Fsf 3d printer

LulzBot TAZ 6 3D printer now FSF-certified to respect your freedom — Free Software Foundation — Working together for free software

by Joshua Gay Contributions — Published on Jun 13, 2016 10:25 AM

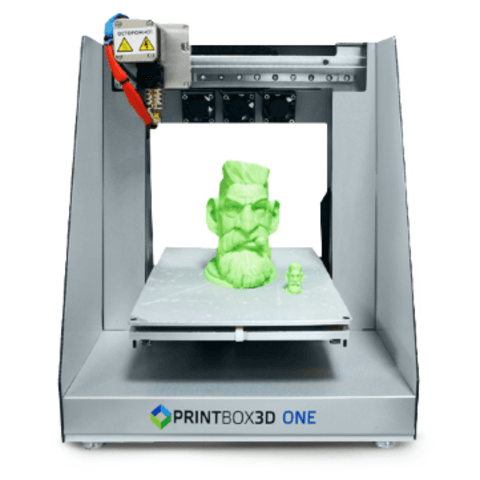

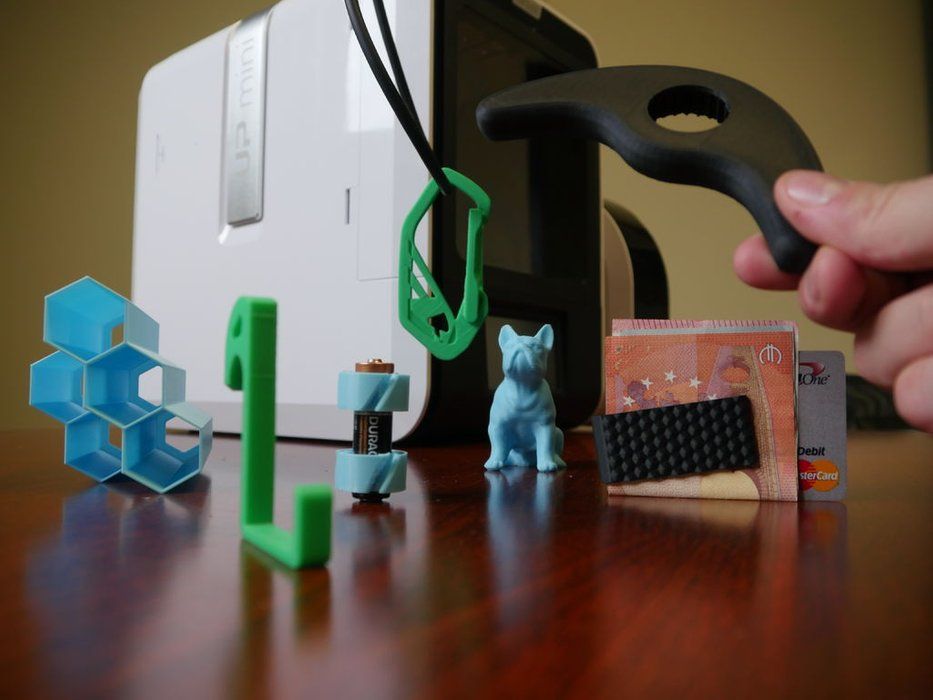

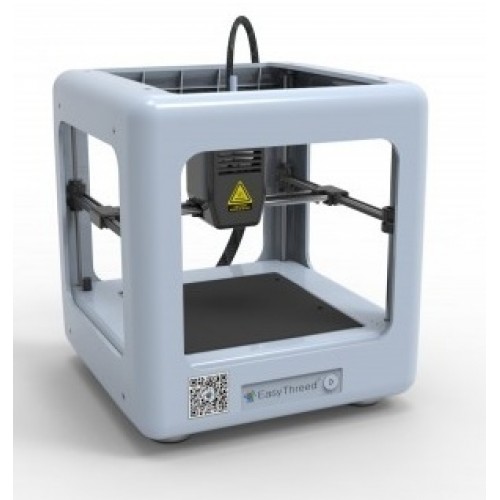

BOSTON, Massachusetts, USA -- Friday, June 10, 2016 -- The Free Software Foundation (FSF) today awarded Respects Your Freedom (RYF) certification to the TAZ 6, the sixth model in the LulzBot TAZ line of 3D printers by Aleph Objects, Inc., and their 10th product to be awarded RYF certification. The RYF certification mark means that the product meets the FSF's standards in regard to users' freedom, control over the product, and privacy.

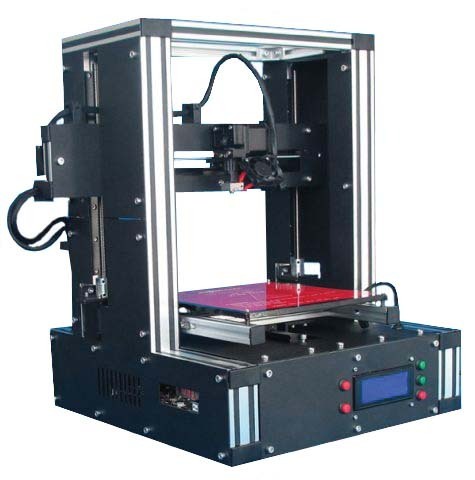

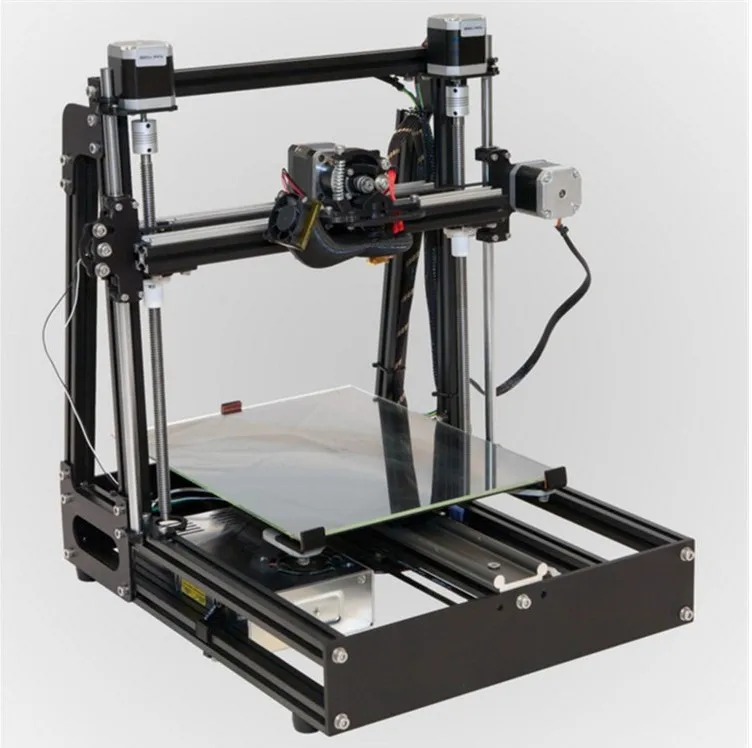

In October 2012, the LulzBot AO-100 3D printer became the first hardware product to be awarded use of the FSF's RYF certification mark. Since that time, Aleph Objects, Inc. has continued to release new and improved successors to the AO-100 model, including the AO-101, the Mini, and five successor TAZ models. The latest model, which can be purchased from LulzBot.com, has numerous hardware improvements, including a self-leveling printing bed made of borosilicate glass with a PEI surface, a self-cleaning nozzle system, and an integrated power supply. It uses 100% free software: from the low-level firmware that controls the motors and heats the printing bed, to end-user software, including Cura LulzBot Edition, which allows users to both prepare 3D digital objects for printing as well as control the operation of the 3D printer itself.

"Aleph Objects, Inc. continues to be one of the most innovative and impressive makers of desktop 3D printers in the world, and they have done it without compromising their core values and commitment to computer user freedom," said Joshua Gay, FSF licensing & compliance manager.

"The Free Software Foundation is the preeminent voice advancing technology that respects user freedom. It is a privilege to receive their seal of approval on the new LulzBot TAZ 6 desktop 3D printer," said Jeff Moe, president of Aleph Objects, Inc.

To learn more about the Respects Your Freedom hardware certification program visit https://fsf.org/ryf.

Hardware sellers interested in applying for certification can consult https://www.fsf.org/resources/hw/endorsement/criteria.

About the Free Software Foundation

The Free Software Foundation, founded in 1985, is dedicated to promoting computer users' right to use, study, copy, modify, and redistribute computer programs. The FSF promotes the development and use of free (as in freedom) software -- particularly the GNU operating system and its GNU/Linux variants -- and free documentation for free software. The FSF also helps to spread awareness of the ethical and political issues of freedom in the use of software, and its Web sites, located at fsf.org and gnu.org, are an important source of information about GNU/Linux. Donations to support the FSF's work can be made at https://donate.fsf.org. Its headquarters are in Boston, MA, USA.

More information about the FSF, as well as important information for journalists and publishers, is at https://www. fsf.org/press.

fsf.org/press.

Media Contacts

Joshua Gay

Licensing & Compliance Manager

Free Software Foundation

+1 (617) 542 5942

[email protected]

Kara Sawinska

Media Contact

Aleph Objects, Inc.

+1 (970) 377 1111

[email protected]

LulzBot TAZ 3 3D printer now FSF-certified to respect your freedom — Free Software Foundation — Working together for free software

by Free Software Foundation Contributions — Published on Feb 07, 2014 03:57 PM

BOSTON, Massachusetts, USA -- Friday, February 7, 2014 -- The Free Software Foundation (FSF) today awarded Respects Your Freedom (RYF) certification to the TAZ 3, the fifth model in the LulzBot line of 3D printers by Aleph Objects, Inc. The RYF certification mark means that the product meets the FSF's standards in regard to users' freedom, control over the product, and privacy.

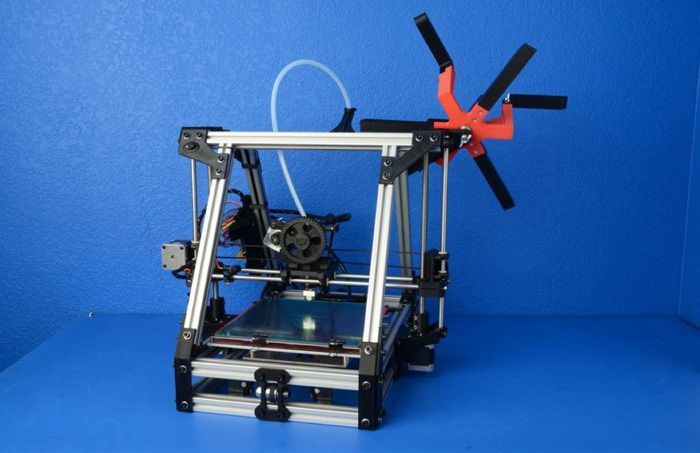

In October 2012, the LulzBot AO-100 3D printer became the first hardware product to be awarded use of the FSF's RYF certification mark. Since that time, Aleph Objects, Inc. has continued to release new and improved successors to the AO-100 model, including the AO-101, TAZ, TAZ 2, and TAZ 3, each of which have complied with RYF certification mark requirements. The latest model, which can be purchased online, has both hardware and software improvements, including a controller with a graphical LCD interface that allows users to print from an SD card and to perform printer start up, selection, and configuration changes.

Since that time, Aleph Objects, Inc. has continued to release new and improved successors to the AO-100 model, including the AO-101, TAZ, TAZ 2, and TAZ 3, each of which have complied with RYF certification mark requirements. The latest model, which can be purchased online, has both hardware and software improvements, including a controller with a graphical LCD interface that allows users to print from an SD card and to perform printer start up, selection, and configuration changes.

"Aleph Objects, Inc. has become a leader in the free software movement, not only in terms of producing hardware products that respect users' freedom, but also in terms of their engagement with and contributions to the free software community each step of the way," said Joshua Gay, FSF licensing & compliance manager.

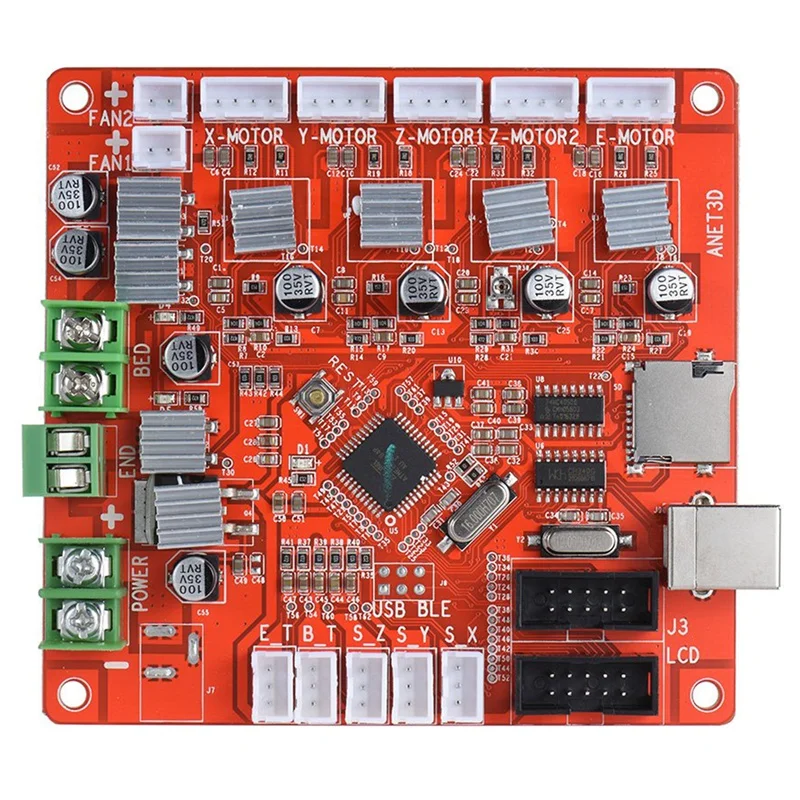

The software reviewed by Gay as part of the certification for the TAZ 3 printer includes the Marlin firmware for the RAMBo electronics board and ATmega chipset; the Python printing host software suite, which includes Pronterface, Pronsole, and Printcore; and a Slic3r, a program used to convert a digital 3D models into printing instructions.

"Aleph Objects, Inc. is honored to receive RYF certification for our latest 3D printer, the TAZ 3. No organization has greater credibility when it comes to user freedom than the Free Software Foundation, which for nearly thirty years has been prescient about technology issues that threaten user freedom. Our goal is to continue to practice these principles as we develop new technology," said Jeff Moe, president of Aleph Objects, Inc.

In addition to the the LulzBot line of 3D printers, a total of nine products have been awarded use of the RYF certification mark, including: the RAMBo all-in-one 3D printer electronics board used in the LulzBot printers; two USB wireless adapters sold by ThinkPenguin; and the Gluglug X60 laptop.

To learn more about the Respects Your Freedom hardware certification program visit https://www.fsf.org/ryf.

Hardware sellers interested in applying for certification can consult https://www.fsf.org/resources/hw/endorsement/criteria.

About the Free Software Foundation

The Free Software Foundation, founded in 1985, is dedicated to promoting computer users' right to use, study, copy, modify, and redistribute computer programs. The FSF promotes the development and use of free (as in freedom) software -- particularly the GNU operating system and its GNU/Linux variants -- and free documentation for free software. The FSF also helps to spread awareness of the ethical and political issues of freedom in the use of software, and its Web sites, located at fsf.org and gnu.org, are an important source of information about GNU/Linux. Donations to support the FSF's work can be made at https://donate.fsf.org. Its headquarters are in Boston, MA, USA.

The FSF promotes the development and use of free (as in freedom) software -- particularly the GNU operating system and its GNU/Linux variants -- and free documentation for free software. The FSF also helps to spread awareness of the ethical and political issues of freedom in the use of software, and its Web sites, located at fsf.org and gnu.org, are an important source of information about GNU/Linux. Donations to support the FSF's work can be made at https://donate.fsf.org. Its headquarters are in Boston, MA, USA.

About Aleph Objects, Inc.

Built upon the philosophy of freedom, Aleph Objects, Inc. is transforming the 3D printer industry. Based in Loveland, Colo., they are committed to Libre Hardware, which means their hardware and software will not be locked down, become obsolete, or require licensed upgrades over time. Empowering customers is part of their innovative spirit and LulzBot users are encouraged to be part of the ongoing conversation. Join in and learn more online at http://lulzbot. com.

com.

Media Contacts

Joshua Gay

Licensing & Compliance Manager

Free Software Foundation

+1 (617) 542 5942

[email protected]

Kristin Golliher

Media Contact, LulzBot/Aleph Objects, Inc.

(970) 449 6870

[email protected]

www.LulzBot.com

which is better to choose and which one is needed

A lot depends on the correct choice of starting material. Therefore, it is so important to understand before starting work what points you need to pay special attention to when buying plywood for laser cutting. This will help keep the number of marriages to a minimum.

What is plywood?

This is a multi-layered material, for the manufacture of which thin sheets of veneer and adhesive are used. Wood sheets, placed in each layer perpendicular to the previous one, are covered with glue and pressed together, forming a single strong wood layer.

Special placement of veneers relative to each other gives strength and density to the material. And the type of glue depends on its moisture resistance and scope.

And the type of glue depends on its moisture resistance and scope.

For example, FK plywood, which uses a carbamide resin adhesive, has a low level of moisture resistance, but at the same time reduced toxicity, which is ideal for indoor use. While the PSF brand based on phenol-formaldehyde glue boasts excellent moisture resistance, but toxicity is also at a high level. In this regard, this material is recommended for outdoor use.

Which plywood can be used for laser cutting?

It is possible to cut with a laser any piece of wood and plywood as well. But what the result will be is another question. Indeed, the quality of the cut, the amount of marriage and how presentable the final product will look depends on what kind of material is used.

Glue for gluing sheets

Various adhesive materials are used to connect thin wood sheets to each other: resins, glues. Moisture resistance and environmental safety of plywood depends on what kind of material is used in production.

There are two main groups:

- Animal origin (casein, albumin and albumin-casein). With a clear conscience, they can be called environmentally friendly, since the raw material for glue is protein from milk or animal blood.

- Synthetic origin (based on urea-formaldehyde, phenol-formaldehyde and other resins). It is worth remembering that all synthetic adhesives release chemicals into the air to one degree or another. The only question is the amount of these substances.

The best properties in terms of price, quality and environmental friendliness are possessed by FK grade sheets with glue based on urea-formaldehyde resin, when heated, a very small amount of substances harmful to humans is released into the environment.

IMPORTANT : Plywood (PSF) that uses phenol-formaldehyde glue is not recommended for use due to increased toxicity and low laser penetration.

Plywood grade

The grade of plywood is affected by the presence of defects: knots, cracks, wormholes, glue seepage, uneven edges and uneven sheet thickness. In total, 5 varieties are distinguished, the differences of which are presented in the table.

In total, 5 varieties are distinguished, the differences of which are presented in the table.

| variety | partially fused, consumed knots, wormholes | Large prevailing knots | are allowed |

| 0044 | |||

| I | Up to 6 mm diameter, max. 3 pcs. per 1 m 2 | Diameter up to 15 mm, max. 5 pcs. per 1 m 2 | Minor brown veins |

| II | Up to 6 mm in diameter, not more than 6 pcs. per 1 m 2 | Diameter up to 25 mm, max. 10 pcs. per 1 m 2 | Repairing the sheet surface |

| III | Up to 6 mm in diameter, no more than 10 pcs. per 1 m

The type of plywood directly affects the laser cutting process (the amount of rejects) and the appearance of the finished product (charred edges when passing knots due to the need to increase the laser power; undercut due to the walking thickness of the material or the uneven surface of the sheet). That is why grades E, I and II are ideal for laser cutting. It is allowed in certain cases to use plywood marked 2/3. ThicknessFK grade plywood, which is most often used for laser cutting, can have a thickness of 3 to 21 mm. But from the point of view of the ratio of price and quality, it is optimal to stop at a material with a thickness of 3 to 6 mm. Processing thicker sheets will require an increase in time and energy costs, which will ultimately affect the cost of the product. Moreover, the increase in laser power required to cut a thick sheet results in an unsightly charred edge. Type of wood veneer The choice of wood used in the production of plywood depends on the purpose and effect to be achieved. There are three types of plywood according to the type of wood veneer (only the composition of the outer layers is taken into account):

Other criteriaIn addition to the above, it is necessary to pay attention to such criteria as:

Differences in plywood for laser and milling cutsMilling cutters are not as sensitive to defects in the raw material. And this means that plywood of all five grades from grade E to grade 4 can be processed on a milling machine without any problems. Moreover, the thickness in this case is not limited to 6 mm. The milling cutter can easily cope with a sheet up to 100 mm thick. What is the best plywood for laser cutting?The ideal option for laser cutting is FK grade plywood, grade at least 2/2, thickness from 3 to 6 mm. As for the type of wood veneer, it depends on the goals and the effect that needs to be obtained. With the right approach to the choice of material for laser cutting, you can achieve excellent results, both aesthetic and economic.

Get expert advice the best way to level the surfaceDespite the fact that many modern building materials are now appearing, plywood is still firmly occupying its niche. Many options for sheet sizes and thicknesses greatly simplifies installation. And the possibility of any finish adds more points in its favor. Contents

Puttying plywood for subsequent finishing

Plywood is a wood-based building material consisting of layers of veneer glued together. Is it possible to do this, features of the processIf it is planned to paint the walls and ceiling, and plywood sheets were used during construction, then the question arises quite reasonably whether it is possible to putty plywood. Experts believe that it is not only possible, but necessary. The main feature is that it is a wooden material and it is important to choose the right building mixes for the work. Putty for plywood is allowed only on certain grades of sheets (FSF, FSF-TV, FB, BBS, FK), since moisture resistance is a mandatory requirement for the material. Like other wood-based materials, plywood must be impregnated with a deep-penetrating primer with antiseptic properties. Particular attention is paid to the joints of the sheets. The filling process itself is no different from working with other surfaces. Finishing technology for wood fiber boardsBefore you start puttying plywood, all sheets must be thoroughly dedusted and treated with a moisture-resistant wood primer twice. Sheets can rarely fit absolutely exactly and if there are differences, then they need to be sanded before leveling. Then fill the gaps between the sheets with putty, cover up fasteners and other irregularities, if any. If the distance between the sheets is large, then a sickle is glued onto the first layer of the mixture. After re-puttying and drying the solution with sandpaper, grind the surface. When the surface is puttied and sanded, you can move on to painting or wallpapering, regardless of whether it is a wall or a ceiling. If the plywood lies on the floor and it is planned to cover it with linoleum, then the base is treated with drying oil or PVA.

After complete drying, the floor is treated with an antiseptic solution to prevent mold and mildew. At the last stage, the surface is covered with acrylic varnish. How to choose the right mixture, consumption per m2

The following compositions are most suitable as putty on plywood:

Types of plywood and methods of processing it for painting or wallpapering

Plywood differs in different degrees of water resistance.

Depending on the degree of processing, they distinguish:

If plywood with a sanded side (W1) was taken during construction, then it can be immediately primed and wallpapered. The primer is applied in two layers and waiting for complete drying.

For decorative painting, puttied plywood. For this, it is best to take unpolished plywood (NSh), since there will be good adhesion to the building mixture. If it is planned to finish with liquid wallpaper, it is also better to use untreated plywood, having previously primed it twice. How to properly putty, tools

In general, the technique for applying putty on plywood is no different from other substrates such as brick or concrete. Of the tools you will need:

|

And his price is high.

And his price is high.

Having familiarized yourself with the main criteria in advance, it is possible to avoid many problems with marriage and cut defects.

Having familiarized yourself with the main criteria in advance, it is possible to avoid many problems with marriage and cut defects.  The veneer can be coniferous, birch or hardwood, it is glued together in different directions to increase the bending strength of the final sheet.

The veneer can be coniferous, birch or hardwood, it is glued together in different directions to increase the bending strength of the final sheet.

To do this, PVA is mixed with ground wood dust. The resulting solution can be brought to the desired viscosity. Of the obvious advantages - low price compared to store options. Approximate consumption - 0.5 kg per 1 m2;

To do this, PVA is mixed with ground wood dust. The resulting solution can be brought to the desired viscosity. Of the obvious advantages - low price compared to store options. Approximate consumption - 0.5 kg per 1 m2;