3D printers for dental labs

3D Printing for Dental Practices

Simple print preparation

Import digital impressions directly and prepare models for printing in just a few clicks.

Download PreForm

Rigorously tested materials

Fully validated workflows with our proprietary resins give you peace of mind.

Browse Materials

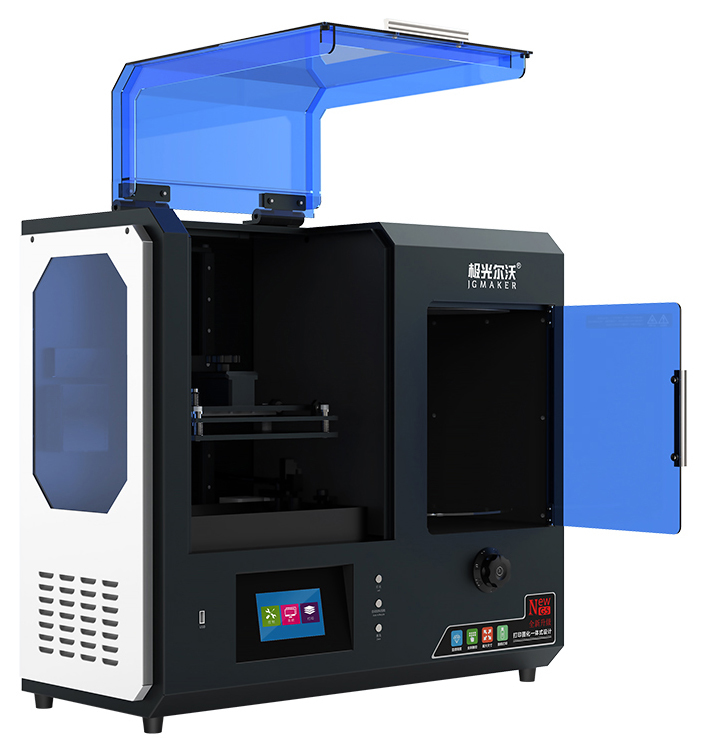

The easiest 3D printer to use

The intuitively designed Form 3B makes in-office printing clean and hassle-free.

Meet Form 3B

Hands-off post-processing

Automated washing and curing units take the guesswork out of finishing printed parts for clinical use.

Automate Your Post-Processing

“The printers from Formlabs are simply the best, simplest printers on the market. Best in class user experience. Fast change of material. The biggest choice of certified and tested resins on the market. Every print was a success in the last 5 years. No failure at all.”

Dr. Antonino Cacioppo, DDS, PhD, Prosthodontist, Studio Dentistico Associato Cacioppo

Diagnostic models

Up to 9 models per print in ~3.5 hr or 1 model in 20 min for $2-3 a model.

Get started with diagnostic models

Clear aligner models

Up to 9 models per print in ~3.5 hr or 1 model in ~20 min for $2-3 a model.

Scale production and ROI with aligner models

Surgical guides

Up to 29 quadrant surgical guides per print in ~5 h for $2-$4 a part.

Secure safer, faster operations

Occlusal guards

Up to 8 guards per print in ~2.5 h for $4-$6 a part.

Protect your patients and their oral health

See How Much You Can Save

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs dental 3D printers.

Calculate Your Savings

Direct printed full dentures and try-ins

Meet Digital Denture Resins

Temporary crowns, bridges, inlays, onlays, and veneers

Meet Temporary CB Resin

Permanent crowns, inlays, onlays, and veneers

Meet Permanent Crown Resin

From CE-certified courses to quick videos that can quickly teach you a new skill, learn with Formlabs Dental Academy.

Browse Educational Content

With 75+ support and service staff and 150+ engineers, Formlabs backs its products with the strongest team in 3D printing.

Don’t want to learn one more software program?

Ask if your lab will do appliance design for you. Otherwise, fully digital services can take this off your plate.

Our Dental Service Plan (DSP) includes personalized onboarding training, proactive check-ins, and the best phone and email support in the industry.

Learn More About Dental Service Plan

Learn how digital dentistry is transforming dental workflows and how you can integrate 3D printing into your practice with our free resources.

Explore Dental Resources

The Form 3B Complete Package includes all of the tools required to bring high-precision 3D printing into your office.

Order NowRequest a Sample Part

Professional 3D Printing Materials for Digital Dentistry

Professional 3D Printing Materials for Digital DentistrySkip to Main Content

Dental Resins

Bring production in-house or improve existing workflows with industry-leading Formlabs 3D printers. Our Dental Resins empower dental labs and practices to rapidly manufacture biocompatible surgical guides, splints, fixed patterns and models, clear aligner models, and full dentures.

Visit the Formlabs Store

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your lab or practice.

Request a Free Sample Part

The Form 3B+ and Form 3BL are compatible with the complete Formlabs resin library of more than 20 general purpose and speciality materials.

Explore All Formlabs Materials

Data Sheets

Download safety and technical data sheets for all Formlabs materials.

Handling & Safety

Handling & Safety

Resin should be handled with care. Proper handling will ensure safe printing and efficient use. Our resins have been designed to be similar or safer to handle as other household chemicals or adhesives. Formlabs materials do not contain volatile solvents so special ventilation is not required. Skin contact should be avoided.

The Safety Data Sheets (SDS) are up to date for every resin product and follow the latest government guidelines. Always consult the SDS as the primary source of information to understand safety and handling of Formlabs materials. For more information about handling resin, learn more tips for resin maintenance in our Help Center.

Technical Data

Technical Data

Plastics are complex materials, and finding the right one for your specific application requires balancing multiple attributes. Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Our library of resins is ideal for product development, rapid prototyping, and a variety of specialized applications. Download our Technical Data Sheets to explore the mechanical properties of each material.

Material

– Select –BioMed AmberBioMed BlackBioMed ClearBioMed WhiteBlackCastableCastable WaxCeramicClearColor BaseColor PigmentsCustom TrayDental LT ClearDental LT Clear V2Dental SGDigital DenturesDraftDurableESDElasticElastic 50AFlexibleFlexible 80AFull Materials LibraryGreyGrey ProHigh TempIBTModelModel V3Nylon 11Nylon 12Permanent CrownRigid 10KRigid 4000Soft TissueSurgical GuideTemporary CBToughTough 2000White

Language

– Select –BulgarianChineseCroatianCzechDanishDutchEnglishEstonianFinnishFrenchGermanGreekHungarianIrishItalianJapaneseKoreanLatvianLithuanianMalteseNorwegianPolishPortugueseRomanianRussianSlovakSlovenianSpanishSwedishTurkish

Technical Data Sheets

There is no technical data sheet available for the chosen material.

Safety Data Sheets

There is no safety data sheet available for the chosen material.

For more information, help choosing a material, or bulk orders, we're here to help.

3D printing of teeth and other products

Home

Top 3D Shop Dental Laboratory

Top 3D Shop Dental Laboratory

Top 3D Shop Laboratory manufactures a full range of dental products using additive and classical methods, materials and equipment from leading manufacturers: crowns and implants, bridges and caps abutments, inlays, frames and beams, clasp, veneers, caps, surgical templates, models.

Types of structures:

Abates

Crings

9000 Veneers Models0007 templates Implants Bugly We take Stl files with any intraoral scanners: Workpiece materials: Implant systems: A prosthesis on a 3D printer is no longer a fantasy, but a completely familiar and ordinary solution to many issues related to prosthetics. The production of abutments, crowns or bridges can be quite time consuming using classical methods. The manufacture of dentures and other products in a modern laboratory equipped with appropriate equipment is a completely different direction, which allows you to reduce the cost of the process as much as possible, but not reduce the quality of the products obtained. Even artificial gums, thanks to printing in a private clinic, are not a problem - all activities in our dental laboratory are carried out quickly and professionally. To date, 3D printing of teeth and prosthetic services in general are a fairly relevant area, without which dentistry would not have developed for a very long time and was a very expensive “pleasure”. Thanks to our research in this area, the availability of modern 3D printers and other specialized equipment, we are ready to make a model of any kind of structure. These can be crowns, frameworks, bridges, inlays, as well as veneers, templates, clasp and more. It is worth noting that our specialists accept STL files regardless of the type of intraoral scanner. As raw materials, we use a wide variety of materials, including special composites from leading manufacturers. You can order everything you need from us, while the cost of services always remains acceptable for each client. The development of technology forces us to analyze the tools we use every day again and again. Examples of work performed at the 3D printing center of MyDent24 LLC. The main question is what do we print in a dental laboratory?

3D Dentistry – new in the world of dental technology

Now, many modern advances are used in dental clinics, thanks to which it is possible to solve problems as simply as possible and much cheaper than it was before. Unfortunately, not everyone has access to 3D dentistry, since such equipment requires additional costs and the ability to work with special equipment. But our services can be considered a way out of the situation, because we represent the whole range of work that a dental laboratory can perform. Our only difference is the 3D technologies used, thanks to which it is possible to print almost any products and designs.

Now, many modern advances are used in dental clinics, thanks to which it is possible to solve problems as simply as possible and much cheaper than it was before. Unfortunately, not everyone has access to 3D dentistry, since such equipment requires additional costs and the ability to work with special equipment. But our services can be considered a way out of the situation, because we represent the whole range of work that a dental laboratory can perform. Our only difference is the 3D technologies used, thanks to which it is possible to print almost any products and designs.

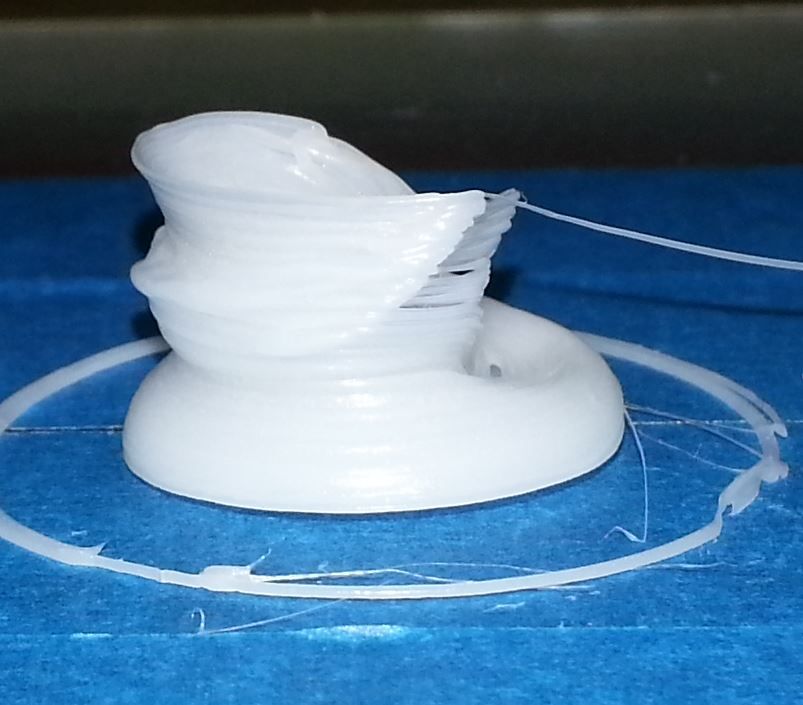

3D printing of teeth and other dental structures

Medical applications of 3D printers | 3D printing news

Thus, classical manufacturing techniques are increasingly being replaced by automated production systems that optimize time and material costs.

Thus, classical manufacturing techniques are increasingly being replaced by automated production systems that optimize time and material costs.

It is the norm in dental laboratories to save time down to the second to ensure maximum productivity. In this regard, a constant search for the best solutions for optimizing labor is required, the introduction of innovations, one of which was the use of CAD / CAM technology and milling machines. In a short period of time, this technology has become the standard for the manufacture of orthopedic structures with a high quality of the end result, which ensured its widespread popularity.

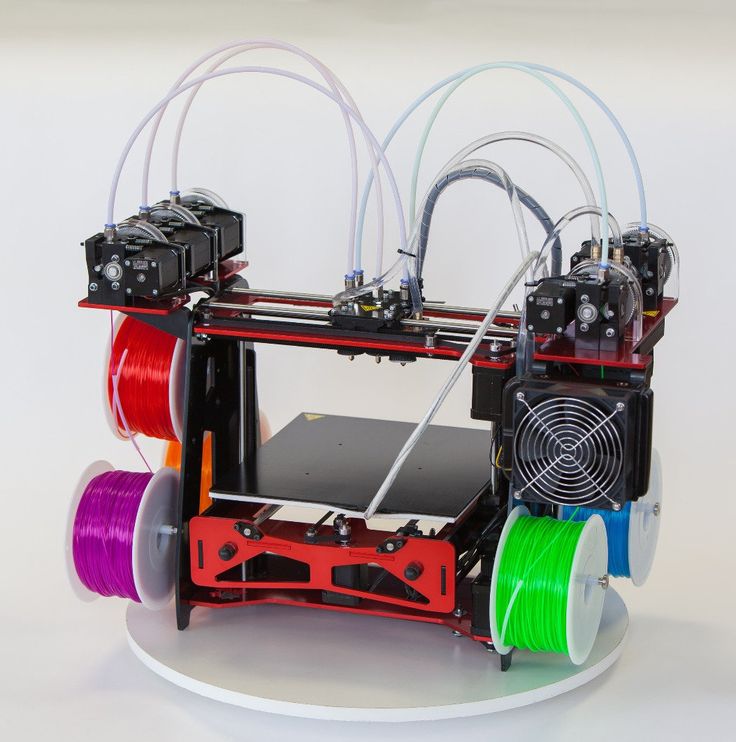

Today, we are on the verge of a new technological revolution, which, like the introduction of the assembly line at the beginning of the last century and the widespread use of personal computers at the end of the century, portends us to a different level of production. We are talking about professional 3D equipment that can free the hands and head of a dental technician to solve more creative tasks.

Stereolithography (SLA) and digital LED projection (DLP) have taken root in the vast array of existing 3D printing technologies in dentistry. Both technologies have a similar principle of operation - the object is divided into flat layers of equal thickness, then the printer recreates the original object layer by layer with the help of alternate illumination. The difference between the above printing methods is the light source - UV laser for SLA and digital LED projector for DLP.

Both printing technologies use photopolymer resins, a liquid material cured by light.

Photopolymer resins are graded according to application. Using the DETAX Freeprint® materials as an example, we highlight three key groups used in dentistry.

Freeprint® model is a material for making dental models. Suitable for creating jaw models or other solid objects. It has three colors: gray, sand and ivory.

Freeprint® cast is a burn-out material for precision casting technology. Finished printing products are placed in the investment mass and cast from the required metal.

Freeprint® splint is a biocompatible material for the manufacture of surgical templates, mouthguards and other objects in contact with the patient.

The above DETAX Freeprint® materials have a registration certificate for use in dentistry on the territory of the Russian Federation.

Having appeared on the Russian market more than 5 years ago, modern photopolymer printers using stereolithography technology have found their application in the jewelry industry, where the accuracy of design reproduction in accordance with the developed layout is extremely important. In addition to precision, the use of 3D printers has made it possible to reduce the production time of burn-in jewelry models by moving from classical technology with hand-modeling to digital and further printing. A significant advantage is the possibility of modeling a unique shape of the final product at the stage of digital modeling, giving the most complex shapes and their exact reproduction during casting. We have similar requirements for products in the production of dental structures.

Made from DETAX Freeprint® materials on Asiga PICO2 and Way2Production SolFlex 650 printers

The answer to this question is key when choosing equipment. Today, there are three key areas for using 3D printing in this direction:

• production of demonstration and collapsible models of the jaw, sectoral reproduction of the upper and lower jaws in bite;

• production of ashless constructions, caps, bases for crowns and bridges, clasp prostheses;

• production of surgical templates for implantation, guides for maxillofacial surgery, individual mouth guards.

The printing of temporary and permanent orthopedic structures, as well as the production of bases for removable dentures, is actively developing. In the near future, these biocompatible materials will become available on the Russian market.

In our 3D printing center we use Way2Production SolFlex 650 (Austria) and Asiga PICO 2 (Australia) DLP printers. Both printers cure materials with 385 nanometer (UV) wavelength radiation.

DLP printers are distinguished by light intensity and print accuracy, depending on the projector resolution and layer thickness. For example, for printing crowns, bridges, the base of clasp prostheses and other structures that require an exact fit, you should choose a layer thickness in the range of 25 - 50 microns. For the manufacture of surgical templates, jaw models and other volumetric tasks, a layer thickness of 100 microns is optimal.

The range of tasks solved with the help of 3D printing is growing every day due to the emergence of new technologies and an increase in the level of skill in using existing ones. Today, 3D printing has ceased to be the lot of professionals and has moved into the consumer market.

It is important not to miss the time now, to get the necessary skills and opportunities, so that tomorrow, when we cannot imagine our life without 3D printing, to be at the top.

Learn more