3D printer for drone parts

7 Best 3D Printers for Drones, Nerf Parts, RC & Robotics Parts – 3D Printerly

Choosing the right 3D printer can be overwhelming when you see just how many choices there are, which I can definitely understand since I had a similar experience.

If you are looking for a 3D printer that is specific to a hobby or goal, you’re going to want certain features that you may not find in another machine.

For the people looking for 3D printers for drones, nerf parts, RC (remote control) cars/boats/planes, or robotic parts, this is an article that will help you pick the best of the best.

Let’s waste no more time and dive straight into this list of high quality 3D printers.

The Artillery Sidewinder X1 V4 was released in the market in 2018 and people started to comment that this 3D printer will give proper competition to many well-known 3D printer manufacturing companies such as Creality.

It has a lot of amazing features that are not present or need upgrading in most 3D printers under this price tag of about $400.

Whether it is the AC heated bed, direct drive system, or its completely quiet fans and motherboard, the Artillery Sidewinder X1 V4 (Amazon) has the ability to stand out in the crowd of its competitors.

As this 3D printer comes with a build volume of 300 x 300 x 400mm and an appealing look, this could be a great choice for both beginners and experienced 3D printer users.

Features of the Artillery Sidewinder X1 V4

- Rapid Heating Ceramic Glass Print Bed

- Direct Drive Extruder System

- Large Build Volume

- Print Resume Capability After a Power Outage

- Ultra-Quiet Stepper Motor

- Filament Detector Sensor

- LCD-Color Touch Screen

- Safe & Secure Quality Packaging

- Synchronized Dual Z-Axis System

Specifications of the Artillery Sidewinder X1 V4

- Build Volume: 300 x 300 x 400mm

- Printing Speed: 150mm/s

- Layer Height/Print Resolution: 0.1mm

- Maximum Extruder Temperature: 265°C

- Maximum Bed Temperature: 130°C

- Filament Diameter: 1.

75mm

75mm - Nozzle Diameter: 0.4mm

- Extruder: Single

- Control Board: MKS Gen L

- Nozzle Type: Volcano

- Connectivity: USB A, MicroSD card

- Bed Levelling: Manual

- Build Area: Open

- Compatible Printing Materials: PLA / ABS / TPU / Flexible materials

User Experience of the Artillery Sidewinder X1 V4

The Sidewinder X1 V4 includes some of the most advanced technologies such as AC heat bed and direct drive extruder, combined with this huge build volume and excellent performance.

However, you may need to upgrade or replace some of its parts for extra convenience.

This 3D printer may wobble sometimes at the top of Z-Axis, but this is an extremely easy to use and inexpensive 3D printer that is capable of printing some not so common 3D prints ranging from simple 3D models to 3D parts of robotics, drone, boats, etc.

One of the many buyers who have been using this machine from when it first got released and it has had many iterations for improvements that were based completely on user feedback.

The user said in his feedback that with this list of impressive features, technology, reasonable price, and ease of usage, you may rarely find another 3D printer with such abilities.

Print quality varies quite a bit right out of the box. There are plenty of unboxing and setup videos on YouTube that can help you to make necessary adjustments even before turning your machine ON so that you can achieve a great degree of print quality.

One user said in his feedback that after using this popular 3D printer for about 2 months without any break, he can safely say that this is one of his top 3 3D printers.

The user said that he hasn’t upgraded or replaced a single component in the machine and is totally happy with the printer’s quality and performance.

Pros of the Artillery Sidewinder X1 V4

- Heated glass build plate

- It supported both USB and MicroSD cards for more choice

- Well-organized bunch of ribbon cables for better organization

- Large build volume

- Quiet printing operation

- Has large leveling knobs for easier leveling

- A smooth and firmly placed print bed gives the bottom of your prints a shiny finish

- Fast heating of the heated bed

- Very quiet operation in the steppers

- Easy to assemble

- A helpful community that will guide you through any issues that come up

- Prints reliable, consistently, and at a high quality

- Amazing build volume for the price

Cons of the Artillery Sidewinder X1 V4

- Uneven heat distribution on the print bed

- Delicate wiring on the heat pad and extruder

- The spool holder is pretty tricky and hard to adjust

- EEPROM save is not supported by the unit

Final Thoughts

If you are a person who needs a 3D printer that allows you to print models of your choice such as robotics or nerf parts while offering convenience, comfort, and ease of usage, this 3D printer could be a great option.

Secure yourself the Artillery Sidewinder X1 V4 from Amazon for a competitive price.

The Ender 3 is a well-known and appreciated series of Creality 3D printers. Previous versions of the Ender 3 have some features and parts that were not much satisfactory for some of the 3D printer users.

To fill those gaps and to bring the best printing experience for their users, Creality has come up with this amazing machine, the Ender 3 V2 (Amazon).

Although most of the previous features and components are improved, some new features are also added such as silent stepper motor drivers, 32-bit mainboard, classy look, and many other minor components.

Features of the Creality Ender 3 V2

- Open Build Space

- Glass Platform

- High-Quality Meanwell Power Supply

- 3-Inch LCD Color Screen

- XY-Axis Tensioners

- Built-In Storage Compartment

- New Silent Motherboard

- Fully Upgraded Hotend & Fan Duct

- Smart Filament Run Out Detection

- Effortless Filament Feeding

- Print Resume Capabilities

- Quick-Heating Hot Bed

Specifications of the Creality Ender 3 V2

- Build Volume: 220 x 220 x 250mm

- Maximum Printing Speed: 180mm/s

- Layer Height/Print Resolution: 0.

1mm

1mm - Maximum Extruder Temperature: 255°C

- Maximum Bed Temperature: 100°C

- Filament Diameter: 1.75mm

- Nozzle Diameter: 0.4mm

- Extruder: Single

- Connectivity: MicroSD Card, USB.

- Bed Levelling: Manual

- Build Area: Open

- Compatible Printing Materials: PLA, TPU, PETG

User Experience of the Creality Ender 3

Textured glass print bed is widely appreciated for its excellence and smooth printing experience and the Ender 3 V2 has this component pre-installed.

You can easily print complex 3D models such as nerf parts, robotics, drones, or other such accessories because when the bed is hot, filament sticks perfectly to the platform and when it turns cold, the model can be removed easily without any hassle.

As the Ender 3 V2 uses a V-guide rail pulley with stable movement, it emits relatively low noise and prints models with high wear resistance abilities and much longer life.

The 3D printer is equipped with XY-Axis tensioners which offer a great deal of ease and convenience. You can easily lose or tighten the 3D printer’s belt by simply adjusting these tensioners.

You can easily lose or tighten the 3D printer’s belt by simply adjusting these tensioners.

Its 4.3 inches color screen enhances the user experience with the newly designed user interface system. This color screen is not only easy to use and operate but can be removed easily for repair. This factor can save a lot of time and energy.

Right out of the box, the 3D printer is not completely assembled and it may take less than one hour to assemble all parts perfectly. You may have doubts about its print quality and efficiency but all these doubts will be cleared after your first print.

Pros of the Creality Ender 3 V2

- Easy to use for beginners, giving out high performance and much enjoyment

- Relatively cheap and great value for money

- Great support community.

- Design and structure look very aesthetically pleasing

- High precision printing

- 5 minutes to heat up

- The all-metal body gives stability and durability

- Easy to assemble and maintain

- The power supply is integrated underneath the build-plate unlike the Ender 3

- It is modular and easy to customize

Cons of the Creality Ender 3 V2

- A bit difficult to assemble

- Open build space is not ideal for minors

- Only 1 motor on the Z-axis

- Glass beds do tend to be heavier so it may lead to ringing in prints

- No touchscreen interface like some other modern printers

Final Thoughts

Although there are many reasons that may urge you to buy this amazing 3D printer.

If you are looking for one of the best 3D printers for objects such as robotics, nerf parts, remote control cars, and planes, then you’ll do great with the Ender 3 V2 from Amazon.

The Anycubic Mega X (Amazon) is a convincing 3D printer that attracts users with its excellent appearance and high-quality prints.

It offers a respectable printing volume and the company says in its advertisement that this 3D printer has enough space to print a bike helmet as a single model.

Its all-metal frame with a compact design not only enhances its charm but also ensures a high build quality and minimum printer’s movement.

Together with the Anycubic Ultrabase, the Anycubic Mega X has the ability to produce consistently high-quality 3D prints with all of your commonly used filaments. This thing not only makes it a good machine to know 3D printing but could be a perfect option for experienced users.

Features of the Anycubic Mega X

- Large Build Volume

- Rapid Heating Ultrabase Print Bed

- Filament Runout Detector

- Z-Axis Dual Screw Rod Design

- Resume Print Function

- Rigid Metal Frame

- 5-Inch LCD Touch Screen

- Multiple Filament Support

- Powerful Titan Extruder

Specifications of the Anycubic Mega X

- Build Volume: 300 x 300 x 305mm

- Printing Speed: 100mm/s

- Layer Height/Print Resolution: 0.

05 – 0.3mm

05 – 0.3mm - Maximum Extruder Temperature: 250°C

- Maximum Bed Temperature: 100°C

- Filament Diameter: 0.75mm

- Nozzle Diameter: 0.4mm

- Extruder: Single

- Connectivity: USB A, MicroSD card

- Bed Levelling: Manual

- Build Area: Open

- Compatible Printing Materials: PLA, ABS, HIPS, Wood

User Experience of the Anycubic Mega X

This 3D printer is extremely easy to get started with. The Anycubic Mega X comes as a pre-assembled package along with all necessary instructions present in a USB flash drive and a manual guide as well.

You are only required to set up your 3D printer while initiating, once your printer is set up, you don’t have to tweak its settings and waste your time every time you are going to print a 3D model.

A team of experts used this 3D printer for testing and their final verdict claimed that this 3D printer has met all their requirements and expectations.

They said that some of its features and printed models are so good that they consider the Anycubic Mega X as one of the best 3D printers ever made in this price range.

One buyer said in his review that he has tried many 3D printers with various upgrades and improvements but if you don’t have the right machine, you can never be satisfied.

According to him, Anycubic Mega X is “The Right Machine” because of the following reasons:

- You don’t need an all-metal hotend upgrade as the printer can easily heat up to 260 Degrees Celsius.

- This model has the best extruder than almost all 3D printers in this price category.

- You don’t need a MOSFET upgrade to reach a higher temperature as the heated bed can get a maximum temperature of 90 Degrees Celsius.

- This 3D printer comes with some extra nozzles of different sizes which ultimately save a bit of your money and a lot of your time.

Pros of the Anycubic Mega X

- Overall an easy-to-use 3D printer with features perfect for beginners

- Large build volume means more freedom for bigger projects

- Solid, premium build quality

- User-friendly touchscreen interface

- Very competitive price for a high-quality printer

- Great quality prints straight out of the box without necessary upgrades

- Improved packaging to ensure safe delivery to your door

Cons of the Anycubic Mega X

- Low maximum temperature of the print bed

- Noisy operation

- Buggy resume print function

- No auto-leveling – manual leveling system

Final Thoughts

This 3D printer offers a respectable build volume, as well as excellent performance and ease of use. It’s a great choice for 3D printing parts to do with robotics, RC cars and planes, drones, and nerf parts.

It’s a great choice for 3D printing parts to do with robotics, RC cars and planes, drones, and nerf parts.

I’d recommend checking out the Anycubic Mega X from Amazon for your 3D printing needs.

Creality is constantly focusing on improvement and getting new things. The CR-10 Max is a modern version of the CR-10 series, but incorporating some serious build volume along with it.

The build volume of the CR-10 Max has been dramatically increased, branded components and many life-enhancing features have been included, all this is available for $1,000.

This is considered the best and most premium 3D printer in the CR-10 line and it is only a bit less than being a perfect 3D printer.

The CR-10 Max (Amazon) included upgrades and improvements so that you can get the most from your 3D printer which cannot be achieved using its predecessors.

Features of the Creality CR-10 Max

- Super-Large Build Volume

- Golden Triangle Stability

- Auto Bed Leveling

- Power Off Resume Function

- Low Filament Detection

- Two Models of Nozzles

- Fast Heating Build Platform

- Dual Output Power Supply

- Capricorn Teflon Tubing

- Certified BondTech Double Drive Extruder

- Double Y-Axis Transmission Belts

- Double Screw Rod-Driven

- HD Touch Screen

Specifications of the Creality CR-10 Max

- Brand: Creality

- Model: CR-10 Max

- Printing Technology: FDM

- Extrusion Platform board: Aluminum Base

- Nozzle Quantity: Single

- Nozzle Diameter: 0.

4mm & 0.8mm

4mm & 0.8mm - Platform Temperature: up to 100°C

- Nozzle Temperature: up to 250°C

- Build Volume: 450 x 450 x 470mm

- Printer Dimensions: 735 x 735 x 305 mm

- Layer Thickness: 0.1-0.4mm

- Working Mode: Online or TF card offline

- Print Speed: 180mm/s

- Supporting Material: PETG, PLA, TPU, Wood

- Material diameter: 1.75mm

- Display: 4.3-inch touch screen

- File format: AMF, OBJ, STL

- Machine Power: 750W

- Voltage: 100-240V

- Software: Cura, Simplify3D

- Connector Type: TF card, USB

User Experience of the Creality CR-10 Max

You rarely have to change settings while printing simple 3D models but you may need to tweak the printer’s settings if you are going to print complex models such as robotics, drones, planes, or nerf parts.

The CR-10 Max has the ability to print for a much longer time as compared to many other 3D printers in the market. One of the CR-10 Max users said in his feedback that he has constantly printed for 200 hours without facing any kind of issues.

Because of its advanced, unique, and creative design, you can easily switch or change filaments while printing so that you don’t have to stop your printing process while working on some major projects such as nerf parts, robotics, RC boats, etc.

You may not be able to print on 100% area of the build platform in many common 3D printers in the market, but this 3D printer comes with upgraded hardware that has the ability to heat up the 100% area of the platform.

It means that you can print a 3D model of the exact platform’s size without any hassle.

Pros of the Creality CR-10 Max

- Have a massive build volume to print larger 3D models

- Provide a high degree of printing precision

- Its stable structure reduces vibration and improves stability

- High print success rate with auto-leveling

- Quality certification: ISO9001 for guaranteed quality

- Great customer service and response times

- 1-year warranty and lifetime maintenance

- Simple return and refund system if necessary

- For a large-scale 3D printer the heated bed is relatively fast

Cons of the Creality CR-10 Max

- The bed turns off when the filament runs out

- The heated bed doesn’t heat up very fast compared to average 3D printers

- Some printers have come with the incorrect firmware

- Very heavy 3D printer

- Layer shifting can occur after replacing the filament

Final Thoughts

If you are looking for a 3D printer that allows you to print very large models with maximum success while providing expected results, this 3D printer should be considered.

You can check out the Creality CR-10 Max on Amazon today.

The CR-10 V3 comes with more powerful components and advanced features than its previous versions such as CR-10 and CR-10 V2.

This 3D printer can reach high temperatures allowing you to print hard filament such as ABS and PETG with ease.

As the Creality CR-10 V3 (Amazon) comes with a glass print bed, it offers maximum convenience when it comes to adhesion and removal of the model from the build platform.

Because of its sharp printing quality and reasonable pricing, this printer is considered a complete package of required features that can be operated without any hassle.

Features of the Creality CR-10 V3

- Direct Titan Drive

- Dual Port Cooling Fan

- TMC2208 Ultra-Silent Motherboard

- Filament Breakage Sensor

- Resume Printing Sensor

- 350W Branded Power Supply

- BL-Touch Supported

- UI Navigation

Specifications of the Creality CR-10 V3

- Build Volume: 300 x 300 x 400mm

- Feeder System: Direct Drive

- Extruder Type: Single Nozzle

- Nozzle Size: 0.

4mm

4mm - Hot End Temperature: 260°C

- Heated Bed Temperature: 100°C

- Print Bed Material: Carborundum glass platform

- Frame: Metal

- Bed Leveling: Automatic optional

- Connectivity: SD card

- Print Recovery: Yes

- Filament Sensor: Yes

User Experience of the Creality CR-10 V3

Direct drive extruders are not so common in this price range but the CR-10 V3 comes with these most favorite features which could bring a lot of ease and better performance while printing.

Its build plate is not the best but provides excellent support and can bring better results.

One of the buyers said in his review that he runs a big engineering company and was looking for a 3D printer that can not only print parts like robotics and drones but brings significant reliability and durability as well.

The Creality CR-10 V3 is one of his most favorite and trusted 3D printers in this regard to this day.

One buyer said in his review that the Creality CR-10 V3 is his 6th 3D printer and 2nd Creality 3D printer and it is the cheapest yet most reliable 3D printer he has ever used.

The user said that the machine was 80% assembled right out of the box and it only took less than 30 minutes to get things started.

One user said that he has printed 74 hours in less than a week. One of his prints took about 54 hours and the 3D printed model is more than perfect.

Pros of the Creality CR-10 V3

- Easy to assembly and operate

- Quick heating for faster printing

- Parts pop of the print bed after cooling

- Great customer service with Comgrow

- Amazing value compared to other 3D printers out there

Cons of the Creality CR-10 V3

- Not any significant cons really!

Final Thoughts

Considering its large build volume, high-end features, precision, and quality, this 3D printer is likely to bring you nothing but comfort and happiness.

Check out and order the Creality CR-10 V3 3D printer on Amazon today.

Creality is well known for its high-quality 3D printers and the Creality Ender 5 Plus (Amazon) is truly a perfect candidate to become the best 3D printer.

It brings a build volume of 350 x 350 x 400mm which is quite massive and helpful when it comes to print larger parts at once instead of printing in various separate parts.

It comes with a lot of valuable features that offer incredible 3D quality, but there are still some features that may need some upgrades or improvements.

When it comes to the Ender 5 Plus, Creality has focused mainly on its features and functionality instead of style.

This is the reason that makes it worthy of being listed as one of the best 3D printers for drones, nerf guns, RC, and robotics parts. When you have the Ender 5 Plus on your side, you can expect 3D print models of great quality.

Features of the Ender 5 Plus

- Large Build Volume

- BL Touch Pre-Installed

- Filament Run-out Sensor

- Resume Printing Function

- Dual Z-Axis

- 3-Inch Touch Screen

- Removable Tempered Glass Plates

- Branded Power Supply

Specifications of the Ender 5 Plus

- Build Volume: 350 x 350 x 400mm

- Display: 4.

3 Inch

3 Inch - Print Accuracy: ±0.1mm

- Nozzle Temperature: ≤ 260℃

- Hot Bed Temperature: ≤ 110℃

- File Formats: STL, OBJ

- Printing Materials: PLA, ABS

- Machine Size: 632 x 666 x 619mm

- Net Weight: 18.2 KG

User Experience of the Ender 5 Plus

The Ender 5 Plus is one of the well-engineered 3D printers that offer a premium print experience. You will be amazed to see the quality, detail, and precision of your 3D printed parts on the Ender 5 Plus.

Whether you are a beginner or an experienced person who wants to try some new things, this could be a great choice with its large build volume and reasonable price.

Some users faced issues with the stock extruder not working properly at full capacity but with the help of Creality’s experienced and professional customer support, users were able to deal with and fix such issues without any major efforts.

One buyer said in his feedback that this 3D printer offers great print quality right out of the box. The user printed a model, its layer lines are smooth and well-aligned that are creating the least amount of unwanted texture.

The user printed a model, its layer lines are smooth and well-aligned that are creating the least amount of unwanted texture.

The best thing about this 3D model is that it took more than 50 hours to get completed without causing any issues.

As this 3D printer has a filament runout sensor, you will be immediately notified in case of filament shortage. The 3D printer will display a message with two options, either to change the filament manually or cancel the print.

You can go with the first option and then resume the print from where it was paused.

Pros of the Ender 5 Plus

- The dual z-axis rods provide great stability

- Prints reliably and with good quality

- Has great cable management

- Touch display makes for easy operation

- Can be assembled in just 10 minutes

- Very popular among customers, especially liked for the build volume

Cons of the Ender 5 Plus

- Has the non-silent mainboard meaning the 3D printer is loud but can be upgraded

- Fans are also loud

- Really heavy 3D printer

- Some people have complained about the plastic extruder not being strong enough

Final Thoughts

The Ender 5 Plus is a fully open-source, durable, and reliable 3D printer that offers room to print larger models.

I’d definitely look into getting the Ender 5 Plus from Amazon.

Sovol mainly focuses on manufacturing 3D printers that can provide their users with all major features at a minimum price tag. Well, with its SV01 and SV03, Sovol has achieved its goal to a great extent.

Although Sovol is not so well known in the 3D printers market, the Sovol SV03 should not be ignored for any reason. It only costs you about $450 and comes up with a full range of amazing features.

One of the major factors behind its best-selling streak is its large build volume.

The Sovol SV03 (Amazon) can be classified as a big brother of the SV01 which has similar direct drive extrusion but the SV03 has plenty of upgrades as well as new features and components.

Features of the Sovol SV03

- Immense Build Volume

- BLTouch Preinstalled

- TMC2208 Silent Motherboard

- Direct Drive Extrusion

- Filament Run-Out Sensor

- Dual Z-Axis Design

- Print Recovery Function

- Meanwell Power Supply

Specifications of the Sovol SV03

- Technology: FDM

- Assembly: Semi-assembled

- 3D Printer Type: Cartesian-XY

- Build Volume: 350 x 350 x 400 mm

- Extrusion System: Direct Drive

- Print Head: Single

- Nozzle Size: 0.

4 mm

4 mm - Maximum Hot End Temperature: 260°C

- Bed-Leveling: BL-Touch

- Connectivity: SD Card, USB

- Print Recovery: Yes

- Camera: No

- Filament Diameter: 1.75 mm

- Third-Party Filaments: Yes

- Materials: PLA, TPU, HIPS, ABS, PETG, Wood

User Experience of the Sovol SV03

The Sovol SV03 is a machine worthy of being purchased because this 3D printer has a bunch of features that make it capable of doing its job in the best way possible.

Its new 32-bit motherboard is almost silent and gives a greater boost to printer operating performance. With its advancement, all the new features that come with the Marlin firmware can be utilized with the Sovol SV03.

If you are a beginner or even an experienced user, bed leveling can sometimes become a lot more difficult, wasting a lot of your time. The SV03 is equipped with BL-Touch automatic bed leveling system that offers huge ease and convenience.

A beginner 3D printer user shared his first-time experience of 3D printing stating that he purchased the Sovol SV03, took it out of the box, assembled it, leveled the x-axis, leveled the bed, and started the printing process.

The user only used the recommended settings without any further modification or tweaking of the settings. Although the resultant print was not 100% perfect, it can be classified as a good 3D print without any modification.

Pros of the Sovol SV03

- The Sovol SV03 is well-built and has a sturdy aluminum frame

- Exceptional for making large-sized prints

- Has a purchasable bundle with a touchscreen and Tungsten nozzles

- Comes ready for action out of the box and requires little effort in assembly

- The upgraded motherboard can run better versions of Marlin firmware

- Performs extremely well

Cons of the Sovol SV03

- The ribbon cable wire harness could pose issues in the long run

- The SV03 occupies a footprint that might seem too space-taking for most users

- Bed heating can take longer due to the sheer size of the build plate

Final Thoughts

With this price tag, auto-bed leveling system, filament run-out sensor, power recovery, and many other powerful features, this 3D printer can compete with many 3D printers of well-known manufacturing brands.

You can get yourself the Sovol SV03 from Amazon today for your drone, RC, robotics and nerf parts.

Make Drone Parts with 3D priting– All You Need to Know

3D Printed Drone Parts: Things to Consider First

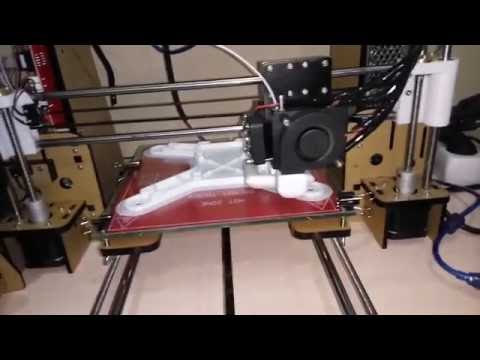

First, 3D printing takes time. It can take up to several hours to print a small sized part of sufficient quality.

Moreover, becoming an expert in 3D modeling and 3D printing requires skills you have to develop and practice. In the early stages, a beginner may experience frustration when designing the parts they need.

But don’t worry, there are plenty of tutorials online, plus websites where you can find. STL files of 3d printable drone parts which you can download and print without having to create them yourself.

Other than the above, there aren’t many reasons why you shouldn’t just go ahead and 3D print your own parts!

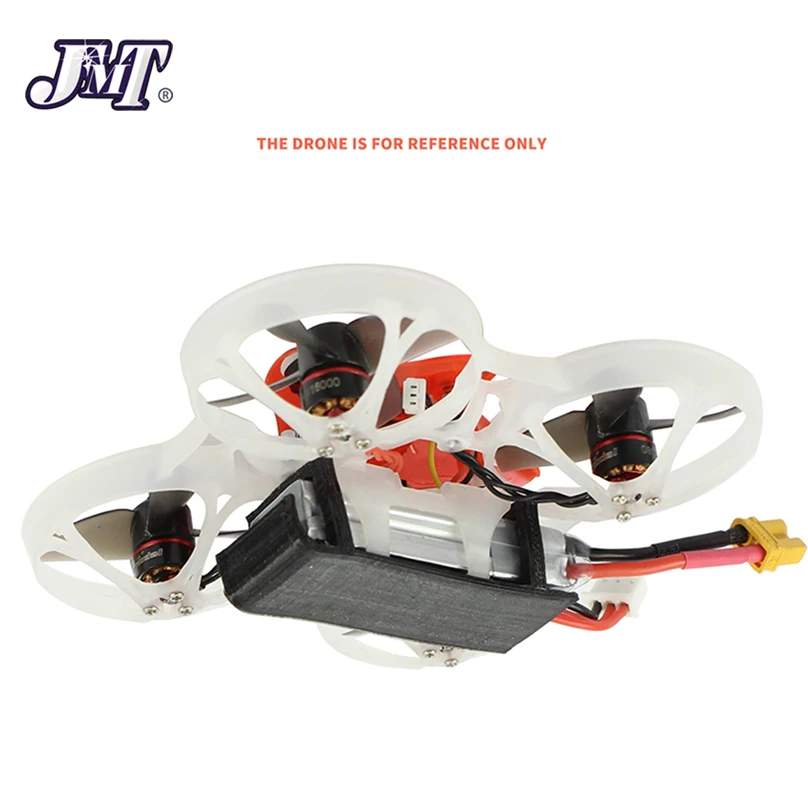

3D Printed Drone Parts: The Parts You Can 3D Print

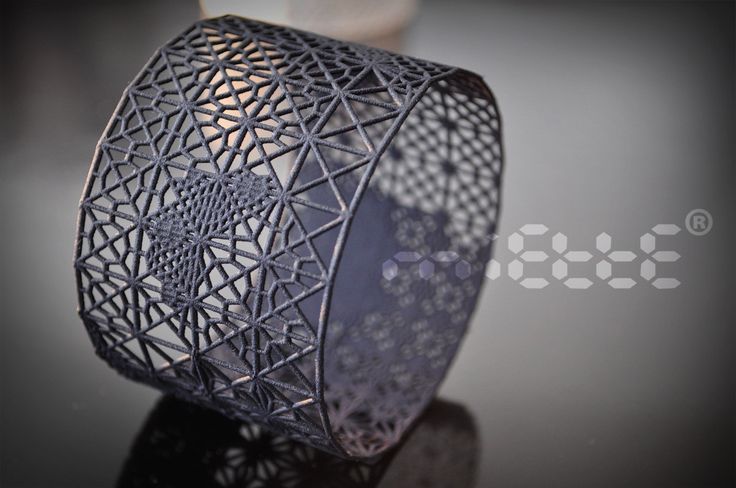

The good thing is: You can 3D print almost every part of a drone except the electronic components. Here are some components:

Here are some components:

- Propellers

- Frame

- Landing gear

- Camera mounts

- Antenna holder

- Protective equipment (i.e. prop guards)

- Remote casing

- Battery pack casing

Even some commercial drone manufacturers are using 3D printing. For example, Southern Californian company Blue Robotics uses 3D printing for their submarine drones. Their creations are open source, the digital blueprints are available for everyone who wants a 3D printed drone.

3D Printed Drone Parts: The Best Resources

There are many resources online that not only offer 3D printed drone parts for existing makes and models but also instructions how to build your own 3D printed drone parts.

You’ll need to buy the electronic components in most cases, but a significant chunk of the parts can be fabricated on any 3D printer.

Resources for 3D Printed Drones:

- For starters, check out this list of 3D printed multi-rotors on the RCgroups forum.

- Another good resource is the “3D printing drone parts” group on DIYdrones.com. Here you’ll find an overview of the best DIY drones with 3D printed parts.

- But by far the best-looking 3D printed drone project is probably the DJI Inspired 3D Printed Quadcopter. It’s a 3D printable copycat of the actual DJI Inspire One. Instructions and parts can be downloaded here and the discussion with a huge load of tips here. You can also buy the .STL files on the RC Hobbies UK website.

Watch the amazing mechanism that moves the landing struts up when in mid-air (to lower the center of gravity) and down while landing… It’s a really sophisticated piece of design.

3D Printed Drone Parts: 3D Printing Accessories

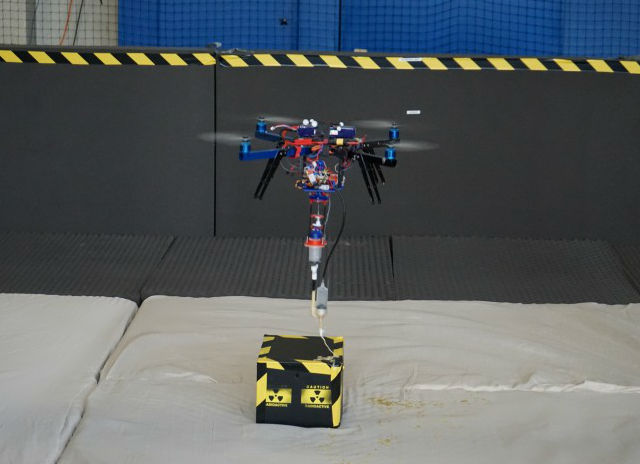

Aside from vital components, there is a huge variety of extra things you can add to your quadcopter. There are functional accessories… and then less functional accessories.

One might make a flying Helicarrier from The Avengers movie out of their drone (which would be awesome). Others will stick to more practical applications like 3D printed propeller guards, cases for transportation and mounts for various cameras used on FPV drones (which is also awesome).

The possibilities are limited only by your imagination.

3D Printed Drone Accessories #1: Protect your Vehicle

Parts you can 3D print range from optional accessories to add-on protective equipment like prop guards. The latter are useful for small indoor quadcopters like the Hubsan X4 and gear protectors for the very popular Parrot AR versions.

Every part that will commonly bump into obstacles (including the ground) may need replacement at some point. If you 3D print drone spares, you won’t suffer from much downtime when this occurs.

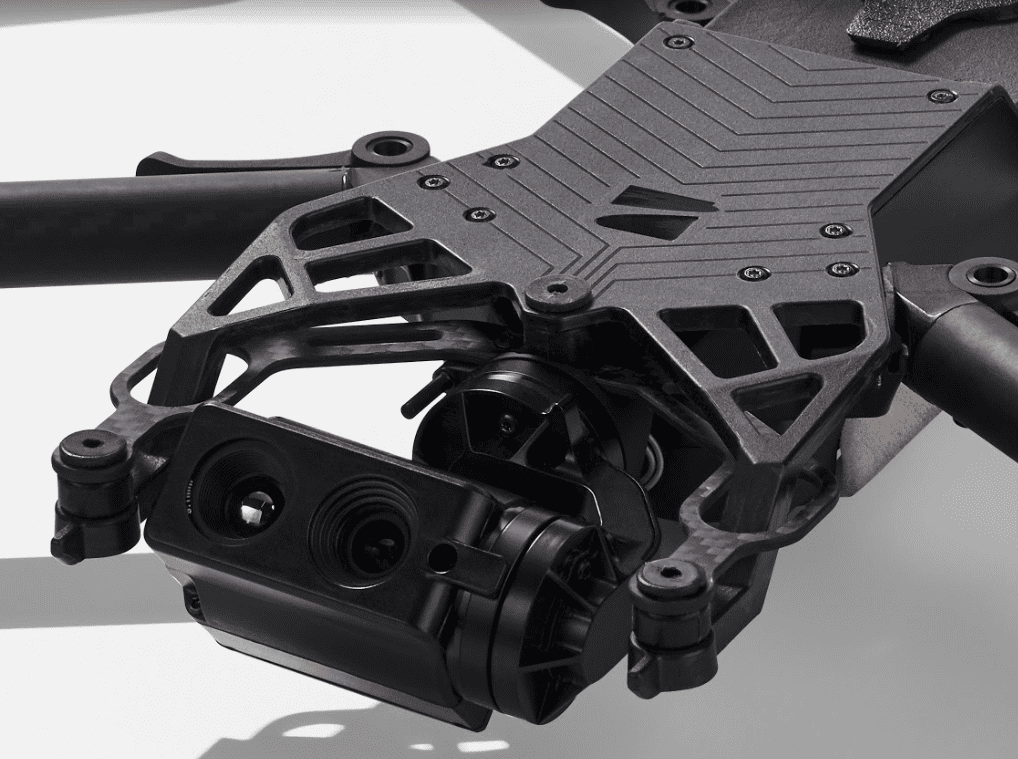

3D Printed Drone Accessories #2: 3D Printed Drone Mounts

Of course, we’re not referring to mounting the drone onto something, that would be pointless. Rather, the idea is to mount accessories onto the drone.

And if you’re planning on getting started with FPV drone racing, 3D printed parts like a camera mount as well as mounts for the live video transmitter or maybe an additional antenna holder are highly useful.

Elsewhere, the GoPro mount for the Phantom 2 lets you add the standard GoPro accessories onto your aerial vehicle.

If you want to know more, please consult this article.

3D Printed Drone Accessories #3: Boost the drone’s range with 3D Printed Parts

There are many ways you can come up with iterations of existing parts that may or may not improve your drone – and it’s fun to experiment for sure!

For different use cases, different designs will prove worthwhile. For the hobbyist that buys a fully assembled quadcopter (like the DJI Phantom or Inspire models), they’ll still appreciate a simple 3D printed range boosterthat, acting as a parabolic reflector with some metallic tape, will increase the range of the remote control threefold.

For the hobbyist that buys a fully assembled quadcopter (like the DJI Phantom or Inspire models), they’ll still appreciate a simple 3D printed range boosterthat, acting as a parabolic reflector with some metallic tape, will increase the range of the remote control threefold.

Elsewhere, the tech enthusiast that builds his own drone from scratch can improve the accuracy of his onboard electronics by eliminating general shakiness with a 3D Printed Anti Vibration Mount, which still conducts major movements that come from actual changes in flight.

3D Printed Drone Parts: The Best Materials

Choosing the right material is vital because every gram of weight will cost you flight time. Why? Because the heavier the drone, the faster the drain on the drone’s battery. At the same time, it would be foolish to try to navigate properly with a wobbly construction made from shoddy parts.

There are many “high-grade” 3D printing filaments available. They are sold as extra-strong and durable alternatives to the widely used PLA and ABS. You can also spend extra cash on some enhanced filament spools with carbon fiber. So, should you print in nylon, PET or rather use some exotic stuff you haven’t even heard of yet?

They are sold as extra-strong and durable alternatives to the widely used PLA and ABS. You can also spend extra cash on some enhanced filament spools with carbon fiber. So, should you print in nylon, PET or rather use some exotic stuff you haven’t even heard of yet?

3D Printed Drone Parts – Material #1: PET/PETG

PET / PETG is stable and shockproof, but it requires a heated print bed, is relatively expensive, and quite heavy.

In conclusion, you can almost always print in PLA when you’re an absolute beginner and should transition to ABS when you’re ready for the big leagues. Advanced 3D printing and drone pros will also enjoy printing with Nylon.

3D Printed Drone Parts – Material #2: TPU/TPE

Because it is flexibel and absorbs vibrations.

3D Printed Drone Parts – Material #3: PLA

PLA is easy to work with, has no odor, and is cheap and widely available. However, it’s not UV or heat-resistant.

However, it’s not UV or heat-resistant.

3D Printed Drone Parts – Material #4: ABS

ABS is tough and stable, lightweight, and has better temperature resistance. It’s also cheap and widely available. However, you need a heated print bed for optimal results, and there are the dreaded toxic fumes to consider.

3D Printed Drone Parts – Material #5: Nylon

Nylon has amazing strength and temperature resistance and is lightweight, but it’s tricky to print with.

If you want more information on filaments, please continue here.

The Best 3D Printed Drones

Here’s a short collection of the best drones and quadcopters you can 3D print:

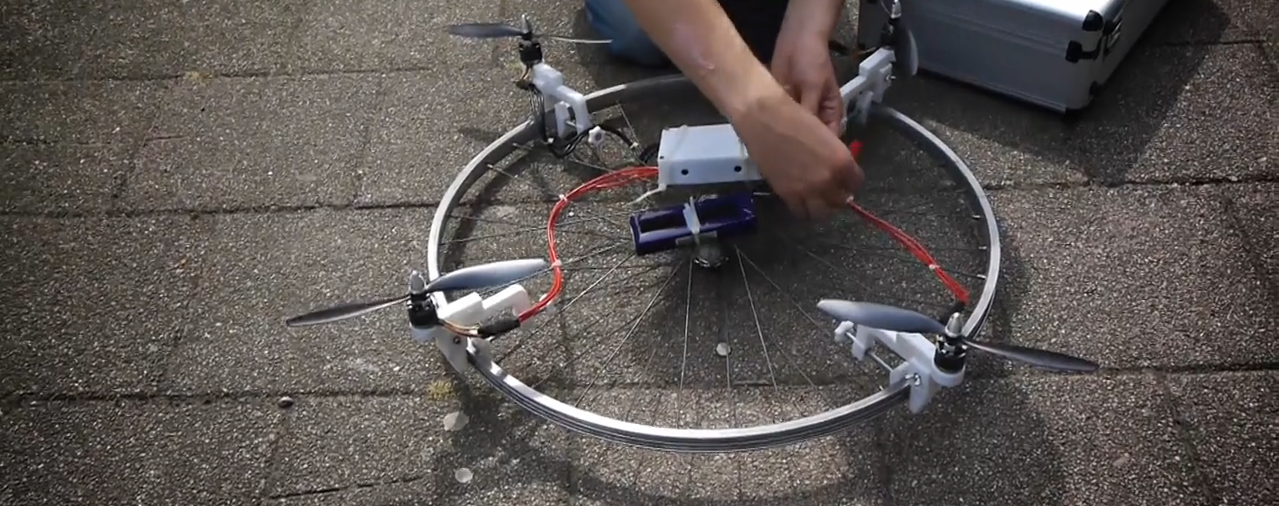

3D Printed Quadcopter #1: PIXXY (Pocket drone / FPV quad)

The Pixxy is of the smallest FPV miniature quadcopters you can build yourself. It only weighs 4 gram, can be easily stored and relatively easy to manufacture. You need some simple soldering skills, the parts widely available in common online hobby and toy shops. The cost for this 3D printed drone shouldn‘t exceed USD $100.

You need some simple soldering skills, the parts widely available in common online hobby and toy shops. The cost for this 3D printed drone shouldn‘t exceed USD $100.

Get it at Thingiverse.

3D Printed Quadcopter #2: Hovership MHQ2 (Quadcopter)

Being one of the most popular designs of 3D printed drones, this redesigned MHQ2 folding mini quadcopter is built like a tank! Building on the success of the original MHQ frame, it offers improved functionality, durability, and stability of this frame.

Get it at Thingiverse.

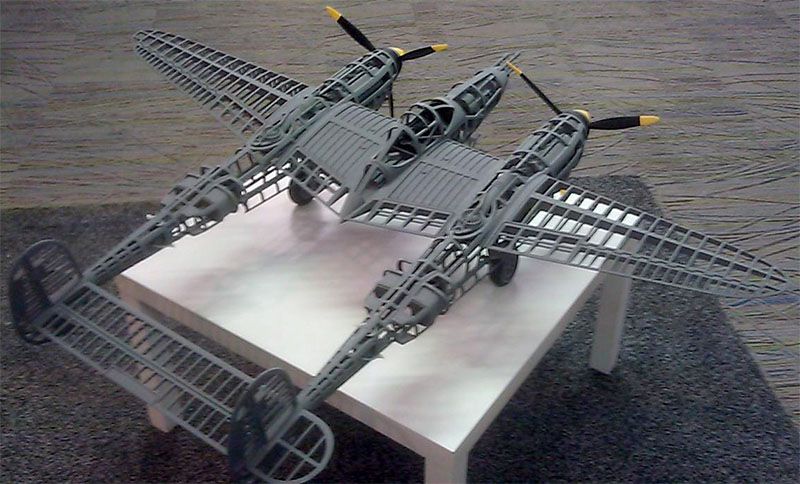

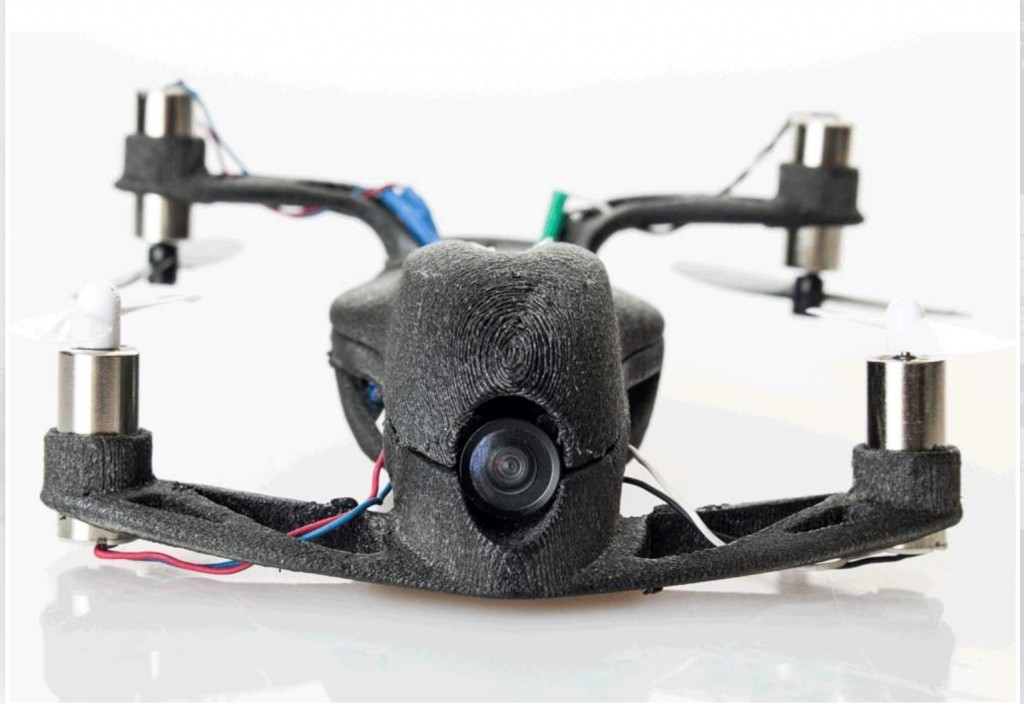

3D Printed Quadcopter #3: Firefly

This beauty of a 3D printed drone can go really fast: The Firefly is a fully featured racing quad with amazing flight characteristics. If you’re into DIY racing drones, this is one to consider.

Get it here.

3D Printed Quadcopter #4: Rey’s Speeder Bike (Quadcopter)

This is custom quadcopter inspired by Rey’s Speeder Bike from new Episode 7 Star Wars The Force Awakens trailer. This is one of the 3D printed drones that just look beautiful – but beware, there’s a lot of work to do until Rey takes off.

This is one of the 3D printed drones that just look beautiful – but beware, there’s a lot of work to do until Rey takes off.

Get it at Thingiverse.

3D Printed Quadcopter #5: Foldable Brushed Microquad

It looks like a flying circuit board, right? Well, that’s pretty much what it is. This 3D printed drone is foldable to 83 x 58mm, consists of affordable components and is relatively easy to build, if you have some DIY experience.

Get it at Thingiverse.

Flight platform for customize industrial Specially designed for industry applications. with modular design concept, the main components can be quickly disassembled and assembled, flexible and multi-purpose, convenient for customized demand expansion, and the whole frame adopts dumb black coating, which shows processional stability.

PREVIOUS:Flying drones to be legal in India from December 2018 NEXT:Drones Application In Precision Agriculture

90,000 everything you need to know before startingContent

- 1 Introduction

- 2 Fundamentals of 3D prints of drone details

- 2.

1 advantages

1 advantages - 2.2 The best materials

- 2.4 Applosability of materials 9000 2.5 Details of details

- 2.

- 2.6 Functional Components

- 2.7 Security

Introduction

If you are looking to 3D print a drone from scratch or make related parts for an already finished quadcopter, then this guide is for you. Read on to learn all about how to make your printed components fly!

Fundamentals of 3D printing drone parts

5" mini quad with printed Hero 8 mount (Source: Rob Davey via All3DP) are vehicles capable of operating autonomously. In other words, a drone is not necessarily an aircraft; they can also include cars, boats and even hovercraft. However, the term is used to refer specifically to an aircraft that has three or more rotors to provide lift and thrust. They are also commonly referred to as multicopters, tricopters, quadcopters, and so on.

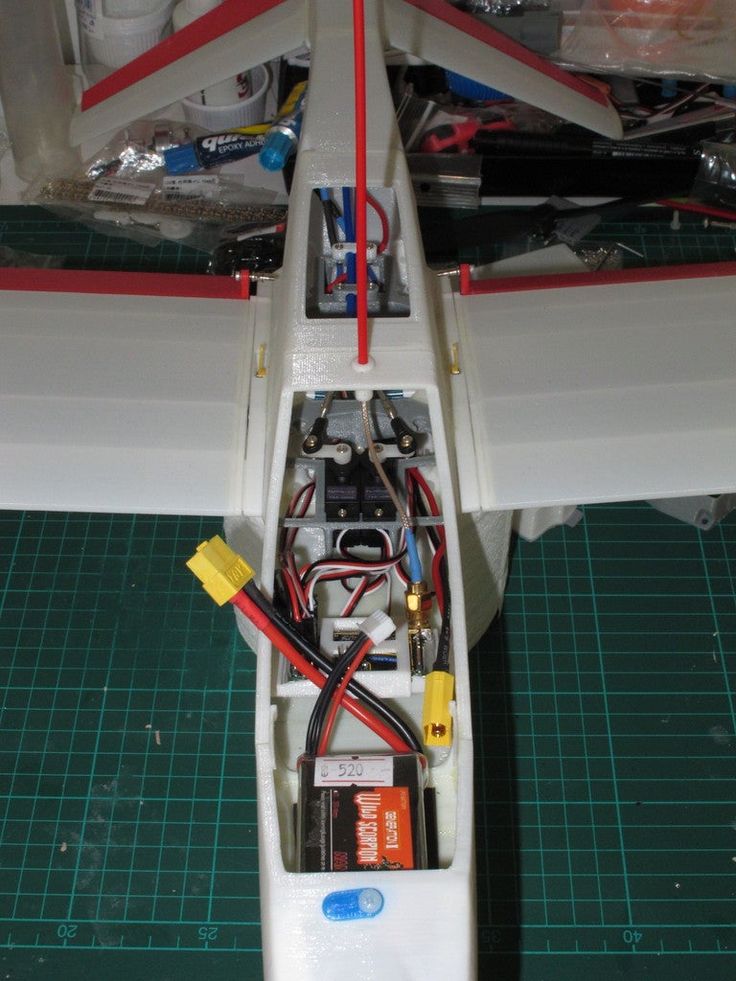

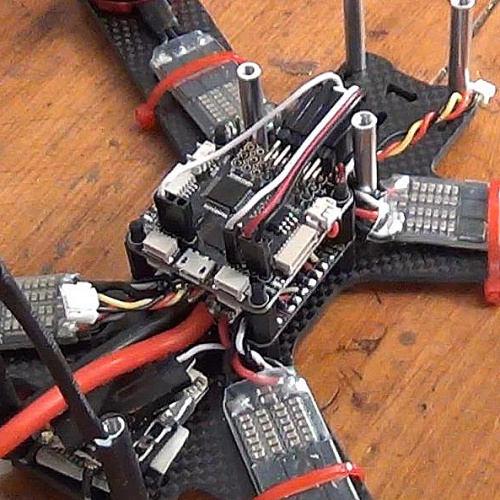

In general, UAVs are mechanically very simple and consist of a frame, flight controller, el. motors, propellers, speed controllers and possibly first person view (FPV) equipment.

3D printing has long been a great drone hobby. This technology allows the user to easily produce many different parts on their own. This can be anything from protective bumpers and action camera mounts to accessories that add functionality to the quad.

In this article, we'll talk about what to consider when 3D printing drone parts, the most relevant parts to print, and where to find models and resources. We'll then wrap things up with a few projects to get you started. But first, let's figure out why you even need to print parts on a 3D printer. Read on to find out more!

Benefits

Smartphone holder (Source: Digit Design and Prints via Facebook)

- The main advantage of 3D printed parts is that they can be completely customized.

In addition, they are generally inexpensive (assuming you already have a printer and filament (3D printing filament)), and the design can be quickly iterated from initial to final version.

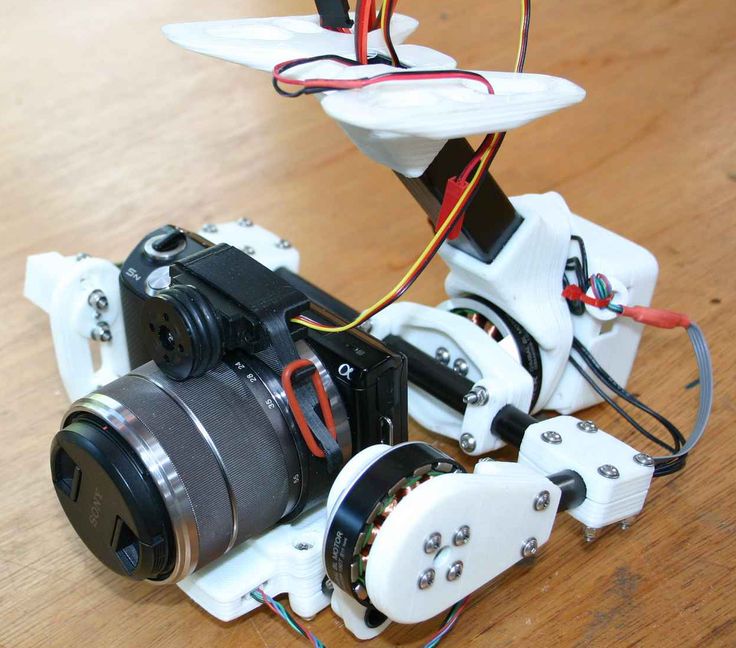

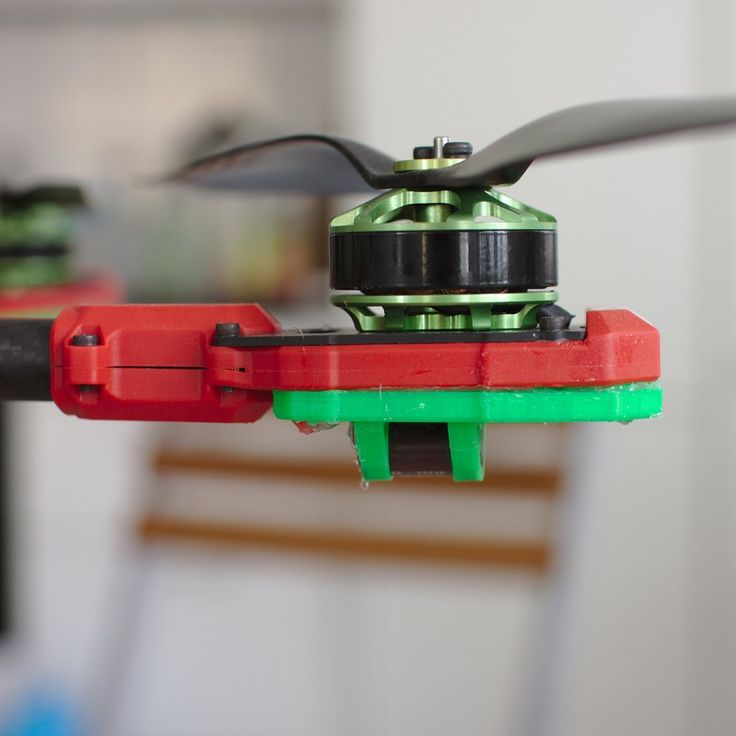

In addition, they are generally inexpensive (assuming you already have a printer and filament (3D printing filament)), and the design can be quickly iterated from initial to final version. - The printed parts can be made from different materials and in different colors. This approach allows the use of a material with better mechanical properties for specific elements. For example, your GoPro mount might be blue TPU with nylon prop guards. Camera holders are best printed with TPU (Thermoplastic Polyurethane; TPU) as this material absorbs vibration from the frame and holds the GoPro tightly in place, while the durable nylon can absorb shock and protect both the propellers and the object/obstacle itself. Other durable materials such as reinforced nylon can even be used to create gliders, awnings and camera hangers.

- Another plus when using printed parts is their relatively low density. With 3D printing, parameters such as the number of perimeters and infill percentage can be adjusted to significantly reduce weight, with the former more predetermined in the final result.

This photo shows the manufacturing sequence for an FPV drone canupee. For example, when designing a canupi, the first draft of the blank can be printed from an inexpensive material such as PLA, and after the fitting process, all required changes can be easily made into the next iteration. Once the model is considered complete, it can be printed in more expensive material such as carbon fiber, nylon, or even, if budget allows, PEEK carbon fiber. Do you need all these components? (Source: Rob Davey via All3DP) While 3D printing opens up a whole new world of possibilities in terms of additional features, the most important thing to keep in mind is the weight of your aircraft. You may also notice that large companies such as DJI who sell UAVs and similar aircraft usually offer the necessary mounts and accessories; they are all printed, but their number is as limited as possible, because they simply add weight. In addition, in many countries, including the Russian Federation, the rules require registration of models weighing more than 250 grams. Accordingly, the demand for quadcopters weighing below this limit is much higher. Beam shield, GoPro mount and antenna mount all printed in TPU (Source: Digit Design and prints via Facebook) The most commonly used material for quads (especially for the mini niche) ) is TPU. The main parts printed on TPU are bumpers, camera mounts, antenna mounts and propeller guards. Nylon can also be used to protect props, but is less common because it is harder to print. While TPU and nylon are versatile, they are not suitable for all parts. Where more rigidity and strength are required, such as in the manufacture of gliders, carbon-fiber-reinforced nylon (CFRPA6) is recommended. This approach will provide the benefits of standard nylon, coupled with the rigidity of carbon fiber. It's also easier to print on than regular nylon because it warps less and sticks better to the 3D printer's build plate. One way to protect the underside of the boat's frame, as well as the motor mounting bolts, is to add 3D-printed "stands or landing pads". They are especially useful when flying over concrete surfaces. The ideal material for this is CFRPA6. You can also print them in TPU, but the abrasion resistance won't be as good. 5" Racing Quadcopter with Turtle or Turtle Mode Tandem Fin (Source: Rob Davey via All3DP) If racing drones are your hobby, you should try using a fin. This component is especially relevant in tandem with the mode known as "turtle or turtle". When the drone is flipped upside down, thanks to the fin, the two motors free from contact with the surface will be able to rotate freely, which will subsequently allow you to quickly flip the quad and continue the race. They are most often printed in TPU and sometimes in nylon. FPV transmitter antenna holder printed in TPU (Source: rapnit via Thingiverse) If you are flying in FPV mode, VTX antennas are vital. It is also possible to enable head tracking in FPV mode, when the FPV camera is mounted in a motorized drive, allowing it to move in two or three dimensions according to your FPV goggles. Thus, the camera copies the movements of your head, contributing to greater immersion. For this, inflexible materials such as PETG, ABS, ASA or even PC should be used. Rigidity is needed to eliminate play in the components. The 2-axis gimbal (to stabilize the camera) was printed in PLA (Source: turbi via Thingiverse). If FPV flying or racing isn't your thing, you can always print the parts to expand the functionality. This stick protection was designed by Fusion 360 (Source: Motorpixiegimbals via Thingiverse) Finally, another good print option is parts to protect elements such as the control sticks of a remote control. They can be either flexible or non-flexible, depending on your preference. GrabCAD search results for "Drones" (Source: GrabCAD) This site has an active user base and many helpful discussions (Source: DIYDrones) While many of the individual components can be downloaded from the sites listed above, there are also additional resources such as forums. Canupee model with custom molded GoPro holder (Source: basdelfos via Thingiverse). The only real limit to what you can print is your imagination! Before proceeding, it will be necessary to take into account the intended purpose of both the drone and the part, as well as the impact of any additional weight. Here are some ideas from Thingiverse for printing, whether it's an entire quadcopter or just parts of it: That's all for now. Visual process of printing rays for an FPV drone made of carbon fiber reinforced nylon (CFRPA6). 3DELO Loading 28/10/2017 22936 Application Considerations

Not everything that can be printed and installed is useful! It should be understood that every gram of a drone affects the flight time and flight characteristics, especially for rotorcraft. In other words, on a UAV whose primary purpose is long flight, the presence of components such as a GoPro mount, a head tracker, and a reset mechanism is not necessary.

Not everything that can be printed and installed is useful! It should be understood that every gram of a drone affects the flight time and flight characteristics, especially for rotorcraft. In other words, on a UAV whose primary purpose is long flight, the presence of components such as a GoPro mount, a head tracker, and a reset mechanism is not necessary. Best materials

This is because it is highly flexible and can deform on impact, absorbing energy and protecting important UAV components. Due to its flexibility, it can also absorb vibration, reducing visible artifacts in recorded video. Fortunately, this has become less of an issue with the introduction of in-camera stabilization. Another suitable material is nylon. It is stiffer than TPU, but still has some flexibility.

This is because it is highly flexible and can deform on impact, absorbing energy and protecting important UAV components. Due to its flexibility, it can also absorb vibration, reducing visible artifacts in recorded video. Fortunately, this has become less of an issue with the introduction of in-camera stabilization. Another suitable material is nylon. It is stiffer than TPU, but still has some flexibility. Material Applicability

Variety of Parts

Fins

Antenna Mount

Thus, there are many mounting options for such components. If the device is intended for flights over long distances, then enclosing the active part of the antenna in a TPU is not a good idea, as this will adversely affect the video signal. For them, TPU is the preferred choice because it is very elastic and can deform without breaking for a long time.

Thus, there are many mounting options for such components. If the device is intended for flights over long distances, then enclosing the active part of the antenna in a TPU is not a good idea, as this will adversely affect the video signal. For them, TPU is the preferred choice because it is very elastic and can deform without breaking for a long time. Functional components

Maybe it's a camera stabilizer for aerial photography or video shooting, or a mechanism for grabbing and dropping objects? For a gimbal, the moving parts must be printed on a non-flexible material to eliminate play.

Maybe it's a camera stabilizer for aerial photography or video shooting, or a mechanism for grabbing and dropping objects? For a gimbal, the moving parts must be printed on a non-flexible material to eliminate play.

When installing the stabilizer on the drone, there must be a flexible part between it and the gimbal to isolate it from vibration. Protection

Model sources

Please note that you will need an account to upload models (remarkably for Thingiverse this is not necessary).

Please note that you will need an account to upload models (remarkably for Thingiverse this is not necessary).

If you download models from any repositories (including the websites listed above), be sure to check the license under which they are in order not to infringe copyright when selling.

Resources

The main forums for drone manufacturers are DIYDrones and RCGroups. A complete list of printable gliders on RCgroups can be found in one helpful thread, or similar listings can be found on DIYDrones. In addition, there is a subreddit for drones that discusses 3D printing topics, as well as a subreddit for do-it-yourself drones.

The main forums for drone manufacturers are DIYDrones and RCGroups. A complete list of printable gliders on RCgroups can be found in one helpful thread, or similar listings can be found on DIYDrones. In addition, there is a subreddit for drones that discusses 3D printing topics, as well as a subreddit for do-it-yourself drones. Projects to get you started

Thank you for your attention. We hope the presented material was useful for you. Stay with us!

Thank you for your attention. We hope the presented material was useful for you. Stay with us! video

3D printing housing for Mavic

quadcopter This is a new edition of the Mavic quadcopter for a different controller.

3D printing in Arkhangelsk is made by 3DELO 3D Technology Center. Materials of the REC company were used for the work. 3D printing was done with ABS plastic. Many thanks to my colleagues for the reliable and high-quality plastic for the 3D printer. It is always calm and confident with him on any 3D printers. We recommend these materials for the manufacture of functional and high-quality parts.

Many thanks to my colleagues for the reliable and high-quality plastic for the 3D printer. It is always calm and confident with him on any 3D printers. We recommend these materials for the manufacture of functional and high-quality parts.

This is what Mavic Pro quadcopters look like. we will present to your attention a slightly different and miniature unmanned aerial vehicle - a quadrocopter. Mavic is a portable quadcopter with a set of modern technologies. Our quadcopter body is 3D printed, DJI NAZA Lite brains, 2213 9 motors35kv Emax, speed controller DYS XSD20A DShot , battery 3s 2200 mAh.

The Mavic drone keeps up with the previous Phantom in terms of engines. Flight control is now possible at a distance of more than 2-5 kilometers - thanks to the signal transmission system. It's safe to say that the Mavic quadcopter is superior to many of its predecessors. Upon noticing an obstacle, the Mavic may decide to fly around it or stop and hover in the air. And sometimes you don't have to worry about its safety. Well, there are many more additional features. Those who are passionate about this topic will appreciate all the advantages of this device. And for a simple reader, the idea of using 3D printing for practical purposes will be interesting. The cost savings when making a hull using 3D printing is obvious. Making changes to the model is a huge advantage compared to purchased items. The ability to quickly change and choose colors and materials is also a big plus.

And sometimes you don't have to worry about its safety. Well, there are many more additional features. Those who are passionate about this topic will appreciate all the advantages of this device. And for a simple reader, the idea of using 3D printing for practical purposes will be interesting. The cost savings when making a hull using 3D printing is obvious. Making changes to the model is a huge advantage compared to purchased items. The ability to quickly change and choose colors and materials is also a big plus.

Now for the process. The ABS plastic in 3DELO was selected for each part in accordance with the planned appearance. Everything is carefully laid out and tuned for high-quality filling of parts, without compromising the weight of the aircraft and the strength of the structural elements. Well, in flight .... while printing on a 3D printer, and then into the sky!

Lots of detail photos.

Installation of the internals went without any problems.

So this is how the assembled Mavic quadcopter looks like.

Everything is mounted, everything fits. Checked - it flies! For those who are interested, there is a video.

The 3DELO team in Arkhangelsk wishes everyone the pleasure of the work done. Let your result please those around you. Contribute to the development of 3D technologies.

Detailed information on this work made on a 3D printer can be found at this link.

Follow author

Follow

Don't want

33

Article comments

More interesting articles

16

Subscribe to the author

Subscribe

Don't want

Hello everyone! In this article, if you can call it that, there will be nothing special, just an experience of creating .