3D printing oslo

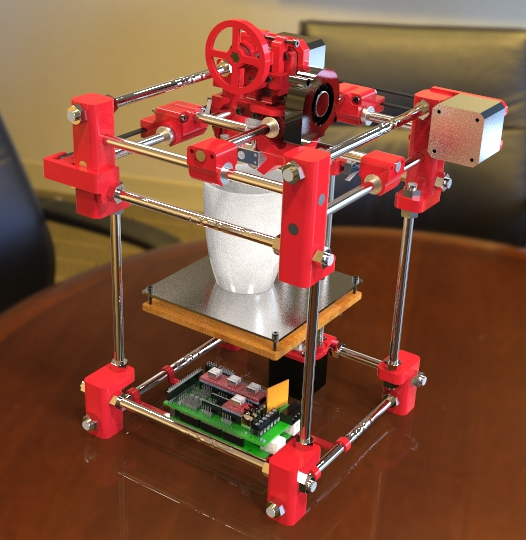

3D Print Lab — NORDIC3D

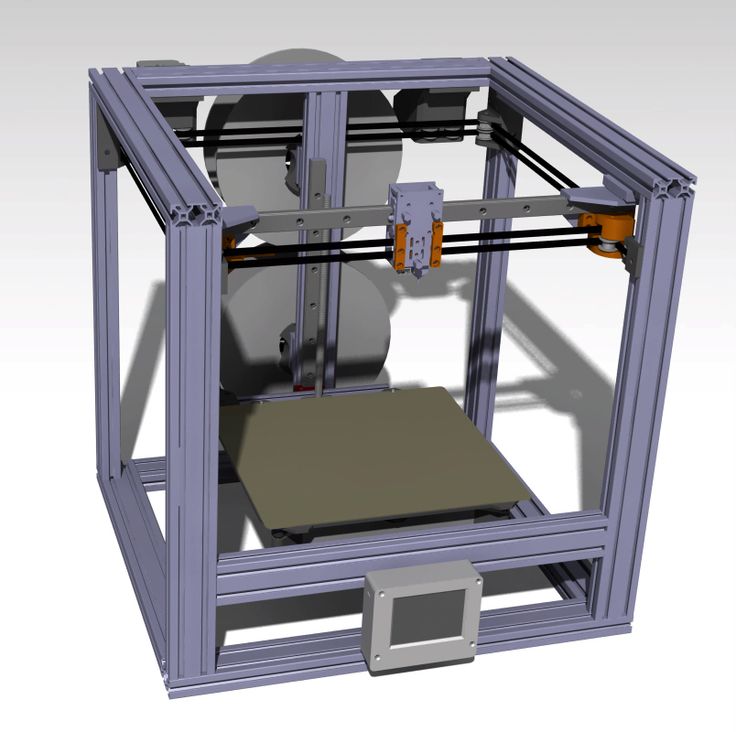

SLS, Polyjet and Additive Process

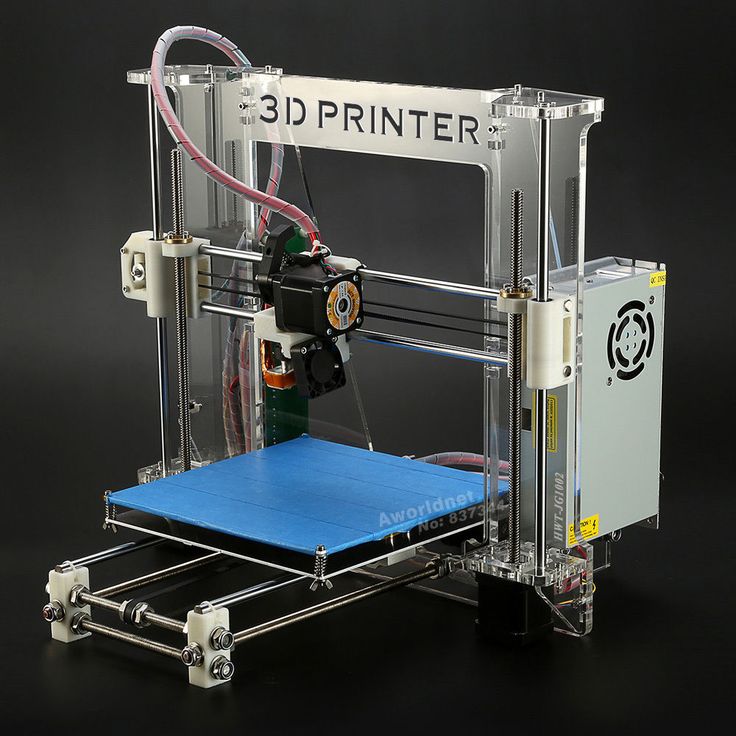

Technology | SLS | PolyJet | SLA |

Features | Durable models with high precision, optimal for prototypes, series and larger scale models | Very precise models, with many material options, 2 materials in composite | Cheap and precise, but slower process |

Machine | EOS P395 and P396 | Stratasys Objet 260 Connex3 | FormLabs Form 3 |

Description | Builds by melting very thin layers of polyamid (nylon) plastic into each other with laser. A great choice for series and larger models | A technology that involves a liquid acrylic material that hardens when hit by UV-light. It builds layer by layer to extreme precision. A good choice for detailed models and prototypes. A combination of two materials in the same print (with different hardness)is possible | Precise models |

Precision | 0,1 mm layer | 0,016 mm layer | 0,025 mm layer |

Finish | White Plastic, Plastic with aluminum / glass Any solid color in post-process | Transparent and Opaque alternatives, total of 12 different plastic types, even flexible and solid | White plaster composite with unlimited CMYK color |

Max sizeL × W × H | 320 × 320 × 620 mm | 255 × 255 × 200 mm | 145 × 145 × 185mm |

Price | Example: 600mm Z-height 30 000 NOK | Material: | Material: |

Delivery time | 1 - 2 days (normal) | 1 - 2 days (normal) | 1 - 2 days (normal) |

Materials | PA2200 White Flexible plastic that som is suitable for locking mechanisms, cogs and other parts that needs to be durable, but still precise. PA3200 GF Polyamide with glass particles. Hard models. Alumide Polyamid with aluminium. Light gray models that are thermally conductive. Can be used to make injection molds and things that has to withstand heat. | Transparent: FullCure 720 and VeroClear Hard materials (shore D85): VeroWhite, VeroBlack, VeroGrey og VeroBlue Similar to polypropylen: DurusWhite (shore D76) Flexible rubber like: TangoGrey (ShoreA75), TangoBlack (shore A60) og TangoBlackPlus / TangoPlus (shore A27) Heat resistant materials: Endur (shore D87) will withstand temperatures up to 75 - 80 Celsius Visit Stratasys for more information about the materials Digital ABS |

|

3D Printing Service Oslo Norway

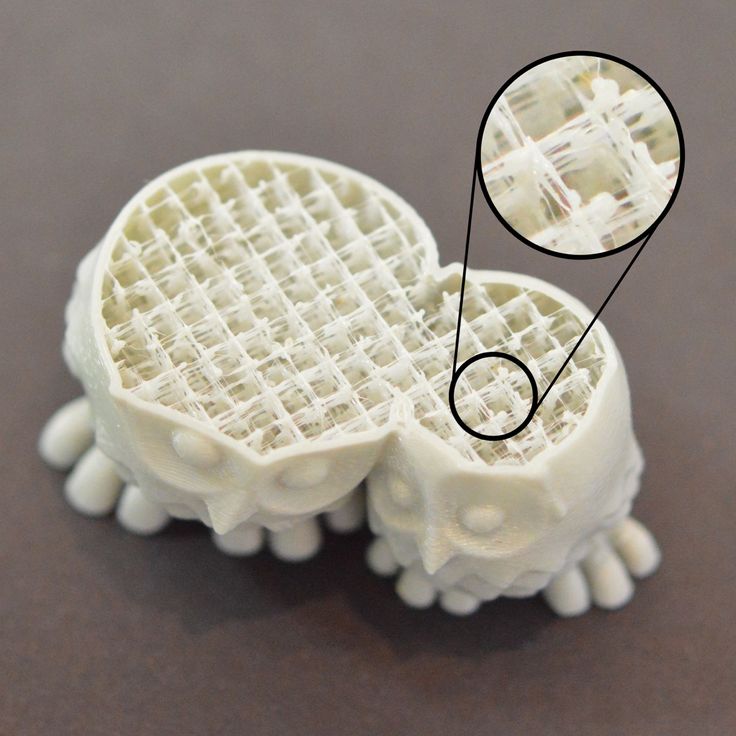

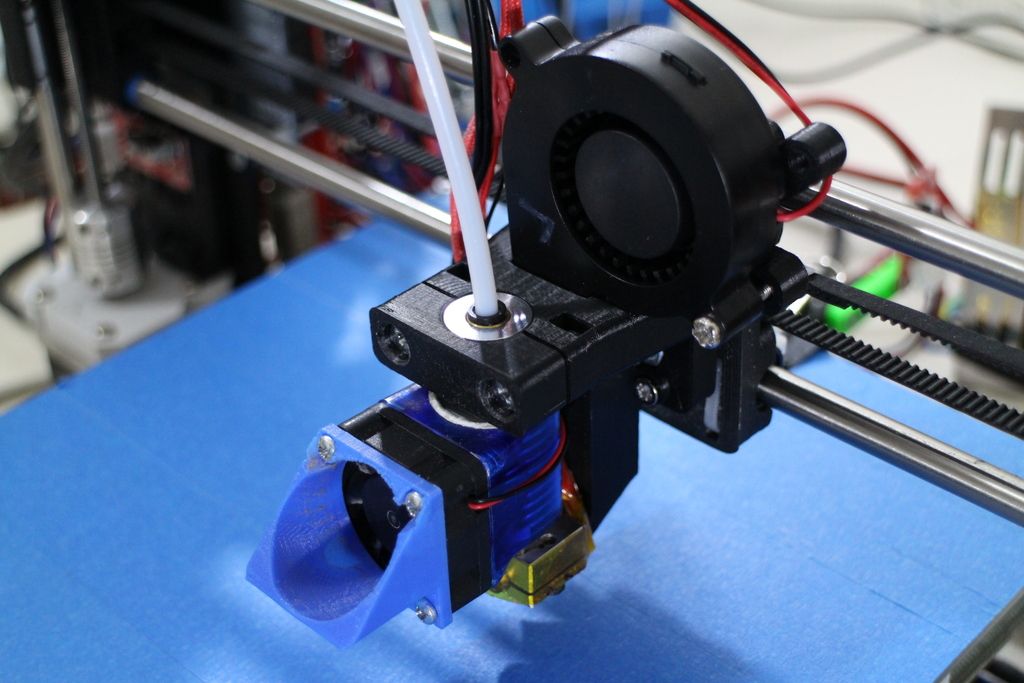

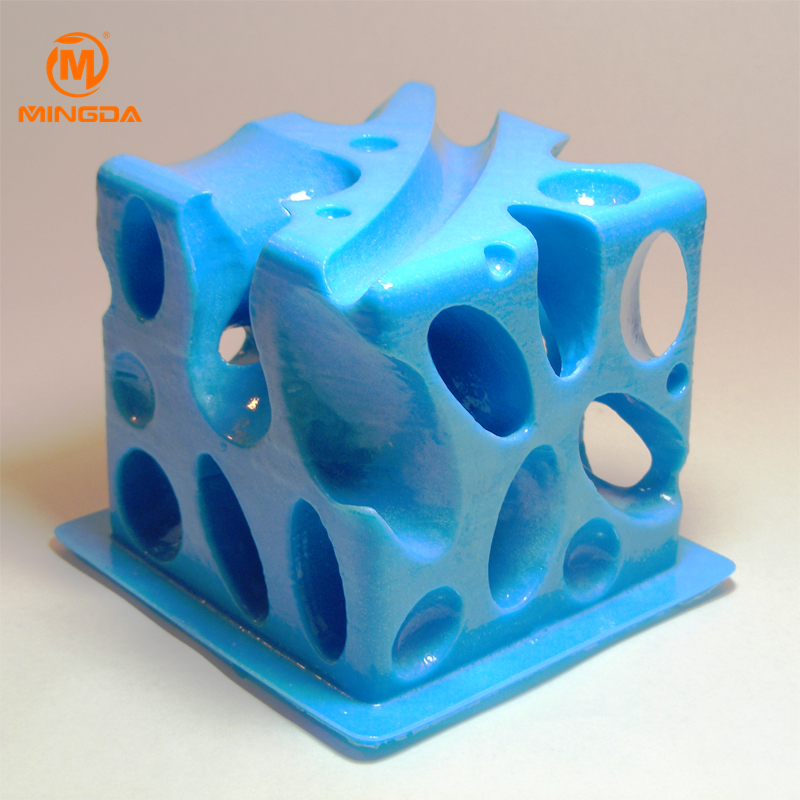

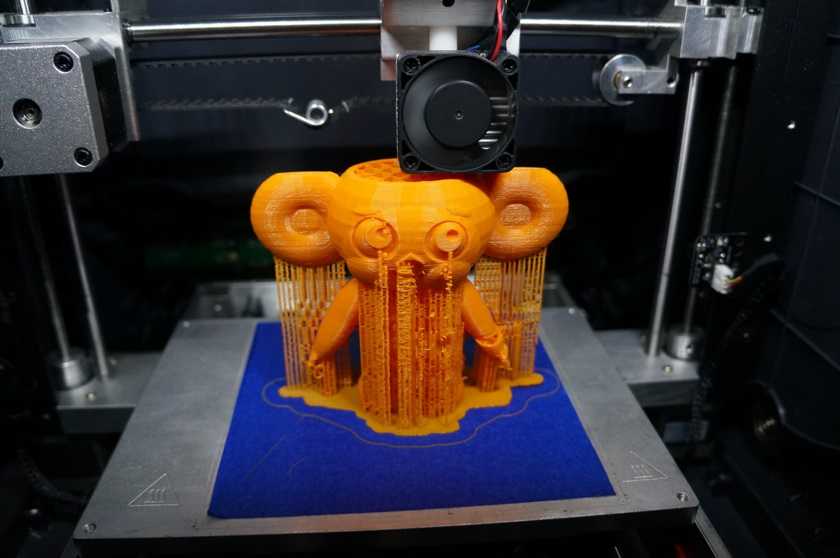

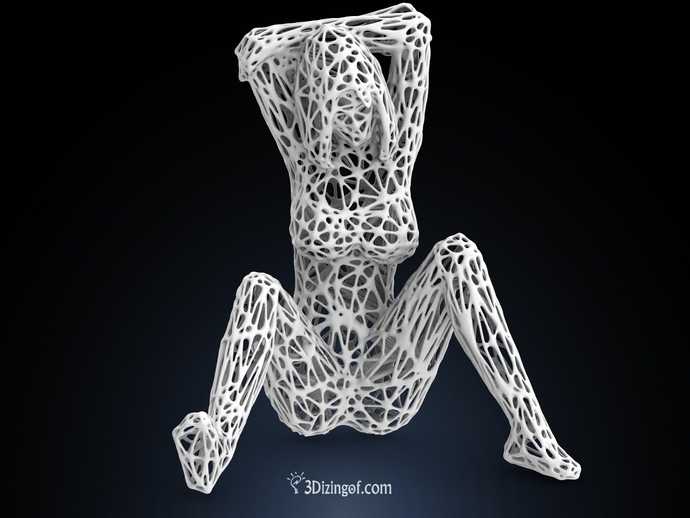

3D printing technology has come a long way in recent years, and one of the latest advancements is the ability to create highly detailed and visually appealing surface finishes using poly jet technology.

read more...

CNC machining is a process used to produce precision parts and components by removing ma

read more...

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

read more...

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

It is a three-dimensional object that is made from polyurethane.

read more...

Choosing the right China injection molding company is vital to the success of your project. There are several aspects to consider when choosing a China injection molding company.

read more...

Designing with Multi Jet Fusion is a process of 3D printing that is done by using different types of lasers.

read more...

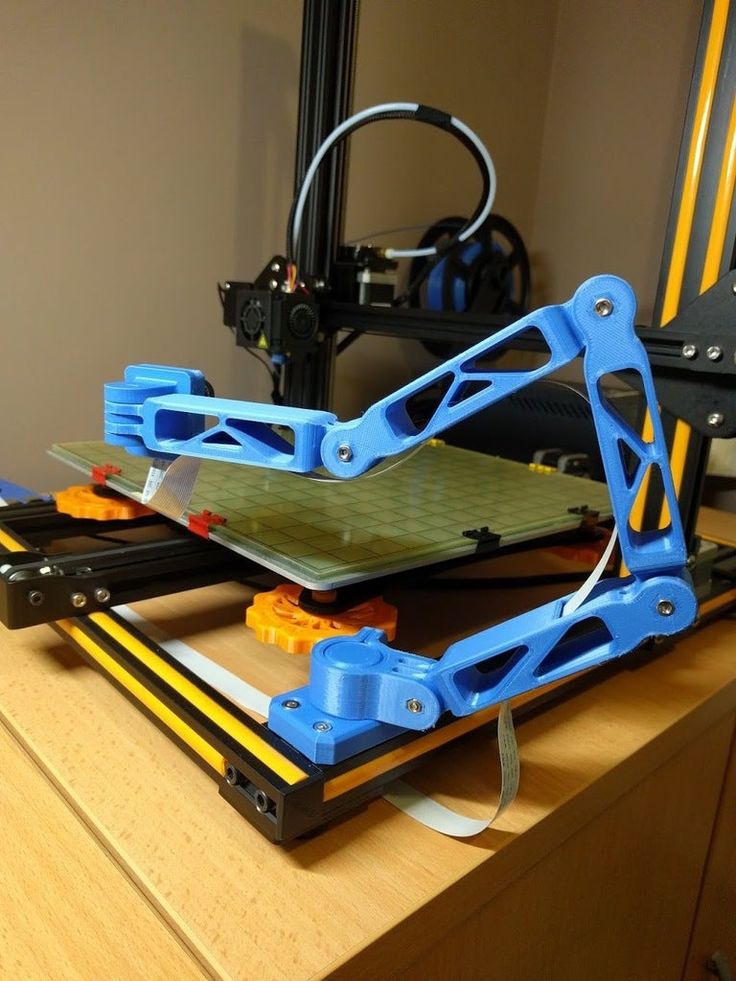

3D printing is a great way to prototype and produce parts that are not accessible by other means

read more...

Introduction: What is a 3D Printing and Why Have They Become So Popular In The Last Decade?

read more...

With the promise of low costs and fast turnaround times, Chinese CNC machining services are a popular choice for companies looking to outsource their machining needs. In fact, carrying out CNC machining in China is a vital step for many product developers, since few other countries can match China for cost and efficiency.

read more...

Cyient additive manufacturing is new supplier in partZpro network

read more...

The first benefit of using CNC machining for prototyping is the ability to make changes at any time before the part is finalized.

read more...

Stainless steel is a useful material and has many applications that can be found in many different industries.

read more...

Customized manufacturing has become more popular in the last decade, and it is not hard to understand

read more...

Anodizing is an electrochemical process that changes the surface of a metal or alloy and the thickness of its oxide layer.

read more...

A coordinate measuring machine or CMM is a device that is used to manually measure 3D coordinates of a surface

read more. ..

..

Precision CNC machining has many benefits. It can be used to produce highly accurate parts, parts that are difficult to produce by other methods,

read more...

Sheet metal is a thin metal sheets, cut, folded and then tapered to a specific edge and from a single pattern

read more...

Hardware startups have many risk factors that often make things harder for them than others startups.

read more...

Industry 4.0 has become a trend in the business world. With the emergence of the internet of things, robots and 3D printers,

read more...

CNC milling is a manufacturing process where raw materials are carved and sculpted into shapes to produce a finished product.

read more...

3D printing is one of the most intricate, innovative, and revolutionary technologies that has ever been developed.

read more...

Scientists around the world declared COVID-19 a global pandemic just one year ago.

read more...

CNC Turning is a process in which a CNC machine takes a block of material and shapes it for a specific use.

read more...

Finding a proper and reputable CNC machine shop in China is easier than you might think

read more...

Medical devices can take a number of shapes and sizes and plastic injection molding is often used in the manufacturing process

read more...

The newest system for 3D printing is the SLS 3D printing technology

read more...

Plastic injection molding is a manufacturing process that converts a lot of liquid plastic into a number

read more...

Manufacturers of medical devices have a new, cost-effective way to produce their products

read more. ..

..

There is a mindset among product manufacturers that by just moving the manufacturing to any Chinese manufacturer they would reduce their costs helping them in today's competitive market.Given the growing number of Asian custom manufacturers, it is difficult for designers to pick the right suppliers while

read more...

All top global economies have adopted many new inventions. People and companies are developing new products, and this has created a gap in research and development that is costly and takes considerable time.

read more...

Times are changing, and so are businesses. Companies are adapting to new operation methods and are evolving swiftly.Recently, numerous organizations have begun utilizing prototypes for doing business.

read more...

3D printing started as just another means for people and companies to print and get things done. Now, it’s the cornerstone of printing. Hardly anyone had access to 3D printers about a decade ago. Now, they’re as ubiquitous as you can imagine.

Hardly anyone had access to 3D printers about a decade ago. Now, they’re as ubiquitous as you can imagine.

read more...

The corona virus is already the watershed moment for 2020. The virus that started like a minor issue in China quickly spread like wildfire, and soon enough, just about every continent has now had to deal with it in one way or the other over the course of the past few months.

read more...

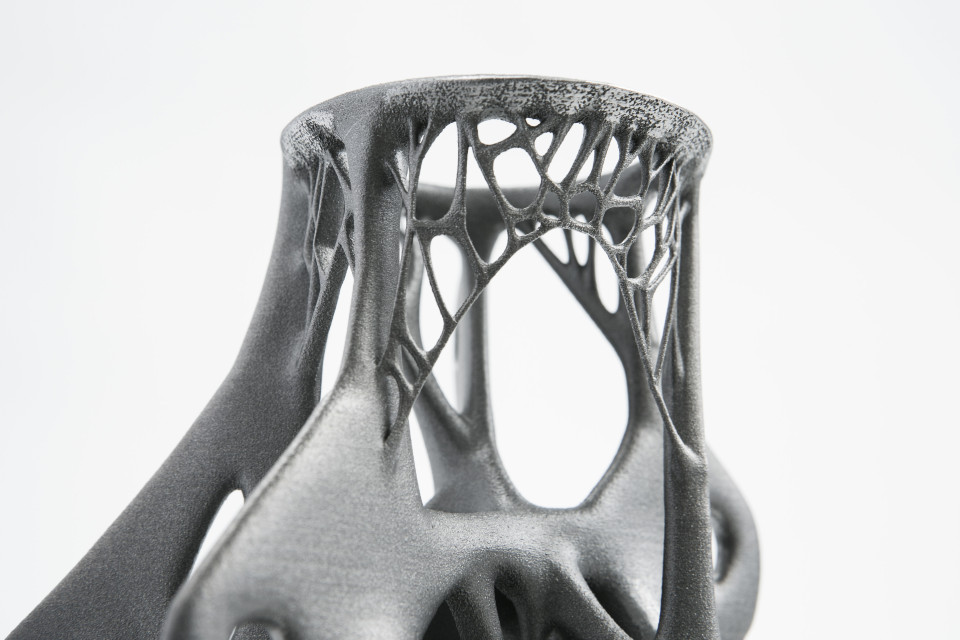

Also known as DMLS, Direct Metal Laser Sintering is a manufacturing method where technicians create metal parts from 3D CAD data without the need for any cumbersome tooling.

read more...

Plastic injection molding has grown to be the most popular molding technique. The process used varies in a wide array of ways, including but not limited to applications. To wit, here is some top industries hat apply this molding technique in their operations.

read more. ..

..

Injection molding is an interesting concept that a lot of companies use these days. However, the trend is also getting an exciting twist thanks to various innovations. Here are some of the most popular of those:

read more...

The injection molding industry is changing rapidly. With the times moving once more, it’s worth looking into the trends that drive change the most.

read more...

Plastic injection molding is a multifaceted production method that can help to improve plastic production. So far, it has provided various benefits over the other forms of plastic molding. Some of these benefits include:

read more...

Rapid prototyping can speed up the development process. Every product is formed and manufactured depending on the materials used and the type of prototyping that will best suit the product. The following are the different types of rapid-prototyping:

read more. ..

..

With the rapid growth of cloud computing in the second decade of the 21st century, the manufacturing industry has changed dramatically.

read more...

Recently machining center is shifting toward five-axis control. The five-axis machining has high precision and effectiveness. For instance, the high-end numerical control system with a five-axis linkage can also perform high-precision machining on complex spatial surfaces. Also, it is more suitable for processing modern molds such as automobile parts and aircraft structural components.

read more...

What precisely is Computer numerical-controlled (CNC) machining? It's a way to make parts by expelling material using fast, exactness mechanical machines that utilization a variety of cutting tools to make the Final Design. CNC machines usually used to make the geometric shapes required by clients are vertical processing machines, horizontal milling machines, and many more.

read more...

partZpro uses it's China manufacturers as China's most significant manufacturing network for on-demand manufacturing

read more...

Advantages of CNC processing:Material cost is low, and the material selection range is wideThe machine and equipment are stable and easy to operate.Parts can be appropriately decomposedIt can be easily adapted to parts with large size and simple structure.

read more...

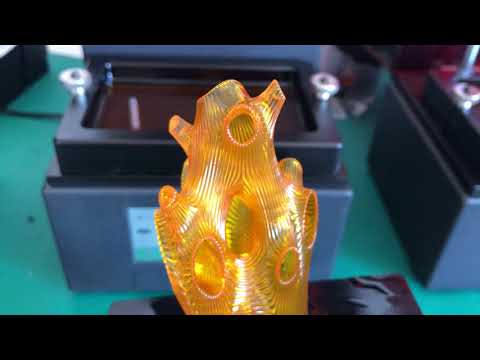

Stereolithography 3D printing is a processing technique that is utilized in developing prototypes, models, and parts production layer after layer through a photo-chemical process. Monomers are often cross-linked together to create superior polymers. SLA processing has gained popularity over the years for producing parts with high precision and an excellent surface finish. It is considered the most cost-effective hence economically viable for the manufacturing of components. SLA 3D printing has helped professionals in optimizing production, cutting down on cost and manufacture of high-quality industrial parts. This article aims to provide designers with a profound decision-making background to the creation of quality products by employing SLA 3D printing.

SLA 3D printing has helped professionals in optimizing production, cutting down on cost and manufacture of high-quality industrial parts. This article aims to provide designers with a profound decision-making background to the creation of quality products by employing SLA 3D printing.

read more...

Sign up at our sign up page. Our machine shops or we will use your email for DFM analysis, and also platform will send your final quote to your email provided on this page.

read more...

partZpro is an online machine shop service that its idea originated in Orange County. It connects customers who are looking for CNC machining service in Southern California to machine shops in a few simple-to-follow steps. By having over 100 CNC machines at the fingertips of our Southern California customers, you can rest assured that you will get your quality parts in a fast turnaround while you have full payment protection by our platform.

read more...

Product finishing services can be in form of metal finishing, industrial finishing, quality finishing among others. It is important to know the type of finishing that is suitable for your product as this will ensure that you have the right and proper finishing.

read more...

Stereolithography is an additive manufacturing process that, in its most common form, works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat.

read more...

The Computer Numerical Control also known as the CNC is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers.

read more...

There are many benefits of CNC Machining today such that there has been an increase in the use of CNC machines across different parts of the world. Some of the benefits of CNC Machining includes but are not limited to the following:

read more...

A computer numerical control (CNC) router is a computer-controlled cutting machine related to the hand-held router used for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, glass, and foams. CNC routers can fill the roles of many carpentry dealers such as saw panels, spindles and drills.

read more...

The increase in the use of CNC Machining has left a lot of people wondering what it is about and how it came to be. This article highlights some interesting facts about CNC Machining you might not be aware of. These facts include:

read more. ..

..

Thanks to technology, a handful of websites have addressed some of the issues in the method (A). An engineer can upload their 3D files on their platform and enjoy the user-friendly interface on some of these websites to get an instant quote. Also, they can pay for their orders on the same platform, and these companies will take care of CNC machining of the parts using their network of qualified manufacturers. With the help of machine shops locally or in China, they can get the parts CNC machined in the time frame and to the price they had quoted to the customers.

read more...

A Computer Numerical Control (CNC) system offers an advanced combination skill and technology that is mostly controlled by an alphanumeric system that has been coded. A CNC machine is made up of five basic parts. These parts have their different functions but are blended in such a way that they work in synchronization with one another. This synchronic working of the basic parts of the CNC is what makes it a very great and advanced tool.

read more...

Ensure that when choosing the CNC Machining service company/outlet, you are honest with what you want and are willing to pay to get the best services. Also, make sure that you verify the CNC service before going on with them. If possible, ask for samples of what they have done.

read more...

A CNC Machine is defined as a Computer Numerical Control Machine. A CNC machine comprises of the mini computer or the microcomputer that acts as the controller unit of the machine in the machine shops. Also, it can be defined as the automated control of machining tools (drills, boring tools, lathes). A CNC machine processes a piece of stock material (metal, plastic, wood, ceramic, or composite) to manufacture a CNC machined part by following code instructions or programmed instruction that usually come out of a cam software.

read more...

Often times people do not know what to check out for when choosing a machine shop to help them out with their equipment. Choosing a machine shop is more than just searching for a machine shop near you, one might be tempted to just search for “machine shops near me” and just go with the ones listed. We are not saying it is bad to search for machine shops close to you however, we want to make sure that you do not just visit any machine shop and not be totally satisfied with the services that they offer.

Choosing a machine shop is more than just searching for a machine shop near you, one might be tempted to just search for “machine shops near me” and just go with the ones listed. We are not saying it is bad to search for machine shops close to you however, we want to make sure that you do not just visit any machine shop and not be totally satisfied with the services that they offer.

read more...

Traditional machining has evolved over the years, giving way to an era of more complex machining systems that are cost-effective and highly efficient. Computer numerical control (CNC) machining is a subtractive process of manufacturing that utilizes an automated power that is computer-integrated to control tools such as lathes, boring, and drilling machines. It is used to produce parts of high quality with high dimensional accuracy in a cost-effective manner. There has been tremendous growth in the use of CNC machining, thereby revolutionizing the manufacturing industry. As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

read more...

The CNC is a very vital and important part of handling any manufacturing job as it pays detailed attention to texture, length, and direction. Making use of the CNC during any form of manufacturing guarantees you that the work to be done will be done in a neat and smart manner such that you do not bother about how the work to be done is carried out. CNC systems usually offer far more expansive computational capacity.

read more...

3D printing technology has come a long way in recent years, and one of the latest advancements is the ability to create highly detailed and visually appealing surface finishes using poly jet technology.

read more...

CNC machining is a process used to produce precision parts and components by removing ma

read more...

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

read more...

Polyurethane castings are a type of mold making that is primarily used in the automotive industry. It is a three-dimensional object that is made from polyurethane.

read more...

Choosing the right China injection molding company is vital to the success of your project. There are several aspects to consider when choosing a China injection molding company.

read more...

Designing with Multi Jet Fusion is a process of 3D printing that is done by using different types of lasers.

read more. ..

..

3D printing is a great way to prototype and produce parts that are not accessible by other means

read more...

Introduction: What is a 3D Printing and Why Have They Become So Popular In The Last Decade?

read more...

With the promise of low costs and fast turnaround times, Chinese CNC machining services are a popular choice for companies looking to outsource their machining needs. In fact, carrying out CNC machining in China is a vital step for many product developers, since few other countries can match China for cost and efficiency.

read more...

Cyient additive manufacturing is new supplier in partZpro network

read more...

The first benefit of using CNC machining for prototyping is the ability to make changes at any time before the part is finalized.

read more...

Stainless steel is a useful material and has many applications that can be found in many different industries.

read more...

Customized manufacturing has become more popular in the last decade, and it is not hard to understand

read more...

Anodizing is an electrochemical process that changes the surface of a metal or alloy and the thickness of its oxide layer.

read more...

A coordinate measuring machine or CMM is a device that is used to manually measure 3D coordinates of a surface

read more...

Precision CNC machining has many benefits. It can be used to produce highly accurate parts, parts that are difficult to produce by other methods,

read more...

Sheet metal is a thin metal sheets, cut, folded and then tapered to a specific edge and from a single pattern

read more...

Hardware startups have many risk factors that often make things harder for them than others startups.

read more...

Industry 4.0 has become a trend in the business world. With the emergence of the internet of things, robots and 3D printers,

read more...

CNC milling is a manufacturing process where raw materials are carved and sculpted into shapes to produce a finished product.

read more...

3D printing is one of the most intricate, innovative, and revolutionary technologies that has ever been developed.

read more...

Scientists around the world declared COVID-19 a global pandemic just one year ago.

read more...

CNC Turning is a process in which a CNC machine takes a block of material and shapes it for a specific use.

read more...

Finding a proper and reputable CNC machine shop in China is easier than you might think

read more. ..

..

Medical devices can take a number of shapes and sizes and plastic injection molding is often used in the manufacturing process

read more...

The newest system for 3D printing is the SLS 3D printing technology

read more...

Plastic injection molding is a manufacturing process that converts a lot of liquid plastic into a number

read more...

Manufacturers of medical devices have a new, cost-effective way to produce their products

read more...

There is a mindset among product manufacturers that by just moving the manufacturing to any Chinese manufacturer they would reduce their costs helping them in today's competitive market.Given the growing number of Asian custom manufacturers, it is difficult for designers to pick the right suppliers while

read more...

All top global economies have adopted many new inventions. People and companies are developing new products, and this has created a gap in research and development that is costly and takes considerable time.

People and companies are developing new products, and this has created a gap in research and development that is costly and takes considerable time.

read more...

Times are changing, and so are businesses. Companies are adapting to new operation methods and are evolving swiftly.Recently, numerous organizations have begun utilizing prototypes for doing business.

read more...

3D printing started as just another means for people and companies to print and get things done. Now, it’s the cornerstone of printing. Hardly anyone had access to 3D printers about a decade ago. Now, they’re as ubiquitous as you can imagine.

read more...

The corona virus is already the watershed moment for 2020. The virus that started like a minor issue in China quickly spread like wildfire, and soon enough, just about every continent has now had to deal with it in one way or the other over the course of the past few months.

read more...

Also known as DMLS, Direct Metal Laser Sintering is a manufacturing method where technicians create metal parts from 3D CAD data without the need for any cumbersome tooling.

read more...

Plastic injection molding has grown to be the most popular molding technique. The process used varies in a wide array of ways, including but not limited to applications. To wit, here is some top industries hat apply this molding technique in their operations.

read more...

Injection molding is an interesting concept that a lot of companies use these days. However, the trend is also getting an exciting twist thanks to various innovations. Here are some of the most popular of those:

read more...

The injection molding industry is changing rapidly. With the times moving once more, it’s worth looking into the trends that drive change the most.

read more...

Plastic injection molding is a multifaceted production method that can help to improve plastic production. So far, it has provided various benefits over the other forms of plastic molding. Some of these benefits include:

read more...

Rapid prototyping can speed up the development process. Every product is formed and manufactured depending on the materials used and the type of prototyping that will best suit the product. The following are the different types of rapid-prototyping:

read more...

With the rapid growth of cloud computing in the second decade of the 21st century, the manufacturing industry has changed dramatically.

read more...

Recently machining center is shifting toward five-axis control. The five-axis machining has high precision and effectiveness. For instance, the high-end numerical control system with a five-axis linkage can also perform high-precision machining on complex spatial surfaces. Also, it is more suitable for processing modern molds such as automobile parts and aircraft structural components.

Also, it is more suitable for processing modern molds such as automobile parts and aircraft structural components.

read more...

What precisely is Computer numerical-controlled (CNC) machining? It's a way to make parts by expelling material using fast, exactness mechanical machines that utilization a variety of cutting tools to make the Final Design. CNC machines usually used to make the geometric shapes required by clients are vertical processing machines, horizontal milling machines, and many more.

read more...

partZpro uses it's China manufacturers as China's most significant manufacturing network for on-demand manufacturing

read more...

Advantages of CNC processing:Material cost is low, and the material selection range is wideThe machine and equipment are stable and easy to operate.Parts can be appropriately decomposedIt can be easily adapted to parts with large size and simple structure.

read more...

Stereolithography 3D printing is a processing technique that is utilized in developing prototypes, models, and parts production layer after layer through a photo-chemical process. Monomers are often cross-linked together to create superior polymers. SLA processing has gained popularity over the years for producing parts with high precision and an excellent surface finish. It is considered the most cost-effective hence economically viable for the manufacturing of components. SLA 3D printing has helped professionals in optimizing production, cutting down on cost and manufacture of high-quality industrial parts. This article aims to provide designers with a profound decision-making background to the creation of quality products by employing SLA 3D printing.

read more...

Sign up at our sign up page. Our machine shops or we will use your email for DFM analysis, and also platform will send your final quote to your email provided on this page.

read more...

partZpro is an online machine shop service that its idea originated in Orange County. It connects customers who are looking for CNC machining service in Southern California to machine shops in a few simple-to-follow steps. By having over 100 CNC machines at the fingertips of our Southern California customers, you can rest assured that you will get your quality parts in a fast turnaround while you have full payment protection by our platform.

read more...

Product finishing services can be in form of metal finishing, industrial finishing, quality finishing among others. It is important to know the type of finishing that is suitable for your product as this will ensure that you have the right and proper finishing.

read more...

Stereolithography is an additive manufacturing process that, in its most common form, works by focusing an ultraviolet (UV) laser on to a vat of photopolymer resin. With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat.

With the help of computer aided manufacturing or computer-aided design (CAM/CAD) software, the UV laser is used to draw a pre-programmed design or shape on to the surface of the photopolymer vat.

read more...

The Computer Numerical Control also known as the CNC is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and routers.

read more...

There are many benefits of CNC Machining today such that there has been an increase in the use of CNC machines across different parts of the world. Some of the benefits of CNC Machining includes but are not limited to the following:

read more...

A computer numerical control (CNC) router is a computer-controlled cutting machine related to the hand-held router used for cutting various hard materials, such as wood, composites, aluminum, steel, plastics, glass, and foams. CNC routers can fill the roles of many carpentry dealers such as saw panels, spindles and drills.

CNC routers can fill the roles of many carpentry dealers such as saw panels, spindles and drills.

read more...

The increase in the use of CNC Machining has left a lot of people wondering what it is about and how it came to be. This article highlights some interesting facts about CNC Machining you might not be aware of. These facts include:

read more...

Thanks to technology, a handful of websites have addressed some of the issues in the method (A). An engineer can upload their 3D files on their platform and enjoy the user-friendly interface on some of these websites to get an instant quote. Also, they can pay for their orders on the same platform, and these companies will take care of CNC machining of the parts using their network of qualified manufacturers. With the help of machine shops locally or in China, they can get the parts CNC machined in the time frame and to the price they had quoted to the customers.

read more...

A Computer Numerical Control (CNC) system offers an advanced combination skill and technology that is mostly controlled by an alphanumeric system that has been coded. A CNC machine is made up of five basic parts. These parts have their different functions but are blended in such a way that they work in synchronization with one another. This synchronic working of the basic parts of the CNC is what makes it a very great and advanced tool.

read more...

Ensure that when choosing the CNC Machining service company/outlet, you are honest with what you want and are willing to pay to get the best services. Also, make sure that you verify the CNC service before going on with them. If possible, ask for samples of what they have done.

read more...

A CNC Machine is defined as a Computer Numerical Control Machine. A CNC machine comprises of the mini computer or the microcomputer that acts as the controller unit of the machine in the machine shops. Also, it can be defined as the automated control of machining tools (drills, boring tools, lathes). A CNC machine processes a piece of stock material (metal, plastic, wood, ceramic, or composite) to manufacture a CNC machined part by following code instructions or programmed instruction that usually come out of a cam software.

Also, it can be defined as the automated control of machining tools (drills, boring tools, lathes). A CNC machine processes a piece of stock material (metal, plastic, wood, ceramic, or composite) to manufacture a CNC machined part by following code instructions or programmed instruction that usually come out of a cam software.

read more...

Often times people do not know what to check out for when choosing a machine shop to help them out with their equipment. Choosing a machine shop is more than just searching for a machine shop near you, one might be tempted to just search for “machine shops near me” and just go with the ones listed. We are not saying it is bad to search for machine shops close to you however, we want to make sure that you do not just visit any machine shop and not be totally satisfied with the services that they offer.

read more...

Traditional machining has evolved over the years, giving way to an era of more complex machining systems that are cost-effective and highly efficient. Computer numerical control (CNC) machining is a subtractive process of manufacturing that utilizes an automated power that is computer-integrated to control tools such as lathes, boring, and drilling machines. It is used to produce parts of high quality with high dimensional accuracy in a cost-effective manner. There has been tremendous growth in the use of CNC machining, thereby revolutionizing the manufacturing industry. As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

Computer numerical control (CNC) machining is a subtractive process of manufacturing that utilizes an automated power that is computer-integrated to control tools such as lathes, boring, and drilling machines. It is used to produce parts of high quality with high dimensional accuracy in a cost-effective manner. There has been tremendous growth in the use of CNC machining, thereby revolutionizing the manufacturing industry. As such, this technology has reduced the human resources required in the production of sophisticated parts as the machines can work on a large number of work-pieces for mass production. This way, the consumer’s demands are easily met over a short period of time while at the same time producing high-quality products

read more...

The CNC is a very vital and important part of handling any manufacturing job as it pays detailed attention to texture, length, and direction. Making use of the CNC during any form of manufacturing guarantees you that the work to be done will be done in a neat and smart manner such that you do not bother about how the work to be done is carried out. CNC systems usually offer far more expansive computational capacity.

CNC systems usually offer far more expansive computational capacity.

read more...

STL 3D Oslo file | Digital Files | 3D STL File | Oslo 3D Map | 3D City Art | 3D Printed Landmark | Model of Oslo Skyline

3D Manhattan | Digital files | 3D STL file | NYC 3D map | 3D city art | 3D printed landmark | Model of New York skyline | 3D art

30 €

3D Paris | Digital files | 3D STL file | 3D map of Paris | 3D city art | 3D printed landmark | Paris skyline model | 3D art

15 €

3D London | Digital Files | 3D STL File | London 3D Map | 3D City Art | 3D Printed Landmark | Model of London Skyline | 3D Art

15 €

LAS VEGAS FRAME WALL ART CITY LANDSCAPE ARCHITECTURE BUILDINGS SOUVENIR CITY MAP ART

15 €

SYDNEY FRAME WALL ART CITY LANDSCAPE ARCHITECTURE BUILDINGS SOUVENIR CITY MAP ART

15 €

AMSTERDAM FRAME WALL ART CITY LANDSCAPE ARCHITECTURE BUILDINGS SOUVENIR CITY MAP ART

15 €

3D Hamburg | Digital Files | 3D STL File | Hamburg 3D Map | 3D City Art | 3D Printed Landmark | Model of Hamburg Skyline | 3D Art

15 €

3D Milwaukee | Digital files | 3D STL file | 3D map of Milwaukee | 3D city art | 3D printed landmark | Milwaukee skyline model | 3D art

18 €

Best 3D Printer Files in Architecture Category

Zollverein Colliery

20 €

Parametric wall shelf

3,80 €

Swayanbhunath in Nepal

Free

Autoport Garage Scale 143 Dr!ft Racer Storm Kids Diorama

2. 99 €

99 €

Deactivated

HO Scale Model Train Home

Free

AERODYNAMIC WIND TURBINE

22 €

Cereal box, Art Nouveau house

Free

Bestsellers in the category Architecture nine0037

Cinderella's Parisian castle at Disneyland

3.50 €

1-100th scale furniture Architecture

0,74 €

Cessna 172 Skyhawk 1:72

2 €

Birdhouse -3 pieces

3,80 €

Elbphilharmonie Hamburg

€5.90

HO tunnel entrance

0,50 €

Hole fronts for hobbits

5 €

EMPIRE STATE BUILDING - NEW YORK

3. 99 €

99 €

[Japanese capsule toy car] EduColon (rich design set)

4.70 €

nine0003 1/64 Generic Showroom1 €

NEW YORK - EMPIRE STATE BUILDING - MANHATTAN

1.80 €

Telegraph pole HO

1 €

Grain tank

1.75 €

CLUMSY PRINT-IN-PLACE SPIDER Flexi

3,12 €

nine0003 Table scale shipping container ASSEMBLY6.15 €

House "Christmas holidays Lampuna"

4.75 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in maintaining activities and making future designs of is very easy. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

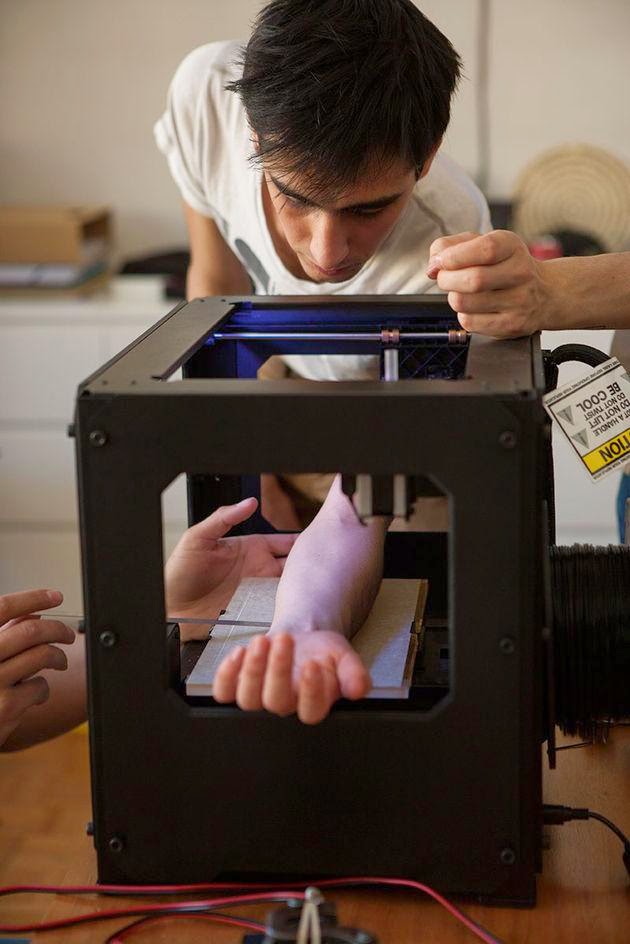

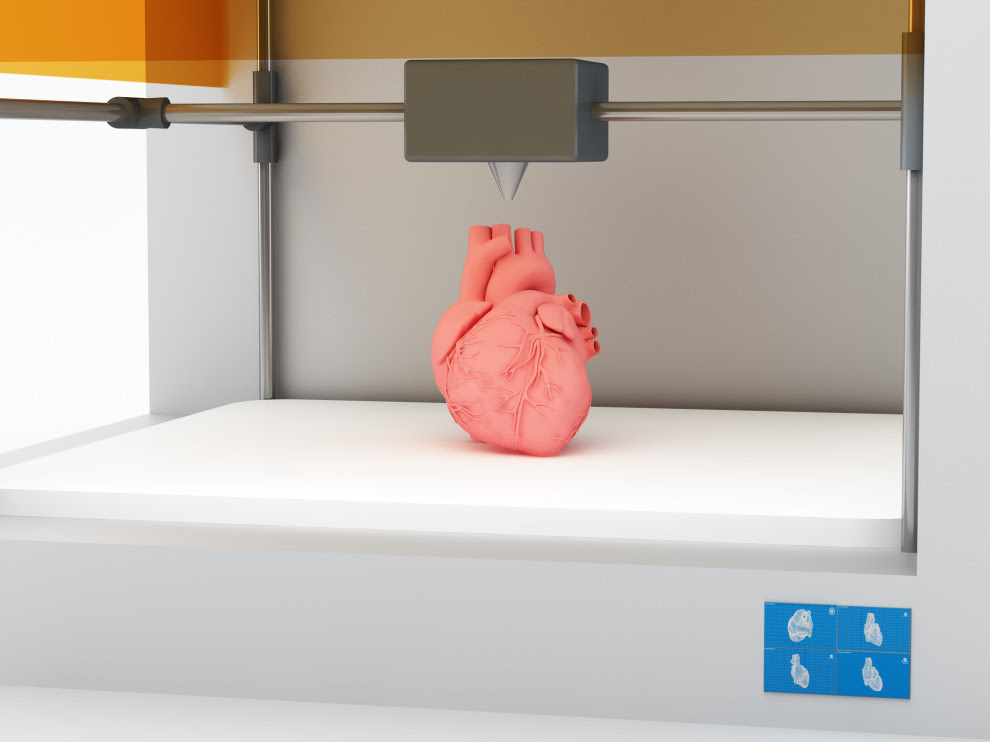

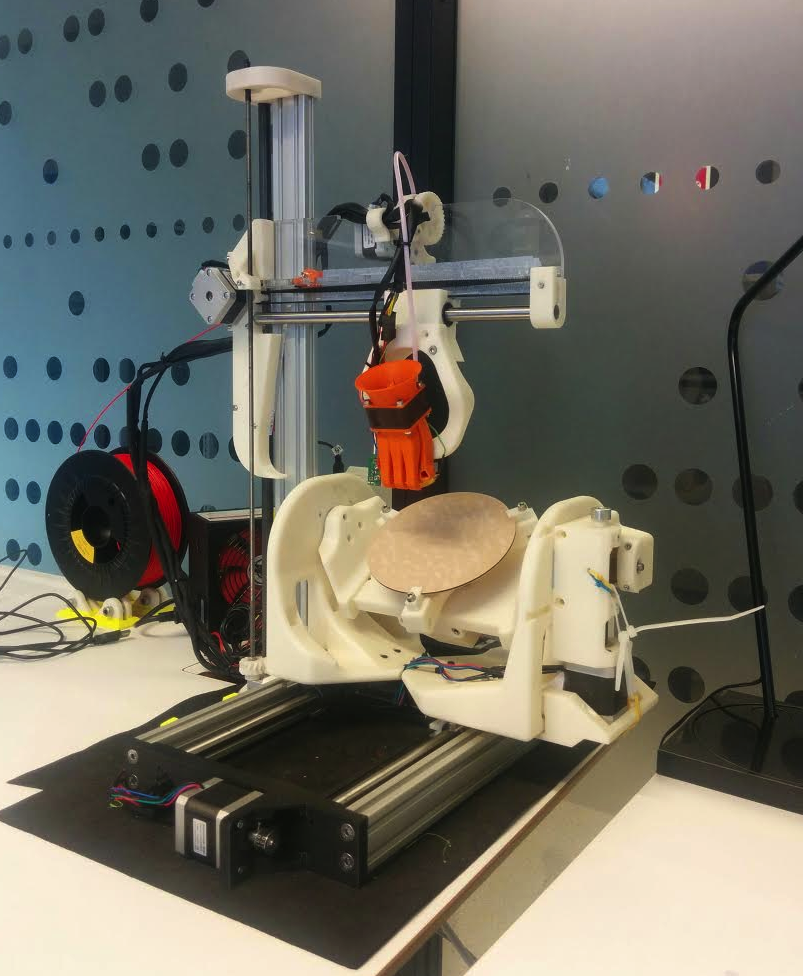

3D printing of human organs / Sudo Null IT News Submitted to their corporate blog. Questions can be addressed directly to them.

This is from the new Organ 3D Printing Lab. An impressive microscope is in front, and two medical engineers behind AutoCAD are visible further – they are making a mock-up of a site for the formation of tissue spheroids. nine0188

A laboratory for 3D organ bioprinting (Invitro project) has recently opened here. Some kind of fierce extravaganza of misunderstanding of what is being done is going on around her. In general, although I am not a microbiologist, I became interested. I made my way to the developer - V.A. Mironov. It was he who invented the technology for printing organs and patented it in the USA, participated in the development of three modifications of bioprinters, and it was he who was the “chief in science” in the new laboratory in Moscow:

In general, although I am not a microbiologist, I became interested. I made my way to the developer - V.A. Mironov. It was he who invented the technology for printing organs and patented it in the USA, participated in the development of three modifications of bioprinters, and it was he who was the “chief in science” in the new laboratory in Moscow:

V.A. Mironov (M.D., Ph.D., professor with 20 years of experience in microbiology, in particular, on the border with IT) - in the process of explaining the essence of the technology to me for an hour and a half, he painted a bunch of paper.

In a nutshell, he could not tell about printing, because first you need to understand some of the history of the issue. For example, why it was necessary to discard the bright idea of growing an embryo without a head in a surrogate mother, and then removing a kidney from it and placing it in a bio-solution for accelerated maturation. nine0006

In the meantime, the main thing. Do not rush to drink everything that burns: a new liver is still very far away . Go.

Do not rush to drink everything that burns: a new liver is still very far away . Go.

Evolution of methods

So, first there was gene therapy : the corresponding complexes were introduced to the patient. Certain cells were isolated, the necessary genes were introduced into them, then the cells were placed in the human body. There was not enough insulin - here is the gene that produces its creation. We take a cellular complex, modify it, inject it into the patient. The idea is excellent, though with one fundamental drawback: the patient is cured immediately, and there is no need to buy anything after the operation. That is, guess who it was across the throat. The case was difficult, and then one of the patients died - and a wave of lawsuits and bans, characteristic of the United States, began, as a result of which the research had to be curtailed. As a result, there is a method, but it has not really been tested. nine0006

The next trend was cell therapy - the use of embryonic stem cells. The method is excellent: "universal" cells are taken, which can be developed to any required by the patient. The problem is that in order to get them somewhere, you need an embryo. The embryo in the process of obtaining cells is obviously consumed. And this is already a moral and ethical problem that caused the ban on the use of such cells.

The method is excellent: "universal" cells are taken, which can be developed to any required by the patient. The problem is that in order to get them somewhere, you need an embryo. The embryo in the process of obtaining cells is obviously consumed. And this is already a moral and ethical problem that caused the ban on the use of such cells.

Next - tissue engineering - this is when you take a base, put cells on it, put it all into a bioreactor, and at the output you get the result (organ) that the patient needs. Like a prosthesis, only alive. Here is an important point: the main difference from the prosthesis is that the prosthesis is originally from inorganic matter, and is unlikely to ever be integrated into the body “like a native”. You can't scratch a wooden leg. nine0006

Methods of tissue engineering are scaffold - when a leached (de-livered) cadaveric organ is used, which is then "populated" with the patient's cells. Other scientific groups have tried to work with porcine organ protein scaffolds (human donors are not needed, but immunocompatibility rises to its full potential). Frames are artificial - from different materials, some scientific groups even experimented with sugar.

Frames are artificial - from different materials, some scientific groups even experimented with sugar.

Mironov himself practices frameless technology (using hydrogel as a base). In his method, the base polymer rapidly degrades, leaving only cellular material as a result. In other words, first a frame made of neo-boundaries with placed cells is inserted, and then the frame “dissolves”, and the cells of the already grown organ take over its functions. For scaffolds, the same material is used as for surgical sutures: it easily and simply degrades in the human body.

The main question here is why 3D printing is needed. To understand this, let's dig a little deeper into the available tissue engineering methods. nine0006

Approaching the goal

In general, the idea of inserting a pre-grown organic organ into a person is excellent. Let's look at three options for the development of technology:

- You take an inorganic framework, seed it with cells, and you get a finished organ .

The method is crude, but working. It is about him that we are talking about in most of those cases when they say "we printed the organ." The problem is that somewhere you need to take the "building material" - the cells themselves. And if they are, then it is foolish to use some kind of external frame when it is possible to simply assemble an organ from them. But the most painful problem is incomplete endothelialization. For example, for bronchi made like this, the level is about 70%. This means that superficial vessels are thrombogenic - by curing a patient, you immediately bring him a new disease. Then he must live on heparin or other drugs, or wait for a blood clot and embolism to form. And here, US lawyers are already looking forward to playing back according to the old scenario. And the problem of endothelialization has not been solved yet. A possible option is to isolate bone marrow progenitor cells by mobilization with special preparations and homing on the organ, but this is still a fantasy far from practice.

The method is crude, but working. It is about him that we are talking about in most of those cases when they say "we printed the organ." The problem is that somewhere you need to take the "building material" - the cells themselves. And if they are, then it is foolish to use some kind of external frame when it is possible to simply assemble an organ from them. But the most painful problem is incomplete endothelialization. For example, for bronchi made like this, the level is about 70%. This means that superficial vessels are thrombogenic - by curing a patient, you immediately bring him a new disease. Then he must live on heparin or other drugs, or wait for a blood clot and embolism to form. And here, US lawyers are already looking forward to playing back according to the old scenario. And the problem of endothelialization has not been solved yet. A possible option is to isolate bone marrow progenitor cells by mobilization with special preparations and homing on the organ, but this is still a fantasy far from practice. nine0159

nine0159 - The second method is extremely original and very pleasing with its cynicism . We take a cell (fibroblast) of the patient, add 4 genes. We put the resulting cell into a blastocyst (animal embryo) and begin to grow the animal. It turns out, for example, a pig with a human pancreas - the so-called chimera. The organ is completely “native”, only the entire infrastructure around – blood vessels, tissues, and so on – is from a pig. And they will be rejected. But nothing. We take a pig, cut out the desired organ (the pig is completely consumed), and then remove all the pig tissues with the help of special processing - it turns out, as it were, an organic frame of an organ that can be used to grow a new one. Some researchers have gone further and proposed the following life hack: let's replace the pig with a surrogate mother. Here's how: in addition to 4 genes, another one is added to the cell, which is responsible for acephaly (lack of a head). A surrogate mother is hired to carry our mutual embryo friend.

It develops without a head, acephalus is good at it. Then - an ultrasound, finding out that the child is defective, and a legally permitted abortion. There is no head - there is no person, which means that we did not kill anyone. And here - time! - we have here a theoretically legal biomaterial with undeveloped organs of the patient. Implant them fast! Of the obvious disadvantages - well, except for the moral side - organizational complexity and possible legal complications in the future. nine0159

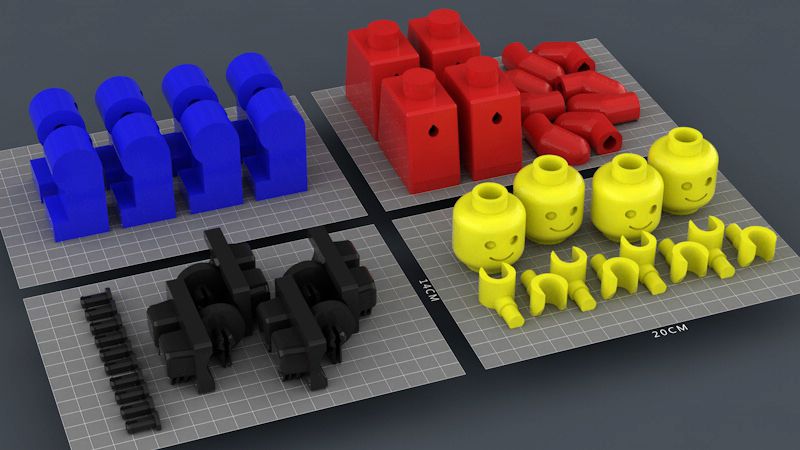

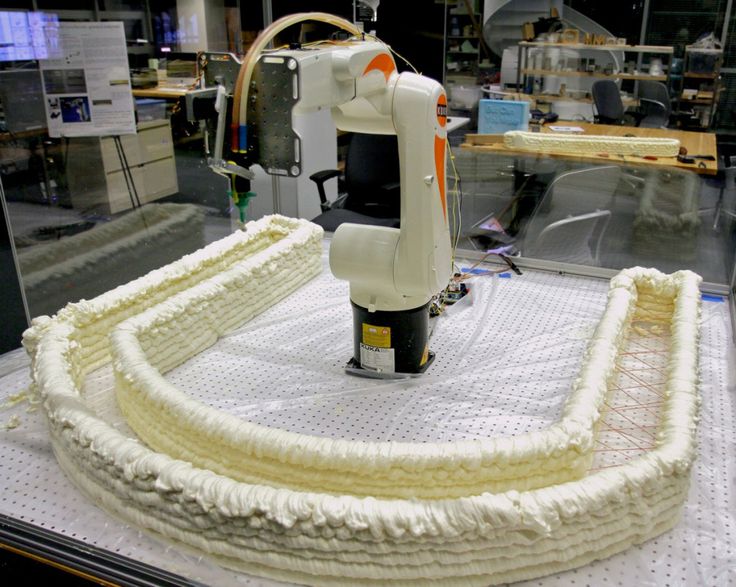

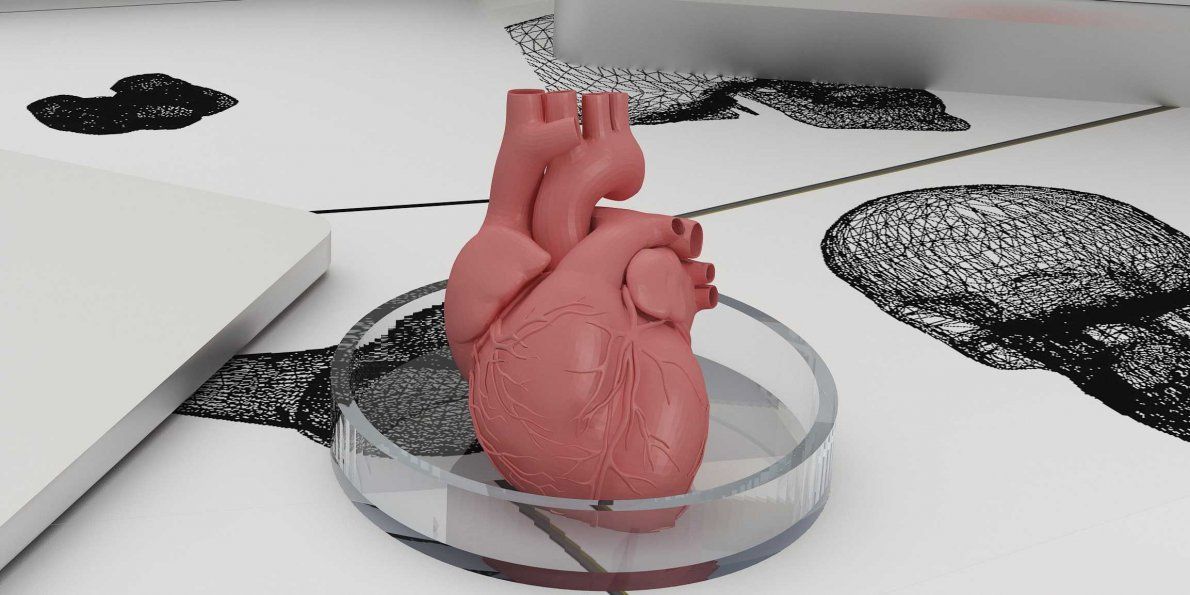

It develops without a head, acephalus is good at it. Then - an ultrasound, finding out that the child is defective, and a legally permitted abortion. There is no head - there is no person, which means that we did not kill anyone. And here - time! - we have here a theoretically legal biomaterial with undeveloped organs of the patient. Implant them fast! Of the obvious disadvantages - well, except for the moral side - organizational complexity and possible legal complications in the future. nine0159 - And finally, there is a third method, about which we are talking . It is also the most modern - three-dimensional printing of organs. And that is what they are doing in the new laboratory. The meaning is this: no inorganic scaffolds are needed (cells hold themselves perfectly), no need to take organs from someone. The patient gives a little of his adipose tissue (everyone has it, only skinny Japanese complained during the experiments), from which the necessary structural elements are obtained by sequential processing of cells.

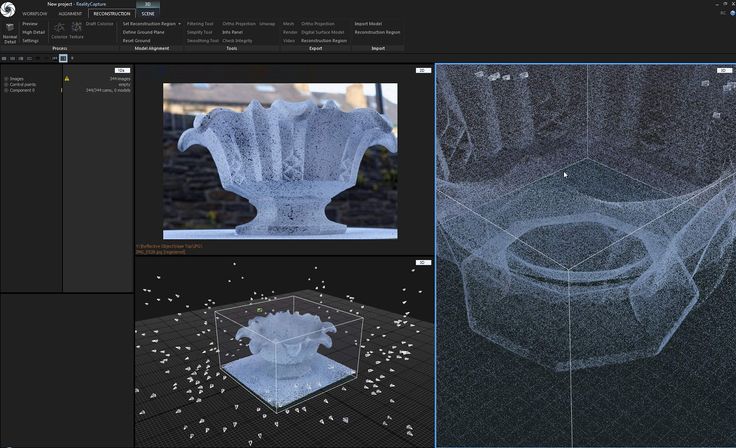

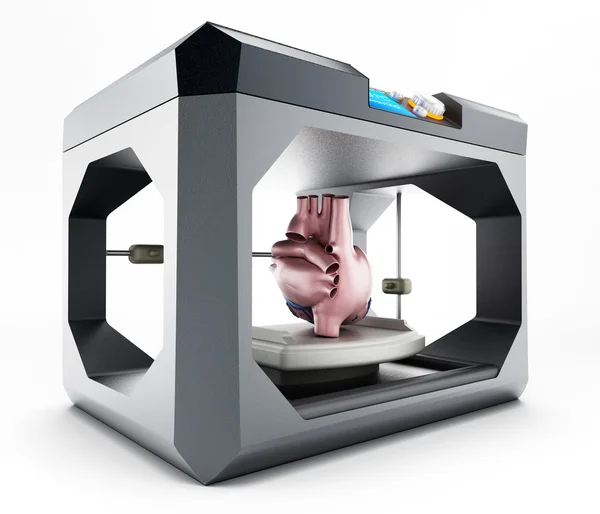

A three-dimensional model of an organ is created, converted into a CAD file, then this one is given to a 3D printer that can print with our cells and understands at what point in three-dimensional space it needs to “lay” a specific type of cell. The output is a tissue construct, which must be placed in a special environment until problems with hypoxia begin. In the bioreactor, the tissue construct "ripens". Then the organ can be "transplanted" to the patient. nine0159

A three-dimensional model of an organ is created, converted into a CAD file, then this one is given to a 3D printer that can print with our cells and understands at what point in three-dimensional space it needs to “lay” a specific type of cell. The output is a tissue construct, which must be placed in a special environment until problems with hypoxia begin. In the bioreactor, the tissue construct "ripens". Then the organ can be "transplanted" to the patient. nine0159

Obvious complexities of the method are as follows:

- Obtaining an organ model. You need to get a diagram from somewhere. It's pretty simple.

- Obtaining the cells themselves. Obviously, we need material to print the organ.

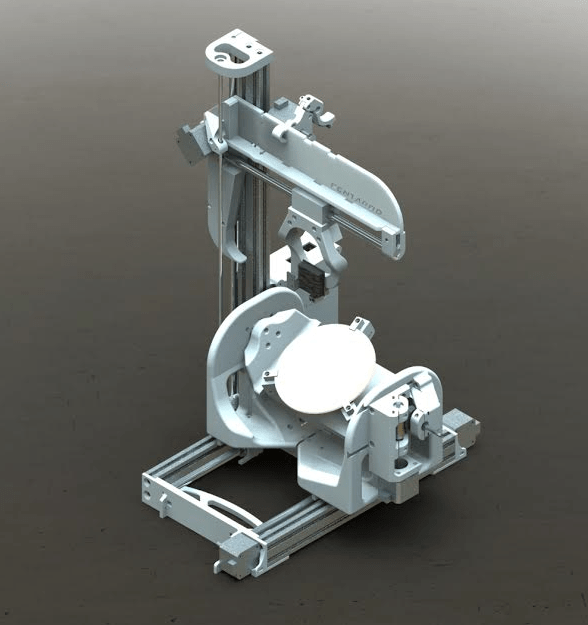

- Assembling a printer so that cells can print (a lot of problems with the formation of an organ structure).

- Hypoxia (lack of oxygen) during organ creation.

- Realization of nutrition of the organ and its maturation to readiness.

nine0159

nine0159

So, a 3D printer is only a piece of the organ fabrication line: it needs to be provided with a drawing, material, and then the resulting organ model must be grown from cells. Now let's see step by step how all the tasks described above are solved.

Organ Model

So, a CAD file is taken (now in stl format) with a model of an organ. The easiest way to get a model is to make a 3D scan of the patient himself, and then modify the data by hand. Now the current constructs are modeled in AutoCAD. nine0006

Modeling visible. The 3D structure is like that of a regular part, only instead of plastic there will be fabric spheroids.

Material

The material is taken - tissue spheroids, which will be used for printing. As a basis, a hydrogel is used, which acts as a connecting structure. The 3D printer then prints the organ from these tissue spheroids.

The first experiment confirming that a whole organ can be assembled from pieces: scientists cut the heart of a chicken into fragments and spliced it again. Successfully. nine0188

Now the question is where to get cells for this material. The best are human embryonic stem cells, which can be used to make cells for any tissue by sequential differentiation. But, as we know, you can't touch them. But you can take iPS - induced pluripotent stem cells. They can be made from bone marrow, dental pulp, or a patient's normal adipose tissue, and are made by various companies around the world.

The scheme is as follows: a person goes to the clinic, undergoes liposuction, the adipose tissue is frozen and placed in a repository. If necessary, they get it, the necessary cells are made from it (ATDSC, there is one such complex in Russia) and then differentiated according to their intended purpose. For example, iPS can be made from fibroblasts, from them - the renal epithelium, and then - the functional epithelium. nine0006

nine0006

Machines for the automatic production of such cells are manufactured by General Electric, for example.

Centrifuge. The first stage of separation of material from adipose tissue.

These cells are formed into balls in special micropits on the solid material. A cell suspension is placed in the recess on the mold, then the cells are fused, and a ball is formed. More precisely, it is not a very smooth spheroid.

Block processing

The next problem is that the cells in the carddig are eager to grow together. Tissue spheroids must be isolated from each other, otherwise they will begin to fuse prematurely. They need to be encapsulated, and for this, hyaluronic acid, obtained from blood serum, is used. It needs very little - just one very thin layer. It also quickly "leaves" after printing. nine0006

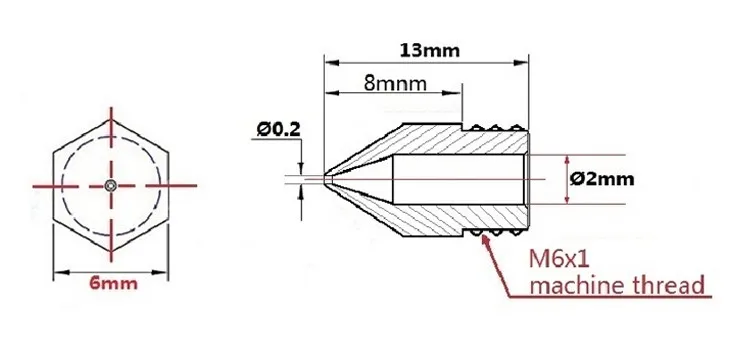

Seal

The head of the 3D printer has three extruders: two nozzles with gel and a device that produces tissue spheroids. Thrombin is in the first nozzle with the gel, fibrinogen is in the second one. Both gels are relatively stable until they touch. But when the fibrinogen protein is cleaved by thrombin, a fibrin monomer is formed. It is to them, like concrete, that tissue spheroids are fastened. With a layer depth corresponding to the diameter of the spheroid, one can sequentially apply the material row by row - they made a layer, fixed it, and moved on to the next one. Then fibrin is easily degraded in the medium and washed out during perfusion, and only the desired tissue remains. nine0006

Thrombin is in the first nozzle with the gel, fibrinogen is in the second one. Both gels are relatively stable until they touch. But when the fibrinogen protein is cleaved by thrombin, a fibrin monomer is formed. It is to them, like concrete, that tissue spheroids are fastened. With a layer depth corresponding to the diameter of the spheroid, one can sequentially apply the material row by row - they made a layer, fixed it, and moved on to the next one. Then fibrin is easily degraded in the medium and washed out during perfusion, and only the desired tissue remains. nine0006

This is how the tubes will be printed

The printer prints in layers of 250 micrometers: this is a balance between the optimal block size and the risk of hypoxia in the spheroid. In half an hour, you can print a tissue-engineering structure 10x10 centimeters - but this is not yet an organ, but a tissue-engineering structure, “snot” in jargon. For a structure to become an organ, it must live, have a clear form, and carry out functions.

A microscope with a huge focal length looks at a glass cube with a 3D printer. nine0188

Print head. So far, tests of the complex on plastic are underway. The printer now prints consumables, plastic molds for creating spheroids. In parallel, tests are underway on a sterile box for a 3D printer with a working electronic device.

Post-processing

The main question is that it would be good for cells to have access to oxygen and nutrients . Otherwise, they begin, roughly speaking, to rot. When the organ is thin, there are no problems, but already from a couple of millimeters it is important. True, an elephant, for example, has cartilage up to 5 millimeters - but they are built in where a lot of pressure is created due to the mass of the rest of the elephant. So, in order for the printed organ not to deteriorate during the fabrication process, microcirculation is needed. This is done by printing real vessels and capillaries, plus with the help of the thinnest perfusion holes made by inorganic instruments (roughly speaking, the structural blocks arrive on a polymer "skewer", which is then removed). nine0006

nine0006

Tissue compaction

Tissue union of several cell types without mixing

The future organ is placed in a bioreactor. This is, greatly simplifying, a jar with a controlled environment, in which the necessary substances are supplied to the inputs and outputs of the organ, plus accelerated maturation is ensured due to exposure to growth factors.

Here's what's interesting - the architecture of an organ is usually similar to the usual encapsulated object in OOP - an input artery, an output vein - and a bunch of functions inside. It is assumed that the bioreactor will provide the desired input and output. But this is still a theory, it has not yet been possible to collect a single one. But the project has been worked out to the stage “you can assemble a prototype”. nine0006

Hanging in the lab. You can see the first stage: obtaining the basic elements, the second - a 3D printer with three extruders, the third - moving from a prototype to an industrial model, then testing on animals, then going to an IPO and installation for people.

Complete line - cell sorter, tissue spheroid fabricator, printer, perfusion unit

Markets

Now who needs all this at the stage, while there are no organs themselves.

The first major customers are the military . Actually, as you might guess, DARPA visits all scientists involved in this topic. They have two applications - testing (a lot of things cannot be tested on living people, but you want to - a separate organ would be very useful) and therapeutic. For example, a fighter of democracy tears off his arm, and it takes a day to crawl to the hospital. It would be nice to close the hole, relieve the pain, give him the opportunity to shoot another 5 hours, and then come to the nurse on his own two feet. In theory, either robots are possible that will collect all this in place, or patches from human tissues, which are already seriously thinking of putting on burns. nine0006

Second customer - Pharma . There, drugs are tested for 15 years before entering the market. As the Americans joke, it's easier to kill a colleague than a mouse. On the mouse you need to collect a bunch of documents in your hand thick. Certified mice are very expensive as a result. Yes, and the results on the animal are different from human ones. Existing test models in flat cell models and in animals are not sufficiently revalent. I was told in the lab that about 7% of the world's new drug formulas don't make it to clinical trials due to nephrotoxicity detected in preclinical testing. Of those that have reached, about a third have problems with toxicity. That is why, by the way, one of the first tasks is to test the functionality of nephrons made in the laboratory. Tissues and organs from the printer will significantly accelerate the development of drugs, and this is a lot of money. nine0006

There, drugs are tested for 15 years before entering the market. As the Americans joke, it's easier to kill a colleague than a mouse. On the mouse you need to collect a bunch of documents in your hand thick. Certified mice are very expensive as a result. Yes, and the results on the animal are different from human ones. Existing test models in flat cell models and in animals are not sufficiently revalent. I was told in the lab that about 7% of the world's new drug formulas don't make it to clinical trials due to nephrotoxicity detected in preclinical testing. Of those that have reached, about a third have problems with toxicity. That is why, by the way, one of the first tasks is to test the functionality of nephrons made in the laboratory. Tissues and organs from the printer will significantly accelerate the development of drugs, and this is a lot of money. nine0006

The third client is hospitals. The US kidney transplant market, for example, is $25 billion. At first, it is supposed to just sell 3D printers to hospitals so that the patient can get what they need. The next (theoretical) step is the creation of complexes for printing organs directly inside the patient. The fact is that it is often much easier to deliver a miniature printhead inside a patient than a large organ. But this is still a dream, although the necessary robots exist.

The next (theoretical) step is the creation of complexes for printing organs directly inside the patient. The fact is that it is often much easier to deliver a miniature printhead inside a patient than a large organ. But this is still a dream, although the necessary robots exist.

This is how it should work

Yes, there is another important topic here: in parallel, research is being conducted on the control of tissue spheroids due to magnetic levitation. The first experiments were simple - iron “nano-sawdust” was thrust into the fabric, and the spheroids really flew as they should in the magnin field and were delivered to the place. But differentiation suffered. With sawdust it is difficult to perform the necessary functions. The next logical step is the metal in the encapsulating layer. But even cooler are microsuits with magnetic particles. These spacesuits cover the spheroid and can also act as a connector frame that snaps into place right away, which gives a huge scope for the rapid printing of organs. nine0006

nine0006

Links

— Company at Skolkovo

— About the Russian conference on regenerative medicine that this team did

A bunch of links in English that talks about gradual progress:

www.ncbi.nlm.nih.gov/pubmed/12679063

www.ncbi.nlm.nih .gov/pubmed/11500808

www.ncbi.nlm.nih.gov/pubmed/20603872

www.ncbi.nlm.nih.gov/pubmed/21419621

www.ncbi.nlm.nih.gov/pubmed/18423666

www .ncbi.nlm.nih.gov/pubmed/16805712

www.ncbi.nlm.nih.gov/pubmed/15174961

www.ncbi.nlm.nih.gov/pubmed/18333793

www.ncbi.nlm.nih.gov/pubmed/18194071

www.ncbi.nlm.nih .gov/pubmed/18154465

www.ncbi.nlm.nih.gov/pubmed/14981244

www.ncbi.nlm.nih.gov/pubmed/20811099

www.ncbi.nlm.nih.gov/pubmed/19176247

www .ncbi.nlm.nih.gov/pubmed/12740943

A pile of paper that Mironov drew during the story. Handwriting like a doctor :)

Important facts

- No 3D printed organ has yet been implanted in humans.

But there are about a dozen different cases of successful "installation" of such organs in animals.

But there are about a dozen different cases of successful "installation" of such organs in animals. - Mironov has already assembled three operating 3D bioprinters: 2 in Canada, one in Brazil. The new one in Russia should be better than all the existing ones.

- When spheroids are spliced, tissue becomes compacted - for example, a kidney will have to be printed three times more than it will be inside the patient - already at the last stage of fabrication it will become a normal size. nine0159

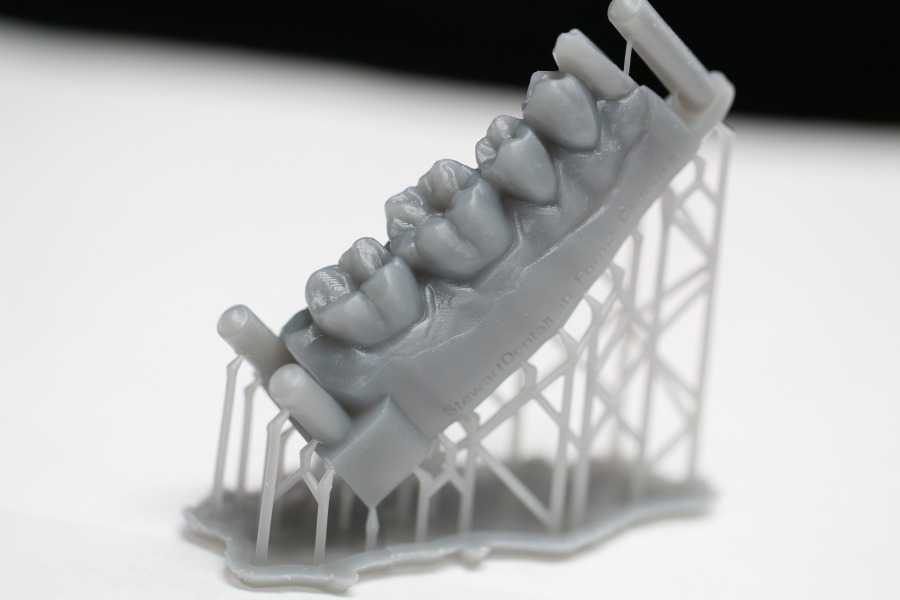

- Now we have learned how to make basic things, for example, tubes from different types of fabric. After checking the functionality of the cells, complex designs can be made. For example, a nephron is easily obtained from tubules, and a kidney is easily obtained from many nephrons.

- Robots needed. In the bronchi, for example, there are 10 orders of branching - it is somewhat tiring to collect this with your hands, and the patient is not ready to wait thousands of years.

Learn more

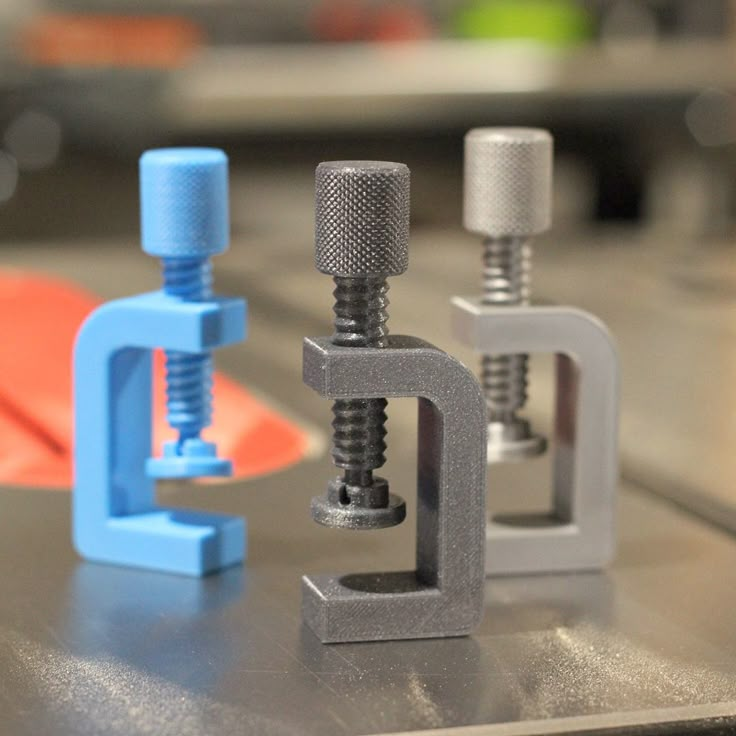

Good for prototyping

Good for prototyping 45 MPa)

45 MPa)