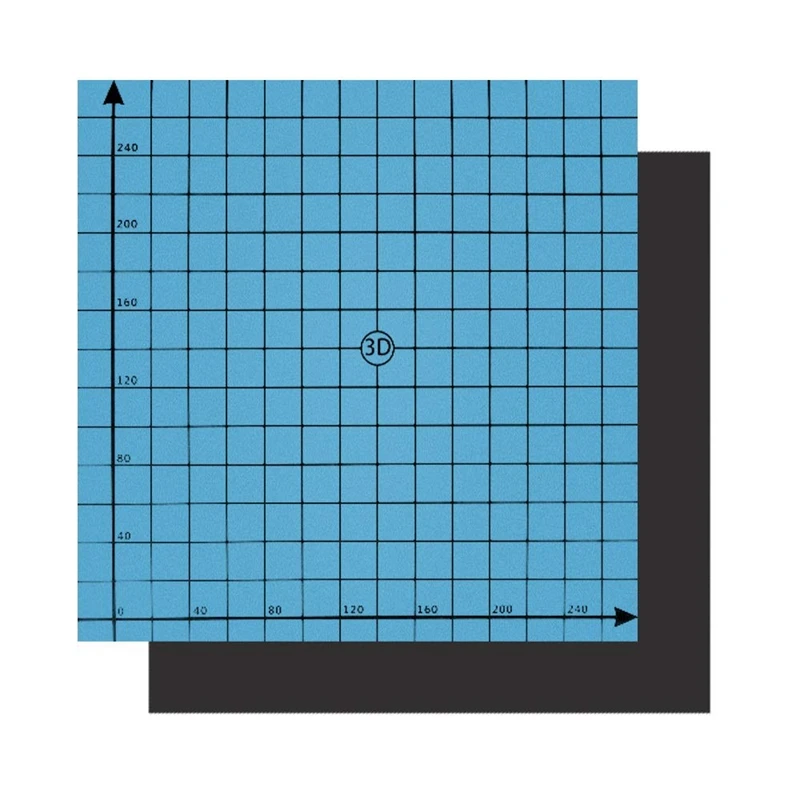

3D print build surface

LayerLock 3D Printer Build Surfaces

- Home

- Store

- 3D Printer Accessories

- Build Surfaces

- LayerLock Build Surfaces

LayerLock provides a variety of build surfaces and build plates designed for stronger bed adhesion for both advanced and standard materials. With LayerLock Garolite Build Surfaces, successfully printing warp-free parts out of NylonX, NylonG, and other nylon filaments will be a breeze. This type of surface also successfully prints standard filaments such as PLA, PETG, TPU and more for a plethora of material compatibility. With LayerLock Powder Coated PEI Build Plates, users have a reliable alternative bed surface for successfully printing standard filaments such as PLA, ABS, PETG and flexibles. Both types of bed surfaces are durable, dependable, and require little to no maintenance so strong bed adhesion is attainable without the huge hassle. Take your 3D printing to the next level with these advanced build surfaces that will help you successfully achieve warp-free projects for a lifetime.

LayerLock Build Surfaces Collections

All LayerLock Build Surfaces 3D Printer Build Surfaces

Technical Specifications

- Material Surfaces Available: Garolite, PEI, Surface for Polypropylene, Surface for SLA

- Available in various sizes—check individual products for guaranteed printer compatibility

- Material compatibility for Garolite: NylonX, NylonG, Nylon, PLA, PETG, TPU, and more

- Material compatibility for PEI: PLA, ABS, PETG, and flexibles such as TPU and TPE

- Material compatibility for Surface for Polypropylene: Polypropylene and OBC

- Material compatibility for Surface for SLA: Most LCD / MSLA, Laser, and DLP resins

LayerLock Build Surfaces

LayerLock Garolite Build Surfaces

Superior bed adhesion to Nylon based materials like NylonG

LayerLock Build Surfaces for Polypropylene

Get the best first layer with polypropylene and OBC filament

LayerLock Powder Coated PEI Build Plates

Great first layers and easy part removal with this flexible build plate

LayerLock SLA Resin 3D Printing Build Surface

Achieve strong bed adhesion in SLA printing with this surface

LayerLock MagBase

Easily add a magnetic base to your 3D printer for interchangeable surfaces

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

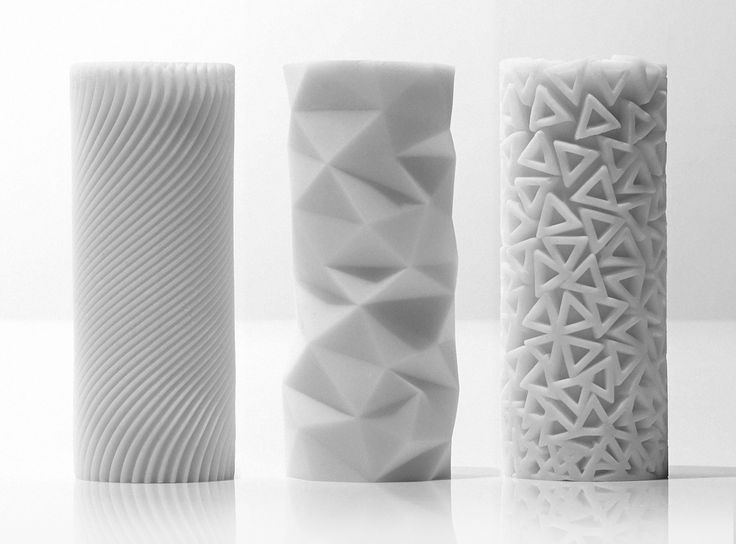

LayerLock 3D Printer Build Surfaces strengthen the bond between the print bed and both advanced and standard materials. LayerLock Garolite Build Surfaces are made out of linen-based phenolic sheets, allowing for just enough texture on the surface to provide a sturdy grip for prints to hold onto while still having a fairly smooth finishing surface. Alternatively, LayerLock Powder Coated PEI Build Plates have PEI powder coated onto a flexible spring steel sheet which leaves behind a bumpy surface on the plate and produces a charming, rugged finishing texture on the bottom of prints. Both types of bed surfaces are engineered for easy installation and to withstand thousands of print jobs. Successfully achieve warp-free prints with zero hassle using LayerLock 3D Printer Build Surfaces.

LayerLock Garolite Build Surfaces are made out of linen-based phenolic sheets, allowing for just enough texture on the surface to provide a sturdy grip for prints to hold onto while still having a fairly smooth finishing surface. Alternatively, LayerLock Powder Coated PEI Build Plates have PEI powder coated onto a flexible spring steel sheet which leaves behind a bumpy surface on the plate and produces a charming, rugged finishing texture on the bottom of prints. Both types of bed surfaces are engineered for easy installation and to withstand thousands of print jobs. Successfully achieve warp-free prints with zero hassle using LayerLock 3D Printer Build Surfaces.

3D Printer Build Surfaces - 3DJake International

Sort byRelevanceBestsellersCustomer ReviewsPrice, Low to HighPrice, High to LowNew arrivalsHighest Discount

-

Creality Magnetic Build Surface 12 Model types- An original spare part from Creality 3D

- Available for various 3D printers

-

BuildTak PEI film 32 sizes- First-class production

- Easy to apply

- Ideal with the FlexPlate system

-

BuildTak FlexPlate System 26 sizes- Easy to use

- Variety of Different Sizes

- Complete System

-

Creality PEI Flexible Build Plate 18 Model types- Powder-coated surface

- Good adhesion

- Flame retardant

-

3DJAKE Magnetic Plate 7 Model types- Good adhesion

- Flexible

- High quality

-

BuildTak 3D Print Surface 28 sizes- Perfect adhesion

- Optimal bond

- Reusable

-

Elegoo Platform 9 Model types- Original spare part

- From Elegoo

-

Creality Carborundum Glass Plate 23 Model types- Strong adhesion

- Easy removal

- Original spare part

-

3DJAKE Resin Flexplate System 15 Model types- Flexible plate

- Different sizes

- Easy to use

-

Qidi Tech Magnetic Build Board 4 Model types- An original spare part from Qidi Tech

- Coated on both sides

- Magnetic

-

Creality Heated Bed 22 Model types- Original spare part

- From Creality

-

3DJAKE Flexplate System with Nano-Coating 4 Model types- Flexible steel plate & magnetic base

- Different sizes available

- Better adhesion

-

3DJAKE Resin Flexplate Build Plate 16 Model types- For easy print removal

- No kinking or warping

- Specially patterned surface

-

Zimple Ziflex Ultimate Surface - High Temp 4 sizes- Good adhesion and easy removal

- Ultra flexible

- Magnetic positioning

-

3DJAKE Glass Plate with Chemical Coating 5 Model types- Very good adhesion

- Easy removal of prints

- Resistant to heat

-

FLSUN PEI Flexible Build Plate 3 Model types- Powder-coated finish

- Good adhesion

- Flame retardant

-

Zortrax Perforated Plate v2 2 Model types- Compatible with the Zortrax M200

-

3DJAKE Resin Flex Plate Magnetic Base 16 Model types- 1.

5mm thick

5mm thick

- Amazing strength

- Adhesive backing

- 1.

-

Creality 3D Printer Build Surface 14 Model types- Original spare part from Creality

- Available for various 3D printers

-

Qidi Tech PEI Build Surface 4 Model types- Powder-coated surface

- Good adhesion

- Flame retardant

-

Anycubic Heated Bed Including Ultrabase 3 Model types- Original spare part

- By Anycubic

-

Artillery Heated Bed 4 Model types- Original spare part

-

3DJAKE PEI Flexplate Black Edition 4 Model types- Flexible steel plate

- With magnetic base

- In different sizes

-

Phrozen Build Platform 10 Model types- Original spare part

- From Phrozen

All prices incl. VAT.

VAT.

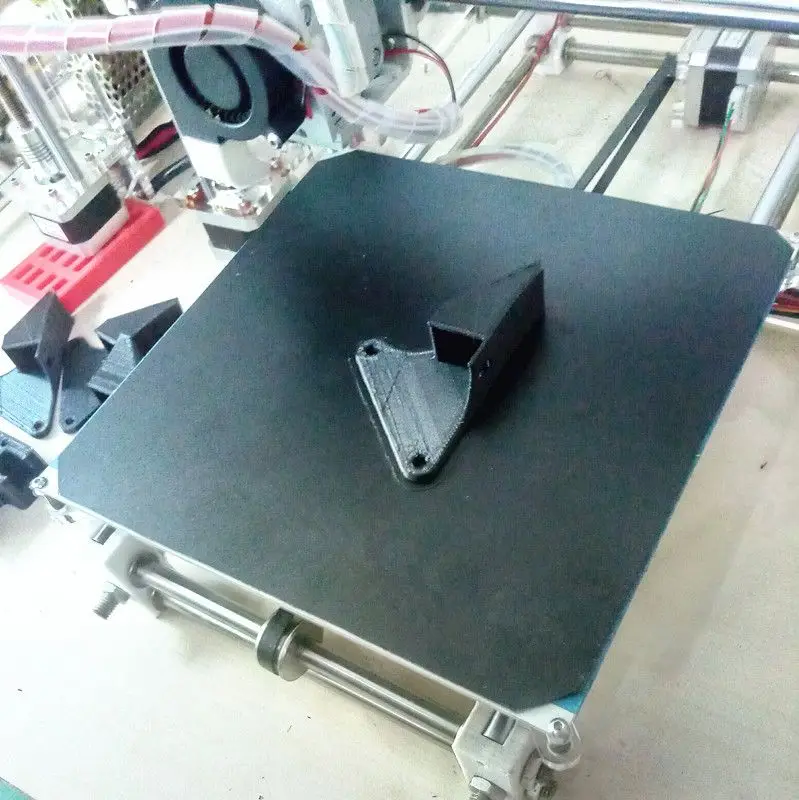

Excellent printable surface!

vdm

Loading

08/09/2017

6455

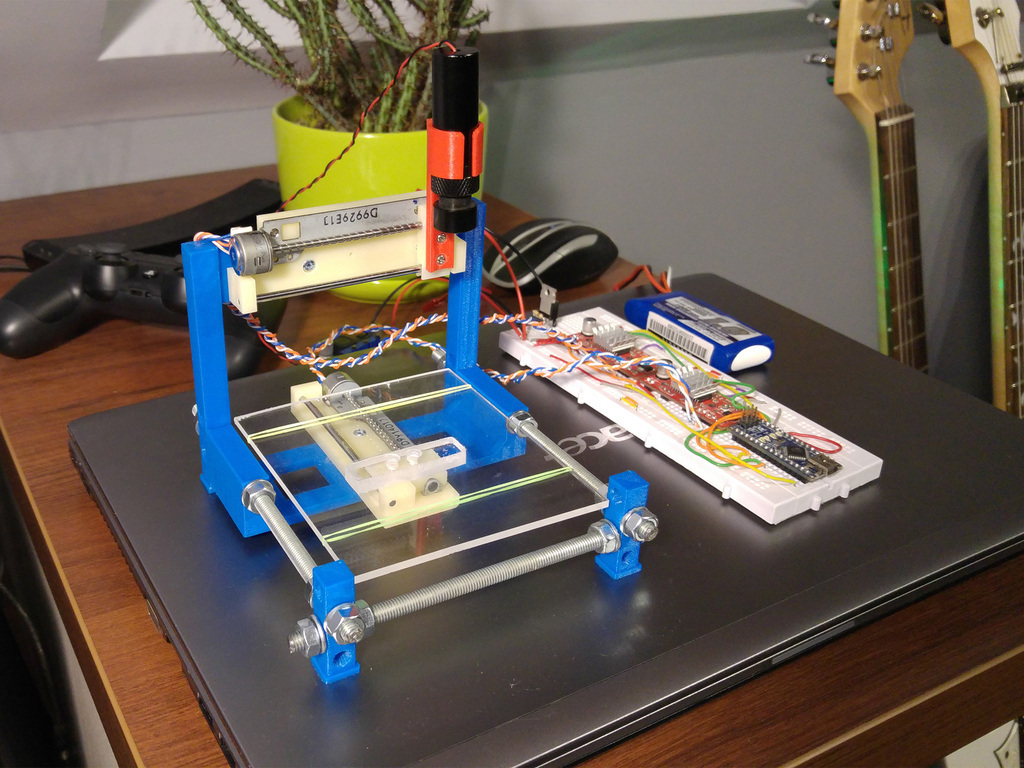

Sandbox

Flipping through the pages of foreign 3d printers I found an interesting post. What follows is my frivolous translation from Marican English.

Excellent print surface!

I don't have a heated table, but I found a simple and effective solution. I print ABS, PETG, PLA, Nylon and flexible filament on... Fabric surface! It works just fine! With this extremely cheap and effective trick, you can print with any filament without a heated bed and without fear of starting a fire! nine0003

Just cut a piece of denim (can be from old denim pants) the size of your printer table, stick it on the table surface and reduce the gap between the table and the nozzle a little.

You can use any fabric with at least 30% cotton content

Very easy to remove printed objects. If there are difficulties, then apply one layer of ABS juice. This should make it easier to remove the part.

If there are difficulties, then apply one layer of ABS juice. This should make it easier to remove the part.

Link to original article: http://medelis.se/diy%203d.html nine0003

Follow author

Follow

Don't want

7

Article comments

More interesting articles

81

Subscribe to the author

Subscribe

Don't want

I'll tell you a little about my personal experience of using FDplast.

We meet a lot on the site...

Read more

SE-Atmn

Loading

30. 04.2017

04.2017

13598

72

Subscribe to the author

Subscribe

Don't want to

I spied a way to create pendants, brooches and other jewelry on one site and decided to try it....

Read more

Pangani

Loading

01/23/2018

11012

40

Subscribe to the author

Subscribe to the author

Subscribe

Don't want

Good day to everyone, I present to your attention a short review, or rather my review and personal ...

Read more

Read blogs

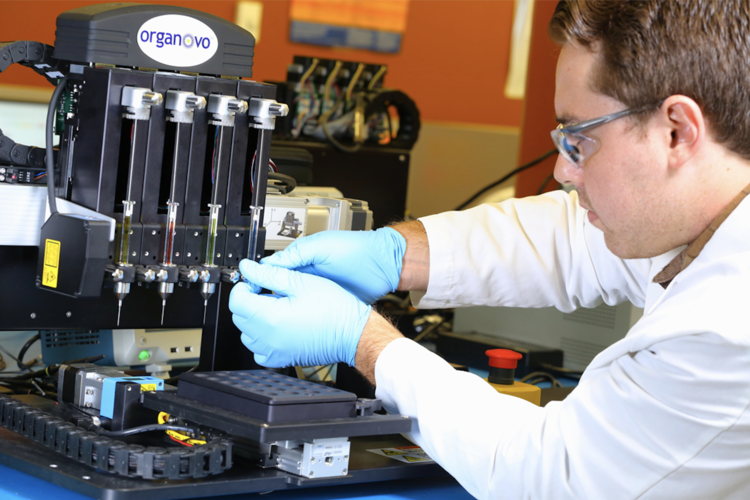

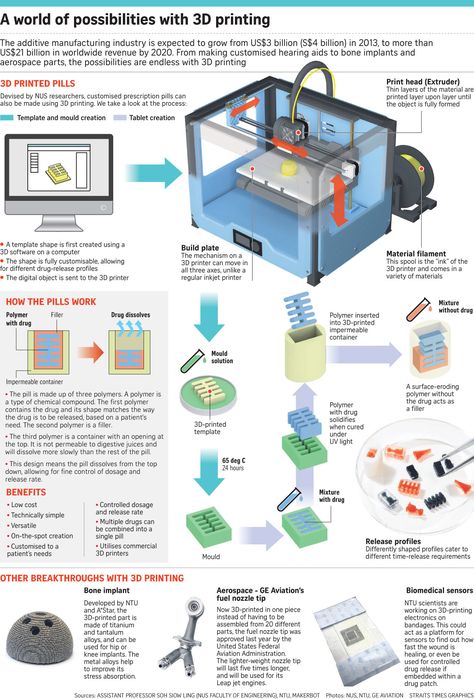

Techno Print Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

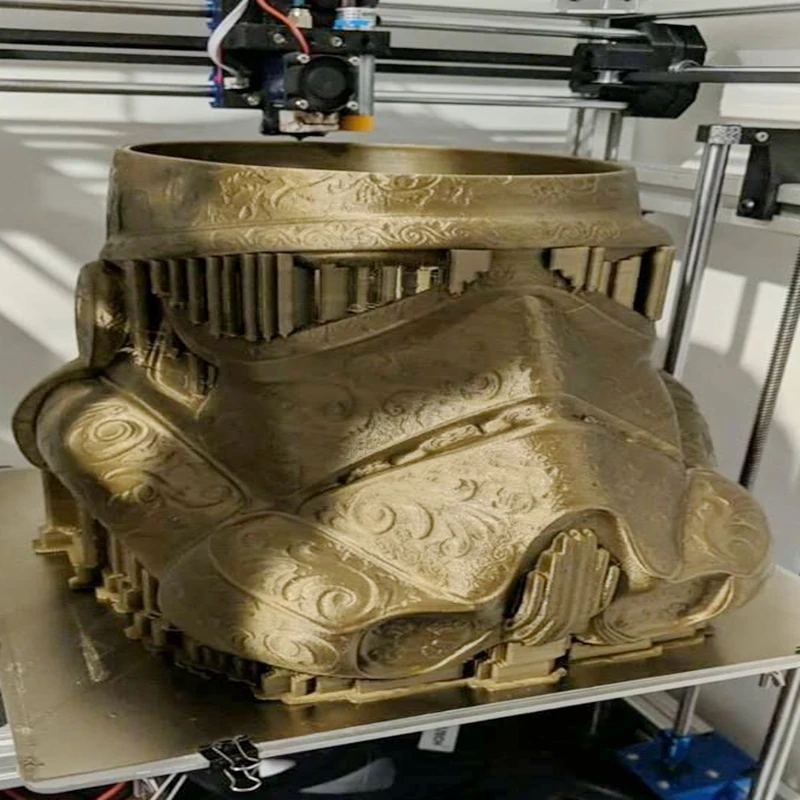

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with.