3D printer etf

Total 3D-Printing Index - ETF Tracker

ETFs Tracking Other Mutual Funds

Mutual Fund to ETF Converter Tool

- Overview

- Returns

- Fund Flows

- Expenses

- Dividends

- Holdings

- Taxes

- Technicals

- Analysis

- Realtime Ratings

ETFs Tracking The Total 3D-Printing Index – ETF List

ETFs tracking the Total 3D-Printing Index are presented in the following table.

ETFs Tracking The Total 3D-Printing Index – ETF Returns

The following table presents historical return data for ETFs tracking the Total 3D-Printing Index.

ETFs Tracking The Total 3D-Printing Index – ETF Fund Flow

The table below includes fund flow data for all U.S. listed Highland Capital Management ETFs. Total fund flow is the capital inflow into an ETF minus the capital outflow from the ETF for a particular time period.

Fund Flows in millions of U.S. Dollars.

ETFs Tracking The Total 3D-Printing Index – ETF Expenses

The following table presents expense information for ETFs tracking the Total 3D-Printing Index.

ETFs Tracking The Total 3D-Printing Index – ETF Dividends

The following table presents dividend information for ETFs tracking the Total 3D-Printing Index, including yield and dividend date.

ETFs Tracking The Total 3D-Printing Index – ETF Holdings

The following table presents holdings data for all ETFs tracking the Total 3D-Printing Index. For more detailed holdings data for an ETF click the ‘View’ link in the right column.

ETFs Tracking The Total 3D-Printing Index – ETF Tax Rates

The following table presents sortable tax data for ETFs currently tracking the Total 3D-Printing Index.

ETFs Tracking The Total 3D-Printing Index – ETF Technicals

The following table presents certain technical indicators for ETFs tracking the Total 3D-Printing Index. To see complete technical metrics click the ‘View’ link in the right column.

ETFs Tracking The Total 3D-Printing Index – ETF Analysis

The following table presents links to in-depth analysis for ETFs tracking the Total 3D-Printing Index.

ETFs Tracking The Total 3D-Printing Index – ETF Realtime Ratings

The following table presents a proprietary ETF Database rating for ETFs tracking the Total 3D-Printing Index.

Total 3D-Printing Index - ETF Tracker

| Symbol | ETF Name | Asset Class | Total Assets* | YTD | Avg Volume | Previous Closing Price | 1-Day Change | Overall Rating | 1 Week | 1 Month | 1 Year | 3 Year | 5 Year | YTD FF | 1 Week FF | 4 Week FF | 1 Year FF | 3 Year FF | 5 Year FF | ETF Database | Inception | ER | Commission Free | Annual Dividend Rate | Dividend Date | Dividend | Annual Dividend Yield % | P/E Ratio | Beta | # of Holdings | % In Top 10 | Complete | ST Cap Gain Rate | LT Cap Gain Rate | Tax Form | Lower Bollinger | Upper Bollinger | Support 1 | Resistance 1 | RSI | Advanced | Fact Sheet | ETF Holdings | Chart | ETF Home Page | Head-To-Head | Liquidity Rating | Expenses Rating | Returns Rating | Volatility Rating | Dividend Rating | Concentration Rating |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PRNT | 3D Printing ETF | Equity | $173,166 | -43. 5% 5% | 29,995.0 | $19.39 | -1.52% | -8.1% | -15.6% | -45.0% | -3.7% | -23.6% | Technology Equities | 2016-07-19 | 0.66% | N/A | $0.00 | 2019-12-27 | $0.02 | 0.00% | 39.1 | 1.30 | 58 | 42.5% | View | 40% | 20% | 1099 | $19. 04 04 | $22.19 | $19.12 | $19.73 | 37.00 | View | View | View | View | View | View | B+ | B- |

Sort By:

- Overview

- Returns

- Fund Flows

- Expenses

- Dividends

- Holdings

- Taxes

- Technicals

- Analysis

- Realtime Ratings

ETFs Tracking Other Technology Equities

ETF Database staff has allocated each ETF in the ETF database, as well as each index, to a single ‘best-fit’ ETF Database Category. Other ETFs in the Technology Equities ETF Database Category are presented in the following table.

Other ETFs in the Technology Equities ETF Database Category are presented in the following table.

* Assets in thousands of U.S. Dollars. Assets and Average Volume as of 2022-10-11 16:16:04 -0400

ETFs Tracking Other Technology Equities

Historical return data for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Fund flow information for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Expense information for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Dividend information for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Holdings data for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Tax Rate data for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Technical information for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Links to analysis of other ETFs in the Technology Equities ETF Database Category is presented in the following table.

ETFs Tracking Other Technology Equities

Links to a proprietary ETF Database rating for other ETFs in the Technology Equities ETF Database Category is presented in the following table.

| Symbol | ETF Name | Asset Class | Total Assets* | YTD | Avg Volume | Previous Closing Price | 1-Day Change | Overall Rating | 1 Week | 1 Month | 1 Year | 3 Year | 5 Year | YTD FF | 1 Week FF | 4 Week FF | 1 Year FF | 3 Year FF | 5 Year FF | ETF Database | Inception | ER | Commission Free | Annual Dividend Rate | Dividend Date | Dividend | Annual Dividend Yield % | P/E Ratio | Beta | # of Holdings | % In Top 10 | Complete | ST Cap Gain Rate | LT Cap Gain Rate | Tax Form | Lower Bollinger | Upper Bollinger | Support 1 | Resistance 1 | RSI | Advanced | Fact Sheet | ETF Holdings | Chart | ETF Home Page | Head-To-Head | Liquidity Rating | Expenses Rating | Returns Rating | Volatility Rating | Dividend Rating | Concentration Rating |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| VGT | Vanguard Information Technology ETF | Equity | $37,346,400 | -33. 7% 7% | 686,635.0 | $302.11 | -1.63% | -7.8% | -14.6% | -25.0% | 44.1% | 105.0% | Technology Equities | 2004-01-26 | 0.10% | Vanguard | $2.79 | 2021-09-29 | $0.89 | 0.63% | 32.8 | 1.08 | 375 | 58.6% | View | 40% | 20% | 1099 | $302. 57 57 | $342.24 | $298.84 | $306.35 | 34.83 | View | View | View | View | View | View | A | A | |||||||||||

| XLK | Technology Select Sector SPDR Fund | Equity | $35,581,200 | -32.3% | 7,003,555.0 | $116.92 | -1.53% | -7.6% | -14. 6% 6% | -22.0% | 49.8% | 106.0% | Technology Equities | 1998-12-16 | 0.10% | N/A | $1.10 | 2021-09-20 | $0.27 | 0.67% | 27.5 | 1.04 | 77 | 67.3% | View | 40% | 20% | 1099 | $117.11 | $132.33 | $115.69 | $118. 51 51 | 34.26 | View | View | View | View | View | View | A+ | A | |||||||||||

| IYW | iShares U.S. Technology ETF | Equity | $5,721,100 | -37.1% | 422,023.0 | $72.06 | -1.66% | -8.0% | -15.3% | -29.5% | 43.2% | 94.8% | Technology Equities | 2000-05-15 | 0. 39% 39% | N/A | $0.32 | 2021-09-24 | $0.07 | 0.29% | 39.3 | 1.06 | 148 | 61.6% | View | 40% | 20% | 1099 | $72.25 | $81.68 | $71.22 | $73.16 | 34.74 | View | View | View | View | View | View | A | A- | |||||||||||

| SMH | VanEck Semiconductor ETF | Equity | $5,622,000 | -42. 8% 8% | 4,036,103.0 | $176.55 | -3.15% | -11.7% | -18.6% | -29.9% | 51.6% | 95.2% | Technology Equities | 2000-05-05 | 0.35% | N/A | $1.50 | 2020-12-21 | $1.50 | 0.50% | 28.2 | 1.17 | 26 | 58.9% | View | 40% | 20% | 1099 | $179. 67 67 | $210.84 | $173.80 | $179.69 | 33.68 | View | View | View | View | View | View | A | A | |||||||||||

| FTEC | Fidelity MSCI Information Technology Index ETF | Equity | $4,753,300 | -33.6% | 192,185.0 | $89.39 | -1.56% | -7.8% | -14. 6% 6% | -24.8% | 44.3% | 99.7% | Technology Equities | 2013-10-21 | 0.08% | Fidelity | $0.79 | 2021-09-17 | $0.20 | 0.60% | 31.7 | 1.08 | 381 | 59.1% | View | 40% | 20% | 1099 | $89.47 | $101.19 | $88.47 | $90. 56 56 | 34.89 | View | View | View | View | View | View | A- | A+ | |||||||||||

| CIBR | First Trust NASDAQ Cybersecurity ETF | Equity | $4,694,100 | -29.0% | 658,788.0 | $37.45 | -1.73% | -8.5% | -14.3% | -24.2% | 39.3% | 73.6% | Technology Equities | 2015-07-07 | 0. 60% 60% | N/A | $0.06 | 2021-06-24 | $0.03 | 0.11% | 28.0 | 1.02 | 38 | 46.5% | View | 40% | 20% | 1099 | $37.38 | $42.38 | $37.06 | $38.00 | 37.37 | View | View | View | View | View | View | A | B- | |||||||||||

| IGV | iShares Expanded Tech-Software Sector ETF | Equity | $4,554,190 | -38. 4% 4% | 1,155,921.0 | $245.01 | -1.75% | -8.2% | -15.7% | -39.2% | 15.9% | 66.3% | Technology Equities | 2001-07-10 | 0.40% | N/A | $0.00 | 2020-06-15 | $0.07 | 0.00% | 50.1 | 0.99 | 118 | 54.4% | View | 40% | 20% | 1099 | $243. 17 17 | $277.11 | $241.97 | $248.55 | 36.25 | View | View | View | View | View | View | A | A- | |||||||||||

| SKYY | First Trust Cloud Computing ETF | Equity | $2,877,610 | -44.1% | 428,658.0 | $58.22 | -1.72% | -10.6% | -17. 2% 2% | -45.4% | 5.5% | 40.7% | Technology Equities | 2011-07-05 | 0.60% | N/A | $0.18 | 2021-09-23 | $0.04 | 0.15% | N/A | 0.97 | 67 | 36.4% | View | 40% | 20% | 1099 | $57.73 | $68.20 | $57.00 | $59. 43 43 | 37.02 | View | View | View | View | View | View | A | B | |||||||||||

| IGM | iShares Expanded Tech Sector ETF | Equity | $2,779,280 | -38.0% | 70,274.0 | $271.65 | -1.78% | -7.8% | -15.2% | -32.9% | 26.8% | 74.9% | Technology Equities | 2001-03-13 | 0. 40% 40% | N/A | $0.71 | 2021-09-24 | $0.18 | 0.16% | 43.2 | 1.08 | 329 | 51.2% | View | 40% | 20% | 1099 | $270.86 | $307.26 | $268.99 | $275.21 | 35.34 | View | View | View | View | View | View | B+ | A- | |||||||||||

| IXN | iShares Global Tech ETF | Equity | $2,747,890 | -35. 0% 0% | 308,009.0 | $41.68 | -1.63% | -7.6% | -14.5% | -26.2% | 37.8% | 79.4% | Technology Equities | 2001-11-12 | 0.40% | N/A | $1.13 | 2021-06-10 | $0.20 | 1.82% | 38.5 | 1.03 | 132 | 58.3% | View | 40% | 20% | 1099 | $41. 63 63 | $47.21 | $41.27 | $42.23 | 34.35 | View | View | View | View | View | View | A | A- | |||||||||||

| Click Here to Join to ETF Database Pro for 14 Days Free, Export This Data & So Much More | ||||||||||||||||||||||||||||||||||||||||||||||||||||

Content continues below advertisement

NewLoading Articles...

3D Printing ETF: Long-Term Bet On A Megatrend (BATS:PRNT)

- ETF Analysis

- Tech

Oct. 29, 2021 9:38 PM ET3D Printing ETF (PRNT)DM, DDD, CLLKF, CFMS, SLGRF14 Comments

Main Street Investor

3. 9K Followers

9K Followers

Summary

- ARK's printing ETF offers exposure to the 3D printing industry while diversifying individual risk to investors.

- The ETF successfully rotates along the most promising companies engaging in the 3D printing industry.

- While the ETF is trading below all-time highs reached earlier this year, the ETF still outperformed the broader market.

- Looking for more investing ideas like this one? Get them exclusively at Blue Ocean Investing. Learn More »

izusek/E+ via Getty Images

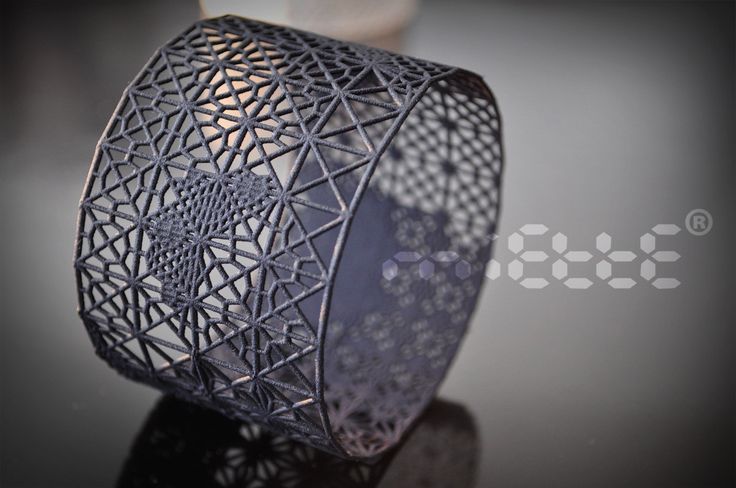

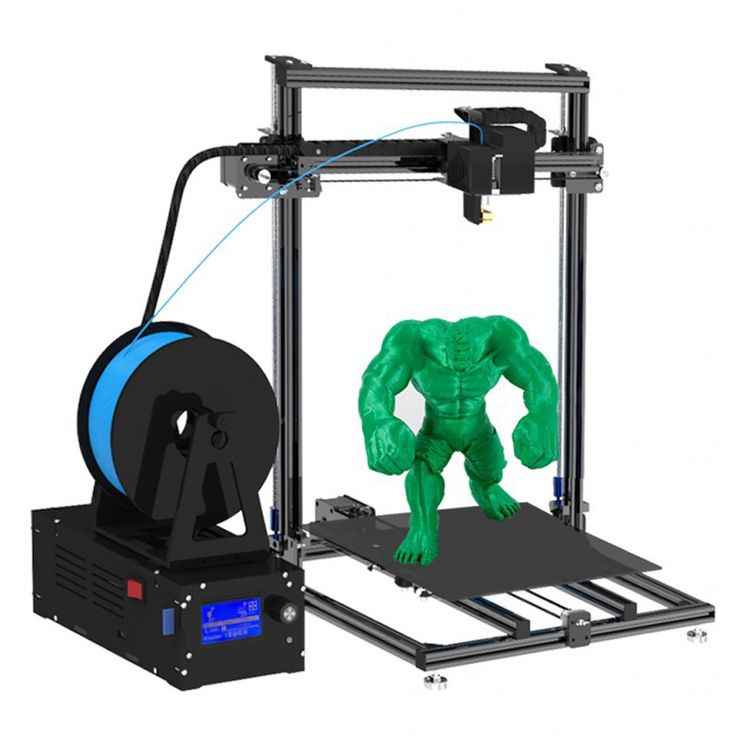

Overview

3D Printing ETF (BATS:PRNT) offers an attractive investment opportunity to capitalize on the massive growth of 3D printing in the future. The technology, which has been characterized as a 'hobby' for long, is used increasingly for commercial use and is underestimated in terms of applications. In this regard, 3D printing is being adopted in nearly every significant industry, ranging from the private sector to health, manufacturing, education and more. The market for 3D solutions is growing quickly, therefore the ETF offers a chance to capture growth while diversifying individual risk.

In this regard, 3D printing is being adopted in nearly every significant industry, ranging from the private sector to health, manufacturing, education and more. The market for 3D solutions is growing quickly, therefore the ETF offers a chance to capture growth while diversifying individual risk.

Source: ETF.com

The ETF focuses specifically on 3D printing, including physical printers, hardware, software, printing centers, and materials. Within each category, the selected securities are given equal weight. The top 10 holdings of PRNT ETF account for 50%, while it includes 52 holdings in total. Roughly 66% of the holdings are American companies, while the remaining are well diversified across Europe.

The ETF is rebalanced quarterly and has an average expense ratio of 0.66%, representing the cost of an initial investment. That said, Cathie Woods' ARK fund has gained significant traction at the end of 2020, as innovation technologies surged. However, after trading sideways for some time, the question remains as to whether the ETF can break out once more.

Holdings

Source: Ark Funds

ExOne Co. (NASDAQ:XONE): Being the largest holding of the ETF, the firm develops, manufactures, and markets three-dimensional (3D) printing machines, 3D printed and other products, materials, and services to industrial customers in the United States, Germany, and Japan. It directly sells 3D printing machines as well as indirect applications, including components and tools for 3D printing. Although shares are still down roughly 65% from all-time highs, the stock is trading 120% higher year-over-year.

3D Systems Corp. (NYSE:DDD): Headquartered in the U.S., the company offers 3D printers, such as stereolithography, selective laser sintering, direct metal printing, multi-jet printing, and color jet printers that transform digital data input generated by 3D design software, computer-aided design software, or other 3D design tools into printed parts. The stock has surged over 372% YoY as sales jumped 44% last quarter.

BICO Group (OTCPK:CLLKF): The Swedish bio convergence startup designs and supplies technologies and services to enhance biology research by commercializing bioprinting through artificial intelligence, robotics, multi-omics, and diagnostics. The company is in an ultra growth stage, as sales surged nearly 500% last quarter to $38 million. As a result, Stockholm-listed shares are up 147% YoY.

Conformis Inc. (NASDAQ:CFMS): The medical company develops and manufactures joint replacement implants through the use of 3D printing technologies. It markets and sells its products to orthopedic surgeons, hospitals, and other medical facilities in the United States, Argentina, Europe, the Middle East, and Australia. Trading at just $1.2, Conformis shares have been surging 72% over the last year.

SLM Solutions (OTC:SLGRF): The German-based company engages in the development, production, marketing, and sale of machines and peripheral equipment for selective laser melting. These machines operate based on 3D technology and serve the aerospace, mechanical engineering, tool construction, and automotive industries. The stock is up roughly 100% year-over-year.

These machines operate based on 3D technology and serve the aerospace, mechanical engineering, tool construction, and automotive industries. The stock is up roughly 100% year-over-year.

Data by YCharts

As briefly mentioned earlier, the ETF jumped sharply in early 2021, as the underlying stocks benefited from a momentum-driven rally in the technology market. However, after giving up some gains, the ETF has mostly traded sideways, which can be tied back to an overall rotation from growth to value stocks, after rising inflation and the reopening of the economy have made investors more cautious of technology solutions. Still, the ETF has returned 50% to investors, outperforming the broader technology market, which has gained only 35%. It has also outperformed its 'parent ETF' ARK Innovation ETF, which bundles future technologies including Genomics, Internet, Artificial Intelligence, and 3D Printing.

Defiance Quantum ETF (QTUM) has slightly outperformed the ETF, although the ETF rather concentrates on machine learning such as quantum computers and semiconductors. This is also reflected in its holdings including Analog Devices, AMD, and Ambarella. As a result of the semiconductor shortage, the ETF performed slightly better.

This is also reflected in its holdings including Analog Devices, AMD, and Ambarella. As a result of the semiconductor shortage, the ETF performed slightly better.

Attractive Valuation-Even Now

Data by YCharts

Despite the massive rally in 3D stocks, valuations remain attractive concerning the growth potential. In this regard, most 3D printing stocks in PRNT trade below 10x EV to Sales, indicating general undervaluation, IMO. HP Inc. (NYSE:HPQ) especially catches my attention, yet it should be noted that the market cap stands at $35 billion; thus, it may not be as volatile to the upside as other stocks such as Conformis, which is worth around only $220 million.

On the other hand, Bico Group and Straumann Holdings appear more pricey at 42 times Price to Sales and 17 times Price to Sales, although it should be noted that they also hold strong growth rates. Thus, from a valuation standpoint, PRNT remains attractive, although higher valuations than in past years could lead to short to mid-term weakness in the ETF's performance.

Moreover, if we compare these valuations to the main ARKK Innovation ETF, the individual holdings appear reasonably priced when accounting for growth rates and future growth aspects. While almost no securities trade above 20 times sales, the opposite can be said about ARRK's holdings, although margins and growth rates in the fund tend to be higher.

Risks

Despite the enormous opportunity of investing in a quickly-growing industry through a diversified portfolio, various risks should be considered. The commercial 3D printing industry is still relatively new and thus nowhere near saturation. It is still unclear which companies will win the race of 3D printing in the future and many new startups should arise in the next few decades.

Therefore, it is not guaranteed that PRNT ETF will include all these winners and miss out. Also, the ETF performed well in 2020 due to a broad rally in the stock market, and more specifically in Tech stocks. However, when a bear market occurs, the ETF will likely fall proportionally more, as its underlying volatility is higher.

Takeaways

3D Printing ETF is an attractive bundled fund, which deserves more attention from growth-focused investors. The 3D printing industry has more useful applications than most would imagine. The ETF offers exposure to an ultra-growing multibillion-dollar industry, including the most promising companies in the space. Unsurprisingly, investors have been rewarded mightily, as the ETF outperformed the broader market and competing ETFs. Even after an impressive surge of 3D printing stocks, valuations remain attractive, considering the industry's massive potential.

On the other hand, investors have a reason to stay cautious: While the ETF benefitted from a pandemic-induced rally among tech stocks, a higher return converts into higher risk. Thus, if the current bull market fades (or turns into a bear market), performance will reverse quickly. Either way, 3D Printing ETF remains an attractive investment opportunity and is among the only diversified ETFs concentrating solely on 3D printing.

Blue Ocean Investing focuses on finding the next big disruptors that can multiply many times over the long run. We consistently screen and research the most innovative businesses that enjoy gigantic competitive advantages and may be discounted by the market. With a membership you will gain access to:

- Portfolio and Watchlist

- Deep-dive investment research

- 24/7 Live-Chat

- Upcoming IPOs

- An interactive investment community

Get your free 14-day trial now!

This article was written by

Main Street Investor

3.9K Followers

I am a 22 year old investor with a Bachelors degree in Finance and Business. My investing strategy is focused on finding the best opportunities from every sector: value or growth - there is value in everything. For all my investment decisions I undertake extensive research, collecting relevant data, charts and graphs for the given company. The three most crucial ratios for my analysis are margins, CAGR revenue growth and marketing spend as a % of revenue. These measures are all based on 2024 estimates in order to evaluate the given moat of a company/stock. Therefore, all my investments are long-term, with the exception of large fluctuations in the fundamentals of an investment or drastic valuation changes. I hope that I am able to share some of my investment opinions with you and look forward to learning more in the process! Best regards

The three most crucial ratios for my analysis are margins, CAGR revenue growth and marketing spend as a % of revenue. These measures are all based on 2024 estimates in order to evaluate the given moat of a company/stock. Therefore, all my investments are long-term, with the exception of large fluctuations in the fundamentals of an investment or drastic valuation changes. I hope that I am able to share some of my investment opinions with you and look forward to learning more in the process! Best regards

Disclosure: I/we have no stock, option or similar derivative position in any of the companies mentioned, and no plans to initiate any such positions within the next 72 hours. I wrote this article myself, and it expresses my own opinions. I am not receiving compensation for it (other than from Seeking Alpha). I have no business relationship with any company whose stock is mentioned in this article.

Comments (14)Recommended For You

To ensure this doesn’t happen in the future, please enable Javascript and cookies in your browser.

Is this happening to you frequently? Please report it on our feedback forum.

If you have an ad-blocker enabled you may be blocked from proceeding. Please disable your ad-blocker and refresh.

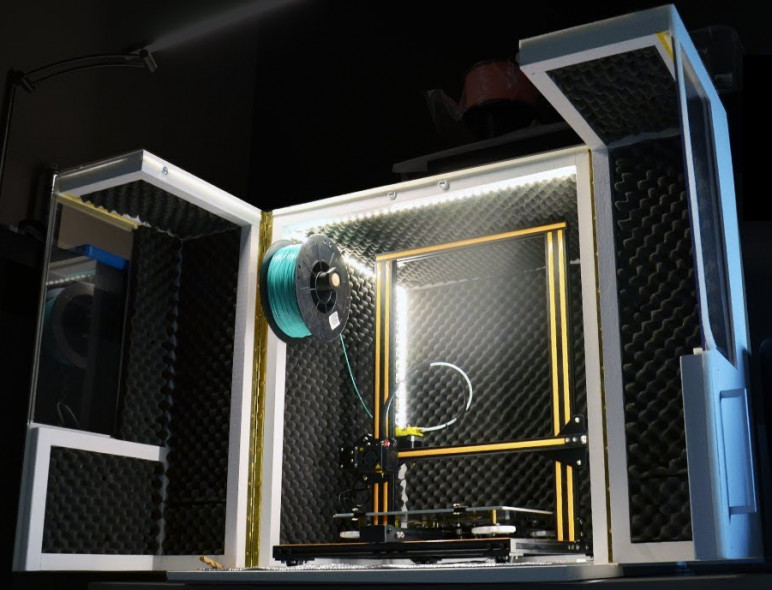

Overview of current 3D printers for production, printing with refractory materials (PEEK, PEKK, PAEK, Ultem, etc.)

The article applies to printers:

Zortrax Endureal TotalZ Anyform 1200-PRO/PRO(2X) TotalZ Anyform 950-PRO/PRO(2X)

Today we will get acquainted with the real industrial giants - 3D printers that are used in various industries. Their main feature is the high heating temperature of the extruder, which allows printing with refractory materials. The review presents equipment from Russian manufacturers, Chinese industrial 3D printers, as well as European and American brands.

Contents:

- Equipment of Russian manufacturers

- Chest SM-A284

- F2 Pro

- Total Z AnyForm PRO Series (HOT+)

- Equipment of foreign manufacturers (China)

- CreatBot F1000

- CreatBot PEEK 300

- IEMAI MAGIC-HT-MAX

- IEMAI MAGIC-HT-PRO

- Intamsys Funmat PRO 410

- Intamsys Funmat PRO 610 HT

- Equipment manufacturers from Europe and America

- Stratasys Fortus 450mc

- Stratasys F900

- 3DGence Industry F421

- 3DGence Industry F350

- 3DGence Industry F340

- Zortrax Endureal

- Which 3D printers print with thermoplastics?

- Why are refractory materials so good?

Russian equipment

Domestic manufacturers do not remain in the shadows, and develop really cool equipment that perfectly copes with printing with refractory materials.

► Casket SM-A284

Industrial FDM printer Casket SM-A284 is a development of KBSM JSC, which was intended to solve the company's own problems. This robust, reliable and stable additive plant can operate in any environment.

Spacious print chamber with build area of 300x300x300 mm and heated bed allows you to achieve high-quality results. The unit is compatible with most refractory and general purpose materials. The company continues to introduce new technologies and materials that will be available to users after trials and tests.

Casket SM-A284 has 2 high-temperature extruders (with heating up to 500⁰С). Their lightweight design ensures stability when working at high speeds.

For comfortable work, the box is equipped with a powerful ventilation system and a built-in Wi-Fi module.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer body: Closed

- Thread diameter: 1.

75 mm

75 mm - Extruder type: Bowden

- Number of print nozzles: 2 pcs.

- Independent extruders: Yes

- Number of independent extruders: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 180°C

- Print chamber temperature: 130°C

- Print area: 300x300x300 mm

- Calibration: Automatic

- Print/grow speed: 120 mm/s

- Layer thickness: 0.05 mm

- XY-axis accuracy: 0.05 mm

- Number of colors: 2 colors

- Video camera: Yes

- Supported materials: PLA, ABS, PETG, HIPS, TPU, PA, PC, PPSU, PA/CF, ASA, ESD-Safe, ULTEM, PEEK

► F2 Pro

An industrial printer with endless possibilities. FDM equipment works on the unique F2 technology, which allows you to heat the extruder to operating temperature in just 3 seconds. High accuracy of temperature maintenance (up to 0.3⁰С) allows to achieve unsurpassed quality.

F2 Pro has a large print area of 1000x600x1000 mm, which allows you to set up mass production or production of large-sized parts. The F2 Pro has everything you need in industrial printing: a heated chamber with forced air convection, quick-change extruders with a nozzle setting from 0.15 to 1 mm, and an automatic calibration platform.

The 3D printer is equipped with electronics developed by the company, but nevertheless, the operation of the printer remains intuitive.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of print nozzles: 2 pcs.

- Independent extruders: Yes

- Number of independent extruders: 2 pcs.

- Extruder temperature: 550 °C

- Table temperature: 140 - 160 °C

- Print chamber temperature: 80 - 160 °C

- Print area: 1000x600x1000 mm

- Calibration: Automatic

- Print/grow speed: 150 mm/s

- Layer thickness: 50 - 500 µm

- XY accuracy: 5 µm

- Z-axis accuracy: 2 µm

- Number of colors: 2 colors

- Nozzle: 0.

4 - 1 mm

4 - 1 mm - Supported materials: PETG, ABS, PEKK, SBS, PEI, PEEK-CF, PC, Nylon, PA and derivatives, Flex, TPE, TPU, etc., ABS-PC, PEEK, WAX3D, Ultem, PLA, HIPS, ASA, PP

► Total Z AnyForm series PRO (HOT+)

We decided to present this series of industrial 3D printers with 3 models: 1200 PRO(HOT+), 950 PRO (HOT+) and 650 PRO (HOT+), which differ only in the construction area . Total Z AnyForm PRO has several configurations, including those with a high-temperature heating module for the HOT + extruder. The HOT+ series printers have 2 independent extruders with a maximum heating temperature of up to 500⁰С, which allows you to work with materials such as ULTEM, PEEK, PPSU, PSU, PEI, as well as with the original material of TOTAL-PEEK's own production.

AnyForm 1200 PRO (HOT+) with a construction area of 1200x650x1200 mm is one of the largest FDM devices on the market. The 3D printer can easily cope with printing large-sized products or mass production.

AnyForm 950 PRO (HOT+) with a construction area of 950x650x950 mm and 650 PRO (HOT+) with 650x500x650 mm have all the advantages of the older model. They can print multiple materials at the same time, which can be fed automatically, up to 4 spools of 2.5 kg without operator intervention.

AnyForm PRO (HOT+) 3D printers are complete workstations equipped with a computer. Mobile units are easily integrated into production.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 1 pc. (option 2 pcs.)

- Extruder temperature: 500°C

- Table temperature: 200°C

- Print chamber temperature: 300°C

- Print area: 650x1200x1200 mm

- Layer thickness: 50 µm

- Full color printing: No

- Heated table: Yes

- High Temperature Printing: Yes

- Video camera: Yes

You can find the full catalog of Total Z equipment on our website.

Equipment of foreign manufacturers (China)

China's 3D equipment industry has long since stepped forward. The largest manufacturers create equipment for various industries - from medicine to heavy and defense industries. Industrial high-temperature 3D printers from Chinese companies are easily introduced into production of any scale.

► CreatBot F1000

Manufacturer's top model with the largest build area. The printable area of 1000x1000x1000 mm allows you to implement almost any project. Versatile equipment has a wide range of features for comfortable printing, as well as a camera to monitor progress and built-in Wi-Fi module. Heated oven and heated table with auto leveling function for high quality prints.

The maximum extruder temperature of 420°C allows the CreatBot F1000 to print on a variety of materials, including engineering and high-temperature plastics - Carbon Fiber, Nylon, PC and others.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 420°C

- Table temperature: 100°C

- Print chamber temperature: 60°C

- Print area: 1000x1000x1000 mm

- Calibration: Automatic

- Print/grow speed: 120 mm/s

- Layer thickness: 50 µm

- XY-axis accuracy: 0.011 mm

- Z-axis accuracy: 0.0025 mm

- Heated table: Yes

- High Temperature Printing: Yes

- Video camera: Yes

- Plastic detection: Yes

- Resume system: Yes

- Supported materials: PLA, ABS, PETG, HIPS, PVA, Carbon Fiber, Nylon, PC, TPU, PEEK, ULTEM

► CreatBot PEEK 300

A professional, high performance 3D printer built for the toughest jobs. Thanks to the extruder with a heating temperature of up to 500°C, it can work with most refractory materials. The heated chamber and working platform allow you to get the highest quality result, without delamination and deformation.

Thanks to the extruder with a heating temperature of up to 500°C, it can work with most refractory materials. The heated chamber and working platform allow you to get the highest quality result, without delamination and deformation.

The CreatBot PEEK 300 has a build area of 300x300x400mm which is ideal for making small items, mass production of small objects or printing for science and research applications.

The industrial unit is equipped with all the successful CreatBot solutions - a built-in filtering system, a convenient color touchscreen for control, high-quality cooling and others.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 200°C

- Print chamber temperature: 120°C

- Print area: 300x300x400 mm

- Print/grow speed: 150 mm/s

- Layer thickness: 40 µm

- Heated table: Yes

- High Temperature Printing: Yes

► IEMAI MAGIC-HT-MAX

The IEMAI MAGIC-HT-MAX 3D printer is designed specifically for tough environments and can handle any task. This 3D printer has everything you need for high-quality thermoplastic printing - a high temperature extruder, a heated chamber and print platform, as well as a built-in progress camera.

This 3D printer has everything you need for high-quality thermoplastic printing - a high temperature extruder, a heated chamber and print platform, as well as a built-in progress camera.

IEMAI MAGIC-HT-MAX can handle a wide range of materials. A special box for loading, storing and drying plastic before printing allows you to achieve impressive results.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 180°C

- Print chamber temperature: 150°C

- Printing area: 500x500x700 mm

- Print / grow speed: up to 150 mm/s

- Layer thickness: 0.

05 – 0.3 mm

05 – 0.3 mm - XY Accuracy: 2.5 µm

- Z-axis accuracy: 0.78 µm

- Number of colors: 2 colors

- High Temperature Printing: Yes

- Video camera: Yes

- Nozzle: 0.4 - 1 mm

- Supported materials: PEEK, CF-PEEK, PEKK, CF-PEKK, PEI 1010/9085, PPSU, PC, CF-PC, PA, CF-PA, GF-PA, ASA, ABS, CF-ABS, PETG HIPS , TPU, PLA, CF-PLA, PVA

► IEMAI MAGIC-HT-PRO

The IEMAI MAGIC-HT-PRO professional high temperature 3D printer can be placed on the table or on the floor. This fairly compact printer can be used for high-quality functional prototypes and small-scale production.

Robust metal housing and carbon filtration system make it possible to work even in small production areas. The 3D printer has impressive precision and high performance.

The printer comes with a cabinet-stand, which also serves as a compartment for storing material.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer body: Closed

- Thread diameter: 1.

75 mm

75 mm - Number of print nozzles: 2 pcs.

- Independent extruders: No

- Extruder temperature: 500°C

- Table temperature: 170°C

- Print chamber temperature: 120°C

- Printing area: 310x310x410 mm

- Print/grow speed: up to 150 mm/s

- Layer thickness: 0.05 – 0.3 mm

- XY Accuracy: 12.5 µm

- Z-axis accuracy: 1.25 µm

- Number of colors: 2 colors

- High temperature printing: Yes

- Video camera: Optional

- Nozzle: 0.4 - 1 mm

- Supported materials: PEEK, CF-PEEK, PEKK, CF-PEKK, PEI 1010/9085, PPSU, PC, CF-PC, PA, CF-PA, GF-PA, ASA, ABS, CF-ABS, PETG HIPS , TPU, PLA, CF-PLA, PVA

► Intamsys Funmat PRO 410

Intamsys Funmat PRO 410 professional high-temperature 3D printer is designed for use in various industries. A feature of the device is a closed-type build chamber, which maintains a stable temperature to improve adhesion between layers.

All-metal extruder has a heating temperature of 450°C, which allows you to work with most refractory materials. A nice bonus is the ability to work with two materials at the same time, for example, for printing with soluble supports.

For convenient data exchange, the manufacturer has equipped the Funmat PRO 410 with a built-in Wi-Fi module.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Independent extruders: No

- Extruder temperature: 450°C

- Table temperature: 160°C

- Print chamber temperature: 90°C

- Printable area: 305x305x406 mm

- Calibration: Automatic

- Print / grow speed: 30 - 300 mm/s

- Layer thickness: 50 µm

- XY-axis accuracy: 0.

016 mm

016 mm - Z-axis accuracy: 0.0016 mm

- High Temperature Printing: Yes

- Video camera: Yes

- Nozzle: 0.4 mm (0.25, 0.5, 0.6, 0.8, 1.2 mm)

- Supported materials: ABS, ABS-ESD, FLEX, HIPS, NYLON 12, NYLON 12 CF, NYLON 6, NYLON 6 CF, PC, PC-ABS, PEEK, PEEK CF, PET-G, PLA, PVA, Tough PLA , TPE, Wood-filled, Carbon-filled

► Intamsys Funmat PRO 610 HT

Intamsys Funmat PRO 610 HT is the top model in the line. The 3D printer easily solves the most complex problems of production and prototyping. The manufacturer equipped the Intamsys Funmat PRO 610 HT with an all-metal extruder with a heating temperature of 500°C, which can work with any thermoplastics, including ULTEM and PEEK.

Intamsys offers not only high-quality and reliable equipment, but also materials for printing on its 3D printers. For example, soluble support materials for PLA and engineering plastics.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Extruder temperature: 500°C

- Table temperature: 300°C

- Print chamber temperature: 300°C

- Print area: 610x508x508 mm

- Calibration: Automatic

- Print / grow speed: 30 - 300 mm/s

- Layer thickness: 50 µm

- XY-axis accuracy: 0.016 mm

- Z-axis accuracy: 0.0016 mm

- High Temperature Printing: Yes

- Video camera: Yes

- Nozzle: 0.4 mm

- Supported materials: PEEK, PEKK, PEI, PPSU, PC, Nylon, ABS, PLA, PVA, TPU, Carbonfiber Reinforcement

European and American equipment

Equipment made in the USA and Europe relies on high precision and full automation of the 3D printing process. All equipment presented in this section are high-tech devices that demonstrate maximum accuracy and repeatability of the result.

All equipment presented in this section are high-tech devices that demonstrate maximum accuracy and repeatability of the result.

► Stratasys Fortus 450mc

This additive machine, despite its rather compact size, has high accuracy and productivity. The construction chamber 406x355x406 mm allows you to start mass production, create prototypes and final parts.

The equipment works according to proven algorithms and has a built-in data protection function. Stratasys printers can be used for the defense and space industries. They are compatible with all thermoplastics and show consistently good results.

The Stratasys Fortus 450mc comes preloaded with software.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Independent extruders: Yes

- Number of independent extruders: 2 pcs.

- Print area: 406x355x406 mm

- Calibration: Automatic

- Layer thickness: 12.7 - 33 µm

- XY-axis accuracy: 0.127 mm

- Heated table: Yes

- High Temperature Printing: Yes

- Supported materials: ULTEM, Nylon 12 CF, PEI, PEKK

► Stratasys F900

The Stratasys F900 3D printer sets the standard for quality and precision in 3D printing. The large build area is perfect for printing large parts or mass-producing small parts. The printer can cover any production needs in the creation and development of products.

Integrated software allows you not to waste time converting data to the desired format, but print directly from CAD. This significantly reduces the time from development to launch into production.

Data-protected device can be used in defense, space, automotive and other industries.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Number of print nozzles: 2 pcs.

- Number of independent extruders: 2 pcs.

- Print area: 914x609x914 mm

- Calibration: Automatic

- Layer thickness: 12.7 - 50.8 µm

- XY-axis accuracy: 0.089 mm

- Heated table: Yes

- High Temperature Printing: Yes

- Supported materials: ABS, PC, ULTEM, Nylon 6 and Nylon 12

► 3DGence Industry F421

Polish brand 3DGence Industry F421 high-speed, reliable and productive 3D printer has excellent kinematics. Special algorithms monitor the operation of stepper motors and correct it if something goes wrong. This allows you to achieve the most accurate results even in unstable conditions on the production floor.

3DGence Industry F421 has a modular system to meet different needs. Interchangeable extruders with heating temperatures from 280°C to 500°C allow you to print on a variety of materials, including high temperature ULTEM and PEEK. A convenient system for reading information about the material allows you to automatically determine the type of plastic and its weight.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of independent extruders: 2 pcs.

- Extruder temperature: 280 - 500°C

- Table temperature: 180°C

- Print chamber temperature: 180°C

- Print area: 380x380x420 mm

- Calibration: Automatic

- Print / grow speed: up to 400 mm/s

- Layer thickness: 50 - 300 µm

- XY accuracy: 6 µm

- Z-axis accuracy: 7 µm

- Number of colors: 2 colors

- Video camera: Yes

- Nozzle: 0.

5/0.5 mm or 0.4/0.4 mm

5/0.5 mm or 0.4/0.4 mm - Supported materials: PLA, ABS, ASA, PA6/69, PC, ULTEM™ filament, PEEK

► 3DGence Industry F350

The 3D printer with the 3DGence Industry F350 Modular System can print a variety of plastics. Interchangeable extruders with different heating temperatures allow you to adapt this 3D printer to any task.

The system can print with different materials and, like the previous one, is equipped with a material recognition function. The smart assistant not only determines the weight and type of plastic, but tells you when you need to load an additional spool.

The manufacturer offers a cloud service for managing a 3D printer, which makes work as comfortable as possible.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic filament

- Printer housing: Closed

- Thread diameter: 1.

75 mm

75 mm - Extruder type: Direct

- Number of print nozzles: 2 pcs.

- Extruder temperature: 280 - 500°C

- Table temperature: 180°C

- Print chamber temperature: 130°C

- Print area: 340x340x350 mm

- Calibration: Automatic

- Layer thickness: 40 - 300 µm

- XY accuracy: 6 µm

- Z-axis accuracy: 0.7 µm

- High Temperature Printing: Yes

- Nozzle: 0.5/0.5 mm or 0.4/0.4 mm

- Supported media: PLA, ABS, ASA, PA6/69, PC, PEEK

► 3DGence Industry F340

The 3DGence Industry F340 Professional FDM Printer is a user-friendly additive machine with smart features and convenient controls. The manufacturer has equipped this model with all the latest developments that make 3D plastic printing of high quality.

Modular system with different extruders allows you to adapt to any production requirements. Printing with high temperature resins or standard plastics allows you to select and install a replacement module that is ideal for the task at hand.

Maintaining the required moisture content of the material and automatic supply of plastic make the work as comfortable as possible.

Specifications:

- Print technology: FDM / FFF

- Print material: Plastic thread

- Printer housing: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of print nozzles: 1 pc.

- Extruder temperature: 190 - 500°C

- Table temperature: 140 -160°C

- Print chamber temperature: 85°C

- Print area: 260x300x340 mm

- Calibration: Automatic

- Layer thickness: 40 µm

- High Temperature Printing: Yes

- Nozzle: 0.4 mm

- Supported materials: PLA, ABS, PET, Nylon, PP, ASA, PC, PC-ABS, PC-ESD, PEEK

► Zortrax Endureal

Another Polish manufacturer Zortrax introduces a new generation of industrial printers. High-tech equipment of this brand is chosen by many manufacturers from around the world. Zortrax produces not only 3D printers, but also its own line of materials for 3D printing, as well as software that makes working with additive technology as comfortable as possible.

High-tech equipment of this brand is chosen by many manufacturers from around the world. Zortrax produces not only 3D printers, but also its own line of materials for 3D printing, as well as software that makes working with additive technology as comfortable as possible.

Despite being easy to use, Zortrax 3D printers offer innovative solutions that take printing to the next level. The company's equipment is chosen by individual users and companies representing different industries.

TheEndureal from Zortrax is a third generation 3D printer that works effectively with a variety of plastics. To achieve the highest quality results while maintaining all the properties of the material, the manufacturer has equipped Endureal with perfect temperature control. Accurate tracking of parameters at each stage allows you to save all the properties of the material.

Filament storage in closed heated chamber, auto-annealing function after printing helps to achieve high mechanical properties of the material.

Zortrax Endureal uses LPD Plus (Layer Plastic Deposition Plus) technology. This technology is similar to FDM, but differs from it in that products are created with detachable soluble supports.

The equipment is supplied with a service and repair tool kit. This significantly reduces the cost and time for maintenance and minor troubleshooting, as well as reduces downtime.

Although Endureal is an industrial unit, it is easy to operate. Thanks to its user-friendly interface, Zortrax Endureal is easily integrated into any production.

Specifications:

- Print technology: LPD Plus

- Print material: Plastic thread

- Printer body: Closed

- Thread diameter: 1.75 mm

- Extruder type: Direct

- Number of independent extruders: 2 pcs.

- Extruder temperature: 480°C

- Table temperature: 220°C

- Print chamber temperature: 200°C

- Print area: 400x300x300 mm

- Guides: XY rails, Z shafts

- Calibration: Automatic

- Layer thickness: 450 µm

- Z-axis accuracy: 200 - 250 µm

- Video camera: Yes

- Nozzle: 0.4 mm

- Materials supported: Z-PEI 9085, Z-ULTRAT Plus (single extruder), Z-PEI 1010, Z-PEI 9085, Z-ULTRAT Plus, Z-SUPPORT High-Temp (tear-off), Z-SUPPORT ATP ( for two extruders)

Which 3D printers print with thermoplastics?

Since 3D printing with refractory materials is practically not used for everyday tasks, all thermoplastic printing equipment is professional or industrial. Manufacturers create different 3D printers - from compact desktop models to industrial plants and robotic systems that can handle any print volume.

The main difference between 3D printers for printing with refractory materials from other devices is the high extrusion temperature, which is usually 400⁰С and higher. Also, equipment for working with high-temperature plastics has design features:

Also, equipment for working with high-temperature plastics has design features:

- Closed heated print chamber. Provides good adhesion between layers, allows you to evenly cool the part after printing.

- Heated work table. Helps improve first coat adhesion and print stability.

- Compartments for storing or drying plastics. There are without heating (in more budget models) and with heating. They allow you to prepare plastic for printing and keep it dry, which is especially important for hygroscopic materials.

- Air cleaning system. Powerful built-in filters reduce the amount of harmful fumes during the printing process.

Why are refractory materials so good?

When it comes to professional printing or industrial applications, special attention is paid to the quality of the material and its properties. Standard plastics such as ABS, as well as engineering polymers (Nylon, PA, PP, carbon fiber materials) perform well in the manufacture of functional prototypes, small products and even final parts in various industries. But some industries have a need for better and more reliable materials that have exceptional characteristics.

But some industries have a need for better and more reliable materials that have exceptional characteristics.

Refractory materials, and more precisely products made from them, can be used in the most severe conditions. High wear resistance, chemical and temperature resistance make it possible to successfully replace metal products, parts made of alloys and ceramics. Some experts believe that plastics based on PEI, PAEK and PSU will partially replace metal production in the near future.

High temperature plastics can be used in the manufacture of components for the aerospace, defense, automotive and mechanical industries. Due to the special properties of products made of refractory materials, they can be used in research and scientific activities.

Thank you all, the material was prepared by a team of LIDER-3D specialists, we will be glad to hear your questions in the comments.

If you are interested in equipment made of this material, please contact us at LIDER-3D to get detailed expert advice, as well as purchase this equipment on our website.

Follow us on social networks: VKontakte, Telegram, Instagram, YouTube, Ya.Zen, Twitter, Facebook to be the first to receive the most interesting materials!

3D technologies in shipbuilding

Shipbuilding

Implementation stories

Author: Semen Popadyuk

Author: Semyon Popadyuk

Shipbuilding is one of the many industries where 3D printing technology is being used more and more: we have already seen solutions ranging from a certified 3D printed propeller to high-tech and intellectual property regulation in maritime shipping. The Spanish state company Navantia is a leading technology company specializing in the design and manufacture of high-tech civil and military ships, control and combat systems, as well as diesel engines and turbines.

The company is committed to using innovation to improve performance in what is known as the fourth industrial revolution. This collective concept refers to the digital revolution, which is taking place through the development of automation, information exchange and manufacturing technologies, including 3D printing. According to Forbes magazine, "there is a blurring of the boundaries between the real world and the world of technology."

According to Forbes magazine, "there is a blurring of the boundaries between the real world and the world of technology."

In order to reduce production costs and increase productivity in accordance with the concept of Industry 4.0, Navantia has implemented the Shipyard 4.0 model (Shipyard 4.0), which involves the use and optimization of these technologies in shipbuilding. The model was applied at the company's shipyard in the Spanish city of Ferrol during the construction of the new generation F110 frigates by order of the Spanish Navy. Shipyard 4.0 will also be implemented by Navantia Australia after being adapted to the specific conditions of the Australian continent.

According to Pablo López, director of the Ferrol shipyard, “Navantia's main goal is to develop sustainable development in the naval and strategic industries, on a global scale, through the development of competitive programs for shipbuilding. This task is served by the strategy we created called Shipyard 4. 0, which consists in introducing into our production processes the advanced technologies of the fourth industrial revolution, in which we are involved. The Shipyard 4.0 model has clear goals to reduce costs and time, improve the quality of our products and technologies to achieve a sustainable competitiveness for the company.”

0, which consists in introducing into our production processes the advanced technologies of the fourth industrial revolution, in which we are involved. The Shipyard 4.0 model has clear goals to reduce costs and time, improve the quality of our products and technologies to achieve a sustainable competitiveness for the company.”

The new model will improve the results of the Navantia Australia SEA 5000 program and the Continuous Build Program. Shipyard 4.0 will help develop competitive shipbuilding for the navy, create a new skilled workforce and create modern equipment - both for the shipyard and for the supplier network. Also, this concept will contribute to the development of a modern infrastructure of information and communication technologies to support the digital twin (ship zero) at the shipyard and on the ship. The concept of a digital twin will allow modeling and developing new products and processes on virtual workstations.

Navantia operates in a very competitive environment, using 12 key advanced technologies to implement its solutions, which are used in conjunction with shipbuilding technologies in the Shipbuilding 4. 0 model:

0 model:

- 3D printing,

- artificial intelligence,

- autonomous vehicles,

- big data sets and their analysis,

- cybersecurity,

- health, safety and environmental protection,

- new materials,

- robotic process automation,

- secure cloud services,

- ubiquitous communications and internet of things,

- virtual and augmented reality,

- virtual modeling (including simulation).

Objects printed on the Super Discovery 3D Printer for the 3DCABINS project:

- modular toilet, material: flame retardant ABS, dimensions: 2200 x 1700 x 1200 mm, weight: 250 kg

– ventilation grille, material: ABS with carbon fibre, dimensions: 59 x 89 x 4.5 cm, weight: 3500 g

Navantia's R&D+i project, supported by the INNANOMAT R&D team at the University of Cadiz, uses 3D printing technology. In January 2018, the company presented one of its projects for the transition to the Shipbuilding 4. 0 model.

0 model.

“Late last year, we got our first practical results with the completion of Navantia's first R&D project for additive manufacturing called 3DCABINS. It consisted of integrated 3D printing of a modular toilet and the installation of ventilation grilles on board, also grown on a 3D printer, ”explained Lopez.

The 3DCABINS project is an unqualified success, as it allowed the company to produce two prototype naval vessel toilets at a much lower cost, while reducing the weight of the products by almost 50%. Such a result would not have been possible without the use of 3D printing.

“This year we launched the second project of the R&D + i program called ADIBUQUE, with which we aim to unify the practice of using this technology on our ships,” says Lopez. Both projects involve large-format Discovery 3D Printer FDM machines from the Spanish manufacturer CNC Barcenas.

As part of this project, AM parts will be analyzed after installation on ships.