3D printer powerpoint

A PowerPoint 3D Printer: Missouri Teacher is Building a Unique $20 3D Printer with His Students - 3DPrint.com

When it comes to 3D printing within the classroom environment, there are some teachers who welcome it with open arms, while there are others who are deathly afraid of the technology. Some teachers have taken it upon themselves to learn how to use various 3D printers, while others have come up with some very unique lesson plans built around these new machines. However, one high school teacher in Union, Missouri is taking 3D printing to an entirely new level.

Dustin Klenke is a physics, robotics, and biology teacher at Union High School, and as part of an NSTA (National Science Teachers Association) conference that he recently attended, he learned a great deal about building his very own microstereolithographic (micro SLA) 3D printer. The presentation, which was given by a man named Joe Muskin, is part of a project run through the University of Illinois at Urbana-Champaign. It showed those in attendance the ins and outs of how to build their very own 3D printer, a printer that is based on the same concepts we see in today’s desktop DLP-based SLA printers, but which operates in its own unique way.

“The process uses an SLA gel, but instead of a laser to initiate polymerization, an ordinary data projector focused through a $3 magnifying glass displays a 2D image of each layer,” Klenke tells 3DPrint.com. “The images can be created with simple shapes in PowerPoint or slides. This solidifies an entire layer at once which eliminates the need for any moving components in the x and y-direction.”

The process is actually based on a research project that was headed up by Professor Nicholas Fang and developed at the University of Illinois. It is called microstereolithography, and it uses a simple projector to create objects with layers as small as just 400nm. Klenke tells us that $20 is enough to purchase all of the needed supplies at a hardware store. This of course doesn’t include the cost of the projector, but then again, projectors are quite common within just about every school.

This of course doesn’t include the cost of the projector, but then again, projectors are quite common within just about every school.

“The only mechanical piece is the elevator which precisely lowers the build platform after each layer has solidified,” explains Klenke.

The way the process works is very similar to how other desktop DLP SLA 3D printers operate. A beaker is filled with a liquid polymer, while PowerPoint or a slide show is loaded up on a connected PC. To begin printing, the first PowerPoint slide is displayed through the projector which is focused on the beaker of liquid. Each image slide is exposed for about 5-10 seconds, and after each image slide comes a blank “all black” slide. When this “all black” slide is loaded, the stage on which the beaker sits is lowered, allowing the liquid polymer to flow over the existing structure. Then the next image slide is exposed, and this entire process is repeated until a full 3-dimensional object is complete.

Virtually anyone with a projector can recreate this 3D printer using the following materials:

- Drawer slide

- ¼ x 20 threaded rod

- ¼ x 20 t-nut

- 2” L-bracket (2)

- 3” straight bracket

- Carpenters Square

- 1” x 6” wood

- 2” x 4” wood

- Tape measure

- Screwdriver

- Wood screws

- Saw

- Hammer

- Tin snips

- Aluminum sheet metal

- Sharpie

- 8 x 32 threaded rod

- 8 x 32 nuts

- Drill (with 9/16 bit)

- Dremel tool

- WD-40 (Lubricant)

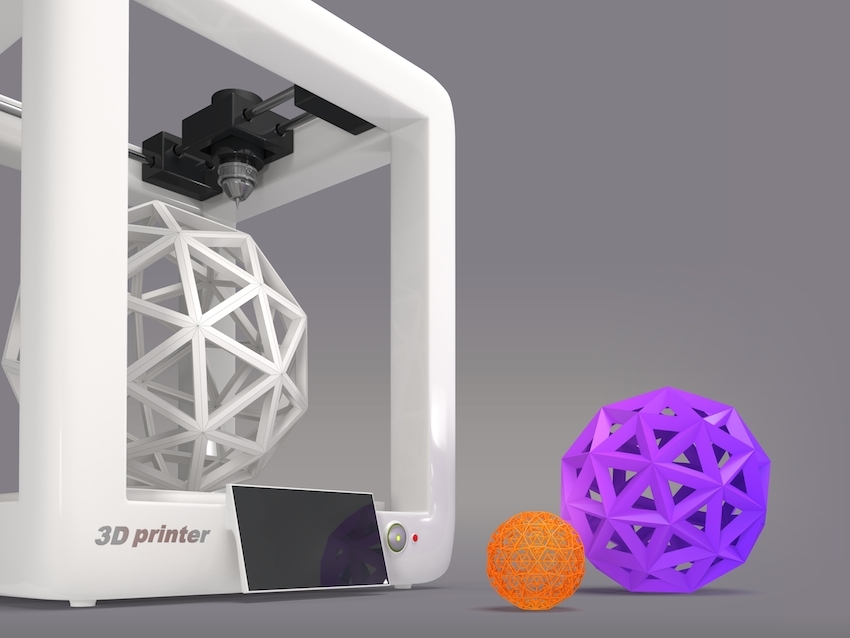

The elevator design, which Klenke’s class is in the process of building, is constructed mostly of wood, and as you can see in the images provided, the objects that this printer can create are very detailed and of the utmost quality. Klenke is one more example of a teacher who understands the importance of bringing 3D printing into the classroom. He, unlike most, is taking things a step further by allowing his students to actually build their class’ 3D printer.

What do you think about this process, and what Klenke is doing with his students? Should more teachers be following in his footsteps? Discuss in the PowerPoint MicroSLA 3D Printer forum thread on 3DPB.com.

[image source: University of Illinois]

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printer • 3d printing in school • dlp sla • education • high school • micro sla • micro stereolithography • Missouri • PowerPoint • sla 3d printer • stereolithography • university of illinois

Please enable JavaScript to view the comments powered by Disqus.

PPT – 3D Printing Future And Benefits PowerPoint presentation | free to download

About This Presentation

Transcript and Presenter's Notes

Title: 3D Printing Future And Benefits

1

3D Printing Future And Benefits

- Current and future applications of 3D Printing

2

Biomedical Engineering

- In recent years, scientists and engineers have

already been able to use 3D printing technology

to create body parts and parts of organs. The

The

first entire organ created through 3D Printing is

expected to be done in the coming years. The

process of creating the organ or body part is

exactly the same as if you were to create a

plastic or metal part, however, instead the raw

material used are biological cells created in a

lab. By creating the cells specifically for a

particular patient, one can be certain that the

patients body will not reject the organ. - Another application of 3D printing in the

biomedical field is that of creating limbs and

other body parts out of metal or other materials

to replace lost or damaged limbs. Prosthetic

limbs are required in many parts of the world due

to injuries sustained during war or by disease.

Currently prosthetic limbs are very expensive and

generally are not customized for the patients

needs. 3D printing is being used to design and

produce custom prosthetic limbs to meet the

patients exact requirements. By scanning the

By scanning the

patients body and existing bone structure,

designers and engineers are able to re-create the

lost part of that limb.

3

Aerospace and Automobile Manufacturing

- High technology companies such as aerospace and

automobile manufacturers have been using 3D

printing as a prototyping tool for some time now.

However, in recently years, with further

advancement in 3D printing technology, they have

been able to create functional parts that can be

used for testing. This process of design and 3D

printing has allowed these companies to advance

their designs faster than ever before due to the

large decrease in the design cycle. From what

used to take months between design and the

physical prototype, now within hours the design

team can have a prototype in their hands for

checks and testing. - The future of 3D printing in these industries

lies with creating working parts directly from a

3D printer for use in the final product, not just

for testing purposes. This process is already

This process is already

underway for future cars and aircraft. The way in

which 3D printing works (creating a part layer by

layer) allows the designer to create the part

exactly the way is needs to be to accomplish the

task at hand.Extremely complex geometry can be

easily created using a 3D printer, allowing for

parts to be lighter, yet stronger than their

machined counterparts.

4

Construction and Architecture

- Architects and city planners have been using 3D

printers to create a model of the layout or shape

of a building for many years.Now they are looking

for ways of employing the 3D printing concept to

create entire buildings. There are already

prototype printer systems that use concrete and

other more specialized materials to create a

structure similar to a small house. - The goal is the replace many cranes and even

construction workers with these printing systems.

They would work by using the 3D design model

created on CAD software, to create a layer by

layer pattern on the building just as a normal 3D

printer works today. Most of the innovation in

this area will have to come from the creation of

the appropriate materials.

5

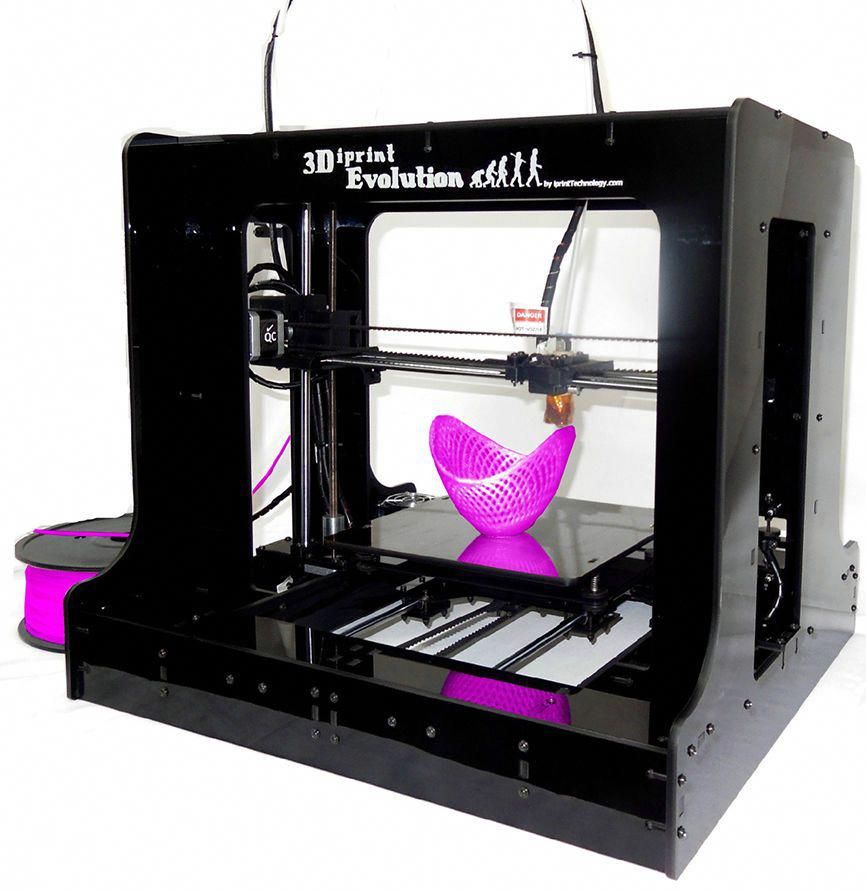

Product Prototyping

- The creation of a new product has been always one

that involves many iterations of the same

design.3D Printing revolutionized the industry by

allows designers to create and the next day see

and touch their design. No longer did it take

several meetings for everyone to agree on one

design to create, and then wait months for the

actual part to arrive. Nowadays a version of each

idea is created and the next day, all are

reviewed together, thus giving the ability to

compare and contrast each ones features.Plastic

parts, for example, require molds and tooling to

be created, these custom parts are expensive to

create, therefore one must be certain the part

designed meets the requirements. With 3D printing

With 3D printing

you can create a part that will look and feel

exactly like the finished product. Some parts can

also be tested just as the real injection molded

part would.

6

3D Printing Benefits Value

- 3D printing, whether at an industrial, local or

personal level,brings a host of bene fits that

traditional methods of manufacture (or

prototyping) simply cannot. - Customisation

- 3D printing processes allow for mass

customization the ability to personalize

products according to individual needs and

requirements. Even within the same build chamber,

the nature of 3D printing means that numerous

products can be manufactured at the same

time,according to the end-users requirements at

no additional process cost.

7

- Complexity

- The advent of 3D printing has seen a

proliferation of products (designed in digital

environments), which involve levels of

complexity that simply could not be produced

physically in any other way. While this advantage

While this advantage

has been taken up by designers and artists to

impressive visual effect, it hasalsomade a

significant impact on industrial applications,

whereby applications are being developed to

materialize complex components that are proving

to be both lighter and stronger than their

predecessors. Notable uses are emerging in the

aerospace sector where these issues are of

primary importance.

8

- Tool-less

- For industrial, manufacturing, one of the most

cost-, time- and labor-intensive stages of the

product development process is the production of

the tools. For low to medium volume applications,

industrial 3D printing or additive

manufacturing can eliminate the need for tool

production and, therefore, the costs, lead times

and labour associated with it. This is an

extremely attractive proposition, that an

increasing number or manufacturers are taking

advantage of. Furthermore, because of the

Furthermore, because of the

complexity advantages stated above, products and

components can be designed specifically to avoid

assembly requirements with intricate geometry and

complex features further eliminating the labour

and costs associated with assembly processes.

9

- Sustainable / Environmentally Friendly

- 3D printing is also emerging as an energy-e

efficient technology that can provide

environmental efficiencies in terms of both the

manufacturing process itself, utilizing up to 90

of standard materials, and, therefore, creating

less waste, but also throughout an

additivelymanufactured products operating life,

by way of lighter and stronger design that

imposes a reduced carbon footprint compared with

traditionally manufactured products.!Furthermore,

3D printing is showing great promise in terms of

fulfilling a local manufacturing model, whereby

products are produced on demand in the place

where they are needed eliminating huge

inventories and unsustainable logistics for

shipping high volumes of products around the

world.

10

- Thank You

- www.jewelkreator.com

About PowerShow.com

Presentation Food from 3D printer report, project

- Home

- Miscellaneous

- Education

- Sport

- Natural science

- Natural history

- Religious Studies

- French

- Drafting

- English

- Astronomy

- Algebra

- Biology

- Geography

- Geometry

- Children's presentations

- Informatics

- History

- Literature

- Mathematics

- Music

- MHK

- German

- OBZh

- Social studies

- World around

- Pedagogy

- Russian language

- Technology

- Physics

- Philosophy

- Chemistry

- Templates, backgrounds, pictures for presentations

- Ecology

- Economy

Presentation on the topic Presentation Food from a 3D printer, presentation subject: Miscellaneous. This material in pptx (PowerPoint) format contains 10 slides, use the player to view. A presentation on a given topic can be downloaded at the bottom of the page by sharing the link on social networks! Presentations are taken from open access or uploaded by their authors, the site administration is not responsible for the accuracy of the information in them, all rights belong to the authors of the presentations and can be deleted at their request.

This material in pptx (PowerPoint) format contains 10 slides, use the player to view. A presentation on a given topic can be downloaded at the bottom of the page by sharing the link on social networks! Presentations are taken from open access or uploaded by their authors, the site administration is not responsible for the accuracy of the information in them, all rights belong to the authors of the presentations and can be deleted at their request.

“Food from 3 D-printer”

were performed by students of gr. 216 PC:

Normantas Daria,

Nagurny Ksenia

Soviet, Soviet 2018

Purpose:

to prepare people's minds for the inevitable evolution of foods in our diet in the near future

Objectives:

to share about promising developments in the food industry;

show how the products of the future look like

Sovetsk, 2018

Three -dimensional method of food production

Food Ingredient Cartridges

Sovetsk, 2018

Not all food ingredients can be 3D printed;

3D cooking process is quite slow;

the finished dish must be cooled before eating

Limitations when using a 3D printer:

3D printing is used in the following culinary industries: - baking flour products; - preparation of coffee products; - confectionery production.

Sovetsk, 2018

Restaurant 3D-printed food Food

Sovetka, 2018 Sovetka, 2018 Sovetka, 2018 Sovetka, 2018 printed on a 3D printer

Sovetsk, 2018

Range of 3D printers:

Confectionery 3D printer,

Price from 265 thousand rubles

coffee 3D printer,

Price from 100 thousand rubles

Sovetsk, 2018

Download presentation

What is shareslide.ru?

This is a presentation site where you can store and share your presentations, reports, projects, templates in PowerPoint format with other users. We help schoolchildren, students, teachers, teachers to store and exchange educational materials.

We help schoolchildren, students, teachers, teachers to store and exchange educational materials.

For copyright holders

Feedback

Email: Click to see

3D Print and 3D Printer Presentation, Report

Author Salatina E. A., Salatin S. A.

Material taken from: make-3d.ru

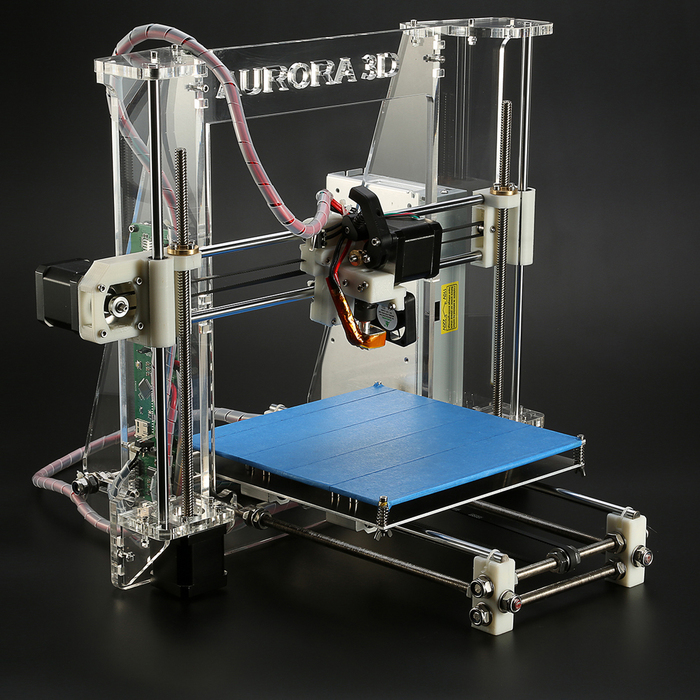

What is a 3D printer?

The principle of operation of a 3d printer is based on the principle of gradual (layered) creation of a solid model, which, as it were, is “grown” from a certain material. The advantages of 3D printing over the usual, manual methods of building models are high speed, simplicity and relatively low cost.

Technologies

There are various 3D printing technologies. The difference between them lies in the way the product layers are applied.

The most common are SLS (selective laser plexus), HPM (molten material overlay) and SLA (stereolithiography).

The most widely used technology due to the high speed of building objects is stereolithography or SLA.

SLA technology

The technology works like this: a laser beam is directed at a photopolymer, after which the material hardens.

The photopolymer is a translucent material that deforms when exposed to atmospheric moisture.

Once cured, it can be easily bonded, machined and painted. The working table (elevator) is in a container with a photopolymer. After the laser beam passes through the polymer and the layer hardens, the working surface of the table moves down.

SLS technology

Laser beam sintering of powder reagents - aka SLS - is the only 3D printing technology that is used in the manufacture of molds for both metal and plastic casting.

Plastic models have excellent mechanical properties, which make them suitable for making full-featured items. SLS technology uses materials that are similar in properties to the brands of the final product: ceramics, powdered plastic, metal.

The 3D printer device looks like this: powder substances are applied to the surface of the elevator and sintered under the action of a laser beam into a solid layer that corresponds to the parameters of the model and determines its shape.

DLP technology

DLP technology is new to the 3D printing market. Stereolithographic printers are positioned today as the main alternative to FDM equipment. This type of printer uses digital light processing technology. Many people wonder what the 3d printer of this sample prints with?

This type of printer uses digital light processing technology. Many people wonder what the 3d printer of this sample prints with?

Instead of a plastic filament and a heating head, photopolymer resins and a DLP projector are used to create three-dimensional figures.

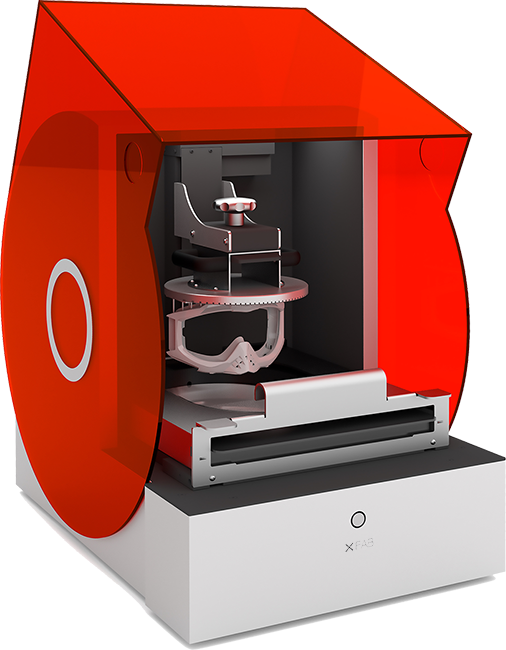

Despite the intricate name, the device is almost indistinguishable from other desktop printers. Its developers, represented by

QSQM Technology Corporation, have already launched the first samples of high-tech equipment into a series. It looks like this:

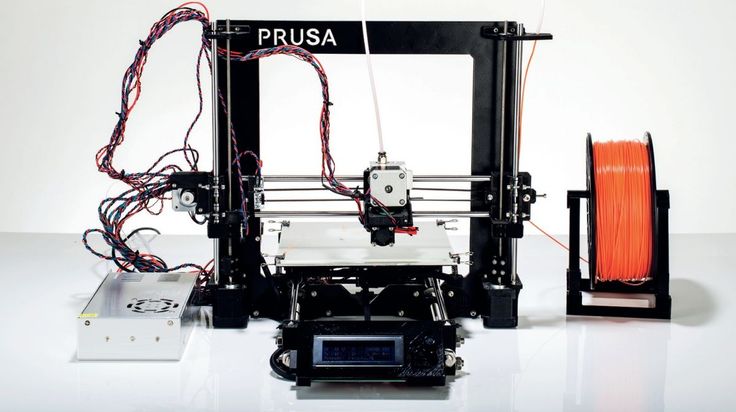

HPM technology (FDM) HPM

Allows you to create not only models, but also final parts from standard, structural and high-performance thermoplastics. It is the only technology that uses production grade thermoplastics to provide unparalleled mechanical, thermal and chemical strength to parts.

HPM Printing stands out for its cleanliness, ease of use and suitability for office use. Thermoplastic parts are resistant to high temperatures, mechanical stress, various chemicals, wet or dry environments.

Thermoplastic parts are resistant to high temperatures, mechanical stress, various chemicals, wet or dry environments.

Soluble auxiliary materials allow the creation of complex multi-level shapes, cavities and holes that would be problematic to obtain with conventional methods. HPM 3D printers create parts layer by layer by heating the material to a semi-liquid state and extruding it according to computer-generated paths.

When the 3D printer has finished creating the part, it remains to separate the auxiliary material mechanically, or dissolve it with detergent, after which the product is ready for use.

3D pens

Hand-printing pens are also popular these days. Moreover, it would be correct to call them not printing devices, but pens for drawing three-dimensional objects.

Pens are made in the same way as fusing printers. The plastic thread is fed into the pen, where it melts to the desired consistency and is immediately squeezed out through a miniature nozzle.

Applications of 3D printing

3D printing has opened up great opportunities for experimentation in areas such as architecture, construction, medicine, education, fashion design, small-scale production, jewelry, and even in the food industry. In architecture, for example, 3D printing allows you to create three-dimensional models of buildings, or even entire microdistricts with all the infrastructure - squares, parks, roads and street lighting.

Thanks to the cheap gypsum composite used, the cost of finished models is low. And more than 390 thousand CMYK shades make it possible to embody any, even the most daring, imagination of an architect in color.

3D printer: application in the field of construction

In construction, there is every reason to believe that in the near future the process of erecting buildings will be much faster and easier.