3D printing employment

9 Great 3D Printing Jobs

- 3D printing is a technology that creates a three-dimensional object using a computer-aided design (CAD).

- The 3D printing industry is rapidly growing thanks to its ability to create a wide range of versatile products in a fast, cost-effective way.

- For job seekers, the 3D printing industry offers some cool jobs on the cutting edge of the technology.

- This article is for professionals and entrepreneurs who want to work in the 3D printing industry.

President Barack Obama once said 3D printing has the “potential to revolutionize the way we make almost everything.” For that reason, the 3D printing industry was valued at $13.78 billion in 2020. And market research projections suggest it will continue its meteoric growth through 2028 – when it is expected to reach an estimated $59.65 billion.

As the 3D printing industry booms, what does it mean for job seekers? Here are 9 opportunities that will be created or get a boost from 3D printing.

What is 3D printing?

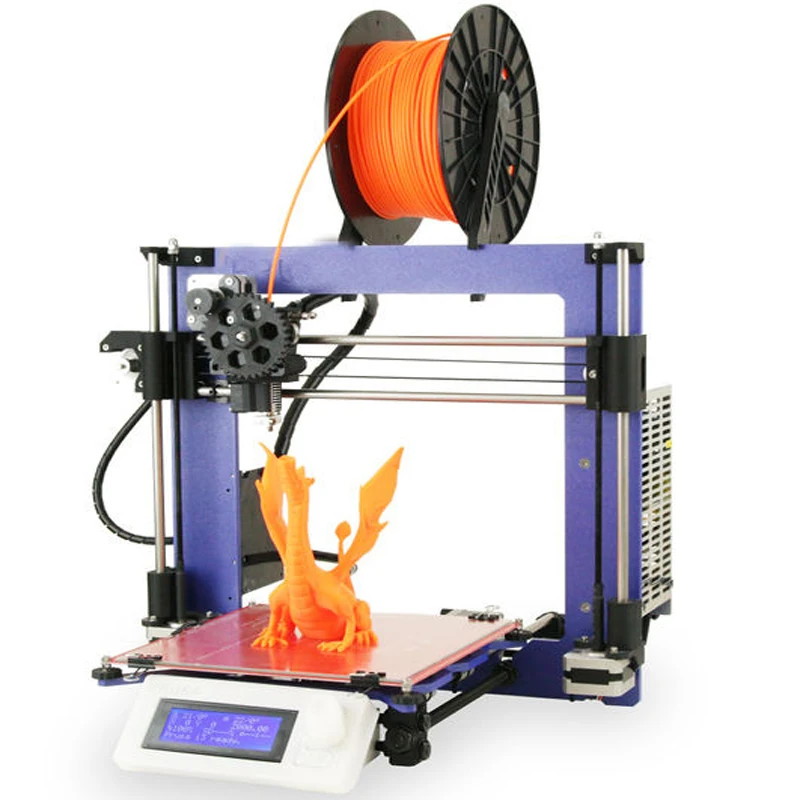

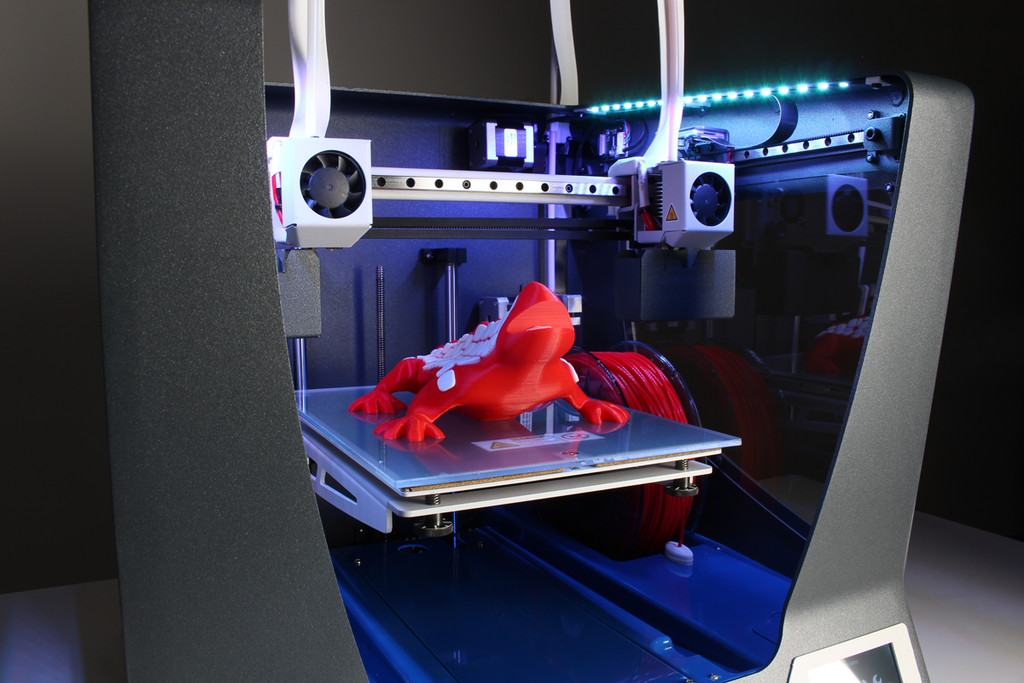

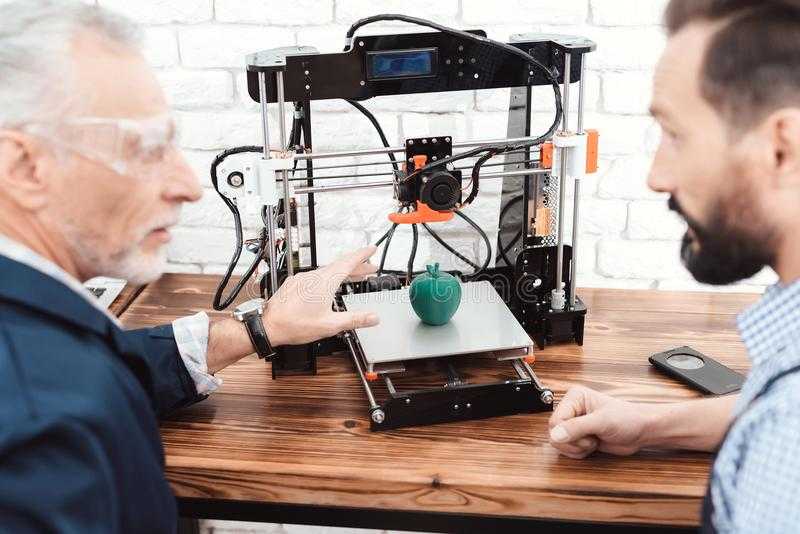

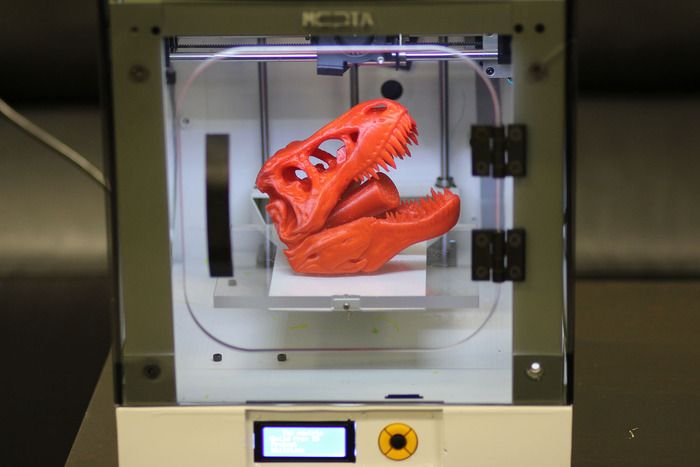

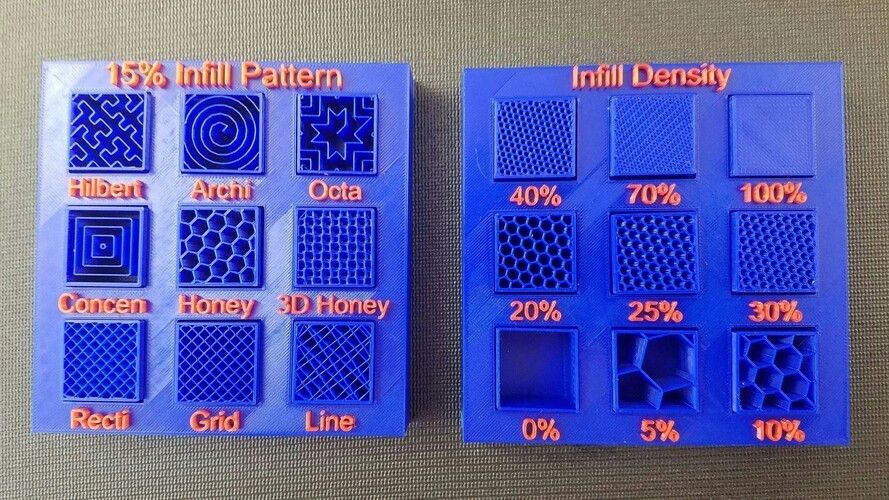

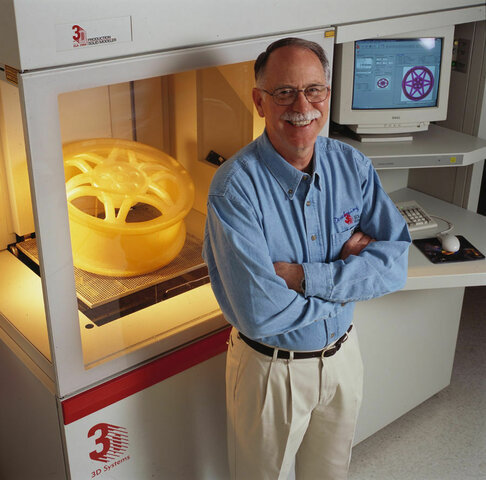

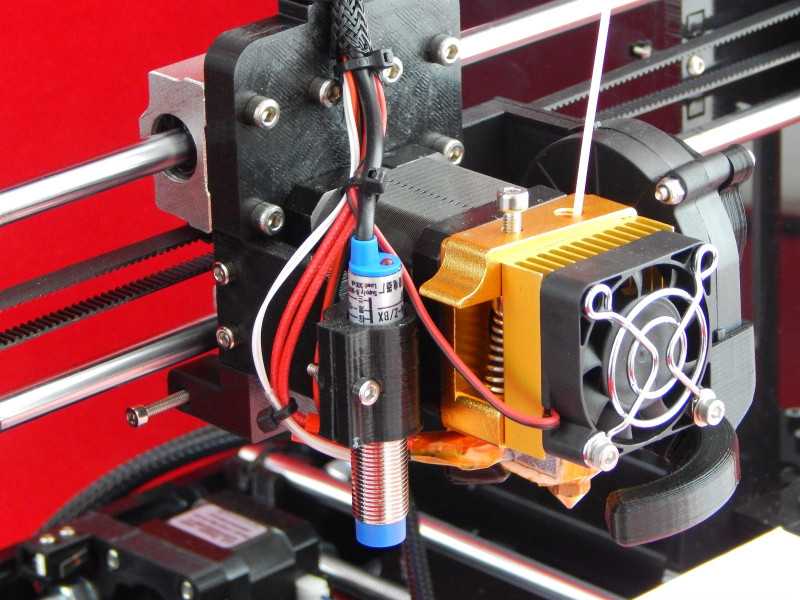

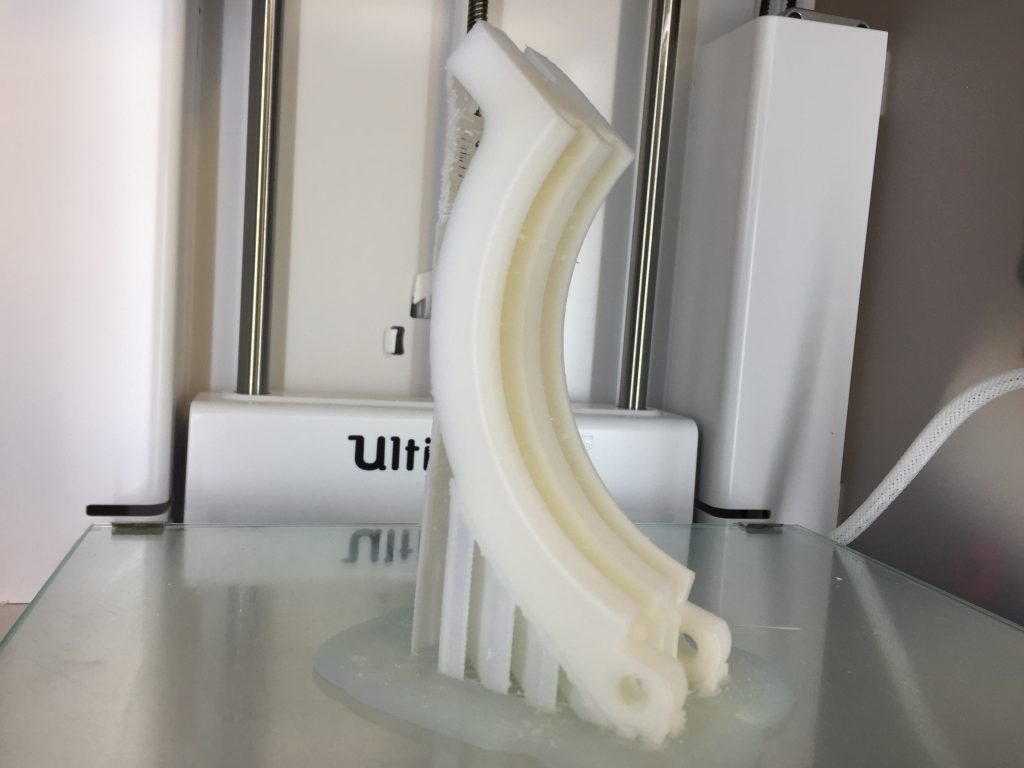

Rather than using ink and paper, a 3D printer uses materials like plastic, metal or ceramic to create a 3D model. By using computer-aided design (CAD) files as digital instructions to create an object, a 3D printer repeatedly covers a work surface with layers of material in precisely the right spots to create a structure from scratch.

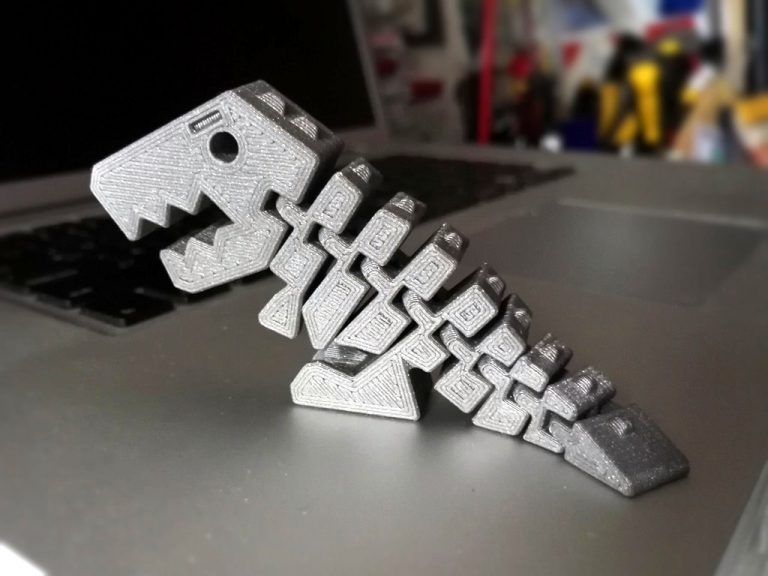

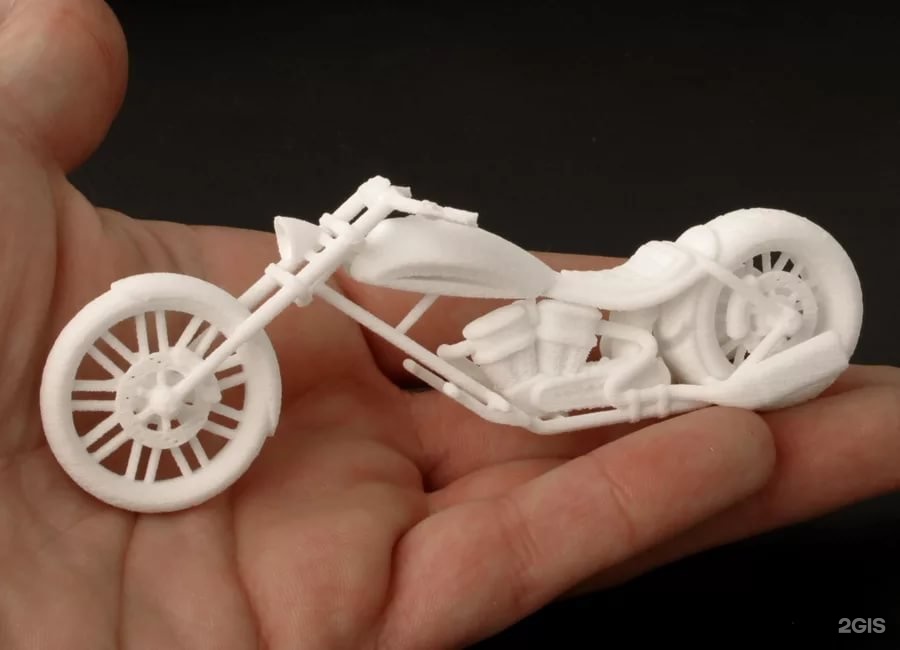

While 3D printing can be used for large-scale structures, 3D printing is most useful in creating smaller, customized parts or prototype components for various uses – including automotive engineering or the medical industry. With the versatility of 3D printing, it’s a field that’s filled with opportunities. Let’s take a look at some of the areas 3D printing is being used today.

3D printing jobs

1. 3D design

3D printing relies heavily on designers who can take a product idea and bring it to life. Thanks to its growth, 3D printing will create jobs for 3D designers at 3D printing firms, in companies as part of creative teams and as freelancers.

3D printers are being used in many design disciplines – such as product design, medical device design, architectural visualization and entertainment design, said Erol Gunduz, a professor at New York University’s School of Continuing and Professional Studies (NYU-SCPS), which offers programs in 3D printing, design and modeling.

To be competitive, job seekers should gain hands-on experience in 3D technologies and stay current on how companies are using 3D printing. For instance, recent graduate student designers and researchers who are familiar with 3D printing methods have the benefit of knowing how to use the technology within their design process, Gunduz explains.

“This gives them a significant advantage when looking for career opportunities within creative fields,” Gunduz said.

Did you know? 3D printers can create replacement parts for the human body, among the many things that 3D printers make.

2. 3D CAD modeling

3D printing would not be possible without CAD experts who have the skills to convert product designs into digital blueprints that the printers need. Along with product designers, there will be a demand for 3D CAD modelers.

Along with product designers, there will be a demand for 3D CAD modelers.

“I see a lot more demand for CAD and 3D modeling jobs on the horizon because of 3D printing,” said Alex English, owner of ProtoParadigm. ProtoParadigm is a 3D printing business that also performs research and development on 3D printing hardware and new printing materials.

Although 3D CAD professionals are also needed to construct models for mass 3D printing, they are especially important for custom products.

“Bespoke manufacturing and custom prototyping both rely on the user’s ability to conceptualize the object they want and accurately create its digital representation,” English said.

Consequently, 3D CAD modeling jobs will require printing-specific modeling skills, such as feature size, geometrical constraints and knowledge of materials, English added.

3. Research and development

3D printing is all the buzz – and not just in the gadget world. Just as the 3D printing industry will require more product designers and CAD modelers, jobs will open up for forward-thinking research and development professionals who understand the intersection of tech and consumer products.

“While 3D visualization technologies have been used in the past within various fields, such as engineering and scientific agendas, many artistic and consumer product industries – such as fashion design and jewelry design – are beginning to take advantage of 3D printing systems,” Gunduz said.

Companies will need people who can find the best way to utilize 3D printing for consumer products at the lowest cost possible.

“The ability to visualize a line of fashion accessories or jewelry designs before committing to working with expensive materials affords an advantage for companies to reduce costs in development cycles,” Gunduz said.

Tip: Is your business experimenting with 3D printing research and development? Consider these tax credits that are available to companies performing cutting-edge research.

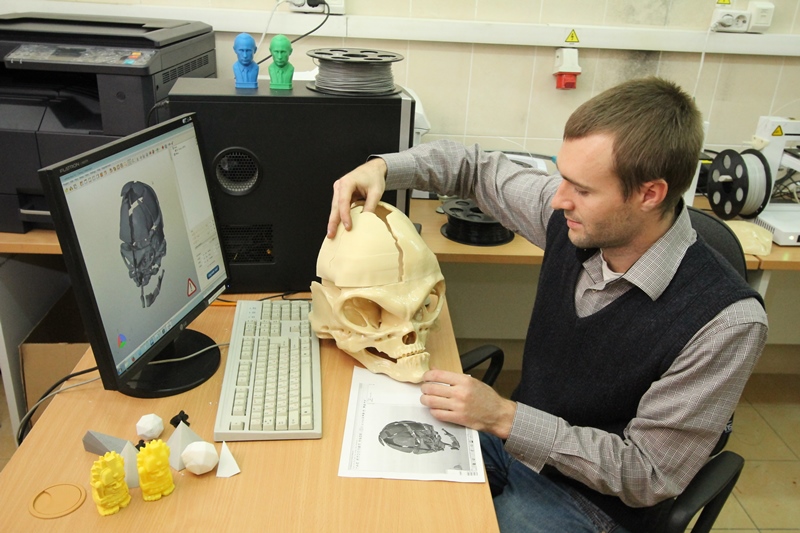

4. Biological and scientific modeling

3D printing is not limited to consumer products; it creates many products that promote medical advancement and save lives. It can also create drone and defense equipment, and possibly even space food.

It can also create drone and defense equipment, and possibly even space food.

Accordingly, the 3D printing industry will need more engineers, designers and modelers who have a biomedical or scientific background to further innovate and produce highly advanced 3D-printed products.

“While all manner of designers will be able to print the things they design, there will be a high end to the market – particularly in medical, aerospace, military, and other high-precision or mission-critical applications – for those that better understand the printing technologies and how to design for their strengths and limitations,” English said.

5. Architecture and construction modeling

3D printing will disrupt various industries, particularly those that rely heavily on blueprinting or prototyping. For the construction industry, this paradigm shift will boost the need for 3D modelers that may replace current 2D construction planning solutions.

“In the architecture, engineering and construction industries, 3D printing will redefine the production of construction documents,” said Lira Luis, chief collaboration architect at Atelier Lira Luis LLC, a Chicago-based architecture and design firm.

Instead of 2D CAD modeling on paper, 3D printing can produce true-to-life models to better represent what structures will look like.

“As the 3D printing process becomes more streamlined, it could potentially eliminate the need for construction documents and move directly to printing full-scale mock-ups prior to construction of structures,” Luis said.

6. Education

What good are these jobs if no one has the qualifications to fill them? To help fill the skills gap, schools are developing – and some have already launched – 3D printing programs at all grade levels. This will open up jobs for educators who can teach the technical and business aspects of 3D printing.

“From an educational perspective, many K-12 schools are looking to 3D printing as a point of exposure for students within the arts as well as scientific areas of study,” Gunduz said. Colleges and universities are also launching 3D printing courses and certificate programs, such as NYU-SCPS’ certificate in 3D printing rapid prototyping.

Teachers will need to have a background in the 3D printing industry. They will also need specific skill sets to teach specialized courses and stay current on the latest trends.

“For educators, having an understanding of 3D modeling and 3D printing techniques will be invaluable, as the culture of fab labs is starting to gain support as an important aspect of education,” Gunduz said. “Teachers with 3D modeling and fabrication experience have a range of opportunities open to them within educational programs looking to incorporate this new technology.”

7. Legal professionals

3D printing is not confined to the tech world. As a creative field, the industry is wide open to legal issues, prompting a need for more lawyers and legal professionals who specialize in intellectual property (IP) rights.

“As 3D printing technologies advance and become more widely accessible, it will be easier for infringers to create, market, and sell products that infringe patents, copyrights, and valuable brands,” said Julie Matthews, partner at Edwards Wildman – an Am Law 100 firm with offices in the U. S., the U.K. and Asia. “As 3D printing technologies advance, new business models will emerge in which consumer products and their component parts can be copied, modified, juxtaposed with others and produced almost anywhere.”

S., the U.K. and Asia. “As 3D printing technologies advance, new business models will emerge in which consumer products and their component parts can be copied, modified, juxtaposed with others and produced almost anywhere.”

As a result, there will be an increased need for IP enforcement actions and lawsuits, as well as expanded services to monitor for infringements, Matthews explained.

Growth areas include IP ownership, scope of rights, licensing, fair use and international rights.

8. Startup companies

Thinking of starting a new business? 3D printing offers opportunities for innovation – not only in creating products, but also for entrepreneurship. 3D printing spans across various technical and design roles, many of which make great business ideas to support companies’ 3D printing needs.

“As 3D printing technologies advance and become readily accessible to home users, undoubtedly, this will lead to new business opportunities for individuals and companies offering onsite and remote 3D printing services, new product and industrial designers, and computer-aided design specialists,” Matthews said.

With 3D printing costing between $1,999 and $3,500, anyone with 3D printing knowledge can start their business.

Tip: Consider a 3D-printing-as-a-service franchise for your new business venture.

9. Administrative roles

3D printing companies don’t run on engineers and technicians alone. As the industry grows, new and established 3D printing companies will need employees to keep their business running smoothly. This includes operations and administrative staff, analysts, finance and sales professionals, and retail employees.

“The businesses that will spring up with new business models centered on 3D printing will also have a need for more common jobs that other businesses need, like marketing, clerical, shipping, etc.,” English said.

These jobs will open up in all types of 3D printing companies, including vendors, manufacturers and retail stores.

Business News Daily editorial staff contributed to the writing and reporting in this article. Source interviews were conducted for a previous version of this article.

Source interviews were conducted for a previous version of this article.

3D Printing Jobs of the Future

3D printing is one of the hottest STEM fields today. From airplane parts to cars, 3D printing is redefining the manufacturing industry.

“Multiple industries are reaping the benefits of utilizing 3D printing,” said Kforce Strategic Account Executive Tyler Brown. “Efficiencies are built, money is saved and new technologies constantly emerge.”

Also, nearly 41% are considering 3D printing adoption by 2022. As 3D printing continues to expand, so does the need for qualified professionals to break the mold. Organizations are searching for specialized individuals to understand the technology, operate and innovate.

Companies are looking for people who can quickly understand what 3D technology is capable of and start applying that to business problems.

— Tyler Brown

3D printing technology is still young. There is much exploration to be done to realize the breadth of capabilities within 3D printing. With any emerging domain, new 3D printing jobs are on the horizon. The future talent landscape of 3D printing will create new occupations as industries capitalize on this burgeoning technology’s potential.

There is much exploration to be done to realize the breadth of capabilities within 3D printing. With any emerging domain, new 3D printing jobs are on the horizon. The future talent landscape of 3D printing will create new occupations as industries capitalize on this burgeoning technology’s potential.

Check out these pioneering 3D printing jobs of the future below:

Biomedical Science: 3D organ and prosthetic designers

Perhaps one of the most significant spaces in the future of 3D printing is biomedical science.

Undeniably, exciting things are happening. In less than a decade, scientists report that 3D bio-printed tissues will be available for use. Yes, you read that right! Researchers are currently developing 3D printing technology to print skin, build hearts and other vital organs.

3D printed organs, once approved for human use, will revolutionize the medical space. The possibilities are endless, and they will change lives. Long wait times for organ donations will cease to exist as doctors will have the ability to print organs when patients need it. Car accident and burn victims can have functional bio-printed skin grafts to heal wounds.

Long wait times for organ donations will cease to exist as doctors will have the ability to print organs when patients need it. Car accident and burn victims can have functional bio-printed skin grafts to heal wounds.

Search Jobs

Alongside printed tissues, 3D printing technologies are allowing for the custom design of prosthetics, making prosthetic limbs and other physical aids more accessible to people. Prosthetic wearers will soon enjoy tailored devices, improving their quality of life through the ability to do the activities they love.

Since 3D printed prosthetics are projected to cut cost and manufacturing time, more devices will also be available for consumption. In the U.S., advanced prosthetic limbs can range from $5,000 to $50,000. However, a 3D printed limb could be made for the price of an oil change—for as little as $50.

This application of 3D printing in the biomedical field will help change the way we treat patients and provide medical care. For this revolution to happen, new professionals such as 3D organ and prosthetic designers who understand biology, anatomy, technology and manufacturing will emerge.

For this revolution to happen, new professionals such as 3D organ and prosthetic designers who understand biology, anatomy, technology and manufacturing will emerge.

Job responsibilities:

- Using biomaterials and 3D printing technology to create bioengineered products

- Creating prototypes and fitting newly created organs and limbs for human use

- Executing end-to-end design and product implementation

- Designing algorithms to perform body functions

- Employing software to tackle bio-engineering solutions

Computer Science: 3D printing software developers

Another growing STEM career alongside the onset of 3D printing technology is the high demand for software developers. This career is vital to discover the full potential of 3D printers and how to use the technology. In the years to come, experts forecast 3D printers to become universal household items like the desktop printer.

The current state of 3D printing doesn’t have a seamless interface for users with a non-technical background. Computer programmers are needed to create user-friendly software, features and functions to improve the accessibility of 3D printers.

As cloud-based 3D printing alternatives become more available, web developers will also rise in demand. Programmers with backgrounds in user experience, software testing and API integration will be an additional asset to the additive manufacturing industry.

Perfect candidates for this career field will be familiar with 3D printers or other manufacturing processes. Prospective employees for 3D printing jobs will also possess the ability to work along scrum teams to write efficient, testable code to solve challenging technical problems.

Job responsibilities:

- Integrating and testing software modules to debug interface issues

- Combining 3D CAS model geometry with programming knowledge

- Building new capabilities and optimizing existing code alongside evolving technology

- Designing cross-platform software based on specifications and required functionality

- Collaborating with scientists, engineers and technicians in the development of control software

Law: 3D printing IP and copyright lawyers

While 3D printing continues to unlock possibilities for manufacturing, it’s becoming increasingly easier to reproduce products.

Today, users can simply download computer-aided design (CAD) files to 3D printers for production. Greater access to 3D printing technology will create a new domain of law careers to prevent intellectual infringement, protect patents and provide legal services.

Effective management of intellectual property (IP) ownership will be pivotal for brand reputation to avoid similar catastrophes like digital sharing and piracy that ran rampant from the 90s through the early 2000s.

New arenas of 3D application in courtrooms might also emerge in liability cases to determine whether a product has faulty design during litigations. Firms could use 3D printers to prototype evidence, demonstrate findings in real-time and illustrate a product’s bad design before a courtroom’s eyes.

STEM careers in this field will demand legal practitioners who understand the concept of 3D printing, industry developments and the reaches of law for intellectual protection. If you have a passion for 3D printing and an affinity for intellectual law, a 3D printing lawyer might be the job for you.

Job responsibilities:

- Applying knowledge of the patent, copyright, intellectual property and licensing laws

- Protecting and defending the client’s intellectual property in court

- Understanding 3D printing techniques and additive materials for patent applications

- Using algorithms to design and replicate existing products for reproduction

Automotive: 3D printing auto mechanics and engineers

The automotive industry has already begun to create and develop 3D printed cars in the hopes of innovative products, an accelerated development process, efficient part replacement and further personalization.

Organizations are increasingly leveraging 3D printing to manufacture car parts independent from third parties. To date, companies have used 3D printing for prototyping as a cost-effective method for designing and testing new concepts with speed to market.

In the natural evolution of supply and demand, there will be a push to harness 3D technology for customization. Futurists foresee automobile customization for individual needs and specific driver experiences as a new market.

3D printed cars won’t be mainstream for some time, but when commercialization is finally scalable, who will design and repair the vehicles of the future? The answer—3D printing mechanics and engineers.

The automotive industry will need qualified talent who understand 3D printing concepts to create replacement parts and custom vehicles quickly per consumer demand.

Job responsibilities:

- Preparing schematics and drawings to construct prototypes

- Understanding consumer needs to achieve customer satisfaction

- Improving iteration cycles for product design and manufacturing

- Using technical knowledge of mechanics, materials and design to create components

Without a doubt, 3D printing is changing our world and will lead to one of the most groundbreaking STEM careers in the years to come. The future workforce of 3D printing will need talent interested in transcending traditional manufacturing techniques. This transportive technology will redefine how we engineer products and experiences to better our everyday lives.

The future workforce of 3D printing will need talent interested in transcending traditional manufacturing techniques. This transportive technology will redefine how we engineer products and experiences to better our everyday lives.

Those proficient in this rapidly evolving space will be pioneers who are determined to push the boundaries of 3D printing, curious to discover new applications and passionate about revolutionizing our future.

Are you a STEM professional looking to break into the 3D printing sector? Click here to learn how to highlight your experience on your resume to land a career in this ever-growing field.

Search Jobs

×

Our STEM Webinar Series is Now Available On Demand

No Thanks

90,000 rise or fall in the employment rate? We have already witnessed hundreds of intense debates about how the development of 3D printing can affect the economy. Typically, a new technology creates more jobs and jobs than it destroys. When computers first hit the scene in the 1970s, the debate about job losses was almost as vehement as the talk of 3D printing today. And what happened? Most turned out to be wrong. Just think about how many jobs Google, Apple and Microsoft have created around the world in just the last ten years. nine0003

Typically, a new technology creates more jobs and jobs than it destroys. When computers first hit the scene in the 1970s, the debate about job losses was almost as vehement as the talk of 3D printing today. And what happened? Most turned out to be wrong. Just think about how many jobs Google, Apple and Microsoft have created around the world in just the last ten years. nine0003

The main pessimistic point of view is as follows: the job market will be destroyed, the losses will amount to tens of millions. Automation of production, coupled with robotics and machines with artificial intelligence, will grow. The question is, will the development of 3D printing and other technologies lead to the massive disappearance of jobs?

Job losses in manufacturing

There is no doubt that many workers in various industries will lose their jobs. 3D printing methods are getting faster, more precise, and new materials are available, which means companies will soon be investing more and more in an automated workforce. Why pay ten workers on a conveyor line to assemble a product when a 3D printer can print parts with all the necessary parameters, and "smart" robotic arms assemble them into a product in a matter of minutes? And at the same time, the company's current expenses for new technologies will not exceed the costs of electricity and maintenance of machines. Undoubtedly, in some 15-20 years, production will change in the most radical way. nine0003

Why pay ten workers on a conveyor line to assemble a product when a 3D printer can print parts with all the necessary parameters, and "smart" robotic arms assemble them into a product in a matter of minutes? And at the same time, the company's current expenses for new technologies will not exceed the costs of electricity and maintenance of machines. Undoubtedly, in some 15-20 years, production will change in the most radical way. nine0003

Job losses in trade

Trade will also undergo major changes. Who wants to go to the store to buy fashionable shoes if their model can be simply downloaded from an open source on the Internet, add some edits of their own, and then send it to print right at home. And all this at the lowest possible price. We will probably have to wait another ten years, maybe a little more, until we can print shoes with the same material and the same quality that are now on the shelves in stores, but time is running very fast. People will start to lose jobs as owners will have to close their stores, they may also have to go online and offer digital models to customers at a very low price. nine0003

nine0003

It is more likely that many people who lose their jobs will not be able to find a new job. Jobs are likely to be lost by unskilled workers, while jobs created by new technology will be reserved for skilled workers and managers. As a result, income inequality will begin. The cost of higher education will fall sharply in the next ten years. There are already plenty of educational opportunities on the internet, such as the KhanAcademy, as well as free courses offered by popular universities and colleges. This means that those who want to get another education will be able to do it with a minimum investment of money. Well, now that we have gone through all the negative aspects, it's time to find out why we can be in the very epicenter of a giant economic boom. nine0003

New jobs created

Yes, many millions of jobs will be lost, but for every job lost there will be a few new ones. As manufacturers and retailers start laying off their employees, companies' actual costs will fall sharply. This trend will be passed on to the consumer. In turn, this can lead to the development of the economy, because the released money will be invested in new types of business, new developments, thereby contributing to the emergence of millions of new jobs. Let the ratio of jobs to GNP decrease, in general, the economy and GNP can grow significantly. This means that actual employment will also grow. Have you already noticed how many new jobs have appeared in the field of 3D printing? And their number will only grow in the coming years and even decades. We need people who can tune cars, assemble them, sell them, and run the companies that will do it all. In addition, there will be completely new professions. nine0003

This trend will be passed on to the consumer. In turn, this can lead to the development of the economy, because the released money will be invested in new types of business, new developments, thereby contributing to the emergence of millions of new jobs. Let the ratio of jobs to GNP decrease, in general, the economy and GNP can grow significantly. This means that actual employment will also grow. Have you already noticed how many new jobs have appeared in the field of 3D printing? And their number will only grow in the coming years and even decades. We need people who can tune cars, assemble them, sell them, and run the companies that will do it all. In addition, there will be completely new professions. nine0003

3D printing technology has launched a new wave of innovation that hasn't been seen in years. Today there are artists who are engaged in 3D modeling. There is a growing commotion in the design automation software market, which means that companies will need smart programmers in the near future. Those who can learn quickly will always find a job and will succeed.

Those who can learn quickly will always find a job and will succeed.

Jobs are returning home

The largest percentage of layoffs will come from mass-produced companies such as Foxconn, a Chinese manufacturer of electronic gadgets such as the iPhone. As manufacturing costs start to rise in China and fall in the US, for example (because machines can run around the clock for much less money), more and more jobs will begin to return to their home countries. In fact, we have already seen the beginning of this trend at Apple and Google. Let many jobs be occupied by machines, but someone will have to manage them, build value chains and oversee the work process. nine0003

You could ask a hundred economists what will happen when the 3D printing and robotics market matures and get a hundred different answers. We already know what the advent of technology has done in the past, how it has destroyed millions of jobs, but in the process of its development has contributed to the creation of tens of millions of new ones. It is unlikely that this wave of progress will take place in a different way. Or not? How do you think? Share with us your opinion.

It is unlikely that this wave of progress will take place in a different way. Or not? How do you think? Share with us your opinion.

Article prepared for 3DToday.ru

3D printers are able to "print" copies of objects and people

Computer technology is increasingly intertwined with real life. A real industrial revolution was made by 3D printers, capable of "printing" copies of any object and even a person. New technologies, in the development of which they began to actively invest in China, make it easier to realize their creative potential and allow dreams to materialize literally.

Unlike traditional printing methods, 3D printing is the process of creating three-dimensional solid objects with a dedicated digital printer. You can make a copy of not only any object, but also a person. nine0003

Shakhirezada Yeraliyeva, CCTV Correspondent-Russian:

"The digital model created by the scanner is edited in a special computer program. Then this model is reproduced by the printer. Printing is based on the layer-by-layer principle."

Then this model is reproduced by the printer. Printing is based on the layer-by-layer principle."

Shao Moyu, Director of 3D Printing Center:

"3D printing can be used in areas such as mechanical engineering, aviation, electrical engineering, medicine and construction, as well as innovative design. Materials for printing are very different: gypsum, nylon, metal, plastic, resin and others. nine0003

After a few hours, the copy is ready. Its quality depends on how accurately the scan was made. Copy sizes can be set to a variety of sizes, printing is also done by different types of printers, depending on the complexity of the job.

This innovation is called the industrial revolution, the prerequisites for which have been outlined for a long time. But since that time, 3D printing has greatly pushed the boundaries of possibilities, the number of components suitable as raw materials is growing, as well as the quality of the objects created is improving. The new technology has been tried in the creation of clothing, medical items, weapons, and in the near future, 3D printing will be used in the construction of houses. nine0003

nine0003

Shao Moyu, Director of the 3D printing center:

"This technology is not the latest, it appeared in the late 80s of the last century, and is more used in the industrial sector, so little is known about it in wide circles. By Compared with traditional manufacturing, 3D printing has the advantage of greater efficiency and lower costs.It cannot completely replace traditional manufacturing, but it has great development potential."

You can print not only a scanned object, but also an object drawn or copied on the Internet. This is how design studios began to work with 3D printing. Everything that they create in their head, and then on paper or in a computer, then the printer puts it into a solid form. With the advent of home 3D printers, it will be possible to purchase any item without leaving home. nine0003

Experts predict great prospects for a new type of industry, the performance of which is growing even in the stock markets.