3D printer to make jewelry

5 Best 3D Printers For Jewelry 2023 (All Price Ranges!)

3D printing jewelry rarely means 3D printing actual wearable pieces made from filament or resin, but instead using a jewelry 3D printer to create high-resolution wax models of the eventual gold or platinum design, used to create a mold that is burned out and cast via investment casting or lost wax casting.

- We also have an article ranking some of the most beautiful 3D printed jewelry.

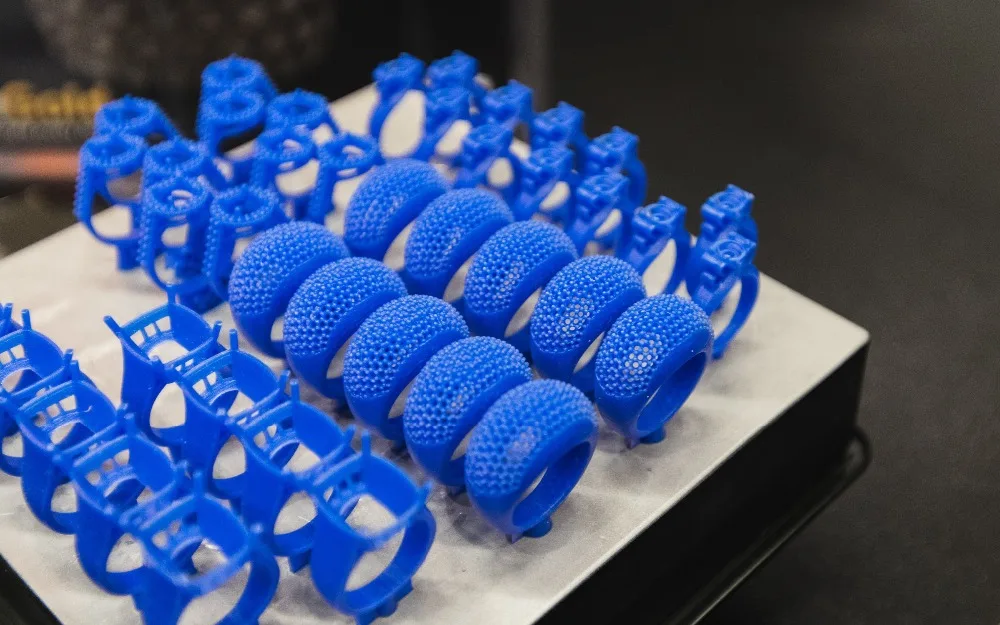

In fact, much jewelry is now created this way. There are entire factories of resin 3D printers set up to create castable wax resin models to be molded and then melted to create high-end jewelry.

However, owning your own jewelry 3D printer gives you more control over your production, and saves you money compared with paying someone to print your own molds. Castable resin molds can be produced for rings and other jewelry pieces for just the cost of the resin used, perhaps a dollar or two, whereas you could end up paying $25+ for someone to print it for you.

To insert the table into a page, post, or text widget, copy the Shortcode and paste it into the editor.

| Name | Build volume (mm) | Price | Where to buy |

|---|---|---|---|

| Elegoo Mars 2 Pro | 129 x 80 x 160 | $250 | Elegoo here |

| Peopoly Phenom | 276 x 155 x 400 | $1,999 | Matterhackers here |

| Formlabs Form 3 | 145 x 145 x 185 | $3,499 | Dynamism Store here |

| Solidscape S325 | 6″ x 6″ x 4″ | Quote | Get a Quote here |

| EnvisionTEC D4K Jewelry | 148 x 83 x 110 | Quote | Get a Quote here |

- CAD File: Either design your own jewelry piece on CAD software, pay someone to design your desired piece, or pay for an existing jewelry STL file online and download it.

- Slice & Prepare: If not already an STL or other compatible file, export it as one.

Then import it into your 3D slicer and slice it for printing.

Then import it into your 3D slicer and slice it for printing. - Print the model: Use a castable wax resin designed for jewelry model 3D printing.

- Molding: Pour your molding material over your wax jewelry model, and leave it to harden.

- Melt the wax: Heat your new mold so that the original wax model melts and evaporates, leaving a hollow empty space inside with the exact dimensions of your planned jewelry piece.

- Casting: Pour melted liquid metal e.g. gold, silver or platinum into the mold to cast it.

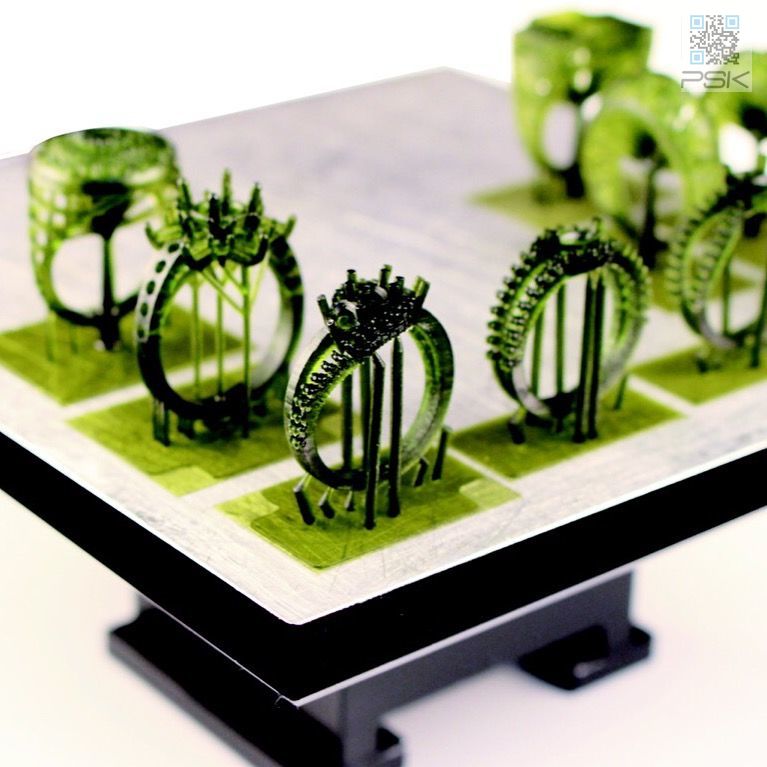

Resin 3D printers are considered the best 3D printers for jewelry. They are used with specialized castable wax resins, which rather than going from solid to liquid when heated, transition directly into a gas from their solid state.

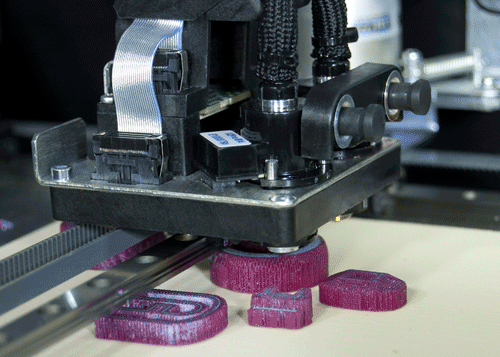

Though prevalent, FDM 3D printers are very rarely used as 3D printers for jewelry. They are not capable of the same resolutions, crisp surface finishes or accuracies required for intricate and delicate jewelry pieces. Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

Jewelry 3D prints need to be incredibly highly detailed and accurate — an inaccurate mold will create inaccurate and unimpressive jewelry.

Additionally, the better the jewelry 3D printer quality, the less finishing the resulting jewelry piece will need to perfect it.

What do jewelry 3D printers make?Usually they 3D print wax jewelry molds, for example of ring designs before any stones are set, or individual chain links.

However, they can also be used to create like-for-like “fitting pieces” for testing the fit of an as-yet unmade ring for a client’s finger. Though making the final ring would be expensive and take time, an exact replica can be made on a jewelry 3D printer in just minutes to test the sizing.

This saves the trouble of creating a piece just to find it doesn’t fit properly. Whereas for jewelry molds specialized castable resins are required, for these fitting pieces standard resins can be used.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

Learn more

The best 3D printers for jewelry

1 — Elegoo Mars 2 Pro

- Jewelry 3D printer price: $250 — Available at Elegoo store here / Available on Amazon here

- Build volume: 129 x 80 x 160 mm

Featuring a 6-inch monochrome LCD screen offering HD 2K resolution, the Elegoo Mars 2 Pro offers precise jewelry printing for the price. Rather than DLP or SLA, the Mars 2 Pro uses LCD printing to cure entire resin layers at once, quickening print speeds and able to print at 30-50mm/h.

Other 3D printers for jewelry on this list offer better quality, but for the price the Mars 2 Pro is a great option. It is sturdily built with its CNC-machined aluminum structure for better stability, and the mono LCD is upgraded for improved lifespan to save you money over the long term. It’s one of the best 3D printers for jewelry under $500.This is the detail we achieved when using the Elegoo Mars 2 pro – enough for fine jewelry pieces.

The Elegoo Mars has Z-axis resolutions of up to 0.00125mm, XY-resolutions of 0.05mm, and weighs 6.2kg. It also supports 12 different languages, so if you’re not a native English speaker you can choose your own language.

The video below even shows, from start to finish, how accurately you can make wax models for gold jewelry using a standard Elegoo Mars. Even this standard version produces good quality wax models, and the Elegoo Mars 2 Pro comes with several upgrades on the original.

2 — Peopoly Phenom

- Jewelry 3D printer price: $1,999 — Available on Matterhackers here

- Build volume: 276 x 155 x 400 mm

The Peopoly Phenom offers truly enormous printing volumes, almost unheard of for a jewelry 3D printer. For jewelers looking to produce many rings or other pieces simultaneously, this larger volume provides space for dozens of wax jewelry models. If you’re in demand for jewelry and want to make as many as possible then this larger build volume is crucial.

With its 4K high resolution projection quality using MSLA technologies, the Phenom produces crisp, accurate and consistent jewelry molds. MSLA takes elements from both LED and LCD technologies, the result being fast, accurate and repeatable jewelry 3D printing.

- The even larger version, the Peopoly Phenom L, is available here.

- For faster print speeds, the premium Peopoly Noir is available here.

The Phenom uses Chitubox resin 3D slicer, useful if you’ve previously used it previously on another printer. Overall, it’s one of the best 3D printers for jewelry, and a great choice for people looking to make large numbers of castable wax jewelry models.

3 — Formlabs Form 3

- 3D for jewelry price: $3,499 — Available on Dynamism here

- Build volume: 145 x 145 x 185 mm

Seen as the gold-standard in professional resin printing, the Form 3 is capable of fantastic precision, with its new custom Light Processing Unit (LPU) using lenses and mirrors to accurately print jewelry models.

For the price, the Form 3 offers 25-micron resolutions and very consistent and repeatable printing. For those looking for a 3D printer for jewelry able to produce the same design flawlessly again and again, or for producing custom intricate designs, the Form 3 can handle both without issue.

Formlabs make their own castable wax resins designed for jewelry with “crisp settings, sharp prongs and smooth shanks.” Within the Formlabs workflow therefore is a complete jewelry production process for wax models, though the Form 3 also excels as a dental 3D printer and in other industries, too.

4 — Solidscape S325

- Price: Requires a quote

- Build volume: 6” x 6” x 4”

Soliscape make specially designed jewelry 3D printers, so any Solidscape printer you buy is optimized for jewelry printing. Whereas other printers like the Form 3 are designed to excel in a number of industries, the Solidscape S325 is designed with jewelry wholly in mind.

The S325 is the cheapest of Solidscape’s jewelry 3D printer range. It offers great accuracy, material jetting wax models for the precise and effective investment casting of precious metals. Solidscape stress that all their models are castable in gold and platinum, and do not expand or shrink during the investment casting process.

It offers great accuracy, material jetting wax models for the precise and effective investment casting of precious metals. Solidscape stress that all their models are castable in gold and platinum, and do not expand or shrink during the investment casting process.

The S325 is capable of 0.001-inch layer thicknesses, with accuracies of 0.005 inches. Overall, as a specialized 3D printer for jewelry, Solidscape have a rich history in jewelry 3D printing and can be trusted to deliver high-quality and precise ring wax models, time and time again.

5 — EnvisionTEC D4K Pro Jewelry 3D printer

- Jewelry 3D printer price: Requires a quote

- Build volume: 148 x 83 x 110 mm

Described by EnvisionTEC are the highest resolution professional-grade desktop 3D printer, as well as claiming to have the fastest speed, the D4K is well suited to jewelry 3D printing. Speed and accuracy are key to jewelry production, with the printer’s 4K UV DLP projector able to create crisp wax models at speed to be cast into stunning jewelry pieces.

EnvisionTEC are the originators of DLP 3D printing, having pioneered the process more than a decade ago. Now, their advanced D4K Pro can produce accuracies of up to 25 microns in the XY resolution, and 1 micron on the Z axis.

The jewelry 3D printer works well with EnvisionTEC’s WIC100 Series wax material, used to then burn out and investment cast precious jewelry. Though it’s an industrial 3D printer costing over $10,000, larger jewelers will find the D4K one of the best 3D jewelry mold printers.

Advantages of owning a jewelry 3D printer

- Saves money long term: rather than paying a 3D printing service $20+ to print your mold for you, you can print your own wax jewelry molds for just a dollar each.

- Control your own jewelry production: with the ability to print jewelry in-house, you control your own workflow and apart from resin shortages, cannot be slowed down by supplier failures. Your order will always be top priority.

- Fast: going from CAD model to a piece ready to be investment cast is quick, especially when you can print and cast everything in one place.

- Very accurate: precise, smooth and intricate jewelry is not an issue for jewelry 3D printers, some able to print with below 10-micron accuracy to capture your ring’s most delicate and beautiful features.

- Repeatable and scalable: 3D printers for jewelry can create potentially dozens of identical or customized ring molds at once, perfect for scalable jewelry production.

Printing with Metals, Plastics, and Castable Resins

Rapid development of additive manufacturing leads to considerable changes in a lot of industries. Some of them use 3D technologies at all the stages of production, starting with 3D scanning and then employing 3D printing for prototyping or end-use parts production. Jewelry is one of the fields where digital technologies have only started their expansion, often being a bridge to traditional methods.

Credit: n-e-r-v-o-u-s.com

Digital revolution in jewelry

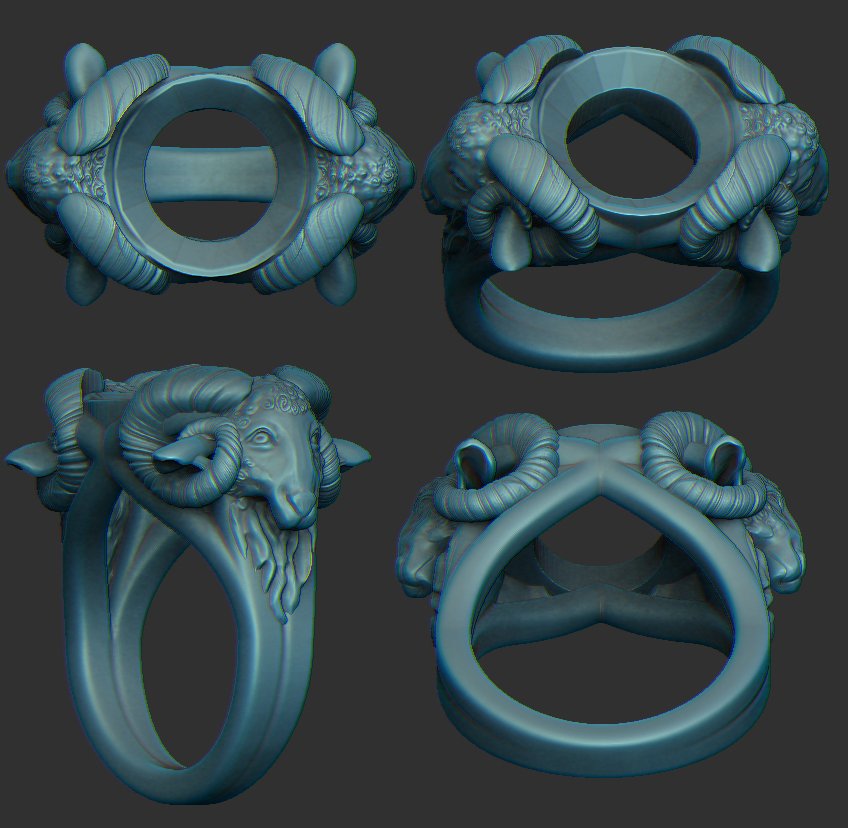

The craft of jewelry is as old as time, and it has always involved a lot of skill and time spent on every single item creation. Besides, there are always limitations to human possibilities — however skillful a craftsman was, some most intricate design concepts could only exist in their imagination.

Besides, there are always limitations to human possibilities — however skillful a craftsman was, some most intricate design concepts could only exist in their imagination.

Credit: Pinterest

With 3D printing development, more and more people in the jewelry industry are discovering the opportunities it provides both from the artistic and business perspective.

The traditional method of jewelry manufacturing implies lost-wax casting. Casting patterns creation is an expensive and time-consuming part of the process, and this is where 3D printing can be of great help, becoming a bridge to conventional manufacturing. What’s so good about using digital technologies in such a traditional field? Let’s see.

Credit: fastcastings.com

Why 3D print jewelry

Complete design freedom

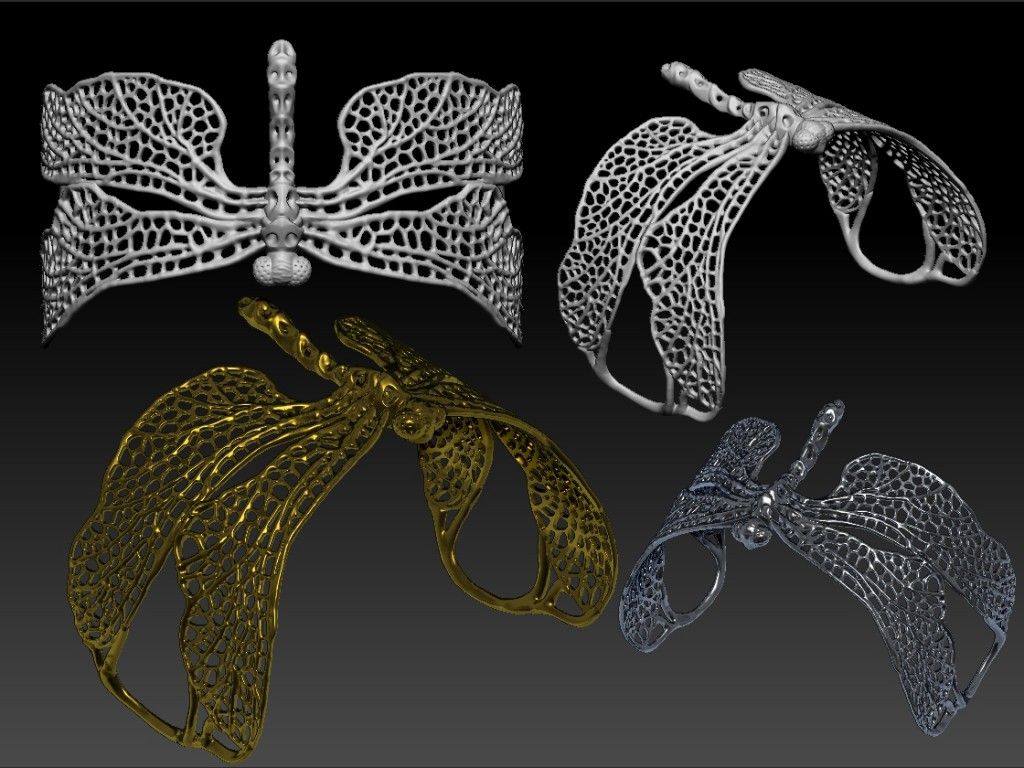

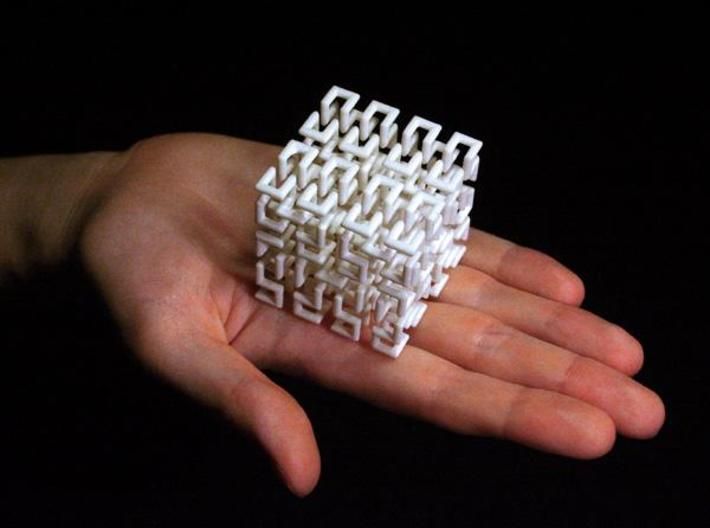

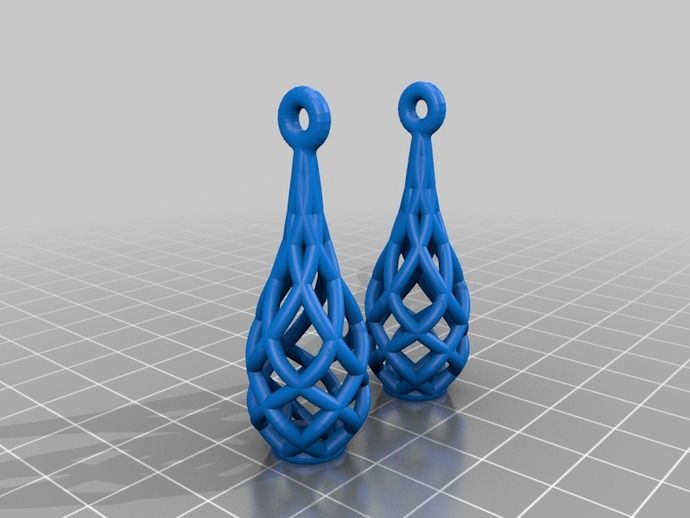

As mentioned, there are certain design limitations in traditional production of casting patterns that are made either by hand or using CNC machines. With digital design opportunities and 3D printers capable of reproducing the digital models with extreme precision and accuracy, it’s now possible to create wax casting patterns of any complexity. The use of 3D printing has brought up new standards in the art of jewelry, allowing for the designs that could have never been realized before.

With digital design opportunities and 3D printers capable of reproducing the digital models with extreme precision and accuracy, it’s now possible to create wax casting patterns of any complexity. The use of 3D printing has brought up new standards in the art of jewelry, allowing for the designs that could have never been realized before.

Credit: indiamart.com

Unlimited customization opportunities

Customization is of considerable importance in jewelry as customers often want to get one of a kind adornment. 3D printing provides vast opportunities for custom products, either created from scratch, or by adjusting the already existing design according to the customer’s wish. The customization process doesn’t require additional costs and takes considerably less time and effort than in traditional production, where any changes made upon the product jacked up the price.

Credit: sculpteo.com

Faster prototyping

With 3D printing, customers have a try-on option to make sure the model fits perfectly and completely meets all their needs, before the final part is made. Printed resin prototypes are affordable and quick to make, they feature high quality and precision and can give the true-to-life impression of the future model.

Printed resin prototypes are affordable and quick to make, they feature high quality and precision and can give the true-to-life impression of the future model.

Credit: additive-plus.com

Lower cost

Batch-manufacturing in jewelry 3D printing allows reducing the production costs, as a whole run of wax patterns can be printed in one go, thus saving material and shortening the production time; you can also print different designs at a time. All this makes jewelry manufacturing more cost-effective than ever before.

Credit: hubs.com

3D Printing technologies in jewelry production

Basically, there are two ways of implementing additive manufacture into the jewelry business, namely direct and indirect 3D printing, the former being less common, at least for now.

Direct 3D printing

Direct 3D printing of jewelry implies using metal (SLM or DMLS-based) printers to build the final parts right from the digital models, created in CAD software. The parts can be printed with gold, silver, or platinum alloys or other metal powders. Such an approach completely excludes traditional techniques from the production cycle and turns it entirely digital.

The parts can be printed with gold, silver, or platinum alloys or other metal powders. Such an approach completely excludes traditional techniques from the production cycle and turns it entirely digital.

Credit: Pinterest

Despite all the general advantages of 3D printing, discussed above, this particular method is not very popular as it is more expensive than investment casting, and the printed parts require significant post-processing. Besides, precious metals are very difficult to print as they are highly reflective and thermally conductive. So, there are few printers in the market that can work with them. Still, rapid progress in digital technologies can change the situation for the better.

Indirect 3D printing

In this method, 3D printing is used to optimize the traditional lost-wax casting process to speed up the production and make it more flexible and cost-effective.

Credit: reddit.com

The jewelry 3D printing process

- First the design of the future piece is created using CAD software.

The STL (or other compatible) file is imported to a 3D slicer and prepared for printing.

The STL (or other compatible) file is imported to a 3D slicer and prepared for printing. - The model is printed using castable wax materials to make a wax casting pattern. At this stage you may want to print a try-on part first to ensure the fit and design are just right.

- The liquid molding material is poured over the wax pattern and left to solidify. Thus a mold for the future part is created.

- When the mold is hard, it is placed into a furnace to melt or burn out the wax pattern, forming a so-called negative mold.

- The final casting material, which is usually melted gold, silver, brass, or other metal, is poured into the mold and left to cool and solidify.

- The mold is removed and the final part is ready for post-processing.

What are 3D printers for jewelry?

For direct metal printing, SLM or DMLS printers are used. However, very few of them can work with precious metals alloys, so other metals, like steel or bronze, can also be used.

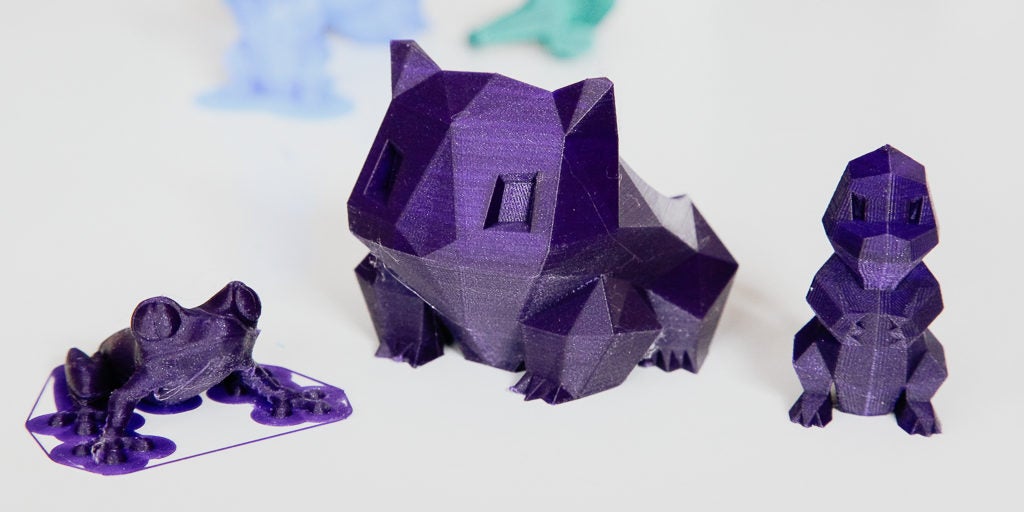

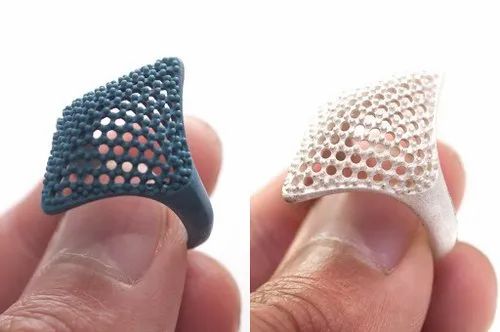

Some jewelers create their collections using SLS technology, printing unique modern jewelry pieces with nylon or polyamide.

Credit: dianalaw.com

3D printing of wax casting patterns requires exceptional precision and accuracy, as well as the use of appropriate wax-like materials that can be completely melted or burnt out afterwards. So, the best options possible here are resin or material jetting technologies.

Now let’s see which printer models are the most suitable for jewelry manufacturing.

The best 3D printers for jewelry 2022

Flashforge WaxJet 400

The Flashforge WaxJet 400 is a professional 3D printer based on MJP (MultiJet Printing) technology. It prints wax casting patterns for investment casting and works with proprietary materials for parts and support structures printing. The device can print layers at the height of 16 microns with the printing resolution of 1200 x 1200 x 1600 dpi and the accuracy of ±0. 04 mm / 20 mm, which provides accurate highly detailed models with smooth surface finish. The large build volume of 289 x 218 x 150 mm allows printing multiple models in one go and together with fast print speed makes for high productivity of the WaxJet 400.

04 mm / 20 mm, which provides accurate highly detailed models with smooth surface finish. The large build volume of 289 x 218 x 150 mm allows printing multiple models in one go and together with fast print speed makes for high productivity of the WaxJet 400.

Pros

- High print quality

- Extreme productivity

- Highly automated printing process

- Large build volume

Cons

- Can print with only proprietary materials

Phrozen Sonic 4K 2022

The Phrozen Sonic 4K 2022 is a large resin 3D printer designed for the dental industry, and it absolutely meets the requirements of jewelry production. It sports a monochrome LCD matrix with a resolution of 3840 x 2160 and a build volume of 135 x 75 x 200 mm. The optical system of the device has been improved compared to the previous models. The Phrozen Sonic 4K is equipped with a powerful ParaLED® 3.0 module which provides uniform light exposure and, consequently, uniform layer thickness over the entire area of the print. The minimum layer height of 10 microns ensures exceptional print quality. Phrozen offers a choice of castable resins that can be used with the Sonic 4K 2022 to print mold patterns for investment casting.

The minimum layer height of 10 microns ensures exceptional print quality. Phrozen offers a choice of castable resins that can be used with the Sonic 4K 2022 to print mold patterns for investment casting.

Credit: @georgebulte / Instagram

Pros

- Fine precision and uniformity of the prints

- Fast print speed

- Wide choice of materials, including castable resins

- Wide connectivity options

Cons

- Rather small build volume

Anycubic Photon Mono X

The Anycubic Photon MonoX is a large-format resin 3D printer based on LCD technology. Uniform light exposure over the entire print area is provided by the 8.9" 4K LCD screen and a new parallel light source. The build volume of 192 x 120 x 245 mm and fast print speed stand for high productivity, while the 10-micron minimum layer height allows printing high quality casting patterns for jewelry manufacturing. For better performance and more convenient post-processing the Photon Mono X can be supplemented with the Anycubic Wash and Cure Machine 2.0.

For better performance and more convenient post-processing the Photon Mono X can be supplemented with the Anycubic Wash and Cure Machine 2.0.

Pros

- Fast print speed

- Great print quality

- Large build volume

- Built-in safety functions

- Fast and easy set-up

Cons

- Print bed is difficult to clean

Original Prusa SL1S Speed

The Original Prusa SL1S Speed is an LCD-based resin 3D printer featuring a 5.96'' monochrome LCD screen with 2560 x 1620 resolution and a new optical system with a four times more powerful UV LED panel than the previous SL1 model. The print speed of the SL1S Speed is remarkably fast — the curing time for a single layer is just 1.4 seconds. Fast accurate printing and compatibility with different types of 405 nm UV resin make the Prusa SL1S a great option to use in jewelry for casting patterns production. The printer can be bought stand-alone or as part of a special bundle of the Original Prusa SL1S 3D printer and the Curing and Washing Machine.

Pros

- Fast speed

- Excellent print quality

- Easy operation

- Compatible with third-party materials

Cons

- Rather small build volume

Farsoon FS273M

The Farsoon FS273M is an MLS (metal laser sintering) industrial 3D printer featuring rather compact size for a professional machine, still high throughput and impressive build volume which is a cylinder of 275 x 275 x 355 mm. The FS273M can be equipped with a single or dual 500W fiber laser and a high-precision digital galvo system, and can print layers at the height of 20 microns providing detailed precise models that are a must while printing jewelry. The printer is an open material system and is compatible with a great variety of proprietary and third-party metal powders, some of them being suitable for printing end-use jewelry pieces.

Pros

- Industrial-grade print quality

- High print speed

- Sizable build volume

- Open material system

- User-friendly operation

BLT-S210

The BLT-S210 is an SLM 3D printer capable of printing with a large number of metal alloys, including Titanium, Aluminum, Cobalt Chromium, Stainless Steel, Copper, and a lot more. The 500W laser and F-Theta optical system ensure high-quality metal parts with excellent mechanical properties and repeatability. The compact build area of 105 x 105 x 200 mm is perfect for batch-manufacturing of small jewelry items or for printing larger parts. Operation and maintenance of the device are easy and convenient due to the modular design of the S210. The printer is an open-parameter system, so the user is able to edit 294 parameters to precisely adjust the printing process and get the best result possible.

The 500W laser and F-Theta optical system ensure high-quality metal parts with excellent mechanical properties and repeatability. The compact build area of 105 x 105 x 200 mm is perfect for batch-manufacturing of small jewelry items or for printing larger parts. Operation and maintenance of the device are easy and convenient due to the modular design of the S210. The printer is an open-parameter system, so the user is able to edit 294 parameters to precisely adjust the printing process and get the best result possible.

Pros

- 15 microns minimum layer height

- High-quality prints with great repeatability

- Wide material compatibility

- Intelligent software

Cons

- Needs a lot of installation space

Bottom line

The use of additive manufacture technologies in jewelry has given a boost to the industry development and set up new standards in jewelry design. The possibility to print objects of extremely complex geometries and ultimate customization options open unlimited opportunities for the designers and provide the customers with absolutely new fascinating jewelry pieces.

Choice of technology and 3D printer for jewelry making, pros and cons

Currently, there are many new technologies that are designed to simplify production in various industries. Progress does not stand still and, despite some opponents, 3D printing has its own niche in the production of jewelry.

3D printing can speed up and reduce the cost of jewelry production due to the low cost of consumables. With 3D printers, jewelers have the ability to quickly change the design of a product and make prototypes at least several times a day. For many jewelry industries, 3D printing is becoming a good alternative or addition to milling machines and other equipment.

Until now, some believe that handmade is a sign of craftsmanship, especially when it comes to creative work, and models made using 3D modeling and printing are amateurish. But many people forget that behind the computer is the same person who not only mechanically presses the buttons, but also puts his soul into his creation.

Benefits of 3D printing

In order to understand how justified the use of a 3D printer is, you need to know how jewelry is made. This is very painstaking work. No wonder the expression "jewelry work" appeared, denoting a very delicate and complex work.

Any decoration begins with a sketch. Usually several sketches are made in order to accurately determine the design and location of the inserts. Not only stones are used as decor, it can be elements made of wood, bone, precious metals, it all depends on the designer's imagination.

At the next stage, the product is drawn in a 3D editor. This allows not only to visualize the future product, but also to correct some errors and inaccuracies made at the design stage.

Ring model

Some craftsmen still carve "stencils" by hand. Such work requires certain skills and perseverance. Usually this is how products are made that will be cast in a single copy.

A finished 3D model can have several ways to be implemented in a physical version - this is milling or 3D printing.

Stencil milling

Currently, 3D printing is not much inferior in accuracy to a milling machine and often has a significant advantage in speed, despite the fact that after printing it is still necessary to separate the supports and clean up the points of contact with the model. Once a physical model has been obtained, it can be cast immediately if the material used is wax or a burnable polymer.

If it is necessary to cast a large batch of products, then a mold is made from the master model made with the help of special rubber for subsequent wax casting. There are many types of rubber that vary in hardness and curing temperature. Rubber is selected depending on the material from which the master model is made.

For pouring molds, a special machine is usually used - an injector. In some models, you can not only heat the wax, but also vacuum it or leave it under pressure. This helps to reduce the number and size of air bubbles for better pouring of the rubber mold.

This helps to reduce the number and size of air bubbles for better pouring of the rubber mold.

In home workshops, silicone is used instead of special rubber. After all, a special machine is needed to vulcanize rubber. But rubber molds are too soft and short-lived for making a large batch of stencils.

After making the required number of stencils, they are collected in "Christmas trees". "Elks" are waxes soldered to a wax rod. To save space, the distance between them is very small and they resemble fluffy Christmas trees, hence the name. The finished Christmas tree is weighed to calculate the required amount of metal. In some places, stones are immediately inserted into the stencils, unless another mounting option is provided.

Stencil Christmas trees

Ready "Christmas trees" are placed in a special cylindrical "cassette" without a bottom, which is called a flask, and filled with a gypsum-based molding mass. The flask with uncured gypsum must be evacuated to get rid of unnecessary air bubbles that can lead to defects on the surface of the finished casting.

The flask with uncured gypsum must be evacuated to get rid of unnecessary air bubbles that can lead to defects on the surface of the finished casting.

After hardening, the gypsum flask is sent to a muffle furnace to melt the wax.

The calcination mode is selected depending on the material of the wax. For wax or burnout polymer, different modes are needed in order for the material to be completely removed from the gypsum!!!!!!

When all the wax is melted, cavities are formed inside the gypsum, repeating the contours of the wax. Metal is poured into these voids. After casting, the flask is cooled and the gypsum mold mass is washed out under the pressure of water. The result is a metal Christmas tree.

Herringbone after casting

Finished castings are cut from the Christmas tree and washed, polished, if necessary, blackened by the master until the desired appearance is achieved.

3D printers for jewelers

There are several 3D printing technologies that may be suitable for the needs of jewelers. Each has its pros and cons. Some 3D printers are ideal for a large workshop, and some are ideal for a small workshop.

SLA

SLA or stereolithography is based on the principle of layer-by-layer solidification of a photopolymer resin under the action of a UV beam. The UV beam is focused by means of mirrors on the surface of the resin and illuminates the model in layers.

How the SLA Printer Works

SLA 3D printers were the first to be noticed by jewelers. SLA devices are compact, while they have high printing accuracy.

Pros and cons

pros

Minuses

Print examples

From prototype to finished product

Cast and printed ring

Rating of printers.

Leadership among the production of SLA 3D printers is held by Formlabs.

Formlabs Form 3

Formlabs Form 3

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 14.5×14.5×18.5cm

Layer thickness: 25 – 300 µm

A professional 3D printer that is popular with professional jewelers and dentists.

Formlabs Form 3L

Formlabs Form 3L

Specifications:

XY resolution: 25 µm

Laser spot size: 85 µm

Laser power: One 250mW laser

Working area size: 33.5×20×30cm

Layer thickness: 25 – 300 µm

Form 3L differs from younger models in its large print area, which allows you to produce truly large products without losing quality and accuracy.

DLP/LCD

DLP is very similar to SLA, only as a source of UV radiation, to illuminate the photopolymer resin, not a directed beam of light is used, but a DLP projector. DLP printers illuminate the entire work area at once, so they greatly outperform SLA in print speed.

DLP printers illuminate the entire work area at once, so they greatly outperform SLA in print speed.

How a DLP Printer Works

Today it is one of the most affordable photopolymer 3D printing technologies. In terms of cost, LCD printers have caught up with the price level of amateur FDM. DLP printers are much more expensive due to the use of an expensive projector as a UV source.

The projector is of course more expensive, but more durable, on the other hand, the LCD display is not so expensive and can be easily seen, unlike the projector. What to choose each user decides for himself.

Pros and cons.

pros

Minuses

Print examples

Comparison between 3D printed master model and molded part

Burnout resin model and finished product

Demonstration of products cast with burnout resin

Rating of printers.

The print accuracy of LCD printers depends on the pixel size, so you should pay attention to this parameter when choosing a printer.

Anycubic Photon Mono

Anycubic Photon Mono

Specifications:

LCD display resolution: 2560x1620 (2K)

XY Positioning Accuracy: 0.051mm

UV wavelength: 405 nm

Working area size: 130x80x165 mm

Layer thickness: 0.01-0.15mm

The Anycubic Photon Mono is an inexpensive LCD machine ideal for hobby printing. The monochrome display allows you to reduce the exposure time and speed up printing.

Phrozen Sonic 4K

Phrozen Sonic 4K

Specifications:

LCD resolution: 6.1" 4K Mono LCD

XY positioning accuracy: 35 microns

UV wavelength: 405 nm

Working area size: 134x75x200 mm

Layer thickness: 0.01-0.30mm

Phrozen Sonic 4K is specifically designed for use in the dental and jewelry industry. Despite its compact size, the printer is not inferior to professional machines in accuracy, and the exposure time of one layer is only a few seconds.

Phrozen Sonic Mighty 4K

Phrozen Sonic Mighty 4K

Specifications:

LCD resolution: 9.3" 4K Mono LCD

XY positioning accuracy: 52 microns

UV wavelength: 405 nm

Working area size: 200x125x220 mm

Layer thickness: 0.01-0.3mm

Phrozen Sonic Mighty 4K is a professional device with a large print area. This allows you to quickly produce small batches of models.

Phrozen Sonic XL 4K

Phrozen Sonic XL 4K

Specifications:

LCD resolution: 8.9" 4K Mono-LCD

XY positioning accuracy: 50 microns

UV wavelength: 405 nm

Working area size: 190x120x200 mm

Layer thickness: 0.01-0.3mm

The Phrozen Sonic XL 4K is a professional machine with a large print area and a high resolution monochrome LCD display. This allows you to quickly produce batches of products with high accuracy.

Peopoly Phenom XXL

Peopoly Phenom XXL

Specifications:

LCD display resolution: 3840x2160 (23.8", 16:9, UHD 4K)

XY positioning accuracy: 137 µm

UV wavelength: 405 nm

Working area size: 527x296x550 mm

Layer thickness: 0.01-0.3mm

The Peopoly Phenom XXL is a device with a huge build area, which is ideal for serial production of not only jewelry.

Phrozen Sonic MEGA 8K

Phrozen Sonic MEGA 8K

Specifications:

LCD resolution: 15" 8K Mono LCD

XY Positioning Accuracy: 43 µm

UV wavelength: 405 nm

Working area size: 330 x 185 x 400 mm

Layer thickness: 0.01-0.3mm

This is the first LCD printer with 8k monochrome matrix resolution, and a huge working area allows you to produce large batches of products in one print.

MJM/MJP

MJM (or similar PolyJet technology) is a technology for layering photopolymer or wax through many fine nozzles. Typically, the print head is located from 96 to 448, depending on the printer model.

If a photopolymer is used as a material, it is immediately cured by a UV lamp, which is located on the printer's head.

How the MJM printer works

In addition to photopolymer, MJM 3D printers can use wax as a material for printing.

MJM printers can print multiple materials at the same time. This allows you to print complex models with soluble or investment supports. This makes it possible to produce complex models with a smooth surface quickly and easily.

Pros and cons

pros

-

Ability to print multiple materials at the same time. This means that another, soluble material can be used as a support. This allows you to save a lot of time on removing the support from the finished model and cleaning up the places where the supports come into contact with the print.

Minuses

-

To install the printer, most likely, you will need a separate room. 3D printers based on MJM technology are quite bulky in their dimensions, this is not a device that can simply be placed on a desktop or nightstand.

Print examples

Seal of a lot of stencils

Ring printed with wax

Master models made on MJM printer

Lot of jewelry stencils for further casting

Printer rating

FlashForge WaxJet 410

FlashForge WaxJet 410

Specifications:

Materials: Wax, support material.

Resolution: 1200*1200*1600

Building area size: 289*218*150mm

Layer thickness: 16 microns

Accuracy: ±0. 04mm / 20mm

The FlashForge WaxJet 410 is an industrial machine designed for serial printing of wax models, which will then be cast from metal. Machines of this class can be useful not only in jewelry production, but also in the dental industry, aerospace, mechanical engineering, prototyping, etc.

Totals

Photopolymer 3D printers are no longer inferior in detail to professional milling machines. The main advantage of a 3D printer is the ability to produce models of complex geometry with many internal cavities that are physically impossible to produce on a router.

Large firms will appreciate the flexibility that allows them to quickly adapt to customer requirements, as well as quickly produce large and small batches of products due to the shortening of the production chain.

And for a small workshop, a small photopolymer printer with a can of burn-out resin can be a good help, eliminating the need to purchase some expensive machines.

Printing jewelry on a 3D printer - an overview of the most interesting models

The days when 3D printing of jewelry seemed like something fantastic are over. Today, more and more designers are using 3D equipment to bring their ideas to life. Some printers work with filament, others use powder, and still others print with liquid resin or wax. 3D printed jewelry looks and feels exactly like traditionally molded pieces.

Highlights

White and black Gemino & Orbis Nylon earrings printed in nylon resin using SLS technology. The material has a very light weight, which makes the jewelry comfortable, ideal for everyday wear. An interesting design will organically fit into both a classic and a shocking look.

3D printed wedding rings. Original custom-made symbols of eternal love accurately convey the details that are important for the newlyweds. With a unique asymmetrical line and elegant twists, Ray's ring will appeal to fans of the original designs. For lovers of clean, minimalist silhouettes, the Clio is the way to go. For connoisseurs of unconventional solutions, the Amar diamond ring will suit, the design of which forms a loose knot of two lines that merge, symbolizing an unbreakable union.

Gorgeous 3D printed face jewelry by Iris van Herpen. Cellchemy 3D printed jewelry designs look like a mask and the way it sits on the face of the wearer looks like something otherworldly. The wire masks are printed with a high resolution multi-material printer. Each part of the mask, custom-designed for a specific runway model, was created using a generative design process after a 3D scan of her face.

Guinness World Record-listed diamond ring. India's major 3D printing service provider Imaginarium helped Kotti Shrikant win the Guinness World Record for having the most diamonds set in a single ring. The process of developing a masterpiece called "Divine - 7801 Brahma Vajra Kamalam" went through several iterations. The design team chose the Himalayan camellia flower, which strikes the perfect balance between traditional and contemporary forms. Computer-aided design (CAD) was then used to calculate the number of diamonds. Imaginarium managed to make petals of gold and helped to set the intended number of stones.

18K Gold Charm 3D print by Elizabeth Landis. The spectacular pendant reminds of natural harmony and succinctly complements the luxurious look. Honeycombs are formed into an openwork pattern, and the figure of a bee symbolizes wisdom, diligence, purity.

Frog Ring 3D Gold Plated Brass Object by Peter Donders. The designer rejects classical forms and traditional solutions. He uses 3D printing to revolutionize the jewelry industry, be it in the areas of jewelry making or designing finishes. The frog ring emphasizes the grace, sense of humor of the fair sex.

A charming decoration that can effectively complement a creative look.

"Opposites" collection by Francesca Paolin "spring-summer 2015", printed in polyamide. The MA in Fashion Design from Domus Academy channeled her creativity into creating body jewelry from alternative materials using 3D technology. The author drew inspiration for the development of the collection from ancient history and culture.

Solar nylon bracelet. The Septem brand offers unique fashion items from designers around the world. All products are made on 3D printers. The customer can choose their favorite materials, colors, sizes from the list. The original bracelet attracts with its futuristic design and adds creativity to the image.

N-E-R-V-O-U-S necklace is a 3D printed necklace made up of 175 unique pieces. It is a 21st century piece of jewelry designed and manufactured using methods that did not exist until recently. The necklace is built in layers of durable yet flexible nylon using selective laser sintering technology. The design comes out of the printer fully assembled. The necklace attaches simply and securely with a hidden magnetic clasp.

Plumeria Nylon Earrings have a matte texture, ideal for original, bold looks. You can choose any color from 12 possible. Earrings with a floral pattern will appeal not only to young fashionistas, but also to elegant ladies.

Ide Bag Nylon is a stylish element of the look. A model that imitates openwork knitting will add charm to the ensemble, plus it will allow you to create a harmonious, feminine, exclusive look.

The Orbits Bracelet Nylon is your own galaxy on your wrist. 3D printed space-inspired jewelry is the choice of daring experimenters who are not afraid to try on new looks. Unusual material plus an innovative manufacturing method add enchantment and extravagance to the little thing.

Jewelry designers are constantly testing new materials and experimenting with different design approaches.