Fathom 3d print

FATHOM | IBM

Business challenge story

3D printing is transforming our world, helping to drive ground-breaking advances in industries such as healthcare, electronics, and aerospace. These advanced technologies are enabling major scientific discoveries and revolutionizing manufacturing processes.

The 3D printing industry itself is also undergoing a transformation, as it shifts to additive manufacturing, using this technology for real products, and not just prototypes. It is now used to create everything from prosthetic limbs for humans and animals, to futuristic concept cars, soft robotics for navigating hazardous environments during rescue operations, and miniature satellites for the European Space Agency.

At the heart of this major growth industry—one that is expanding at around 30 percent each year and is expected to be worth more than USD 30 billion by 2022—is a company called FATHOM. Having started out in 2008 as an authorized partner of Objet and Stratasys 3D printing and additive manufacturing systems, FATHOM has grown to provide full high-end advanced manufacturing services, as well as pioneering research into new uses for additive technologies and the ways in which it can “make the unmakeable”.

FATHOM leads innovative projects across all industries; its work continually demonstrates freedom of design and high complexity in ways not previously possible: Project Crucible, a scientific incubator that enables biologists to develop synthetic organisms in a simulated Martian-like environment; Project Pyra, a 3D printed oven showcasing the divergence between additive technologies and traditional methods, and BOOMcast, an IoT-enabled leg cast, 3D printed for TV show host Mike North, which allowed doctors to monitor his leg from anywhere in the world.

Dr. Carlo Quiñonez, Director of Research at FATHOM, explains: “We provide the full range of manufacturing services during product development from one or two prototypes, to engineering foundation runs, and even short-run production of up to 100,000 units.”

As FATHOM operates with relatively new technologies, the company has had to overcome many hidden complexities to take its place at the forefront of the additive manufacturing revolution, applying skills and experience to this new transformation.

As companies increase the scale and volume of their additive manufacturing operations, FATHOM realized that it had the knowledge and experience to help other companies optimize their advanced manufacturing processes. FATHOM began planning a software tool to improve 3D print business performance, and knew that it would need a rock-solid infrastructure to underpin the solution.

Transformation story

To support FATHOM Analytics, its business intelligence tool specifically engineered for companies operating multiple 3D printing and additive manufacturing systems, FATHOM chose to implement IBM Compose database-as-a-service (DBaaS) technology. FATHOM has a lean development team experienced with additive technologies, and required specialists that typically handle databases and system operations—making the DBaaS model an ideal fit for the company.

Compose enables the team at FATHOM to build its analytics application using open source technology—without the need for database expertise. FATHOM deployed instances using IBM Compose for MongoDB as the back-end for the analytics software. MongoDB was particularly appealing to FATHOM on account of features such as simple cluster configuration, high availability and support for changefeeds, which enable real-time updating.

FATHOM deployed instances using IBM Compose for MongoDB as the back-end for the analytics software. MongoDB was particularly appealing to FATHOM on account of features such as simple cluster configuration, high availability and support for changefeeds, which enable real-time updating.

The rapid one-click deployment of database instances through IBM Compose is also particularly useful, as Quiñonez explains: “For us, getting things provisioned quickly is way more important than trying to do it all ourselves and save money.”

The FATHOM Analytics software runs across multiple systems. One part of the system gathers data on manufacturing processes within the 3D printing production center—this manufacturing data covers print jobs, part costs, error states, and more. In short, the solution collects data on every aspect of each printed part and then transfers it to a Kafka cluster.

Cloud-based processes compile the data from the previous seven days of print jobs and events stored in Kafka, extracting meaningful messages and alerts, before transferring it to MongoDB. From there, another service makes the data available via a RESTful API, through which clients have web access to analysis and insights.

From there, another service makes the data available via a RESTful API, through which clients have web access to analysis and insights.

FATHOM has also developed an established online ordering platform for 3D printing and additive manufacturing. The platform is based on MongoDB, provisioned and managed through IBM Compose, and enables clients to organize and manage orders for 3D printed parts.

Quiñonez elaborates: “We provide a central portal for ordering, costing and pricing; our clients can then integrate that system with whatever internal systems they need to—whether they are customer relationship management, manufacturing resource planning, or accounting systems.”

The ordering platform builds on an existing development of a tool that FATHOM has been using internally to manage its own production processes. IBM Compose provides the crucial underlying scalability to add more and more users.

Quiñonez continues: “The nice thing is that because we’re a professional production center, we’re actually using FATHOM Analytics internally for our network of commercial 3D printing and additive manufacturing systems—so, in effect, we’re our own first customer. ”

”

Results story

Supported by IBM technology, FATHOM is sharing its extensive knowledge and experience with its customers, and helping to advance the 3D printing industry at large as it continues to grow into new application areas.

Armed with FATHOM Analytics, clients can optimize their manufacturing processes to perform the most efficient print runs possible. Users in 3D print farms receive real-time metrics that show how best to schedule builds to generate the best yields, and how to eliminate even the smallest 3D printing errors.

Underlying the success of the FATHOM applications is the ability to select and deploy the databases required to support FATHOM’s developers’ workloads. IBM Compose puts that critical database infrastructure just a click away, and the fully managed service—covering backups and full server administration—ensures FATHOM’s developers have no need to worry about day-to-day database management, and can focus on adding functionality to the applications.

Quiñonez concludes: “It was really clear to me that the best way is to just go with the managed database service, rather than doing it ourselves. Maybe at some point, we’ll revisit that value proposition. But that’s way down the road—for now, working with IBM Compose enables us to focus on helping other companies push additive technologies to the forefront of their respective industries. As the product grows, I'm confident IBM will be able to help us through the challenges of scaling our platform as well."

FATHOM Company Profile - Digital Engineering 24/7

620 3rd Street

Oakland, California, 94607

United States of America

studiofathom.com/

Follow FATHOM

The FATHOM team is driven by advanced technologies that enhance and accelerate today's product development and production processes—we’re changing the way products are being designed and manufactured by helping designers and engineers make the unmakeable.

- Experts Focused on Accelerated Prototype Fabrication & Low- to High-Volume Production Part Services

- Additive, Traditional, & Hybrid Manufacturing Expertise with an Industry-Leading Advantage of Agility

- 3D Printing, Additive Manufacturing, CNC Machining, Urethane Casting, Tooling, & Injection Molding

We are uniquely blending additive technologies and materials with legacy manufacturing methods so companies can go from concept to prototype to manufacturing in a way that wasn’t previously possible.

Featured Video

FATHOM Resources

STL Guidelines To Get The Best 3D Printed Parts

Created by FATHOM's Application Engineering Team, this 4-page STL guideline for 3D printing and additive manufacturing will help you get the best quality parts for your project. The easy-to-read PDF includes sections on why STL files are used, export best practices, difficulties you should expect to encounter, and much more.

Learn more

FATHOM in the News

Fathom & Evolve Additive Solutions Enter into Commercialization Partnership

Fathom will be the first provider of Evolve's additive technology, Selective Thermoplastic Electrophotographic Process, in North America, according to the companies.

Fathom Digital Manufacturing Goes Public

The transaction is expected to enhance Fathom’s position in additive and traditional advanced manufacturing capabilities and accelerate Fathom’s investments in organic and inorganic growth opportunities.

Fathom Manufacturing Buys Summit Tooling and Summit Plastics

This acquisition will expand Fathom's domestic injection molding capabilities, companies report.

FATHOM Acquires GPI Prototype & Manufacturing Services

GPI offers Direct Metal Laser Sintering (DMLS) additive manufacturing and CNC machining services, producing metal parts with complex geometries for on-demand manufacturing applications.

FATHOM & Abiogenix Supply 3D Printed NP Swabs to Address Shortage

The Abiogenix spiral design, made by FATHOM, was selected as the preferred 3D printed swab by clinicians and patients alike.

FATHOM’s SLS Production Increases 650% in Capacity

With FATHOM's recent announcement of its acquisition by CORE Industrial Partners, FATHOM will continue to expand its capabilities and provide industry-leading solutions for additive manufacturing.

FATHOM Acquired by CORE Industrial Partners, a Private Equity Firm

The acquisition will bring together FATHOM and Midwest Composite Technologies, acquired by CORE in 2018, to form a large privately held digital manufacturing service provider.

Design Guidelines for 3D Printing & Additive Manufacturing

Created by FATHOM's Application Engineering Team, this design guideline on 3D printing and manufacturing technologies includes PolyJet, SLA, FDM, SLS, and MJF. The easy-to-use chart highlights wall thickness, hole diameter, clearance for assemblies, escape holes, minimum detail, pin diameter, accuracy,

Tooling Delays? Get Parts in Days! Consider Additive Manufacturing

As designers and engineers become more accustomed to using AM, and more materials become readily available at lower prices, additive technologies will only continue to grow as a significant force in the manufacturing process.

FATHOM Issued Patent For on Demand Digital Manufacturing Platform

FATHOM, an advanced manufacturer with an expertise in 3D printing and additive manufacturing, announced the issuance of a United States Patent for the systems and methods powering its online digital manufacturing platform.

A New Way to Manufacture

Online portals are quickly becoming the industry standard for parts. Here's a look at the benefits and when to bring in specialists.

Provider Boosts Your Prototyping and Manufacturing Resources

Everybody gets in a crunch when they must rev up prototyping and production to get to market fast. Here's a way.

Designing Prosthetics: When Customization is Crucial

Engineers, designers and the medical world are using 3D printing and sensors technologies to create innovative prosthetics.

Photopolymer 3D printer

3D printers can be sorted not only by the printing technologies used, but also by the consumables used. In this section, we will look at devices that use photopolymer resins to build models.

In this section, we will look at devices that use photopolymer resins to build models.

- 1 Consumables

- 2 Laser stereolithography (SLA)

- 3 Projector stereolithography (DLP)

- 4 Multi-jet (MJM and PolyJet)

- 5 3D pens

- 6 Additional illumination

Consumables

Photopolymer resins are liquid polymers that harden when exposed to light. As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting. nine0003

Photopolymer resin loaded into Form 1 3D printer

The physical properties of resins after polymerization vary widely. Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

The last aspect to consider when choosing a material is its toxicity. There are both quite toxic options and biologically safe ones. nine0003

The cost of consumables can be considered the Achilles' heel of photopolymer printing. The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

Laser Stereolithography (SLA)

SLA Model

The firstborn of photopolymer printing and modern 3D printing in general. The technology was developed in 1984 by Charles Hall, who later founded 3D Systems.

SLA printers use laser emitters to cure the photopolymer supply.

A typical SLA printer consists of a consumable tray sitting under a build platform driven vertically by a raise/lower mechanism.

Alternatively, the cuvette itself can be driven - what matters is the relative movement of the platform and the container. Above the cuvette is a laser emitter and a mirror system for deflecting the laser beam. nine0003

During the printing process, the platform is immersed in the consumable for the thickness of one layer of the digital model.

Since photopolymer resins can be quite thick, a leveling mechanism is often used to speed up the process.

SLA printer operation scheme

After leveling, the process of illumination of the material begins. Illumination is produced by laser irradiation. Most photopolymer resins are designed to cure (polymerize) when exposed to ultraviolet light, which determines the choice of laser frequency. The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors. nine0003

The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors. nine0003

After the drawing of the layer is completed, the platform is immersed in the material for the thickness of one more layer, and the process is repeated with the drawing of the next layer of the digital model.

Model building animation

SLA printing takes quite a long time, and printers using this method tend to have relatively small build areas.

This is mainly due to the high cost of laser emitters: printing large objects with a single laser will take too much time, and installing additional emitters and mirrors will complicate the design, increase the dimensions of the installation and raise the price to an unacceptable level for most users. nine0003

Despite the success of this technology, projected stereolithography is considered to be a more promising, although very similar method.

Projector Stereolithography (DLP)

Formlabs Form 1 Desktop DLP Printer

A close relative of laser stereolithography, this method uses digital LED projectors instead of laser machines with mirror deflection systems. The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments. nine0003

The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments. nine0003

Layers are illuminated using a digital projector that highlights patterns of the entire layer, which distinguishes this method from SLA, where the "picture" emerges progressively using an ultraviolet laser.

A similar approach has previously been used on SGC-type plants, but this technology used physical photomasks, making the process costly, time consuming, slow and noisy.

At the moment, the FTI technology continues to exist - the development of SGC, almost indistinguishable from DLP printing, since it also uses digital LED projectors. nine0003

DLP printer design

Simultaneous illumination of an entire layer using projectors can significantly speed up the printing process even compared to SLA printers that have a high scanning speed (ie beam movement).

In addition, these printers are less sensitive to rough physical impact due to the absence of delicate mirror systems.

The absence of mechanical mirror systems improves accuracy. Finally, the cost of projectors sets them apart from laser systems. nine0003

Projection size can be quite significant, reaching the average of popular FDM printers.

An interesting feature of DLP printers is the ability to "reverse" or "reverse" printing.

In this case, the projector is installed under a transparent (material choice for transparency in relation to ultraviolet light) cuvette, and the platform does not sink into the material, but gradually rises, pulling out the layers of exposed polymer. nine0003

This approach eliminates the alignment mechanism and achieves even higher Z resolution than SLA printers.

In addition, the size of models in height is not limited by the depth of the cuvette, which favorably affects the dimensions of the printer and the possibility of increasing the build area.

Multi-jet printing (MJM and PolyJet)

3D Systems ProJet 3500HDMax MJM printer

MJM and PolyJet technologies are practically indistinguishable from each other. The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys. nine0003

The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys. nine0003

The very principle of multi-jet polymer printing was developed by the Israeli company Objet, which eventually became a division of Stratasys.

Multi-jet printing technology combines features of 3D inkjet printing (3DP) and projection stereolithography (DLP).

How the MJM PolyJet printer works

Models are built by spraying photopolymer using linear arrays consisting of multiple nozzles.

The applied layer is immediately exposed to ultraviolet lamps - as a rule, two processes occur simultaneously.

By the time the array reaches the end of the build chamber, the previously deposited material is hard enough to print a new layer.

Composite models created on the ProJet 3500 DP dental printer

This approach allows to achieve very high printing speed, but is characterized by high design complexity, which negatively affects the cost of such installations and limits their distribution to professional use. nine0003

nine0003

One of the advantages of MJM and PolyJet technologies is the ability to create composite structures from photopolymer resins with different physical characteristics.

It is therefore possible to create models with easily removable supports, use multiple colors and use flexible and rigid materials in parallel within the same model.

3D Pens

CreoPop 3D Pen

Recently, there has been a craze for hand-held printing devices called 3D pens. At the moment, there are three main options for such devices: drip-jet pens (DOD), called BioPen and used in the development of new methods for treating damaged tissues, FDM 3D pens, which are manual extruders (essentially similar to the usual hot glue guns, but using thermoplastics) and developments in 3D-drawing with photopolymer resins.

CreoPop 3D pen was the first "handheld resin printer". The design of this device is quite simple, because the most complex function, positioning, is performed by the user himself. The pen only extrudes resin through the tip surrounded by LED emitters. nine0003

The pen only extrudes resin through the tip surrounded by LED emitters. nine0003

CreoPop 3D pen in action

This way the resin hardens immediately after application, allowing you to literally draw on air.

The advantage of such handles over FDM-analogues is the low operating temperature - there are no heating elements in the device. As a result, with such pens you can even draw on the skin.

In addition, a wide range of photopolymer resins with different physical properties can be used with such devices, which greatly expands the range of possible applications. At a minimum, this is a relatively inexpensive, but entertaining toy. nine0003

The only drawback is the relatively high cost of consumables, but such devices are unlikely to require large volumes of photopolymer resin when used in everyday life.

Additional Lighting

Final Lighting of Resin Models in a Homemade Camera

Full curing of models can take quite a long time, so models during SLA and DLP printing are only partially polymerized, sufficient to maintain the physical shape of the part. nine0003

nine0003

After production, the models are usually placed in chambers equipped with ultraviolet lamps until fully cured. Of course, if possible, you can simply lay out the models in the sun - the effect will be the same.

Just keep in mind that ordinary glass practically does not transmit ultraviolet light, so exposure to sunlight must be direct.

If desired, a UV-transparent quartz glass container can be used. nine0003

Go to the main page of the Encyclopedia of 3D Printing

information on how it works, description of what it does

Most people have heard of 3D printing technology. It appeared quite a long time ago, but for many, the principle of operation is still a mystery. The article will look at what a 3D printer is, how it works and its main applications.

What is a 3D printer?

A 3D printer is a device that can be used to create real spatial objects from various materials. nine0003

In most cases, 3D printers are similar to conventional printers in terms of their design, as they consist of the same parts. The main difference is that the 3D printer is capable of printing in all three planes. In addition to height and width, there is also depth.

The main difference is that the 3D printer is capable of printing in all three planes. In addition to height and width, there is also depth.

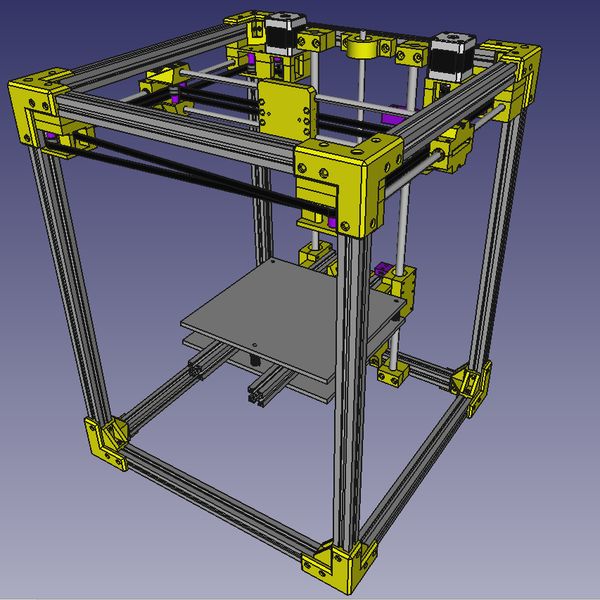

3D printer consists of the following parts:

- Housing.

- Frame. This design connects all other parts of the device.

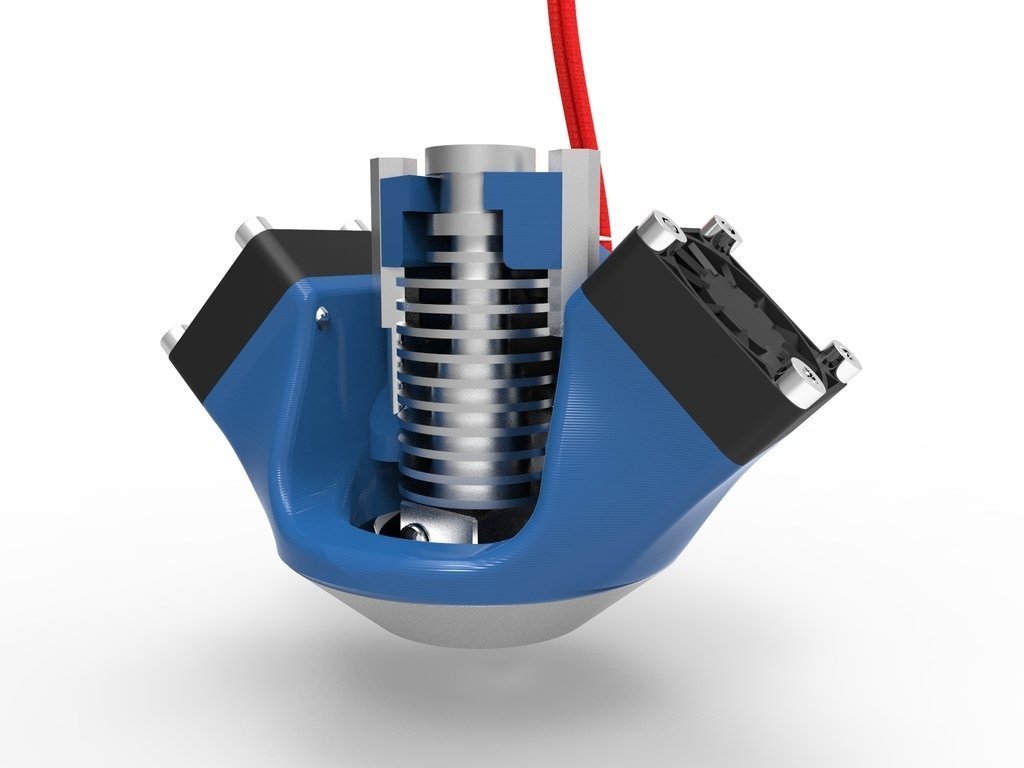

- Extruder. This part of the device heats up the material and measures the required amount of plastic using a gripping system. Semi-liquid plastic is extruded in the form of thin threads. nine0006

- Work table. Also, this part may be called the print surface or the work platform. Products are formed on the desktop.

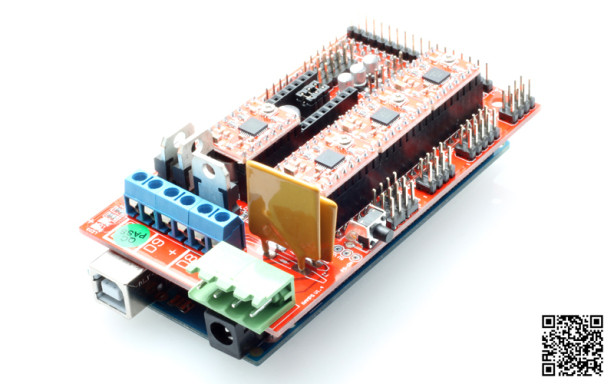

- Stepper and linear motors. They are necessary to set other parts in motion.

- Retainers. This is the name of the sensors by which the coordinates of the print are determined. Also, the clamps limit the moving parts. This is necessary so that the extruder does not go beyond the working space.

3D printers use plastic filaments of various colors as the working material. They may differ in other characteristics, such as melting point, stiffness, strength, etc. Threads are wound on spools and sold by weight. Nylon, polycarbonate, polyethylene, ABS, etc. can be used for printing.

There are also photopolymer 3D printers. For them, photopolymer resins are used. They are liquid, but under the influence of ultraviolet light begin to harden. nine0003

The principle of operation of all printers is the layer-by-layer build-up of the product. The device creates an object gradually, applying the material layer by layer. In this way, you can print anything, for example, spare parts for various equipment, toys, layouts of structures, etc. Everything is limited only by the user's imagination and modeling skills.

What is 3D printing?

3D printing is the creation of a real object from a 3D model. The digital model is saved in STL format and translated into G-code (universal programming language for 3D printers). After that, the device begins to layer-by-layer form the product. nine0003

After that, the device begins to layer-by-layer form the product. nine0003

The printing process itself consists of repeated cycles associated with the application of consumables to the working surface. After each cycle, the table is lowered (or the extruder is raised) to a height equal to the layer thickness.

Application

3D printers have a lot of possibilities. These devices have already become familiar tools in architecture, industrial design, engineering, manufacturing, jewelry, dentistry, etc.

Typical use cases:

- Creation of personalized models. In this case, the products fully meet the requirements of the user in terms of shape and size.

- Rapid prototyping. Thanks to 3D printing, a prototype or model can be made very quickly. This greatly helps designers and engineers in their work.

- Create objects with complex geometry. Models that are even difficult to imagine are very easy to create on a 3D printer.

Learn more