3D printing battery

3D Printed Solid-State Battery Rivals Lithium-Ion

Utrecht, a largely bicycle-propelled city of 350,000 just south of Amsterdam, has become a proving ground for the bidirectional-charging techniques that have the rapt interest of automakers, engineers, city managers, and power utilities the world over. This initiative is taking place in an environment where everyday citizens want to travel without causing emissions and are increasingly aware of the value of renewables and energy security.

“We wanted to change,” says Eelco Eerenberg, one of Utrecht's deputy mayors and alderman for development, education, and public health. And part of the change involves extending the city’s EV-charging network. “We want to predict where we need to build the next electric charging station.”

So it’s a good moment to consider where vehicle-to-grid concepts first emerged and to see in Utrecht how far they’ve come.

It’s been 25 years since University of Delaware energy and environmental expert Willett Kempton and Green Mountain College energy economist Steve Letendre outlined what they saw as a “dawning interaction between electric-drive vehicles and the electric supply system. ” This duo, alongside Timothy Lipman of the University of California, Berkeley, and Alec Brooks of AC Propulsion, laid the foundation for vehicle-to-grid power.

The inverter converts alternating current to direct current when charging the vehicle and back the other way when sending power into the grid. This is good for the grid. It’s yet to be shown clearly why that’s good for the driver.

Their initial idea was that garaged vehicles would have a two-way computer-controlled connection to the electric grid, which could receive power from the vehicle as well as provide power to it. Kempton and Letendre’s 1997 paper in the journal Transportation Research describes how battery power from EVs in people’s homes would feed the grid during a utility emergency or blackout. With on-street chargers, you wouldn’t even need the house.

Bidirectional charging uses an inverter about the size of a breadbasket, located either in a dedicated charging box or onboard the car. The inverter converts alternating current to direct current when charging the vehicle and back the other way when sending power into the grid. This is good for the grid. It’s yet to be shown clearly why that’s good for the driver.

The inverter converts alternating current to direct current when charging the vehicle and back the other way when sending power into the grid. This is good for the grid. It’s yet to be shown clearly why that’s good for the driver.

This is a vexing question. Car owners can earn some money by giving a little energy back to the grid at opportune times, or can save on their power bills, or can indirectly subsidize operation of their cars this way. But from the time Kempton and Letendre outlined the concept, potential users also feared losing money, through battery wear and tear. That is, would cycling the battery more than necessary prematurely degrade the very heart of the car? Those lingering questions made it unclear whether vehicle-to-grid technologies would ever catch on.

Market watchers have seen a parade of “just about there” moments for vehicle-to-grid technology. In the United States in 2011, the University of Delaware and the New Jersey–based utility NRG Energy signed a technology-license deal for the first commercial deployment of vehicle-to-grid technology. Their research partnership ran for four years.

Their research partnership ran for four years.

In recent years, there’s been an uptick in these pilot projects across Europe and the United States, as well as in China, Japan, and South Korea. In the United Kingdom, experiments are now taking place in suburban homes, using outside wall-mounted chargers metered to give credit to vehicle owners on their utility bills in exchange for uploading battery juice during peak hours. Other trials include commercial auto fleets, a set of utility vans in Copenhagen, two electric school buses in Illinois, and five in New York.

These pilot programs have remained just that, though—pilots. None evolved into a large-scale system. That could change soon. Concerns about battery wear and tear are abating. Last year, Heta Gandhi and Andrew White of the University of Rochestermodeled vehicle-to-grid economics and found battery-degradation costs to be minimal. Gandhi and White also noted that battery capital costs have gone down markedly over time, falling from well over US $1,000 per kilowatt-hour in 2010 to about $140 in 2020.

As vehicle-to-grid technology becomes feasible, Utrecht is one of the first places to fully embrace it.

The key force behind the changes taking place in this windswept Dutch city is not a global market trend or the maturity of the engineering solutions. It’s having motivated people who are also in the right place at the right time.

One is Robin Berg, who started a company called We Drive Solar from his Utrecht home in 2016. It has evolved into a car-sharing fleet operator with 225 electric vehicles of various makes and models—mostly Renault Zoes, but also Tesla Model 3s, Hyundai Konas, and Hyundai Ioniq 5s. Drawing in partners along the way, Berg has plotted ways to bring bidirectional charging to the We Drive Solar fleet. His company now has 27 vehicles with bidirectional capabilities, with another 150 expected to be added in coming months.

In 2019, Willem-Alexander, king of the Netherlands, presided over the installation of a bidirectional charging station in Utrecht. Here the king [middle] is shown with Robin Berg [left], founder of We Drive Solar, and Jerôme Pannaud [right], Renault's general manager for Belgium, the Netherlands, and Luxembourg.Patrick van Katwijk/Getty Images

Here the king [middle] is shown with Robin Berg [left], founder of We Drive Solar, and Jerôme Pannaud [right], Renault's general manager for Belgium, the Netherlands, and Luxembourg.Patrick van Katwijk/Getty Images

Amassing that fleet wasn’t easy. We Drive Solar’s two bidirectional Renault Zoes are prototypes, which Berg obtained by partnering with the French automaker. Production Zoes capable of bidirectional charging have yet to come out. Last April, Hyundai delivered 25 bidirectionally capable long-range Ioniq 5s to We Drive Solar. These are production cars with modified software, which Hyundai is making in small numbers. It plans to introduce the technology as standard in an upcoming model.

We Drive Solar’s 1,500 subscribers don’t have to worry about battery wear and tear—that’s the company’s problem, if it is one, and Berg doesn’t think it is. “We never go to the edges of the battery,” he says, meaning that the battery is never put into a charge state high or low enough to shorten its life materially.

We Drive Solar is not a free-flowing, pick-up-by-app-and-drop-where-you-want service. Cars have dedicated parking spots. Subscribers reserve their vehicles, pick them up and drop them off in the same place, and drive them wherever they like. On the day I visited Berg, two of his cars were headed as far as the Swiss Alps, and one was going to Norway. Berg wants his customers to view particular cars (and the associated parking spots) as theirs and to use the same vehicle regularly, gaining a sense of ownership for something they don’t own at all.

That Berg took the plunge into EV ride-sharing and, in particular, into power-networking technology like bidirectional charging, isn’t surprising. In the early 2000s, he started a local service provider called LomboXnet, installing line-of-sight Wi-Fi antennas on a church steeple and on the rooftop of one of the tallest hotels in town. When Internet traffic began to crowd his radio-based network, he rolled out fiber-optic cable.

In 2007, Berg landed a contract to install rooftop solar at a local school, with the idea to set up a microgrid. He now manages 10,000 schoolhouse rooftop panels across the city. A collection of power meters lines his hallway closet, and they monitor solar energy flowing, in part, to his company’s electric-car batteries—hence the company name, We Drive Solar.

Berg did not learn about bidirectional charging through Kempton or any of the other early champions of vehicle-to-grid technology. He heard about it because of the Fukushima nuclear-plant disaster a decade ago. He owned a Nissan Leaf at the time, and he read about how these cars supplied emergency power in the Fukushima region.

“Okay, this is interesting technology,” Berg recalls thinking. “Is there a way to scale it up here?” Nissan agreed to ship him a bidirectional charger, and Berg called Utrecht city planners, saying he wanted to install a cable for it. That led to more contacts, including at the company managing the local low-voltage grid, Stedin. After he installed his charger, Stedin engineers wanted to know why his meter sometimes ran backward. Later, Irene ten Dam at the Utrecht regional development agency got wind of his experiment and was intrigued, becoming an advocate for bidirectional charging.

After he installed his charger, Stedin engineers wanted to know why his meter sometimes ran backward. Later, Irene ten Dam at the Utrecht regional development agency got wind of his experiment and was intrigued, becoming an advocate for bidirectional charging.

Berg and the people working for the city who liked what he was doing attracted further partners, including Stedin, software developers, and a charging-station manufacturer. By 2019, Willem-Alexander, king of the Netherlands, was presiding over the installation of a bidirectional charging station in Utrecht. “With both the city and the grid operator, the great thing is, they are always looking for ways to scale up,” Berg says. They don’t just want to do a project and do a report on it, he says. They really want to get to the next step.

Those next steps are taking place at a quickening pace. Utrecht now has 800 bidirectional chargers designed and manufactured by the Dutch engineering firm NieuweWeme. The city will soon need many more.

The city will soon need many more.

The number of charging stations in Utrecht has risen sharply over the past decade.

“People are buying more and more electric cars,” says Eerenberg, the alderman. City officials noticed a surge in such purchases in recent years, only to hear complaints from Utrechters that they then had to go through a long application process to have a charger installed where they could use it. Eerenberg, a computer scientist by training, is still working to unwind these knots. He realizes that the city has to go faster if it is to meet the Dutch government’s mandate for all new cars to be zero-emission in eight years.

The amount of energy being used to charge EVs in Utrecht has skyrocketed in recent years.

Although similar mandates to put more zero-emission vehicles on the road in New York and California failed in the past, the pressure for vehicle electrification is higher now. And Utrecht city officials want to get ahead of demand for greener transportation solutions. This is a city that just built a central underground parking garage for 12,500 bicycles and spent years digging up a freeway that ran through the center of town, replacing it with a canal in the name of clean air and healthy urban living.

This is a city that just built a central underground parking garage for 12,500 bicycles and spent years digging up a freeway that ran through the center of town, replacing it with a canal in the name of clean air and healthy urban living.

A driving force in shaping these changes is Matthijs Kok, the city’s energy-transition manager. He took me on a tour—by bicycle, naturally—of Utrecht’s new green infrastructure, pointing to some recent additions, like a stationary battery designed to store solar energy from the many panels slated for installation at a local public housing development.

This map of Utrecht shows the city’s EV-charging infrastructure. Orange dots are the locations of existing charging stations; red dots denote charging stations under development. Green dots are possible sites for future charging stations.

“This is why we all do it,” Kok says, stepping away from his propped-up bike and pointing to a brick shed that houses a 400-kilowatt transformer. These transformers are the final link in the chain that runs from the power-generating plant to high-tension wires to medium-voltage substations to low-voltage transformers to people’s kitchens.

These transformers are the final link in the chain that runs from the power-generating plant to high-tension wires to medium-voltage substations to low-voltage transformers to people’s kitchens.

There are thousands of these transformers in a typical city. But if too many electric cars in one area need charging, transformers like this can easily become overloaded. Bidirectional charging promises to ease such problems.

Kok works with others in city government to compile data and create maps, dividing the city into neighborhoods. Each one is annotated with data on population, types of households, vehicles, and other data. Together with a contracted data-science group, and with input from ordinary citizens, they developed a policy-driven algorithm to help pick the best locations for new charging stations. The city also included incentives for deploying bidirectional chargers in its 10-year contracts with vehicle charge-station operators. So, in these chargers went.

Experts expect bidirectional charging to work particularly well for vehicles that are part of a fleet whose movements are predictable. In such cases, an operator can readily program when to charge and discharge a car’s battery.

In such cases, an operator can readily program when to charge and discharge a car’s battery.

We Drive Solar earns credit by sending battery power from its fleet to the local grid during times of peak demand and charges the cars’ batteries back up during off-peak hours. If it does that well, drivers don’t lose any range they might need when they pick up their cars. And these daily energy trades help to keep prices down for subscribers.

Encouraging car-sharing schemes like We Drive Solar appeals to Utrecht officials because of the struggle with parking—a chronic ailment common to most growing cities. A huge construction site near the Utrecht city center will soon add 10,000 new apartments. Additional housing is welcome, but 10,000 additional cars would not be. Planners want the ratio to be more like one car for every 10 households—and the amount of dedicated public parking in the new neighborhoods will reflect that goal.

Some of the cars available from We Drive Solar, including these Hyundai Ioniq 5s, are capable of bidirectional charging. We Drive Solar

We Drive Solar

Projections for the large-scale electrification of transportation in Europe are daunting. According to a Eurelectric/Deloitte report, there could be 50 million to 70 million electric vehicles in Europe by 2030, requiring several million new charging points, bidirectional or otherwise. Power-distribution grids will need hundreds of billions of euros in investment to support these new stations.

The morning before Eerenberg sat down with me at city hall to explain Utrecht’s charge-station planning algorithm, war broke out in Ukraine. Energy prices now strain many households to the breaking point. Gasoline has reached $6 a gallon (if not more) in some places in the United States. In Germany in mid-June, the driver of a modest VW Golf had to pay about €100 (more than $100) to fill the tank. In the U.K., utility bills shot up on average by more than 50 percent on the first of April.

The war upended energy policies across the European continent and around the world, focusing people’s attention on energy independence and security, and reinforcing policies already in motion, such as the creation of emission-free zones in city centers and the replacement of conventional cars with electric ones. How best to bring about the needed changes is often unclear, but modeling can help.

How best to bring about the needed changes is often unclear, but modeling can help.

Nico Brinkel, who is working on his doctorate in Wilfried van Sark’s photovoltaics-integration lab at Utrecht University, focuses his models at the local level. In his calculations, he figures that, in and around Utrecht, low-voltage grid reinforcements cost about €17,000 per transformer and about €100,000 per kilometer of replacement cable. “If we are moving to a fully electrical system, if we’re adding a lot of wind energy, a lot of solar, a lot of heat pumps, a lot of electric vehicles…,” his voice trails off. “Our grid was not designed for this.”

But the electrical infrastructure will have to keep up. One of Brinkel’s studies suggests that if a good fraction of the EV chargers are bidirectional, such costs could be spread out in a more manageable way. “Ideally, I think it would be best if all of the new chargers were bidirectional,” he says. “The extra costs are not that high. ”

”

Berg doesn’t need convincing. He has been thinking about what bidirectional charging offers the whole of the Netherlands. He figures that 1.5 million EVs with bidirectional capabilities—in a country of 8 million cars—would balance the national grid. “You could do anything with renewable energy then,” he says.

Seeing that his country is starting with just hundreds of cars capable of bidirectional charging, 1.5 million is a big number. But one day, the Dutch might actually get there.

This article appears in the August 2022 print issue as “A Road Test for Vehicle-to-Grid Tech.”

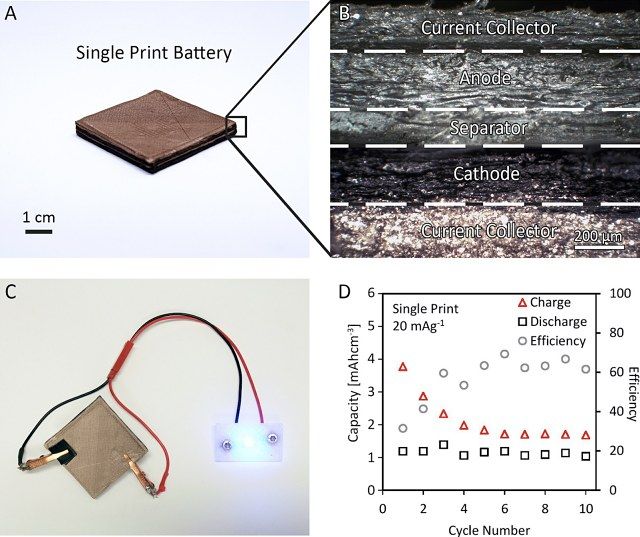

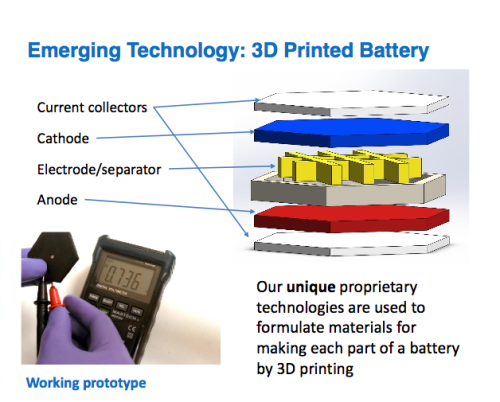

A California Startup Says 3D Printing Batteries Could Double Capacity

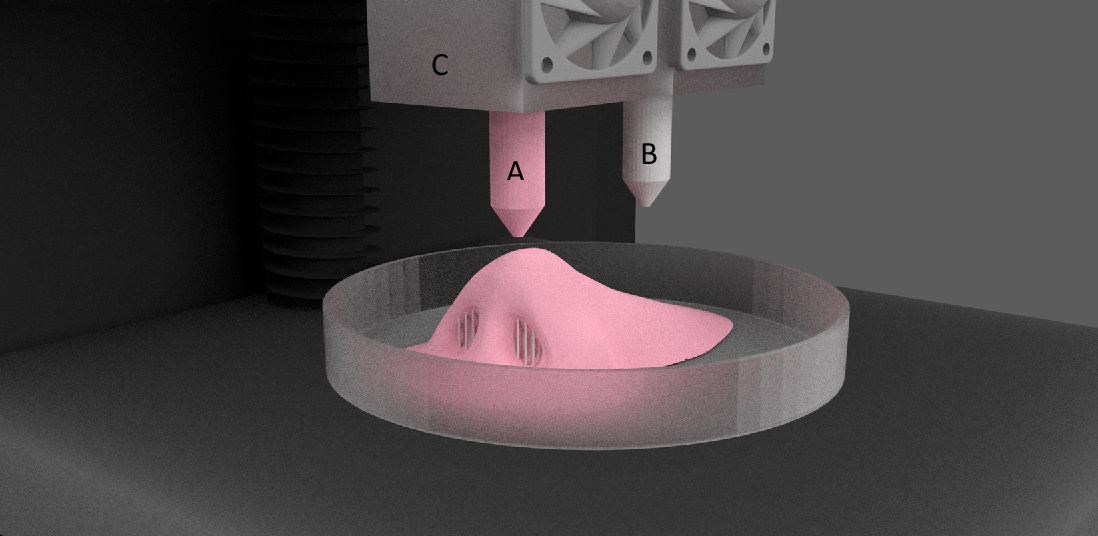

Solid-state batteries could be more energy dense, safer, and faster charging than today’s technology, but finding a way to make them commercially viable is challenging. One company thinks 3D printing holds the answer.

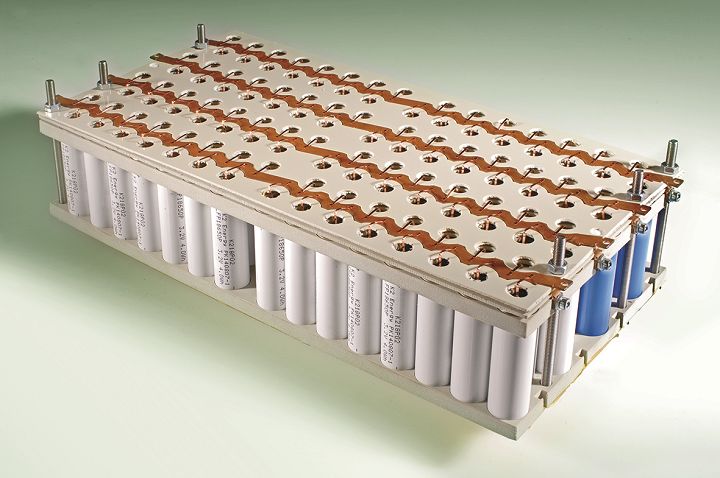

In recent years, the lithium-ion batteries that power everything from smartphones to electric vehicles have seen huge improvements in their safety and energy density (a measure of how much power they pack in per pound). But progress is slowing, and it seems likely that we will need to switch to novel battery designs if we want to banish the gas-powered car to the history books.

But progress is slowing, and it seems likely that we will need to switch to novel battery designs if we want to banish the gas-powered car to the history books.

Solid-state batteries, which replace the liquid electrolyte found in today’s cells with a solid one, are some of the most promising candidates in the near term. They would not only make batteries safer by removing the flammable liquid electrolyte, but could also boost energy density and allow faster charging.

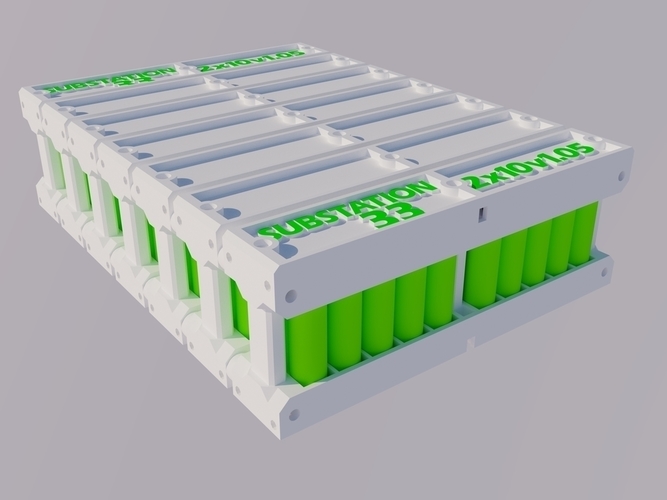

A number of startups have developed promising prototypes, but working out how to manufacture these kinds of batteries at scale is a major challenge. California-based startup Sakuú thinks the answer is to use 3D printing, which would allow them to make much more efficient use of space and therefore produce batteries with much higher capacity than competitors.

Batteries are made up of three key components: a positive electrode called an anode, a negative electrode called a cathode, and an electrolyte that allows ions to travel between the two. In today’s most advanced lithium-ion batteries, the electrodes are made using a production process known as “roll-to-roll” manufacturing.

In today’s most advanced lithium-ion batteries, the electrodes are made using a production process known as “roll-to-roll” manufacturing.

The materials used to make each of the electrodes are mixed into a slurry and then coated onto a long roll of metal foil before being dried. These long rolls are then sliced up into smaller sections and stacked on top of each other with a separator between each electrode. These stacks are placed in an enclosure that is then filled with liquid electrolyte.

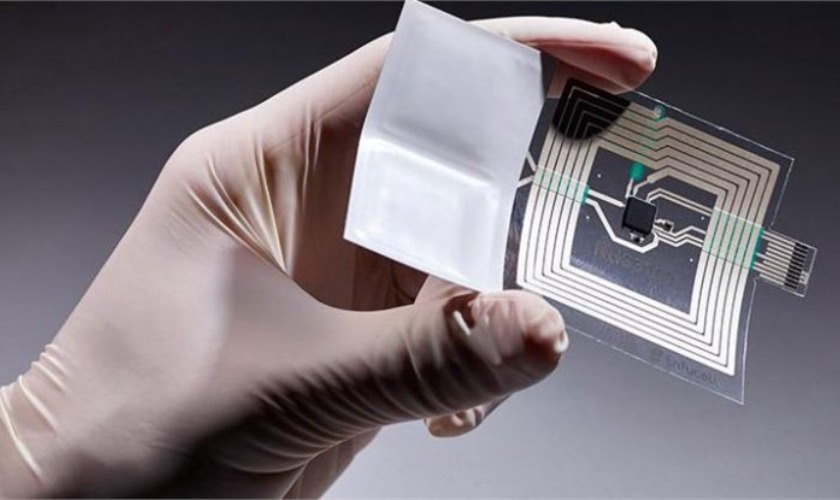

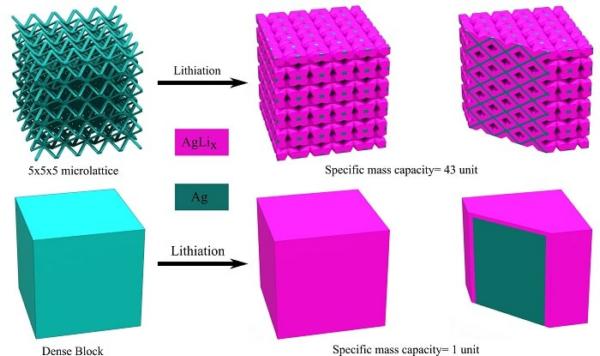

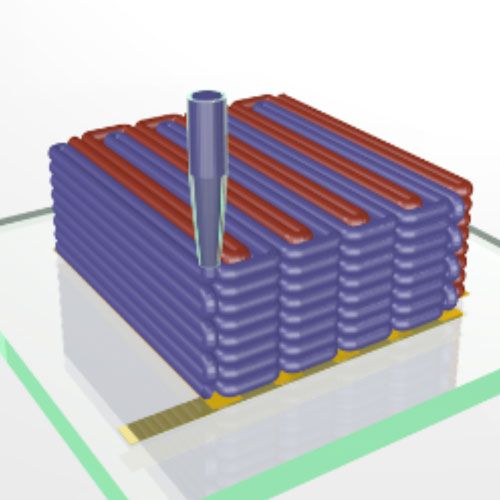

Even newer solid-state battery companies are proposing to use the same production process, but Sakuú is taking a completely different approach. It has created a 10-meter-long multi-material printer that can work with both ceramics and metals. The machine first lays down patterns of powdered material before depositing a jet of polymer binder that sticks the particles together. It then deposits conductive metal on top. These layers are stacked on top of each other to produce cells.

The company told The Verge that the approach allows it to stack more layers into a given space than conventional approaches. On its website, Sakuú claims this is because its manufacturing process allows for thinner structural layers and a novel stacked structure. This means it can either provide 100 percent greater capacity than current lithium-ion cells, or make batteries 50 percent smaller and 40 percent lighter.

Another attractive benefit of using 3D printing is that it should be possible to build batteries in all kinds of different shapes, which is difficult with traditional roll-to-roll manufacturing. This could make it possible to build batteries into the structure of products rather than having to dedicate space for them.

This is something that has become a major focus for the electric vehicle industry, as companies attempt to boost the battery capacity of their vehicles without adding extra weight. Chinese battery maker Contemporary Amperex Technology and electric vehicle Leapmotor are working on ways to build batteries into the chassis of cars, while Tesla says it has devised a new glue that will make its batteries load-bearing, allowing them to be used as structural parts.

The ability to 3D print batteries in a variety of shapes could turbocharge this trend, but it’s likely to be some time before Sakuú’s batteries hit the road. While it told The Verge that each of its printers will eventually be able to churn out about 40 megawatt hours of energy storage—the equivalent of 500 electric car batteries—so far it only has a prototype of its machine, and it has not yet been used to make any batteries.

If they can get their printers up and running, though, this could provide a big boost to efforts to increase the range and reliability of electric vehicles and push them further into the mainstream.

Image Credit: Sakuú

| 3DNews Technologies and IT market. News at the forefront of science Americans have created a 3D printer for industrial. The most interesting in the reviews 08/17/2021 [11:30], Gennady Detinich US startup Sakku unveiled a prototype 3D printer for printing solid-state lithium metal batteries. According to the developer, printing allows you to create the perfect battery, which will not have anything superfluous. This means that the element will have the highest energy storage density, and industrial printing will reduce production costs. Image Source: Sakku Sakku's prototype 3D printer can print prototype 3 Ah batteries. The company does not disclose other characteristics, but reports that it was able to increase the energy storage density by 100 times in a year of development. “In order to get batteries with maximum energy density, we want to minimize the volume of all elements that do not add anything to battery performance, ,” said Karl Littau, CTO of Sakku. - That's what printing really does. Sakku used metal printing technology developed by scientists at the Massachusetts Institute of Technology in its development. To this technology is added the printing of a ceramic composition using special binders. Ceramics in this case plays the role of an electrolyte and is the highlight of the Sakku solid-state battery. The company plans to introduce the first automated printer for industrial printing of solid-state lithium batteries by the end of this year. Compared to the existing prototype, the production of battery cells will increase by an order of magnitude or more. The company is not going to limit themselves to one or another application for batteries, they promise to print batteries for any application. It should be added that lithium metal batteries, one of the variants offered by Sakku, have problems such as the growth of needle dendrite on lithium metal electrodes. Each charge causes the growth of dendrites, which can eventually puncture the separator and cause a short circuit in the battery. Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: News Hardware, power supplies, adapters, power supplies, cutting edge science, Tags: lithium ion, solid state battery, 3d printing, battery ← В past To the future → |

3d laboratorio Accessories

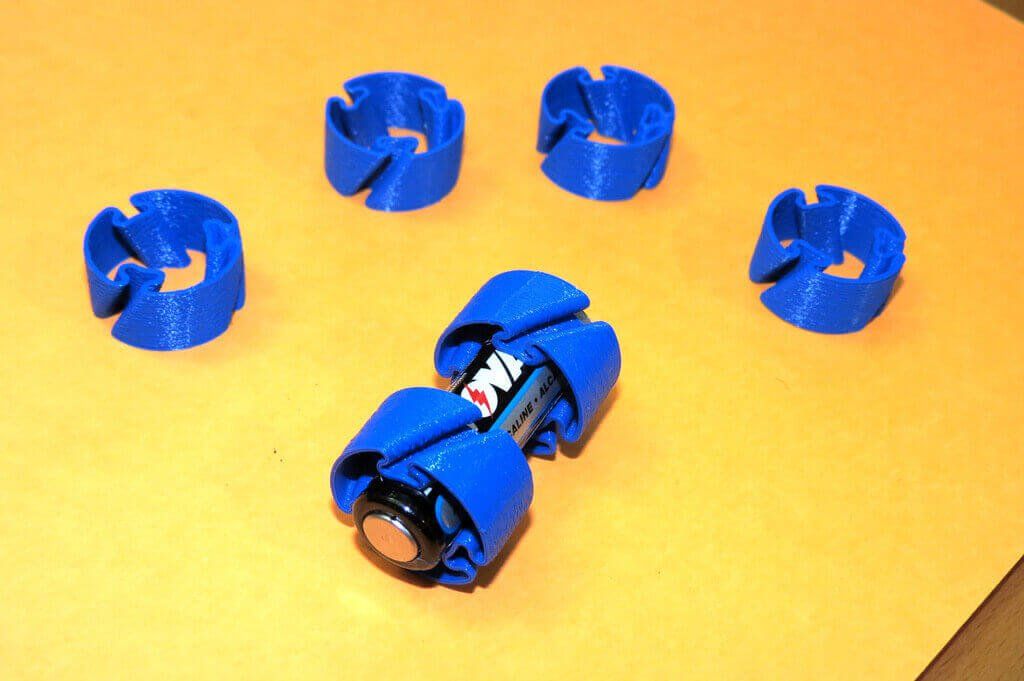

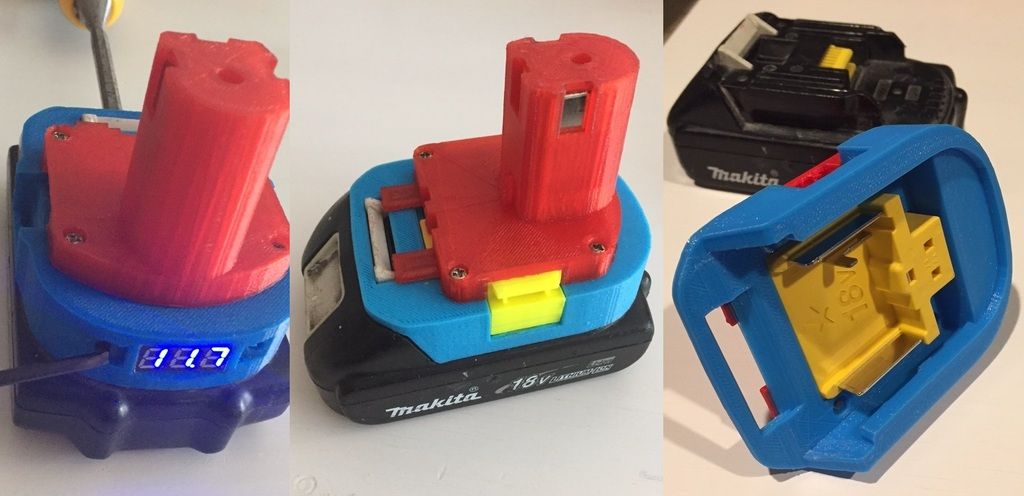

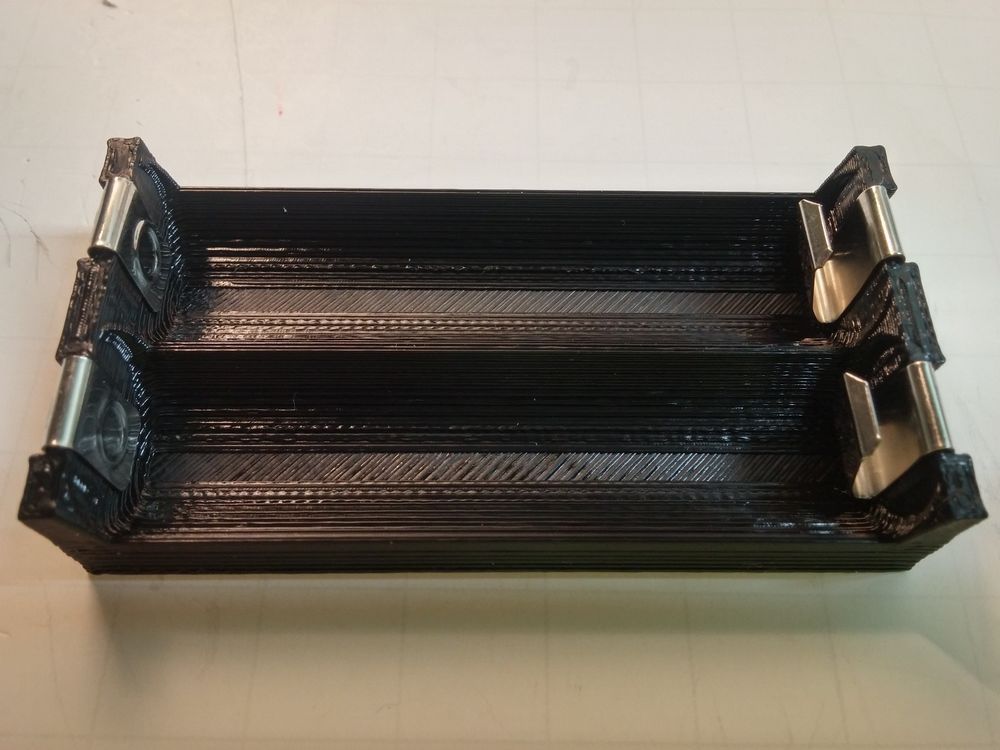

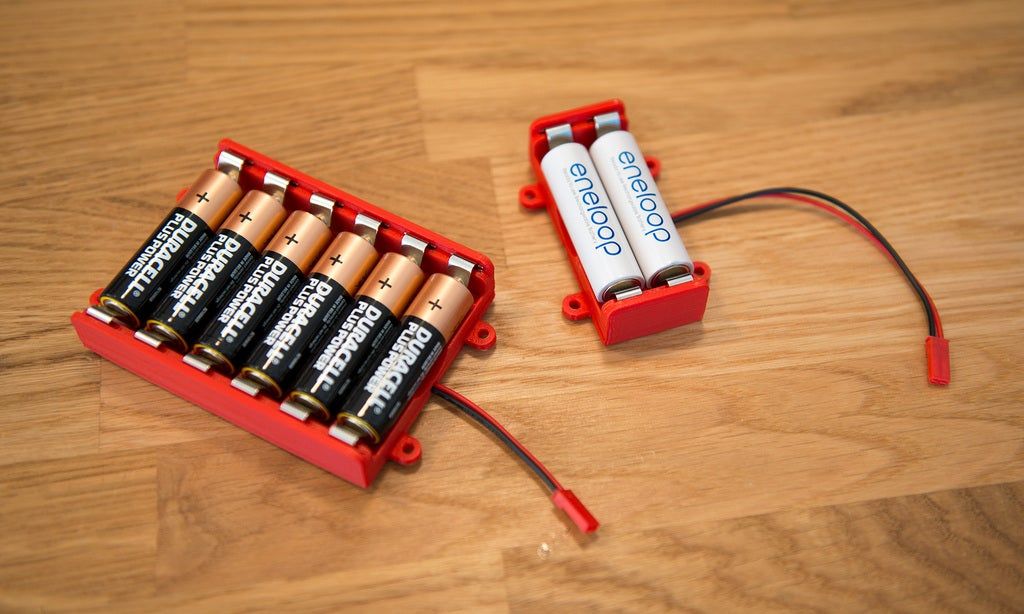

battery case screwdriver batteries

Models Related to Cordless Screwdriver Translation Project on a Li-ion battery.

Model printing has been tested on a SkyOne 3D printer.

Download

Charger housing for Li-ion battery screwdriver

Models related to the project of converting a cordless screwdriver to a Li-ion battery.

Model printing has been tested on a SkyOne 3D printer.

Download

Couplings and adapters for nozzles of vacuum cleaners and tools - 35mm and 32mm

The archive contains all kinds of models of couplings and adapters for the most common nozzle diameters vacuum cleaners and tool - 35 mm and 32 mm. All inlet connections are slightly tapered for easy articulation. Models adapted for printing using FFF technology without the use of supports.

Model printing has been tested on a SkyOne 3D printer.

Download

Flexible coupling 35 mm - 32 mm

The archive contains parts for assembling a flexible coupling, which is convenient for supplying a vacuum system to the source dust (for example, to the cutter of the machine). The coupling is made for a diameter of 35 mm, to connect it with a diameter of 32 mm you can use adapter located on the link. The inlet connection has a slight taper to facilitate joints. Models adapted for printing using FFF technology without the use of supports.

The coupling is made for a diameter of 35 mm, to connect it with a diameter of 32 mm you can use adapter located on the link. The inlet connection has a slight taper to facilitate joints. Models adapted for printing using FFF technology without the use of supports.

Model printing has been tested on a SkyOne 3D printer.

Download

Narrow nozzle for vacuum cleaner, 35 mm

In the archive there are a pair of nozzles for removing dust in hard-to-reach places. Nozzles are made for diameter 35 mm, for connecting them with a diameter of 32 mm, you can use the adapter located at the link. All input connections has slight taper for easy connection. Models are adapted for printing using FFF technology without use support.

Model printing has been tested on a SkyOne 3D printer.

Download

Vacuum nozzle for drilling, 35 mm

Very handy nozzle to remove dust while drilling. The area of the nozzle is calculated so that it could fixed on the wall due to the vacuum created by the vacuum cleaner. The nozzle is made for a diameter of 35 mm, for connecting them with with a diameter of 32 mm, you can use the adapter located at the link. The input connection has slight taper to facilitate articulation. Models are adapted for printing using FFF technology without the use of supports.

Model printing has been tested on a SkyOne 3D printer.

Download

peristaltic pump

Models related to the peristaltic pump printing project.

..

..  "

"  Everyone struggles with this problem in different ways, as it was decided in Sakku, it is not reported.

Everyone struggles with this problem in different ways, as it was decided in Sakku, it is not reported.