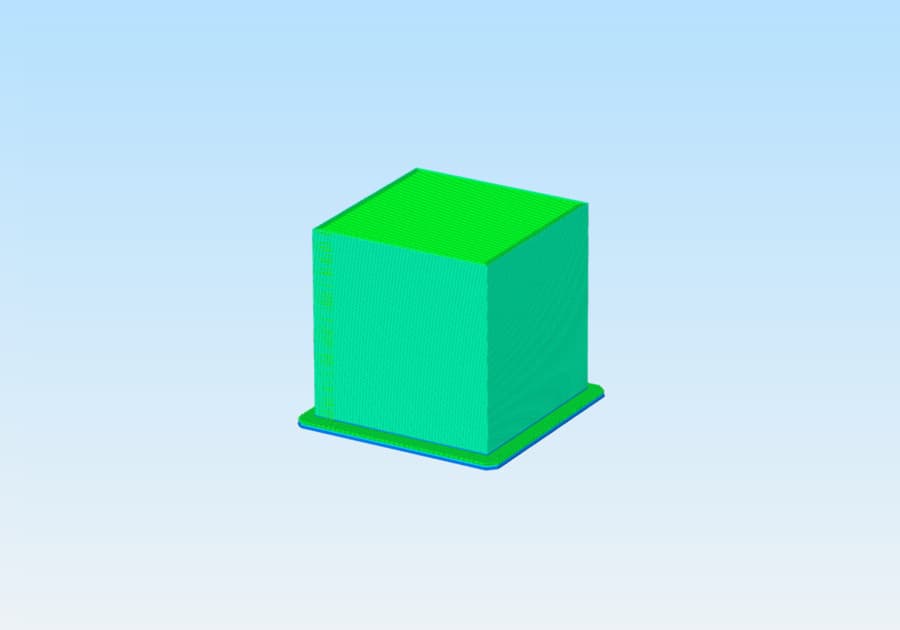

How to get raft off 3d print

How to Easily Remove Brims & Rafts From Your 3D Prints – 3D Printerly

When it comes to 3D printing, it can be difficult to get a good first layer without the help of rafts and brims, with certain filaments out there. Once your 3D print is complete, removing the rafts & brims can be troublesome.

I went out and researched how to best remove rafts and brims that are stuck to 3D prints.

You should implement settings that increase the gap distance between your model and the brim or raft structure that you use. Rather than forcing the raft or brim off, you can simply cut them off with the right tools, such as a flat-edged cutting tool.

Keep on reading for more details on how to easily remove rafts and brims from your 3D models, plus more.

What is a Brim & Raft in 3D Printing?

A brim, is a horizontal plane of material attached to the external dimensions of the model.

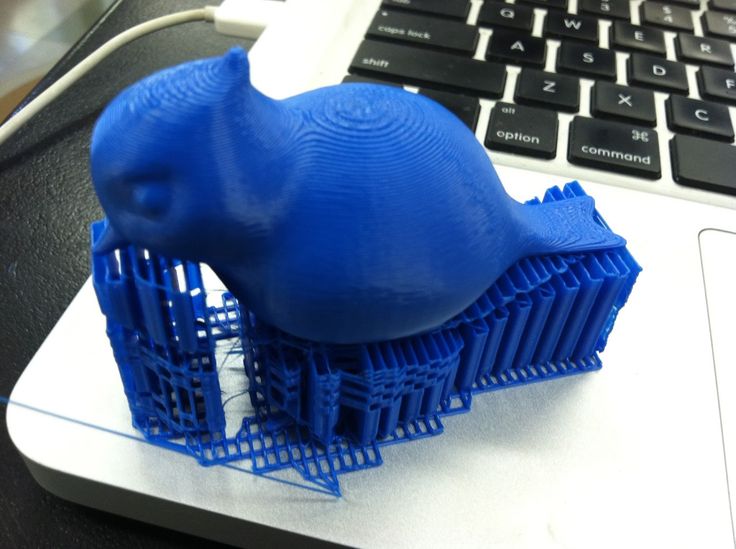

A raft is a horizontal layer of material that’s deposited on the print bed by the printer before printing the model.

Both these layers serve as the support or foundation on which the model is built on.

A raft covers the entire bottom of the model while a brim only extends out from the model’s outside. They are excess materials and are usually removed after the model is done printing.

They help increase bed adhesion, prevent warping, and provide extra stability for models that may be statically unstable.

Best Ways for Removing Rafts & Brims From 3D Prints

Rafts and brims are very useful during the printing process but after that, they are no longer useful. This is why they have to be removed.

Normally rafts and brims are designed to be easily peeled off, but sometimes they remain stuck to the model. I’ve heard many instances where people were unable to remove the rafts from the 3D print model.

When that happens, you have to be careful when removing them because using inappropriate methods can damage your model.

Let’s take you through the best ways rafts and brims can be removed without damaging the model.

Using The Proper Software Settings

Using the proper settings when slicing the model can make a world of a difference when it’s time to remove rafts and brims.

Most slicing software comes with its own presets for building rafts and brims but there are still some tricks and tips that can help make things easier. Let’s go through some of them.

There is a setting called the ‘Raft Air Gap’ which you can adjust to make the raft easier to peel off. It is defined as the gap beween the final raft layer and the first layer of the model.

It only raises the first layer by the specified amount to decrease the bonding between the raft layer and the model. Adjusting these type of settings in your slicer will make rafts a lot easier to remove, rather than requiring a special technique to remove it.

The Cura default for the Raft Air Gap is 0.3mm, so try adjusting this to see if it helps.

Make sure the top layer of the raft is built with two or more layers to achieve a smooth surface. This is important because the top layer joins with the bottom of the model and a smooth surface make it easier to remove.

This is important because the top layer joins with the bottom of the model and a smooth surface make it easier to remove.

It also gives the bottom of the model a good finish.

If the temperature of your material is a little too high, it can contribute to adhesion between your raft and model, so try lowering your printing temperature

Cutting The Rafts Off

Most people decide to use a needle-nose plier to remove rafts and brims from their 3D prints since they are really effective at removing the thin layers of plastic.

You want to get yourself some high quality pliers to get the job done as best as you can.

A great one that I can recommend is the Irwin Vise-Grip Long Nose Pliers from Amazon. They have a durable nickel chromium steel construction, along with ProTouch grip for extra comfort and ease of use.

They have great reach abilities to get into those harder to reach areas when needed.

Some people also use other tools like a flat-edged cutting tool, a putty knife or even a craft knife to pry away or cut at the raft or brim gradually. This isn’t advised over the needle nosed pliers because you may damage the model when cutting at the bottom of the model.

This isn’t advised over the needle nosed pliers because you may damage the model when cutting at the bottom of the model.

While you are removing the raft and brim from your model, you want to keep safety in mind the whole time. Make sure you are using the adequate safety equipment.

I recommend at least having some Safety Glasses and No-Cut Gloves from Amazon to protect yourself properly from any plastic that flings all over the place. This is especially recommended when removing supports from your models.

Click the glasses below to check out the Amazon page.

Click the gloves below to check out the Amazon page.

I wrote an article about How to Make 3D Printing Supports Easier to Remove which you can find a lot of useful information in, so feel free to check that out as well.

Sanding

After you remove rafts and brims from your model, you are likely to be left with rough surfaces, so we are going to want to clear these up. The best way to do that is by sanding the model, which also helps to remove those support bumps as well.

You can create amazing surface finishes when you start implementing sanding into your 3D printing regimine. Some people manually sand their prints, while others have sanding machine tools.

It’s up to you which one you choose.

Check out the WaterLuu 42 Pcs Sandpaper 120 to 3,000 Grit Assortment from Amazon. It has a sanding block to help you easily sand your 3D models and not have to fumble around with the sandpaper.

The electronic tool used for sanding usually comes down to a rotary tool kit which has small, precision pieces that attach onto the tool itself. The WEN 2305 Cordless Rotary Tool Kit from Amazon is a great choice to start with.

Use Soluble Materials

This is a great way to remove rafts and brims, especially if you have a 3D printer with a double extruder.

Certain filaments dissolve when they come in contact with some liquids. These filaments are very useful in building supports.

Filaments like HIPS and PVA can be used to build the raft or brim before printing the model. When the model is done printing, it is immersed in a solution (mostly water) to dissolve the rafts and brims.

When the model is done printing, it is immersed in a solution (mostly water) to dissolve the rafts and brims.

Gizmo Dorks HIPS Filament is one example that you’ll see people with dual extruders using as soluble materials. Many reviews mention just how great it works for raft/supports.

This is one of the best methods for removing these support structures without leaving marks on the model. It gets rid of any residual material that may still be on the bottom surface of the model.

If you want to check out some great dual extruder 3D printers, take a look at my article Best Dual Extruder 3D Printers Under $500 & $1,000

When Should You Use a Raft for 3D Printing?

Now that you know how to remove rafts from a model, do you know when you need to use them in the first place? The following are some reasons why you might need to use a raft for your 3D model.

Use a Raft To Eliminate Warping

When printing with some materials like the ABS filament, it’s possible to experience warping on the bottom of the model.

This is caused by the uneven cooling of the model. The part in contact with the print bed cools faster than the rest of the model causing the edges of the model to curl upwards.

Using a raft can help solve this problem.

When printing with a raft, the model is deposited on the plastic raft instead of the print bed. The plastic to plastic contact helps the model cool evenly thereby eliminating warping.

Get Better Print Bed Adhesion With a Raft

When printing some 3D models, they can have trouble sticking to the print bed. This can cause problems leading to print failure. With a raft, these problems are solved.

With a horizontal mesh provided by the raft, the 3D model has a greater chance of sticking to the raft. This reduces the chance of the model’s failure and also gives it a level surface for printing.

Use a Raft to Increased Stability

Some models usually have stability problems due to their design. These stability problems can come in many forms. It can be due to unsupported overhanging sections or tiny load-bearing supports at the base.

It can be due to unsupported overhanging sections or tiny load-bearing supports at the base.

With these types of models, using a raft or a brim provides extra support and also helps protect the models against failure.

How Do I 3D Print Without a Raft?

We have seen how useful rafts are and how they can be used to enhance your print.

But using rafts might not be best for some projects due to the material waste they generate and the problems that surface by detaching them.

Let’s take you through some ways you can still print your 3D models without using rafts.

Calibration and Maintenance

Some problems that require you to use a raft can be easily solved by proper calibration and maintenance of the printer. A dirty and poorly calibrated build plate can lead to poor print adhesion.

So before using a raft, consider cleaning your print bed—preferably with an alcohol-based solution—and checking your printer’s settings.

Using A Heated Build Plate

A heated build plate helps keep the model from warping and also ensures firm print adhesion.

The glass build plate works by keeping the temperature of the material just below the glass transition temperature, which is the point where the material solidifies.

This ensures the first layer stays firm and remains connected to the build plate. When using a heated build plate, the temperature of the build plate has to be controlled carefully.

In this case, it’s important to refer to the filament’s manufacturer and find the ideal temperature for the material.

Using Suitable Print Bed Adhesives

Bad print adhesion is one of the major reasons people often use rafts and brims when printing models. Bad print adhesion can be solved by using several types of adhesives.

These adhesives come in several forms like adhesive sprays and tapes. Several of the popular forms of adhesives used are printer tape, blue painter’s tape, and Kapton tape. All these promote print adhesion.

Proper Orientation of the Model

Some parts will require you to print overhangs, which inevitably call for foundational structures like brims and rafts.

However, all that can be avoided if your part orientation is on point. This factor is equally important as other crucial aspects of 3D printing are, such as print resolution, infill pattern, etc.

When your model’s orientation is done properly, you can cut down the need for rafts and brims and print without them instead.

To do this, calibrate your part orientation and try printing anywhere below the 45° angle mark.

I wrote a complete article on the best orientation of parts for 3D printing, so be sure to check that out for more details on this subject.

Use the Ideal Printing Material

Not every 3D printer material is created equal. Some require low temperatures to work with while some may demand you to go higher. At the end of the day, choosing the right material pays off heavily.

PLA, for instance, is an easy-going, biodegradable filament that does not necessarily require a heated bed, and is famous for experiencing low warping. This makes it easier to print with.

Now if we talk about a carbon fiber reinforced PLA, it has even more built-in structural support, therefore being great for more rigid prints.

However, you’ve got other filaments like ABS and Nylon which are well-known to be a lot harder to print with, mainly because they require a higher temperature and lead to being more prone to warping.

PETG is a popular filament for 3D printing, which is great for layer adhesion, though it has been known to stick to the bed quite harshly. If you are using a raft or brim with PETG, you could run into more issues than if you chose PLA.

Nonetheless, you can split a model into different parts so you don’t have to print overhangs that require rafts and brims.

Some people also get great results with bridging and overhangs when they use different types of filaments and brands, so I would definitely try out a few different types until you find your perfect filament.

An article I wrote discusses in detail the Best Filament To Buy on Amazon. Give that a read to find out more.

Give that a read to find out more.

Get a Good Build Surface

A good build surface is essential if you aim to get great quality prints. It provides your model with an even, flat surface on which the 3D printer can perform at its best.

If you want a perfect first layer too, a build surface that’s similar to the quality of PEI or BuildTak will go a long way for improving the standard of your prints.

Gizmo Dorks PEI Sheet 3D Printer Build Surface from Amazon is a great product that works for most users out there. This surface doesn’t need special prep.

All you need to do is peel back the tape liner and carefully place it ontop of your existing surface, borosolicate glass for example. It already has special 3M 468MP adhesive already applied.

One user described their 3D printer going from ‘zero to hero’, and after discovering this amazing surface, decided to not throw their 3D printer in the trash, and actually grow to love 3D printing.

Another user said its a great upgrade for the Ender 3, getting great adhesion consistently with their prints.

A build surface that isn’t worn out or dusty will make sure your prints are adhering to it properly. This will make the need for support structures out of the question.

Choosing the right build surface can seem very difficult for newcomers and experts alike at times.

This is why I’ve done an article where I discuss the Best 3D Printer Build Surface that you can get for your machine today.

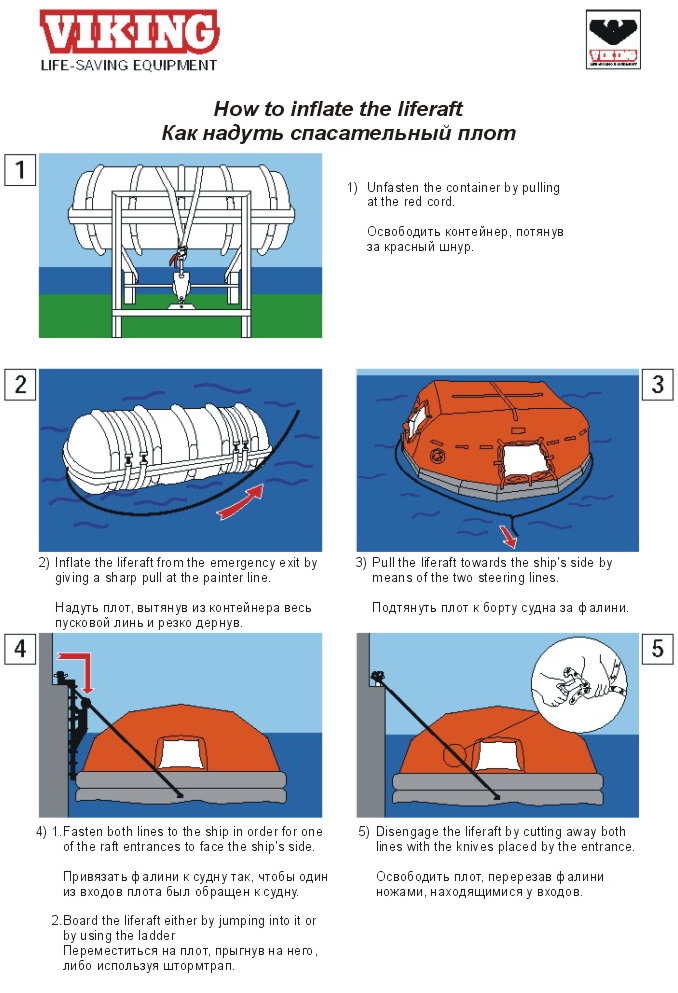

Guide to Dealing with Rafts that Won't Come Off

Most FDM 3D printers can print models on the raft, a flat structure made with the first few layers of filament to increase adhesion and dimensional accuracy. More intricate models also need additional support structures to keep overhangs from falling. In a single-extrusion 3D printer, the raft and support structures need to be manually removed from the model once the 3D printing is done. In most cases it’s a very simple step. But sometimes the raft and supports become so firmly attached to the model that it’s almost impossible to split them up. Here’s why it happens and how to deal with it.

Here’s why it happens and how to deal with it.

Stay Cool

The issue is usually caused by material’s overheating. If ambient temperature in the room exceeds 28°C, the extruded material does not have enough time to cool down. Facts Ambient temperature should be kept below 28°C. Proper platform calibration is very important. Layers bond too heavily when the material is overheated. As a result, the individual layers of the model become viscous, heavily fixed to each other and make the raft and support removal impossible. The next possible reason is platform calibration. If the distance between the nozzle and the platform has not been properly set, which means the platform and the nozzle are too close to each other, the material does not have enough space to be deposited. Thus, the material gets overheated and respective layers of the model bond with each other too much.Another probable reason is a clogged nozzle or hotend. When there are material residues in one of these parts, the extruded material gets overheated and causes the model’s layers to fuse with each other.

Hardware Issues

A simple part-malfunction can make the raft and support firmly bond with the model. The list of parts responsible for proper model-cooling includes: extruder fans,Facts Resistance on the heater exceeding 16 ohm can cause material overheating. Malfunctioning fans cannot provide proper material cooling. Replacement of the extruder’s printed circuit board or the motherboard is the last resort. the heater&thermocouple, extruder printed circuit board (PCB), extruder cable, and motherboard. When the extruder lower fan is not in a good condition, for example, its blades spin too slow or do not spin at all, the model is not accurately cooled down, and the raft and support structures are difficult to remove. Bu there are more possible reasons. If resistance on the heater exceeds 16 ohm, the heater&thermocouple will start to overheat the material.Additionally, when one of the extruder cable’s paths is broken, the cable can’t transmit appropriate information about the temperature from the motherboard to the PCB. Same thing happens when either the PCB the motherboard’s got damaged. If that’s the case, a proper extrusion temperature for a particular material is exceeded and the model gets overheated.

Same thing happens when either the PCB the motherboard’s got damaged. If that’s the case, a proper extrusion temperature for a particular material is exceeded and the model gets overheated.

Fix it Yourself

To prevent your models from overheating, it is important to provide suitable printing conditions by ensuring an ambient temperature stays in between 23 to 28 °C. Facts If side covers are used, try to 3D print without them. Overheating can be caused by a clogged nozzle. Nozzles clogged with ABS can be cleaned with acetone. If you have already encountered the problem and your printer is equipped with side covers, it’s best to remove them. Moreover, remember the platform should be well-calibrated. If you cannot reach proper calibration values, follow the platform maintenance procedure available at our Support Center that will allow you to remove material residues causing bulges under the perforated plate.

If you use ABS-based filaments, try cleaning the nozzle with acetone to get rid of material leftovers. In case you have used other filaments, it is recommended to install a new nozzle. If neither cleaning the nozzle or replacing it has helped, you should get a new hotend. Further, if any of the above-mentioned suggestions has not solved the problem, you need to consider replacing the heater&thermocouple together with the extruder PCB, then the extruder cable, and, as a last resort, the motherboard. That’s how you can deal with 3D printed rafts and supports that won’t come off.

In case you have used other filaments, it is recommended to install a new nozzle. If neither cleaning the nozzle or replacing it has helped, you should get a new hotend. Further, if any of the above-mentioned suggestions has not solved the problem, you need to consider replacing the heater&thermocouple together with the extruder PCB, then the extruder cable, and, as a last resort, the motherboard. That’s how you can deal with 3D printed rafts and supports that won’t come off.

Raft "Rafts", Brim "brims" and Skirt "skirts" - why they are needed and how to use them in 3D printing

Our first layer is the most important

It is widely believed in the 3D printing community that how smoothly and correctly the printing of the first layer went, determines the success or failure of the object as a whole. In most cases, achieving proper adhesion of the first layer to the work surface is 90% winning the battle.

We all know this feeling when you carefully follow how the first layer is laid out, look at how it looks, whether it adheres well, whether the filament flows smoothly . .. And now it's time to invite such tricks to the stage as “ rafts", "fields" and in some way "skirts". nine0005

.. And now it's time to invite such tricks to the stage as “ rafts", "fields" and in some way "skirts". nine0005

Of course, you know that a filament that does not adhere well to the work surface can cause a lot of problems, and an ambush can happen, if not at the very beginning, then at the very end, when you remove from the work surface, it would seem , a beautifully printed object, but only to see that it is somehow skewed, that its corners are somehow strangely twisted.

It's a waste of filament, a waste of money and finally a waste of your time.

And here you may ask: "So how can "rafts" or "fields" radically improve the quality of the first layer in this way?". In this article, we will look at "rafts", "fields" and their sister, "skirt", what they are and how they are best used.

We'll also talk about lesser-known ways to help you deal with other printing problems, such as over or under extrusion and even internal cracking.

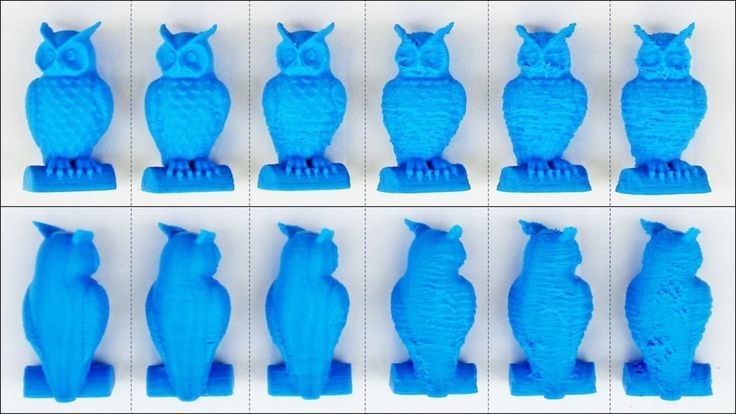

From left to right: "raft", "fields" and "skirt" (Simplify3D screenshot)

What is a "raft" in 3D printing?

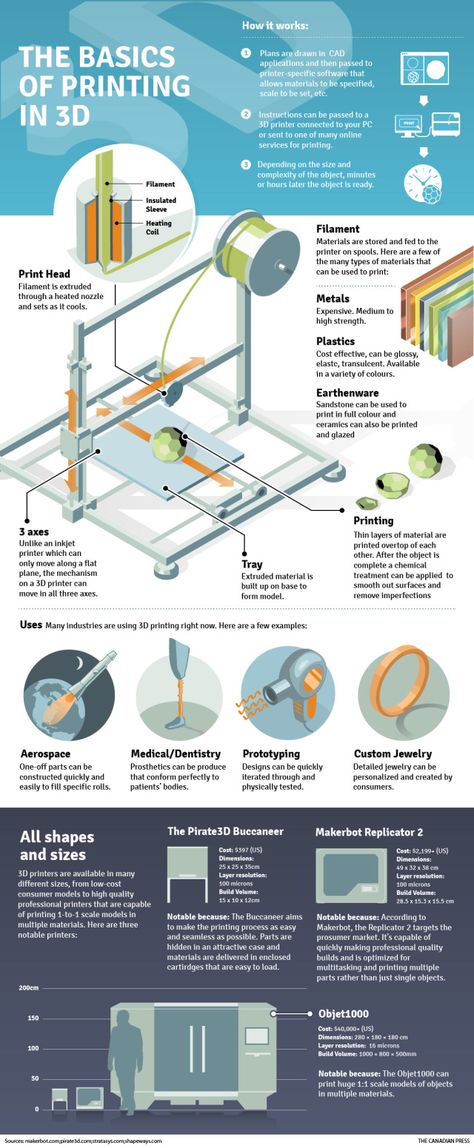

Raft A "raft" is essentially a temporary horizontal surface that sits underneath your object.

It consists of a set number of layers with a specific infill percentage and covers an area slightly larger than the base of the printed object.

The main task of the "raft" is to increase the grip on the work table. Some materials such as ABS benefit greatly from the use of a "raft". Then, first, a “raft” consisting of a certain number of layers is laid out on the desktop, and a printed object is already being built on it. nine0005

You don't have to worry about how to separate this plot from the printout: there is a small gap between the plot and the object, so if you set the plot parameters correctly (we'll explain how later), with its separation after cooling there will be no problems.

Since the printed area of the raft is larger than the base of the object, the cohesive forces generated are also greater. This also reduces the risk of the object being skewed, because the edges of the raft are more likely to be bent, but the bottom of the printout itself will remain flat. nine0005

nine0005

Raft can also be used to provide more stability for objects with a small footprint. In this case, the "raft" acts as a "normal" base. This technique is also useful when printing large objects or objects that can end up quite heavy.

The "raft" can also compensate for small inaccuracies in the calibration of the desktop and even bumps, scratches and dents in the coating.

Here are a few slicer parameters you can play with to get a quality raft without using too much material to create it. nine0005

- Separation Distance. This is perhaps the most important parameter. It defines the width of the gap between the surface of the "raft" and the base of your printout. It is necessary to achieve a balance between ensuring that the printed object is held securely enough on the “raft”, and making it easy to separate it later. Usually 0.1 mm is sufficient, but for more ductile materials this distance can be increased.

- Above Raft Speed.

We are talking about the speed with which the first layer will be laid out on the surface of the "raft". The speed must be low to ensure good grip. nine0048

We are talking about the speed with which the first layer will be laid out on the surface of the "raft". The speed must be low to ensure good grip. nine0048 - Raft Top Layers. This is the number of layers on the surface of the raft. The base of your object will be in contact with this surface, so you need 2-3 coats to get the surface smooth enough. You can increase the number of layers if you get blistering on the bottom of the printout.

- Raft Base Layer. This is the very first layer of the "raft", it prints slowly. It is important that it sticks well to the desktop, otherwise everything will be pointless.

It should be noted that for some FDM printers the use of "rafts" is always mandatory, and for some it is not required at all. For example, Zortrax printers use a heated perforated work surface. Due to the presence of perforation, the "raft" should be used when printing any objects.

On the other hand, solid surface printers very often do not require a "raft" because the temperature of the desktop is already so high, which contributes to a significantly better adhesion and, accordingly, a reduction in spatial distortion of the printout. nine0005

nine0005

Certain drawbacks of the "rafts" are that with some slicer settings these "rafts" can be difficult to separate, especially from objects made of more plastic materials, and also that the bottom of the object is not as glassy smooth as in the case of a solid working surface.

And, of course, the fact that you have to print some kind of “raft”, which is then immediately thrown away, can be annoying – and the filament was of high quality! But it must be borne in mind that in some cases, without the presence of a "raft", the path to the wastebasket is prepared for the entire printout in general. nine0005

It is best to separate the "raft" from the finished object with the same tool as the one with which you separate the printout from the work surface. Slide a thin plate or wide knife between the base of your object and the "raft" and gently lift from one side. Once one end of the "raft" has come off, the rest will come off more easily.

If the separation process was not without difficulty, you may need fine sandpaper, about 400 grit, to sand the base of the printout. nine0005

nine0005

In some cases, it turns out that the only way to make the printed object stick to the desktop is with the help of a “raft”, nothing happens when printing directly onto the surface. This can happen because, at default settings, the raft prints more slowly, has a thicker first layer, and the fans are turned off.

In this situation, you can try to print without a "raft", simulating its settings when printing the first layer, which should increase adhesion. nine0005

What is a "margin" or "side track" in 3D printing?

Brim "Fields" can be considered close relatives of "rafts".

As mentioned earlier, a "raft" is a stabilizing base on which the printed object is placed completely in order to improve adhesion.

"Fields" take place only along the perimeter of the object, not in contact with its base. It turns out that "Fields" is like a hat that a person puts on so that a clever thought comes to his head. nine0005

Both "rafts" and "fields" promote cohesion, sticking. Any of these techniques can be used to stabilize an object that has very little contact with the work surface. However, for smaller and more fragile objects, "fields" may be preferable, since they are in contact with the object only along the outer edge of a very thin layer.

Any of these techniques can be used to stabilize an object that has very little contact with the work surface. However, for smaller and more fragile objects, "fields" may be preferable, since they are in contact with the object only along the outer edge of a very thin layer.

Margins work better for some materials than others. For example, ABS, if the print settings are inaccurate or there are issues with the work surface, may warp (the same effect is achieved when working with just cheap ABS). Therefore, in order to increase grip, it makes sense to reprint the ABS-parts of the “field”. And even more so in the case of supporting structures, if they are installed closely and low. nine0005

The "margins" are easily separated from the work surface, so it's better to print with "margins" just in case of supports. This is especially true for props with weak adhesion. As you might guess, the “fields” are made in such a way that they can be easily broken off from the model after printing is completed, and it would not be necessary to grind or solvent-treat its base, as, for example, in the case of soluble supports made of PVA or HIPS.

In other words, it is easier to separate the "fields" from the object than to separate the "raft" from it. This, in turn, means that there is less chance of damaging the object during detachment. nine0005

And if there are any rough spots on the printout, they are very easy to clean up. Margins are also excellently removed with special deburring tools.

What is a "skirt" in 3D printing?

Skirt "Skirts" are more common than the two previous options.

The slicer most likely adds a "skirt" at the start of any printing process. The "skirt" is nothing more than "fields", which, however, do not come into contact with the printed object.

"Skirts" have a couple of uses and are usually a couple of layers thick. Firstly, the “skirt” is good for getting an idea of how the equipment works, how the material flows, i.e. before starting to print the model. it allows you to make sure that everything is fine with extrusion and the filament is laid out on the work surface correctly. nine0005

nine0005

You simply lay out the “skirt” with a few lines at a relatively low speed and, by the way it turned out, make a diagnosis. If the "skirt" is printed clearly, you can continue. If not, it is better to interrupt the process and what needs to be adjusted, thus saving time and money.

"Skirts" can also serve as a temperature barrier. The "skirt" can be laid out over the entire work surface to thermally insulate it, leaving only the place where the higher temperature should be maintained. nine0005

Or another option: if, for example, you need to isolate the printed object from temperature fluctuations in a draft.

Rafts, brims and skirts are some of the easiest ways to avoid bad grip and skewed print.

For example, printing with ASA UV-resistant filament (like ABS) is very sensitive to rapid cooling, and if there is a draft during cooling, the part may simply crack.

The height of the “skirt” is also possible, it can even be as high as the object itself. This kind of "skirt" will protect the printout from drafts, ensuring uniform cooling. If a "skirt" is used in this way, it may be called a "draft screen". nine0005

This kind of "skirt" will protect the printout from drafts, ensuring uniform cooling. If a "skirt" is used in this way, it may be called a "draft screen". nine0005

Finally, if the printer has a dual extruder, an object-high "skirt" can be used to avoid "spider webs" and "blobs". The "skirt" will catch any material that may be escaping from the second extruder before it travels to the object. Then the "skirt" can be called a "leak shield".

Rafts, brims and skirts are some of the easiest ways to improve print results. Yes, you will have to spend more filament, but you will also have to spend it on unsuccessful printouts, which can be avoided with rafts, fields and skirts. nine0005

If you're interested in improving print reliability, you might like our Quality Printing Cheat Sheets, which will come in handy when working with any 3D printer and any material. In them you will certainly find some very useful tips that will improve your printouts, no matter how experienced you are in this matter.

In short, a few supportive preventive measures in the form of "rafts", "fields" or "skirts" give a good chance that your efforts will result in a great result. nine0005

A little trick in Cura. A skirt instead of a border

Personal diaries

Follow the author

Subscribe

Don't want

3

hello everyone

in cura there are several types of sticking to the table: border and skirt.

So here are some complex models, for printing, for example, with ABS plastic, you need to print with a border, but despite the checkbox "print border only outside" is on, the following picture is observed:

The border inside will interfere and it is inconvenient to remove it, and indeed it should not be so.

If you put a skirt on, the picture looks like this and with normal settings it will not help printing ABS, or rather it will not resist coming off:

costs 5 mm.

You can set this parameter to 0-0.1, then it will act as a border and there will be no extra lines inside the model. Looks like this:

At the time of writing I'm using Cura 4.1 slicer. Link to the model in the slicer: https://www.thingiverse.com/thing:53451

Cura Settings Border Skirt

Subscribe to the author

Subscribe

Don't want

3

Article comments