3D printer arm cast

Custom 3D-Printed Casts and Splints

You Have Casting Options!

When you have a broken bone, you can choose a custom fit, waterproof 3D printed cast for the remainder of your healing, just as soon as your fracture is stabilized and your swelling goes down.

Your Clinic Can Provide ActivArmor Today!

No equipment or inventory to buy. Get started now with our free iPhone app!

What is ActivArmor™?

ActivArmor is the only waterproof, breathable, sanitizable custom plastic cast in the U.S. consumer marketplace. It empowers patients with the freedom to be able to stay safe and maintain their active lifestyles.

No rubbing or slipping. Custom fabricated to within 1mm of your body map.

Clips are locked on like a cast or easily removable like a splint, per doctor’s orders.

Kids love the colorful options and comfort. It’s breathable and does not trap bacteria.

Shower, bathe or swim as you normally would. Easy to clean dirt, sweat and grime.

ActivArmor™ allows you to continue to be active while you are healing from your injuries, and can reduce downtime in your active lifestyle and/or training.

ActivArmor™ is covered by most insurance plans and is affordable or even free depending on your individual coverage.

ActivArmor™ is the only commercially available, 3D printed custom splint in the United States and is FDA listed.

Participate in daily activities such as bathing and showering; convenient for children or those with mobility problems.

No need for a 3D printer in the doc’s office. All you need is an Rx pad and you can prescribe from the comfort of your own desk.

Listed with FDA as a Class 1 splint, doctors love the patient outcomes and patients love the faster recovery. ISO-10993 certified for biocompatibility.

ActivArmor is designed and made in Pueblo, Colorado in a United States EDWOSB, and was developed by an American entrepreneur.

When you no longer have a need for your ActivArmor™ custom splint, rest assured you can recycle it and help keep our planet beautiful.

Doctors Love ActivArmor™

ActivArmor saves physicians time and increases clinic efficiencies by reducing cast removals, material inventory, recasting, and skin irritation complaints.

Custom RX Pad

Scan with your iphone in your office, or just write a script to have our certified staff fill your patient’s DME order.

Very Easy to Prescribe

it really is…

You can also become an ActivArmor partnering clinic

Learn More

Increase Traffic to Clinics

Your patients become walking billboards for your practice, marketing for you while they heal.

Zero Upfront Costs

Help more patients

Clinics are viewed as innovative, and are given the opportunity to provide patients with the latest in high tech healing options with no upfront equipment cost.

Learn More

Advanced Treatments

Provide your patients with the latest in high-tech immobilization, custom adapted for advanced healing technologies like ultrasound, bone and muscle stimulators and TENS units.

Advanced Treatments

Any doctor can do it

Because ActivArmor™ devices are custom designed and fabricated, physicians and patients now have an infinite number of unique design options.

Learn More

Improve Patient Satisfaction

Patients prefer ActivArmor™ over traditional casting and splinting options.

Patient Satisfaction

Patients can stay active

Referring physicians for ActivArmor™ have reported that their patients prefer it over traditional casting and splinting options.

Learn More

Actor

ActivArmor has changed my life! When I was diagnosed with severe never damage by my doctor and needed to be put into a cast, it really hurt me because I knew what they meant. My nerve damage is extensive and will take a year or more to heal, but I still wanted to work out, shower, wash. This is making my healing process so much more enjoyable and while I have a long road of healing ahead, I’m very happy with the cast I have, seeing what I can do with it! These should be all across America and replace fiberglass casts everywhere!

Pro Circuit Rider

"My brace has given me the freedom to do things I couldn't do with a standard cast while giving me the support I need to protect my wrist fracture. I love it and would recommend it to anyone with any problem requiring extra support!"

I love it and would recommend it to anyone with any problem requiring extra support!"

Mother

"My son, Robert, is a very active child: water skiing, climbing, baseball, swimming, you name it and as such he injured his arm the first week of summer vacation. Knowing his injury required a cast, we assumed Robert would miss out on all of the summer fun with his friends. He was going to have to wear a stinky itchy cast like his sister did before him. given that Robert had just been invited to a pool party, I asked the doctor if there were any options. When the doctor prescribed an ActivArmor™ cast we were thrilled! ActivArmor™ was the answer to what would've been a dreary summer otherwise. My son said it was very comfortable to wear. He loved being able to shower with the cast on. No smell, no discomfort, and no irritated/itchy skin."

Patient

"Out and about with my ActivArmor™ cast... I have sent more people to your site than you can believe. Everyone asks about it and I love telling your story. Thank you for giving me back my summer. I have been boating, swimming everyday, paddleboarding, kayaking, and rafting since I got my cast. I am able to shower, and unfortunately do dishes. I can wash my dogs, and hose down my hogs. If when I am throwing hay, it shakes out of the cast. It is not smelly either. My baby Toy Chihuahua loves to chew on it. I just wish I had more than one color to coordinate with my clothes. But I am always answering questions about it and sending people to your site."

Thank you for giving me back my summer. I have been boating, swimming everyday, paddleboarding, kayaking, and rafting since I got my cast. I am able to shower, and unfortunately do dishes. I can wash my dogs, and hose down my hogs. If when I am throwing hay, it shakes out of the cast. It is not smelly either. My baby Toy Chihuahua loves to chew on it. I just wish I had more than one color to coordinate with my clothes. But I am always answering questions about it and sending people to your site."

MD

"The ActivArmor™ brace is the next generation of patient immobilization. Custom fit, 3D printed, waterproof, and breathable! All of the previous problems of inability to shower, swim or workout, itching, hygiene, and incision exposure are solved. Patients will love the comfort and convenience of going back to a more normal life!"

19

"After breaking my wrist and having to have surgery, I thought I wouldn't be able work as a lifeguard this summer. But thanks to ActivArmor™, I'm able to be in a cast to heal my wrist and still be able to lifeguard and get in the water whenever, and however many times needed!"

Ironman World Championships Competitor

"Literally couldn't do it without you!!!"

Product Info and Technical Blogs

ActivArmor for Diabetic/Charcot Foot

May 3, 2022

How much does ActivArmor Cost?

November 10, 2021

How to scan with the iPhone App

September 2, 2021

How To Do Fittings and Adjustments

May 20, 2021

But what about that turnaround time??

January 27, 2021

ActivArmor is Adjustable for Swelling

January 27, 2021

Casting Option Comparison

March 11, 2020

ActivArmor Improves Clinical Staff Efficiency and Patient Throughput

February 19, 2020

Observation of Skin While Immobilized Can Catch Infections Earlier

November 9, 2019

“We get fewer complaints, replacements and adjustments”

October 18, 2019

3D Printing In Your Clinic

July 27, 2019

ActivArmor Saves Patients AND Clinics Time and Money

January 27, 2019

ActivArmor and Edema (Swelling)

January 27, 2019

ActivArmor: customized protection and exposure of wounds, incisions and post-surgical hardware for observation and treatment

January 27, 2019

Prescriber Testimonial – We use ActivArmor for 70% of our casting and splinting

January 27, 2019

ActivArmor – Safe and Skin Friendly

January 27, 2019

ActivArmor – A Strong Competitive Advantage for Providing Clinics

January 27, 2019

ActivArmor Improves Clinical Staff Efficiency and Patient Throughput

January 27, 2019

ActivArmor Clinical Flow Process

January 27, 2019

ActivArmor Casting/Splinting Use Cases

January 27, 2019

ActivArmor Transitions from Cast to Splint Through Healing Phases

January 27, 2019

Pediatric Compliance: Will my child be able to take it off?

January 24, 2019

Get Custom Logos on your ActivArmor!

December 13, 2018

ActivArmor Supports Improved Patient Compliance

August 11, 2018

ActivArmor and Carpal Tunnel Syndrome

August 11, 2018

ActivArmor – A Welcome Alternative For Pediatrics

August 11, 2018

Some Patients Choosing Surgery over a Cast

August 11, 2018

ActivArmor Benefits Geriatric Patients

August 11, 2018

ActivArmor Gets Worker’s Comp Patients Back to Work!

August 11, 2018

ActivArmor for Athletes

May 24, 2018

ActivArmor – The Solution for Cast Claustrophobia

May 23, 2018

How Does ActivArmor Compare to Off-the-Shelf Splints?

May 20, 2018

Athletes Love ActivArmor!

May 17, 2018

ActivArmor In Action

May 11, 2018

Casting and Splinting for Patients with Diabetes

March 17, 2018

ActivArmor: Designed for use with Advanced Healing Technologies

March 3, 2018

Casting: Leaving Physicians in the Dark

February 20, 2018

ActivArmor – A digital solution in an analog market

February 17, 2018

Custom Care through 3D Printing

February 17, 2018

Set for 3d casts in the category "Beauty and Health"

Set for creating a 3D cast "For two" PORUCH

In stock in Poltava

Delivery in Ukraine

399 UAH

Buy

PORUCH Set for 3D cast of hands for two Romantic set for loversIn stock in Kyiv

Delivery in Ukraine

499 UAH

Buy

Online Store KoreaLab

Set for creating a 3D cast "Family" PORUCH 9Ol000

399 UAH

Buy

PORUCH STORE

Set for creating a 3D cast "CHILD" PORUCH

In stock in Poltava

Delivery across Ukraine

2900 UAH0003

Porruch Store

3D Hand cast set for pairs

in a warehouse in Kyiv

Delivery in Ukraine

499 UAH

Buy

online store Korealab

Set for creating 3D cast "Children In stock in Poltava

Delivery across Ukraine

UAH 299

Buy

PORUCH STORE

0002 In a warehouse in Uzhhorod

Delivery across Ukraine

578 UAH

Buy

Fox-Toys

3D set for family hand cast (up to 4 people) + GIFT BOX, family hand cast (from 603)

In a warehouse in Uzhgorod

Delivery in Ukraine

758 UAH

Buy

Fox-Toys

Set for creating 3D Family Porch

in a warehouse in Poltava

Delivery in Ukraine

599 UAH

Buy

Porrech Store

Set for creating 3D Hands for two

Delivery from Dnieper

500 UAH

Buy

Gift Shop in the Dnieper Kozadereza

Set for creating 3D blind "Family" Family "Family" Family "Family " PORUCH

In a warehouse in Poltava

Delivery across Ukraine

599 UAH

Buy

PORUCH STORE

Children's 3D Drawing pen with eco-friendly plastic 3D 3D-6-3 Yellow top9 set New 3D-6-3 Tray0003

In stock

Delivery across Ukraine

645 UAH

545 UAH

Buy

Shop_trend_buy

Set TM Zlokost of hands up to 4 liters together for creating a 3D cast of adults up to 4 liters.

Delivery across Ukraine

for 450 UAH

from 2 sellers

450 UAH

Buy

Online store "Fedchishina Art"

Set for creating a 3D cast "For two" 90 030002 In stock in Poltava

Delivery across Ukraine

399 UAH

Buy

PORUCH STORE

In stock in Kyiv

Delivery across Ukraine

UAH 1,101

UAH 1,099

Buy

Ananas SHOP

Set Eco-friendly 2nd generation plastic 3D drawing pen with LCD display A.N.S.

In stock in Kyiv

Delivery across Ukraine

781 UAH

622 UAH

Buy

Ananas SHOP

Children's 3D plastic pen for drawing with LCD display

In stock in Kyiv

Delivery across Ukraine

781 UAH

622 UAH

Buy

Ananas SHOP

3D Plastic Set Violet Peno Peno 2 generation drawing pen with LCD Display0003

In a warehouse in Kyiv

Delivery across Ukraine

781 UAH

622 UAH

Buy

Ananas SHOP

Children's 2-D plastic drawing pen with LCD universal display ANS

In a warehouse in Kyiv

Delivery across Ukraine

781 UAH

622 UAH

Buy

Ananas SHOP

Ananas SHOP

Plastic 3D pen for children's creativity with LCD display pen 2 Children's 3D0 pen set with LCD display pen 2Ol000

in a warehouse in Kyiv

Delivery in Ukraine

1 083 UAH

883 UAH

Buy

Khaki Shop

set 3D handles MCH Plastic thread 100 meters bright colors KHK 9Ol000 In a warehouse in Kyiv

Delivery across Ukraine

669 UAH

583 UAH

Buy

KHAKI SHOP

Children's 3D pen with LCD display for drawing 2nd generation K0 Plastic Pen 2 Set with Eco Plastic Pen 2

In stock in Kyiv

Delivery across Ukraine

1 360 UAH

1 160 UAH

Buy

KHAKI SHOP

KHAKI SHOP

. TM Zlipok

TM Zlipok

Delivery across Ukraine

for 290 UAH

from 2 sellers

290 UAH

Buy

Online store "Fedchishina Art"

5D Love Story set for creating a cast of two hands. Gift for lovers. TM Zlipok 9Ol000 Poltava

Delivery across Ukraine

399 UAH

Buy

PORUCH STORE

Set for creating a 3D cast of Two hands of an adult and a child together ZLIPOK

Ending

Delivery across Ukraine0003

580 UAH

522 UAH

Buy

90,000 Treatment of fractures using 3D printsContent

-

- History The appearance of technology

- OPERATIONS OPENED OFFICES

903D-printing ORTASS - Best Business Cases for 3D Printed Orthoses

- Pros and Cons

- Further Development of the Technology

3D printed models of fixators or so-called orthoses have been used in the treatment of fractures for a long time, but so far this technology has not received wide application. In this article, we will consider all the pros and cons of this method compared to the traditional plaster cast, and also try to predict the future technological revolution in this most conservative, but very reliable and effective treatment method.

In this article, we will consider all the pros and cons of this method compared to the traditional plaster cast, and also try to predict the future technological revolution in this most conservative, but very reliable and effective treatment method.

The history of the emergence of technology

Orthopedic plasters are used to facilitate the healing process of broken bones. Acting like a pin, the cast keeps the limbs in place to prevent the bone from healing improperly. Modern dressings are made mainly of gypsum or fiberglass, and the idea of creating a fixing (immobilizing) dressing belongs to the Russian surgeon Nikolai Ivanovich Pirogov. In 1847, during the fighting in the Caucasus, he first used a fixing "stuck bandage". At first, starch was used as a hardening agent, which Pirogov later replaced with gutta-percha, and, finally, with gypsum. A modern plaster cast is a hygroscopic bandage sprinkled with plaster. Produced industrially, in sealed packaging. When soaked in water, gypsum plaster begins to harden. Application can take up to 45 minutes, and a full cast can take 24 to 72 hours. Removing plaster is also a difficult procedure: hardened plaster can only be broken safely with a special power saw.

Application can take up to 45 minutes, and a full cast can take 24 to 72 hours. Removing plaster is also a difficult procedure: hardened plaster can only be broken safely with a special power saw.

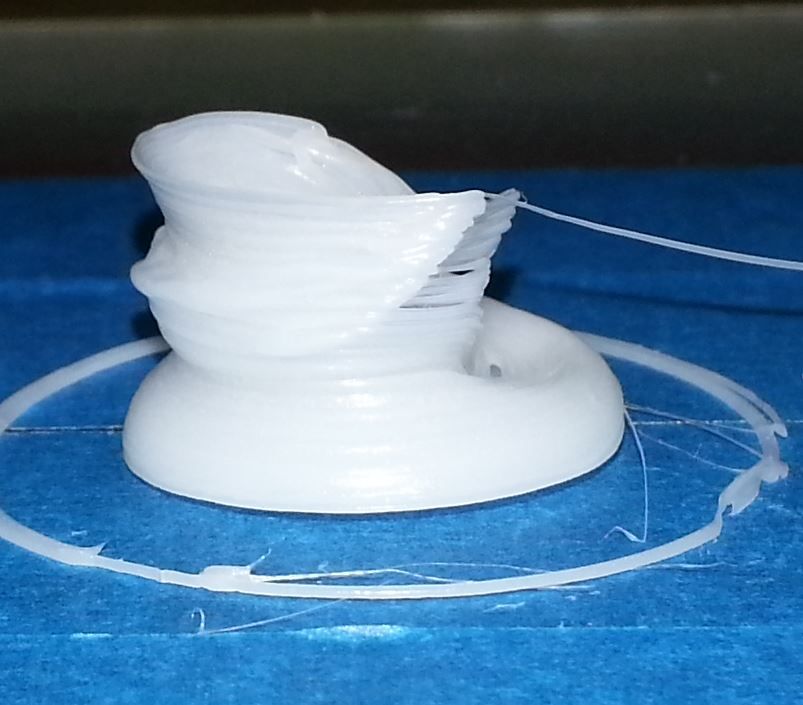

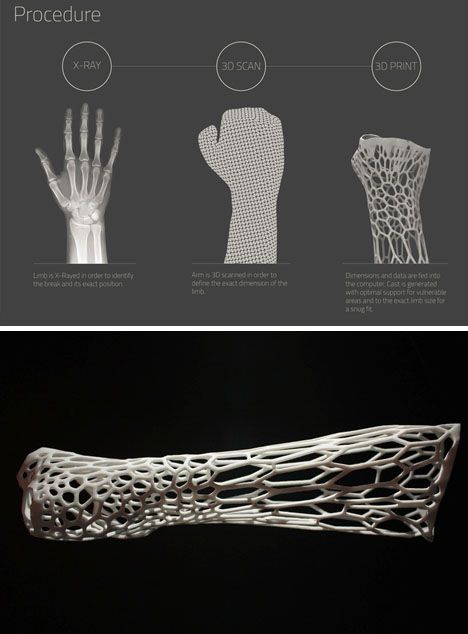

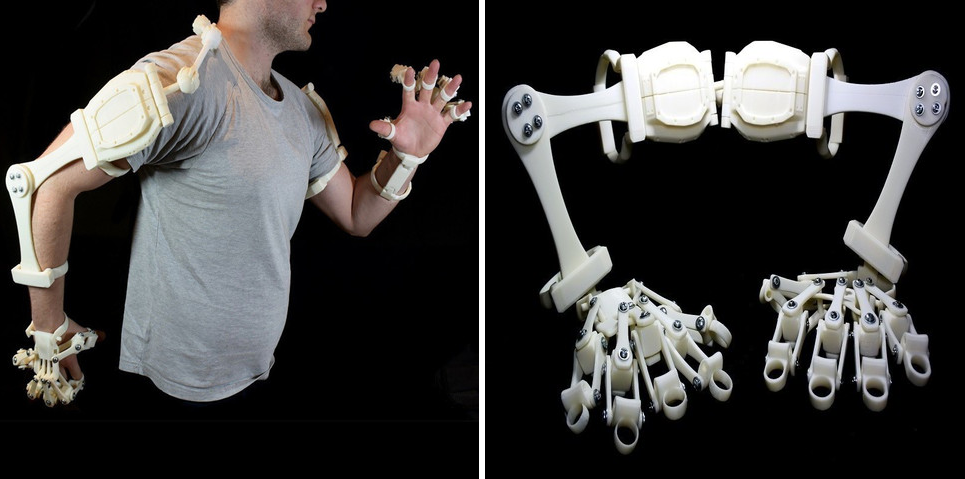

Naturally, there are many opportunities to improve this technology, and the pioneers of 3D printing saw the potential of additive manufacturing to solve the emerging problems. The first 3D printed retainers were introduced in 2013. At the same time, the scheme for the production of an orthosis became clear. It consists of 3 main steps.

Stage 1: X-Ray

To determine the exact position of the broken bone, a standard x-ray of the patient's limb is taken.

Stage 2: 3D modeling

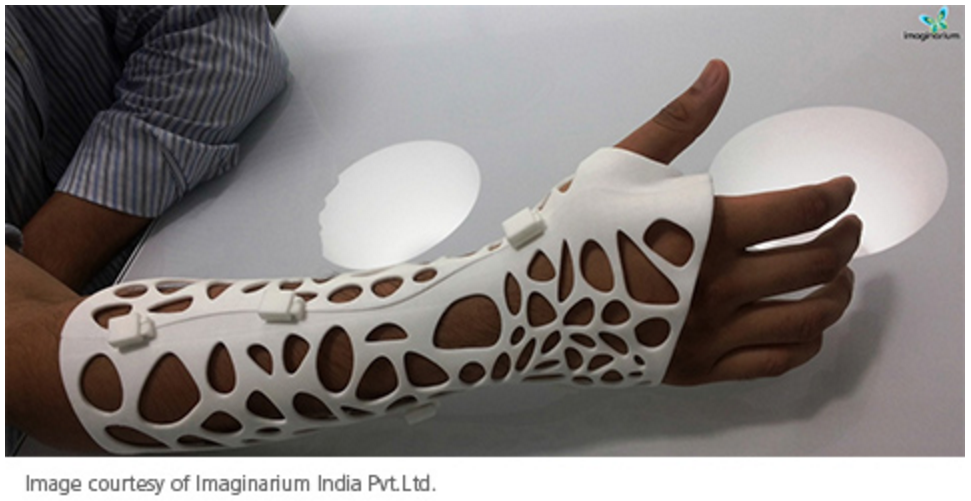

The patient's arm is scanned with a 3D scanner to create a 3D model. Based on the exact dimensions of the patient's hand, a perfectly fitting impression shape can be made.

Stage 3: 3D printing

The orthosis is 3D printed from lightweight plastic and can be fitted to the patient in seconds.

Although the technology has been around for nearly a decade, 3D printed orthoses have yet to see significant adoption. This is mainly due to the lack of specific data on their practical benefits. But the situation began to change.

In a 2020 study, Chinese scientists compared 3D printed orthoses for treating hand fractures with traditional casts and external fixed splints. The results of the study showed that, compared to a cast, 3D orthoses provide a higher level of comfort and a reduction in pain. Technology is being used more and more. Children's Hospital in Colorado announced that it is the first pediatric hospital in the United States to begin fitting 3D printed orthoses for children. The new technology improves the results of treatment, and also removes a number of restrictions that exist when using traditional methods of treatment.

The possibilities offered by 3D printed orthoses

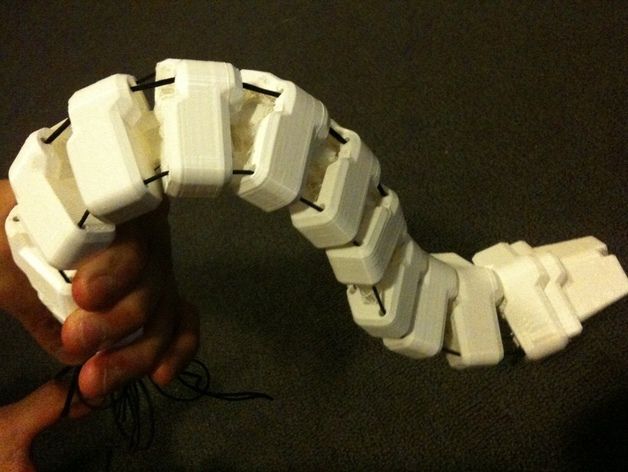

The invention of plaster was one of the greatest medical discoveries. But nevertheless, it has a number of significant drawbacks that can be overcome with the help of 3D printing. Putting on a cast can be a long, laborious, messy, and even painful process. Very careful measurements are required. 3D printing solves all these problems. The orthosis can be easily fixed in seconds with a pair of clips. Removal is also simple, and does not require the use of dangerous electric saws.

But nevertheless, it has a number of significant drawbacks that can be overcome with the help of 3D printing. Putting on a cast can be a long, laborious, messy, and even painful process. Very careful measurements are required. 3D printing solves all these problems. The orthosis can be easily fixed in seconds with a pair of clips. Removal is also simple, and does not require the use of dangerous electric saws.

One of the significant disadvantages of plaster is that it does not breathe. The plaster prevents air from contacting the skin. This can lead to clogged pores, and some patients may develop dangerous skin infections in the wounds. Moreover, constant heat, sweat and pressure can cause very unpleasant itching. In turn, 3D-printed orthoses are made in the form of a lattice, consisting of open sections with plastic racks. This ensures the necessary structure and incomplete coverage of the hand, and therefore a higher level of comfort.

Gypsum cannot be wetted, water will destroy the structure. The patient cannot take a shower, he is afraid to get caught in the rain. 3D printed orthoses are made of waterproof plastic, so you can even swim with them.

The patient cannot take a shower, he is afraid to get caught in the rain. 3D printed orthoses are made of waterproof plastic, so you can even swim with them.

Another disadvantage of conventional gypsum is the inability to properly distribute pressure. Perhaps this is the biggest negative, and it slows down the healing process. A 3D printed orthosis is custom designed and its lattice structure can be designed to add strength to specific areas that need support and relieve pressure elsewhere.

The idea for the mesh structure of the orthosis came from New Zealand engineers Ollie and Jake Eville. They developed a prototype in 2013 and later created one of the world's first orthopedic orthoses using 3D printing. Lightweight, breathable, high-tech and providing localized support for broken bones, the orthosis showed everyone the promise of this technology. This work earned them 2nd place at the International James Dyson Technology Awards and their design vision led them to work as designers on the recent Hollywood blockbuster Blade Runner 2049.

Well, now I would like to talk a little about specific 3D printing technologies in the field of creating orthoses and companies that provide such a service to patients and doctors.

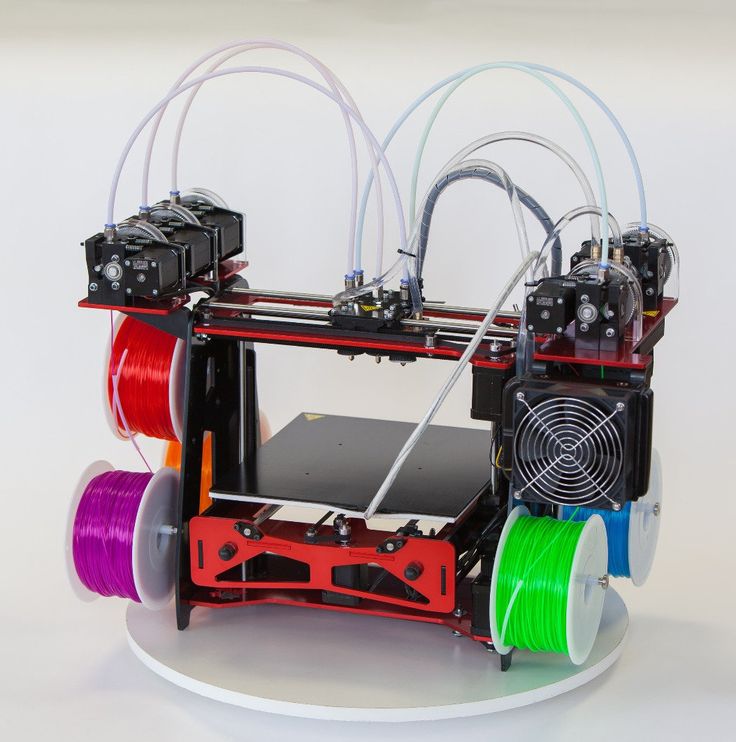

3D printed orthoses

In most cases, 3D printers using FDM technology are used to create 3D printed orthoses. The model is formed by layer-by-layer application of molten plastic thread. The main advantage of the technology is the low cost of the material, and hence the low cost of the model itself. But the main disadvantage is the printing speed, which does not allow you to create a model in the presence of the patient. It is also worth considering the maximum height of the building. Large-format printers such as the Raise3D Pro2 Plus and Picaso Designer XL are great for these tasks, and are highly reliable and capable of 24/7 operation.

Recently, orthoses have also begun to be printed on photopolymer 3D printers, the speed of which is higher, and the finish surface of the finished models is more pleasant to the touch. But this technology has its drawbacks: the need for post-processing of models and the many times higher cost of printing materials. Phrozen Transform Fast and FormLabs 3L photopolymer 3D printers suitable for this task are worth noting. The printer from the American company FormLabs, together with the whole ecosystem built by the manufacturer, can become an indispensable tool, but the model from the Taiwanese manufacturer Phrozen will attract those who are not ready to immediately make big investments, but want to try the possibilities of 3D printing.

But this technology has its drawbacks: the need for post-processing of models and the many times higher cost of printing materials. Phrozen Transform Fast and FormLabs 3L photopolymer 3D printers suitable for this task are worth noting. The printer from the American company FormLabs, together with the whole ecosystem built by the manufacturer, can become an indispensable tool, but the model from the Taiwanese manufacturer Phrozen will attract those who are not ready to immediately make big investments, but want to try the possibilities of 3D printing.

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Formlabs |

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | 9Raise3D 0475

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | Phrozen

Free Shipping

Add to compare

Product added to compare Go

| Manufacturer | PICASO 3D |

3D Printed Orthosis Business Cases

Well, now some interesting examples of businesses from around the world built on the use of this innovative treatment technology.

CastPrint is a service bureau founded by entrepreneurs Janis Olins and Sigvards Krongorns in Latvia. What makes it special is that the bureau develops not only orthoses for certain parts of the hands (wrist, thumb, other fingers), but also one of the first for the treatment of leg injuries.

CastPrint has expanded its business to the point where its technologies have become commonplace in the Latvian healthcare market, and last year expanded to the UK, where several private healthcare firms have adopted the technology into everyday practice.

Spanish company Xkelet decided to speed up the 3D printing of orthoses. Its COO Tim Dobrinich was unhappy with the 2-hour process from scanning to production and decided to cut it down to 15-30 minutes. He used a special camera mount on an iPad and a custom app. The patient's limb is photographed from all sides, and the cast model is formed in seconds. Thus, there is no need for longer separate 3D scanning and modeling. Xkelet orthoses use anchor points called o-rings. They allow you to recast the same model several times, making the product reusable. In April 2021, the company received an award at the international design festival Red Dot Award in Berlin for the design of a 3D printed orthosis.

Xkelet orthoses use anchor points called o-rings. They allow you to recast the same model several times, making the product reusable. In April 2021, the company received an award at the international design festival Red Dot Award in Berlin for the design of a 3D printed orthosis.

The Russian company Zdravprint took a different path and began to create orthoses based on the patient's biometric parameters. A special program converts the dimensions of the patient's arm into a 3D model of an individual orthosis. Printing time is 15 to 90 minutes. Products have an internal three-dimensional structure, which makes the thermoforming process more convenient. Forming the product for the patient takes 5 minutes.

Zdravprint works with leading Moscow medical institutions, for example, from 294th City Clinical Hospital of Moscow and 4th City Clinical Hospital of Moscow. Hundreds of patients have already been treated with the company's products.

Pros and cons

Summing up, I would like to once again emphasize the pros and cons of the new method. The advantages include patient comfort, easy application and removal, as well as a lower cost compared to a plaster cast. The custom design of the 3D printed orthosis makes the treatment process much more efficient, and the open lattice structure improves breathability, which is especially important when treating children. It is strong and lightweight, and does not restrict movement like regular plaster. Reuse also reduces costs (as suggested by Xkelet). Orthoses can be redesigned and modified using existing structure and less material.

The advantages include patient comfort, easy application and removal, as well as a lower cost compared to a plaster cast. The custom design of the 3D printed orthosis makes the treatment process much more efficient, and the open lattice structure improves breathability, which is especially important when treating children. It is strong and lightweight, and does not restrict movement like regular plaster. Reuse also reduces costs (as suggested by Xkelet). Orthoses can be redesigned and modified using existing structure and less material.

On the negative side, there is less data on the effectiveness of use in the treatment of injuries than on the use of gypsum. Even now, as more and more studies are being conducted that support this effectiveness, a medical consensus has yet to be reached. For this reason, the technology has not yet been widely adopted. It will take time to collect the evidence base, and we just have to wait a bit. It is also difficult to use orthoses for the treatment of leg fractures. They are comparatively larger and more uncomfortable than their counterparts for hand fractures, make it difficult to wear socks and shoes, and have more restrictions.

They are comparatively larger and more uncomfortable than their counterparts for hand fractures, make it difficult to wear socks and shoes, and have more restrictions.

Further development of technology

One of the next tasks that 3D printed orthoses should solve is to fix entire limbs, and not just a hand, wrist, foot or ankle. Industry leaders are trying to develop hand orthoses that extend beyond the elbow to reach the shoulder and biceps as well as the hip to treat leg fractures. Some of the most devastating and hard-to-heal injuries occur in these areas, mostly as a result of car and motorcycle accidents, and casts are used for such injuries as well.

3D printed orthoses are currently available worldwide in the paid healthcare market. However, patients receiving free public health care are unlikely to hear about them. This is primarily due to the same lack of the necessary research base, clearly confirming the effectiveness and safety of the technology.