3D printer lead screws

Helix Blog | Lead Screws in 3D Printer

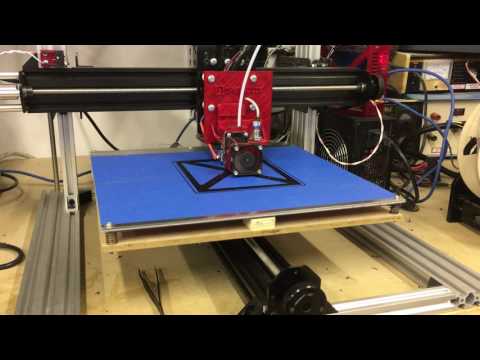

With a 3D printer, product developers can quickly and cost effectively create actual physical parts of product designs directly from product design data. Just as a desktop printer produces type on a 2D page, a 3D printer builds a physical object in 3D space, layer by layer.

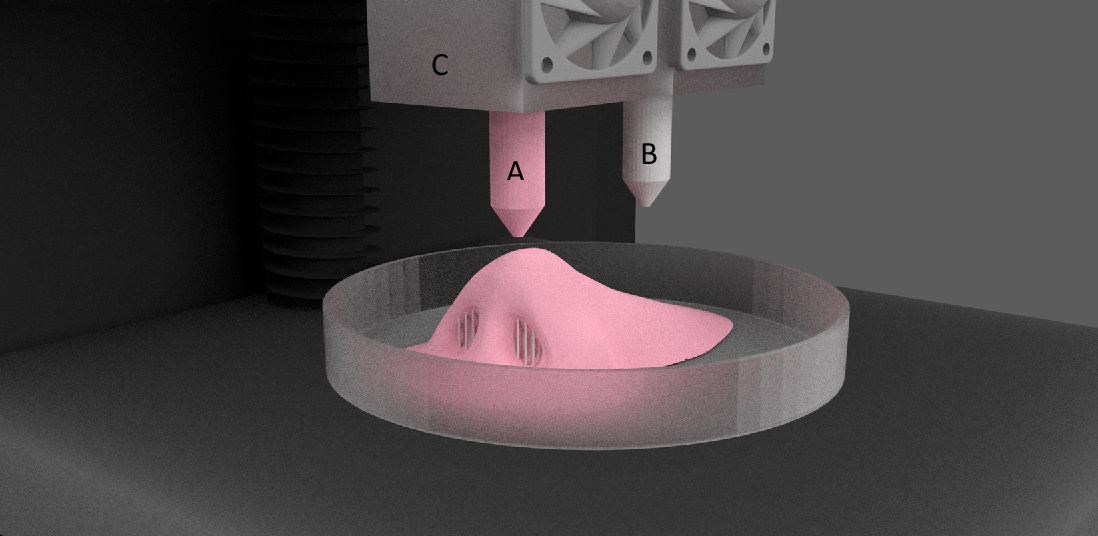

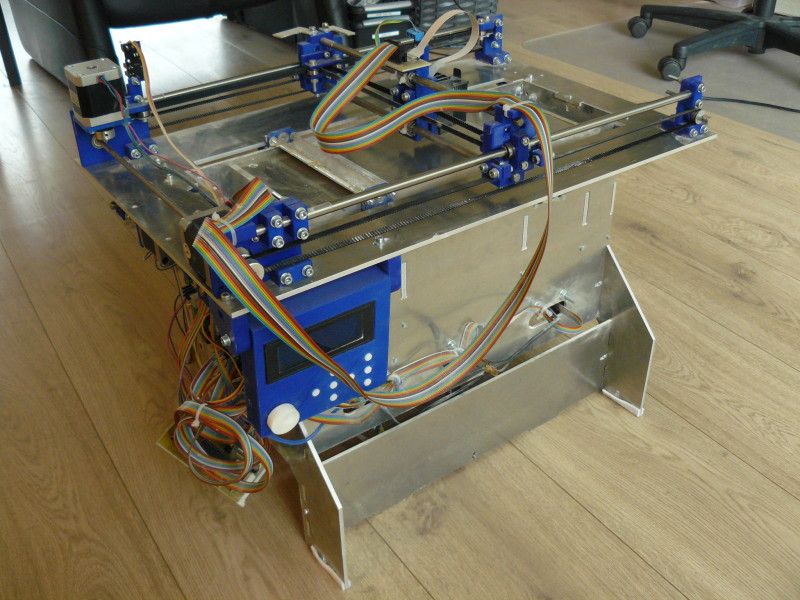

Rapid Prototyping 3D Multi-Material Printers

For many of today’s manufacturing organizations, 3D printers have become a fixture for the rapid prototyping of parts and products prior to their release for manufacture. With a 3D printer, product developers can quickly and cost effectively create actual physical parts of product designs directly from product design data. Just as a desktop printer produces type on a 2D page, a 3D printer builds a physical object in 3D space, layer by layer. The majority of 3D prints are used for design interrogation and evaluation purposes. Some parts produced on a 3D printer are production-ready. Still others serve as the basis for creating molds for investment castings.

The benefits of using a 3D printer to rapid prototype parts versus the historical practice of machining prototypes as preview parts is that it’s faster and less expensive. However, not all 3D printers are created equal. This article will examine the advantages of using precision engineered lead screws for driving linear motion control applications in 3D printing systems.

Lead Screws Outperform Belt Drives in 3D Printers

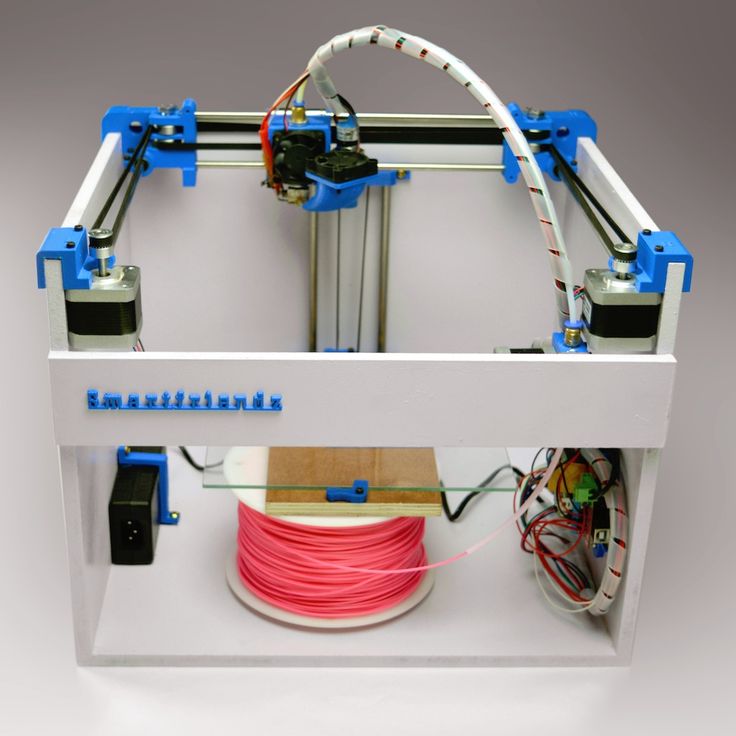

Many of the 3D printers on the market today utilize belt-drive technology, which results in inferior performance characteristics when compared to precision-engineered screws. With belt-drive technology, accuracy and repeatability can be issues because belt-drives simply have more play in them, delivering less-precise linear motion control than precision formed or

thread-rolled screws.

Because of the imprecision associated with belt-drive technology, 3D printers that use belt-drives for linear motion control output parts of less than optimal quality, with undesirable surface patterns, and with less resolution on certain types of part features, such as holes and cavities. Screws, on the other hand, provide higher levels of accuracy, repeatability, and performance when used in 3D printers. Thus, 3D printers that operate with lead screws output more precise, better quality parts.

Screws, on the other hand, provide higher levels of accuracy, repeatability, and performance when used in 3D printers. Thus, 3D printers that operate with lead screws output more precise, better quality parts.

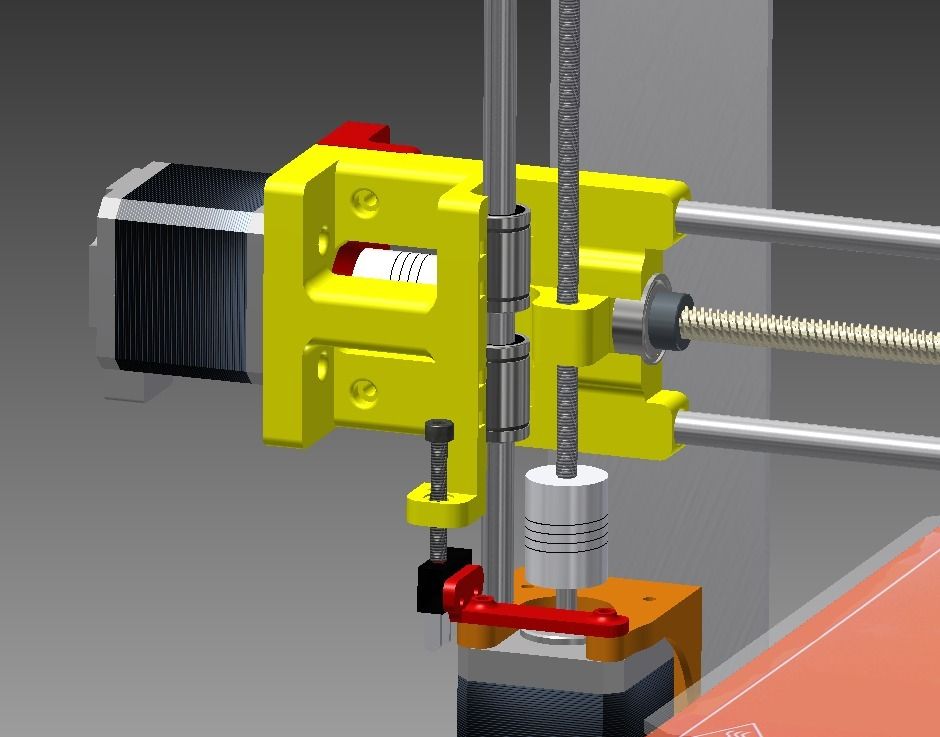

A Screw's Function in a 3D Printer

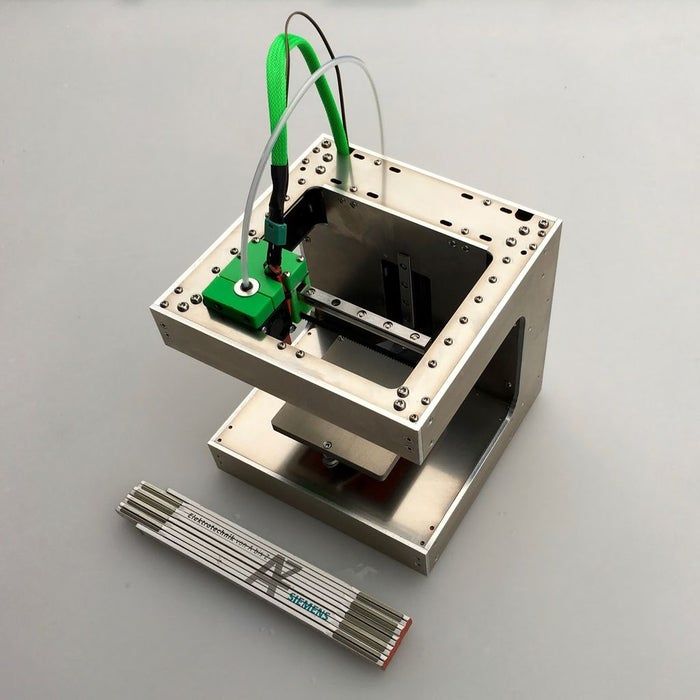

Within a 3D printing application, screws are typically driven by a stepper motor and guided by profile rails on the X and Y axes. Precision engineered acme nuts are connected to the carriage mechanism. All axes are actuated with a stepper motor- driven screw with an anti-backlash nut, and move along linear ball bearing guides.

An important advantage of the screw-rail configuration for controlling linear motion in 3D printers is that it requires a fraction of the number of components that are necessary for belt-driven 3D printers and takes much less time to assemble.

Compared to belt-drives, which deliver linear motion with repeatability of ±0.1 mm/m and a layer height of 100 microns in 3D printing applications, screws offer linear motion with repeatability of ±0. 02 mm/m and a layer height of 50 microns, making them a lot more precise and accurate for controlling 3D printer performance.

02 mm/m and a layer height of 50 microns, making them a lot more precise and accurate for controlling 3D printer performance.

Precision-grade screws have increasingly become the preferred option for low-cost, desktop 3D printers because they deliver the accuracy, repeatability, and performance that users demand - all at at an affordable price. In other words, 3D printer designers no longer need opt for belt drives for controlling linear motion in 3D printers just to keep the cost down. With precision-engineered screws, you can produce high-resolution parts while reducing cost.

Use Helix to Build Top-Performing, Cost-Effective 3D Printers

Contact Helix Linear Technologies to learn how you can use precision-engineered lead and acme screws to develop cost-effective, high-performance 3D printers and rapid prototyping systems. Helix offers a wide array of highly configurable lead and acme screw assemblies that can provide the accuracy, repeatability, and performance that you need to outperform other 3D printing systems on the market.

Download our "How Are Lead Screws Used in a 3D Printer?" Case Study

This 4 page case study includes more information about how screws control the precision needed for 3D printers.

Products

Lead Screws

Acme Screws

Lead Screw Nuts

Additional Reading

Are Lead Screws for You?

Lead Screw Actuators Enable World Class Rail Car Design

Additive Manufacturing

3D Printed Lead Screws and Nuts

- Home

- 3D lead screw nuts

Upload CAD file to order

Buy 3D printing filament

Contact a lead screw expert

Our 3D-printed lead screw nuts and drive nuts are created using our engineered composite plastic iglide® printing materials, which have been proven to last up to 50 times longer inside moving applications than standard 3D-printing materials. igus® engineers extensively test our iglide® plastics inside our 41,000-square-foot test lab based in Cologne, Germany to ensure that every 3D-printed component offers exceptional wear resistance comparable to injection-molded components. All igus® 3D-printed parts are low-friction, maintenance-free and self-lubricating. Metric and trapezoidal threads can be printed directly on the component from size M6 to TR6.

igus® engineers extensively test our iglide® plastics inside our 41,000-square-foot test lab based in Cologne, Germany to ensure that every 3D-printed component offers exceptional wear resistance comparable to injection-molded components. All igus® 3D-printed parts are low-friction, maintenance-free and self-lubricating. Metric and trapezoidal threads can be printed directly on the component from size M6 to TR6.

Benefits:

- Various special iglide® polymers available for moving applications

- 3D-printed parts with wear resistance comparable to injection-molded components or bar stock

- Rapid production – even for complex parts

- Easily upload and order your CAD file online

- Necessary component adaptations and optimizations possible

- Prototypes, special components and small batches – no minimum order quantity required!

3D printing service

Here, you can easily upload and order your drive nut or lead screw nut’s CAD file, choose which iglide® material meets your requirements, and check your component for any weak points using our wall thickness analyzer.

3D printing filament materials

igus® offers a wide range of high-performance iglide® materials that have been engineered to offer wear resistance that’s similar to injection-molded components.

Learn more about our materials

View our 3D printing test lab

igus® engineers extensively test the tribological properties of our engineered composite plastics inside our 41,000-square-foot test lab to ensure every 3D-printed part will last 50 times longer than typical 3D-printing materials inside moving applications.

View the 3D printing test lab

Discuss your project with a 3D Printing expert

Whether you're interested in turnkey, fully assembled solutions or looking to build your own customizable project, learn more about how igus® can assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!

Contact an Expert

Leadscrews: an extended experience of long-term use

Sandbox

So, the printer has already printed enough for me to tell absolutely everything about the screws.

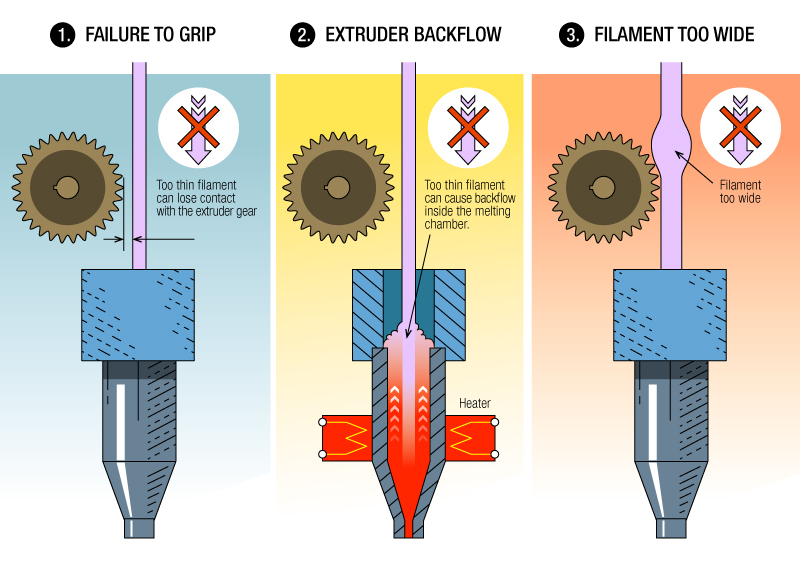

The original idea was that the belts need to be tightened, and the print resolution on them is not very high. Decided to try the screws in connection with this.

First, let's talk about speed. The achieved 100mm/s proved to be unstable. In reality, the initially found 60 mm / s turned out to be reinforced concrete stable. What is most offensive is that the speed cannot be raised even on movements without printing. That is, the printer constantly crawls 60mm / s, regardless of the job. What generates a bunch of snot on the models, the retract does not help much. This is partly a feature of my extruder: the hot zone is quite large, and there is a lot of liquid plastic.

In an attempt to increase speed and to complete the experiment, I had very, VERY thick 60mm NEMA17 sliders:

The idea was simple: larger sliders would give more torque and holding moment, which is so necessary for the lead screws. But in real life, everything turned out to be almost the opposite: it was not possible to get stable 60mm on them. In the course of the experiments, I reached the full step mode of the stepper motor, but this did not help either. In addition, the printer just yelled from resonant phenomena. These engines turned out to have too much magnetic coupling (? I don’t know how to call it correctly), and they do not digest high speeds. As a result, I sent them to supply plastic to another printer.

In the course of the experiments, I reached the full step mode of the stepper motor, but this did not help either. In addition, the printer just yelled from resonant phenomena. These engines turned out to have too much magnetic coupling (? I don’t know how to call it correctly), and they do not digest high speeds. As a result, I sent them to supply plastic to another printer.

Speaking of noise... The printer is noticeably louder than it was on the belts. And it's not just the aforementioned resonant phenomena and the 1/4 step mode. The point is the backlash of the nut-lead screw connection. When changing direction, a distinctly audible knock is heard. Sleep next to him is impossible in principle, a knock is heard even behind two closed doors.

Not all is well with the nuts themselves either. If the screw is under the table (as with the Y-axis), then everything is more or less smooth, but if it is above the table, as in the case of the X-axis, then the table will always be strewn with black chips that fall off the nut as it wears out.

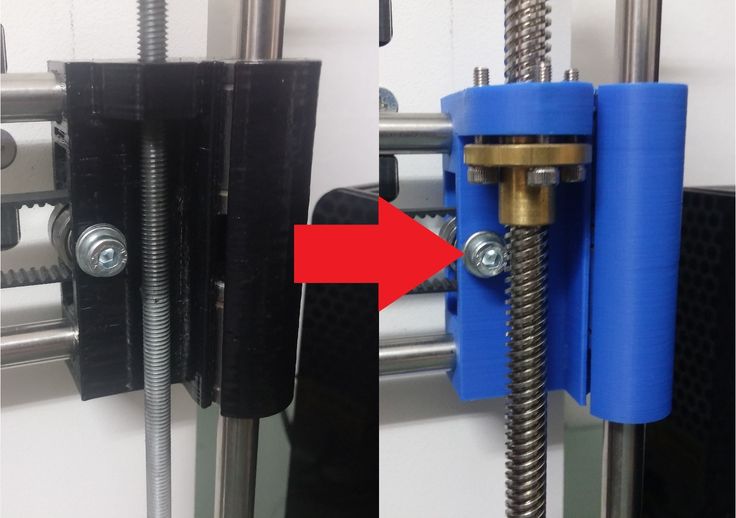

Nut play must also be constantly monitored. If the backlash becomes more than 0.1 mm, you can forget about accurate printing. This is due to the fact that a heavy X-carriage (as in my case) after a stop by inertia chooses backlash in the opposite direction. And as a result of this, X-wobbling and Y-wobbling are added to the notorious Z-wobbling characteristic of i3, and any printout turns into something unforgettable in the most terrible sense. Software backlash compensation partly saves, but only up to 0.1 mm. The next step is to replace the nut.

I had some misalignment of the nut with the screw in the X axis, and the nut was eaten very vigorously, in about 400 hours of printing. The slightest unnecessary friction - and wear increases almost exponentially. Here someone described the solution to the backlash problem in the form of 2 nuts and a spring between them (I did not find the link), and so: this is nonsense. Nuts will gobble up even faster than in my case, and even doubly cover everything with bronze chips (this is true for X and Y - axes that constantly rotate). By the way, here is a photo of a new and used nuts:

By the way, here is a photo of a new and used nuts:

Wear visible to the naked eye.

Another non-obvious minus: when the table is parked, and it needs to be pulled out for applying abs-juice or cleaning, you have to tediously turn the screw to do this, while with straps you could just pull the table towards you.

Based on all of the above, I sum up the disappointing result: the screws are not applicable for a 3D printer, except for the Z axis. I'm getting ready to return to the belts. Don't repeat my mistake.

Adios

Follow author

Follow

Don't want

4

More interesting articles

SE-Atmn

Loading

30.04.2017

13478

72

Subscribe to the author

Subscribe

Don't want to

I spied on one site a way to create pendants, brooches and other jewelry and decided to try it. ...

...

Read more

alsten

Loading

09/10/2021

5009

48

Subscribe to author

Subscribe

Don't want

Eight months after I bought the Ender, I'm summarizing its upgrades to date. This...

Read more

Pangani

Loading

01/23/2018

10949

40

Subscribe to the author

Subscribe to the author

Subscribe

Don't want

Good day to everyone, I present to your attention a small review, or rather my review and personal ...

Read more

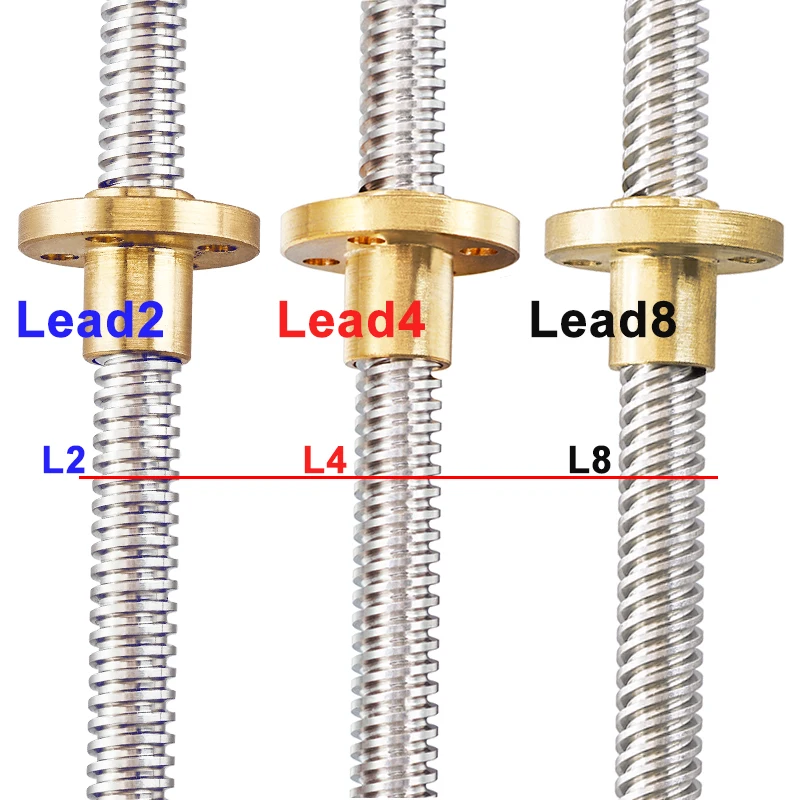

Trapezoidal lead screws and nuts Trapezoid 9080001

1 with flange, four start

Article: NutBrass-T8-L8-D4

Stroke 8 mm per shaft revolution

Diameter: 8 mm Number of thread starts: 4 (quadruple) Thread travel: 8 mm

Available

Trapezoidal caprolon nut T8 POM with flange, four-start

Article: NutPOM-T8-L8-D4

Stroke 8 mm per shaft revolution

Diameter: 8 mm :8 mm

In stock

Trapezoidal lead screw T8 mm, length 200 mm

Article: Shaft-Trapez-8mm-200

Trapezoidal four-start thread.

Diameter: 8 mm Number of thread starts: 4 (quadruple) Thread lead: 8 mm

Available

Trapezoidal lead screw T8 mm, length 300 mm

Article: Shaft-Trapez-8mm-300

Trapezoidal four-start thread.

Diameter: 8 mm Number of thread starts: 4 (four-start) Thread stroke: 8 mm

In stock

Diameter: 8 mm Number of thread starts: 4 (quadruple) Thread lead: 8 mm

Available

Trapezoidal lead screw T8 mm, length 500 mm

Article: Shaft-Trapez-8mm-500

Trapezoidal four-start thread.

Diameter: 8 mm Number of thread starts: 4 (four-start) Thread stroke: 8 mm

In stock

Trapezoidal four-start thread.

Diameter: 8 mm Number of thread starts: 4 (quadruple) Thread lead: 8 mm

Available

1 260 ₽

Trapezoidal lead screw T8 mm, length 800 mm

Article: Shaft-Trapez-8mm-800

Trapezoidal four-start thread.

Diameter: 8 mm Number of thread starts: 4 (four-start) Thread stroke: 8 mm

In stock

Trapezoidal four-start thread.

Diameter: 8 mm Number of thread starts: 4 (quadruple) Thread lead: 8 mm

Available

Thread travel: 2 mm

On request

Trapezoidal nut T8 with flange, double start

Article: NutBrass-T8-L4-D2

Stroke 4 mm per shaft revolution

Diameter: 8 mm )Thread stroke: 4mm

On request

Trapezoidal nut T8 with H-flange, four start

Part Number: NutBrass-T8-L8-D4-H

Stroke 8 mm per shaft revolution

) Thread travel: 8 mm

On request

Backlash-free acme nut TR8, four start

Article: NutBrass-T8-L8-D4-Anti

Stroke 8 mm per shaft revolution

Diameter: 8 mm (four-start) Thread travel: 8 mm

On request

Backlash-free caprolon nut TR8 POM, four-start

Article: NutPOM-T8-L8-Anti

Stroke 8 mm per shaft revolution

Diameter: 8 mm Thread start: 4 8 mm

On request

Trapezoidal lead screw T8 mm, length 1200 mm

Article: Shaft-Trapez-8mm-1200

Trapezoidal four-start thread.

Diameter: 8 mm Number of thread starts: 4 (quadruple) Thread lead: 8 mm

On request

2 500 ₽

Trapezoidal lead screw T8 mm, length 300 mm

Article: Shaft-Trapez-T8-L4-300

Trapezoidal two-start thread.

Diameter: 8 mm Number of thread starts: 2 (double start) Thread travel: 4 mm thread.

Diameter: 8 mm Number of thread starts: 2 (double start) Thread lead: 4 mm

On request

Trapezoidal lead screw T8 mm, length 500 mm

Article: Shaft-Trapez-T8-L4-500

Trapezoidal two-start thread.

Diameter: 8 mm Number of thread starts: 2 (double start) Thread travel: 4 mm (2 pcs.), sleeve 5 x 8 mm.

Diameter: 8 mm Number of thread starts: 4 (quadruple) Thread lead: 8 mm

On request

Price on request

Trapezoidal gear T8

Article: T8-Lead-Screw-Kit-400

T8 nut, 400 mm screw, KP08 (2 pcs.), 5 x 8 mm socket.

Diameter: 8 mm Number of thread starts: 4 (quadruple) Lead: 8 mm screw 500 mm, KP08 (2 pcs.