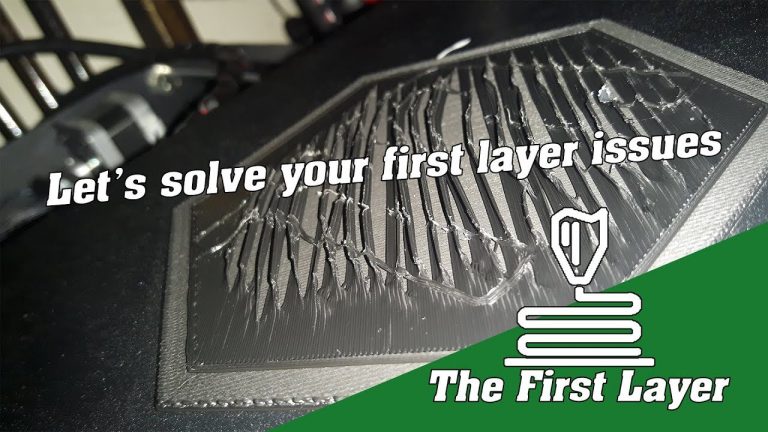

3D printing bad first layer

3D Printing first layer problems

Contents

- 1 3D print first layer

- 2 3D printer bad first layer

- 3 3D printer troubleshooting first layer

- 3.1 Perfectly calibrated bed

- 3.2 Extruder at the right distance

- 3.2.1 3D print stringy first layer

- 3.2.2 3D print first layer is rough

- 3.3 Slow down

- 3.4 No cooling

- 4 Correctly calibrated extrusion

- 5 First layer height 3D printing

- 5.1 First layer too thin

- 6 3D printer first layer doesn’t stick

- 7 3D printer bed cleaning

- 8 Use some help

- 9 Mind the materials

- 10 Conclusion

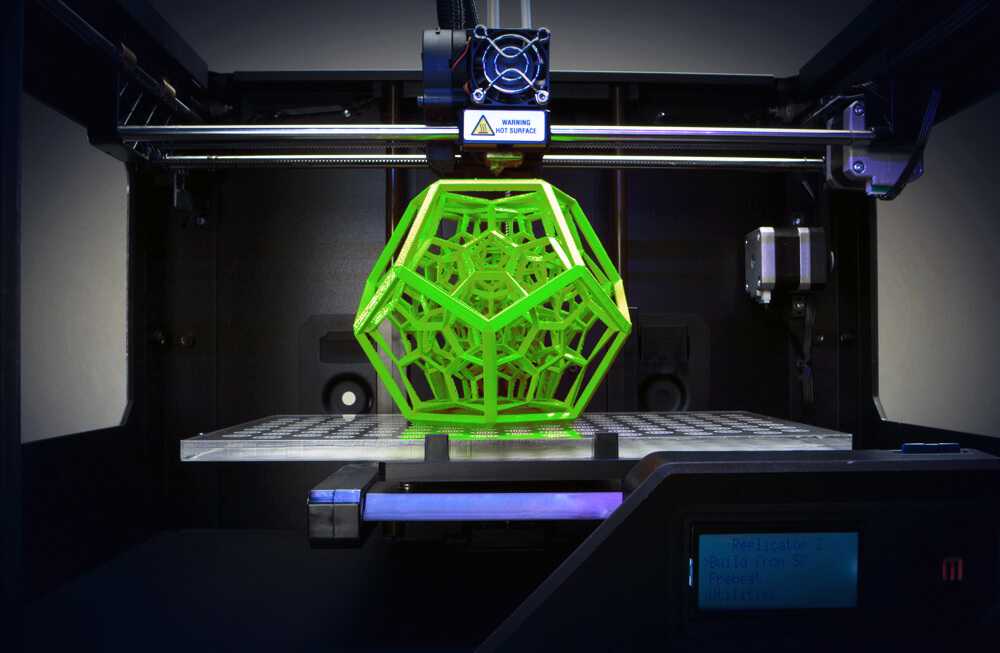

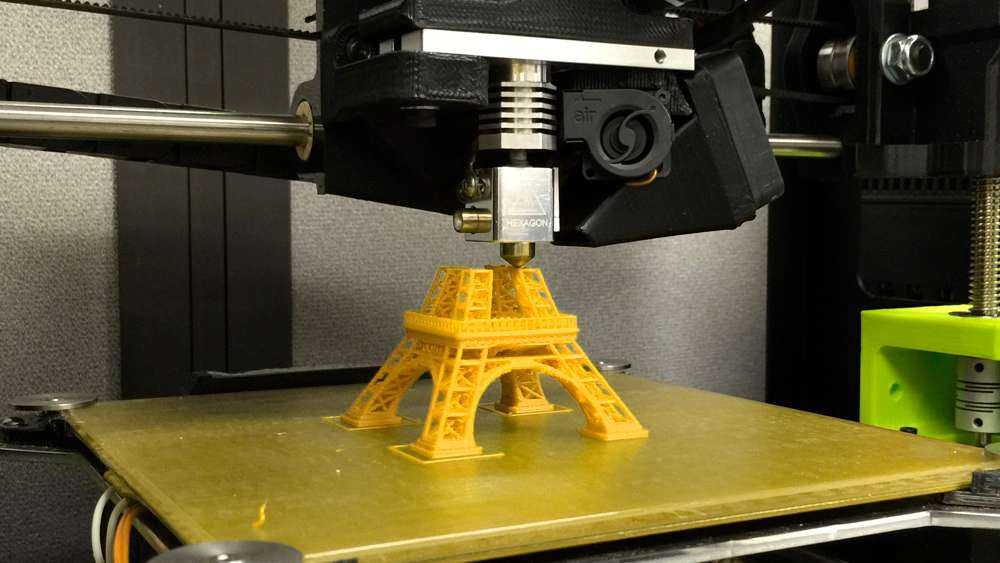

3D print first layer

The first layer represents the foundations of the print, and as they always say, those who start well are halfway through the work. Below are listed a series of measures to improve the perfection of this layer, and to achieve perfect bed adhesion.

3D printer bad first layer

I have already talked about the first layer in other articles, but now its time to analyze it furthermore! The first layer of every print is important for the overall success of the printing process. A bad first layer can lead to

- Bad bed adhesion – When you have problems with bed adhesion most of the time you can’t rely on your printer for long prints. For who makes long prints that can last for days it is fundamental to have a proper bed adhesion so you don’t lose your print halfway

- Bad layer consistency – If you’re bed height is not calibrated properly most certainly you’re going to have an inconsistent layer. This is an aesthetic issue as the side that lays flat on the bed will look bad.

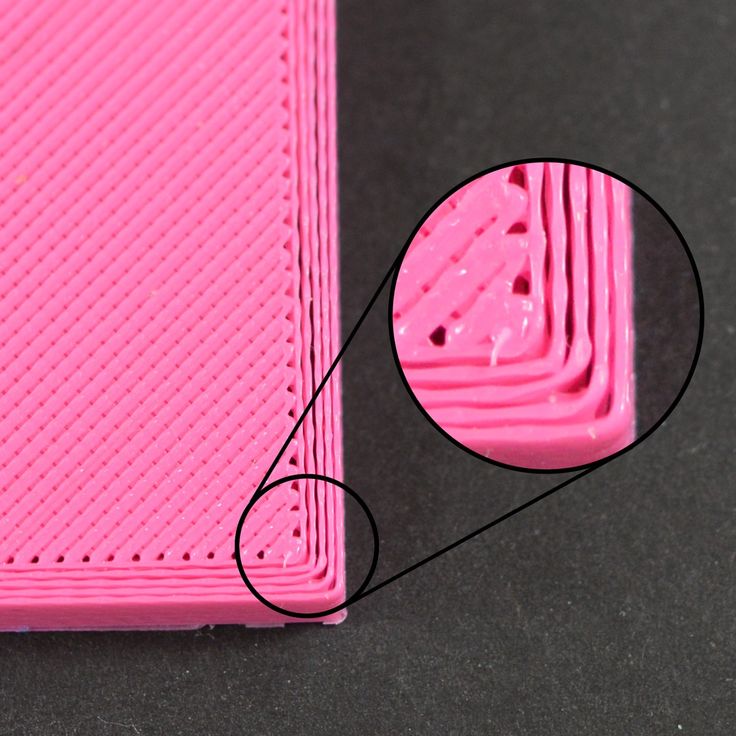

- Elephant foot -In some cases when the extruder is too close to the bed the excess plastic is pushed outwards. As the layers increase, the imperfections will disappear but the first few layers will look over extruded.

3D printer troubleshooting first layer

Perfectly calibrated bed

The first and fundamental rule to get an excellent first layer is to work with a perfectly flat build plate. Having a deformation-free and calibrated printing bed will allow us to have the first layer without errors. Getting a uniform line in height and consistency is an excellent starting point for any print.

Getting a uniform line in height and consistency is an excellent starting point for any print.

If you have doubts about your bed and if you think it may be warped then you should get a glass plate to eliminate warping.

Extruder at the right distance

The second and perhaps the most important point is the printing distance between the build plate and extruder.

| ||||||||||||

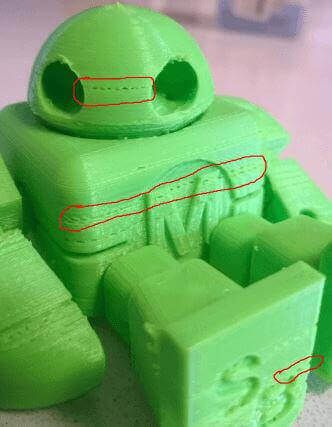

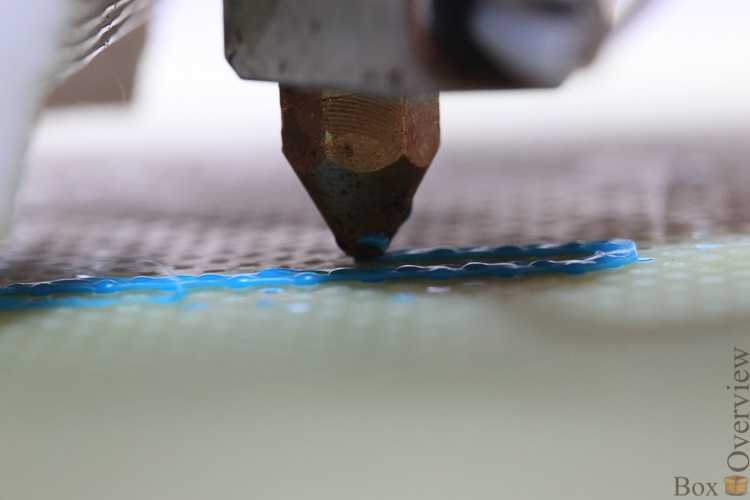

3D print stringy first layer

An excessive distance will be recognizable by the lines drawn by the nozzle, they will appear stringy and not connected. These lines will not match each other as they should but will present spaces between them. In addition to the aesthetic factor, we may also have problems with very low bed adhesion, which could compromise the success of the print.

These lines will not match each other as they should but will present spaces between them. In addition to the aesthetic factor, we may also have problems with very low bed adhesion, which could compromise the success of the print.

In the worst-case scenario, the filament will not even stick to the bed and it will get dragged all around the nozzle.

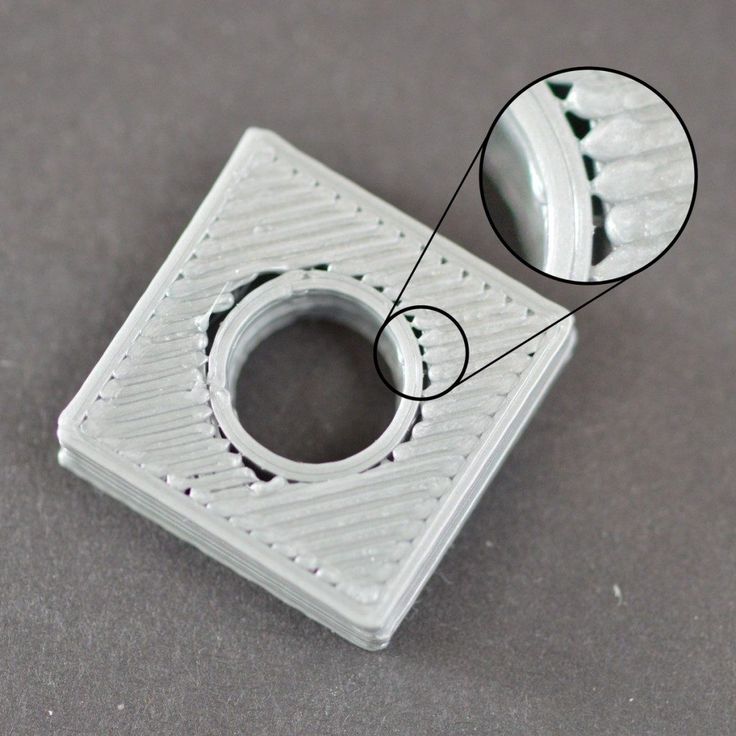

3D print first layer is roughIf your first layer seems rough on the touch then you’re bed is to close to the hotend. When the distance is too small, the first layer will result in a mass of material spread on the plate. Even if bringing the nozzle closer to the plate can in some cases reduce some adhesion problems, it can certainly create others.

A rather common problem is the loss of steps of the extruder motor. In some cases, the motor cannot push all the filament it should with the little space available between the plate and the extruder. This could damage the whole system in the long run.

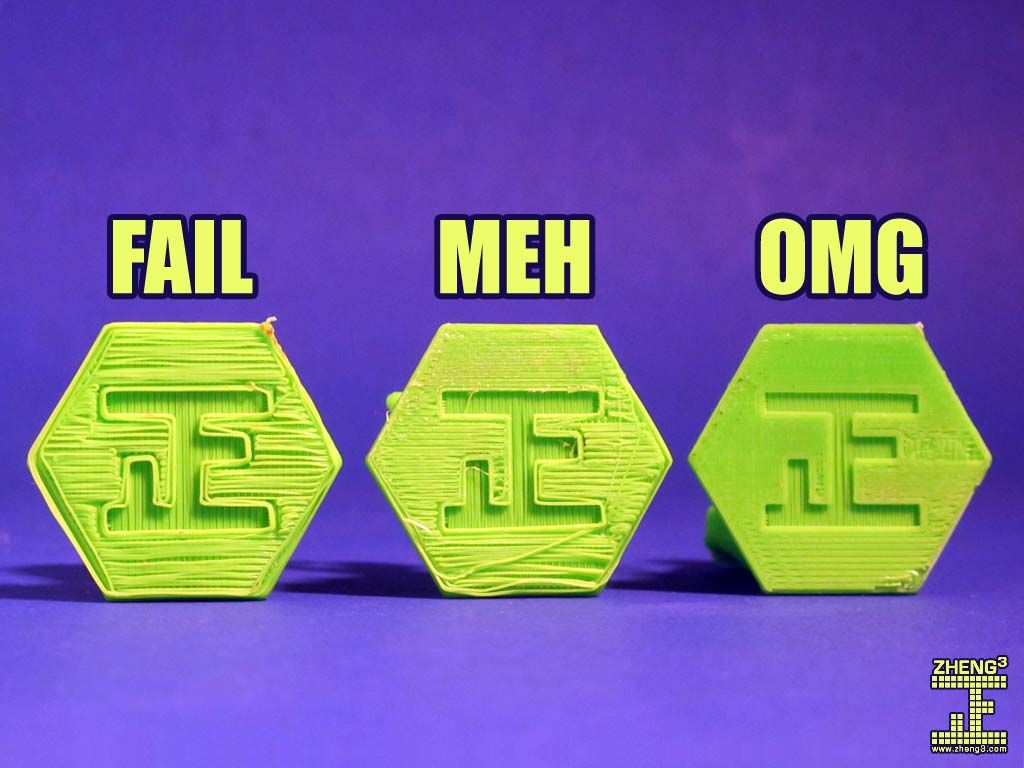

I have illustrated different types of heights and it’s not that easy to spot the difference, but with training, you will be able to recognize a perfect first layer withing seconds! It’s a skill that will never abandon us.

One easy way to eliminate this problem is by using an automatic bed leveler like the BL-touch. It is a great investment! It reduces failed prints but also it spares you lots of time manually leveling the bed!

Creality BLTouch V3. | Official Artillery Genius-Pro 3D Printer Latest Model 98% Integrity, Silent Mainboard | ||

Slow

downSlowing down the movements for the first layer reduces the forces applied to the molten material, reducing the possibility of poor adhesion. It is advisable to reduce the speed of the first layer to 50% / 60% of the normal printing speed and to avoid going below this threshold, only in cases of particular problems(Like with PETG).

No cooling

Although cooling for PLA printing is one of the essential elements for obtaining quality prints, it is strongly discouraged to ventilate the first layer. The longer the first layer remains hot, the more it binds to the plate. In fact, all slicers have the default setting to turn off cooling for the first layer of the print. However, it doesn’t hurt to repeat it, no cooling, at least for the first layer.

What I’ve described so far are the cardinal principles, and by applying them surely you will get excellent results but I wanted to give a few more tips, in order not to leave anything to chance.

Correctly calibrated extrusion

It is very important to have the amount of extrusion well set as an under-extrusion / over-extrusion could be exchanged for incorrect positioning of the plate. Obviously, in these cases, the corrective maneuvers at the level of the bed would not bring any benefit and we will see over extrusion/under extrusion within the next few layers. If even after leveling you find yourself with a first layer that does not satisfy you, before checking and re-carrying out the whole calibration process, you can spare a few minutes and test if the quantity of extruded material is correct.

If even after leveling you find yourself with a first layer that does not satisfy you, before checking and re-carrying out the whole calibration process, you can spare a few minutes and test if the quantity of extruded material is correct.

First layer height 3D printing

First layer too thin

A higher layer height will provide more flow, therefore more heat, better adhering to the printer bed. A greater thickness of the first layer also has the property of increasing the tolerance of the leveling error of the build plate. It is recommended to increase the height of the first layer in combination with the nozzle diameter, e.g. with a 0.4 mm nozzle it is recommended not to exceed 0.3 mm. This is possible due to the low printing speed, so never use a 0.4 nozzle to print at 0.3 layer height if not for the first layer.

AS you can see a 0.1 layer height isn’t enough to compensate for the errors when manually leveling.

3D printer first layer doesn’t stick

To increase the adhesion, the consistency, and the appearance of the first layer, it is possible to set a temperature slightly higher than normal. A 5/10 degree increase in nozzle and plate will make the plastic more viscous and helps eliminate the low adhesion.

A 5/10 degree increase in nozzle and plate will make the plastic more viscous and helps eliminate the low adhesion.

The temperature can be set by a slicer or by hand, in the second case remember to return to the usual temperature once the first layer has been completed.

3D printer bed cleaning

It is pretty obvious that without proper cleaning you’re going to have problems with adhesion.Wipe the bed with alcohol and in extreme cases use acetone (especially with a glass build plate).

Use some help

In some cases, we need some extra help from rafts or brim. When printing small parts we must use something to increase the volume of the print so that it won’t unstick that easily.

3D Printer Adhesive Glue Bed Weld Original, Strong Grip Reduces Warping for ABS, ASA, PLA, and PETG Filament on Heated Build Plates, 118ml, 4 fl oz | |||

Mind the materials

Every material act in a different way. Some need some extra help, others may stick to much.

Some need some extra help, others may stick to much.

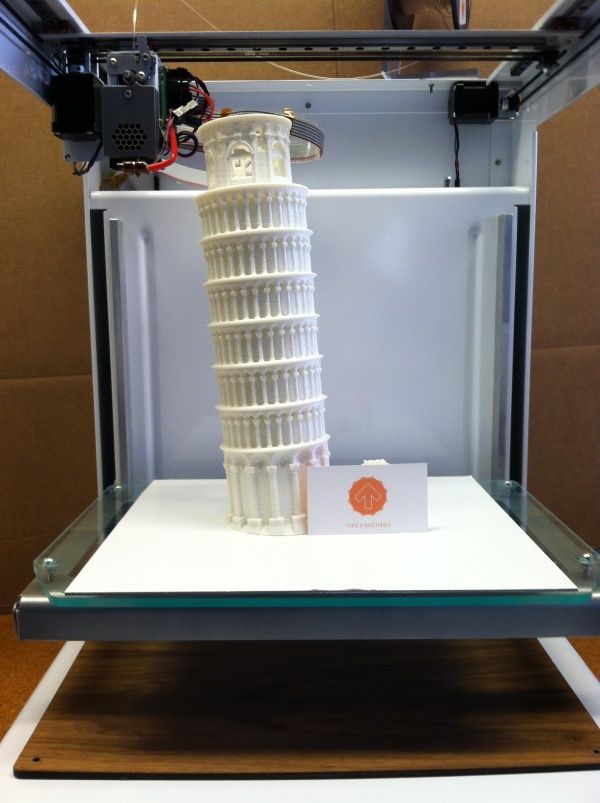

If you have followed this guide carefully you will be able to have the first layer like this:

Conclusion

The key to a perfect first layer is a perfectly flat build plate and a correct bed leveling even if this means losing some bed adhesion. Bad bed adhesion can be solved by tweaking speed and temperature.

This post may contain affiliate links

Summary

First layer issues | Prusa Knowledge Base

Relevant for

:

MINIMINI+MK2.5MK2.5SMK3MK3SMK3S+Plus 1.75 mm

Last updated

10 months ago

This article is also available in following languages:

This is by far the most common 3D printing problem, and probably the first one you may encounter. The first layer is the essential one because it is the base of the printed object. Therefore, if it isn’t perfect, the chance of print failure increases. Many common 3D printing problems stem from a poor first layer. There’s a couple of things that can go wrong when printing your first layer, so let’s take a look at what can be done to avoid these problems.

The first layer is the essential one because it is the base of the printed object. Therefore, if it isn’t perfect, the chance of print failure increases. Many common 3D printing problems stem from a poor first layer. There’s a couple of things that can go wrong when printing your first layer, so let’s take a look at what can be done to avoid these problems.

The print surface should be regularly maintained to achieve optimal printing quality and minimize the chance of failed prints. It's an easy procedure, so let's take a look at our tips and recommendations.

How to prepare your print-surface

If you don't touch the print surface with your hands or dirty tools, then you don't have to clean it before every print. Clean your tools the same way as you would the bed, and you will be able to start your next print right away.

Isopropyl alcohol

To achieve the best adhesion of the print surface, it is vital to keep it clean. The best option when printing with ABS, PLA, and many other materials is 90% Isopropyl alcohol, which can usually be sourced locally at drugstores or hardware stores. Denatured alcohol is also an option. We recommend always using 90% IPA. Lower percentage solutions may contain unsuitable chemicals and oils.

Denatured alcohol is also an option. We recommend always using 90% IPA. Lower percentage solutions may contain unsuitable chemicals and oils.

PETG, ABS, ASA, XT, and CPH filaments are an exception - the adhesion may be too strong, and you can damage your Smooth PEI sheet. We recommend using a separating agent (e.g. a glue stick). For more information on how to print with these materials, check out our Material guides.

Any cleaning agent (e.g. IPA) which is dermal/cosmetic, i.e. for skin or nails, may contain additives like moisturizers and oils which are not suitable.

Dish soap and water

If the adhesion seems to decrease over time even when using IPA, you can clean the steel sheet with a few drops of dish soap and warm water (not hot!). This should not be done often, and do not submerge the sheet completely in hot water, but it will dissolve some oils and sugars that gather over time and that IPA does not remove. Make sure to use only dish soap and dry the sheet well before using it.

Make sure to use only dish soap and dry the sheet well before using it.

Acetone

PEI can lose its adhesive powers after a couple of hundred hours. When you see models coming loose regularly, wipe the surface thoroughly with acetone to restore the adhesion. This should only be used in the smooth PEI sheet and only around once per month. Do not overuse acetone. Extended use makes PEI surface brittle. Also, do not use acetone before printing with PETG.

For the textured and the satin steel sheets, do not use acetone at all! Other chemical solvents, like Nail polish remover or brake-cleaner, can also contain acetone (acetates).

Glue

Glue is a great, easy-to-use tool to increase adhesion. It also creates a protective separation layer. No need for glue specially made for 3D printing. You can use a basic (PVA-based) glue stick. This is supplied with the printer. From our experience, it is not needed when printing PLA, but may it be advisable when printing:

This is supplied with the printer. From our experience, it is not needed when printing PLA, but may it be advisable when printing:

- Polyamide (Nylon)

- PETG

- Polycarbonate (PC)

- PET-based materials

- ABS

- ASA

- Other more exotic materials

- Flexible materials

You can easily wipe off PVA glue with dish soap and water.

Other types of glue should not be used as a substitute. Don't put Superglue on your sheet! When removing prints with a large surface area, you may have to assist the process using a spatula. Be gentle when flexing the sheet and removing the print as the smooth PEI foil can tear.

ABS juice

'ABS juice' should only be used on the Smooth PEI sheet, when printing ABS prints. It is a mixture of Acetone and ABS pellets. ABS scraps, brims, or failed prints can be used too. Be very gentle when applying the juice and do so only when the bed is cold. Prints will adhere very strongly.

Prints will adhere very strongly.

Ready-made juice can be purchased in our e-shop. Unfortunately, most carriers do not allow shipping any acetone-based products via air transport due to shipping constraints.

For the textured and satin steel sheets, do not use ABS juice at all!

Resurface it

It can happen that you will leave some small marks on the print surface with your nozzle or tools. Typically, they will be shinier than the rest of the pad. It does not affect functionality or adhesion. However, if you want to have the same surface look on the whole print bed, you can resurface it.

The easiest way is to take the hard side of a dry kitchen sponge and gently wipe the affected area in a circular motion a few times. Another option is to use fine-grit sandpaper (400-600) and lightly give the sheet a rub. Wipe over with IPA after doing so.

| Smooth PEI sheet |

|

|

| Textured powder-coated sheet |

|

|

| Satin powder-coated sheet |

|

|

For more information on the different properties and guidelines of each flexible steel sheet, please see Flexible steel sheets (guidepost).

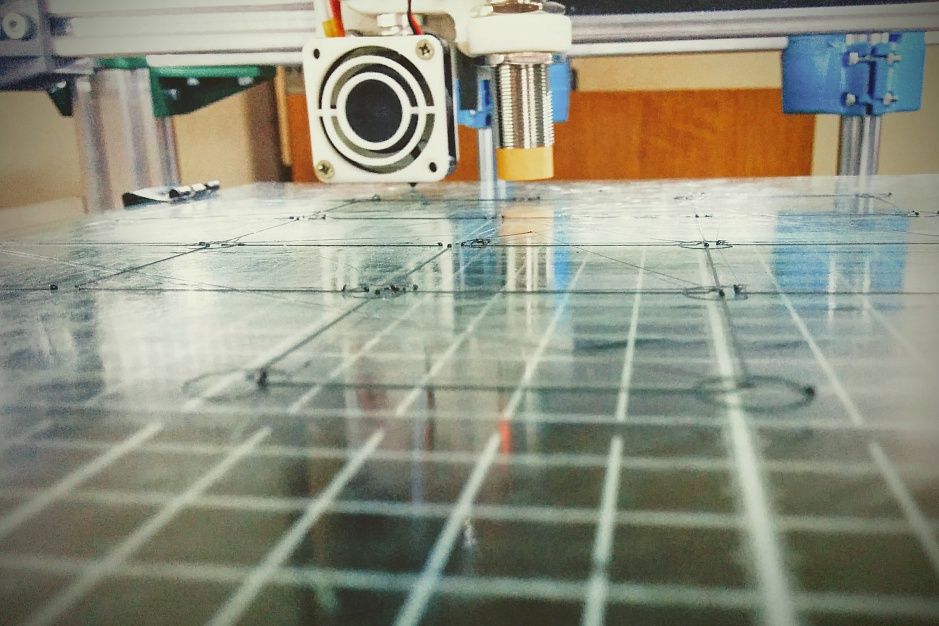

The nozzle is too close/far from the sheet

If the nozzle is too close to the printing bed, there won’t be enough room for the plastic to come out of the extruder. By having the nozzle too close to the print surface, you will essentially block its opening, so that no plastic can be extruded. You can easily recognize this issue when the printer does not extrude plastic for the first layer or two. Use Live Adjust Z function and First Layer Calibration (i3) options to tweak the height of the nozzle. You perform the calibration from LCD Menu –> Calibration –> First layer calibration. For more information on this procedure, please see the dedicated article First Layer Calibration (i3).

You can easily recognize this issue when the printer does not extrude plastic for the first layer or two. Use Live Adjust Z function and First Layer Calibration (i3) options to tweak the height of the nozzle. You perform the calibration from LCD Menu –> Calibration –> First layer calibration. For more information on this procedure, please see the dedicated article First Layer Calibration (i3).

Avoid compensating for a lack of adhesion by setting a lower Live Adjust Z (squishing the first layer). If lowered too much, the nozzle can damage the steel sheet and cause excessive vibrations. Any damage caused by incorrect Live Adjust Z value is not covered by the warranty.

Speed and temperature

Decrease the printing speed

If the steps described above didn’t help, then try decreasing the printing speed. The easiest way how to do it is by rotating the knob during the printing process, lowering the percentage. Counterclockwise = decrease speed, Clockwise = increase speed. We suggest decreasing the speed to about 75% for the first three layers, then returning it to normal.

Counterclockwise = decrease speed, Clockwise = increase speed. We suggest decreasing the speed to about 75% for the first three layers, then returning it to normal.

Use recommended printing temperatures

Make sure to use the recommended nozzle and heatbed temperatures. PrusaSlicer will configure them correctly based on the selected material, so you don’t need to adjust the temperatures manually on the printer itself. If you are experimenting with new materials that don’t adhere well, you can try to increase the heatbed temperature by 5-10 °C. This way the plastic will stick a bit better.

A full or partial clog

The extruder could be clogged. This can happen either when excessive debris gets stuck inside the nozzle, when hot plastic is kept inside the extruder for too long, or when the thermal cooling for the extruder is not sufficient and the filament begins to soften outside of the desired melt zone. Please see our dedicated article Clogged nozzle/hotend (MK3S, MK2.5S).

Please see our dedicated article Clogged nozzle/hotend (MK3S, MK2.5S).

Uneven surface

If your print surface is not flat and the alignment of the mesh does not help, to achieve a flat print surface, a temporary solution is to add a piece of paper under the uneven area of the steel sheet. A more permanent solution would be to perform the firmware Bed Level Correction.

Correctly placed sheet

Before printing, make sure that you have the print plate properly installed, and that there are no leftovers from the previous print or a piece of loose filament that could affect the sheet position. Also, make sure that the sheet is straight and not bent or damaged.

Brim

Before you consider applying extra adhesion materials onto the bed, consider using the Brim option in PrusaSlicer which increases the surface area of the first layer. See our dedicated article Skirt and Brim.

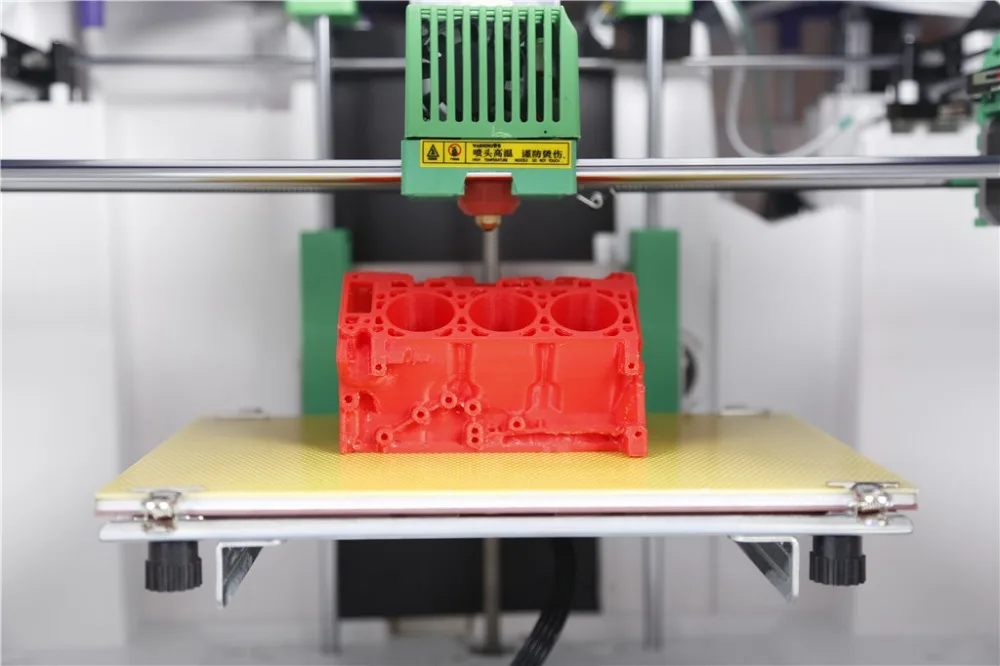

Problems, defects, 3D printing errors and solutions

Often during the operation of a 3D printer, problems may arise due to which defects appear on the finished model. Or instead of a neat product, plastic noodles suddenly appear on the table.

Or instead of a neat product, plastic noodles suddenly appear on the table.

In fact, the causes of defects can be conditionally divided into 2 types - these are physical and software.

Physical ones are those that arise due to problems with the mechanics or any other causes that can be eliminated physically. These include problems with printer mechanisms (belt tension, backlash), clogged or deformed nozzle, incorrect table geometry, etc.

Software - these are defects that occur due to incorrect slicer settings or, less often, errors in the printer firmware. For example, incorrectly selected print speed, retract settings, incorrectly selected temperature for plastic, etc.

Very rarely, the problem may lie in the wrong or “flying” printer firmware (although usually the printer simply will not start then), overheating of some boards during printing, etc. These are rather special cases, so we will not consider them.

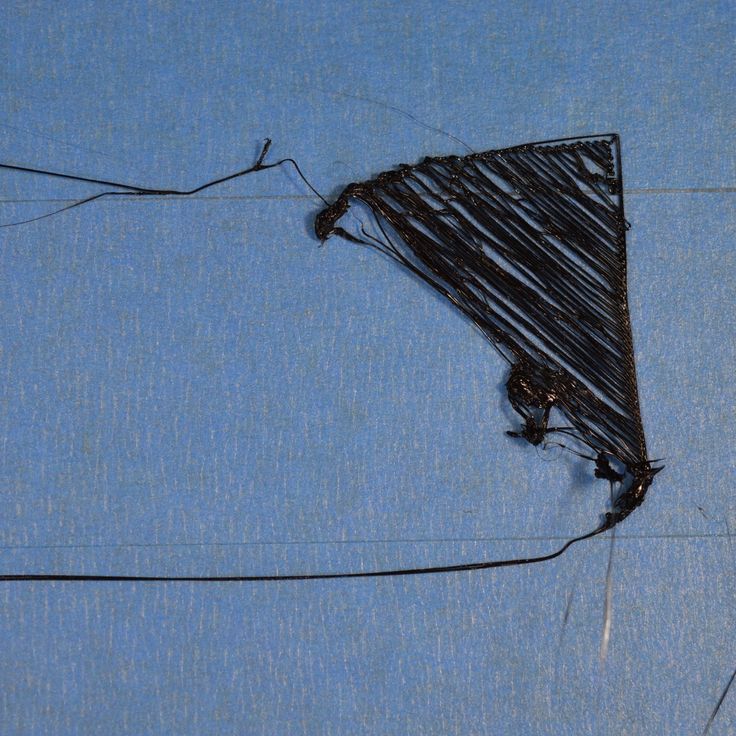

Model peels off or does not stick to the build plate

This is the most common 3D printing problem. Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Every 3D printer has had a case when the first layer treacherously rolls, clinging to the extruder, or the most offensive - when it tears off a partially printed model from the table. The first layer must stick tightly otherwise nothing will be printed.

Gap between table and nozzle 9 too large0023

This is the most common reason. You just need to set the correct gap between the table and the nozzle.

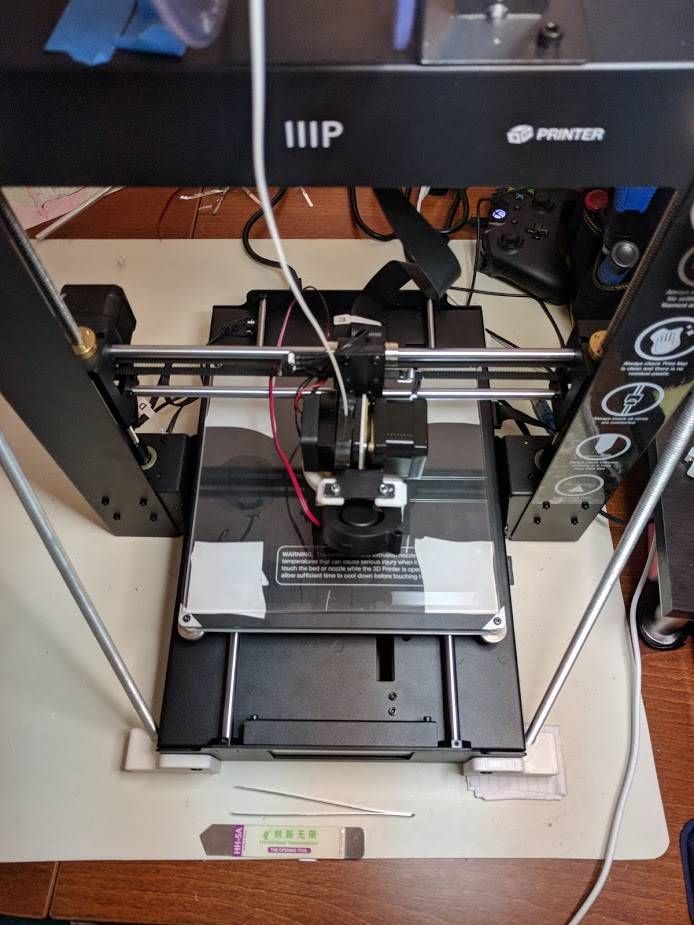

Modern printers often use an auto-calibration (auto-leveling) table system or an auxiliary table leveling program. To calibrate such printers, use the instructions. If there is no manual, it can be downloaded from the manufacturer's website.

If you have a simple printer without auto-calibration, a self-assembly or KIT kit, use a probe or a piece of paper folded in half to calibrate. The probe should be slightly pressed against the table by the nozzle. Before calibration, the table and extruder must be heated. Align the table surface over each adjustment screw (there may be 3 or 4) in turn, and only then check the center point.

If you're having trouble getting your table surface perfectly level, try raft printing. Raft is a thick substrate in several layers that is printed under the model. It will help smooth out the slight curvature of the table.

A small cheat sheet to determine the correct gap on the first layer

Plastic with poor adhesion

Some types of plastic, due to various reasons, such as large shrinkage, do not adhere well to the surface of the printing platform. In this case, try using stickers or special 3D adhesives to improve adhesion between the table and the first layer of plastic.

In the early days of 3D printing, there were experiments with different homemade 3D adhesive recipes. ABS diluted in acetone, BF glue, sugar syrup and even beer. Some experiments have been successful. Until now, some enthusiasts use some types of hairspray or glue sticks as 3D glue. But still they are inferior in their properties to industrial 3D adhesives.

Some types of high temperature plastics with a high percentage of shrinkage (ABS, Nylon, etc.) may peel off the table during printing. This is due to uneven cooling and “compression” of the model (the lower layers have already cooled down, but the upper ones have not yet). For such plastics, it is imperative to use a 3D printer with a heated table and a closed case.

Plastic temperature too low

The hotter the plastic is when it exits the nozzle, the better it will adhere to the print bed. It is better to print the first 5-10 layers at a higher temperature (+ 5-10 degrees) and turn off the blower fan.

Wrong first layer settings (speed and thickness)

A thicker layer sticks easier, so the standard first layer is 0.3mm thick. With an increase in print speed, the heating block may simply not have time to heat the plastic to the desired temperature and it will stick to the table worse. Before printing, check the speed and thickness settings of the first layer in the slicer.

A lot depends on how the 3D printer prints the first layer. Try to control the printing of the first layer and only then leave the printer to work alone.

Plastic does not choke from nozzle

The printer has already begun to print, but the print table remains empty. Or part of the model did not print.

Clogged nozzle

In 3D printing, a nozzle is a consumable. The nozzles are clogged or worn out (frequency depends on the type of plastic). The simplest thing is to replace the nozzle. But if there was no spare at hand, you can try to clean the old one. To do this, there is a whole set of thin needles. Or you can heat a clogged nozzle above the melting point of the plastic and “burn out” the blockage. But later it is still better to replace the nozzle.

Low temperature nozzle

You need to increase the temperature of the extruder in the slicer settings or check the thermistor and heating block. Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

Sometimes the thermistor may not read the temperature correctly due to a malfunction or incorrect 3D printer firmware settings.

If the problem occurs after replacing the thermistor - contact the manufacturer or read articles about PID tuning.

Empty extruder

As the extruder heats up, plastic begins to ooze out of the nozzle. Because of this, the extruder may start printing half empty. Because of this, part of the first layer is not printed. You can push the plastic manually by simply pushing the bar into the nozzle. Or solve this problem programmatically - in the slicer, add a contour print around the model (one line).

Some manufacturers and 3D enthusiasts add a line print on the edge of the table at the beginning of each GCode. This is done so that there is plastic in the nozzle by the time the model is printed.

Feed mechanism does not push through plastic

The plastic pushes the feed mechanism to the extruder - a motor with a special pulley put on the shaft. If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

If for some reason the plastic is not pushed through (nozzle clogged, extruder temperature low, etc.), then the pulley “gnaws” through the bar. You need to push the plastic bar with your hands or cut off the damaged piece.

Elephant foot

The first layers of the model are wider and protrude beyond the boundaries of the model. This is due to the fact that the upper layers put pressure on the first ones that have not yet cooled down and flatten them.

High table temperature

Due to the too high temperature of the table, the lower layers remain soft for a long time. Try lowering the table temperature. It is better to reduce gradually (in increments of 5 degrees). You can try to turn on the blower when printing the first layers.

Small gap between nozzle and platen

If, when printing the first layer, the nozzle is too close to the table, then excess plastic will be forced out. After a few coats, this will not be as noticeable, but can lead to the effect of an “elephant's foot”.

Plastic re-extrusion

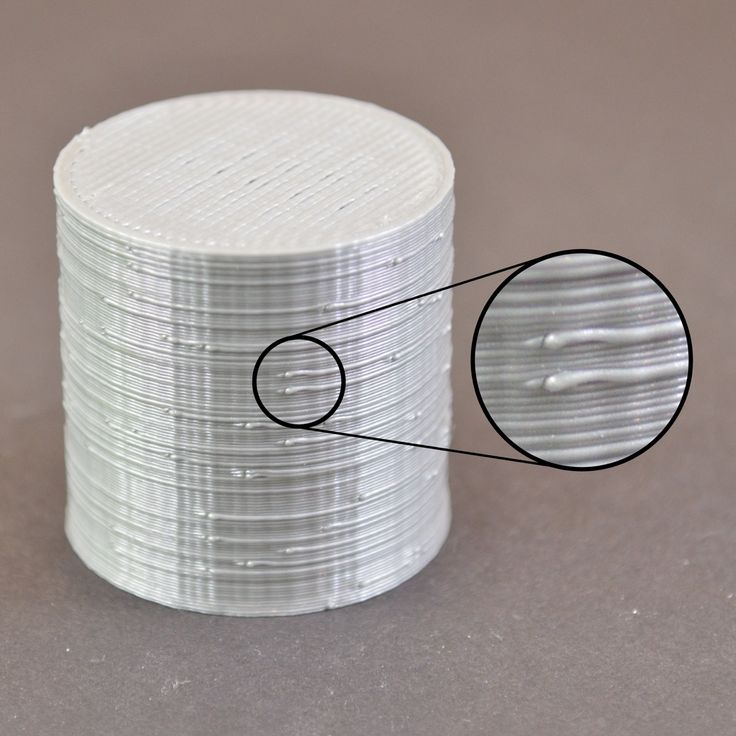

When too much material is squeezed out of the nozzle, the walls of the model are not smooth, but bumpy, with sagging.

The solution is software - in the settings of the slicer, you need to set the material feed rate (fluidity) to a lower value. The average value is 95-98%.

It is worth checking the diameter of the rod. If its size is greater than 1.75, then the plastic will be squeezed out more than necessary.

Plastic underextrusion

The plastic is squeezed out too little, because of this, gaps may appear between the layer. The finished model will be fragile and fragile.

Wrong thread diameter

Check the filament diameter in the slicer settings. Sometimes, instead of the popular 1.75, the default is 2.85.

Incorrect feed factor settings

Check the fluidity settings in the slicer. The average should be 95-98%.

Clogged nozzle

Something could get into the nozzle and partially block the exit of the plastic. Visually, the plastic will choke from the nozzle, but in a smaller amount than necessary for printing.

Hairiness or cobwebs on finished model

Thin threads of plastic protrude from the outer wall of the model (most often on one side). The defect appears due to the flow of plastic from the nozzle during idle movement.

Insufficient retract

A retract is a slight pull of a plastic filament from an extruder. Due to the retract when the extruder is idle (from layer to layer or from model to model), heated plastic does not drip from the nozzle. For some flowable plastics (eg PETG) the speed and amount of retraction must be increased.

"Hairiness" can be easily removed by grinding or cutting off the threads with a sharp scalpel.

High temperature extruder

The higher the extruder temperature, the more liquid the plastic becomes. It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

It is important to find a balance so that the plastic is not too liquid and sticks well in layers.

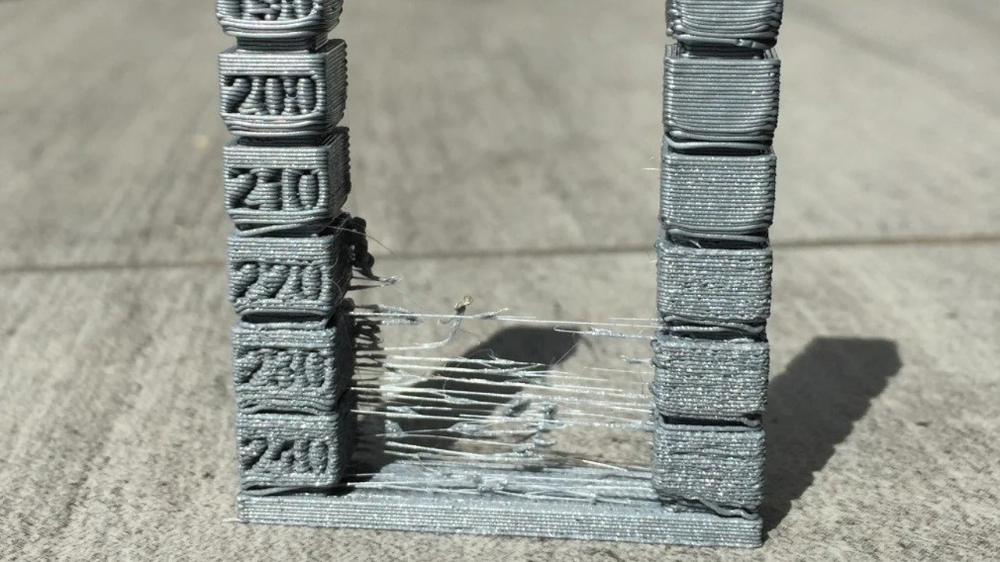

In the selection of the optimal extruder temperature, a test model - a tower - helps a lot. It clearly shows how plastic behaves when printed at different temperatures.

.

Temperature test

Top "perforated" or uneven

The top of the model is bumpy or with holes. The problem may arise if the top of the model is flat. For example, like a cube.

Insufficient airflow

When printing the top plane (cover), the plastic does not have time to cool down and remains too liquid. Because of this, the threads are torn and holes are formed. Increase the fan speed on the last layers.

Few top layers

The top of the print may be too thin and deform as a result. Check slicer settings. The number of upper layers is not recommended to be set less than 6.

Low percentage of filling

If the infill percentage is too low, then the top layer will simply have nothing to rely on. Increase the fill percentage in the slicer settings.

Increase the fill percentage in the slicer settings.

Model deformation

Some parts of the model seem to have melted in some places or on one side. The problem most often occurs when printing with PLA plastic. The defect appears due to the fact that the plastic does not have time to cool and deforms.

Insufficient airflow model

Turn the fans on to maximum. If their power is not enough (in some printers, the fan is located only on one side), you can put a regular desktop fan and direct it to the 3D printer table.

Small model

Small models are difficult to blow well. Try to print small items alongside larger ones, or place several identical models in different corners of the table. So the plastic will have more time to cool.

Layer offset

Layers shift along the x or y axis during printing.

Print head jam

Turn off the printer and try to move the extruder along the x and y axes with your hands. The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

The extruder must move freely. If there are jams, check the mechanics of the printer. Bearing wear or the curvature of the shafts may be to blame.

Electronics overheating

Sometimes electronics problems can be to blame for misaligned layers. The most common cause is overheating of the drivers or too low current exposed to them.

Table top is loose

This is most often seen in 3D printers with glass. During printing, the nozzle may hit the model and move the glass slightly. Before printing, check if the glass or other printing surface is well fixed on the heating table.

Skip layers

Small holes are visible on the print, or the shell of the model is not continuous.

Teflon tube deformed

There are 2 types of thermal barriers - all-metal and with a Teflon tube. If overheated, the Teflon tube may deform. Plastic will pass through it, but in a smaller amount.

Low extruder temperature or high print speed

If the extruder is not heated enough, then the plastic will not be liquid enough and simply will not have time to be forced through the nozzle. The higher the print speed, the higher the extruder temperature should be.

Sometimes the outer walls print well, but the infill is “torn”. In this case, slow down the infill print speed in the slicer.

Model bundle

Cracks form on the surface of the printout during or after printing. Cracks can be large or very small. Most often, this problem occurs with plastics with a high percentage of shrinkage - ABS or Nylon.

Sudden temperature difference (if model delaminates during printing)

With a sharp temperature difference (for example, a draft), part of the model cools down faster. This leads to uneven shrinkage and incorrect distribution of internal stress. For plastics with low shrinkage, this is not critical. But if the shrinkage percentage is more than a few percent, the model may burst in layers.

But if the shrinkage percentage is more than a few percent, the model may burst in layers.

For printing with such plastics, it is recommended to use a printer with a closed housing. If this is not possible, try to avoid drafts and sudden temperature changes in the room where the 3D printer prints as much as possible.

Print temperature

Due to too low printing temperatures, the layers may not “stick” well to each other. Raise the print temperature in the slicer settings.

Hardening (if the model cracks after printing)

Sometimes cracks appear on the model a few days after printing. This is due to uneven distribution of internal stress after cooling. You can try to “harden” the finished product.

For hardening, the model is placed, for example, in an oven, and heated to the softening temperature of the plastic. After that, the heating is turned off and the oven is left to cool slowly with the model inside. Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Due to this, the stress inside the print is distributed more evenly. But accuracy is very important in this method - if you make a little mistake with the temperature, the finished product can “float”.

Ringing

In places where the extruder changed direction, ripples are visible. Most often it looks like a shadow around the “sharp” protruding elements of the model.

Mechanical problems

Sometimes the problem occurs due to extruder play. Check if the extruder mount to the rails is loose. Be sure to check the tension of all belts.

High print speed or high accelerations

Moving the extruder too fast can cause vibrations that cause ripples on the wall of the model. The lighter the weight of the extruder, the less noticeable the ripples will be. To get rid of ringing, simply reduce the print speed in the slicer settings.

Slits for thin-walled models (not solid shell)

The thin wall of the model is not solid, but consists of two thin walls with a narrow gap between them. This problem is often faced by fans of printing "cutting" for baking.

This problem is often faced by fans of printing "cutting" for baking.

Left model with wall defect, right without

Wall thickness and nozzle diameter mismatch

If the wall thickness is 1 mm, and the nozzle diameter is 0.4, it turns out that for a solid wall, 2 nozzle passes are few, and 3 are already many. The result will depend on the slicer algorithm, but most often you will get 2 walls with a thin slot in the middle (the slicer cannot change the wall thickness). The solution to the problem may be a slight refinement of the 3D model or the use of a different slicer.

Algorithms for calculating 3D models are constantly being improved and refined, and now this problem is less common.

When modeling, take into account not only the thickness of the nozzle, but also the percentage of “overlapping” of lines on each other. If you have a nozzle with a diameter of 0.4 - make the wall in your model not 0.

8, but 0.7 - 0.75.

Wrong model geometry

When instead of a circle you get an oval, and instead of a square you get a semblance of a rhombus.

The main reason is malfunctions in the mechanics of the printer. Be sure to check:

Belts

Check belt tension in x and y. Belts stretch over time and may need to be tightened or replaced. Each 3D printer has its own way of tightening the belt. If the belts are slightly stretched, you can tighten them with the help of a "spring".

Loose pulleys, etc.

Check if all bolts and nuts are tight. Are there backlashes. Pay special attention to tightening the pulleys located on the motors along the x and y axes.

Sagging of some parts of the model

Some parts are not printed, broken, or instead of a neat surface, a swollen plastic snot is obtained.

No support for overhangs

A 3D printer cannot print in the air, so if there are overhanging elements in the model, you need to set supports - supports. The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

The slicer can set the necessary support itself, you need to check the appropriate box in the settings.

When printing with soluble support, you can set the gap between the model and support - 0. This will make the surface smoother. If the support material and the model are the same, you need to add a small gap. Otherwise, it will be difficult to separate the support from the model.

Split model

Sometimes the supports can take more plastic than the model. In this case, to save material and time, it will be more convenient to cut the model. If you have more than one 3D printer, then the model will print several times faster.

When cutting the model, you can leave grooves or mortgages so that the pieces of the model are connected without displacement.

Totals

In this article, we talked about the most popular 3D printing defects and how to solve them. Don't be intimidated by such a long list. Some problems are rare and you are unlikely to encounter them.

Some problems are rare and you are unlikely to encounter them.

There is a list of problems that arise due to the design features of a 3D printer, so try to choose a printer that suits your needs. To do this, you need to understand what products and what material you need.

Problems associated with printing algorithms are quickly eliminated by software developers.

Do not be afraid of possible difficulties and each seal will be successful.

20 Most Common 3D Printing Problems (Part 1)

Good afternoon dear 3D Today community! I would like to present you a translation of the article Troubleshooting Guide to 20 Common 3D Printing Problems, which will be divided into 2 parts.

Everyone has problems with printing. We had enough of them to analyze and find solutions for the 20 most common 3D printing problems. In this article, we share our experience and hope that now you do not have to spend extra time diagnosing and solving problems that have arisen.

If you cannot determine what the problem is, compare it with the description.

3D Printing Issue #1: Warp - First Layer Peeling

Description of Issue

At the base of the model, the print rises and does not stick to the platform. This problem can also cause horizontal cracks in the top sections of the printout.

Why did the problem occur?

Deformation of the print base is due to the nature of the plastic. ABS and PLA plastic cools very quickly and this is what can cause the first layer to come off.

Solve 3D printing problem: Printout warped

1. Use heated bed. The easiest solution to this problem is to use a heatbed and set the temperature just below the melting temperature of the plastic. If you set the temperature correctly, the first layer will not come off the platform. The printer bed temperature is often set automatically by the slicer. The recommended temperature for your plastic is listed on the side of the package or reel.

The recommended temperature for your plastic is listed on the side of the package or reel.

2. Use adhesive . If your printout is lifting around the edges, apply a thin layer of glue (or hairspray) to the platform to increase adhesion.

3. Try another platform. Change the platform to a platform with more adhesion. Manufacturers like Lulzbot use a PEI (Polyetherimide) coating that provides a good grip even without the use of glue. XYZPrinting Some printers include a few pieces of thermal tape for the liner. This is a good solution for cool platforms. Zortrax 3D choose a different solution - a perforated backing to which the printout adheres, thereby relieving the user of the problem of deformation at the base.

4. Calibrate the platform. Improper platform calibration can also affect the print quality of the first layer. Check the level of the platform and correct the height if necessary.

5. Increase contact between printout and platform. Often this problem also occurs due to insufficient contact between the model and the substrate. It can be easily corrected using the printer software by adding a skirt or backing.

Often this problem also occurs due to insufficient contact between the model and the substrate. It can be easily corrected using the printer software by adding a skirt or backing.

6. Optimize temperature settings. If none of the methods worked, check the advanced settings of the printer software and the printer itself. Try increasing the platform temperature by 5 degrees.

7. Pay attention to the fan settings. As a general rule, the fans should switch to full power as soon as the print reaches a height of 0.5 millimeters, but you can increase the height to 0.75 millimeters to allow the layers to cool naturally.

8. Even if your printer has a heated bed, it is recommended that you use glue (or varnish) and constantly adjust the bed level.

3D Print Warp: Checklist to Avoid Problems

- Use Heated Platform

- Use Glue (Varnish) for More Adhesion

- Instead of Glass Platform, Use Kapton/Heat Tape/Glue/Varnish

- Recalibrate Platform or substrate

- Adjust temperature and fan settings

3D printing issue #2: First layer misalignment (Elephant's foot)

Problem description

The base of the model is slightly off.

Why did the problem occur?

Typically, the base of the model is shifted due to the weight of the print, which presses on the first layer when the lower layers have not yet had time to cool. Often happens with heated bed printers.

3D Printing Solution: First Layer Offset

1. Correct balance. In order to get rid of the problem of first layer displacement, printed models must be sufficiently cooled to support the weight of the entire structure. Here you should be careful: excessive hypothermia can lead to deformation of the first layer. Finding a balance is hard enough. Start by lowering the platform temperature 5 degrees (but no more than 20 degrees below the recommended temperature). If Bottom / Top Thickness is set to 0.6 millimeters, turn on the fan immediately at a height slightly lower.

2. Platform level. Most 3D printing problems are related to the wrong platform level. For each printer, there is a specific approach for platform level calibration. Check the manufacturer's recommendations to determine what you need. Print out a calibration cube and look at the quality of the plastic feed. The calibration cube will help you determine if the plastic has been laid flat, and if the nozzle is too close to the platform and scrapes the melted plastic, or too high causing the plastic to bubble.

Check the manufacturer's recommendations to determine what you need. Print out a calibration cube and look at the quality of the plastic feed. The calibration cube will help you determine if the plastic has been laid flat, and if the nozzle is too close to the platform and scrapes the melted plastic, or too high causing the plastic to bubble.

3. Raise the nozzle. Raising the nozzle a little can often help. The main thing is not to raise it too high.

4. Smoothen the corners of the model. If all else fails, try chamfering the corners of the model base. Of course, this is only possible if you created the model yourself or if you have access to the source file. Start with 5mm and 45º bevel and experiment to get the best result.

First Layer Offset in 3D Printing: Checklist to Avoid Problems

- Balance Platform Temperature and Fan Speed

- Raise Printer Platform

- Check Floor Height

- Make model corners smoother

Description of the problem

The first layer does not look right, some fragments are missing. There are unnecessary lines at the bottom.

There are unnecessary lines at the bottom.

Why did the problem occur?

Such 3D printing problems usually indicate that the platform level has not been set correctly. If the nozzle is too far from the platform, unnecessary lines often appear at the bottom of the printout or the first layer does not stick. If the nozzle is too close to the platform, this can cause formation bubbling.

Also note that the platform must be clean. Fingerprints on the platform may cause the first layer to not adhere to the platform.

3D printing problem solution: Other first layer problems

1. Set the platform level. Each printer has its own platform level configuration process. For example, the latest Lulzbots use auto-calibration, while Ultimaker offers step-by-step manual calibration. But to set up the Prusa i3 platform level, you will need to spend a lot of time studying the issue.

2. Set nozzle height. If the nozzle is too high, the plastic will not stick to the platform, if it is too low, the nozzle will scrape the printout.

3. Clean the platform. Be sure to clean the printer platform regularly, especially if you are using adhesive. Fingerprints, dust and adhesive residue affect how well the model sticks to the platform.

4. Use glue (varnish). Apply a thin layer of adhesive to the platform to increase the adhesion of the model to the platform. Remember to clean the platform regularly as excess glue can cause the opposite effect.

Layers shift in the middle of the printout.

The printer straps are not tight enough. The top plate is not attached and moves independently of the bottom plate. One of the rods in the Z-axis is not perfectly aligned

Solution to 3D printing problem: Misaligned layers in the model

1. Check the belts. First of all, check how tight the straps are: they shouldn't hang loose, but they shouldn't be too tight either. If you pull on the straps, you should feel a slight resistance. If you feel that the top strap is tighter than the bottom strap, this is a sure sign that they are not tight enough.

2. Check the cap. Check the cover, rods and other parts on top of the printer (if you have coreXY). Make sure all parts are properly fastened.

3. Check the z-axis screws. Many printer manufacturers use threaded studs more often than trapezoid screws, and while both do the job, the studs tend to bend over time. No need to disassemble the printer to check if the rods are straight. Simply use software such as Printrun to move the print head up and down. If one of the Z axis bars is bent, you will definitely notice it. Unfortunately, it is almost impossible to straighten a bent stud, but on the other hand, this is a great reason to replace old threaded rods with trapezoidal screws.

Supreme displacement: Checklist

- Check belts tension

- Check if the upper cover is moving

- Evise that the studs along the zasa are even

describing 3D 903 900: absent layers 9,000) problems

Gaps in the model appear due to the fact that some layers are missing (partially or completely).

The printer was unable to produce the required amount of plastic to print the missing layers. In 3D printing, this problem is also known as under-extruding. The essence of the problem may lie in the plastic itself (for example, a different diameter of the material), in the coil, in the feed mechanism (extruder) or in a clogged nozzle.

Friction can cause plastic to get stuck. It could also be that the z-axis screws (studs) are not properly aligned with the linear bearings.

There may also be a problem with screws (studs) in the Z axis and with the bearings themselves.

3D Printing Solution: Missing Layers

1. Mechanical Check . If suddenly you find missing layers in the print - it's time to take a little care of your printer. Start by checking the screws (studs) and make sure they are firmly attached to the bearings or clamps.

2. Check rod alignment. Check that all screws (studs) are aligned and not misaligned. Turn off the power and gently move the print head along the X and Y axes. If there is any resistance, then there is some problem. It is easy enough to understand what exactly the problem lies in - a slightly bent rod or bearings.

Turn off the power and gently move the print head along the X and Y axes. If there is any resistance, then there is some problem. It is easy enough to understand what exactly the problem lies in - a slightly bent rod or bearings.

3. Worn bearings. Worn bearings make noise. You may also feel the rattle of the print head, while the printer vibrates slightly. In this case, turn off the power and move the print head along the X and Y axes to find out where the worn bearing is.

4. Check the oil. Remember to regularly lubricate the moving parts of the printer. Sewing machine oil is ideal for lubrication - you can buy it at any hardware store at an affordable price. Before applying oil, make sure the studs (screws) are clean. If the studs(screws) have dirt or print material residue, clean them.

Then connect to the printer via a program (eg Pronterface) to move the print head in the X and Y axes and check that the studs are evenly lubricated. If you apply a little more oil, just wipe off the excess.

5. Underextruded . The last cause of the problem may be insufficient extrusion. There can be many solutions to this problem, and all of them are described in Section 9.

Checklist

- Check the printer mechanism to make sure the moving parts are tight.

- Recheck printer design and alignment

- Check for worn bearings and bent pins

- Use some oil to lubricate parts

3D printing issue #6: Cracks in tall objects

Problem description

Cracks on the sides of the model, most commonly in tall models.

The problem can occur unexpectedly, and most often occurs in large printers, especially if you do not monitor their work.

On the upper layers, the material cools faster because the heat from the platform does not reach the required height. Because of this, the adhesion of the upper layers is lower.

3D Printing Solution: Cracks in Tall Objects

1. Extruder Temperature . Start by increasing the extruder temperature - 5-10ºC is best. On the side of the plastic box you will find the highest temperature for plastic, try not to raise the temperature to this value.

Extruder Temperature . Start by increasing the extruder temperature - 5-10ºC is best. On the side of the plastic box you will find the highest temperature for plastic, try not to raise the temperature to this value.

2. Fan direction and speed . Double check your fans and make sure they are pointed at the model. If the direction is correct, reduce their speed.

Checklist

- Check the maximum possible temperature of the extruder and increase the current temperature by 10ºC in one attempt.

- Check the direction and speed of the cooling fans.

3D Printing Issue #7: Holes in the top layer

Description of the issue

Holes and gaps in the top surface of the printout.

The two most common causes of this problem are improper top coat cooling and top coat not thick enough.

Solution to 3D printing problem: Holes on the top layer

1. Filament diameter . Often the problem happens with plastic with a diameter of 1.75 mm. Holes in the top layer are a problem with all 3D printers, but they happen more often with printers that use 1.75mm filament than with printers that print with filament larger than 2.85mm.

Filament diameter . Often the problem happens with plastic with a diameter of 1.75 mm. Holes in the top layer are a problem with all 3D printers, but they happen more often with printers that use 1.75mm filament than with printers that print with filament larger than 2.85mm.

2. Check the location of the fan . Cooling can cause this problem, so check the fans first. When the printer starts printing, the fans are at their lowest speed or off. After printing the first layer, the fans start to work. Check if they start working and also check if they continue working when printing is finished. If all is well, double-check if the direction of the fan is set correctly - they should blow over the model.

3. Set fan speed in G-Code. Another cooling issue is related to excessive plastic in the top layer. It must cool quickly so as not to fall between the already printed supporting elements. The fan speed can be adjusted with G-Code ( is usually G-Code for Fan On is M106 and M107 Fan Off ). Also set the fan speed to maximum for the upper layers.

Also set the fan speed to maximum for the upper layers.

For example, for a 1cm x 1cm cube, the height of the top layer would be 0.1mm. In this case, when generating a G-code through CURA for Prusa i3, the G-code indicates that the number of layers for the cube is 100. Considering that we specified heights of 0.6 mm for the top and bottom layers, it is worth editing the value to LAYER: 94

4. Increase the thickness of the top layer . One of the simplest solutions to the problem is to increase the thickness of the top layer. In most applications, you will be able to adjust the thickness using the ‘Bottom / Top Thickness setting’ advanced settings. You need to increase the thickness of the top and bottom layers up to 6 times the other layers and up to 8 times for smaller nozzles and plastics. If the layer height is 0.1mm, then the height of the top and bottom layers should be 0.6mm. If there are still holes and bald spots in the top layer, increase the thickness to 0. 8mm.

8mm.

Cheklist:

- Use a larger diameter

- Make sure that the direction and speed of the fans are correct

- Manually set the fan speed

- Get the thickness of the upper

- Check the diameter of the Philiment

- Use the caliper diameter

- Check whether

- EXTRITE COMMENTIONS PSYCHETION OF

problem.

Description of the problem

Cobwebs or hairs appear between model elements when printing.

When the printer head moves over an open surface (without extrusion), i.e. from one object to another, the plastic flows out of the nozzle.

3D printing solution: Hairs, webs

1. Turn on retract . Retraction is an important factor for the quality of the finished model and can be enabled in the slicer. It functions quite simply and works by pulling the filament back into the nozzle before the head starts to move. The bottom line is that it prevents plastic from flowing out of the nozzle, which creates a "spider web" between objects.

2. Retraction activation in settings . Most apps like Cura offer pull activation in settings and this is set by default. However, if you want more options, you can customize them further. For example, you can set the minimum head path before activating retraction.

3. Minimum distance (mm) . If retraction is not working correctly, the easiest way to fix this is to reduce the minimum distance. Reduce it by 0.5mm until hairiness disappears. Activate retraction (retract) to increase the speed of printing.

This problem has several causes. First of all, the thread diameter may not match the diameter set in the slicer. Also, the amount of extruded material may be lower due to incorrectly configured firmware. Another problem is that the nozzle can become clogged and this will cause under extrusion.

3D Printing Solution: Underextruding

1. Check filament diameter . Start with the simplest solution - check the filament diameter settings in your slicer. If you are not sure about the filament diameter and the recommended temperature, check the information on the packaging.

If you are not sure about the filament diameter and the recommended temperature, check the information on the packaging.

2. Measure thread . If you still can't get the desired result and filament separation remains a problem, use a caliper to check the filament diameter. After measurement, adjust the settings of the slicing software. ( author's note - if you have a bowden hotend, then you need to unscrew the fitting from the hotend, enter the command (for example, in Pronterface) M302 : Allow cold extrudes and extrude a meter of plastic. If more or less is extruded, then you have an incorrect number steps per mm for the extruder If you have a direct hotend, then you need to unscrew the nozzle ( the nozzle can only be unscrewed when it is hot! ). It is also worth noting that even with the correctly set steps per mm value, when retracting, the distance traveled will be less than when extruding. This is because more resistance is experienced when retracting )

3. Check printhead . After starting printing, most printers lift the print head off the model base. Check if the nozzle is clean.

Check printhead . After starting printing, most printers lift the print head off the model base. Check if the nozzle is clean.

4. Set the extrusion factor to . If there is no difference between the actual extrusion diameter and the software settings, check the extrusion multiplier settings (or flow rate or flow compensation), they may be too low. Each slicing application solves the problem differently, but try increasing the ratio by 5% and restarting the print process.

5. Open the Edit Process Settings window in Simplify3D and go to the Extruder tab - the extrusion factor should be set to 1.0 which corresponds to 100%. Open the Material tab in Cura and increase the Flow settings (you may need to enable Flow in the Preferences window).

Cheklist:

Description of the problem

Excessive extrusion means that the printer is supplying more material than needed.

1 Auto Bed Leveling Sensor Kit Ender 3v2/3/Pro/Ender 5/Pro/CR-10

1 Auto Bed Leveling Sensor Kit Ender 3v2/3/Pro/Ender 5/Pro/CR-10