original RAMBo style design with an Atmel SAM3X8E processor (same as the Arduino Due) and DRV8825 stepper drivers on one integrated PCB. Archim is named after the mathematician Archimedes.

Key Features - 5 built-in 1/32 microstepping motor drivers, 6 full PWM Mosfet outputs, 4 thermistor inputs, PWM motor current control (no tiny knobs to adjust), SMPS supports hostless printing at supply voltages from 10-24VDC , 3 independent power rails with ATC fuse protection, built-in full speed USB protected by ADUM isolator, high quality connectors. It is supported by the Arduino IDE using a third party URL board feature to simplify firmware development.

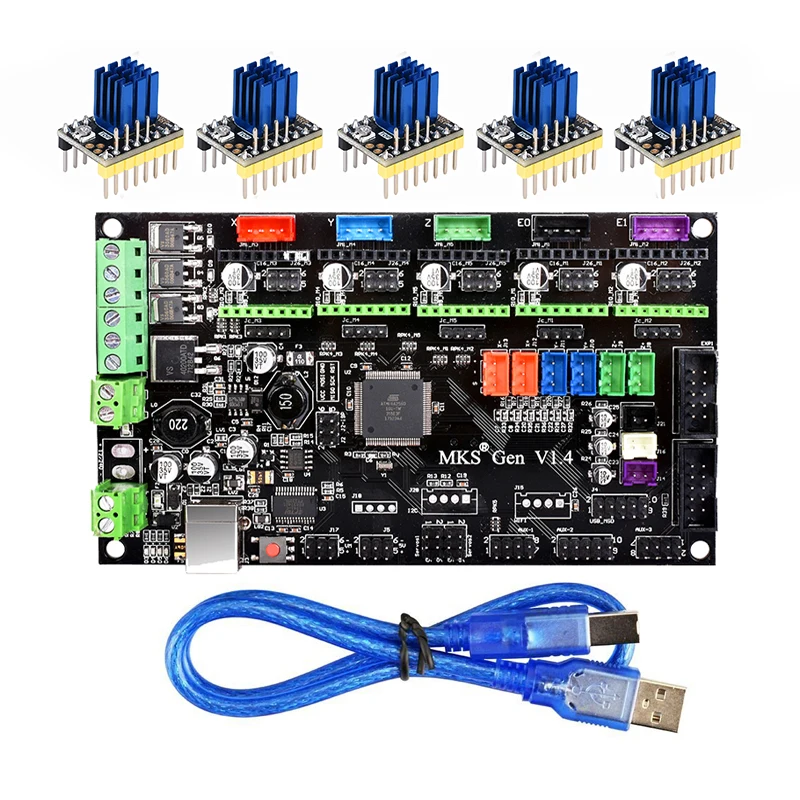

MKS SBASE 1.3

MKS SBASE is a multifunctional electronic solution for Reprap and other CNC machines. It features an embedded ARM-Cortex M3 LPC1768. Its five motor outputs are powered by DRV8825 stepper drivers. The board can use the same firmware as Ramps1.4. MKS SBASE is designed with flexibility in user's power supply selection, allowing any power supply from 12V to 24V to be used.

MKS SBASE is suitable for mass production 3D printer manufacturers and used as the main control board. Relative to Ramps1.4, this adds the heat output of E1. MKS SBASE is suitable for dual extruder machine.

Relative to Ramps1.4, this adds the heat output of E1. MKS SBASE is suitable for dual extruder machine.

Arduino DUE with RAMPS-FD

Ramps-FD's only secure version is V2.A released February 2014. Previous versions carry a high security risk. Unfortunately, the only Ramps-FD available on the market (February 2016) is version 1.2, while its manufacturer has repeatedly warned that the only safe version is 2.A. Beware of confusing wording and lack of clear mention of fee revisions from vendors. Thus, until version 2.A is released, the Ramps-FD board should be avoided.

The Arduino Due is a new Arduino board using the ARM Cortex M3 processor. The Atmel SAM3X8E chip used in the Due operates at 3.3V and is not compatible with 5V. Therefore, the RAMPS shield will not work with the Due, and worse, applying 5V to the Due's inputs may damage the chip. Therefore, there are several options: create a new version of RAMPS that is compatible with the Due.

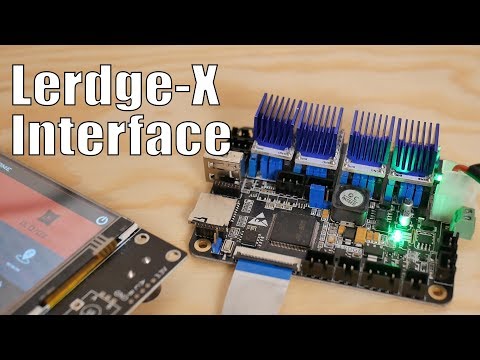

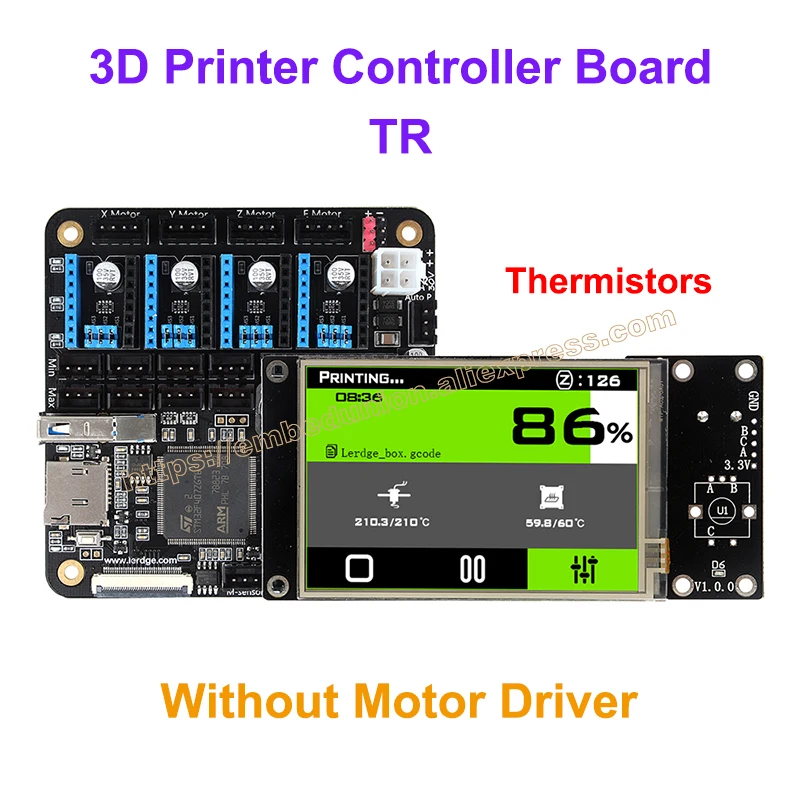

Lerdge-X

Among Lerdge 3D printer boards, Lerdge-X is a highly integrated control board designed for small 3D printers, educational 3D printers and entry-level 3D printers. The motherboard uses 32-bit CoreTX-M4 Core control unit, high and stable performance, feature-rich, price concessions. With a 3.5 inch full color IPS LCD touch screen, it provides simple and smooth operation. The motherboard uses an open interface and can match a variety of motor drive modules (A4988, DRV88225, LV8729, TMC2100 and external driver, etc.) The motherboard optimizes the connection of limit switches and adopts a comprehensive line protection design.

The motherboard uses 32-bit CoreTX-M4 Core control unit, high and stable performance, feature-rich, price concessions. With a 3.5 inch full color IPS LCD touch screen, it provides simple and smooth operation. The motherboard uses an open interface and can match a variety of motor drive modules (A4988, DRV88225, LV8729, TMC2100 and external driver, etc.) The motherboard optimizes the connection of limit switches and adopts a comprehensive line protection design.

Panucatt Azteeg X5

X5 mini WIFI is an ARM-based 32-bit motion controller for 3D printers, CNC machines and laser cutters. X5 mini runs on Smoothieware firmware and is based on the Smoothieboard. X5 mini WIFI uses powerful 32bit 120MHz ARM NXP LPC1769 chipcapable of faster calculations for quick and fluid movements.

Configuration is made easier with a text-based configuration file loaded onto the SD card, no need to download the firmware every time you make a change. Just edit the config file from your PC, then reboot the board with the new config and you're done.

The Wi-Fi module has its own web page for remote control of the printer. You can transfer files directly to the main SD card and edit the configuration file on any PC, phone or tablet using Wi-Fi. Web Control can also display video when using an IP camera.

BIGTREETECH SKR V1.1

BIGTREETECH SKR V1.1 - from Shenzhen Bigtree Technology Co., Ltd. introduced a simplified open source 3D printer control board. It is especially suitable for small and medium printers.

Greatly improved the performance of LPC1768 series ARC-class Cortex-M3 master chip with 32-bit 100M main frequency, equipped with high-modulus smoothieware open source firmware, convenient for DIY and secondary development users, don't worry about not being able to master the main worries code.

SKR V1.1 support Disdplay: 2.8 inch, 3.5 inch color touch screen, LCD12864 screen support;

The factory motherboard is equipped with testing firmware, which can be used to control the 3D printer and print, or you can flash another one yourself.

Russian 32 bit 3D printer control board with HMI display, with proprietary firmware.

Good afternoon!

I would like to present to your attention my new development: software and hardware complex for building industrial-class 3D printers. With the help of such a complex, it is possible to quickly implement various designs of 3D printers that print with granules, filament, composites or food compositions.

The complex was designed as a test platform to simplify the implementation of various new ideas in 3D printers and is a combination of a touch screen HMI and a control board on an STM32F4 series microcontroller.

Display

Initially, the control board program supports only one type of HMI display with a diagonal of 2.4 - 10.1 inches. These are displays familiar to many - Nextion displays. Basically, HMI displays are LCD touch screens with their own microcontroller, the visual control interface of which is typed in a special program from ready-made elements: buttons, graphics, numbers, scales. Thus, using such a ready-made device for the developed control board, it becomes possible to simply and quickly change the menu structure, the color and size of buttons, their number, and the overall design.

Thus, using such a ready-made device for the developed control board, it becomes possible to simply and quickly change the menu structure, the color and size of buttons, their number, and the overall design.

An example of a start window developed - a single-extruder 3D printer with an active camera.

A novelty in the start window is a warning sign (1) that appears during self-diagnosis if there are problems in the system and an additional area - event icons (2) that occur when the board is connected to the computer, the fan is turned on, the plastic presence signal, etc. d.

Video of selecting a file for printing. Display with a diagonal of 4.3 inches.

- In addition to the direct access of the display to the board during the operation of the standard printer menu embedded in the firmware, it is possible to send standard G-codes from the display, which are processed in the command pipeline on the control board.

How it works: you can bind G- to any newly created buttons code, command or their sequence, which are sent to the board to perform an action when a button is pressed. Also, G-code can be assigned to any events or actions on the screen.

How it works: you can bind G- to any newly created buttons code, command or their sequence, which are sent to the board to perform an action when a button is pressed. Also, G-code can be assigned to any events or actions on the screen. - A lot of different information comes up on the screen during printing and when the printer is idle, for example: the percentage of the print, layer height, extruder temperature. In addition, marks of the beginning and end of printing, marks when moving through the layers of printing, values in samples from the ADC on the board are additionally sent. Having this information, using the built-in functions of the HMI display (conditional statements, counters, timers), you can organize additional automation of the printer. All conditions can be started and stopped using the created buttons.

This extended screen support from the board allows you to create personalized solutions in the menu: buttons with preconfigured parameters, calling macros from the processor memory or writing a macro in the display, performing simple printing automation.

Some examples of using the HMI display for automation.

- Implementation of the nozzle cleaning macro on certain print layers. The advantage is that cleaning can be turned on or off, as needed, from the screen. In addition, you can set how long this macro will take after printing has started.

- Implementation of the backlight control algorithm. Changing its brightness and color depending on the ambient light and the percentage of printing completed, signaling problems in the system.

- Implementation of automatic shutdown of the printer at the end of printing using the M81 command.

- Control of 3D printer board ports by a preconfigured algorithm or by events.

Nextion displays have different diagonals, and in order not to produce different firmware, we have made a menu that can be adjusted to the required tasks by changing several parameters in the control board config file. For example, to change the number of lines displayed on the display of files located on a USB drive, you need to specify their number in the config file, then the program starts working for the specified number of lines. Thus, a menu is compiled for various screen sizes, fonts and screen orientations by changing only a few parameters in the configuration file.

Thus, a menu is compiled for various screen sizes, fonts and screen orientations by changing only a few parameters in the configuration file.

Implemented support for switching the interface language (English and Russian) from the printer menu.

Control board

The heart of the board is the processor of the STM32F4 family. Overall dimensions 120x150 mm. The board was created as an experimental platform with which you can implement various configurations of 3D printers. When creating, the main emphasis was placed on its reliability and long-term operation as part of a 3D printer, which led to the widespread use of TRANSIL diodes and assemblies for protection against impulse and static interference. Traditional MOSFETs have been replaced by smart switches with electronic short-circuit protection and output diagnostics. The use of smart keys made it possible to get rid of fuses, which also has a positive effect on the reliability of the control board during operation.

Power terminals for connecting power and powerful loads to the board, used by WAGO-256 - these are modular terminal blocks for printed circuit boards with a convenient push lever for attaching the wire.

All consumers are divided into four groups - PWR1-PWR4. This design allows you to easily combine loads with different operating voltages, as well as implement a standby mode (Standby Power), in which the printer will consume a minimum of energy after printing is completed. In the board, all loads are switched through switches controlled by the central processor. With the help of a special output for an external relay, you can organize two shutdown options: the first is to turn off all electronics from the network and then start it through an external button, and the second - the processor puts all loads into an inactive state: fans, display, USB flash drive, etc. then the processor itself falls asleep, but, at the same time, the board can resume its work on a remote turn-on signal or on a signal from a connected computer. Also, if there is a standby power supply connected to the PWR1 input, the relay can also disconnect the second powerful power supply for the PWR2-PWR4 input from the network (additional energy saving). The second power saving mode with the ability to resume the 3D printer on command will be useful in building 3D printed farms.

Also, if there is a standby power supply connected to the PWR1 input, the relay can also disconnect the second powerful power supply for the PWR2-PWR4 input from the network (additional energy saving). The second power saving mode with the ability to resume the 3D printer on command will be useful in building 3D printed farms.

The board does not have standard sockets for a USB flash drive and a socket for connecting a computer; WAGO spring terminals are installed instead. This solution allows, using extension cables pressed with tips, to place all the necessary sockets in convenient places on the printer without binding the board to the front panel.

As described above, all loads are switched by intelligent keys and, at the same time, information on the self-diagnosis of the system is additionally taken from them. Depending on the type of keys in the channels, the diagnostic information from them is different.

- The smart keys for the hot end channel, the heated platform and the printer chamber heating are the same, the maximum consumer current for each channel is 20A.

Diagnostic information from them is as follows: load break, short circuit in the load, key overheating, power - consumed by the load connected to them.

Diagnostic information from them is as follows: load break, short circuit in the load, key overheating, power - consumed by the load connected to them. - For three fan channels, maximum current consumption 1A. Diagnostic information from them is as follows: load break, short circuit in the load, key overheating.

- For two fan channels and a power channel for limit switches, you can separately set the voltage of 5/12 V, the maximum current consumption for the channels is 0.5 A. Diagnostic information from them is as follows: load break, short circuit in the load, overheating of the key.

- To power the display, a key with output parameters 5V 1A is used, for a USB flash drive 5V 0.5A. Diagnostic information from them is as follows: short circuit in the load, overheating of the key.

Since the board is mainly designed for industrial equipment, the number of drivers on the board is limited to four pieces, but, at the same time, their control pins STEP, DIR and EN are duplicated by buffer microcircuits into sockets for direct control of external stepper motor drivers, logic voltage these outputs are 5V. Also on the board there are additional 10 outputs formed through buffer microcircuits for external connection, with logic levels of 5V, all outputs are protected by TRANSIL diodes.

Also on the board there are additional 10 outputs formed through buffer microcircuits for external connection, with logic levels of 5V, all outputs are protected by TRANSIL diodes.

For external connection of remote sensors with dry contact, the board provides 6 inputs, with optical isolation. Such inputs may be required, for example, to measure the level of granules in the hopper or to connect end sensors on the “large” printer frame.

USB connection to the computer is galvanically isolated from the board and protected by TRANSIL diodes.

Three-channel temperature measurement using a PT100 platinum sensor and MAX31865 custom ICs. Connection is possible with a two-, three- or four-wire circuit of a measuring temperature sensor. Diagnostic information from microcircuits, the following: sensor short circuit, sensor wire break. The use of platinum thermal resistance as a temperature sensor was due to the following considerations: temperature measurement up to +600°C, a wide selection of sensor body versions, no need for calibration, high measurement accuracy, connection via a long cable up to 100 meters.

Communication between the board and external equipment is carried out using the RS485 interface. The choice of this interface is due to its widespread use in the industry. RS485 is supported by various sensors and process controllers (mostly with Modbus protocol).

Output electrolytic capacitors are installed in a special series, with a service life of 6 times longer than standard surface mount electrolytic capacitors.

of the NEXTION Display has a UART interface, but for communication between the control board and the display, an RS232 interface (a standard interface for industrial displays) is implemented, which allows a cable length of up to 15 meters. Therefore, an RS232 - UART adapter is required, which will come with the board. Such a solution will be more reliable when operating in conditions of increased interference.

Also on the board there are two ADC inputs, one for the thermistor, the second for the ambient light sensor.

The board has additional inputs and outputs. Their purpose is one of the subjects of future publications.

Their purpose is one of the subjects of future publications.

Purpose

- The presented board and program for the STM32F4 microcontroller is the fourth generation of the complex initially developed for itself. Together with the HMI display, the complex turned out to be quite versatile in use. On this complex, I plan to reproduce two- or more-extruder 3D printers with automatic measurement of nozzles by a load cell (some analogue of the solution from Josef Prusha (link)). A custom extruder is created for the load cell, and for its manufacture I conducted experiments with aluminum soldering (link). Theoretically, if the extruder has minimal weight and size parameters, and the fans do not create significant vibrations on the measuring part, then a large amount of information can be obtained from such a design, not only about the sizes and coordinates of the nozzles, but also, presumably, indirectly about the pressure of the filament in the melt zone. I will test this hypothesis in the near future.

At this stage, I can only say with certainty that it will be possible to implement automatic measurement of nozzle coordinates. I plan to introduce my filament motion sensor into the extruder, which allows to determine the underextrusion of plastic during printing (link), with the display of a new parameter - plastic slip. I think that together with a load cell, you should get an excellent SMART extruder. In the future, it is interesting to reproduce some analogue of the Ultimaker S5 Pro Bundle system, for 24/7 printing (link), but with its own solutions in the form of boards, sensors and work algorithms.

At this stage, I can only say with certainty that it will be possible to implement automatic measurement of nozzle coordinates. I plan to introduce my filament motion sensor into the extruder, which allows to determine the underextrusion of plastic during printing (link), with the display of a new parameter - plastic slip. I think that together with a load cell, you should get an excellent SMART extruder. In the future, it is interesting to reproduce some analogue of the Ultimaker S5 Pro Bundle system, for 24/7 printing (link), but with its own solutions in the form of boards, sensors and work algorithms. - The board has already been used in one of the commercial projects, so the idea of a third purpose was born.

- I invite Russian companies, start-ups to cooperate. All the solutions I have worked out will allow you to implement your plans in a short time, build a prototype, with its subsequent launch into mass production and joint efforts to compete in the global market for 3D printing solutions! The goal is ambitious, but quite achievable, the main thing from you is an idea and a desire to work! The following areas are interesting: 3D printers printing pellets, large industrial printers with an active camera or MFP printing and milling devices, 3D printers printing food materials, 3D farms.

About the details and plans

The control board may have turned out to be redundant in some circuit solutions, therefore it is relatively expensive and it is not practical to use it to assemble simple, home single-extruder printers, therefore, at this stage it is not available for free sale it will be, since it is cheaper to buy other ready-made kits, but as the project develops and my new functionality grows, I will make the option more accessible.

My plans for the next month are to assemble the board and firmware for its new version, finish the menu. Also, I plan to order a second, small experimental board for a SMART extruder. I decided on its elemental base, it will have a processor on board, smart keys for the extruder heater and two fans, two accelerometers, a strain gauge amplifier and a number of elements for various sensors, communication with the main control board via RS485.

By firmware

The firmware is written on our own. The G-code of the team was borrowed from Marlin 1.0 five years ago, the calculation of the trajectories of movements was also taken from there, so the board does not support other displays than those that we are implementing. The same feature is with sensors. At the moment, we are introducing the possibility of compensating the resonance of the 3D printer mechanics and supporting two other options for HMI displays into the microcontroller program of the board, more expensive than NEXTION - industrial grade and cheaper than NEXTION - this type is being introduced for affordability of the board and display kit. Writing a program for the microcontroller was very slow for us, the board was constantly changing, the solutions for the sensors also changed, but since now all these issues have been resolved, the main emphasis in the work will be aimed at developing and optimizing the firmware.

The G-code of the team was borrowed from Marlin 1.0 five years ago, the calculation of the trajectories of movements was also taken from there, so the board does not support other displays than those that we are implementing. The same feature is with sensors. At the moment, we are introducing the possibility of compensating the resonance of the 3D printer mechanics and supporting two other options for HMI displays into the microcontroller program of the board, more expensive than NEXTION - industrial grade and cheaper than NEXTION - this type is being introduced for affordability of the board and display kit. Writing a program for the microcontroller was very slow for us, the board was constantly changing, the solutions for the sensors also changed, but since now all these issues have been resolved, the main emphasis in the work will be aimed at developing and optimizing the firmware.

Some statistics on the board

Capacitors - 84 pcs.

Resistors - 135 pcs.