3D printer commercial uses

Whats New in Commercial Uses for 3D Printing

Growth of the 3D printing industry is unlikely to slow down any time soon, with 2020’s market totaling $15.4 billion worldwide and projections for 2024 exceeding $34.9 billion. With more and more companies dipping a toe in the waters of this technology, commercial uses for 3D printing are only as limited as the imagination. Learn how this tech is changing almost every major industry and what you can expect in the near future.

What is 3D printing?

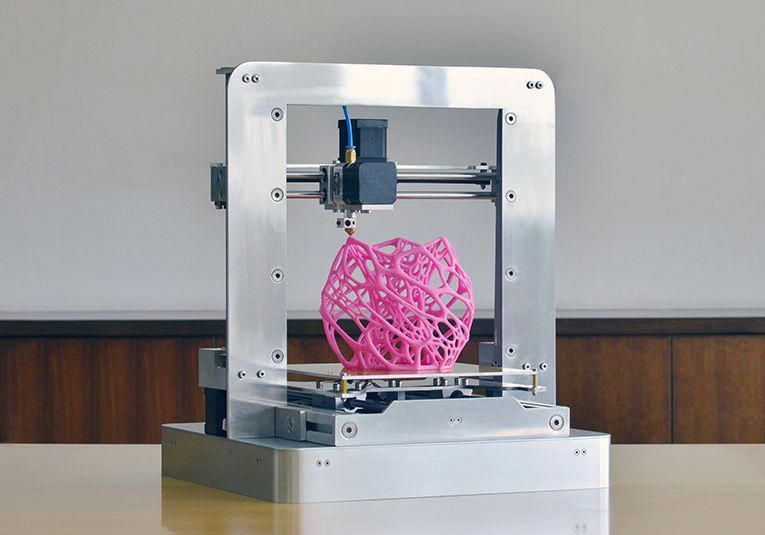

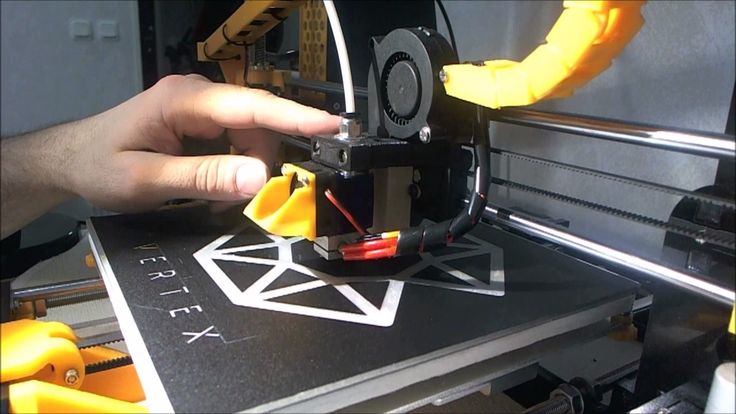

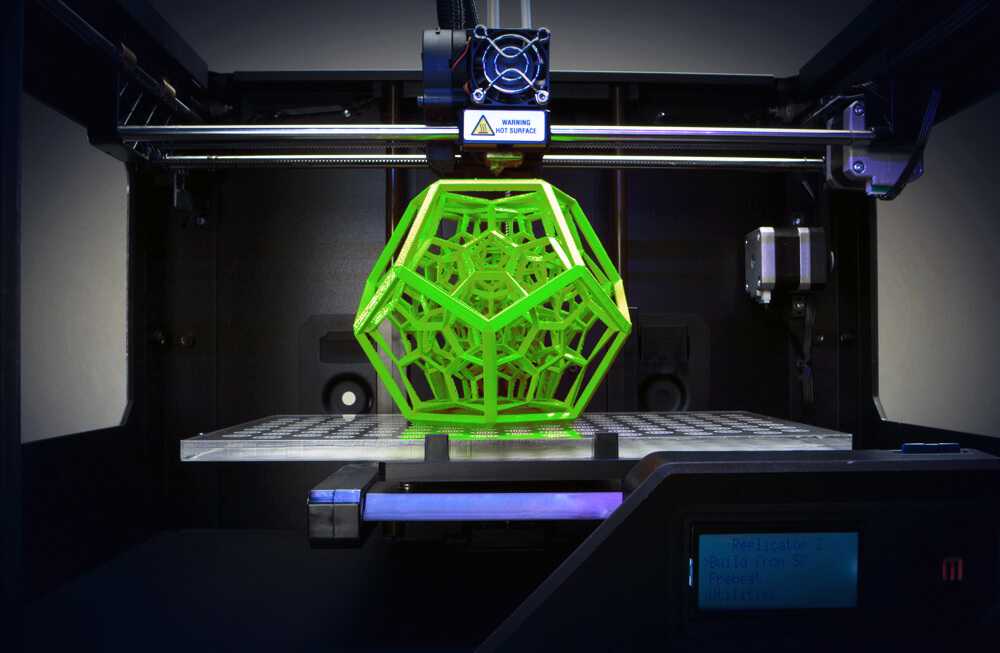

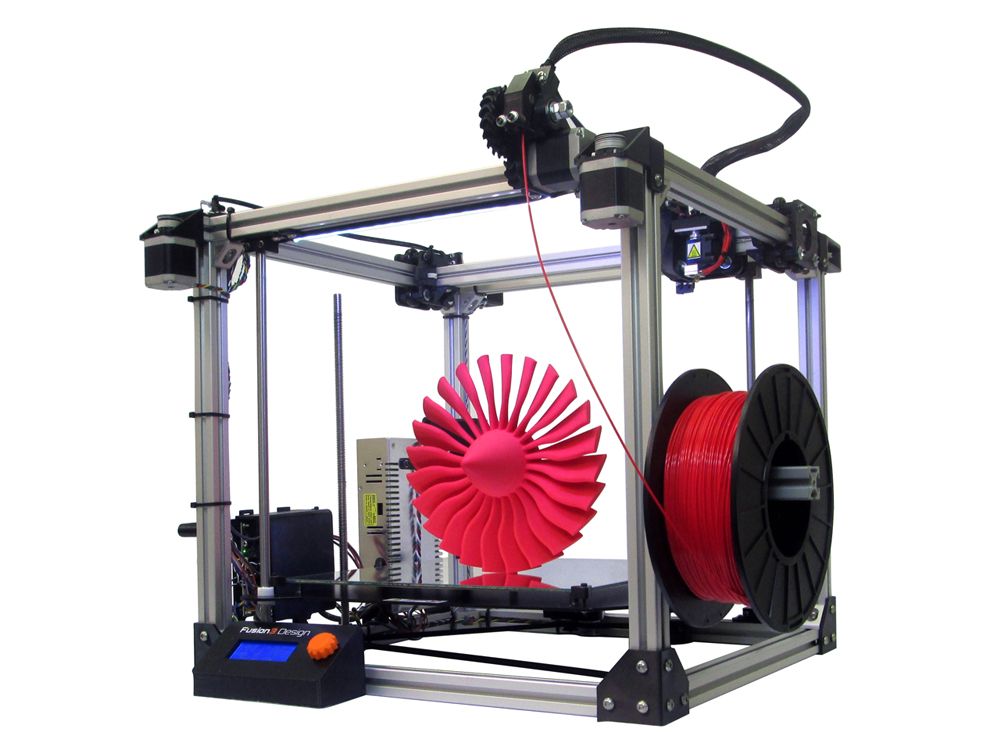

3D printing is the process of using a 3D printer to turn digital files into three-dimensional objects. While the actual production varies among several methods, the most common process uses a roll of string-like filament that is pushed through nozzles, much like ink from an inkjet printer.

The filament material is laid down on the print bed in thin layers, over and over, building on itself, until the entire shape comes to life. Common materials used in 3D printing include PLA, ABS, and nylon, but some even use metal or wood in a particle-board application.

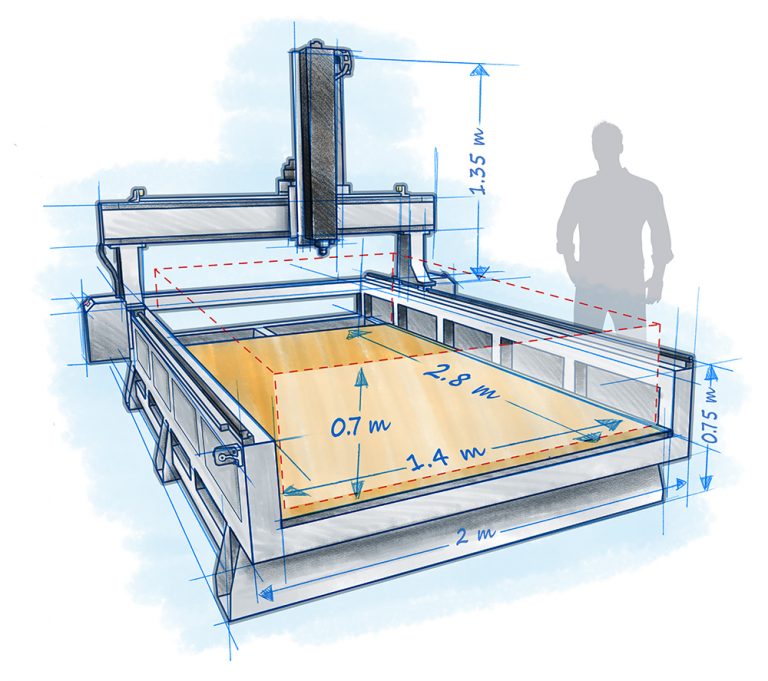

Because the 3D object is created by a continued “adding up” of the layers, it’s considered an “additive” method of creation. Other 3D printers may combine this additive method with a cutting away of material, similar to CNC (Computer Numerical Control) machines, also called “subtractive” method.

3D printing materials from HP

Polymers are among the strongest and most versatile materials, and they are now available from HP. The rigid polymer family has applications in auto accessories, robot arms, and assembly fixtures, or anywhere you need durable, inflexible parts with a low cost per part.

Elastomeric 3D printing polymers bring flexibility to your next project, with applications in lab gear, PPE, and specialty parts that need to give under pressure and resist abrasion.

What about 4D printing?

Yes, 4D printing is now happening, too. This type of printing is largely in the research and development phase, and it features time as the “fourth dimension. ” Objects printed with 4D characteristics are built to shift to new objects or take on new characteristics over time, usually when subjected to light, heat, or other external conditions.

” Objects printed with 4D characteristics are built to shift to new objects or take on new characteristics over time, usually when subjected to light, heat, or other external conditions.

How business 3D printing differs

In the past, 3D printing was mostly done by tech-obsessed, wealthy hobbyists, or cutting-edge companies. But as it becomes more commonplace and easy to use, every-day businesses have stepped up their 3D printing game to do some exciting things.

What are 3D printers used for in business?

Business printing stands out from both high-end R&D and amateur printing in that it fills many pieces of the production cycle. These include anything from initial prototyping to creating the repair parts that may be used to fix actual products.

An electronics manufacturer, for example, could use 3D printing to make a sample for prototyping and then create an entire line of repair parts for retailers and consumers to self-service their own goods.

3D printing and manufacturing are closely tied, and the method is used for a variety of business niches. Jewelry, collectibles, toys, art, appliance repair, office supplies, and organizational materials companies can all benefit from 3D printing.

It may not be profitable to use 3D printing in large-scale volumes of the same item, but it does make sense for custom, limited-edition products. Plus, you can use it to print products that may not warrant the traditional, molded material method.

3D printing now gives even small businesses a way to better serve their customers’ needs. They can make their own limited-run parts and pieces rather than 1) not providing them at all, or 2) outsourcing to another company where intellectual property concerns or cost may become a problem.

New trends for 3D printing in 2021

3D printing capabilities change every year. And as more businesses incorporate the tech into their processes, expect it to evolve even faster. What are major trends in 3D printing applications for industry? What can we look forward to in the near future? Here are some developments worth keeping an eye on.

1. SLM (selective laser melting)

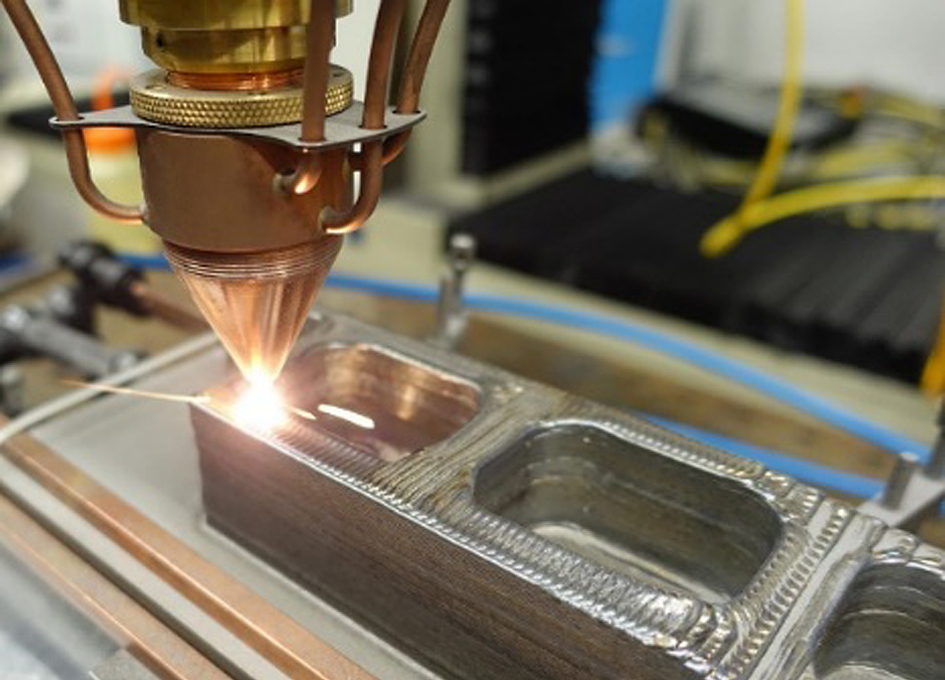

Until now, one of the most proven methods of 3D printing metals is by using metallic powders, then fusing them together with lasers. The process, called selective laser melting (SLM), is a huge opportunity, but the objects printed are prone to cracks and fissures.

With the development of an additional laser treatment, called laser shock peening (LSP), imperfections and weak spots in the newly-formed metal layers can be fortified. As the object is being built, the LSP laser’s “shock treatment” works in harmony with the SLM laser to create metal structures strong enough for use in everything from aeronautics to wind turbines.

Multi-jet fusion (MJF) technology allows for detailed prints other methods can’t match and carefully layers molten material atop another still molten layer, fusing the two together. This additive method creates particularly intricate builds and the potential for embedded electronic circuitry.

Popular in the automotive industry due to its ability to support high-volume metal products with a low per-piece cost, Metal Jet Printing has created a space for everything from custom Key-fobs to impeller parts that previously needed to be created through a more costly casting process. Metal jet supports small-scale detailing and with the strength of common metals.

2. Printing of super magnets

Super magnets are an integral part of today’s machines. They’re used in electric motors, wind power stations, and numerous other applications. The current molding process is limited in how detailed each magnet can get because these often-tiny magnets must be made to exact specifications in order to work properly. With the magnetic material ground down into powdered form, 3D printers can create them through SLM, allowing more flexibility and intricacy of design than ever before.

3. Liquid integrations

Current 3D printing tech allows for some customizations as the build is taking place, such as coloring, which often occurs with liquid hues that are heated just long enough to be extracted but solidify upon cooling. The latest in liquid integrations make even more fluid types possible.

The latest in liquid integrations make even more fluid types possible.

While it’s in the early stages, scientists are also testing ways for pharmaceutical drugs to be integrated into solid builds. Manufacturers can add luminous materials, as well, which have the potential to reveal structural damage to a product over time.

4. Advances in 3D printed food

Custom-printed chocolates and pizza are making their way into homes and restaurants through the magic of 3D printed food. Soon, we may see meat alternatives printed into meat-like shapes for those who want to avoid eating meat.

Another exciting reality? Nutritious food supplements that taste, smell, and look like actual foods, so they’re more likely to be consumed. Food can look like anything you want, thanks to 3D printing possibilities.

5. Changes in the beauty and cosmetics industry

3D printing may just ensure that form and function co-exist in new ways within the beauty industry. The tech prompted an innovative mascara brush, which is designed to be more comfortable for the eye. Expect more beauty brands to follow Chanel’s lead of going all-in on 3D tech with razors, hairstyles, and even piercing trends seeing the potential.

Expect more beauty brands to follow Chanel’s lead of going all-in on 3D tech with razors, hairstyles, and even piercing trends seeing the potential.

6. Medical and life-saving trends

There are some amazing new trends in 3D-printed insteps for orthotics, but could there be even more to come? How about solutions that empower patients and boost longevity? So much is happening in this space, and it’s just a matter of time before “replacement parts” for the human body are just another day's work for the 3D engineer. Prosthetics are one category taking 3D printing to the ceiling. Could heart valves or tracheas be close behind?

7. DIY supplies

As the COVID-19 pandemic forces more consumers to fix things themselves, 3D printing can bridge the gap and help recoup some of the revenue lost when consumers don't bring appliances or items in for repair.

Selling 3D printed parts along with instructions, such as a custom video or a printed guide, can help give customers what they want in this socially-distanced world. It’s also another revenue stream for manufacturers who don’t want their customers buying knock-off replacement parts from third-party sellers.

It’s also another revenue stream for manufacturers who don’t want their customers buying knock-off replacement parts from third-party sellers.

Benefits of 3D printing for companies

There truly is no way to tell which of the upcoming 3D printing developments will offer the best ROI, but these advantages make it worthwhile to consider adding 3D tech to your repertoire.

1. Cost savings

What can 3D printing do to sweeten your bottom line? Companies are already using these printers to cut the price of parts shipping and inventory requirements since you can print just what you need and reduce overhead on custom-items.

There's also a significant benefit in prototyping your own new products compared to outsourcing. If you 3D print instead of using a mold or cutaway method, you'll potentially go through less raw materials and produce less waste.

2. Time savings

It can take weeks or even months to send off prototype specs to a specialized company, get the model back, and continue refining the outcomes to get just the right prototype. Why deal with all the back and forth when you can just do it all in-house in less time? Plus, you'll get the added benefit of keeping your intellectual property with you at all times.

Why deal with all the back and forth when you can just do it all in-house in less time? Plus, you'll get the added benefit of keeping your intellectual property with you at all times.

3. Durability improvements

3D printing isn’t what it once was, and new materials mean the sky’s the limit on creating a solid structure that looks good and lasts longer. Rapid changes in manufacturing mean customers will expect products to reflect the best of materials available, and 3D printing can offer solutions to these demands without reinventing entire manufacturing lines.

Summary

It’s hard to see what the future holds with 3D printing because it advances so rapidly. Researchers (like the ones who discovered liquid integration) will show us what’s possible. Then, it’s up to keen business minds to determine if it’s a profitable risk to use new tech as it’s developed.

Even for the cautious adopter, it’s wise to keep your eyes on the world of 3D printing. Watch for changes that could solve your most pressing issues, potentially at a lower cost and with less hassle than the way you’re doing it now.

About the Author: Linsey Knerl is a contributing writer for HP Tech Takes. Linsey is a Midwest-based author, public speaker, and member of the ASJA. She has a passion for helping consumers and small business owners do more with their resources via the latest tech solutions.

Popular HP Products

3D Printing Applications for Business

- 3D printing can help your business with prototyping or low-volume manufacturing. It also has applications in design, biomedical devices and mechanical parts.

- You should guarantee your supply chain and product quality to protect against unlicensed 3D printing. You should also hire only people with skills and experience relevant to your 3D printing projects.

- Your small business could benefit from a 3D printer, such as the Original Prusa MINI, Ultimaker S3 or Anycubic Vyper.

- This article is for small business owners who manufacture products and are interested in 3D printing.

Manufacturing plays an essential role in the lives of many entrepreneurs and small business owners. As technology continues to improve, new methods of manufacturing continue to emerge as viable methods for small- and mid-scale production. Among these is 3D printing, and its widespread use in manufacturing has grown in recent years.

Just because 3D printing is an exciting way to manufacture doesn’t mean it makes sense for your business. There are still issues regarding cost and speed. In addition to the drawbacks, rumors constantly pop up discussing “the next big thing” in 3D printing.

With a lot of misinformation surrounding the future of 3D printing, we turned to experts to develop a clear picture of how 3D printing can help your business and determine what the future of 3D printing holds.

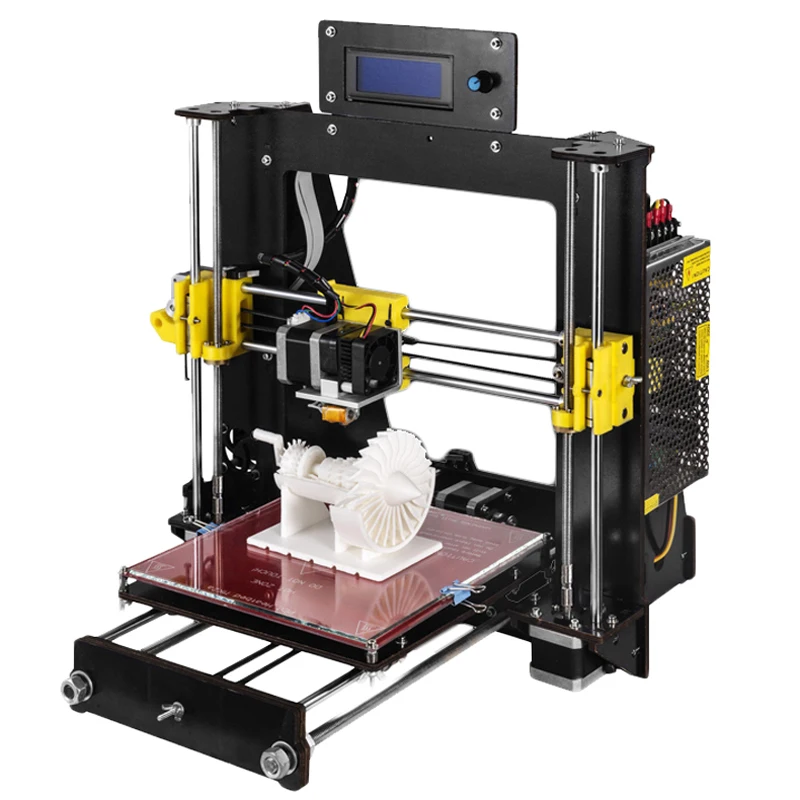

What is 3D printing?

3D printing is the process by which three-dimensional digital models are made into physical objects. Working in tandem with computer software, the 3D printer reads a digital STS file on a computer and then uses a filament or a resin to render the digital representation in tangible material, layer by layer.

3D printers employ a variety of materials, including plastics and polymers, steel, titanium, gold, and ceramic. This versatility means 3D-printed models can be used for various objects, including artistic sculptures and airplane components. Some 3D printers can even print proteins and chemicals, enabling the devices to create foods and medicines.

“I don’t think there’s a component made today that won’t somehow be touched by 3D printing in some fashion or another, whether directly or indirectly,” said Mark Cola, former CEO of 3D printing company Sigma Labs.

Developments in the industry continue to arise. In fact, Statista projects the global 3D printing industry to reach $37.2 billion in 2026. That’s more than double the 2022 projection of $17.4 billion. Still, 3D printing is predominantly used for just a handful of project types.

Did you know? The 3D printing industry could more than double in size by 2026, according to market projections.

Applications for 3D printers

Prototyping

One of the oldest uses for 3D printers is the quick and efficient creation of prototypes. Since the printers were invented in 1983, companies have employed 3D printing to create a workable model of their desired end product, either to test the concept or present it to future investors.

Since the printers were invented in 1983, companies have employed 3D printing to create a workable model of their desired end product, either to test the concept or present it to future investors.

“Before we called it ‘3D printing,’ it was called ‘rapid prototyping,'” said Greg Paulsen, director of applications engineering for third-party manufacturer Xometry. “It was seen as a way to get close enough to a functional model.”

Now that’s changing. While entrepreneurs still gladly use 3D printing for prototyping, the technology has become more accessible and adaptable, leading to new applications.

“The main development I’d summarize is moving from a primarily prototyping solution, currently the killer [application] for 3D printing, to end-part production,” said Filemon Schoffer, co-founder and CCO of online manufacturing platform Hubs. “This is already happening but will continue to accelerate.” [Related: How to Test a Business Idea]

Low-volume manufacturing

Though 3D printers can be slow, they’re adept at fulfilling low-volume production needs. Much like with prototyping, if an entrepreneur is ready to launch a new product and isn’t certain of the demand, they can print a small amount to test the waters. Low-volume production is also common for medical devices, for example, as manufacturers create, test and redesign their products for optimization.

Much like with prototyping, if an entrepreneur is ready to launch a new product and isn’t certain of the demand, they can print a small amount to test the waters. Low-volume production is also common for medical devices, for example, as manufacturers create, test and redesign their products for optimization.

While low-volume manufacturing suits the capabilities of 3D printing, advances in technology make 3D printing a viable option of higher-volume production. Small businesses should consider the potential value of 3D printing in the mass customization of goods.

“Currently, 3D printing is mostly used in industries and applications with low-volume, high-unit cost and the need for customization, where costs of 3D printing are outweighed by the benefits,” said J. Scott Schiller, global head of customer and market development for HP Inc.’s 3D printing business. “However, [technological] improvement has been pushing the limits of the technology and unlocking its use in mass production applications. In the next five years, we’ll see part design become more function- and volume-oriented, and 3D printing will begin to fit into production systems across industries.”

In the next five years, we’ll see part design become more function- and volume-oriented, and 3D printing will begin to fit into production systems across industries.”

Mechanical parts

Another beneficial use for 3D printers is the creation of mechanical parts – either for sale in large industries or for personal repairs. Many products of 3D printing aren’t sold directly to consumers, but are created by companies – or third-party contractors – as components of a larger project. One example is GE Aviation’s 3D-printed fuel nozzle, which rolled out in 2015.

Small machine shops or individuals looking to make home repairs can also employ the same techniques for their projects. 3D printing has made it far easier to reproduce parts for machines that might no longer be in production or would take too long to arrive.

Biomedical devices

One particularly exciting aspect of 3D printing is the ability to print biomedical devices customized to individuals. For example, some companies are developing 3D-printed, custom prosthetics for amputees; these prosthetics are designed to be far more comfortable for the user.

For example, some companies are developing 3D-printed, custom prosthetics for amputees; these prosthetics are designed to be far more comfortable for the user.

“[Biomedical engineers are] 3D printing components for people that better match their characteristics than the off-the-shelf components,” Cola said. “I think where you see this tech going is more toward the performance and athletic side of the business, where you have athletes fully regain their performance levels after injuries, or maybe even enhance their performance levels with 3D components tailored to their needs.”

Other notable uses of 3D printing in the healthcare space are in ongoing efforts to develop printable organs for patients in need of transplants, and the printing of chemicals and proteins to develop new medicines.

Design

When engineers design a product, they must keep in mind the limitations of the production process. 3D printers can create parts previously considered unachievable with traditional manufacturing techniques. This opens an entirely new world in the design phase, which can lead to better, more efficient products and components. Many of these 3D-printed creations add value to important products, while others are downright unusual.

This opens an entirely new world in the design phase, which can lead to better, more efficient products and components. Many of these 3D-printed creations add value to important products, while others are downright unusual.

“It opens your mind up to everything you can do with it,” Paulsen said. “I’d really like to take this technology off the pedestal and say, ‘This is a normal manufacturing process,’ just like anything else.”

Copyrights and 3D printing

As 3D printers proliferate, so do the means of easily reproducing protected intellectual property. Roy Kaufman, managing director of business development and government relations at Copyright Clearance Center, warns that the manufacturing industry could be approaching its “Napster moment.” By that, he means the experience of the entertainment industry when music and movies could be quickly reproduced and pirated online.

“I think we’re going to see, as we see with almost every technology, two things happen: Things get cheaper, and they get better,” Kaufman said. “As the quality of the printers gets better, the available materials to print get better, and as costs come down, you get to that moment – the Napster moment. [That’s] when the means of reproduction are now so diffuse, the ability to reproduce at a low cost had been so spread out, that you can no longer really enforce your rights entirely effectively with existing IP [intellectual property] laws.”

“As the quality of the printers gets better, the available materials to print get better, and as costs come down, you get to that moment – the Napster moment. [That’s] when the means of reproduction are now so diffuse, the ability to reproduce at a low cost had been so spread out, that you can no longer really enforce your rights entirely effectively with existing IP [intellectual property] laws.”

That moment could be coming quickly, Kaufman said, or it might not come at all. However, the mere fact that 3D printers are becoming more widespread makes it a plausible scenario that requires appropriate strategic planning. Kaufman suggested insulating your company by guaranteeing your supply chain and the quality of your products.

Tip: Protect your products from unlicensed 3D printing by guaranteeing your supply chain and your product quality. Also take measures to make sure your own business doesn’t accidentally steal intellectual property.

“[The consumer] might pay a premium for the assurances of the supply chain,” Kaufman added, “but they want to know that it’s not just a matter of what [the product] looks like but that it’s right. Testing and certification will become more important.”

Testing and certification will become more important.”

Within these major developments, there also lies opportunity. 3D printing will allow manufacturers to license the rights to their designs, which could be made downloadable to the licensee to 3D print. The technology could also bring production levels more in line with demand, thereby saving on production, shipment and storage costs.

“If you look at a typical pharmacy, for example, they have all these medicines with a sell-by date and are hoping someone will come in and need a prescription for it before they have to throw it out,” Kaufman said. “They pay to store it, pay to save it, and maybe even have to keep it in a central warehouse. But imagine your local CVS can print everything under license, get the chemicals from the pharmaceutical company, and maybe even [the] machine. The company doesn’t have to make things that might never get taken, never has to ship them, and never has to store them. Everything can be manufactured as needed. ”

The future of the industry

According to Sarah Boisvert, founder of Fab Lab Hub, “we’ve gotten past the hype stage” of 3D printing. The rumors about being able to 3D print everything under the sun have died down, and people are beginning to understand the practical aspects of 3D printing. This doesn’t mean the industry doesn’t face challenges moving forward, though.

Boisvert mentioned the need for skilled manufacturing workers. She isn’t alone in her concern, as the National Association of Manufacturers (NAM) continues to harp on the difficulties manufacturing companies face when seeking qualified employees. In a recent NAM study, 46.3% of small and midsize manufacturers surveyed consider finding quality employees a serious problem.

With 3D printing becoming an increasingly feasible integration into the supply chain for manufacturers, it’s critical that manufacturers have the employees with the skill set to properly work the printers in an efficient and timely manner. Additionally, the current price and speed of 3D printing can pose an issue for supply chain integration, Boisvert explained. At the end of the day, the decision to use 3D printing boils down to whether it truly makes sense for your business and if the cost is worth the benefit.

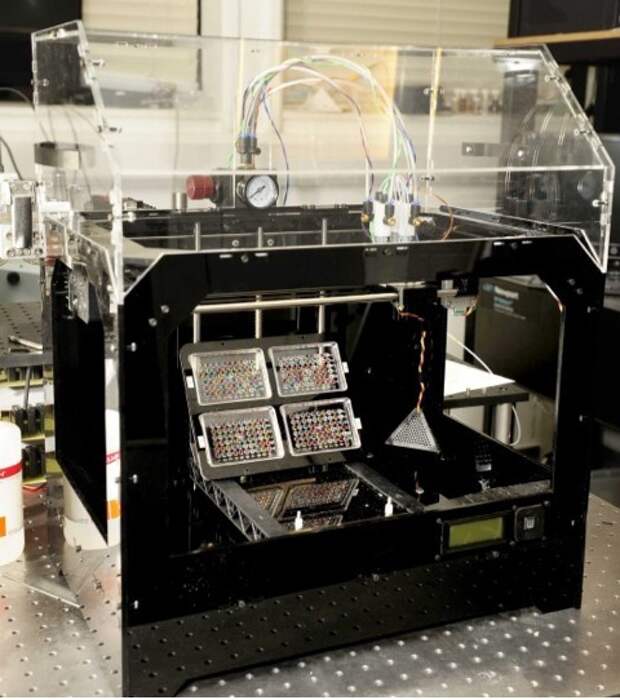

“We use everything,” Boisvert said of her manufacturing process for Potomac Photonics, another company she helped found. “We use 3D printing, laser cutting … I think it’s integrating 3D printing into the production flow and into the supply chain. No matter what tool you have, it’s about choosing the right tool for the job.” [Related: 3D Printing Jobs]

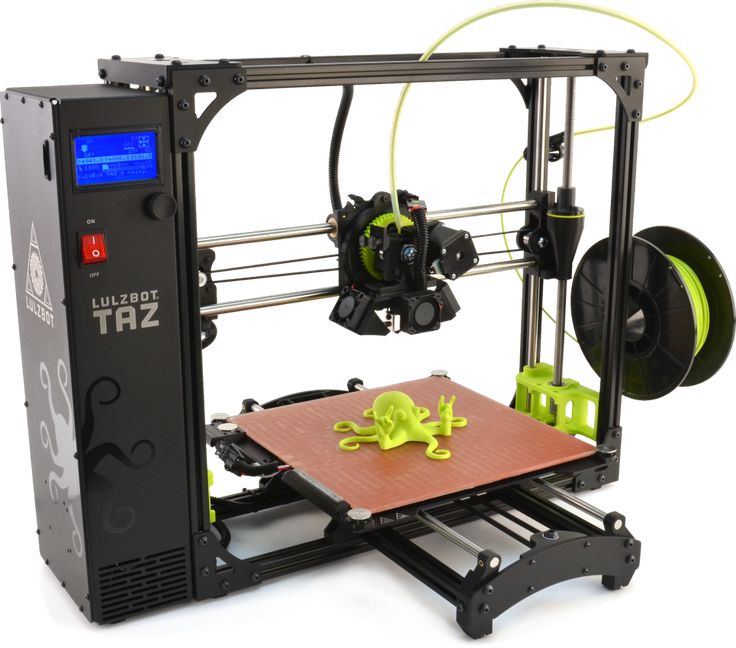

Top 3D printer picks for at-home small businesses

3D printing technology has come far enough that it’s now available at home. In fact, the 3D printers below are great choices for at-home small businesses.

1. Original Prusa MINI

The Original Prusa MINI is the best overall choice for at-home small businesses. It takes up less than 2 square feet of precious desktop space, and its build area occupies about 355 square inches. Its layer resolution spans 50 to 200 microns, and you can easily use it with many types of filaments. Calibration can be challenging, but for the $350 price, this issue might be worth bearing.

2. Ultimaker S3

The Ultimaker S3 is your best bet for printing larger objects. You can use it with many materials and achieve a layer resolution of 20 to 600 microns. It’s also relatively compact for a large object printer, with a build area of about 530 square inches. However, it’s known to be slow to print, and its $4,080 price tag is quite high.

3. Anycubic Vyper

If you need to print large objects but can’t afford Ultimaker’s models, the Anycubic Vyper might better suit your needs – and budget. You’ll get at least 100 microns of layer resolution for $680. You also get about 950 square inches of build area and a built-in accessories drawer. Some reviewers, though, have noted that the Vyper results in excessive initial stringing and uneven build quality.

Some reviewers, though, have noted that the Vyper results in excessive initial stringing and uneven build quality.

3D printing continuously evolves. Years ago, rumors spread about the possibility of 3D printers being in every home by now. While that notion proved too ambitious, there are practical implications of 3D printing that can benefit your small business.

3D printing consistently shows its worth, based on its prototyping, design considerations and mass customization. Keep tabs on changes as the industry evolves, and use 3D printing when it’s cost- and time-effective for your company.

Max Freedman and Adam Uzialko contributed to the writing and reporting in this article. Source interviews were conducted for a previous version of this article.

20 Use Cases for 3D Printing

3D printing has progressed so rapidly in recent years that we will soon stop talking about what can be created using additive manufacturing. It will be easier to mention what cannot be done. Yes, this list will continue to grow rapidly. But for now, let's take a look at some examples showing the wide range of 3D printing possibilities. We warn you in advance: the list is far from complete.

Yes, this list will continue to grow rapidly. But for now, let's take a look at some examples showing the wide range of 3D printing possibilities. We warn you in advance: the list is far from complete.

Fruit

A gift for impatient parents

Young parents often experience an irresistible desire to acquire all sorts of items, one way or another related to their child, even if not yet born. The Japanese company Fasotec offers future parents models of unborn babies made from images of real fetuses obtained using magnetic resonance imaging. The finished model consists of two materials - a fetal figurine made of white photopolymer, and a transparent material that imitates the shape of the mother's womb. At around $1,275, the fun isn't cheap, but Fasotec already has some competition. So, 3D Babies offers a similar service for only $200, although the size of the finished model is much smaller, and the quality is not quite on the same level.

Although the desire to get such a model may seem a bit strange, there is a perfectly logical explanation. As it turns out, the idea was originally aimed at giving blind parents the opportunity to "look" at the ultrasound of the unborn child.

As it turns out, the idea was originally aimed at giving blind parents the opportunity to "look" at the ultrasound of the unborn child.

Weapons

Functional 3D printed receiver from AR-15 without any numbers

The possibility of 3D printing of weapons has seriously alarmed law enforcement agencies around the world. After all, even simple FDM printers allow you to create all-plastic guns. Although such a weapon is primitive, even a disposable pistol with a single cartridge in the hands of a criminal can cost someone a life, and it is impossible to trace such a weapon. However, there are also people who believe that 3D printing of weapons should be allowed. Thus, the US Constitution gives citizens the right to freely carry weapons, although certain restrictions still apply. The non-profit organization Defense Distributed, which released the Liberator plastic pistol into the public domain, went further by unveiling the design of the lower receiver of the AR-15 carbine. AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

AR-15 is actually a civilian counterpart, even a prototype of the M-16 automatic rifle, which is in service with several countries of the world. The lower part of the receiver bears the registration number - this is the only part of the rifle that cannot be purchased as a spare. Thus, the printing of this part can bypass the need to register weapons. Some countries have already banned the 3D printing of weapons, although it is not entirely clear how to apply this ban in practice.

Clothes

One of Snezhana Gross' designs

Some consumables for 3D printing, especially soft photopolymers, are quite suitable for making clothes and even underwear. The bra in the illustration was laser sintered from nylon. This design from Continuum Fashion aims to showcase the possibilities that 3D printing opens up for couturiers. However, don't think this is an experimental model: the company offers finished products for sale on the Shapeways website.

Russian designers did not bypass the new technology either: Snezhana Gross demonstrated casual wear designs integrating functional 3D printed components.

Art

Easy to print. Take a picture - as lucky

Would you like a replica of the Venus de Milo? No problem, just choose the material and printing method. True, marble is not yet on the menu, but sandstone imitators are already available. Gypsum was one of the first materials for 3D printing. A three-dimensional image of the original can be obtained using a regular photo and then converted to 3D. In addition, more and more 3D scanners have recently appeared on the market, including portable hand-held options that can capture images of large objects. It remains a mere trifle - to agree on a stereo photo session with the security of the Louvre.

Although, if you are too lazy to make digital models yourself, you can always download them.

Products

What's for breakfast?

Although giant hot dogs are still far away, 3D printers have already learned how to print minced meat. An example of this is the Foodini culinary printer, a simple and practical device using syringe extrusion. Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

Moreover, printing is possible not only with minced meat, but also with any pasty product - dough, cheese, tomato puree. The only thing that Foodini is not yet capable of is heat treatment. It is to be expected that soon there will be devices that combine 3D printing with refrigeration units and, say, microwave ovens. Then sci-fi tales of "replicators" can come true. One press of a button, and the device will lay out the desired pizza and bake it to the delight of the user. Just one question: do you like thin dough or fluffy?

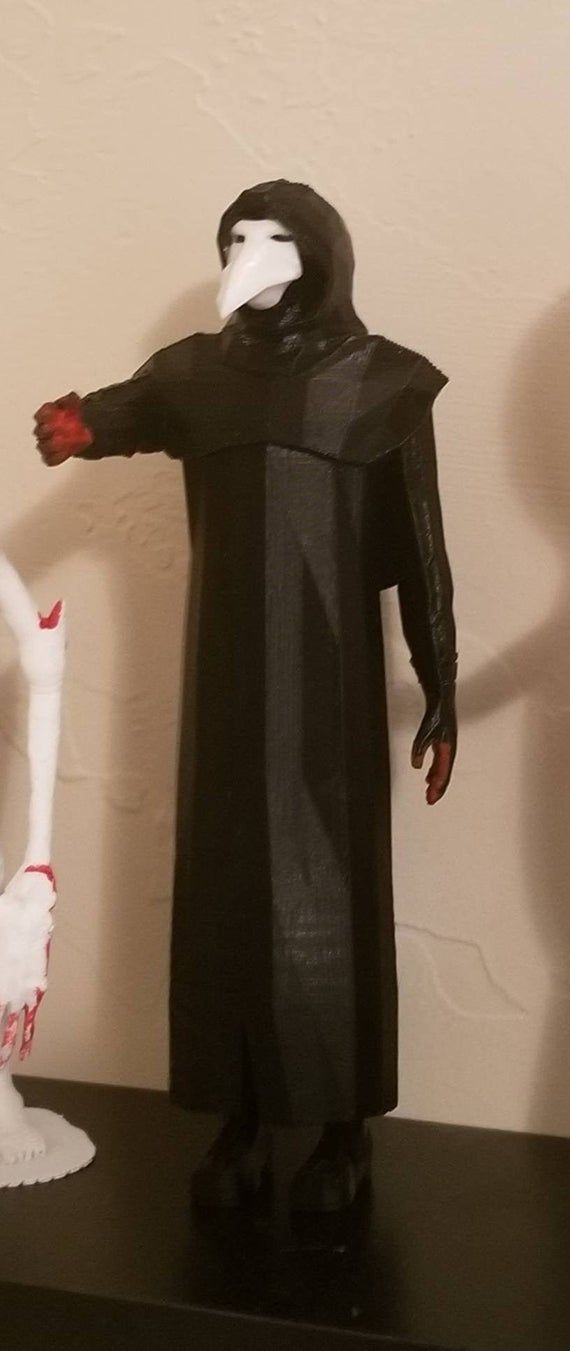

Characters

Parts of models used to animate ParaNorman's protagonist

Whether it's a miniature version of a giant robot from a favorite manga, a creepy alien creature from Alien, or a Keanu Reeves action figure (as in a black cape and sunglasses, and with a beard and a sandwich sitting on a bench), 3D printing allows you to create replicas of game and movie characters for the delight of fans. And the fact that such souvenirs can be printed even on household 3D printers opens up great opportunities for those who like to collect such models - after all, not all of them are available for sale. Do you want a model of a rare aircraft? Print it.

Do you want a model of a rare aircraft? Print it.

And what is most interesting, this application has already had the opposite effect. ParaNorman cartoon characters were still printed. Like the new RoboCop suit. True, inside it was still stuffing from a person. But why stop at simple visualization?

Home Robots

Early Terminator Prototype

The advent of inexpensive Arduino boards made it possible to design a wide variety of electronic devices at home. Here are your own 3D printed robots. You printed the case, inserted the servos and the board, and you have a new au pair. But what about people who do not understand programming or elementary soldering? Scientists from the Massachusetts Institute of Technology are developing a project aimed at automating the design and construction of domestic robots. Ideally, the user will only have to set the necessary functions for the future device, after which the system will compile the required design and send it to print. A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes.

A few hours later, it will be possible to pick up a ready-made device - a robot-spider for wiping chandeliers or a machine for turning pancakes.

Aviation

3D printed part used in Chinese fifth generation fighter aircraft prototypes

The toy airplanes we have already mentioned. What about real ones? There is also a place for additive manufacturing in the aircraft industry, although here one cannot do without expensive industrial plants capable of creating high-quality parts, including all-metal ones. Leading aircraft manufacturers, including Boeing and Lockheed Martin, are already testing laser sintering and melting technologies for the production of ventilation systems, structural components and even jet engine parts. Chinese engineers, on the other hand, set to work on a real scale, creating installations for the additive production of parts weighing up to 300 tons.

Space

Dragon v2 is Space's latest creation

The space industry is not far behind the aviation industry in its interest in 3D printing. NASA has successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

NASA has successfully tested titanium rocket engine nozzles, and a few weeks ago, Elon Musk, the head of the private space company SpaceX, held a presentation of the new Dragon v2 orbiter, which also uses engines with 3D printed parts.

Bioprinting

Biopens can help treat fractures

Vessels, tissues, whole organs - several companies are simultaneously developing the production of organic imitators that are completely similar to natural tissues. Although transplantation of 3D printed organs is still far away, work in this direction is underway. In parallel with the production of organic tissues from scratch, methods are also being developed to restore damaged tissues, such as cartilage or bone. Devices called "biopens" are able to apply living cells to damaged areas, promoting their healing.

Prostheses

Titanium orthopedic prostheses with a porous structure for improved osseointegration

What if the tissues cannot be restored? 3D printing can help with prosthetics. Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies.

Thus, the Swedish company Arcam creates installations for electron-beam melting, which make it possible to create virtually monolithic metal products, including titanium. Titanium orthopedic prostheses have become one of the most sought-after products created on the devices of this company - according to company statistics, their number exceeds thirty thousand copies.

Not only that, 3D printed limbs can compete with high-tech designs with one difference - their cost cannot be compared. How many people can afford a tens of thousands of dollars of prosthetic hands? How about a $50 fully functional prosthesis? And it's possible.

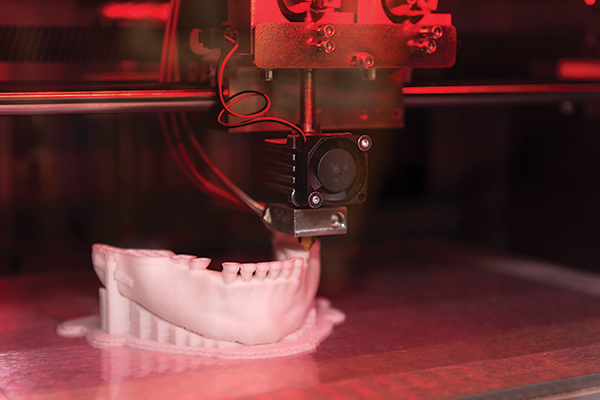

An even more common application of additive manufacturing is in dental prosthetics. If you have recently had a crown or bridge placed, it is possible that they were cast from models created with a stereolithography printer that prints with photopolymer resins.

Musical instruments

3D printed musical instruments

Guitars? Flutes? Drums? Easy. Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not seriously. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy!

Broke your oboe - print a new one. Of course, professional musicians can argue: plastic guitar? Not seriously. But who said that all tools have to be made of plastic? The same neck can be printed from wood resin, similar in density to natural wood. You can even print a composite carbon fiber core. And as far as simply decorating your favorite harpsichord, 3D printing can work wonders here. It would be fantasy!

Shoes

Luc Fusaro's stylish trainers

Eight-time world sprint champion Usain Bolt is famous for his love of gold. This includes not only medals, but also cars and even shoes. During his contract with renowned manufacturer Puma, Bolt wore signature gold-plated sneakers. And more recently, engineer and designer Luke Fusaro has taken on the development of sports shoes that Usain would like. Its distinctive feature is its golden color. Oh yes - and it's also designed for 3D printing. The use of additive manufacturing has one important bonus, namely the ability to produce shoes that are precisely tailored to the size and contours of the athlete's foot. Such shoes are produced by laser sintering, although this technology has already had a competitor.

Such shoes are produced by laser sintering, although this technology has already had a competitor.

Drugs

3D printing can facilitate the production of mixed drugs and help with drug testing on living tissues often in combination with tissue engineering. Thus, the Organovo company directs its efforts to create artificial human liver tissues to test new drugs for toxicity without risk to human health. But the drugs themselves can also be printed by binding the drugs with a gel material. As a result, we get ordinary-looking pills, but with a complex content of drugs, tailored to a particular patient.

Cars

Doc Brown is introduced to 3D printing. That's about the reaction you'd expect.

Most automotive components can be printed, but it's not economically viable when it comes to mass production. But for prototyping new cars, 3D printing is great. As, however, for the production of unique machines or components. For example, you can print replacement parts for low-volume, discontinued models. Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive.

Where else can you find parts for, say, the DeLorean that inspired the Back to the Future time machine? The only small company still making parts for this car is in Texas. Shipping parts can cost more than the machine itself, quite inexpensive.

Customization

Maximum glamor at minimum cost

Why not take a finished product and add decorative elements? Turn your bike into a work of art for everyone to envy. Gold-plated openwork fasteners on a black chassis will make passers-by look back. But it is not necessary to stop at the decorative aspect! Maybe you are not satisfied with the seat? Why not print a new one? Or add more comfortable handles? Klaxon style 1910s?

Furniture

One of Joris Laarman's clever designs

Toy furniture? No, not only. The advent of composite materials for FDM printing makes it possible to print "wooden" furniture, almost indistinguishable from the real thing. Actually, the material Laywoo-D3 could not do without real wood in the form of micro-sawdust. This stuff even smells like wood! Finished products are easily machined and varnished.

This stuff even smells like wood! Finished products are easily machined and varnished.

Or do you prefer metal furniture? Dutch designer Joris Laarman has created his own machine for metal 3D printing, without the use of expensive powders, vacuum chambers and lasers. The device draws with metal in the air, allowing you to create elegant interlaced designs.

Jewelry

Beautiful and functional

A clear demonstration of the precision of 3D printing is its application in jewelry. It should be said right away that not all technologies are suitable for this task. Widespread FDM printers are attractive due to their cost-effectiveness, but in terms of print quality they do not reach the standards of jewelry production. The most popular choice is laser (SLA) and projector (DLP) stereolithography - installations using these technologies allow printing photopolymer parts of extraordinary accuracy. Such products are used as master models when creating jewelry casting molds, greatly simplifying the production process.

But there is also an option for direct additive manufacturing of jewelry: laser sintering and melting technologies make it possible to create finished products from metal powder, including precious metal powders. True, the cost of such installations and materials is often too high for widespread use even by jewelers.

Construction

3D printing of buildings will help solve housing problems experimenting with the construction of concrete "boxes". True, these attempts are still quite primitive, because a real house will also need infrastructure - drainage, wiring ... Andrey Rudenko's attempts to build a full-fledged house are very promising. Andrey designed his own printer capable of printing with commercially available cement mixtures. Moreover, he already had competitors. Thus, the BetAbram company plans to put on sale printers for printing buildings up to 16x9m. The issue price is about $44,000 for the largest of the three models. True, "more" is not necessarily "better". Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Spanish developers are trying to go in the direction of miniaturization of 3D construction printers, creating robots that can use already built building elements as a working support.

Which method will be the most practical, time will tell. But if any of them succeeds, the construction industry can make a qualitative breakthrough, expressed in increased savings, safety and speed of building construction.

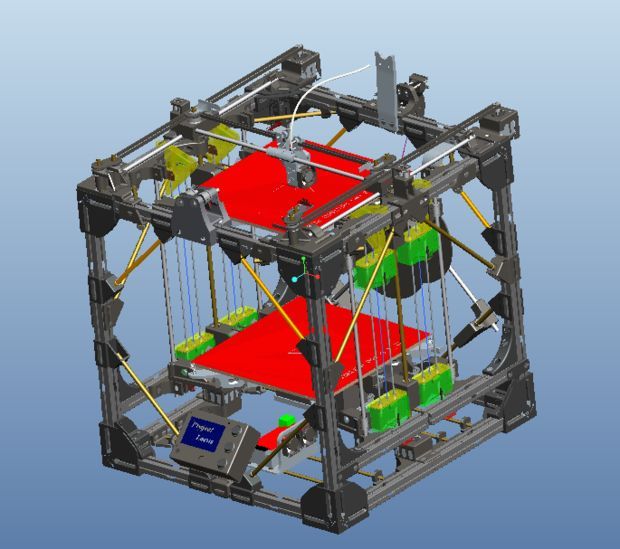

3D printers

What else can I print with a 3D printer? Another 3D printer! Even if not entirely yet: the necessary electronic and electromechanical components are not yet subject to printing, but this is only a matter of time. Almost all materials used or close analogues have already been tested by various additive manufacturing methods. It remains only to wait for the appearance of machines capable of using the full range of consumables. Then the RepRap project, which gave impetus to the development of compact self-replicating 3D printers, will come to a logical conclusion.