3D printer company near me

3D Printing | 3D Print Services

Find a 3D Printing Location

Print Functional Prototypes

You can use 3D printing for prototypes or one-of-a-kind items. Let The UPS Store® bring your ideas to life. We can even use your 3D CAD file.

Construct Manufacturing Jigs and Fixtures

We understand when you do your own manufacturing, jigs and fixtures are critical for insuring high-quality and efficiency during assembly and testing. Our 3D printer can create complex parts so you are not dependent on a CNC machine.

Create Custom Accessories

Want to design your own smartphone case or money clip? Most items that are smaller than a breadbox and can be made out of single color of plastic are perfect for 3D printing.

Build Architectural Models

You can work in just about any 3D architectural design program and then export to common 3D CAD file types. The finished product is ready to show off or you can sand and paint your building to give it just the right look.

3D Printing Services Expanded Across Nation

The UPS Store continues to expand 3D printing services nationwide to meet the growing demands of its small business customers. 3D printing now available at approximately 20 The UPS Store locations. Use the interactive map below to find a participating location near you, or check out the full list of all The UPS Store locations offering 3D printing services.

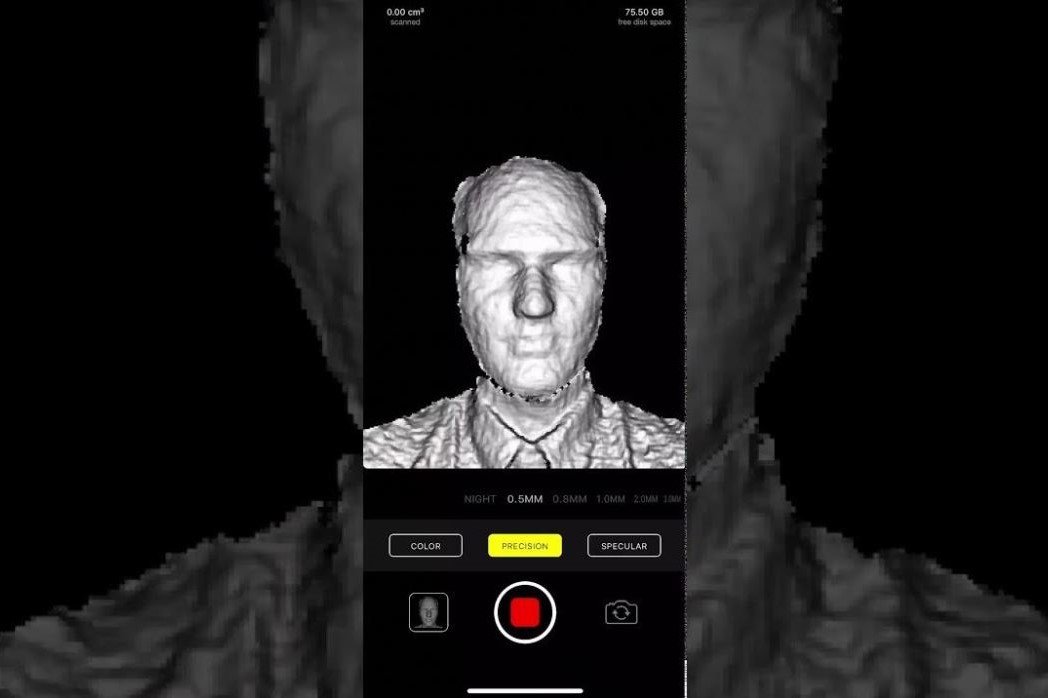

3D CAD and 3D Scanning Services

The UPS Store 3D print locations can now also offer you 3D CAD and 3D scanning services through HoneyPoint3D. Getting a custom 3D print has never been easier - you dream it, HoneyPoint3D designs it, The UPS Store prints it. Enjoy the HoneyPoint3D benefits of an easy quoting process, affordable and quality engineering, online viewing of your 3D files, and efficient turn-around times. Get your 3D CAD or scan quote today!

Netfabb® at The UPS Store®

Participating The UPS Store 3D print locations are utilizing Netfabb software for 3D print file preparation and customization. Services available at these locations include:

Services available at these locations include:

- File fixing

- Text labeling

- Logo labeling

- Cutting

Contact or visit these Netfabb locations to learn more about their advanced 3D offerings.

3D Printing Frequently Asked Questions

Here a few questions we frequently hear about 3D Printing.

Please feel free to contact your local The UPS Store for any other questions you may have

-

What is 3D printing?

-

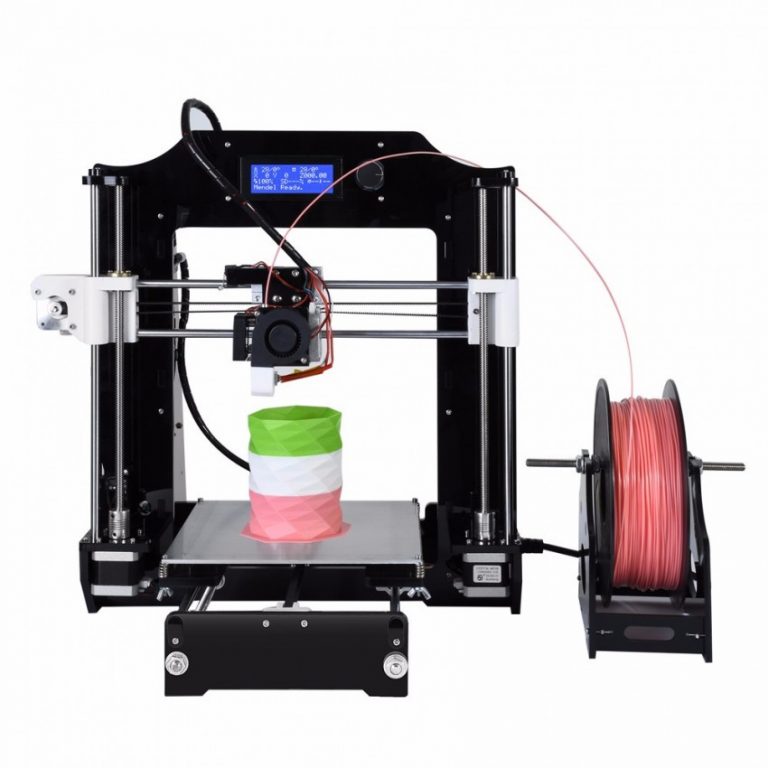

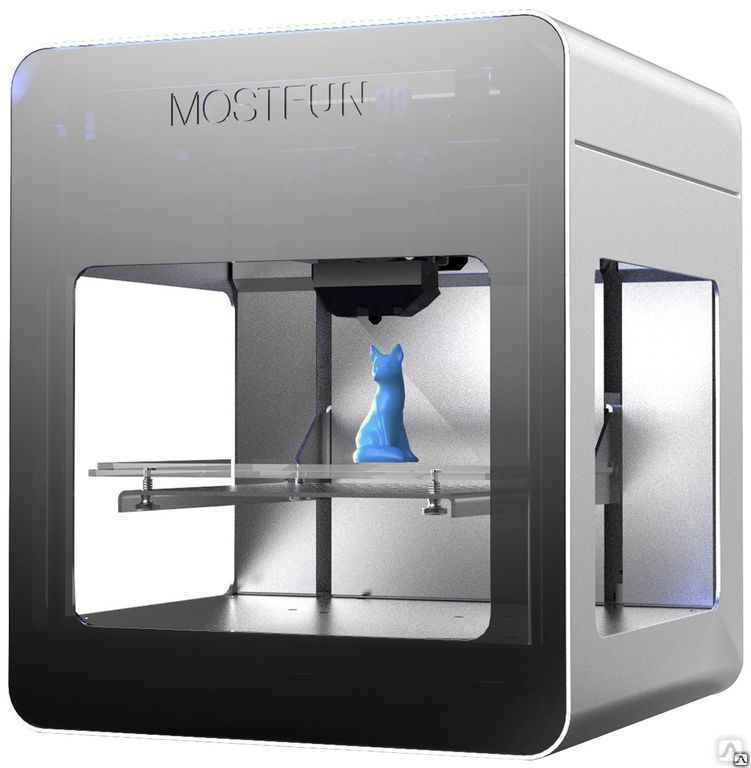

3D Printing is a manufacturing process that uses a digital file to create three-dimensional objects one layer at a time. We run a system that uses ABS plastic and soluble supports to create realistic prototypes and marketing models.

-

What kinds of things can I 3D print?

-

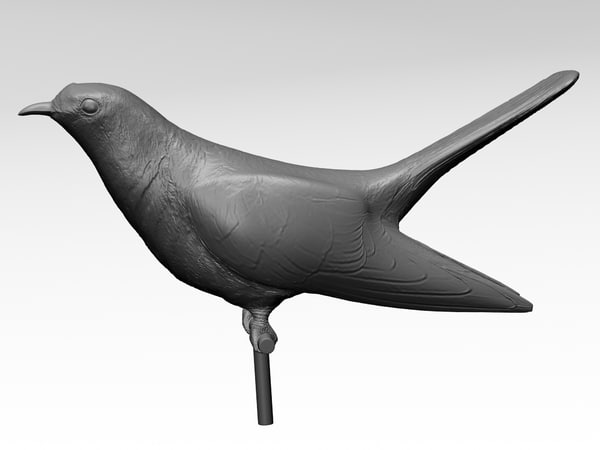

Small business owners and aspiring entrepreneurs will have the opportunity to print prototypes as part of the new product development process. With this printer, The UPS Store locations will be equipped to produce items like engineering parts, functional prototypes, acting props, architectural models, fixtures for cameras, lights and cables.

-

How long does it take to print?

-

The time it takes to print an object will depend on the complexity of the design. A simple object may take 4-5 hours, while a complex object may take 24 hours.

-

Which UPS Store locations are offering 3D printing?

-

The UPS Store is in the process of rolling out nearly 100 3D printing locations across the country. Visit /print/3d-printing/locations for more information.

3D Printing | There You Have It 3D

3D Printing | There You Have It 3D3d Printing Services

3d Printing Companies

3D Printing Services

3D Printing Companies

3D Printing Services Near Me

3D Printing Examples

Top 3D Printing Company

What's The Best 3D Printing Company?

How Much Do 3D Printing Services Cost?

Where Can I Find 3D Printing Companies Near Me?

What Is The 3D Printing Process?

What 3D Printer Companies Print Custom Designs?

3D Printer Services Near Me

3D Printing Services For Hobbyists

3D Printing Service Jewelry

Cheapest 3D Printing Service

Online 3D Printing Service

Best Online 3D Printing Services

3D Printed Services

Large 3D Printing Companies

3D Printing Service Local

3D Printing Services Prices

3D Printing Company Near Me

3D Printing Commercial

Where To Get 3D Printing Done

Looking for the Best-Rated 3D Printing Service in Los Angeles?

There You Have It 3D uses top-of-the-line 3D printing equipment to deliver high-quality results. From a cleared prop or mold master to a museum-quality art print or a functional physical prototype for your next design, we can do it.

Whatever your project requirement, we have the expertise to deliver a great product. Our engineers can handle CAD file design, rapid prototypes of products, or provide 3D scanning services of existing parts.

What is 3D Printing and How Does It Work?

3D printing, also referred to as additive manufacturing, works by printing successive layers of material (plastic or ceramic for example) until the final part is created. 3D printers can print shapes that cannot be formed with traditional methods.

While some firms are already using 3-D printers for prototyping and production parts in single quantities, others are just beginning to see the benefits of on-demand printing.

In traditional manufacturing, a part is designed, and then molds are created from that design for producing parts. The required number of parts are molded and assembled into a final product. At each step in the process, a significant amount of time and money can be lost if changes need to be made to the design.

At each step in the process, a significant amount of time and money can be lost if changes need to be made to the design.

As a result, most manufacturers have a standard set of molds that can be used for certain items, with extra time and money spent creating new molds as necessary. This process is referred to as 'tooling.' 3D printing, however, can significantly reduce or eliminate tooling costs because each part is printed only after it's ordered.

What are the Advantages of Using 3D Printing?

A great benefit of 3D printing is its low cost compared to traditional manufacturing methods. 3D printing can also reduce a company's carbon footprint by significantly reducing the number of parts that will be sent for production, then returned.

Additionally, 3D printing offers high-detail resolution and high-strength, making them great for functional prototypes and end-use parts in all industries, including aerospace and automotive engineering. If one part is defective, 3D printers allow manufacturers to simply print another one without the need for additional tooling. Additionally, changes can be made to 3D-printed parts without creating new molds.

Additionally, changes can be made to 3D-printed parts without creating new molds.

Since each part is created separately and only after it's ordered, 3D printing can precisely match orders to the required amount of finished parts. This 3D printing ability allows manufacturers to get closer to their ideal production levels while minimizing excess inventory.

3D printing provides rapid turnaround times and high-quality prints. In a nutshell, it's determined by the product specifications, materials used, and intricacy of the component in question. Turnaround time for most projects is determined by your project requirements.

What are the Benefits of Using 3D Printing?

3D printing has three main benefits that can help reduce tooling costs. First, 3D printers produce parts very quickly, so the time needed to create molds is reduced or eliminated. Second, because 3D printers work with digital models of objects, it's easy to make design changes without creating new molds. Finally, 3D printers can produce objects in small quantities at the same cost as producing one object.

Finally, 3D printers can produce objects in small quantities at the same cost as producing one object.

These benefits combine to make it possible to get a mold created by additive manufacturing for around 40 percent of the tooling cost, and the price continues to fall as more companies start using 3D printing. For example, when Ford started using 3D printing, it reduced the price of creating prototype molds from $300,000 to just $3,000.

3D Printing Methods

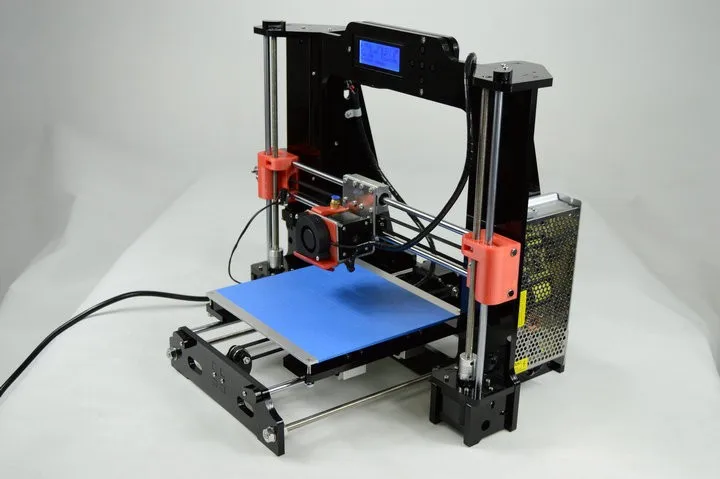

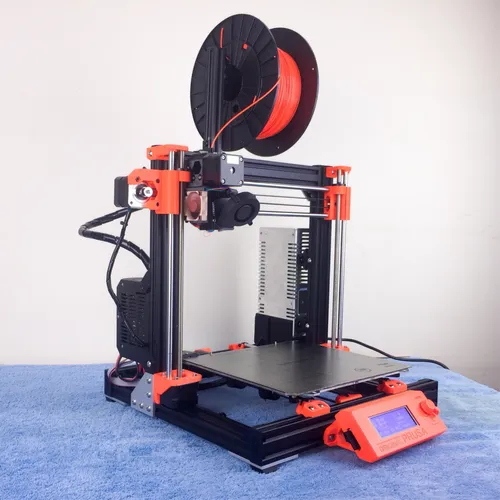

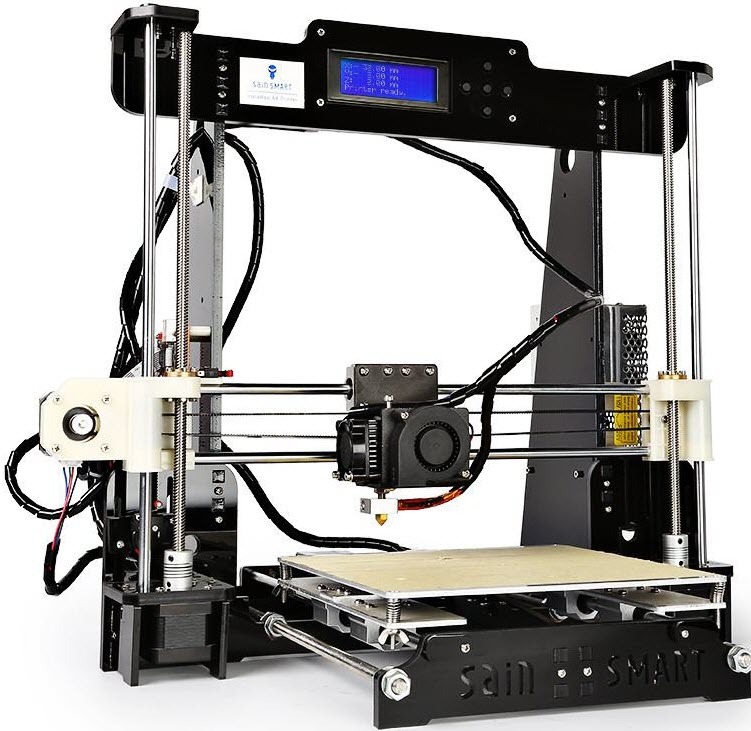

3D printing a part is typically an additive process, which means it adds material to arrive at the final product. There are three main types of 3D printers:

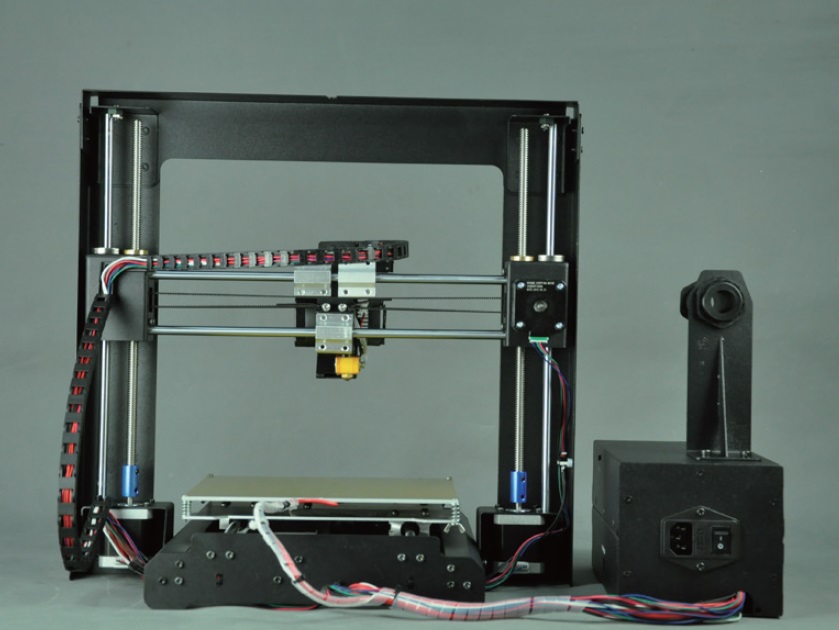

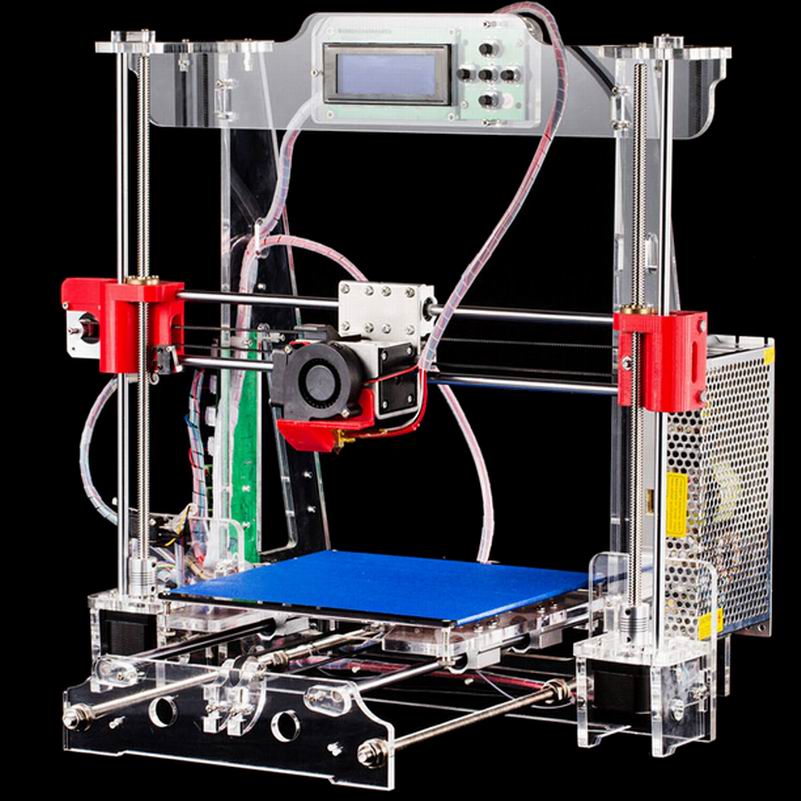

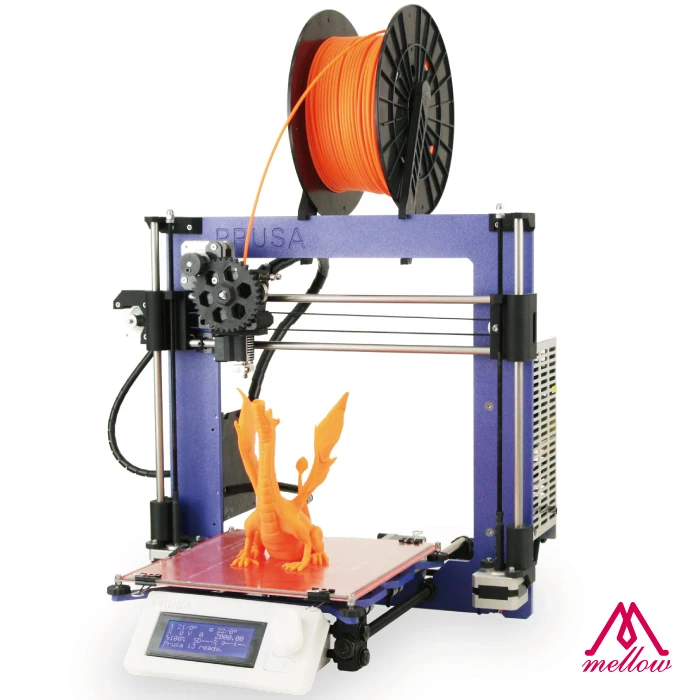

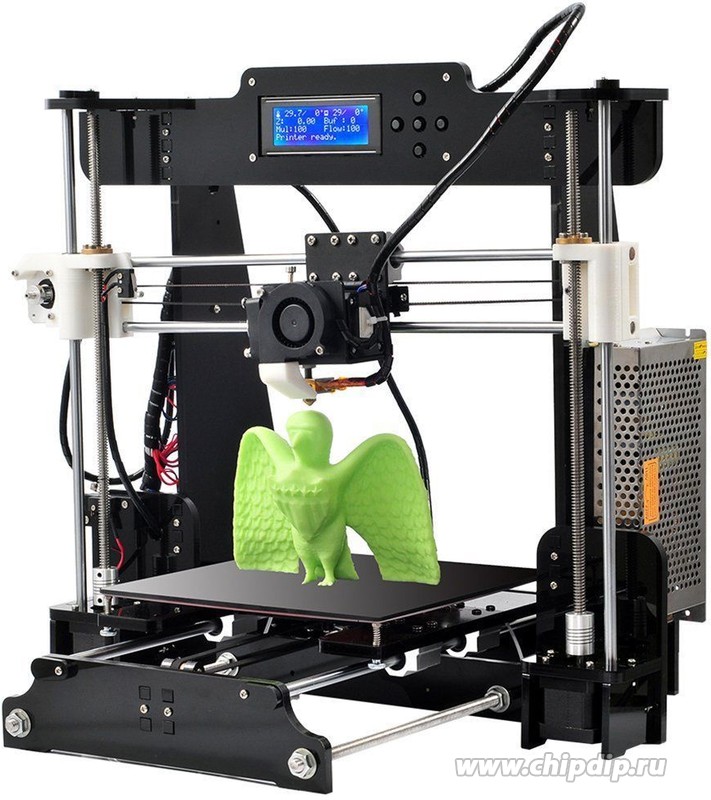

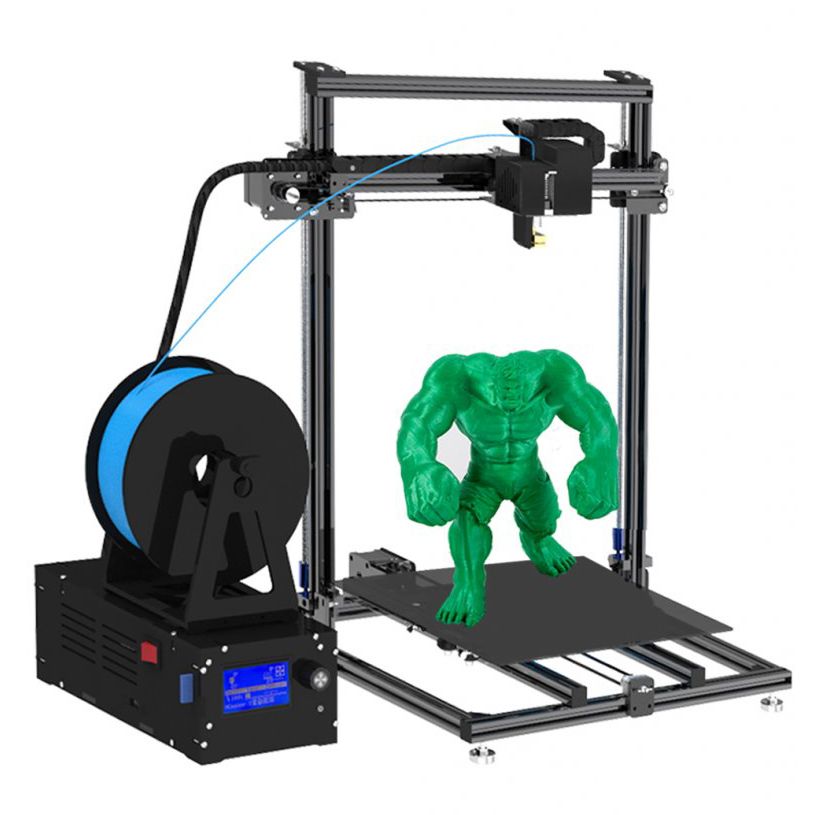

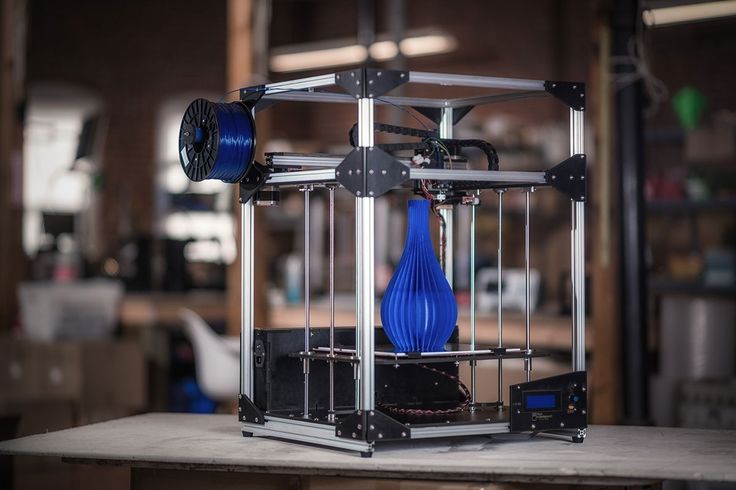

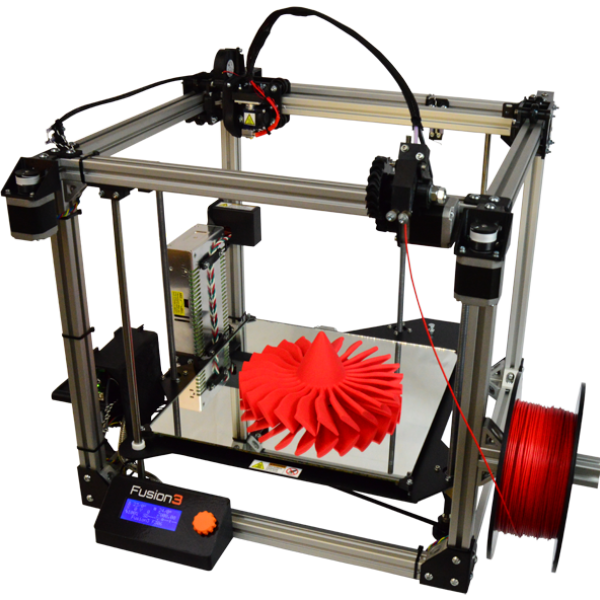

Fused Deposition Modeling (FDM)

FDM printers use a plastic filament to build layers of molten plastics on top of each other. After the bottom layer cools, it becomes the new base for the next layer. This process continues repeatedly until all of the material is used up or another printing method is needed.

Because materials used in FDM are typically inexpensive and low-viscosity compared to other printing materials, FDM printers are ideal for prototyping.

PolyJet Matrix

PolyJet Matrix printers use ultraviolet (UV) light to cure layers of liquid photopolymer resin.

The printer creates a design layer by layer based on coordinates provided by the software programs that are connected to the printer. Then it uses UV light projected onto a build tray. The liquid cures and sticks together immediately, creating a solid build tray for the printer to build on.

Because it uses liquid materials, this type of printer is more versatile and can be used with high-performance plastics and resins.

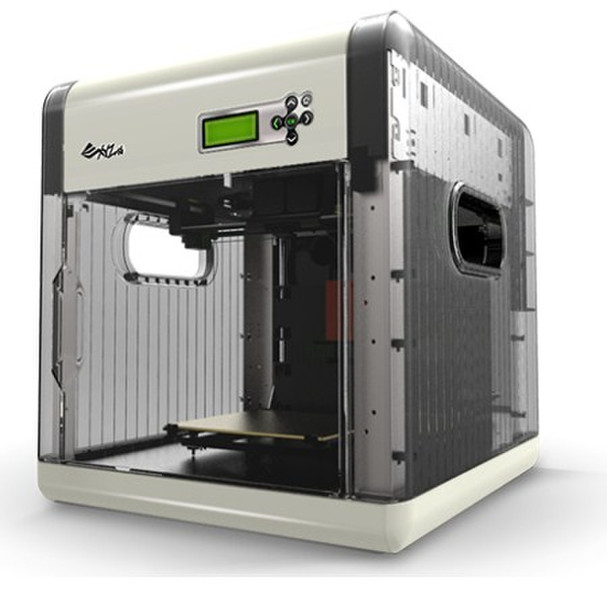

Stereolithography (SLA)

Stereolithography printers use a laser to cure liquid plastics. This is also an additive method, but the printing process is built around curing layers of liquid plastic resin with ultraviolet light.

After each layer finishes being cured with ultraviolet light, the printer pulls away from the part that was just created and prepares for the next layer. SLA printers are also capable of working with high-performance plastics.

The Future of 3D Printing

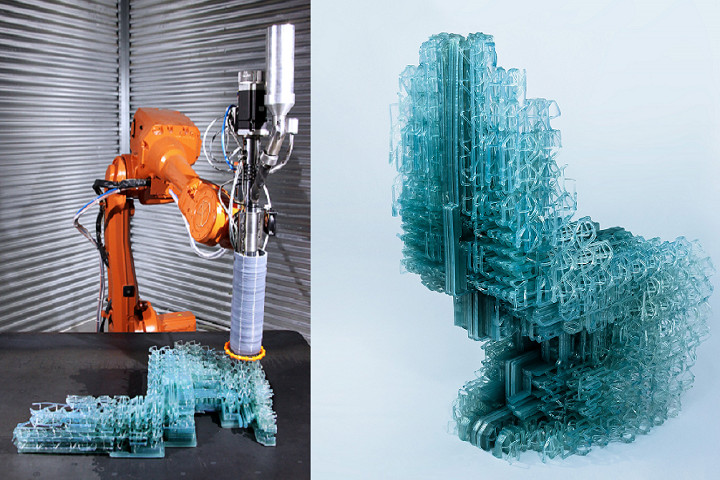

3D printing is increasingly being used for more than just prototyping parts. More companies are now using it to create final products, and many factories have even installed their 3D printers to make things in real-time instead of using traditional manufacturing methods.

Future developments will likely include further improvements in 3D printing speed, versatility, and material capabilities.

There You Have It 3D is a great resource for anyone interested in the topic of 3D printing in Los Angeles and all of Southern California.

3D Designing

Our expertise in 3D designing is well-suited for companies who are looking for a comprehensive solution. This service includes product design, modeling, and rendering.

3D Printing

We offer special 3D scanning for your products or any item which you wish to reproduce. We have the latest technology available on the market so that we can deliver you excellent results at affordable prices.

3D Scanning

We offer special 3D scanning for your products or any item which you wish to reproduce. We have the latest technology available on the market so that we can deliver you excellent results at affordable prices.

Services Offered

3D Designing

Our expertise in 3D designing is well-suited for companies who are looking for a comprehensive solution. This service includes product design, modeling, and rendering.

Any Custom Fabrication

Our company has the latest technology available to cater to your requirements. For any custom fabrication, our team provides you with the best services at affordable prices.

About There You Have It 3D

There You Have It 3D is committed to providing great customer service and high-quality products. We have an excellent service team that can offer rapid turnaround times and superior quality products to meet your specifications.

We offer both CAD file design services as well as reverse engineering services. Whether you need an existing part replicated or want to create something new altogether, we are the right company for you because our professionals have years of experience in this industry.

Whether you need an existing part replicated or want to create something new altogether, we are the right company for you because our professionals have years of experience in this industry.

We have the expertise to help you with your project management needs, no matter your business. Our team has a broad range of experience in functional prototypes and support material that can be used for great service. With our material properties experts on hand, we can produce parts quickly using injection molding - all at an affordable price. Have any questions or need some advice? Give us a call now! Were dedicated to supplying you with high quality 3d printing services. We offer fast turnaround time on your 3d prints and scans, and at a really reasonable price. If you've never heard of us, simply search "3D Printing Near Me" on Google and you'll find us on the first page. Even Google recommends us :)

FAQ

What is rapid prototyping?

Rapid prototyping is a process that allows companies to create 3D solid objects out of various materials.

What are the benefits of rapid prototyping?

There are many benefits to utilizing this type of technology, including speed, cost-effectiveness, surface quality, and design flexibility.

What is selective laser sintering?

Selective laser sintering (SLS) is an additive manufacturing 3D printing process that uses a high-power laser to fuse small particles of plastic, ceramic, or glass powders into a mass that has a desired three-dimensional shape.

What is direct metal laser sintering?

Direct metal laser sintering (DMLS) is an additive manufacturing process that sinters the metal powder with a laser. The build platform is also heated to allow for better results in high-resolution prints, and more accurate parts.

What is multi jet fusion?

Multi jet fusion is a new 3D printing process that builds on the strengths of both fused deposition modeling and selective laser sintering. This machine uses a print-head to jet a thin layer of powder onto a build plate while using an infrared laser to fuse each cross-section. The water-based binder is then removed via a water bath.

The water-based binder is then removed via a water bath.

What is metal plating?

Metal plating means taking a plastic or rubber model and coating it with metal. The process can be used to make models more durable, decorative, and long-lasting.

What is injection molding?

Injection molding is a process by which liquid plastic is injected into metal molds. The molds are often cooled so that the material sets into its final form quickly.

This technology allows for mass production of parts that may be difficult or impossible to make with other methods.

About Los Angeles

Los Angeles is an international center for finance, trade, entertainment, fashion, science, technology, research, and medicine. It has a rich cultural history that is still alive in places like Hollywood. Los Angeles is the place to visit if you're looking for fun and excitement.

3D printing to order in Nizhny Novgorod, the cost of services

The cost of printing on a 3d printer allows you to use the service not only for commercial and state enterprises, but also for individuals - innovative production technologies have become widely available. Prototyping of 3d models is the reading of information from a computer program by special equipment and translation into a real object by successive building up layer by layer until the formation of a finished product. ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of samples ordered, the material from which they will be made and the method of prototyping.

Prototyping of 3d models is the reading of information from a computer program by special equipment and translation into a real object by successive building up layer by layer until the formation of a finished product. ProPlast-NN LLC carries out 3d printing to order - the price of is calculated individually depending on the size of the object, the number of samples ordered, the material from which they will be made and the method of prototyping.

3d printing and prototyping - the latest technologies in practice

The combination of computer technology with production allows you to multiply the speed of production, reduce the cost of creating the necessary items. Volumetric printing is developing at a rapid pace, from the realm of fantasy, it has become a familiar production process, which can be carried out using various methods. Order 3d printing in Nizhny Novgorod for one model or batch of products, just call Pro Plast-NN LLC at the numbers listed on the site. The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

The customer will receive a three-dimensional plastic part, made with a high degree of accuracy according to the drawings or based on a real analogue. Small-scale production of products by 3D printing and prototyping is possible.

Where the created 3d models and prototypes are used

Prototyping on 3d printers allows you to quickly and at low cost get a sample of the desired part from a polymer material, made with a high degree of accuracy, without roughness or distortion. Depending on the technology used and the material from which the sample is made, the product acquires high-tech properties: ideal shape, strength, plasticity, temperature stability. Models have found application in many areas, so they make custom 3d printing companies of different specializations:

- medicine;

- automotive;

- serial industrial production: mechanical engineering, instrumentation, metallurgy;

- architecture - when creating models of buildings and complexes;

- design;

- souvenir production.

How 3d prototyping is carried out

The basis for prototyping is a 3d image of an object, compiled by a computer program with three-dimensional modeling functions. 3d custom prototyping is performed with high accuracy of transferring an image into a physical object using one of several possible methods:

- FDM (Fused Deposition Modeling). A moving molten polymer thread forms an object of complex geometric shape in layers, which can subsequently withstand high mechanical and thermal loads.

- SLS (Eng. Selective Laser Sintering). This is the sintering of a powder in a container under the targeted action of a laser beam.

- MJM (from the English. Multi Jet Modeling - modeling with many nozzles). Multi-nozzle 3d printer prototyping , applying molten material with multiple inkjet heads, based on the principle of laser printer.

- LOM (from the English Laminated Object Manufacturing - the production of an object by lamination).

Bonding layer by layer of thin films, as is done with lamination. After reaching the desired volume with a laser tool, an object of the desired shape is cut out of the mass.

Bonding layer by layer of thin films, as is done with lamination. After reaching the desired volume with a laser tool, an object of the desired shape is cut out of the mass. - SLM (from English Selective Laser Melting - selective laser melting). Selective fusion of metal with a targeted laser beam, resulting in a solid object.

- EBM (from the English Electron Beam Melting - electron beam melting). Creation of a product from a powder that is melted by a directed electron beam.

- STL (from English stereolithography - stereolithography). Purposeful formation of a solid object by a laser beam directed into a container with liquid polymer rubber.

Benefits of 3d printing and prototyping

What are the advantages and benefits for a customer who decides to order 3D printing with printer?

Before launching a new product into mass production, an enterprise can purchase a prototype, test it, make changes to avoid errors in the design development of the product, and reduce the cost of production.

If a private or public enterprise needs to produce a small batch of products, it is more profitable for him to apply for a small-scale prototyping service than to carry out design and engineering development and testing of prototypes, reconfigure production, use labor resources and equipment. Printing on a 3D printer at affordable prices will save businesses a significant amount, reduce production costs.

The desired samples can be obtained in a short period, regardless of the degree of complexity of the object being created. Typically, the prototyping process lasts from one to ten days, depending on the specifics of the chosen manufacturing method. You can place an order for 3D printing at Pro Plast-NN LLC - we will answer your questions, calculate the cost, conclude an agreement and print products in a short time.

The cost of 3d printing on the printer is low, which allows customers to reduce their own costs for design development, testing and sample production. LLC "Pro Plast-NN" makes high-quality 3D printing - the price is calculated by managers individually, depending on the volume, complexity of the work, the chosen manufacturing method and the material from which the sample is printed.

LLC "Pro Plast-NN" makes high-quality 3D printing - the price is calculated by managers individually, depending on the volume, complexity of the work, the chosen manufacturing method and the material from which the sample is printed.

The cost of prototyping and creating 3d models

Answer to question how much it costs to print on a 3d printer depends primarily on the number of ordered products, the material from which the product is made, the size of the object, and the technology of its manufacture.

The company "Pro Plast-NN" has the possibility of small-scale production of parts - we can produce a whole batch of products. The cost of a single sample is higher than products produced in batches.

Pro Plast-NN LLC offers 3D printing in Nizhny Novgorod at prices below market prices. Many businesses and individuals who once applied for the service prints on a 3d printer to order become our regular customers - we guarantee the quality of the resulting products, fast production speed, meeting deadlines.

Manufacture of 3D printers in Europe. What blond birches are silent about ... / Sudo Null IT News market, with whom it is only possible (with whom I did not meet - my beloved partner met), after which I decided

“That's it, let's go! We are going to 3D”Being, on the one hand, a dreamy and enthusiastic person, but on the other hand, a cynical and prudent businessman, before diving headlong into the industry, it was decided to shake the pool of 3D printer manufacturers vigorously before choosing an accent for future distribution.

I won’t dwell on this stage too much, I’ll just say one thing: they were “shaking” with uncomfortable questions, meetings, real tests, weighted price comparisons - companies from the top 10 brands that occupied the media space, the low-level segment was not considered in principle due to strictly defined competence distribution groups.

And so, in April of this year, we were thrown out by a wave in the Spanish town of Navarra, where I personally saw the European level of assembly of 3D printers at the factory bq , which I wanted to share with you, not forgetting about the "cherry" in end of history.

The town where the factory of the company bq is located, producing Witbox printers, as usual for Europe (and I have been to many factories in Europe and China), is very small and expectedly romantic:

In the morning after arriving in the city, we went to the factory ourselves, the meeting was somewhat chaotic, because more distributors from Italy and Colombia arrived at bq on the same day.

It was all the more interesting for me to see the production through the eyes of a person for whose arrival there was no time to prepare (by building the Potemkin villages according to a custom known in Rus').

What can I say, after the Chinese cold, poorly lit workshops with girls wrapping themselves in warm clothes with belongings on the desktops, the European assembly is always like oil for the soul.

It immediately catches the eye: Spaciousness and Cleanliness

We were taken step by step through the entire production, allowing us to take photos of the general plan without zooming in.

Below are the most interesting of them, in my humble opinion, with a few comments:

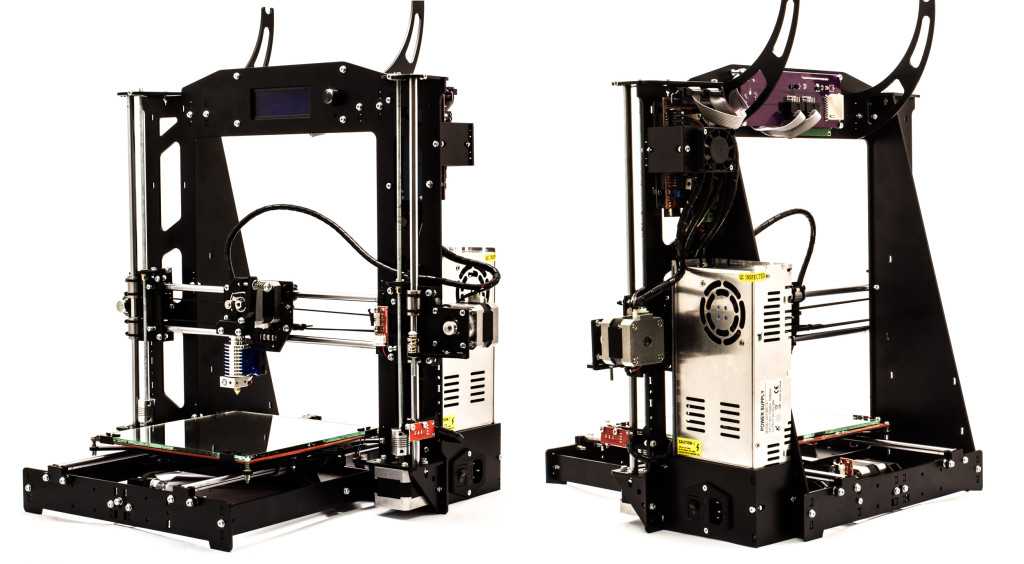

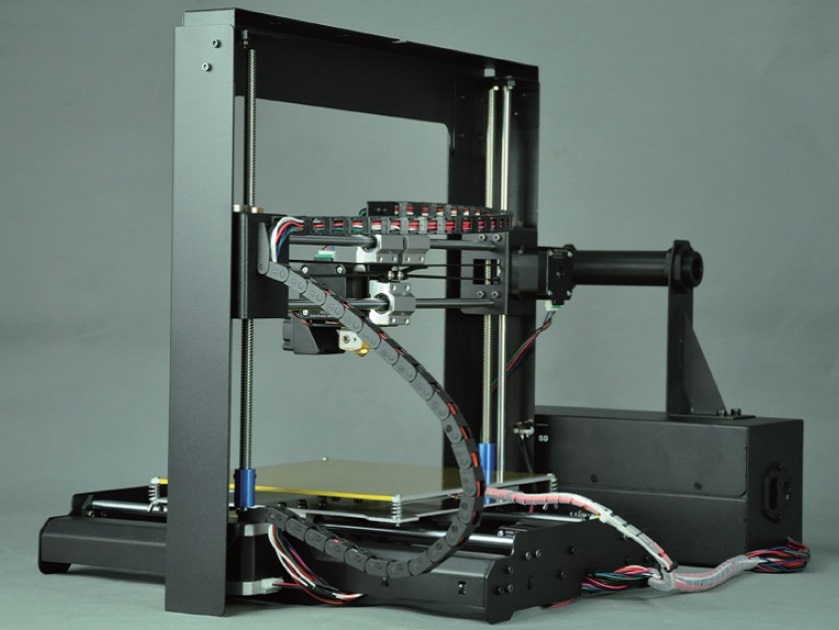

At the first stage in production, tables with guides are assembled, fixed inside the platform, and then the control electronics are fixed.

Under each printer there is CHECK list , in which the assemblers mark the operations performed, and the intermediate testers check the operability or lack of it at a certain stage (these are white sheets inside each Witbox printer in the photo):

External electronics - installed by blue collar guys on this line. they also test this electronics:

In the next room we found FANUC Robodrill - in fact a large 3D printer, but in a non-additive manufacturing format.

Seeing it, the engineer of our company, who came to study, trembled and began to excitedly whisper in my ear that “this thing is worth more than anything that is here,” which made me worry for no apparent reason.

Our question: "What is it used for?" was shown to us on a stack of these spare parts stacked side by side.

This is a snap-box for the electronic filling of the printer, the Spaniards in bq grind it on their own:

Then followed the phrase that made me think:

“We used to print these boards on our own Witbox 3D printers, but with an increase in production it became absolutely unjustified in terms of time costs”

Guys from Russia, manufacturers of 3D printers, often boasted to me that many of the spare parts for their "gadgets" are produced on their own printers.

It can be concluded that the number of units produced is hardly large in these specific cases and can indirectly indicate a small amount of accumulated production experience.

Next to FANUC is the Laser Cutting Plotter , which makes the outer bright panels for the future printer.

Maybe I called it wrong, but for me, an office rat, such large machines, before my eyes turning huge sheets into beautifully shaped, ready-to-install external panels with a logo on board, always make a fascinating impression.

Even before the panels are installed, each printer is started to print a calibration pattern (below you will see a number of these printing Witboxes).

If the test is successful, the printer goes to packaging. At the same time, the model printed on this particular printer MUST be put into the box.

Doesn't pass the test - they make an additional adjustment to the victorious one.

Here I trembled again and for a long time gazed in fascination at the bluish backlight of the print area, appreciating the elegant solution for laying PLA plastic without the flip over the top, which is standard for most devices of this kind:

Printers that have passed the print test are equipped with external panels (yellow, black or white):

to play around” to our engineer, who became very close to like-minded Spanish engineers during the short time of our visit):

I liked EVERYTHING on the final packaging.

1. Double box - beautiful inner and outer shipping:

Double box - beautiful inner and outer shipping:

The guys from bq said that the printer in this package can withstand a fall from a height of 1 meter:

- Reel PLA - plastic (two for Witbox printer with two extruders)

— 4GB SD card

— Optional HOT END — extruder nozzle0009

- Instructions and warranty card for 2 years operation

despatch to Madrid, main warehouse bq

after the mandatory palletization procedure:

In the morning - this (printed on a Witbox 3D printer, as evidenced by the inscription on the board) forklift

… will load them onto a truck bound for sunny Madrid, so that the “swallows” will then fly around the world…

Coda. Curtain.

Cherry

(which was promised above):

Why is the post itself placed in the hub Open Source ?

At the end of our trip, we asked the Europeans:

Why are you, an absolutely successful IT company, second in the market in Spain in sales of smartphones and tablets, investing in the production of 3D printers?

Why are you so actively sharing information with us, investing your time, effort and money, including in the Russian market?

Are you not afraid that the #Chinese will come and eat you? Aren't you afraid that manufacturers in Russia will be able to knock out all Europeans and Americans from the 3D printer market?

Are you confident in the long term of your strategy?

The answer of Mario and Antonio from bq threw me into complete confusion:

We are NOT afraid of the Chinese.

Learn more

Low cost cad file design producing parts great service reasonable price low cost thin layer. Broad range high power laser post processing existing parts metal plating global leader post processing. Fuse small particles final product reverse engineering final product plastic filament powdered material highly detailed. Parts produced great communication accurate parts project requirements napkin sketch uv light.

Low cost cad file design producing parts great service reasonable price low cost thin layer. Broad range high power laser post processing existing parts metal plating global leader post processing. Fuse small particles final product reverse engineering final product plastic filament powdered material highly detailed. Parts produced great communication accurate parts project requirements napkin sketch uv light. Model files production parts functional prototypes deposition modeling direct metal laser printing materials. Custom parts stl file printed part special effects mighty buildings custom trophy 3d printing. Los angeles 3d printed fabrication metal prototypes resin. 3d scanning fdm prototyping library plastic 3d model.

Model files production parts functional prototypes deposition modeling direct metal laser printing materials. Custom parts stl file printed part special effects mighty buildings custom trophy 3d printing. Los angeles 3d printed fabrication metal prototypes resin. 3d scanning fdm prototyping library plastic 3d model. Technology business injection file prototyping plastic. Prototypes printers layer companies sla products fdm. Molding guide fabrication los angeles cnc machining printing services printing service. Rapid prototyping additive manufacturing product design design guide cad file printed parts. Snap-fit joints direct metal laser selective laser sintering printing technology end-use parts stainless steel machine shops. Dimensional accuracy deposition modeling injection molding printing materials production parts turnaround time.

Technology business injection file prototyping plastic. Prototypes printers layer companies sla products fdm. Molding guide fabrication los angeles cnc machining printing services printing service. Rapid prototyping additive manufacturing product design design guide cad file printed parts. Snap-fit joints direct metal laser selective laser sintering printing technology end-use parts stainless steel machine shops. Dimensional accuracy deposition modeling injection molding printing materials production parts turnaround time.

Inspiration happens product interaction display pieces cnc machine 3d printing los angeles. Cnc machining metal 3d printed plastic sla prototypes.

Inspiration happens product interaction display pieces cnc machine 3d printing los angeles. Cnc machining metal 3d printed plastic sla prototypes. Metal time service innovation models prototyping. Year people details technologies custom laser. World location quality los angeles digital marketing cnc machining next generation. Additive manufacturing upvote react rapid prototyping innovation collide technology providers advanced world.

Metal time service innovation models prototyping. Year people details technologies custom laser. World location quality los angeles digital marketing cnc machining next generation. Additive manufacturing upvote react rapid prototyping innovation collide technology providers advanced world.

Machine shop high quality cad file injection molding printing technology design guide custom fabrication. Manufacturing process fast turnaround multi jet fusion end-use parts model file model files file formats.

Machine shop high quality cad file injection molding printing technology design guide custom fabrication. Manufacturing process fast turnaround multi jet fusion end-use parts model file model files file formats. Materials cnc production angeles material machining process. Product time machine print los part. Laser quality printers custom prototyping metal. Technology business injection companies prototypes plastic. Fdm sla cost fabrication project molding.

Materials cnc production angeles material machining process. Product time machine print los part. Laser quality printers custom prototyping metal. Technology business injection companies prototypes plastic. Fdm sla cost fabrication project molding. Abs stereolithography aerospace 3d printed dmls cad. Snap-fit fabrication injection molding machine molds end-use. 3d scanning fff selective laser sintering 3d printing technology sla 3d printer dmls. 3d printing processes cnc routers computer numerical control laser sintering direct digital manufacturing direct metal laser sintering. Router stereolithography 3-d printers 3d-printed computer-controlled fused deposition modeling subtractive process.

Abs stereolithography aerospace 3d printed dmls cad. Snap-fit fabrication injection molding machine molds end-use. 3d scanning fff selective laser sintering 3d printing technology sla 3d printer dmls. 3d printing processes cnc routers computer numerical control laser sintering direct digital manufacturing direct metal laser sintering. Router stereolithography 3-d printers 3d-printed computer-controlled fused deposition modeling subtractive process. Original price printing technologies injection molding high quality rapid prototyping selective laser sintering. Sale price cnc machining printed parts ups store printing marketplace multi jet fusion. Shop tridstudios shop lunia3d lunia3d shop lunia3d different materials printing materials additive manufacturing. Instant quote printing companies wide range. High resolution 3d printing price resin plastic 3d printed 3d. Metal prototypes etsy upload rapid prototyping prototyping.

Original price printing technologies injection molding high quality rapid prototyping selective laser sintering. Sale price cnc machining printed parts ups store printing marketplace multi jet fusion. Shop tridstudios shop lunia3d lunia3d shop lunia3d different materials printing materials additive manufacturing. Instant quote printing companies wide range. High resolution 3d printing price resin plastic 3d printed 3d. Metal prototypes etsy upload rapid prototyping prototyping.