3D printer stocks

Top 3D Printing Stocks for Q4 2022

Table of Contents

Table of Contents

-

Best Value 3D Printing Stocks

-

Fastest Growing 3D Printing Stocks

-

3D Printing Stocks With the Best Performance

SSYS is top for value and performance and NNDM is top for growth

By

Noah Bolton

Full Bio

Noah has about a year of freelance writing experience. He's worked on his investing website dealing with topics such as the stock market and financial advice for beginners.

Learn about our editorial policies

Updated October 06, 2022

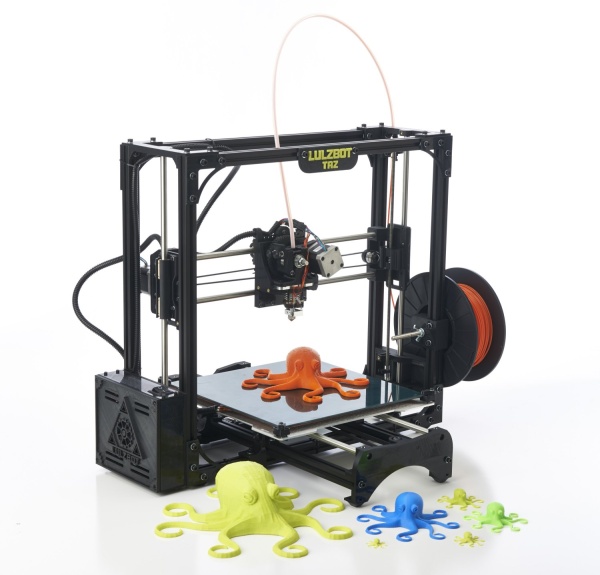

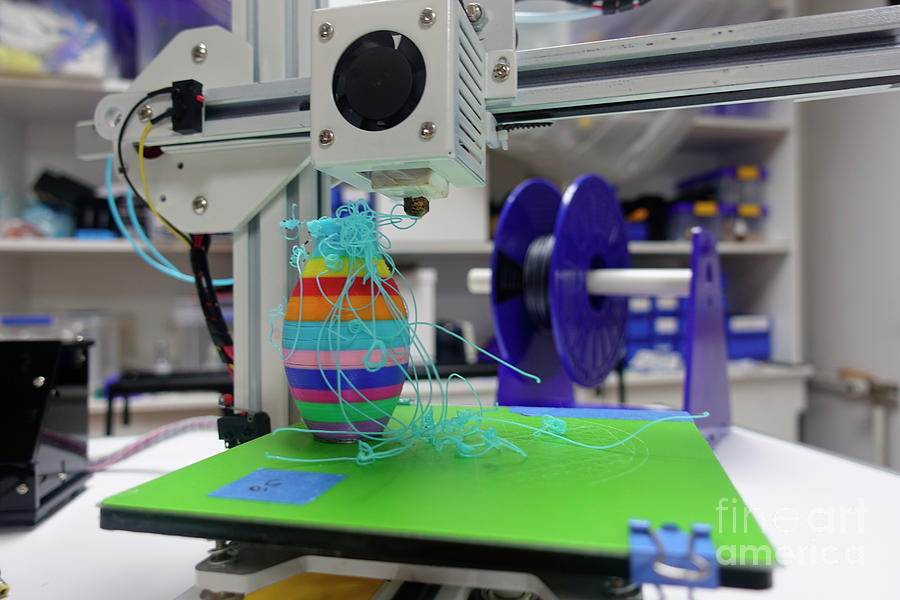

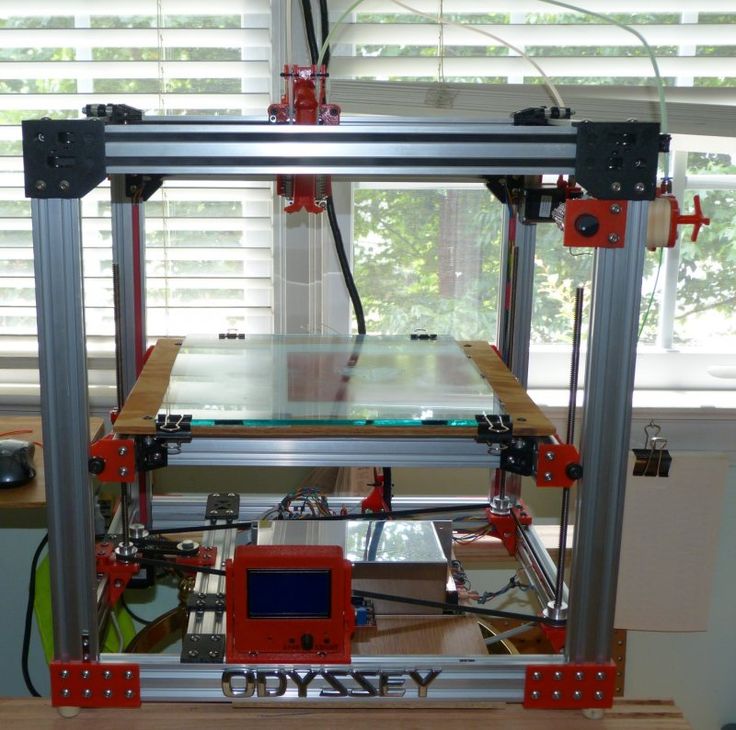

The 3D printing industry is made up of companies that provide products and services capable of manufacturing a range of products. 3D printing, also known as additive manufacturing, creates physical objects from digital designs. The printing process works by laying down thin layers of material in the form of liquid or powdered plastic, metal, or cement, and then fusing the layers together. Though still too slow for mass production, it is a revolutionary technology that has the potential to disrupt the manufacturing logistics and inventory management industries. The 3D printing industry is comprised of only a handful of companies, including players such as Proto Labs Inc., Faro Technologies Inc., and Desktop Metal Inc.

The industry is so young that it has no meaningful benchmark index. But the performance of these stocks can be compared to the broader market as represented by the Russell 1000 Index. These stocks have not performed well. Stratasys Ltd. (SSYS), the best performing 3D printing stock, has dramatically underperformed the Russell 1000, which has provided a total return of -12.5% over the past 12 months. This market performance number and all statistics in the tables below are as of Sept. 20, 2022.

Here are the top three 3D printing stocks with the best value, fastest sales growth, and the best performance.

These are the 3D printing stocks with the lowest 12-month trailing price-to-sales (P/S) ratio. For companies in early stages of development or industries suffering from major shocks, this metric can be substituted as a rough measure of a business's value. A business with higher sales could eventually produce more profit when it achieves (or returns to) profitability. The price-to-sales ratio shows how much you're paying for the stock for each dollar of sales generated.

For companies in early stages of development or industries suffering from major shocks, this metric can be substituted as a rough measure of a business's value. A business with higher sales could eventually produce more profit when it achieves (or returns to) profitability. The price-to-sales ratio shows how much you're paying for the stock for each dollar of sales generated.

| Best Value 3D Printing Stocks | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | 12-Month Trailing P/S Ratio | |

| Stratasys Ltd. (SSYS) | 15.49 | 1.0 | 1.6 |

| 3D Systems Corp. (DDD) | 9.00 | 1.2 | 2.0 |

| Proto Labs Inc. (PRLB) | 37.49 | 1.0 | 2.1 |

Source: YCharts

- Stratasys Ltd.: Stratasys offers 3D printing solutions, such as 3D printers, polymer materials, a software ecosystem, and related parts.

It serves a variety of industries, including aerospace, automotive, consumer products, and healthcare. On Sept. 13, Stratasys completed the merger of its MakerBot subsidiary with Ultimaker, which offers platforms used to make 3-D printers. Ultimaker is backed by NPM Capital. The merged company will keep the Ultimaker name and focus on providing solutions, hardware, software and materials to the industry. NPM Capital will have majority ownership of the new company at 53.5%, and Stratasys will own 46.5%.

It serves a variety of industries, including aerospace, automotive, consumer products, and healthcare. On Sept. 13, Stratasys completed the merger of its MakerBot subsidiary with Ultimaker, which offers platforms used to make 3-D printers. Ultimaker is backed by NPM Capital. The merged company will keep the Ultimaker name and focus on providing solutions, hardware, software and materials to the industry. NPM Capital will have majority ownership of the new company at 53.5%, and Stratasys will own 46.5%. - 3D Systems Corp.: 3D Systems provides 3D printing solutions. The company offers a range of hardware, software, and materials designed for additive manufacturing. Its products and services are used in a variety of industries and sectors, including aerospace, automotive, semiconductor, healthcare, and more.

- Proto Labs Inc.: Proto Labs is an e-commerce-based company that provides digital manufacturing services. It offers 3D printing, injection molding, CNC machining, and sheet metal fabrication.

On Aug. 5, Proto Labs announced financial results for Q2 2022, the three-month period ending on June 30, 2022. Net income fell more than 80% to $2.6 million from the prior-year quarter while revenue rose 3.1%.

On Aug. 5, Proto Labs announced financial results for Q2 2022, the three-month period ending on June 30, 2022. Net income fell more than 80% to $2.6 million from the prior-year quarter while revenue rose 3.1%.

These are the 3D printing stocks with the highest YOY sales growth for the most recent quarter. Rising sales can help investors identify companies that are able to grow revenue organically or through other means and find growing companies that have not yet reached profitability. In addition, accounting factors that may not reflect the overall strength of the business can significantly influence earnings per share. However, sales growth can also be potentially misleading about the strength of a business, because growing sales on money-losing businesses can be harmful if the company has no plan to reach profitability.

| Fastest Growing 3D Printing Stocks | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | Revenue Growth (%) | |

Nano Dimension Ltd. (NNDM) (NNDM) | 2.45 | 0.6 | 1,270 |

| Desktop Metal Inc. (DM) | 3.07 | 1.0 | 203.9 |

| Stratasys Ltd. (SSYS) | 15.49 | 1.0 | 13.3 |

Source: YCharts

- Nano Dimension Ltd.: Nano Dimension is an Israel-based 3D printing company focused on developing equipment and software for 3D-printed electronics. It develops printers for multilayer printed circuit boards and nanotechnology-based inks. The company serves a range of industries, including consumer electronics, healthcare, aerospace, and automotive. On Sept. 1, Nano Dimension released Q2 2022 results. The company's net loss widened sharply to $40.0 million from a loss of $13.6 million in the same quarter a year earlier even as revenue soared more than 13-fold. The larger second-quarter loss was fueled partly by $10.9 million in non-cash adjustments for depreciation and amortization expenses, and share-based payments.

- Desktop Metal Inc.: Desktop Metal manufactures 3D printers and related equipment used to build complex parts from metal. It also offers 3D printing software. The company serves a range of industries, including automotive, consumer products, education, and heavy industry. On Aug. 08, the company reported Q2 2022 results. Desktop Metals' net loss increase nearly seven-fold to $297.3 million compared to the same quarter a year earlier even as revenue tripled.

- Stratasys Ltd.: See above for company description.

These are the 3D printing stocks that had the smallest declines in total return over the past 12 months out of the companies we looked at.

| 3D Printing Stocks With the Best Performance | |||

|---|---|---|---|

| Price ($) | Market Cap ($B) | 12-Month Trailing Total Return (%) | |

Stratasys Ltd. (SSYS) (SSYS) | 15.49 | 1.0 | -34.5 |

| Proto Labs Inc. (PRLB) | 37.49 | 1.0 | -50.6 |

| Materialise NV (MTLS) | 10.95 | 0.6 | -53.9 |

| Russell 1000 | N/A | N/A | -12.5 |

Source: YCharts

- Stratasys Ltd.: See above for company description.

- Proto Labs Inc.: See above for company description.

- Materialise NV: Materialise is a Belgium-based provider of additive manufacturing software and 3D printing services. It serves a range of industries, including healthcare, aerospace, and automotive. On Sept. 7, Materialise completed its acquisition of Identity3D, which makes products that encrypt, distribute, and track digital parts as they move through supply-chains. The value of the deal was not specified in the announcement.

The comments, opinions, and analyses expressed herein are for informational purposes only and should not be considered individual investment advice or recommendations to invest in any security or to adopt any investment strategy. Though we believe the information provided herein is reliable, we do not warrant its accuracy or completeness. The views and strategies described in our content may not be suitable for all investors. Because market and economic conditions are subject to rapid change, all comments, opinions, and analyses contained within our content are rendered as of the date of the posting and may change without notice. The material is not intended as a complete analysis of every material fact regarding any country, region, market, industry, investment, or strategy.

Though we believe the information provided herein is reliable, we do not warrant its accuracy or completeness. The views and strategies described in our content may not be suitable for all investors. Because market and economic conditions are subject to rapid change, all comments, opinions, and analyses contained within our content are rendered as of the date of the posting and may change without notice. The material is not intended as a complete analysis of every material fact regarding any country, region, market, industry, investment, or strategy.

Article Sources

Investopedia requires writers to use primary sources to support their work. These include white papers, government data, original reporting, and interviews with industry experts. We also reference original research from other reputable publishers where appropriate. You can learn more about the standards we follow in producing accurate, unbiased content in our editorial policy.

YCharts. "Financial Data.

"

"Stratasys Ltd. "Stratasys Completes Merger of MakerBot with Ultimaker."

Proto Labs Inc. "Proto Labs Q2 2022 Earnings Release."

Nano Dimension Ltd. "Earnings Press Release for Q2 2022."

Desktop Metals Inc. " Desktop Metals Second Quarter 2022 Earnings."

Materialise NV. "Materialise Acquires Indenity3D."

5 3D Printing Stocks to Consider in 2022

An in-depth look at the leading 3D printing stocks in the U.S stock market this year. Here’s what you need to know.

By Nicholas Rossolillo – Updated Jul 11, 2022 at 2:42PM

Back in the early 2010s, stocks were booming for 3D printing -- also known as additive manufacturing, a computer-controlled process in which three-dimensional objects are made. But the boom was followed by a bust as many pure-play 3D printing companies didn't immediately deliver on lofty expectations.

Rumors of the manufacturing technology's demise are clearly premature. These days, 3D printing is a high-growth niche that is steadily reshaping the manufacturing and industrial sectors. Some estimates point to a doubling in annual revenue from additive manufacturing between 2022 and 2026. Even growth investor Cathie Wood has launched a fund focused on manufacturing tech, The 3D Printing ETF (NYSEMKT:PRNT), via her company ARK Invest.

These days, 3D printing is a high-growth niche that is steadily reshaping the manufacturing and industrial sectors. Some estimates point to a doubling in annual revenue from additive manufacturing between 2022 and 2026. Even growth investor Cathie Wood has launched a fund focused on manufacturing tech, The 3D Printing ETF (NYSEMKT:PRNT), via her company ARK Invest.

Here's what you need to know about 3D printing and additive manufacturing stocks for 2022:

Image source: Getty Images.

Investing in 3D printing stocks

The manufacturing of products in all corners of the economy is being revolutionized by 3D printing, from healthcare equipment to metal fabrication to housing construction. It's invading so many sectors that tech giants such as Microsoft (NASDAQ:MSFT), Autodesk (NASDAQ:ADSK), and HP (NYSE:HPQ) have launched products aimed at 3D printing and additive manufacturing. Other engineering and software outfits such as Dassault Systemes (OTC:DASTY), ANSYS (NASDAQ:ANSS), and Trimble (NASDAQ:TRMB) have also gotten involved in 3D printing technology.

Other engineering and software outfits such as Dassault Systemes (OTC:DASTY), ANSYS (NASDAQ:ANSS), and Trimble (NASDAQ:TRMB) have also gotten involved in 3D printing technology.

Here are five key players to consider for 2022 that are a more focused bet on 3D printing:

| Company | Market Cap | Description |

|---|---|---|

| Desktop Metal (NYSE:DM) | $1.3 billion | Recent IPO that focuses on metal fabrication technology. |

| Stratasys (NASDAQ:SSYS) | $1.5 billion | One of the original 3D printing pioneers, with a wide array of printers and supporting design software. |

| Xometry (NASDAQ:XMTR) | $1.9 billion | A manufacturing marketplace, including access to on-demand 3D printing services. |

| 3D Systems (NYSE:DDD) | $1.9 billion | Another original 3D printing pioneer and the largest pure-play stock on 3D printing technology. |

| PTC (NASDAQ:PTC) | $11.7 billion | A manufacturing technology provider with a suite of software and related services for industrial businesses. |

1. Desktop Metal

This company is a recent entry into the 3D printing space after going public via a SPAC at the end of 2020. The stock has been a terrible market underperformer since then, losing three-quarters of its value as of spring 2022. However, Desktop Metal could still be a promising investment for the long term.

As its name implies, Desktop Metal develops 3D printing hardware and accompanying design software for metal and carbon fiber parts. The company's smaller systems can handle prototyping and one-off parts, and larger printers are production grade-designed for manufacturing facilities. Desktop Metal serves companies operating in automotive, consumer goods, and heavy industrial equipment businesses.

Desktop Metal serves companies operating in automotive, consumer goods, and heavy industrial equipment businesses.

Despite a tenuous start as a public company, Desktop Metal was actually increasing revenue at a torrid triple-digit pace in 2021. Gross profit margins are thin, and the company generated a steep net loss, but that should improve over time as the business scales its operation. Desktop Metal also has several hundred million dollars in cash and investments to fund its expansion. It used some of these funds to acquire additive manufacturing peer ExOne at the end of 2021.

2. Stratasys

Stratasys was part of the early 2010s 3D printing stock boom and bust, but its business has endured. Sales took a dip early in the COVID-19 pandemic but are rebounding as the Israel-based company picks up new manufacturing contracts.

Stratasys serves a diverse set of customers, including aerospace and automotive parts manufacturers, medical and dental companies, and makers of basic consumer products. In addition to a wide array of 3D printer models, Stratasys develops software to help users accelerate the time between design and final printing.

In addition to a wide array of 3D printer models, Stratasys develops software to help users accelerate the time between design and final printing.

It isn't the highest-growth name on this list, but Stratasys is profitable (on a free cash flow basis) and has more than $500 million in cash and investments on its balance sheet, as well as no debt. Management thinks its payoff from years of research and development into additive manufacturing will accelerate in 2022.

3. Xometry

This is another newcomer to public markets. Xometry completed its initial public offering (IPO) over the summer of 2021, raising almost $350 million in cash in the process. As is often the case with new IPOs, the stock has underperformed since then. It has lost over half of its value from the time it started trading on public markets, but the business itself is rapidly growing.

Xometry is a marketplace for on-demand manufacturing of prototyping and mass production. It has a network of more than 5,000 suppliers that companies can call on to meet their fabrication needs. Among the suppliers on the Xometry platform are 3D printing companies, injection molding, and automated machining. The company reported having more than 28,000 active buyers utilizing its platform at the end of 2021.

It has a network of more than 5,000 suppliers that companies can call on to meet their fabrication needs. Among the suppliers on the Xometry platform are 3D printing companies, injection molding, and automated machining. The company reported having more than 28,000 active buyers utilizing its platform at the end of 2021.

Although it isn't profitable yet, Xometry's unique approach to the 3D printing and additive manufacturing industry is growing fast. Like other names on this list, it has a sizable war chest of cash and short-term investments that it can spend on research and marketing as it tries to attract more suppliers and buyers to its marketplace.

4. 3D Systems

3D Systems was another early player in the 3D printing industry, and while it suffered through the boom-and-bust period of the early 2010s, its business has held steady for much of the past decade. After a brief dip during the early days of the pandemic, 3D Systems is back in growth mode.

The company develops printers and design software for all sorts of materials and industries (medical device makers, dental labs, semiconductor designers, aerospace, and automotive manufacturers). It claims leadership among independent 3D printing companies (as measured by sales). As the 3D printing industry expands in the coming years, 3D Systems thinks it will be able to attract lots of new business with its extensive experience and global reach.

As an established tech outfit in the manufacturing sector, 3D Systems offers investors the prospect of more stable growth, along with profitability. It also has a large net cash position from which it can consolidate its lead in 3D printers and software technology.

5. PTC

By far the largest company on this list, PTC is a longtime technology partner of manufacturing and industrial enterprises. Fast approaching $2 billion in annualized sales and highly profitable, PTC has all the tools needed to digitally transform industrial businesses.

Besides 3D printing computer-aided design software (ANSYS is a peer and software partner that also operates in this space), PTC specializes in augmented reality, industrial IoT (Internet of Things), and product life-cycle management software. Most of its revenue is subscription-based (including its Creo software that enables 3D printing), making for a stable and steadily growing business model that generates ample cash flow. PTC puts spare cash to work developing new products for its partners and makes bolt-on acquisitions of other software companies that enhance its overall portfolio.

As a larger company, PTC won't be the fastest-growing stock in the additive manufacturing and 3D printing space. However, the company has established itself as a leader in industrial technology and should be a primary beneficiary as the production of manufactured goods gets more efficient.

The future of 3D printing

Manufacturing technology is making inroads throughout the global economy by reducing the cost of production and localizing and speeding up the time it takes to deliver customer orders. This is far from mere hype. Nevertheless, as is the case with all technology investments, progress won't go straight up. Expect twists and turns in these stocks as they develop new methods to design and make products.

This is far from mere hype. Nevertheless, as is the case with all technology investments, progress won't go straight up. Expect twists and turns in these stocks as they develop new methods to design and make products.

If you decide to invest, do so in a measured way. Maintain a diversified portfolio, be wary of stocks benefiting from investor over-optimism, and always leave spare cash to invest more when there are inevitable dips. Given enough time -- years and decades -- investing in 3D printing could eventually provide a big payoff.

Related communication stocks topics

Investing in 5G Stocks

As the 5G technology rollout continues, these companies look like winners.

Investing in Top Telecommunications Stocks

Our world is increasingly interconnected, and these companies make it happen.

Investing in Communication Stocks

Communications has a broad definition. These companies are the leaders in the space.

Investing in Top Consumer Discretionary Stocks

When people have a little extra cash, they indulge in offerings from these companies.

Nicholas Rossolillo has positions in Autodesk and PTC. The Motley Fool has positions in and recommends Autodesk, HP, and Microsoft. The Motley Fool recommends 3D Systems, ANSYS, Dassault Systemes, PTC, and Trimble Inc. The Motley Fool has a disclosure policy.

Motley Fool Investing Philosophy

- #1 Buy 25+ Companies

- #2 Hold Stocks for 5+ Years

- #3 Add New Savings Regularly

- #4 Hold Through Market Volatility

- #5 Let Winners Run

- #6 Target Long-Term Returns

Why do we invest this way? Learn More

Related Articles

3 Dividend-Paying Tech Stocks to Buy in November

3 Robinhood Stocks to Buy Right Now

Better Buy: Microsoft vs. Alphabet

2 Growth Stocks to Buy and Hold Forever

PTC (PTC) Q4 2022 Earnings Call Transcript

Why Is Everyone Talking About Microsoft?

3 Things About Microsoft That Smart Investors Know

Premium Investing Services

Invest better with The Motley Fool. Get stock recommendations, portfolio guidance, and more from The Motley Fool's premium services.

Get stock recommendations, portfolio guidance, and more from The Motley Fool's premium services.

View Premium Services

Parts and logistics in difficult conditions

Miscellaneous

Hercules

Hello everyone!

Production of 3D printers is an extensive and time-consuming process that requires coordinated action of all participants, including logistics.

In the conditions of sanctions pressure, the question often arises: "How are things at Russian enterprises producing equipment?". For most enterprises, supply chains were disrupted during the pandemic, but the sanctions completely changed the picture on the market. Many companies have closed due to the inability to rebuild the business or have suspended work until the situation clears up.

If the company has a significant market share, stocks of components and components for the assembly of new equipment are an important component of production. With such resources, correcting the flow of missing parts does not pose a threat to the continuation of work.

Our printers are completely assembled in Russia, a significant part of the units and parts is made at our enterprises. We have purchased electronic components of control boards and mechanical components in sufficient quantities. Thanks to these reserves, they successfully withstood the "pause" of the missing parts and reorganized into supply channels from more friendly countries. This gave us the advantage of making 3D printers available in large quantities and allowed us to keep up the pace of developing new equipment.

See How we assemble 3D printers | History of IMPRINTA

All detailed characteristics of 3D printers and interesting cases of our users on our website

A lot of useful videos for users of Hercules 3D printers and not only on our Youtube channel

Announcements of events, news, promotions we write in the Telegram channel

Our active life, 3D printing from us and users of our printers, announcements and news in the VK group

Choose a convenient one and subscribe.

import substitution Imprint imprinta

Subscribe author

Subscribe

Don't want

3

Article comments

More interesting articles

2

Follow author

Follow

Don't want

Yesterday, October 26, 2022, was the first day of the Formlabs User Summit 2022, where Fo...

Read more

2

Subscribe to the author

Subscribe

Don't want

The International Championship of High-Tech Professions High-Tech 2022 will be held in Yekaterinburg from 8 to 10. ..

..

Read more

levscha

Loading

07/16/2016

28907

128

Subscribe to the author

Subscribe

Don't want

Good afternoon!

There was a need to change the color on the desired layer during the printing process....

Read more

How 3D printers will change the footwear supply chain

Logistics plays an important role in moving material around the world. This is, in fact, one of their main tasks. Supply chains exist in every industry, and their efficiency becomes a competitive advantage. The technological cycle of creating a product and its packaging can be comparable in cost to the cost of delivering products to the consumer. Obviously, cost reduction can be achieved by shortening the supply chain, where possible. The second approach is to reduce the cost of production. But this area is specific, narrowly focused and the relevant specialists can optimize the production cycle (process?).

The second approach is to reduce the cost of production. But this area is specific, narrowly focused and the relevant specialists can optimize the production cycle (process?).

If you look at the material flow of footwear production, it is usually the movement of raw materials to factories in Southeast Asia. In parallel, there is a movement of cardboard from all markets. There is a production of finished products and packaging, according to plans drawn up 4-6 months ago. Then the products are sent to large distribution centers (DCs) in consumer countries, undergoing customs clearance. The products received at the DC are distributed through various distribution channels to the consumer directly, or through stores and intermediate warehouses. Traditional tasks that logistics solves.

If we approach the analysis of this material flow, considering it at the molecular level, it does not look so optimal.

It turns out that the factories are supplied with hydrocarbon raw materials obtained from ethylene, which is one of the products of oil cracking, organic and inorganic dyes, plasticizers, flame retardants, and cellulose for packaging. As a result of production, a finished product is obtained, in which the dimensions of the initial molecules have increased due to the polymerization reaction, and the resulting product has acquired a shape and properties. After packaging, the products (nylon, nylon, various plastics) move to the markets, along with 60-80% of the air, as the products are packed in boxes. It should be added that in order to deliver hydrocarbons in the form of products to markets, we are forced to burn a large amount of liquid hydrocarbons with shorter chains.

As a result of production, a finished product is obtained, in which the dimensions of the initial molecules have increased due to the polymerization reaction, and the resulting product has acquired a shape and properties. After packaging, the products (nylon, nylon, various plastics) move to the markets, along with 60-80% of the air, as the products are packed in boxes. It should be added that in order to deliver hydrocarbons in the form of products to markets, we are forced to burn a large amount of liquid hydrocarbons with shorter chains.

It turns out that we brought short hydrocarbon chains to China in order to increase them and return them.

You can optimize the process in terms of organic chemistry by applying new technologies in production.

I was inspired by the information that Adidas planned to produce 100 thousand sneakers in 2018 using a 3D printer, source: http://hitech.vesti.ru/article/652907/ It becomes obvious that the development of these layered production technologies products from feedstock allows us to solve the problem of the movement of hydrocarbons and shorten the supply chain. The implications of this development promise revolutionary change as traditional manufacturing and supply chains become anachronistic.

The implications of this development promise revolutionary change as traditional manufacturing and supply chains become anachronistic.

Let's define two criteria for choosing the most priority areas of application of 3D printing, bringing it closer to the consumer:

1. The coefficient of increase in the volume of finished products . If we can calculate how much finished product can be obtained from 1 cubic meter. raw materials, we will see that there are types of products where the result will exceed 10! An example is toys. Obviously, the larger the coefficient, the more relevant the application of the new method will be. And for example, the production of butter shows the opposite effect - the volume of feedstock will exceed the final volume of production. We should not be surprised by such different comparisons, since from the point of view of organic chemistry, in the case of toys, this is the production of polymers from hydrocarbon raw materials. For example, polypropylene - (C3H6) n

And in the case of oil, it is the movement of fats and water. Fats are salts of fatty acids. In fact, oxygen atoms are present in hydrocarbon molecules.

Fats are salts of fatty acids. In fact, oxygen atoms are present in hydrocarbon molecules.

2. The level of logistics costs in the cost of production . FMCG goods delivered from China to Russia have a cost of about 40% for delivery to the distribution center in Russia. These are shoes, clothes, toys, dishes, leisure goods, beauty and health products.

Using these broad restrictions, we can get a long list of consumer goods where we can and should think about the movement of production towards the consumer.

Another argument in favor of shortening the supply chain is the possibility of not planning. Regardless of the level of planning, there is always both unsatisfied demand and excess inventory that must be sold at a discount.

The ability to produce when needed frees up planning and unloads warehouses that will shrink as the 3D printer's productivity increases.

The use of 3D printers in central warehouses will turn them into a new type of production site.

At the entrance there will be transport with raw materials, and at the exit there will be finished products manufactured a few hours before shipment upon sales in stores and customer orders.

Moreover, the incoming flow is much less than the outgoing due to the coefficient of increase in the volume of finished products. It turns out that the warehouse of finished products is giving way to a warehouse of raw materials for a 3D printer, and planning the volumes of dyes, nylon threads, cellulose, etc. becomes a new task. And the lack of the right component for production becomes a limiting factor, and it will not be possible to fulfill orders. The tasks for the 3D printer are set by a program that manages priorities and receives feedback at the time of the sale of a unit of goods, or an online customer order, or an order generated by the inventory management department for store opening tasks.

These tasks should determine the desired peak performance of the 3D printer. He must provide customers with products at the peak of sales.

He must provide customers with products at the peak of sales.

Further development of this idea will be the further movement of production to the consumer. This means having 3D printers in stores and delivery vehicles. This speeds up the process of receiving the order by the buyer. And it gives the opportunity to improve the product compared to traditional production. By first scanning the foot, we can generate shoes tailored to the individual needs of the client. And this will be a new level of product quality. We get an individual model with unique characteristics.

But as we move production to the consumer and receive dividends from the reduction of the supply chain, it becomes more difficult for us to deliver raw materials. The solution to this problem should be to use a used product. We remember that from the point of view of organic chemistry, new sneakers do not differ from old ones in any way. There is a new requirement for a 3D printer - the ability to process the finished product, not the raw material. In fact, this complication is called depolymerization, to bring old sneakers to the state of the original raw material.

In fact, this complication is called depolymerization, to bring old sneakers to the state of the original raw material.

We can get a closed material cycle between the consumer and the nearest 3D printer. And the question arises - what will the former production workers and logisticians do?

It turns out that the future is preparing major changes in terms of functionality. We need a breakthrough in 3D printing. Must be able to maintain industrial 3D printers. It is necessary to store and move raw materials promptly and correctly.

In conclusion, a few conclusions:

- The development of industrial 3D printer technology will change and reduce the share of traditional production, and as a result, optimize material flows.

- Product manufacturing is shifting towards the consumer, shortening the traditional supply chain and developing the logistics of raw materials.

- The development of technology makes it possible to take into account the individual characteristics of the consumer.

Learn more