3D printer wall art

3d Printed Wall Art - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

Find something memorable, join a community doing good.

(1,000+ relevant results)

3D Art Custom Fabrication Services

3D Art Tradition + Technology

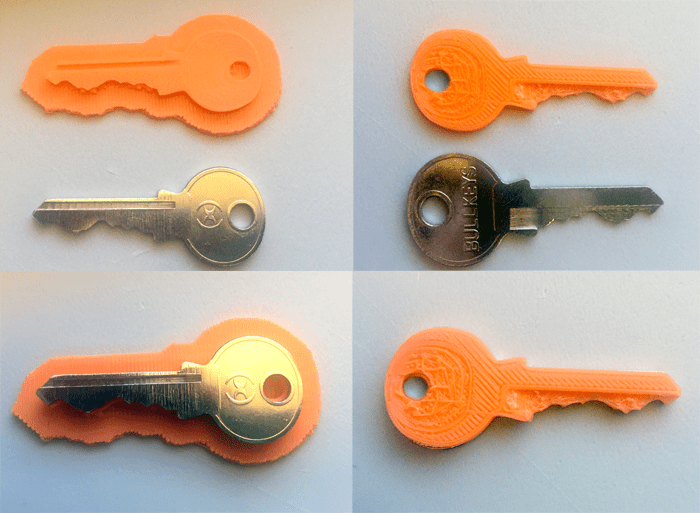

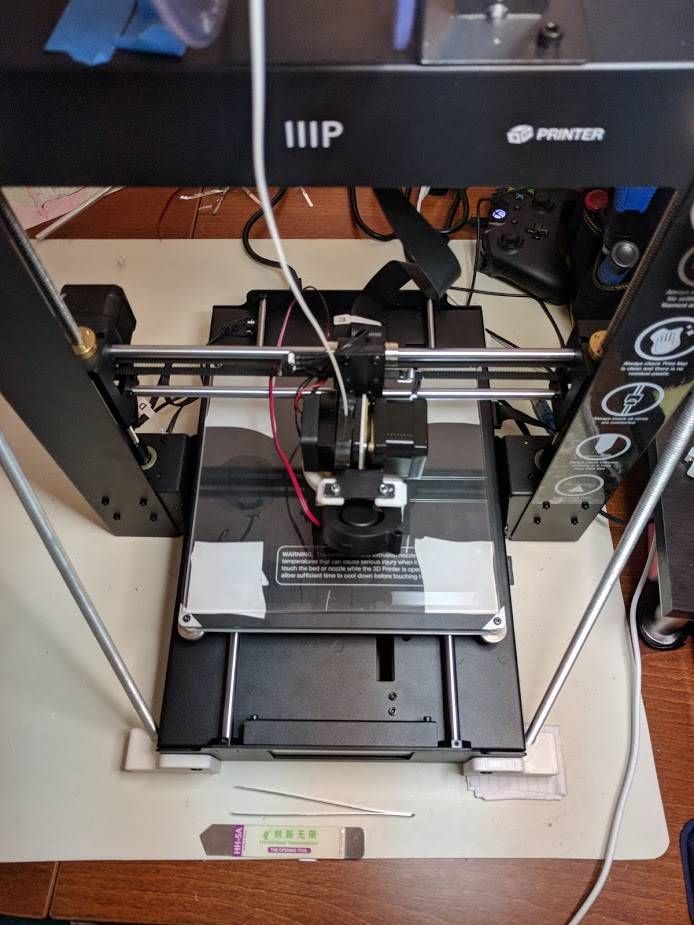

Technology is taking 3D printing to new heights by appealing to the creative market. 3D printing companies are making it more affordable for artists to produce original pieces of art by offering a variety of mediums to fit their needs. 3D printers not only print 3D art for museum exhibits, tradeshows, and movie props but also wall art décor for home and office.

The design possibilites for 3D art empowers artists to think outside the box and create new and innovative 3D art, sculpture, and wall art décor. 3D art created using 3D printing technology is high quality, reasonably priced, easy to transport, and can be texturized and pinted in thousands of colors.

WhiteClouds was commissed to fabricate this large relief sculpture named "HYBRID" by artist Mike HolcombWhiteClouds even offers customized work such as building the bases that a display may rest on, hand painted details, 3D CNC cutting, and 3D foam fabrication. In fact, the WhiteClouds facility supports a large model-making shop for creating supporting elements to its 3D printed designs. We are a full-service 3D model-making company.

We are a full-service 3D model-making company.

Features & Benefits

- Accuracy. 3D art pieces can be printed to scale as accurately as are the files and images provided.

- Excitement. The artwork adds to the excitement of the venue.

- Affordability. Using 3D printing technologies, you can order custom 3D art pieces for a reasonable price.

- Testability. 3D prints are affordable enough to test designs, such as several versions of planned work.

- Consistency. Using modern print technologies, you can easily recreate identical 3D sculptures.

- Portability. 3D art can be created using lighter materials than what was available in the past, making them easier to transport.

3D Art Fabrication

Foam Fabrication:

Creating 3D art with foam fabrication has limitless possibilities – eye-catching 3D wall art for the office; a larger-than-life comic book character for a convention; sculptures for a museum exhibit or sculptures for a tradeshow. Foam fabrication provides the best of creativity and price point to fit every need and budget.

Foam fabrication provides the best of creativity and price point to fit every need and budget.

The benefits of using foam to create 3D art abound. The sculptures and models produced are lightweight, making portability a breeze. Because foam is very durable and resistant to moisture so 3D art can be displayed indoors or outdoors. Fiberglass, cement, metal coatings, and water-based paints can be layered over the foam to complete the finished design.

No project is too large or too small. Whether you’ve got a small foam themed model, one that’s several feet high, or one that includes several peices like foam letters, team or company logos, foam props, or foam sculptures, the possibilities are limitless. Our professional design team prepares your model from scans, drawings, and photos using programs like Maya, Zbrush, and Photoshop. Then our production team takes it from there and creates amazing 3D art sure to please any crowd.

3D Art with 3D Printed Fabrication

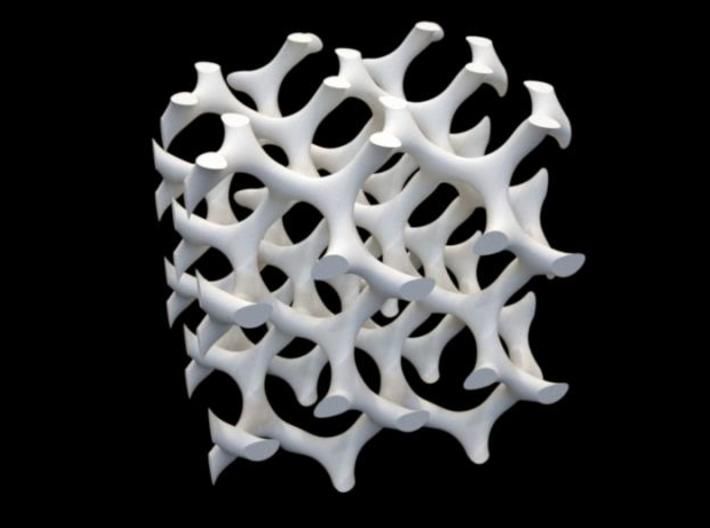

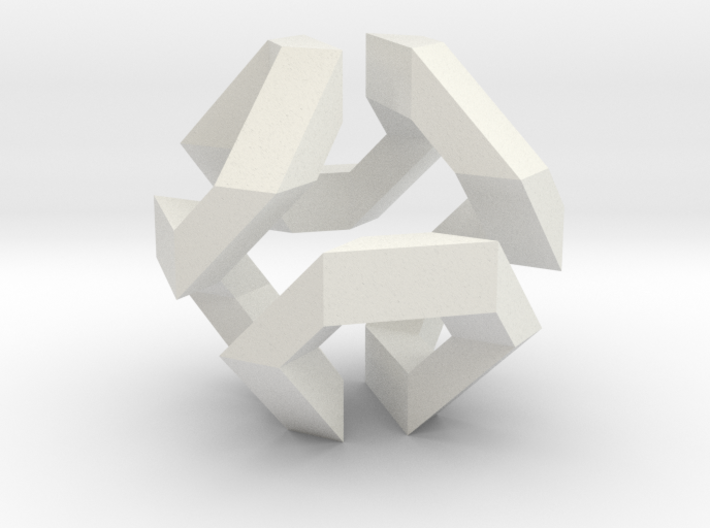

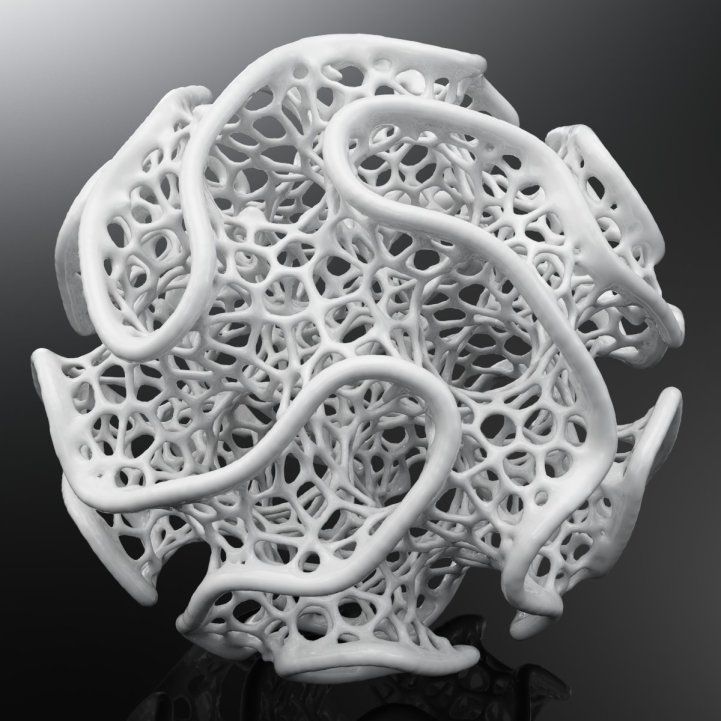

Visionary pioneers are raising the bar when creating art with 3D printed fabrication. The intricate designs that are possible add depth and detail to many pieces of art. Artists are designing innovative pieces that bring science, art, technology, and emotion together. From voice sculpture prints and abstract art to miniatures of famous sculptures and colossal statues, these pieces of 3D art are thought-provoking and engaging.

The intricate designs that are possible add depth and detail to many pieces of art. Artists are designing innovative pieces that bring science, art, technology, and emotion together. From voice sculpture prints and abstract art to miniatures of famous sculptures and colossal statues, these pieces of 3D art are thought-provoking and engaging.

Today, 3D printed art is being used for scenography, replicating ancient statues, mannequins, biodigital living sculptures, museum exhibits, props for tradeshows, and entertainment. 3D printers use a variety of materials to create 3D art. These include nylon powder, ABS plastic, polycarbonate, wood, aluminum, ceramic materials, filament, resin, and gypsum powder. 3D printers are capable of printing minute details that truly make you work a piece of art

3D Art with Metal Fabrication

3D art comes to fruition through metal fabrication. The design possibilities are endless and fit into a variety of different categories including fantasy, wildlife, nature, industrial, and geometric shapes, and are used as decorative art in the home, office, and at trade shows. 3D metal art can be small enough to fit on your desk at work or colossal for a museum exhibit, used in landscaping, and public art. But regardless of size, intricate details can still be seen.

3D metal art can be small enough to fit on your desk at work or colossal for a museum exhibit, used in landscaping, and public art. But regardless of size, intricate details can still be seen.

Beautifully sleek and aesthetically pleasing, 3D art with metal fabrication has been a way to express who we are and how we feel for millenia. Metalworking as it’s commonly known, is an art, a science, an industry, a trade, and a hobby for many people. We see the product of their designs that span civilizations and cultures.

3D metal art is created by assembling, welding, bending, and cutting pieces of sheet metal, steel rods, and rebar into sculpture. Then the artist buffs, paints, and polishes the design. Artists get their inspiration from the Renaissance, Rococo, and Elizabethan eras as well as using their creativity to incoporate old tools, railroad spikes, and scrap metal into their 3D art.

3D Metal Printing, also known as Direct Metal Laser Sintering (DMLS) and Select Laser Melting (SLM) are common in manufacturing parts for the automotive, aerospace, and medical fields. Both of these processes use lasers and high temperatures to bind layers of fine metalic powders together. Even though 3D metal printers can create unique designs the cost is much more expensive than traditional metal working fabrication.

Both of these processes use lasers and high temperatures to bind layers of fine metalic powders together. Even though 3D metal printers can create unique designs the cost is much more expensive than traditional metal working fabrication.

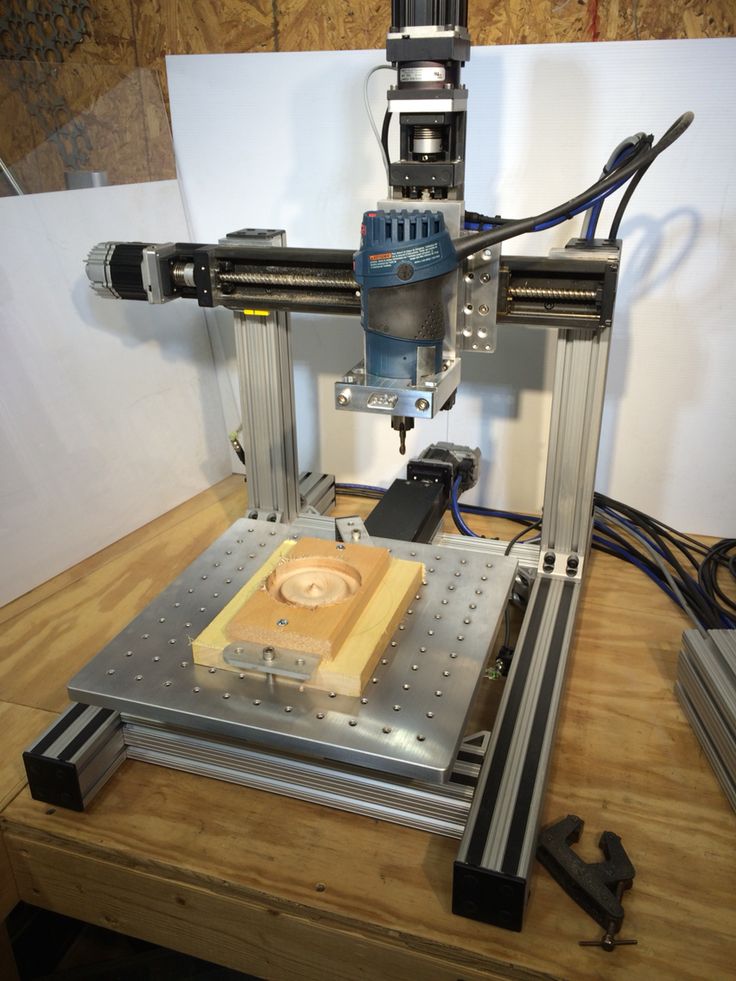

3D Art with CNC Fabrication

The advances in technology have made it possible for businesses and artists to have more freedom to create 3D art with CNC fabrication. What used to take up an entire room can now fit into a much smaller space. Fortunately, the size of the machines doesn’t determine what they are capable of creating.

Computer Numerical Control or CNC fabrication is a process that uses pre-programmed computer software to control the movement of tools and machinery. Foam is ideal for creating detailed foam models, movie props, architectural models, large letters, logos, and tradeshow models. With flawless precision, CNC machines use a hot wire that moves on the horizontal and vertical axes to cut through expanded polystyrene (EPS) foam and extruded polystyrene (XPS) foam. They can also create high-quality 3D art, sculpture, and industrial components out of wood, resin, brass, aluminum, and other types of metal via an electronic contoller connected to a PC and contolled by using a variety of software programs.

They can also create high-quality 3D art, sculpture, and industrial components out of wood, resin, brass, aluminum, and other types of metal via an electronic contoller connected to a PC and contolled by using a variety of software programs.

Once our design team creates and proofs your project in programs such as AutoCAD, they interface it with the CNC machine through enRoute. This workhorse can produce heavy-duty 3D fabrication projects, but it’s precise enough to carve minute details like architectural models and engraving 3D images on acrylic glass. Adding LED rope lights to your 3D art design highlights the intricate detail in your art.

3D Art Using Lighting Effects

3D objects fabricated from metal, resins, foam, and many other types of raw materials and then combined with various types of lighting effects can produce awe-inspiring 3D art pieces. These art pieces can be displayed in tradeshows, conventions, and indoor and outdoor exhibits. Once a piece has been transformed from these raw materials through 3D printing, CNC, or cutting, lighting can be added to create the desired ambiance.

Lighting effects used at WhiteClouds include LED string lighting, uplighting, aura lighting, interactive lighting, and lighting projection.

String Lighting: Lighting effects for our lightbulbs for the Clairity Unleashed project was created with LED string lighting. Once the metal art was shaped, we attached strings of LED lights to the metal along with a motor to bring this piece to life.

Uplighting: Focused lighting can be applied to shine on specific areas of art – sometimes as simple as installing beneath the art-piece, inside the base.

Aura Lighting: Providing background lighting on art pieces or making the lighting the central theme of an art piece, is very simple to accomplish using 3D software. Standard light bulbs combined with thin-walled 3D printing can create unique forms and beauty.

Interactive Lighting: One of our most recent projects included adding LED lighting to a campus-wide architectural model. We used Pulse Width Modulation (PWM) switches that can be controlled remotely with microcontollers and computer programs. A PWM switch allows you to control the brightness of the lighting in specific areas; which is ideal for highlighting different areas of the model for presentations.

We used Pulse Width Modulation (PWM) switches that can be controlled remotely with microcontollers and computer programs. A PWM switch allows you to control the brightness of the lighting in specific areas; which is ideal for highlighting different areas of the model for presentations.

Lighting Projection: New technologies now allow for projecting complex lighting arrangements onto any type of 3D art. This allows for creating epic visuals using projected augmented reality lighting. You can trigger lighting content, static or dynamic, from common off-the-shelf projection devices. This video shows examples of lighting projection.

Combining 3D Art and Mathematical Equations

Combining 3D art and mathematical equations elevate creativity to a new level. Fractals are never-ending patterns found everywhere in nature. Because they are based on mathematical equations, the naturally-occuring patterns can also be created through computer algorithms. When combining fractals, along with other 3D objects and 3D printing, these colorful mathematical equations create elegant pieces of art. For example, a fractal skull represents this combination.

When combining fractals, along with other 3D objects and 3D printing, these colorful mathematical equations create elegant pieces of art. For example, a fractal skull represents this combination.

Each fractal skull begins as a digital, 3D model of a human skull. Then fractal art is wrapped onto the model, and 3D printed using thin layers of gypsum powder. A high-gloss protective coating is added, resulting in a striking porcelain-like model. Ideal for displaying on your desk, at the office, or as holiday and home décor on your mantle. A true piece of art, inspired by nature, each skull is sure to be the subject of conversation for years to come.

Fractals: Nature’s Art – Fractals help us learn about and understand important scientific concepts, such as the way bacteria grows, patterns in freezing water (snowflakes), brain waves, and mapping mountain ranges. Fractals can be found everywhere in nature – pinecones, ferns, seashells, waterfalls, mountains, lightning, peacock feathers, human lungs, and circulatory system. They are all stunning fractals that create artwork on nature’s canvas. The brilliantly-colored art for each skull is generated by sophisticated computer algorithms and printed on a ProJet 660 ColorJet 3D printer.

They are all stunning fractals that create artwork on nature’s canvas. The brilliantly-colored art for each skull is generated by sophisticated computer algorithms and printed on a ProJet 660 ColorJet 3D printer.

Skulls: Life and Mortality – Through the ages, the human skull has symbolized life, awareness, and our own mortality. Combining the mortal skull with the infinite fractal creates an interesting art piece.

Poet William Blake wrote, “To see the world in a grain of sand and heaven in a wild flower, Hold infinity in the palm of your hand and eternity in an hour.” Thanks to Benoit Mandelbrot’s influential work in fractal geometry and today’s technology, you can literally hold infinity in the palm of your hand. This video shows how fractal skulls are manufactured.

3d art of glass balls stuck in spikes 3d art of a cube with a fractal pattern 3d art of a skull with a forest pattern 3d art of a flower

Technology and Materials

- With 3D printing technology, you aren’t limited to straight lines and cubes.

A 3D printer can easily print jagged edges, curves, and intricate details.

A 3D printer can easily print jagged edges, curves, and intricate details. - We can 3D print art in different materials including UV-cured resin. The type of art piece determines which material will produce the best results. We can help you choose the material that is best for your project.

- We use foam fabrication technologies such as CNC Cutting, Hot Wires, Laser Cutting, Hot Knifing, and Sculpting.

- The resolution of our printers is finer than a human hair to show incredible detail in your 3D art piece.

- 3D art can be 3D printed in full-color (over 750,000 variations of color). So, there’s no painting required! But, if you’d like to add a special touch, our in-house spray booth gives us flexibility in different types and grades of paint and finishing capabilities.

Pricing

The cost of a 3D art piece is based on the volume of material (size of the sculpture), the time it takes to create the 3D printable file or CNC file, and other elements of the sculpture. Each 3D art piece is bid individually and the best way to determine cost is to email us, call us at 385-206-8700, or fill out the form below and let us bid on your project.

Each 3D art piece is bid individually and the best way to determine cost is to email us, call us at 385-206-8700, or fill out the form below and let us bid on your project.

Get a Free Price Estimate for Custom 3D Art Fabrication

Custom Fabrication Workflow

Common Questions & Answers

What file type is required to make 3D art?

We work with Maya, Zbrush, and Photoshop, just to name a few. If you design in 3D, we will start with your 3D files. If you have artist’s sketches, we can build sculptures and art pieces from these as well. If all you have is an idea or a napkin drawing, we can start with that and design it to your specifications.What technology do you use for 3D art?

It can be a number of different technologies, individually or combined. These range from 3D Foam, 3D Printing, CNC Cutting, laser cutting, laser etching, casting, molding, sculpting, painting, airbrushing, laminating, vinyl printing, and woodworking — all meant to produce high quality sculptures, 3D wall décor and 3D art that fit your exact needs.

What is the material used?

We match the correct material and fabrication process to your requirements in terms of presentation, size, and transportability. We fabricate in our model shop using different types of foam, wood, metal, resins, and acrylics. We can also 3D print in UV-cured resin, plastic, rubber-like acrylic, and nylon.What is the largest model you can 3D print?

There is no limit to the size of model. Transportability will be your only concern on an extremely large foam sculpture.What is the turnaround time for a 3D-printed sculpture?

This depends on the features of the design itself as well as the scale of the sculpture. We usually ask for six to eight weeks from the time we take the order to when you will receive the sculpture. Large projects can be four to six months or longer. We understand that sometimes deadlines are tight and we can accommodate rush orders.What features can a foam sculpture have?

Besides the physical 3D foam sculpture with the proper color and appearance, you can elect to ask for special lighting, sound, and movement.

If I want a second sculpture is it cheaper?

Our pricing is based on the fabrication costs and the time it takes to prepare your design. The second sculpture is less money because the design portion is complete.

Do you have a question we didn‘t answer? Don’t hesitate to contact us at 1-385-206-8700 or [email protected].

Worldwide Delivery

WhiteClouds has delivered models around the world.

History of 3D Art

Traditionally, 3D art brings to mind sculptures like the Great Sphinx of Giza, David by Michelangelo, The Statue of Liberty by Frederic Auguste Bartholdi, The Thinker by Auguste Rodin, Christ the Redeemer in Rio de Janeiro, Brazil by Paul Landowski. The creation process for masterpieces like this took months to years to complete, depending on the size and scope of the project. These works were created using limestone, marble, bronze, terra cotta and wood through an arduous process with rudimentary tools. The workmanship is exquisite and until now has been very difficult to replicate.

The workmanship is exquisite and until now has been very difficult to replicate.

Early in the 21st century, 3D printing exhibitions began showing what was possible with this innovative technology. It took several years before 3D printed pieces were being shown as actual art. Materials used to create 3D art have evolved to foam, metal, UV-cured resin, plastic, rubber-like acrylic, and nylon.

Today, artists like Amy Karle are designing pieces that are 3D printed with photo-crosslinked poly (ethylene glycol) diacrylate (PEGDA) hydrogels — a product that is biodegradable. She combines art, design, science and technology to create BioArt.

WhiteClouds is a forerunner in the 3D art fabrication arena. Expert designers create 10-foot tall comic book characters, detailed architectural layouts, medical and veterinary models, game worlds, museum replicas, braces and prosthetic limbs.

The possibilities of 3D fabrication are limited only by the imagination.

STL File Bear Wall Art・3D Printer Model Download・Cults

Wall Art DeadPool

2.11 €

Goku wall art

2.11 €

Wall Art IronMan

2.11 €

DeadPool Wall Art

2.11 €

Wolf wall art

2.11 €

Wall art "Dog"

2.11 €

Goku head wall art

2.11 €

Spiderman wall art

2.11 €

Best Files for 3D Printers in the Art Category

Sleepy turtle

Free

No-Supports Nativity Set

Free

SPIDER-MAN (FACE CHANGE)

2. 32 €

32 €

Flexible chessboard

3.87 €

Plane Concorde scale 1/200

4 €

Bath Outlet

Free

HINGED SCORPIO

3.30 €

Mars Attacks

70 €

Art category bestsellers

Cute frog with flexi print

1.88 €

Astronaut on flexi printer

2.85 €

Baby Crystalwing, Cinderwing3D, articulating Flexi Wiggle Pet, print on site, fantasy

3,86 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

2,85 €

Cute T-Rex dinosaur with flexi print

2,85 €

Biting dragon

3 €

Adorable articulated axolotl, imprinted body, snap head, cute flexi

3,28 €

Triceratops on flexi printer

2,85 €

Cute little fox with flexi print

2. 41 €

41 €

Pink Dragon Valentine's Day Articulating Animal Flexi Wiggle Printing In Place Fantasy

3.92 €

FLEXI XXLPRINT-IN-PLACE SKELETON

9.65 €

Cute circus baby elephant with flexi print

2,85 €

Archaeopteryx nibbler

3 €

Funny skull mask for Halloween

1.24 €

GHOST ZU - GHOST WITH FEET

2.78 €

Cute elf with flexi print

1,88 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining the activities of and creating future developments is very simple. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Possibilities of 3D printing: art, fashion, medicine

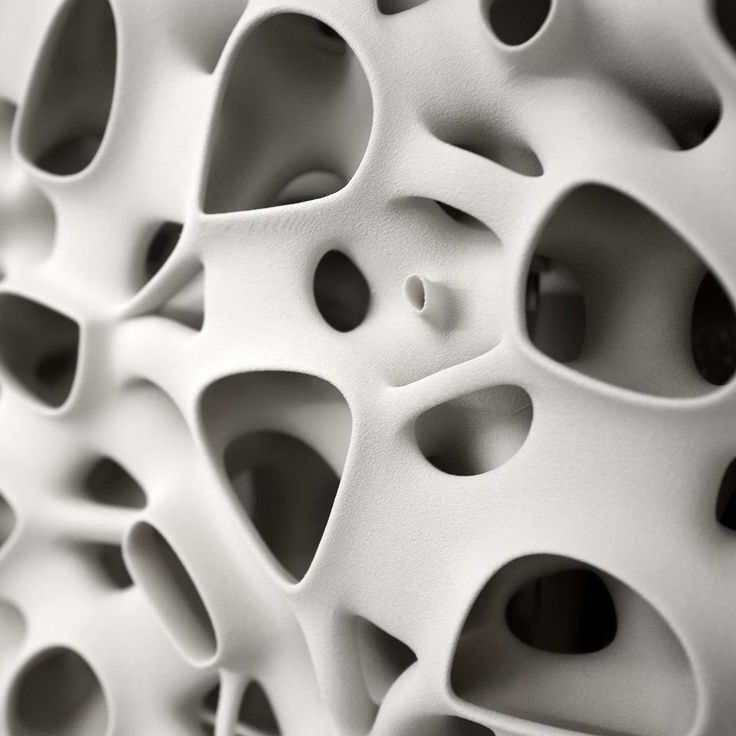

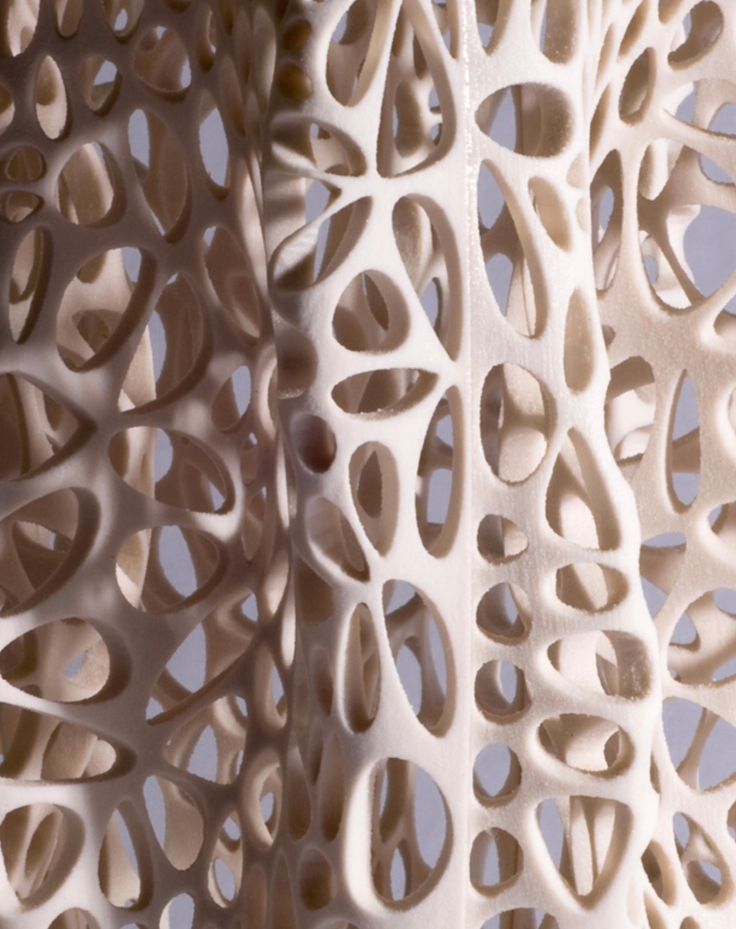

Sculpture by Monika Gorchikova (Czech Republic)

Expressive sculptures by contemporary artists, dresses for fashion shows, architectural models and parts of the human body - a short guide on how to use 3D printing by Artyom Dezhurko .

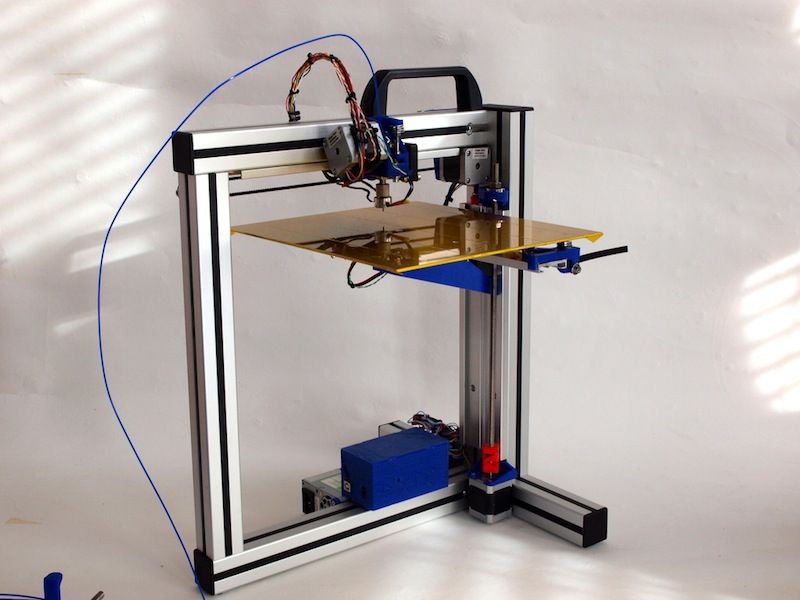

3D printing was invented by American Chuck Hull in 1984. Modern 3D printers are capable of printing large objects, up to a car body; and use different printing techniques (stereolithography invented by Chuck Hull is just one of them). However, whatever the technique may be, the essence is the same: the printer creates an object by building up the material in layers. Thus, you can create an arbitrarily complex shape. 3D printers print from different materials: plastic, cellulose, ceramics, metals, sugar.

However, whatever the technique may be, the essence is the same: the printer creates an object by building up the material in layers. Thus, you can create an arbitrarily complex shape. 3D printers print from different materials: plastic, cellulose, ceramics, metals, sugar.

This material is an illustrated overview of how 3D printing is currently used in various fields: art, architecture, technology, fashion, medicine.

Richard DuPont, USA

Nick Erwink, USA

"Princess", Eric van Straten, Netherlands

A modern 3D printer prints layers so thin that they can no longer be seen with the naked eye. Therefore, sculptors love it: 3D printing is the same casting, but technologically simplified and allowing endless replication of the object. Sculptures with her help are very different: from photographically accurate images of famous football players to the vicious postmodern statuettes of Eric van Straten.

Michael Hansmeyer and Benjamin Dillenburger. Digital Grotesque, 2015

Digital Grotesque, 2015

Study paper by Andy Zheng and Christina Eromenok at RPI School of Architecture

PTW Architects. Model of the Beijing National Water Sports Center, 2007

Most often, 3D printing is used for rapid prototyping - creating models of mechanisms and, especially often, architectural models. In addition, now 3D printers have begun to be used to produce large parts from which prefabricated houses are created. The Chinese company Winsun is experimenting with this technology.

In the automotive industry, 3D printing scale model production is widespread and seems to have completely supplanted the old plasticine sculpting technique. A model of James Bond's car from the movie "Skyfall" was printed on a 3D printer. And in 2010, a prototype of the Urbee car was created, the entire body of which was printed on a 3D printer.

ideas2cycles, Finland, The Fixer, 2012

Several bicycle frames have been created using a 3D printer (and even an entire Airbike bike - developed by EADS), but in their case there is no talk of mass production yet. More promising is the printing of couplings made of durable plastic, with the help of which in small "garage" bicycle workshops it is possible to assemble frames from factory metal tubes.

More promising is the printing of couplings made of durable plastic, with the help of which in small "garage" bicycle workshops it is possible to assemble frames from factory metal tubes.

Gaudi chair (Bram Genin)

A mold is printed on a 3D printer, which is then used to cast the supporting structure of the chair.

Hot Pop Factory

Sculpture of Charles and Ray Eames DSW chairs scanned and 3D printed.

LINK system

Christian Sjöström, Sweden, 2015.

Prototype Node

Modeling in Grasshopper. Charles Freed, UK, 2015.

3D printed as whole furniture (e.g. Gaudi chairs, designed by Bram Genen, 2009) and piece by piece (designed by Benjamin Vermeulen), as well as connections with which prefabricated furniture can be assembled without using bolts and nuts. Such joints have been made before, but 3D printing has greatly simplified their production.

Noah Raviv. Hard copy collection. 2014

Noah Raviv. Hard copy collection. 2014

2014

Chromat. Formula 15 collection. Spring-summer 2015

Michael Schmidt, Francis Bitonti. Dita Von Teese dress. Laser printing (SLS). 2013

Iris van Herpen, Julia Koerner, Voltage Show. Print materialize. 2013

Iris van Herpen. Crystallization Collection. Summer 2010

Iris van Herpen. Autumn-Winter 2013-14

On a 3D printer, you can print elements from which plastic fabric is then woven. Either from this fabric, or directly from plastic, dresses, bathing suits, shoes are created. Iris van Herpen has released several collections of 3D printed dresses and shoes. United Nude prints shoes designed by famous designers and architects: Zaha Hadid, Rem Koolhaas, Ross Lovegrove. But the most famous piece of clothing created using this technology is Dita Von Teese's mesh nylon dress.

#Cast is a custom tire consisting of the letters that the patient most often typed on Twitter. Manufacturer FATHOM, designer Eva DeCapri (USA). 2014

Prosthesis on the model of the patient's skull. Photo from Walter Reed Hospital in Washington

Photo from Walter Reed Hospital in Washington

Arm splint. The developers are UCLA School of Architecture and Urban Planning students Nicholas Solakian, Peter Nguyen and Derek Buell. 2013

Medicine is the most promising application for 3D printing. By scanning the surface of the body, it is possible to create fixation bandages that exactly match the anatomy of a particular patient, “custom” prostheses and implants that reproduce lost parts of the skeleton. One unfortunate man who lost half of his face had the missing half printed on a 3D printer. There is no photo of this person here, but you can easily find it if you wish.

Printer self-reproduction

There are printers that can print parts of themselves. Undoubtedly, in the coming years they will learn to breed.

Growing donor organs

3D printing technologies for living tissues and organs are being developed. Living cells are used as the material, with which the printer "seeds" the matrix.