3D printed useless box

3D file Useless box・Design to download and 3D print・Cults

Keychain Paw patrol

€4.09

Ramp car 1:43

€5.38

Vag group

€3.84

Map of Bulgaria keychain

€0.96

Best 3D printer files of the Game category

F-100D Super Sabre

€0.83

Connect 4

€0.62

R2D2 - RC toy

Free

Tone Titan

€2.90

D10:DADONE

€2.40

FIDGET GEAR 1

Free

P90 airsoft flame cover

€1

3d Printable Chubby Chess Set OBJ 3MF 3D model

€5

Best sellers of the category Game

Nice Flexi Unicorn

€1. 05

Flexi Flying Unicorn

€1.05

RC 1/10 Dodge Challenger

€7.50

Chopper Motorcycle Print-In-Place

€1

Lion Foo

€5.50

Beaky Boyz Builder: PF_MK-Six

€12.01 -15% €10.20

Imperial Heavy Weapons & Regimental Flags [PRESUPPORTED]

€2

Articulated Snowman

€2.87

Lazy Cat

€3.83

Jarl

€6.72

SM Healer Conversion Kit

€6

Articulated Dragon

€3. 83

83

FLEXIBLE CHRISTMAS SNOWMAN

€2.60

Octopus 2.0

€3.83

Alteyr Emberwatch

€9.61

Nice Flexi Dragon

€1.77

Would you like to support Cults?

You like Cults and you want to help us continue the adventure independently? Please note that we are a small team of 3 people, therefore it is very simple to support us to maintain the activity and create future developments. Here are 4 solutions accessible to all:

ADVERTISING: Disable your AdBlock banner blocker and click on our banner ads.

AFFILIATION: Make your purchases online by clicking on our affiliate links here Amazon.

DONATE: If you want, you can make a donation via PayPal.

WORD OF MOUTH: Invite your friends to come, discover the platform and the magnificent 3D files shared by the community!

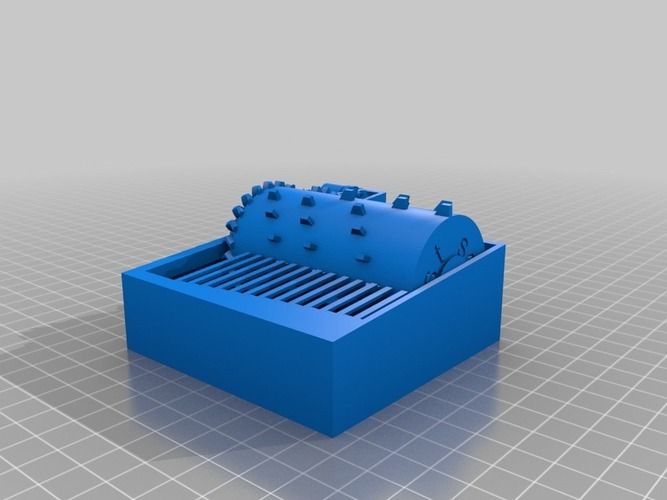

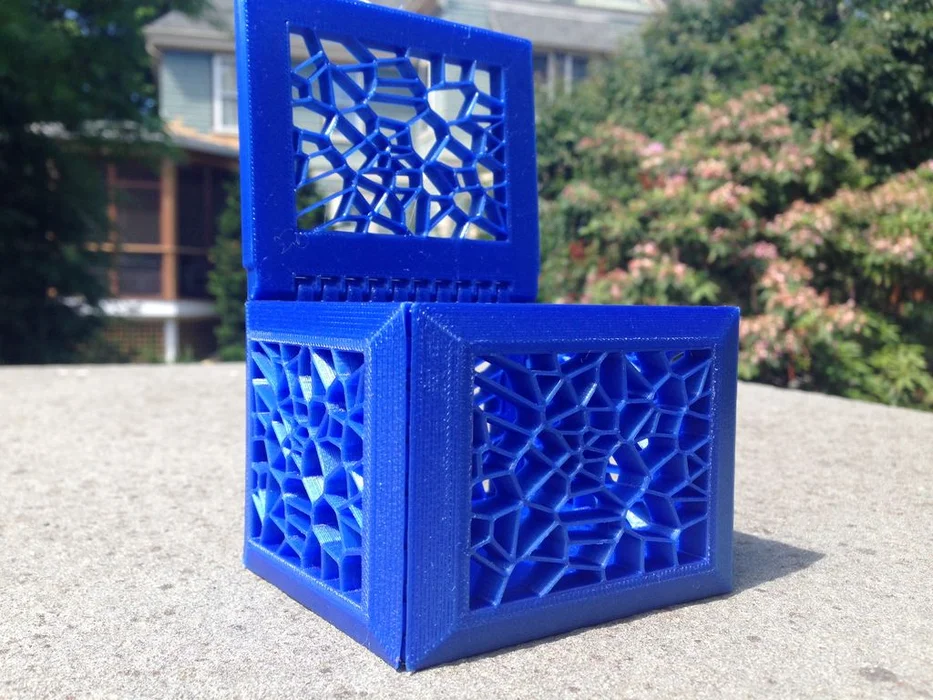

3D file MisteryBox / Useless Machine・3D print design to download・Cults

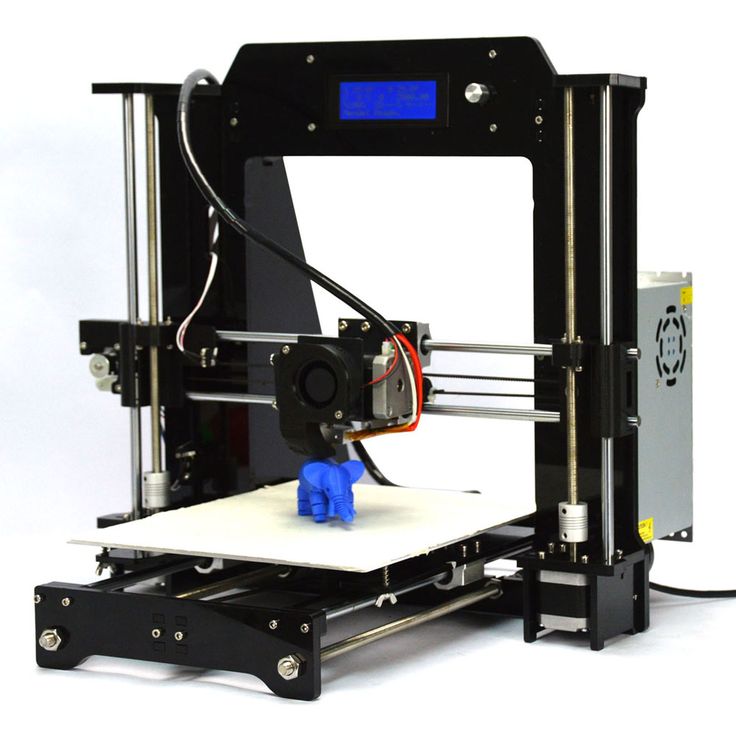

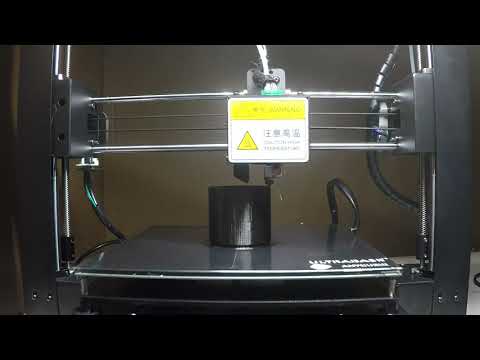

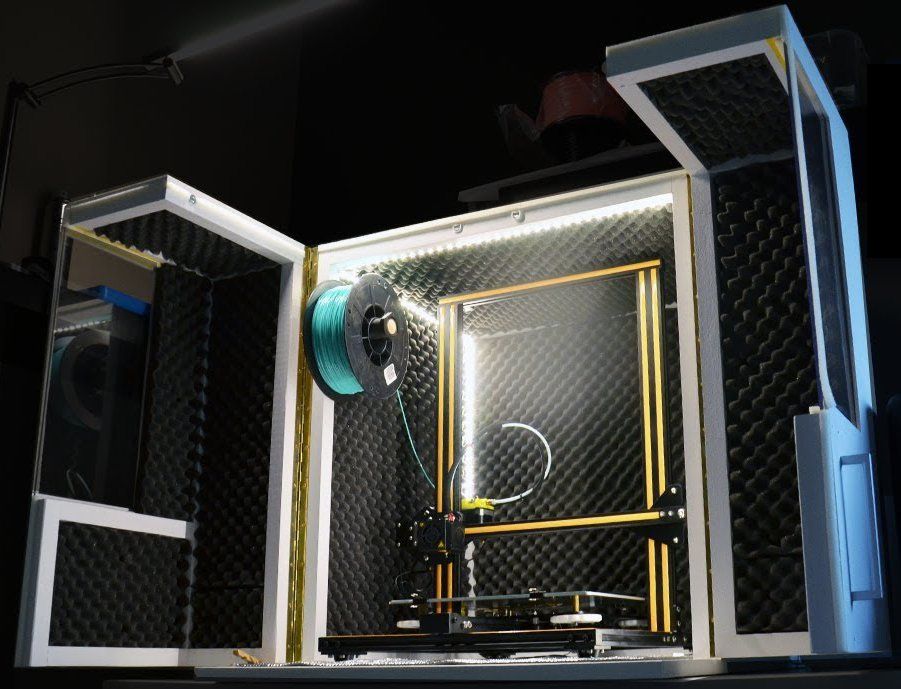

So this is your chance to show everybody that the 3D printer that you bought is not a useless toy. It is in fact a fantastic machine that can produce useless toys...

You can watch TheUselessMachine here: https://www.youtube.com/watch?v=aHDnks3hrzg

This is a simple Useless Machine / Mistery box to be made with a 3D printer and a few basic parts very cheap and very easy to obtain (links provided to all of them).

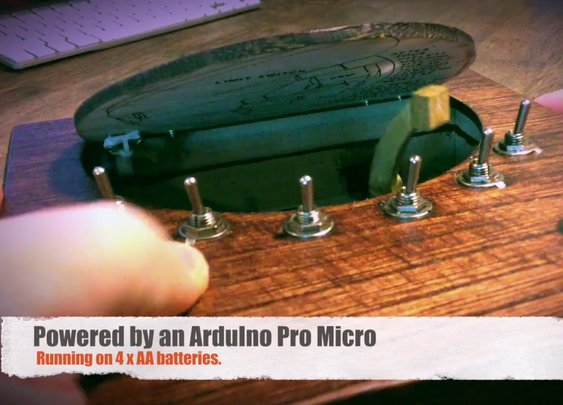

Just a couple of switches and a motor. No hard work, no programming, no nothing. Wiring plan included in the files.

PRINTING

The model has been carefully designed to make it an easy print . Tolerances have been worked out to produce an easy to assemble functioning USELESS MACHINE on all printers. Nonetheless, STEP files are included in case you want to squeeze more the gaps for your extremely accurate resin printer (more on tolerances and plays later) or perhaps you want to redesign the cover with your own embossment, or maybe change the motor mount to assemble the device with a different motor.

Printing of all the parts of this device is pretty strightforward.

The provided STL files already position the part in the recomended printing position.

Only one of the parts (Top,stl) needs additional support. I reccomend using only a support enforcer for the back part of the part, and print the hinge holes with no support. All holes are shaped in a way they will print all right withoul support and perform perfectly as rotating hubs

Only one of the parts (Finger.stl) needed a raft to be printed.

I have printed the model in PETG and in PLA with equal results.

Mechanically, the most solicited parts are the lever ones (MecLever.stl, LeverFixed.stl, LeverFloat,stl). I reccomend printing them with extra perimeters and a nice infill.

TOLERANCE ADJUSTMENT

The design play between rotating shafts and hubs range from 3 to 5 tenths of a millimeter. If, after performing the assembly you think that the device has too much play, and things could be tighter (or too little play and things could be softer), you only need to tweak the design of three parts (MecHinge x3. stp, MecRightCam.stp and MecLeftRoll.stp). Just enlarge (or make smaller) the diameters of the hinges a couple of tenths of a millimeter and try again. The three parts prints in a few minutes, so repeating the prints is no big hassle.

stp, MecRightCam.stp and MecLeftRoll.stp). Just enlarge (or make smaller) the diameters of the hinges a couple of tenths of a millimeter and try again. The three parts prints in a few minutes, so repeating the prints is no big hassle.

TWO COLOUR PRINTING

The cover can be printed with a normal 3D printer and also with a dual extruder printer if you want to get the fancy two colour effect. The ones in the pictures has been printed in a PRUSA MK3 with a multimaterial unit.

If you are using a single color 3D printer just ignore the file CoverColourSecond.stl.

In a dual colour printer just import both CoverColour files (CoverColourMain.stl and CoverColourSecond.stl) to the slicer at the same time. The part only has four filament changes, so there's not much room for errors.

GCODE FILES

The settings I used to make these gcodes (and print the parts) are:

-Layer height 0.3 mm (Except part Finger.stl, that was 0. 15 mm)

15 mm)

All the gcode files provided are to print the MisteryBox in PETG in a PRUSA MK3. If you are using a multimaterial unit, all the parts are set for extruder#1, except the finger (part Finger.gcode) and the second colour for the cover of the box, that are both set for extruder#2

DESIGN IMPROVEMENTS

All small changes.

I included 4 new holes for screws to close the box. They are not necessary. You are not meant to use them unless when you print the part Bottom.stl you get a warped base. In that case, you can use these holes to close the box and avoid repeating this 7 hour print

Batt space has been slightly enlarged and a hole has been added to the top (in case you forget the batteries inside and they bloat, now you can easily get them out). Also, a drill hole has been added so now the battery connector can be locked in place (not that it had room to move before, but it looks tidier this way). The wiring routing out of the batt conpartment has been changed too

I have included a couple of alternative embossments for the cover, though of course, you can use the step file to create your own.

PARTS LIST

Soon to follow, I will include a link where you can buy all the following parts as a kit

Engine - approx 0.90 ? - link

Switch - 0.35 ? - link

Limit switch - 0.24 ? - link

4AA Battery holder - 0.48 ? - link

wire AWG #24,#28 - 80 cm approx

bolt M3x8 - 5 units

bolt M2x7 - 2 units

lag screw 3x16 mm - 4 units (+4 more)

50 Cool Things to 3D Print / Sudo Null IT News

No ideas for 3D printing? Tired of worthless trinkets? Here is a list of 50 cool really useful things for 3D printing.

Like us, you're excited about the possibilities of 3D printing. But, unfortunately, the horizon is littered with trinkets, trinkets and other unnecessary things. We are in danger of being buried under a heap of useless rubbish.

Throw off the shackles of mediocrity! Let's create really useful things! Here is a list of cool things that you can make on a 3D printer right now. Prove to your family and loved ones that this wonderful technology can be used daily and in practice.

Prove to your family and loved ones that this wonderful technology can be used daily and in practice.

No access to 3D printer? No problem. Just upload your files to our 3D printing price comparison system and choose the best price, ONLINE!

Download from Myminifactory

Cool thing for 3D printing No. 29: Form for Snegles

Download from ThingiVerse

Cool 3D Printable Item #30: Wine Bottle Protector

Download from MyMiniFactory170004

Cool thing for 3D printing No. 31: Pocket ashtray

download from Myminifactory

Cool Press No. 32: Rodist Roll for a glass 9000 9000 9000 9000 download from MYMINIFACTORY

3D Printable Cool Item #33: Apple Remote Stand

Download from MyMiniFactory

3D Printable Cool Item #34: Key Holder

Download with Myminifactory

Cool thing for 3D printing No. 35: Holder of the cutlery for people with disabilities

Download from Myminifactory

Current Press No. LIVE wine bottle

Download from MyMiniFactory

Cool thing for 3D printing #37: Paper cup holder

download from Myminifactory

Cool thing for 3D printing No. 38: Case for blades

38: Case for blades

download from Myminifactory

Cool thing for 3D printing No. 39: Holder for a children from MyMiniFactory

3D Printable Cool Item #40: Towel Rack

Download from MyMiniFactory

3D Printable Cool Item #41: Holder for a glass

Download with Myminifactory

Cool thing for 3D Press No. 42: Holder for a phone in the shower

download from Myminifactory

Twisting thing for 3D printing No. 43: Holder No. 43: Holder No. 43: for beer glasses

Download from MyMiniFactory

Cool thing for 3D printing #44: MacBook Pro stand

download from Myminifactory

Cool thing for 3D printing No. 45: Protection for SD-Cart

download from Myminifactory

Cool thing No. 46: BATERIOUS 9000

Download from MyMiniFactory

3D Printable Cool Item #47: Ice Cream Cone Holder

Download from MyMiniFactory

Printable Cool Item #40016 shower set

download from Myminifactory

Cool Spring No. 49: Evacal separator

49: Evacal separator

download from Myminifactory

Cool Press No. 50 for 3D:

Download from MyMiniFactory

Want more exciting news from the world of 3D technology?

Follow us on social. facebook networks:

7 amazing things that can be printed on a 3D printer

August 16Technologies

Real food, a living heart, an eco-house of rice and other useful "printouts" that can solve the world's problems.

Share

01. Human organs

Scientists can now print skin, kidneys, liver tissue, heart and a number of other organs. True, while they are usually smaller than real ones, and therefore suitable only for clinical trials or surgical practice. But in the future, they should seriously help in the fight against various diseases. For example, they want to use 3D skin as a means for healing wounds. And full-fledged printed hearts or kidneys can shorten the queue for donor organs and save more lives: hundreds of thousands of people need transplants every year.

3D organs are created from real living cells, either from adult stem cells or from a sample taken directly from a person. They play the role of ink, which the printer heads put on an organic or synthetic base. The correct shape, texture and tissue layers are programmed based on the results of the scan - this ensures maximum copy accuracy. The main challenge facing scientists now is to find an opportunity to create organs that can function inside the body: to contact the nervous and circulatory systems and perform their tasks correctly.

2. Bones and cartilage

Illustration: Phonlamai Photo / Shutterstock And here they are already being used by surgeons in real life. For example, 3D implants are used to replace femurs. There are also successful examples of transplantation of printed bones of the skull and cartilage of the auricle. The next step in the application of this technology may be the replacement of small damaged areas right inside the person. Such a 3D printing method, according to the researchers, will speed up the process and save in cases where speed of reaction is critical, for example, in the treatment of bone cancer.

3D printers also come in handy in dentistry. They simplify the process of creating crowns, bridges and prostheses: the specialist does not need to select sizes manually - the model is formed and printed on the basis of images of the oral cavity. They can also be used as temporary implants to help patients get used to their new teeth and make sure they fit well in their mouths. The technology is safe: special photopolymer resins are used for printing. They are strong, retain an aesthetic shade for a long time and do not irritate the mucous membrane.

3. Prostheses

Arms, legs and other parts of the body. Due to the simplified manufacturing process, 3D prostheses cost less and are created faster. In the standard scheme, you first need to make a cast of the remaining part of the patient's limb, then cast a trial version from plaster, then try it on, correct inaccuracies, and only then proceed to create the finished product. In the 3D version, it is enough to collect measurements, correct the model on the screen and print it.

However, these prostheses do not necessarily have a purely cosmetic function. 3D hands with touch control, that is, a reaction to body signals, or with a vibrational response to touching objects already exist. In addition, it is easier to replace a printed artificial limb after wear with a similar one by re-creating it according to the saved layout.

3D prostheses can be used for more than just humans. For example, in Australia, an artificial leg for a dog was created on a printer.

The speed and cost of producing 3D prostheses is a chance for many children: conventional options are rendered useless too quickly due to the active growth of the child. And a printed model can be created even for a one-year-old patient who is just learning to move: scientists from Lincoln University have already presented such a development.

4. Food

Brands use 3D printers to model future products or create unusual shapes for everyday food. Creative serving options are also used in some restaurants. In 2016, an entire restaurant was temporarily opened in London, the menu of which consisted entirely of dishes obtained using 3D technology.

Creative serving options are also used in some restaurants. In 2016, an entire restaurant was temporarily opened in London, the menu of which consisted entirely of dishes obtained using 3D technology.

But choosing the look isn't the only benefit of 3D food printing. Due to the possibility of virtual programming of the composition, the dishes created by the printer are easy to adjust to the desired nutritional value: control the calorie content, the amount of proteins, fats, carbohydrates, fiber, vitamins. This will make life easier for people who are on a strict diet for medical reasons. Also, the printer will allow you to cook the usual food, but from budget ingredients. For example, to form a fish fillet from seaweed. This, in theory, should help solve the problem of world hunger.

In the future, 3D printers could make eating more ethical. For example, they will make it possible to stop killing animals for the production of meat products. One of the alternative options here is the creation of meat entirely based on plant components.

Another way is to form "ink" for a 3D printer from a meat sample taken from an animal by biopsy. A device for printing using this technology was created at the Moscow State University of Food Production (MGUPP). True, for a 3D printer to be able to make a whole steak from a tiny piece of fabric, it takes several months. First, the sample is cultured in a bioreactor. When there are enough cells, they begin to form the base - from ingredients of plant origin. After that, animal and vegetable “ink” are alternately applied to it. As a result, the product retains both taste and texture.

The MGUPP 3D printer is capable of printing not only meat, but also, for example, chocolate or dough. University researchers plan to experiment with the technology further to expand their product range.

5. Clothing and footwear

Illustration: asharkyu/Shutterstock Many brands produce 3D printed items. For example, Nike printed the upper part of the sneaker, and Adidas made the midsole. Dresses by Dutch designer Iris van Herpen, sewn using this technology, are regularly worn by celebrities. Austrian Julia Koerner also works with the printer - accessories that she created in collaboration with costume designer Ruth Carter, worn by Angela Bassett in the movie "Black Panther".

Dresses by Dutch designer Iris van Herpen, sewn using this technology, are regularly worn by celebrities. Austrian Julia Koerner also works with the printer - accessories that she created in collaboration with costume designer Ruth Carter, worn by Angela Bassett in the movie "Black Panther".

Fashion 3D printing expands the creative possibilities of designers, allowing for futuristic shapes that are difficult to achieve with conventional sewing methods. However, this is not the main advantage of the technology. A 3D printer reduces resource consumption: a thing or its element immediately appears in the right size - no extra shreds and threads remain. In addition, 3D fabric requires less water to make than cotton, and it can also be quickly created from recycled or recycled materials. In the future, the printing of things can destroy fast fashion, allowing you to create them piece by piece, ideally suited to the parameters and requests of the client.

6. Laboratory Instruments

Printed instruments, due to the speed and cost of production, can help research in poor countries. Now there are several projects that create budget microscopes for diagnosing malaria in Tanzania.

Now there are several projects that create budget microscopes for diagnosing malaria in Tanzania.

3D technology makes science accessible to amateurs too. For example, Australian researchers have developed a microscope attachment for a smartphone and made the files available to the public: anyone who has a printer can create such a device.

7. Houses

There are buildings with printed walls all over the world, including Russia. 3D printers make it possible to build houses in a few days, while reducing costs and not requiring the participation of an entire construction team. Large special equipment is also not needed - you can work even in hard-to-reach places. The construction printer itself weighs a couple of tons, so transporting it to the point is quite realistic.

3D printing expands the creative possibilities: the machine can print curved walls, helical supports and other complex shapes. And the variability of building materials in this technology is great: concrete, sand, volcanic ash or eco-materials like rice husks can act as “ink”.

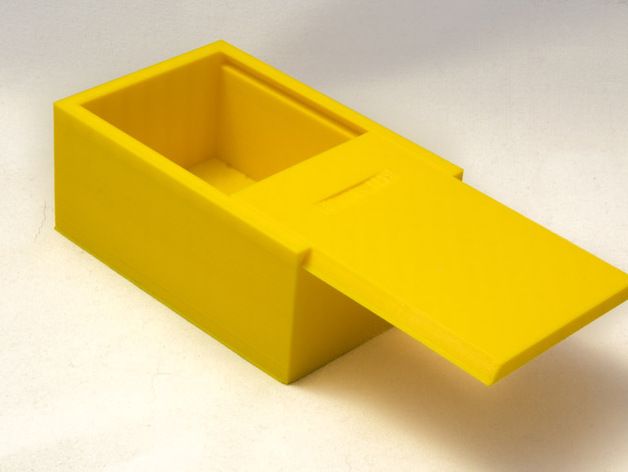

You can change the pattern of the inner pallet if you wish.

You can change the pattern of the inner pallet if you wish.  Print it out and give it to your grandmother. She will appreciate this gesture.

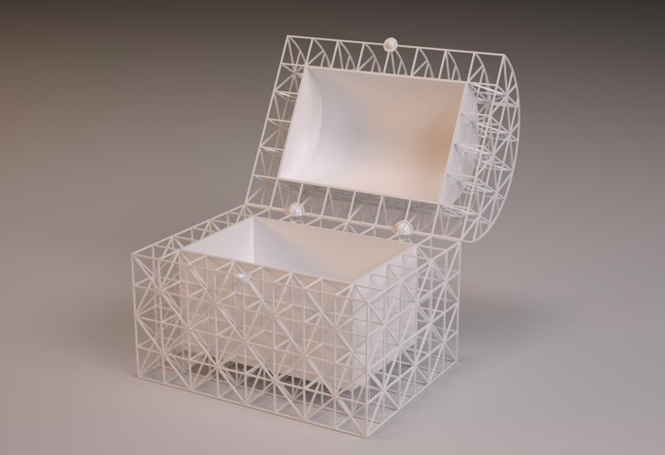

Print it out and give it to your grandmother. She will appreciate this gesture.  " Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

" Do you have such a business card? Find her a pair in the form of this business card holder, printed in its entirety (yes, already with a hinged lid). Instructions for adding a custom logo are included.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.

It is especially suitable for kitchen plants. The next time you buy fresh herbs for cooking, transplant them into this neat device and they'll stay fresh all week long.  It’s great if you have water limits set in the height of summer.

It’s great if you have water limits set in the height of summer.  28: Protection for disk

28: Protection for disk