3D printer components pdf

Sorry, we seem to have a problem to show this page

500USA & Canada

Select your country and region

- Americas

- English

- español (México)

- português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- español (España, alfabetización internacional)

- français

- Italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

Challenges We Solve

Gain a competitive edge through 3D printing solutions

Challenges We Solve

Manufacturing Solutions

Bringing an idea to life is no longer bound by traditional constraints.

Manufacturing

Rapid Prototyping

Create. Test. Refine. Repeat. Prototyping with 3D printing accelerates business.

Rapid Prototyping

Contact Us for Help

Need a little help in bringing your vision to life? Our team of experts are always here for you.

Contact Us

404 | Ogle Models

Search for:

- Home

- Solutions

- Processes

- Industries

- Case Studies

- News

- About

- Contact

- Prototypes

- Form Fit & Function Prototypes

- Engineering Prototypes

- Models

- Aesthetic & Concept Models

- Marketing & Exhibition Models

- Scale Models

- Parts

- Low Volume Production Parts

- Test Parts & Assemblies

- 3D Printing

- CNC Machining

- Painting & Finishing

- Traditional Hand Skills

- Vacuum Casting

- Materials

- Aerospace

- Architecture

- Automotive

- Defence & Security

- Film, TV & Entertainment

- Marine

- Medical

- Product Design

- Environmental

- About Us

- Downloads

- Careers

- Solutions

- Processes

- Industries

- Case Studies

- Contact

Search for:

Get a Quote

Cookie & privacy informationOther pages - Page not found

Other pages - Page not foundRatings and awards Management Expert Council Licenses and accreditations Reviews and thanks Sustainability Management and ESG Cooperation Corporate venture fund

About company >

Accompanying the conclusion of the SPIC Anti-crisis consulting Tax consulting Audit of RAS / IFRS Financial advisory due diligence Investment consulting and valuation HR consulting Management consulting Legal consulting Accounting consulting Transition to FSB Intellectual Property Management Attracting investments

Services and practices ›

Oil and gas Construction and development Mining and exploration Medicine and pharmaceuticals Food industry and agriculture infrastructure construction Energy Transport and logistic mechanical engineering Metallurgy IT industry Retail Light industry Financial sector Science and innovation Management companies Telecommunications and communications Chemical industry Timber industry and woodworking Production

All industries ›

company's news Legislative news Expert Publications Analytical studies

Press Center ›

Jobs Team Internship Alumni

Career >

Send a message and our managers will contact you as soon as possible

We use cookies to improve the site and its user experience. By continuing to use the site, you consent to the use of cookies.

By continuing to use the site, you consent to the use of cookies.

Accept

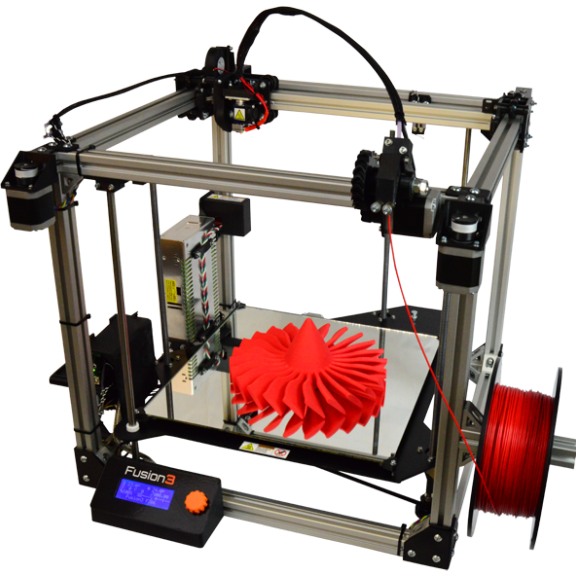

FDM Printer Components... | BeyondWiki

In the last article, we talked about popular 3D printing technologies. In this article, we will look at the structure of FDM - printers.

What does it consist of?

Conventional 3D printer consists of body, motors, extruder, table and electronics. Each of these components is an integral part of any FDM machine. And if everything is very complicated with electronics due to its variability, then with the body, extruder and table everything is somewhat simpler. They will be discussed.

Body

The body is the frame of the 3D machine, it is on it that all components are held. It can be either open or closed. Even though closed case printers are more expensive, they have a number of advantages:

- Noise isolation.

- Insulation of mechanics from dirt, dust, hair, animal hair.

- Isolation of mechanics from children.

- Protection against drafts and temperature changes (they are terrible for engineering plastics).

- The pungent smell of plastics ( ABS ) does not spread throughout the room.

- Better printing with engineering plastics ( ABS, Nylon, HIPS ).

However, despite the preponderance towards printers with a closed case, one should not forget that having an open printer is not critical. Moreover, some craftsmen make the case on their own.

Kinematics

Absolutely every FDM printer has moving parts and platforms that operate according to the kinematic scheme of the device; each type is very different from the others.

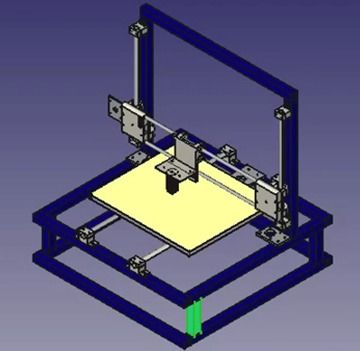

Cartesian/Cartesian

The most popular kinematics among FDM machines is based on three Cartesian axes — X, Y, Z . Most often, the extruder moves along one horizontal axis and one vertical axis, and the platform moves along the other horizontal axis. However, there are also alternative movement configurations.

Most often, the extruder moves along one horizontal axis and one vertical axis, and the platform moves along the other horizontal axis. However, there are also alternative movement configurations.

The Cartesian system has many advantages, which is why it is the most common among 3D printing enthusiasts. Namely:

-

Popularity. Since the printers of this system are the most common, it will not be difficult to find information, spare parts or some guides in Russian.

-

Easy assembly. Usually assembled 3D printers are more expensive, which makes it worthwhile to buy kits for self-assembly. With printer assembly/repair Cartesian system can handle even a beginner.

-

Stability of results. Compared to other kinematic systems, these printers have excellent accuracy and print quality.

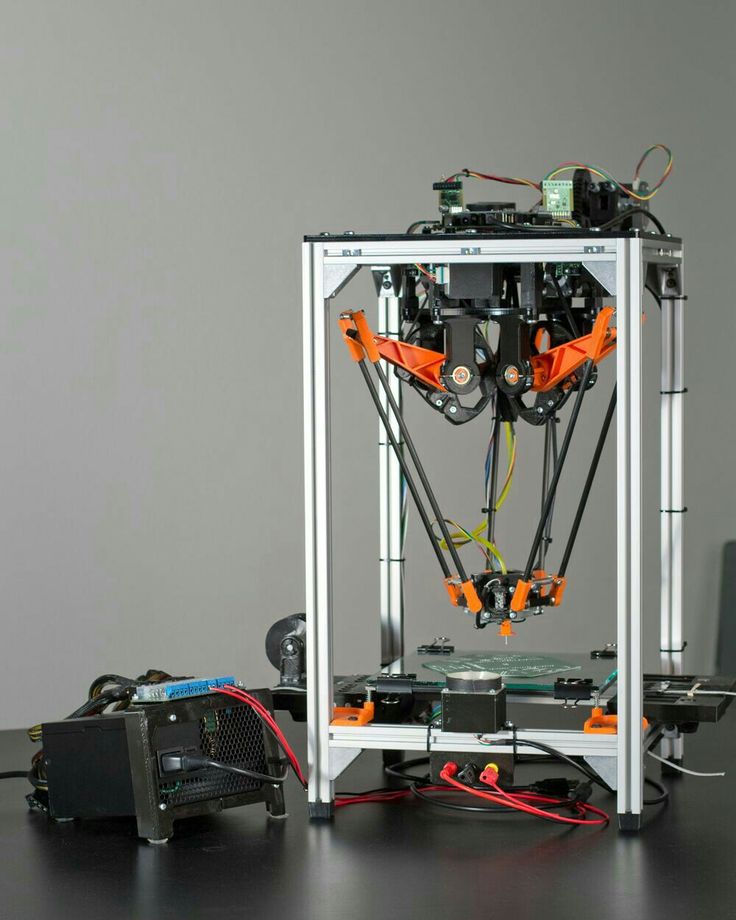

Delta

This type of kinematics includes a fixed print table and an extruder with three attachment and movement points, which gives certain positive and negative sides.

Advantages:

-

Compact. Printers in this system often take up little space in length and width, but can be tall.

-

Print tall details. Although printing long and wide models is difficult, delta system printers are ideal for printing tall models (vases, glasses, towers, etc.).

-

Some printer models are self-extending.

-

Faster print speed than Cartesian system.

Drawbacks:

- Inaccuracy. Due to the specifics of the kinematics system, delta printers tend to make a lot of errors when printing.

- The complexity of the design.

The complexity of the delta type design is much higher than the Cartesian one, which gives a lot of inconvenience, namely the difficulty in self-assembly and repair.

The complexity of the delta type design is much higher than the Cartesian one, which gives a lot of inconvenience, namely the difficulty in self-assembly and repair. - Software and electronics. Since the system for working with coordinates is very different and rather complicated, more powerful, and therefore expensive electronics are needed. The same applies to software.

Extruder

The extruder is an integral part of any 3D printer. This tool is designed to melt the plastic filament and extrude it onto the table. There are two types of material feeding through the extruder .

Direct feed

Feed by stepper motor directly into the extruder , the motor is located on the carriage itself.

Pros:

- Quick plastic change.

- No powerful motor required to feed material.

- Minimum plastic feed error.

- Can be printed with flexible materials.

Cons:

- Complex design creates problems during assembly and repair.

- The mass of the carriage is increased due to the feed motor.

- Due to the large mass, inertia increases, which can lead to inaccuracies.

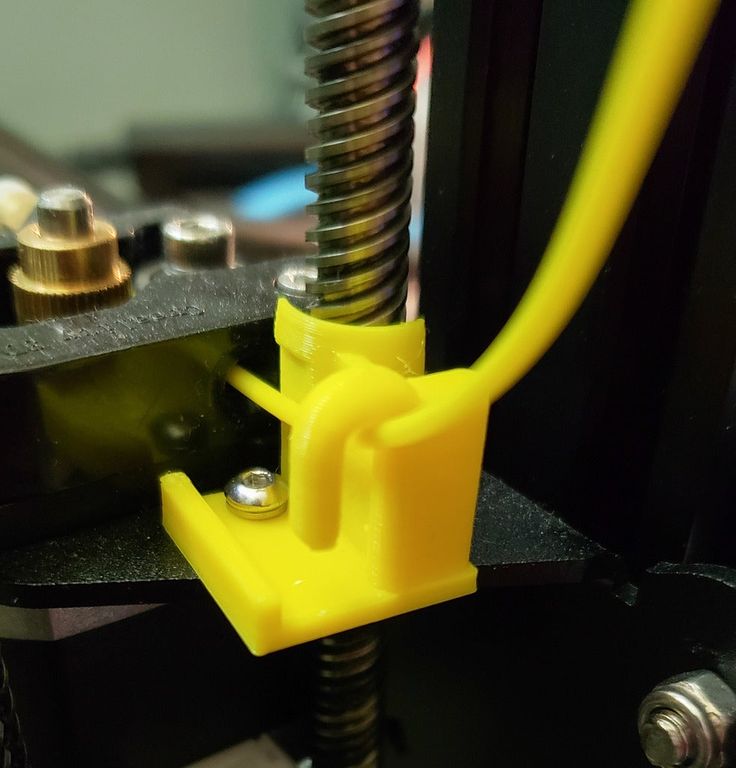

Bowden feed

In this case, the material feed motor is located on the printer body and not on the carriage itself. The material passes through the PTFE -tube into the extruder.

Pros:

- Reduced carriage load.

- Simplified design.

- Higher accuracy than direct feed.

- Higher speed.

Cons:

- Extremely difficult to print with flexible materials.

- The plastic feed error is increasing.

- Long plastic replacement.

- Requires a powerful motor to feed material into the extruder.

Table

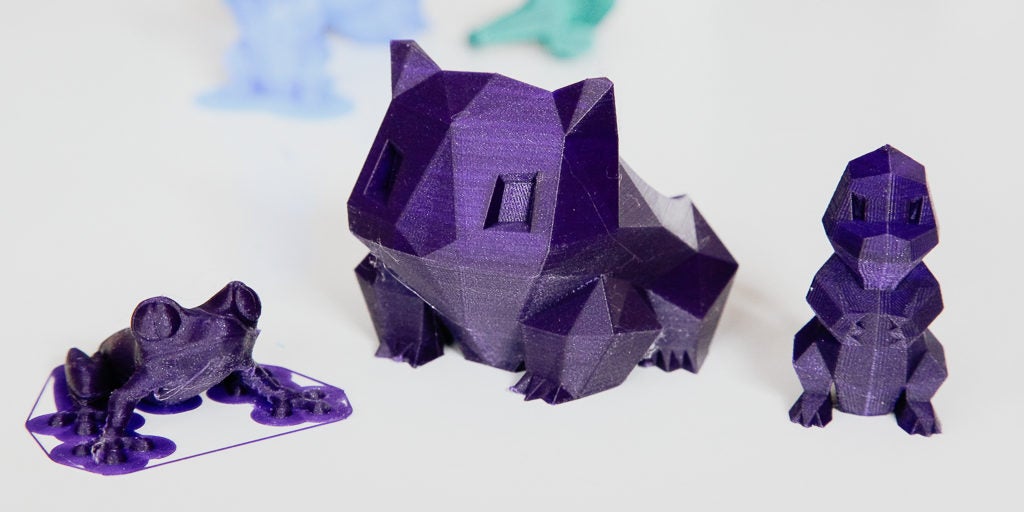

The print table is mostly a heated surface onto which melted material is extruded by an extruder. The task of each table is to keep the model in one place. Different coatings cope with this task in different ways.

The task of each table is to keep the model in one place. Different coatings cope with this task in different ways.

PEI

Polyetherimide film is used on many printers from the factory. This type of coating is great for beginners as it requires minimal effort to print.

Pros:

- Has good adhesion to plastic ( ABS, PLA, PETG, TPU ).

- Heat resistant.

- Pretty strong.

Cons:

- Price.

- Degrease the surface every time.

- Has poor adhesion if printed without heated bed.

Glass/mirror

Glass is also common among 3D printers. The glass can be ordinary window, mirror, borosilicate, phosphate, silicate-lime and other .

Pros:

- Price.

- Easy to install.

- Easy to achieve good adhesion.

Cons:

- Brittle.

- When trying to separate the model from the glass, you can cut yourself if the glass cracks

- Low temperature resistance (but not all types).

Magnetic top

Another type of table top. It has a rough surface made of magnetic material. Great for beginners, just like PEI film.

Pros:

- Flexibility.

- Price.

- Excellent adhesion.

Cons:

- Must be degreased every 3-4 prints.

- Sometimes the adhesion is too strong and it is very difficult to tear off the model.

- Adhesive properties degrade over time.

Total

Despite all the pros and cons of everything described, there is nothing absolutely universal that would work great and would not have any complaints. One way or another, any 3D printer is great for getting to know 3D printing, because most FDM printers are easy to improve yourself.